Page 1

TR-220

MULTIFUNCTION TEST SET

Transponder, TCAS, DME, TIS, and ADS-B

Test Set

Operational Ma nual

Software Revision 3.40 and Later

REVISION

A B C D E F G H J K L M N

P R S T U V W X Y Z

09 May 2007

Tel-Instrument Electronics Corp

728 Garden Street

Carlstadt, NJ 07072

(201) 933-1600

www.telinstrument.com

Page 2

Leading the AVIONICS TEST industry into the 21st Century!

NOTICE:

The information contained in this manual is subject to change without notice.

Tel-Instrument Electronics Corp. makes no warranty of any kind to this material,

nor shall be liable including but not limited to, errors contained herein or for

incidental or consequential damages in connection with the furnishings,

performance, or use of this material.

Chapter I – Introduc tion

Chapter II – Preparation for Use and Operation

Chapter III – Theory of O per ation

Chapter IV – General Maintenance and Servicing Procedures

Chapter V – Schematics

Chapter VI – Ill ustr ated Parts Catalog

PART NUMBER VOLUMES INCLUDED CHAPTERS INCLUDED

90008088-1 VOLUME 1 CHAPTERS I & II

90008088-2 VOLUMES 1 & 2 CHAPTERS I - VI

COPYRIGHT NOTICE

© 2007 Tel-Instrument Electronics Corp

Reproduction of this publication or any portion thereof by any means without the

express written permission of Tel-Instrument Electronics Corp. is prohibited. For

further information, contact the Customer Support Manager, 728 Garden Street,

Carlstadt, NJ 07072. (201) 933-1600

Page 3

A

Safety Precautions

The following ar e general safet y precauti ons that are not rel ated to a parti cul ar test or pr ocedure.

These are recommended procedures that all personnel must apply during many phases of

operation and m aintenance. It is assumed that the op erator has general knowledge of electrical

theory and the dangers associ ated with it.

1. When performing any of the preceding; thoroughly read and understand all

procedures before ac tually performing t hem.

2. The various front panel connectors, switches, and controls specified can be

located by refer ri ng to Figure 2-1 on page 2-3.

3. Take the time to learn the proper operation and function of the Test Set as

outlined in Chapters 1, 2, and 3. Through knowledge of the Test Set and its

capabiliti es greatly improves the time it t ak es to complete the tests.

4. Pay parti cular attenti on to NOTES and WARNINGS that may accompany some

test and operati onal procedures.

lerts the operator to potential dangers associated with a particular test.

Thoroughly understand the warning before proceeding to prevent a

potentially dangerous situation or dam age to the Test Set.

WARNINGS

NOTE

Provides supplemental informati on that enhanc es the procedure or

further explains in detail additional information to ensure understanding or

5. Observe all standard safety procedures when working with live voltages. The

potential f or electric shock exists any tim e the Test Set is removed from its case.

6. DO- NOT serv i ce the uni t or mak e adjustm ent s alone. Al ways be in t he presence

of another person when working with live voltages.

7. Thoroughly inspect the equipm ent and the local area for potent ial hazards. Loose

clothing and j ewelry should b e removed any time the test set is being ut ilized or

being serviced.

8. Be familiar with general first aid procedures and CPR (Cardiopulmonary

Resuscitation). Contact your local Red Cross f or m ore information.

NOTES

proper operati on.

9. Ensure the test equipment and the tools you utilize are in good operational

condition and not damaged in any way.

10. Use only specified replacement parts as listed in the IPB. Failure t o utilize factory

approved part s may cause damage to person nel; the test set’s, and possibly void

the warranty.

Page 4

ESD Safety and Protection

Many parts contai ned in the Test Set are sensit ive to ESD (Electro-St atic Discharge) damage.

ESD can damage integrated cir c uits or semiconduct or s l oc ated within the Test Set. Only qual ified

personnel should serv ice the Test S et to prevent damage. The f ollowing are guideli nes to avoid

ESD damage while still performing tests and or maintenance. These guidelines are meant only as

a reminder, consult local directiv es and f ollow standard operat ing pr ocedures bef ore serv i cing, or

repairi ng the T est S et.

• Wear a properly grounded wrist strap and remain in contact with an approved grounding

point.

• Do not touch the connect or pins or back planes of ESD Sensitive circuits or par ts.

• Ensure solderi ng ir ons are grounded before use.

• Do not remove any components or disconnect any connectors locat ed in the Test Set with

the power “ON”.

• Properly ground all test equipment being utilized. Refer to the test equipment operating

manual for information.

• Place all remov ed c om ponents or parts in or on an approved conductive package.

Most ESD devices or circuit s and common points are readily identifi ed utilizing several different

methods. Below are some ex am ples.

The Following S ymbols may be utilized in diff erent locations thr oughout the Manual and ar e also

located on and in the Test Set. Observe these warnings and markings and follow standard

electrical safety anytime you utilize live ci r c uits.

Caution Alternating Current

CE (IEC) Marking

Protective Conductor

Terminal

Caution, risk of

electrical shock

Page 5

VOLUME 1

OPERATIONAL PROCEDURES

Page 6

Rev E TR-220 90 008 088-1

TR-220 TABLE OF CHANGES1

Date REV ECO Page Description

Prelim. Initial Release

07 Sep 03 A Initial Release

15 July 04 B Updated procedure explanations

16 Mar 05 C

2-5 & 6, 13, 17,

22, 43-46

01 Jul 05 D Chapter 3-6 Added CHAPTERS 3, 4, 5, &6

9 May 07 E Chapter 1 and 2

Provided Detailed EHS and ADS setup

and display info

Add test capability for measuring reply

delay, jitter, MS P6 pulse amplitude

variation, and MS P5 pulse width

1

Changes are also denoted with a solid bar in the Left margin of each affected page.

i

Page 7

Rev E TR-220 90 008 088-1

Table of Contents

Chapter Page

Table of Changes……………………………………………………………………. i

List of Illustrations…………………………………………………….……………… vii

List of Tables……………………………………………………….………………… viii

I INTRODUCTION

Section A- General Information

1.1 Scope of Manual…………………………………………………………… 1-1

1.2 Purpose and Function of Equipment…………………… ………… ……. . 1-1

1.3 Regulatory Responsibilities…………………………………………......... 1-2

1.4 Warranty…………………………………………………………………….. 1-3

1.4.1 Obtaining Warranty Service………………………………………… 1-3

1.4.1 Shipping and Packing the T est Set………………………………... 1-4

Section B- Equipment Description

1.5 Specifications………………………………………………………………… 1-5

1.6 Abbreviations, Acronyms, and Glossary of Terms…………………....... 1-7

II PREPARATION FOR USE AND OPERATION

Section A- General Information

2.1 General………………………………………………………………........... 2-1

2.2 Unpacking…………………………………………………………………… 2-1

2.3 Installation…………………………………………………………………… 2-1

2.4 Accessories…………………………………………………………………. 2-1

ii

Page 8

Rev E TR-220 90 008 088-1

Table of Contents (continued)

Chapter Page

Section B- Operating Controls, Indicators, and Connectors

2.5 General………………………………………………………………........... 2-3

2.6 Controls, Indicat ors, and Connectors……………………………………. 2-3

Section C- Operating Instructions

2.7 General………………………………………………………………........... 2-5

2.8 Battery Operation…………………………………………………………… 2-5

2.8.1 Auto-Shutdown………………………………………………….. 2-6

2.9 TR-220 Supplied Ant enna…………………………………………………. 2-6

2.9.1 Directional Antenna…………………………………………….. 2-6

2.9.2 Direct Connect………………………………………………….. 2-9

2.9.3 TAP-200 Antenna Coupler…………………………………….. 2-9

2.10 Initial Startup and Self-Test……………………………………………….. 2-12

2.11 Transponder Test Sequence……………………………………………… 2-13

2.12 Transponder Manual Sequence of Tests………………………………… 2-14

2.12.1 ATCRBS, Mode A/C Manual Testing………………………… 2-14

2.12.2 Mode S Manual Testing……………………………………….. 2-17

2.13 Transponder Automatic Sequence of T ests…………………………….. 2-24

2.13.1 ATCRBS, Mode A/C Automatic Testing……………………… 2-24

2.13.2 Mode S Automatic Testing…………………………………….. 2-26

2.14 Testing a Transponders “IDENT” Function……………………………… 2-28

2.15 TCAS Tests…………………………………………………………........... 2-29

2.15.1 Typical TCAS Concepts……………………………………….. 2-29

2.15.2 TCAS Scenario Selection and Setup …….……… ………….. 2-29

2.15.3 Erasing the TCAS Scenario Memory………………………… 2-35

2.15.4 Testing a TCAS Equipped Aircraft……………………………. 2-36

2.16 DME Tests………………….……………………………………………….. 2-41

2.16.1 DME Setup…….………………………………………………… 2-41

2.17 Mode S Enhanced Surveillance…………………………………………... 2-43

iii

Page 9

Rev E TR-220 90 008 088-1

Table of Contents (continued)

Chapter Page

2.18 ADS-B and TIS Testing……………………………………………………. 2-47

2.18.1 ADS-B TX……………………………………………………….. 2-47

2.18.2 ADS-B RX………………………………………………………. 2-50

2.19 RS-232 Download Procedures…………………………………………… 2-52

2.19.1 Setting Up your Computer for RS-232 Download………….. 2-53

2.19.2 Downloading the Data…………………………………………. 2-54

2.19.3 Loading the Data to a Microsoft Excel File………………….. 2-55

List of Illustrations (Figures)

Figure Title Page

1-1 TR-220 Multifunction Test Set…………………………… ………… …………. 1-1

2-1 TR-220 Accessories…………………………………………………………….. 2-2

2-2 Controls, Indicators, and Connector Locations………………………………. 2-3

2-3 Directional Antenna Gain……………………………………………………….. 2-7

2-4 Directional Antenna Setup……………………………………………………… 2-8

2-5 TAP-200………………………………………………………………………….. 2-10

2-6 TAP-200 Placement…………………………………………………………….. 2-11

2-7 TAP-200 Adjustment……………………………………………………………. 2-11

2-8 Sequence of Tests………………………………………………………………. 2-13

2-9 Caution, Warning, and Collision Areas……………………………………….. 2-29

2-10 Typical TCAS I Display…………………………………………………………. 2-30

List of Tabl e s

Table Title Page

2-1 TR-220 Accessories……………………………………………………………. 2-2

2-2 Controls, Indicators, and Connectors…………………… …………………… 2-4

2-3 Preprogrammed TCAS Scenarios……………………………………………. 2-30

2-4 TCAS Intruder Parameters…………………………………………………….. 2-33

2-5 Additional TCAS Intruder Scenarios…….……………………………………. 2-34

2-6 TIS Intruders…………………………………………………………………….. 2-51

iv

Page 10

Rev E TR-220 90 008 088-1

CHAPTER I

INTRODUCTION

SECTION A

1.1 Scope of Manual

This manual is intended to familiarize the operator with the operating and maintenance

procedures necessary to utilize the TR-220 Multifunction Test Set. Here-in after known as the

T/S, Test Set, or TR-220.

Figure 1-1

TR-220 Multifunction Test Set

1.2 Purpose and Function of the Equipment

The TR-220 Test Set tests airborne ATCRBS, MODE A/C, and MODE S transponders, TCAS I/II

systems, DME equipment, and ADS-B and TIS Transponders. It is self-contained and battery

operated that requires no direct hardware connection to the Unit Under Test (UUT).

For transponder testing, the Test Set simulates secondary radar to receive and radiate signals to

the UUT from antennas supplied with the Test Set. For accurate power and frequency

1-1

Page 11

Rev E TR-220 90 008 088-1

measurements, the Test Set can be directly connected to the UUT without the use of additional

hardware.

For TIS testing, the Test Set transmits simulated Intruder Flight Data, which is then shown on the

TIS display to verify results.

The Test Set will receive and Decode 1090 MHz ADS-B data including squitter type, airborne

position, surface position, aircraft IDENT category, Airborne velocity, Latitude/Longitude,

North/South velocity, and East/W est Velocity. The ADS-B TX function allows the operator to

receive, decode, and display ADS-B squitters. The ADS-B RX function permits the operator to

simulate a 1090MHz squitter. The TR-220 can be configured to transmit an airborne or surface

position squitter containing position, altitude, velocity, heading, aircraft category, flight ID, and

Mode S address.

The simulation of an intruder aircraft converging on the Aircraft Under Test (AUT) accomplishes

TCAS testing. The simulated target will be displayed on the TCAS display so the operator can

ensure proper advisories.

DME tests simulate an aircraft at a simulated speed converging to or from a selected distance. By

comparing the Test Set displayed distance to the DME under test display, the operator can

confirm proper DME operation.

1.3 Regulatory Responsibilities

Effective April 6, 1987, The Federal Aviation Administration (FAA) has required certain tests be

performed on transponders, both conventional ATCRBS and MODE S. In preparation for the

installation of new air traffic control radar facilities, the FAA required new measurements to be

performed on existing transponders and instituted required tests for MODE S transponders. FAR

(Federal Aviation Regulation) Part 43, Maintenance, Preventive Maintenance, Rebuilding and

Alteration section has been modified to reflect current technologies and improvements. TelInstruments has met all FAA requirements and recommends that the user of this type of

equipment review the appropriate FAR or contact the manufacturer of their particular model of

transponder to ensure that the current procedures and limitations are being correctly adhered to.

Eurocontrol has also incorporated new regulations for Mode S Elementary and Enhanced

Surveillance. These requirements include Selective Identifiers for high-density traffic areas and

will become mandatory beginning in May of 2003 for Elementary Surveillance and March 2005 for

Enhanced Surveillance. The TR-220 Test Set has the capability to thoroughly test these new

functions to comply with upcoming requirements. If you would like further information regarding

these requirements, visit www.eurocontrol.int/

.

1-2

Page 12

Rev E TR-220 90 008 088-1

1.4 Warranty

The Tel-Instrument Electronics Corporation warrants that each product it manufactures is free

from defective material and workmanship for a period of two (2) years subject to the following

terms and conditions. Tel-Instrument Electronics Corp. will remedy any such warranted defect

subject to the following:

This warranty requires the unit to be delivered by the owner to Tel-Instrument intact for

examination, with all transportation charges prepaid to the factory, within two (2) years from the

date of sale to original purchaser. Tel-Instrument will solely determine when such defect exists.

This warranty does not extend to any of Tel products which have been subject to misuse, neglect,

accident, improper installation, or used in violation of operating instructions. This warranty does

not extend to units which have been repaired, calibrated, or altered in any way by a facility that is

not approved, in writing, by Tel-Instrument Electronics Corp. to perform such work. This warranty

does not apply to any product where the seals or serial number thereof has been removed,

defaced or changed, nor to accessories not of our own manufacture.

Repair parts will be made available for a minimum period of five (5) years after the manufacture

of this equipment has been discontinued.

This warranty is in lieu of all other warranties expressed or implied and all such other warranties

are hereby expressly excluded. No representative or person is authorized to assume for us any

other liability or warranty in connection with the sale of Tel’s products.

This warranty does not cover or include batteries (batteries have a separate 90 day warranty).

Additional information with regard to the applications and maintenance of this equipment will be

available from time to time.

1.4.1 O btaining Warranty Service

In the event the Test Set may require service or repair that is included under the

warranty provided with the Test Set; the following is necessary to ensure proper

handling:

1. Contact Tel-Instrument Customer Support before shipping any Test Set

back under a warranty condition.

Tel-Instrument Electronics Corp. Customer Support can be reached by

calling:

¾ (201) 933-1600 (telephone)

¾ (201) 933-7340 (fax)

2. The Customer Support Department will discuss the matter and if validated,

issue an RMA (Return Material Authorization) number and form. Do not

return any product without first receiving this authorization.

3. The Test Set must be returned with the completed RMA form. This will

ensure prompt handling and expedited service.

4. Products must be returned in the Original Shipping Container (see

Paragraph 1.4.1). If the original container is no longer available, please

contact Tel-Instrument for guidance. Include in or on the shipping container

the following information:

1-3

Page 13

Rev E TR-220 90 008 088-1

• RMA Form on top of the product

• The assigned RMA number written in bold letters on the

outside of the shipping container

• Model, Serial Number, and specific details regarding the

problem

• POC name, return address, telephone number, and

email address

5. Freight Charges to the factory are the responsibility of the owner/operator.

Tel-Instrument will provide return shipping if the problem is determined to be

warranty covered.

1.4.2 Shipping and Packing the Test Set

1. Repackage the Test Set in the Original container utilizing the provided

packing material. Do Not Ship the Test Set with out using a shipping

container, this will prevent damage to the case and or finish during transit.

2. Wrap the Test set within plastic sheeting and firmly seat the Test Set in

the original corner molds. Place all necessary documentation (RMA Form,

POC, etc…), on top of the Test Set.

3. Utilize Package Tape and seal all seams. If the use of an industrial box

stapler is used, be sure that they do not protrude through the box to

prevent injury to personnel handling the package.

4. Firmly affix a shipping label and mail the Test Set to the following:

Tel-Instrument Electronics Corp.

728 Garden Street

Carlstadt, NJ 07072

Attn: Repair Department

1-4

Page 14

Rev E TR-220 90 008 088-1

SECTION B

EQUIPMENT DESCRIPTION

1.5 Specifications

Transponder Transmitter

Frequency 1030 MHz ± 10 kHz

Output Power >

Modes A, C, S, ADS B TX/RX,

and TIS

4dBm

Transponder Receiver

Accuracy ± 200 kHz

Accuracy ± 2 dB (direct connect)

± 3 dB (radiated)

Accuracy ± 2 dB (direct connect)

± 3 dB (radiated)

Accuracy ± 1%

Frequency Frequency 1086.5 to 1093.5 MHz

Power Range 47 to 64 dBm

Sensitivity Range. -50 to -87 dBm

Reply Percent Range 0 to 100%

DME

DME Receiver

Frequency Frequency Channel Freq +3.5 MHz

Accuracy ± 200 kHz

Sensitivity Range < -35 dB

DME Transmitter

Frequency Frequency 962 to 1213 MHz

Accuracy ± 100 kHz

Power ≥ 4 dB

TCAS

TCAS Transmitter

Frequency 1090 MHz ± 10 kHz

Output Power >

Modes C & S

Antenna Beamwidth…. 15° Sum & Diff Ports

30° Sum only

4dB

1-5

Page 15

Rev E TR-220 90 008 088-1

TCAS Receiver

Frequency 1026.5 to 1033.5 MHz

Power 47 to 64 dBm

Physical Characteristics

Packaging MIL-PRF-28800 Style C

Size 14.5 x 9.4 x 6.5 inches

Weight. 20 pounds

Operating Temperature -28° to +55° C

Battery Operation. 8 hours at a 20%

Duty Cycle

AC Operation/Charging 100 – 240 VAC

47 – 440 Hz

1-6

Page 16

Rev E TR-220 90 008 088-1

1.6 Abbreviati ons, Acronyms and Glossary of Term1

A/A Air to Air

A/A B Air to Air Beacon

ac or AC Alternating Current

A/D Analog to Digital

ADS-B Automatic Dependent Surveillance - Broadcast

Address The unique code to which a MODE S transponder replies. This is not to

be confused with the 4096 code used for identifying ATCRBS

transponders. The address of a MODE S transponder is not alterable by

the pilot or crew.

Altitude The pressure altitude of the aircraft as transmitted by an ATCRBS or

MODE S transponder. This information is obtained from an external

sensor and transmitted to the transponder.

AM Amplitude Modulation

ATCRBS Air Traffic Control Radar Beacon System

ATCRBS/MODE S All Call Interrogation that causes all ATCRBS/MODE S transponders to reply.

ATC Air Traffic Control

AUT Aircraft Under Test

BIT Built in Test

Comm Refers to the communications and data-link capability of a MODE S

transponder. There are four (4) capabilities: No Comm, Comm A/B,

Comm A/B/C and Comm A/B/C/D. The Comm. capability is displayed

when the transponder is determined to be a MODE S.

CW Continuous Wave

D/A Digital to Analog

DAP Downlinked Aircraft Parameter

dB Decibel

dBm Decibels above 1 milliwatt

dc or DC Direct Current

DME Distance Measuring Equipment

DPSK Differential Phase Shift Keying. The method of modulation used for the

selective MODE S uplink interrogations.

DF Downlink Format. The format included in a MODE S transponder reply to

an interrogation or squitter message that indicates the type of message.

ELM Extended Length Messages

FAA Federal Aviation Administration

FAR Federal Aviation Regulation

FIFO First In First Out

FREQ Frequency

ft. Feet

G/A Ground to Air

Hz Hertz

IF Intermediate Frequency

IFF Identify Friend or Foe

KHz Kilohertz

kts. Knots

LCD Liquid Crystal Display

LED Light Emitting Diode

1

Further definitions may be f ound in the following reference books and documents: Helfrick, A.D. Principles of Avionics.

Leesburg: Quality Books, 2000. RTCA/DO- 181B. Minimum Operation al Performance Standards for Air Traffic Control

RADAR Beacon System/Mode Select (ATCRBS /Mode S) Airborne E quipment. W ashington D.C.: 1999. United States.

Federal A viation Administration. Federal Register Fed 3

, 1987 FAA rules Part 91.

1-7

Page 17

Rev E TR-220 90 008 088-1

MODE S A secondary radar system where transponders can be individually

interrogated or selected (the “S” in MODE S) so that in a crowded air

traffic area, the amount of interference or garble can be reduced to a

minimum.

MHz Megahertz

nmi. Nautical mile

ns Nanosecond

PAM Pulse Amplitude Modulation

PDME Precision Distance Measuring Equipment

PMCS Preventative Maintenance Checks and Services

PPM Pulses per Minute

PRF Pulse Repetition Frequency

PW Pulse Width

PWR Power

RA Resolution Advisories

Receiver Efficiency The Test Set’s Measurement of valid replies received. Displayed as a

Percentage.

Reply Codes A transmitted response, from the airborne transponder, to an

interrogation. Commercial transponders responses are designated as

either ATCRBS/A where the reply includes the pilot selected 4096 ID

code, or ATCRBS/C, where the reply includes the aircraft pressure

altitude. These same responses for military transponders are designated

as MODE 3A and MODE 3C. See Mode S for further information.

RF Radio Frequency

RMS Root Mean Square

R/T Receiver Transmitter

SIF Selective Identification Feature

SLS Side Lobe Suppression. A pulse transmitted from an omni-directional

antenna used as a reference level to prevent replies to interrogations

received from the secondary radar antenna side lobes.

Squitter The self-generated transmissions made by a MODE S transponder, not in

reply to an interrogation, for the use of the collision avoidance system.

And ADS-B Receivers and Transmitters.

SSR Secondary Surveillance Radar

Surveillance Altitude An interrogation that causes only the addressed MODE S transponder to

reply.

Surveillance ID An interrogation that causes only the addressed MODE S transponder to

reply to its “4096” code.

TA Traffic Advisories

TACAN Tactical Air Navigation

TCAS Traffic Alert and Collision Avoidance System

TIS Traffic Information System

TX Transmitter

UF Uplink Format. The format in a MODE S interrogation that indicates the

type of reply expected.

VORTAC VOR and TACAN (co-located)

VOR VHF Omni-Directional Range

VSWR Voltage Standing Wave Ratio

WOW Weight On Wheels

UUT Unit Under Test

XPDR Transponder

XPDR UT Transponder Under Test

4096 Code This refers to the octal number dialed into either an ATCRBS MODE A or

MODE S transponder by the pilot. This is to be distinguished from the

address of the MODE S transponder, which cannot be changed.

1-8

Page 18

Rev E TR-220 90 008 088-1

CHAPTER II

PREPARATION FOR USE AND OPERATION

SECTION A

GENERAL INFORMATION

2.1 General

This Chapter contains all nec es sary inform ation on the initial unpacking, inspection, and set-up of

the TR-220 Multifunction Test Set (Herei naft er call ed the TR-220, Test Set, or T/S).

2.2 Unpacking

When receiv ing the TR-220 for the fi rst time, ensure that there is no damage to the shipping

container. Carefully unpack the unit and save the shipping container in a safe location for

shipping or ext ended stor age.

Examine the unit for obvious signs of damage. Check all displays, switches, and connectors

before utilizing the Test Set.

If any dam age i s found, DO NOT use the T est S et until a deter m ination of the Test Sets functions

can be assessed. Contact Tel-Instrument as soon as possible for further instruc tions.

The TR-220 Test Set batt eri es were installed and fully charged when shipped from the factor y .

2.3 Installation

The Test Set is fully func tional and ready to use from the fact or y. There ar e no inst allation

procedures applicable.

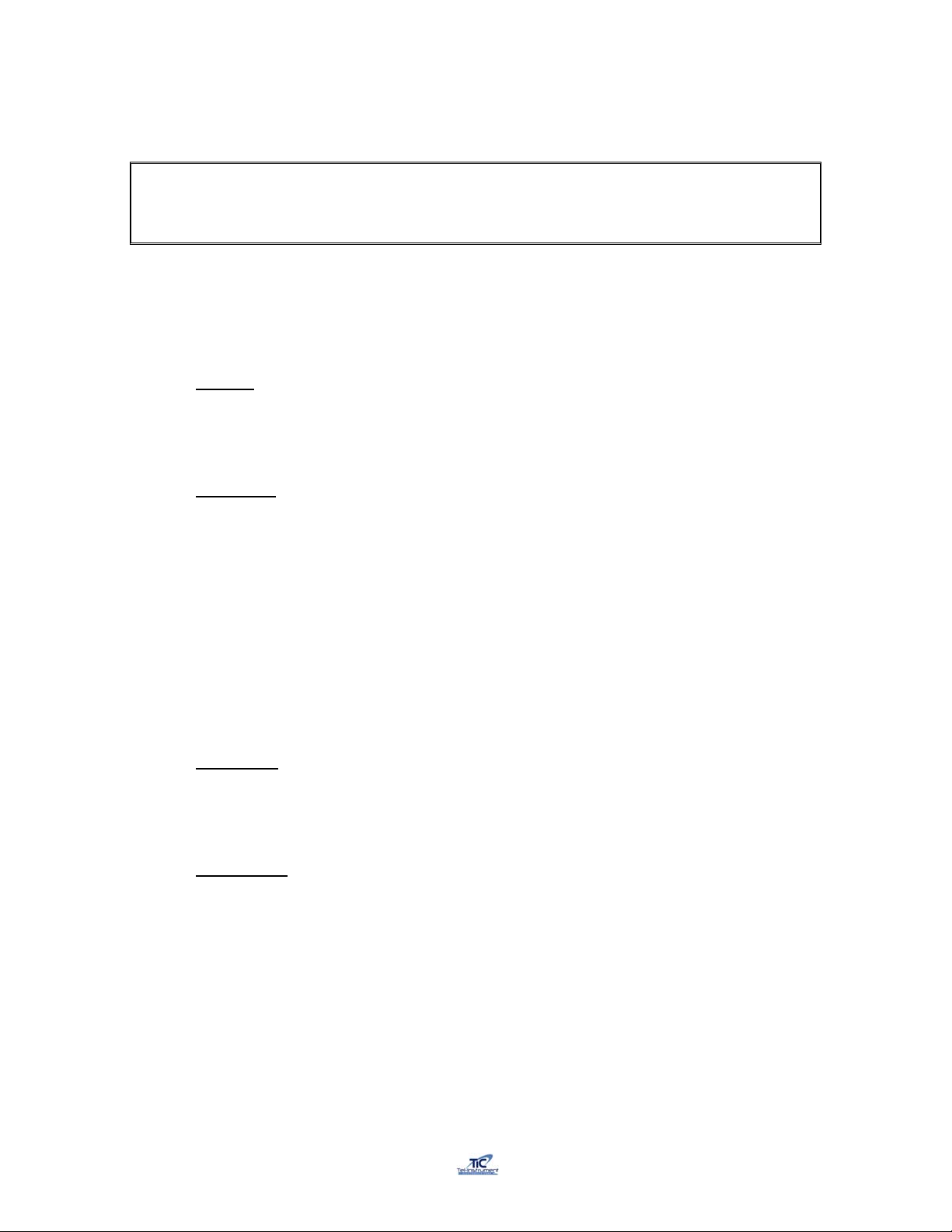

2.4 Accessories

Once opening the Test S et Cover , ensure al l the accessories that were purcha sed with the Test

Set are account ed for. T he TR-220 c om es standard with the following (See next page):

2-1

Page 19

Rev E TR-220 90 008 088-1

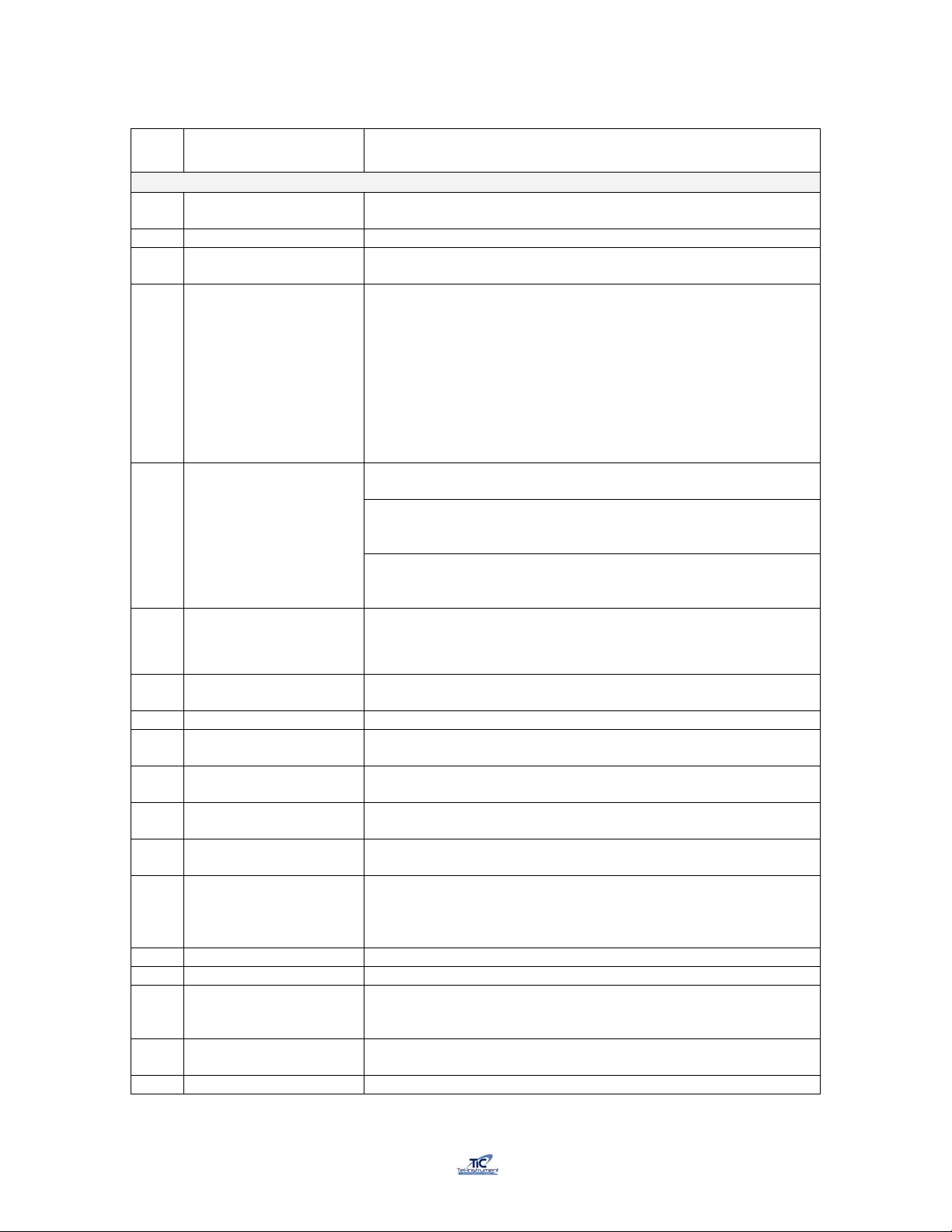

# NOMENCLATURE P/N QTY

1 Test Set 90000088 1

2 Cable Assembly, AC Power Cord 75010025 1

3 Cable Assembly, Direct Connect 75010186 1

4 Extender Cable Assembly, Dir ectional

Antenna

75010078

1

5 Directional Antenna Cabl e Assembl y 75010208-02 1

6 Directional Antenna Assembly 89001158-07 1

7 Directional Antenna Handl e A ssembly 88001002 1

X TAP-200 Antenna Coupler Optional

XX TR-220 Manual (Not Shown) 90008088-1 1

TR-220 Accessories

Table 2-1

1

2

3

4

7

6 5

TR-220 Accessories

Figure 2-1

2-2

Page 20

Rev E TR-220 90 008 088-1

SECTION B

OPERATING CONTROLS, INDICATORS, AND CONNECTORS

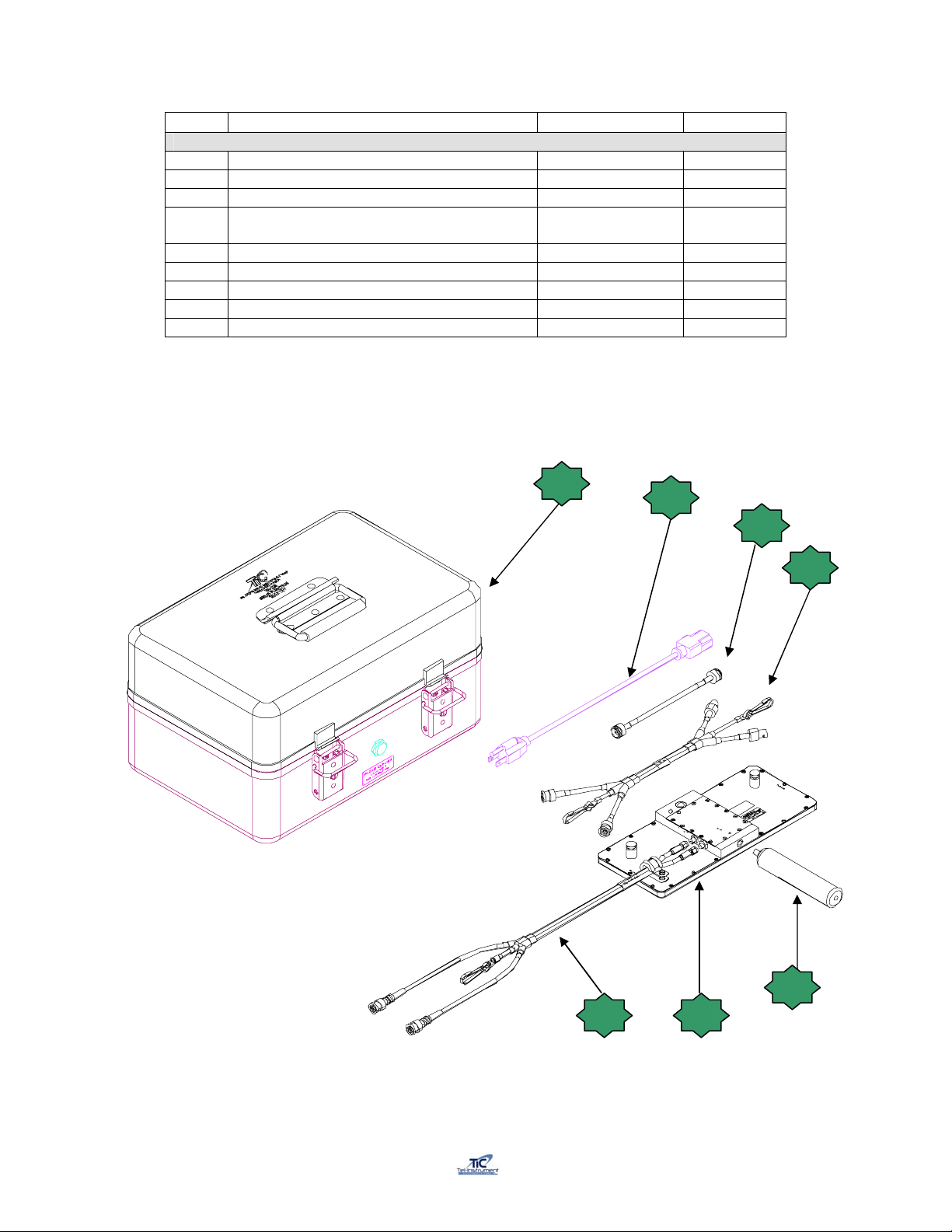

2.5 General

This section c overs loc ation and funct ion of the operat ing c ontrols, indicators, and connectors. Al l

controls, indicators, and connectors are located on the front panel of the T est S et.

2.6 Controls, Indicators, and Connectors

Figure 2-2 and Table 2-2 indicates the location and the f unct ion of each item on the front panel of

the Test Set.

1 2 3 4 5 6 7 8 9 10 11 12

Controls, Indicators, and Connectors

Figure 2-2

2-3

131415 1618 17

Page 21

Rev E TR-220 90 008 088-1

FIG # Control, Indicator, or

Connector

(Table 2-2) FUNCTI O N

1 SUM Antenna Port

2 DIFF Antenna Port Provides Connection to the Directional Antenna Diff Connector

3 Data Display Window

4 UUT FUNCTION Switch

CHN/ALT, DIST, VERT

5

SPEED Switch

UP/FWD, DOWN /RE V

6

7

8 IDENT Switch Initiates a SPI Pulse for verification of transponder IDENT function.

9

10

11 Direct Connect Port

12

13

14 STORE connector RS-232 port for download of stored data to a PC.

15 Test Set charging indicator Indicates to operator that the Test Set Batteries are charging

16 AC Power Panel

17

18 Power ON “LED” Indi cates to the operator that the Test Set is “ON”.

Switch

TO/START – FROM/STOP

Switch

ATCRBS/AI R, MODE S /GND

INTRUDER Switch

INCREASE/DECREASE

VELOCITY

MOM/BACK LIGHT/ON

Switch

AUTO/TEST/MANUAL

Switch

TEST SET ON/OFF

Switch

Provides Connection to the Directional Antenna Sum Connector and the

optional TAP-135 Antenna Coupler.

Alpha/Numeric display (2 lines/20 characters) providing operational

instructions, error messages, scenario progress, and test results.

Provides access to Test Set Menus and Modes.

SETUP- Set Antenna Gain, T/S Distance, TCAS Scenario Selection, Altitude,

Velocity, and Vertical Speed and Distance, Power display (watts or dBm),

Cable Loss, Mode S address, and Latitude and Longitude for ADS-B

Functions.

XPDR- Access ATCRBS and MODE S Transponder test menus.

TCAS- Access TCAS intruder menus.

ADS-B TX- Select ADS-B Transmitter Results.

ADS-B RX- Select ADS-B, and TIS Functions.

DME- Access DME Test menus.

DME- Allows selection of DME Channels. Selectable from 108. 0 MHZ in 50

KHz steps. Used in conjunction with UP/FWD – DOWN/REV switch.

TCAS- Set Intruder altitude offset from 99,900’ t o 50,200’ in 100’ inc/ 50,175’

to -9000’ in 25‘ increments. Default is 0’. Used in conjunction wit h UP/FWD –

DOWN/REV switch.

TCAS- Intruder vertical speed in “feet per minute” (fpm) adjustable in 100’

increments from +7500’ to -7500’. Used in conjunction with UP/FWD –

DOWN/REV switch.

Used in conjunction with CHN/ALT, DIST, VERT SPEED switch to vary

parameters. Also used to set ant enna gain and Test Set di stance in SETUP

mode.

Start and Stop TCAS Intruder scenarios and change DME To/From

parameters.

Selects TCAS Intruder Type (MODE S or ATCRBS), and Air or Ground

position.

Sets TCAS Intruder and DME speed velocities. Also utilized for ADS-B TX/RX

Functions.

For direct connection to a Transponder. Provides accurate RF Power,

frequency and sensitivity measurements.

Activates display backlighting either “ON” or momentarily.

Allows the operator to select an Automatic Sequence of Transponder tests or

a Manual sequence. Initiates TCAS and DME scenarios. Hold AUTO key

when Test Set power is turned “ON” to select CW operation. Use AUTO and

MANUAL to advance through EHS and ADS-B tests.

1. Provides connection to a 115 or 220 VAC power source.

2. AC “ON” / “OFF” switch for battery charging.

3. Fuse Cartridge.

Turns Test Set “ON” and “OFF”.

2-4

Page 22

Rev E TR-220 90 008 088-1

SECTION C

OPERATING INSTRUCTIONS

2.7 General

The TR-220 i s a self-cont ained instrum ent comprised of a Test Set mounted in a r ugged case

with a removable cover. The Test Set front panel contains all the switches necessary to test

Transponders (ATCRB S and MO DE S), ADS- B and TIS , DME and TCAS equipm ent. By t he use

of toggle switches and an easy to read display, the operator m ay quickly test, make accurate

measurements and perform preprogrammed or manually selected TCAS scenarios. The

directional antenna with an active LED display and optical sight are utilized for Transponder,

DME, and TCAS tests. All accessories are stored in the Test Set case for easy storage and

protection.

2.8 Battery Operation

The TR-220 Test S et is equipped with a rechargeable Lead Acid batter y , capable of operating the

Test Set using a 20% dut y cycle f or 8 hours at 77 degrees F (25 Degree s C). This repre sents a

full day of t ypical t esti ng on a si ngle c harge. W hen operat ing t he Test S et i n l ower tem perat ures,

the battery life will decrease slightly .

The operator will be able to utilize the Test Set until the batteries are nearl y depleted. The unit

may then be plugged i nto a standard 115 or 220 VAC / 47 to 440 HZ power source to conti nue

testing. By observi ng a Duty Cycle (DC) of 20%, the Test Set batteri es will begin regaining their

charge while testing is in progress.

The TR-220 provi des a low battery warning system to alert the operator when batt ery strength

has been deplet ed to a poi nt where t esti ng m ay be i nter rupted. Sev eral warni ng are di splayed t o

warn the operator of this condition and to give them a warning that the batteries will require

charging or supplem ental AC power applied to complete ext ended testing.

As the battery capacity decreases, the Test Set will displ ay the following:

Toggle the AUTO switc h to bypass the di spl ay and continue testing. A pproximately 15 minutes of

battery capaci ty is available. As the batter y strength decreases, the di spl ay will indicate:

This indi cates only several minutes of t esti ng time is a v ailable. It i s recomm ended that AC power

be supplied t o continue testing or testing halted at this point and the Test Set charged. Toggle the

AUTO switch to bypass thi s warning. Further t esting will result in the final warni ng:

Low Battery

Press AUTO to cont.

Low Battery

Recharge Required!

Low Battery

SHUTTING DOWN

2-5

Page 23

Rev E TR-220 90 008 088-1

This warning cannot be bypassed, and AC power must be utilized or charging the battery is

necessary.

It is strongly r ec om mended that t he batteries be charged for a short tim e eac h week, r egar dless if

the Test Set has be en utili zed or not. A completely discharged batt ery will require approximat ely

16 hours to fully c harge. Occasional char ges of 16 hours on partiall y depleted bat teries will have

no adverse effec ts.

The current batt er y status display is available in t he SETUP f unction.

T o preserv e batter y strengt h, the TR-220 will autom atically shut down af ter 20 minutes of

inactivity. By toggling any switch during the 20 minutes will reset the timer allowing

extended testi ng.

Shutdown will not occur when AC power is utilized as the source.

2.9 TR-220 Supplied Antenna

Standard equipm ent with the TR-220 is a Directional Antenna. The antenna, stored in the case

cover, can ei ther be hand held, tripod m ounted, or directl y mounted on the Test Set c ase. The

Test Set also contai ns a direct connect cable for accurate power and f requency measurements

(± 2 dB) when connec ted directly to the UUT . The Test Set has a buil t in 50 dB attenuator to

prevent dam age to t he Test Set due t o the High Power RF associated with Transponders.

Battery: EF

Cont: AUTO

2.8.1 Auto Shutdown

2.9.1 Directional Antenna

The Directional Antenna is a printed circuit sandwiched between two opaque Lexan

sheets.

1. Open and rem ov e the TR-220 T est Set c ase cov er. Release the t wo (2) push b utt on

holders

2. The Directional Ant enna can be mount ed on the case or be hand-held ut ilizing the

supplied handle.

2a. To m ount the antenna to t he case, simpl y slide the m ounting Tabs (located on

the back) into the slots located on the front of the Test Set Case.

2b. To utili ze the hand hel d met hod, att ach the suppli ed handl e to the bott om of the

antenna and hand tight en only.

2c. You may also att ach t he antenna t o a tri pod, which will i nc rease the stabil it y due

to high winds or hand movement thus increasing the lock on rat e.

3. The operator m ust fi rst set the pr oper Ant enna Gai n v alue i nto the T est Set memory .

Turn the Test Set “ON” with the UUT FUNCTION switch in the SETUP position.

2-6

Page 24

Rev E TR-220 90 008 088-1

Locate the ANT GAIN menu by toggling the AUTO/MANUAL switch. Enter the

correct val ues that are affixed to the Di rectional Antenna (Figure 2-3) by using the

UP/FWD, DOWN/REV switch. Ensure you enter both values, 1030 MHz and 1090

MHz. Once completed, turn “OFF” the Test Set. The values will remain in the Test

Set memory. You will only need to reenter the values if the antenna i s replaced or

repaired.

Ant Gain 1030: +XXdB

Chg:Up/Dn Cont: AUTO

Directional Antenna Gain

Figure 2-3

4. When using the handheld or tripod method, connect the extender cable supplied with

the Test Set, ensuring to match the appropriate color-coded cables. Connect the

opposite ends of the ANTENNA SUM & DIFF connectors on the Test Set front

panel. If rev ersed, the Test Set will displ ay a fault prompting t he operator to check

their antenna connections.

ANTENNA Connections

ANTENNA DATA

Gain @ 1030 Gain @ 1090

-XX dB -XX dB

Missing or Reversed

5. Maint ain a 10 to 170 ft. (3 to 50 meters) unobstructed path t o the Aircr aft Under Test

(AUT), and point t he Dir ectional antenna to the appropriate antenna on the AUT.

6. Turn the Test Set “ON” wit h the UUT FUNCTION switch in SETUP. Locate the T/S

Distance menu by toggling the AUTO switch and insert the approximate distance

measured from the Test Set to the AUT antenna by toggling the UP/FWD,

DOWN/REV switch. With out turning the Test Set OFF, turn the UUT FUNCTION

switch to the desired sequence of tests.

T/S Distance: 170 ft

Chg: Up/Dn Cont:Auto

7. The optical sight will have a blinking LED indicating the operator must turn the

antenna sli ghtly to gain a strong RF signal. A steady red LED signif ies a good RF

signal and the Test Set will commence testing. The operator may also observ e the

TURN indicator located on t he display. By slowing turni ng the antenna, the TURN

indicator will spin slower until a lock is obtained. At that point, the Test Set will

display the appr opr iate display.

2-7

Page 25

Rev E TR-220 90 008 088-1

NOTE: The TR-220 uses a software technique to n arrow the beam widt h. When

testing inside of a hanger, multi-path reflections can cause erroneous TURN

indications. If unable to eliminate TURN message, remove antenna cable

connection t o DIFF port. Thi s will not affect any test results.

8. Positi on the antenna wit h an unobstruct ed line t o the UUT antenna. Ensure that the

transmitt er or receiver (RX/TX) that you are testi ng is signif icantly cl oser to the T est

Set than another operating RX/TX; else, an undesired reply or erroneous and

inaccurate results may occur.

Directional Antenna Setup

Figure 2-4

M eas ur em en t s util iz in g t h e Dir ec ti on al A nt en na have an acc uracy of ± 3 dB.

2-8

Page 26

Rev E TR-220 90 008 088-1

2.9.2 Direct Connect

The Direct Connect Cable, supplied with the Test Set, allows the operator to conduct

transponder tests directly from the transponder under test. Utilizing the direct connect

method eliminates possible antenna and cable losses and ensures the operator the

transponder is operat ing at its full potenti al. The TR-220 has a built in 50 dB attenuat or,

thus eliminating the need to connect an external attenuator for power and frequency

m easurem ent s. Simply connect the suppl ied c able from t he test set t o the transponder t o

be tested. Ensure that if your tr ansponder has m ultiple ant ennas (div ersit y equipped), to

terminate t he second ant enna to prevent damage to the transponder.

If you are not using t he Direct Connect method, but the directi onal antenna m ethod, you

must install the supplied termination cap on the DIRECT CONNECT port. If it is not

properly installed, the Test Set display will prompt the operator to remov e the ant enna.

Before testing utilizing the supplied Direct Connect cable, the operator must enter the

appropriate c able loss to ensure accurate measurements.

1. Access the ANT GA IN m enu by turni ng t he Test Set “ON” with the UUT FUNCTION

Direct Connection

REMOVE ANTENNA

switch in the SETUP position. Locate the Cable Loss menu by toggling the

AUTO/MANUAL switch. Enter the correct values that are affixed to the supplied

cable by using t he UP/FWD, DOWN/REV switch. If you are using a different cable, it

is important to know the cable loss value or inaccurate results will occur. Once

completed, t urn “OFF” the Test Set or toggl e to AUTO switch. The value will remain

in the Test Set m emory. You will only need to reent er the value if another cable is

utilized or it is repaired.

2.9.3 TAP-200 Antenna Coupler (Optional)

The TR-220 can be used wit h the ( opti onal) T AP-200 Ant i Radiati on Ant enna Coupler for

testing transponders (fig 2-5). The Antenna couplers provide a limited amount of

attenuati on, approximately 20 dB, to prev ent the transmission of the tr ansponder signal

into the airspace above the aircraft under test. The Antenna Couplers may only be

utilized on bl ade ty pe antennas.

Cable Loss: 1.8 dB

Chg: Up/Dn Cont:AUTO

Measurements utilizi ng the direct c onnect method have an acc uracy of ± 2 dB.

2-9

Page 27

Rev E TR-220 90 008 088-1

TAP-200 Coupler

Figure 2-5

1. Connect the TAP-200 Cable to the TR-220 antenna SUM port.

2. Turn the test set ON by toggling the ON/OFF switch Up and turn

the UUT FUNCTION switch to the SETUP position. Scroll to the Antenna

Selection screen usi ng the AUTO/MANUAL switch.

Antenna: TAP

Chg:Up/Dn Cont:AUTO

3. Use the UP/FWD-DOWN/ REV switch to select TAP.

4. To install the coupler, pull the ring, which separates the spri ng- loaded clamp, and

slide the coupler over the blade antenna. Ensure that the EMI gasket of the

coupler is flush with the aircraft skin and that the coupler is centered over the

antenna. Release the ring (fi g 2-6).

5. Ensure that the coupler is centered ov er the antenna to be tested.

6. Due to the availability of numerous styles of antennas, slight adjust of the

Coupler may be necessary to receive accurate measurements. If incorrect

r eadings occur , r e-posit ion and ensure a snug f it on the antenna. Mov e t he TAP 200 forward or back and double check a firm and snug seal on the aircraft

surface (fi g 2- 7).

7. An accurate adjust of the couplers can be accomplished by advancing to the

Manual Mode of tests POWER, RECEIVER, FREQ test page and adjusti ng the

coupler for the maximum power out. O nc e adjusted, the operat or can then restar t

the appropriate series of tests ensuring accurate results.

2-10

Page 28

Rev E TR-220 90 008 088-1

Center the TAP-200 as close to center

as possible for the style of antenna

being tested. If inaccurate results

occur, reposition the coupler slightly

forward or back and check for a snug

flush fit until accurate measurements

are displayed. Due to the many styles

of antennas available, adjustments

may be necessary.

TAP-200 Placement

Figure 2-6

Power, Receiver, Freq

54 dB -77 dB 1090.0

TAP-200 Antenna Adjustment

Figure 2-7

.

8. Proceed with Transponder testing as outlined in paragraph 2.12 or 2.13

2-11

Page 29

Rev E TR-220 90 008 088-1

2.10 Initial Startup and Self-Test

When using t he Test Set, it is advi sable to have a f ully charged battery . This will ensure al l test s

can be complet ed with no int er r uptions or loss of data.

1. Turn on the TR-220 by toggling the ON/OFF switch “UP”. The green LED located

above the switch will illuminate. Briefly, the Test Set display will indicate: Model number,

current software version install ed and tot al hours of operation.

2. The Test Set will immediately commence a SELF TEST.

The Self Test function is automatic, and will test the following components:

a. Digital Board

b. RF Maximum Power

c. RF Minimum Power

d. RF Board

If a failure is detected, a message indicating the failed component or test will be

di splay ed. If no f ailures are det ected, t he result will be briefl y displayed bef ore movi ng to

the initial star t page of the selected tests.

3. Toggle the BACKLIGHT switch to the MOM position and verify the Test Set display

backlighting illuminates. Release the switc h and the backlighting will extinguish.

4. Turn the T est Set “O FF” by toggli ng the ON/OFF switch down. The display will be blank

and the green LED will extinguish.

Tel-Instrument TR-220

REV X.XX 00001 hrs

Self Test

Testing . . .

Self Test

PASS

2-12

Page 30

Rev E TR-220 90 008 088-1

2.11 Transponder Test Sequence

The TR-220 T/ S i s capable of testi ng ATCRB S Mode A, Mode C an d Mode S tr an sponders. T he

operator m ay select bet ween an Automatic series of tests and a Manual series of t ests. Figur e 2-

8 outlines t he sequ ence, i n order , of t ests c onducted. The T est Set will determine the correct set

of tests, either M ode A/C or Mode S upon rec eiv ing the transponder RF signal.

Transponder Sequence

Figure 2-8

2-13

Page 31

Rev E TR-220 90 008 088-1

2.12 Transponder Manual Sequence of Tests

NOTE

When conducting tests in the MANUAL sequence, the operator initializes the sequence by

toggling the AUTO/TEST/MANUAL switch to the MANUAL position. The Test Set then

commences a series of tests and displays the individual results of each test (see figure 2-8)

ending in the POWER, RECEIVER EFFICIENCY and FREQUENCY page. After each test is

completed, the operator must toggle the MANUAL switch to advance to the next test in the

series.

The “IDENT” feature of a t ransponder can onl y be t ested dur ing t he MANUAL seque nce of t ests.

See paragraph 2-14 for detailed instructions.

2.12.1 ATCRBS, Mode A/C Manual Testing

1. Utilize the procedures as outlined in paragraph 2.9 to select the preferred

antenna method for the following tests.

2. Turn the Test Set “ON” by toggling the ON/OFF switch to the ON position.

3. The Test Set commences the Self Test. “PASS” i s displayed bri efly if no fail ures

4. Turn the UUT FUNCTION switch to the XPDR position. The Test Set will

automatically determine the transponder capability as being Mode A and/or C

capable and displ ay the appropr iate start page.

5. Toggle the AUTO/TEST/MANUAL switch to the MANUAL position to begin t he

All illustr ations shown are for demonstrati on pur pose s. Though the test

results may be typic al, they are not meant to replace FAA guidelines and

Ensure the green LED illuminates.

are detected.

manufacturer r ec ommendations.

Self Test

PASS

Capab Mode A/C

Press A/M

sequence.

M A /

Mode A Test initialized.

Testing . . .

2-14

Page 32

Rev E TR-220 90 008 088-1

A

A

g

6. To adv anc e, toggle the AUT O/TEST/MANUAL switch to MANUAL. The next test

in sequence will commence.

7. To adv anc e, toggle the AUT O/TEST/MANUAL switch to MANUAL. The next test

in sequence will commence.

8. To advance, toggle the AUTO/TEST/MANUAL switch to MANUAL. The next t est

in sequence will commence.

M A 1234 100%

0.45–20.35– 0.45 PASS

M A Rply 3.11us P

M A Jitter 25ns P

M C /

Testing . . .

M C 6520 10000’ 100%

0.45 – 20.35 – 0.45 PASS

M C Rply 3.11us P

M C Jitter 25ns P

Mode A SLS Τ

Testing . . .

SLS P1>P2 100% PASS

P1=P2 0% PASS

Sensitivity

Testing . . .

Test Complete. Display indicates the UUT

4096 Octal Code (1234), Receiver

Efficiency as a percentage (100%),

Transponder Framing Pulse widths (0.45)

and separation measured in .05 µs

increments (20. 35 µs).

n alternati ng display indicates the Mode A

Reply Delay and Jitter with a P(ass) or

F(ail) indic ation for each measurement.

Mode C Test initializ ed.

Test Complete. Display indicates the UUT

Altitude Gray Code (6520=1000’), Rcvr.

Efficiency as a percentage (100%),

Transponder Framing Pulse widths (0.45)

and separation measured in .05 µs

increments (20. 35 µs).

n alternating display indicates the Mode

C Reply Delay and Jitter with a P(ass) or

F(ail) indic ation for each measurement

Mode A SLS tests are initiated. The test

set makes alternating interrogations with

and without the SLS pul se.

When P1>P2 (S LS pulse at P1 - 9dB) the

transponder reply efficiency should be

greater than 99%. For P1=P3 (SLS) The

transponder repl y effi ciency should be l ess

than 1%

UUT Receiver sensitivity tests (MTL) for

modes A and C are initiat ed.

** Deno tes a test only a vail able with

Software Revision 5.00 or

**

.**

reater.

2-15

Page 33

Rev E TR-220 90 008 088-1

9. To adv anc e, toggle the AUT O/TEST/MANUAL switch to MANUAL. The next test

in sequence will commence.

NOTE

A: -73.9dB C: -73.9dB

Sens. A&C: PASS

Power, Frequency /

Testing . . .

Power, Frequency

54 dB 1090.0 MHz

Power measurement s are measured in Watts or dBm. The Test Set only

displays dB due to display restrictions. To change the display to indicate

Watts, access the SETUP menu and toggle to the Power in Watts menu.

Use the UP/DOWN toggle to make a selecti on.

END OF MODE A/C MANUAL TESTS

Test Completed. Displ ay indi cates the UUT

receiver sensitivity for mode A (-73.9db)

and Mode C (-73.9dB) PASS is displayed

when Mode A/C sensitivities are within

1dB.

UUT Power and Frequency Test is

initialized.

Test Completed. Displ ay indi cates the UUT

power (54 dB) and Frequency (1090.0) i n

MHz.

2-16

Page 34

Rev E TR-220 90 008 088-1

A

g

2.12.2 Mode S Manual Testing

1. Turn the Test Set “ON” by toggling the ON/OFF switch to the ON position.

Ensure the green LED illuminates. Utilize the procedures as outlined in 2.9 to

select the preferred antenna method for the f ollowing tests.

2. T he Test Set commences the Self Test. “P ASS” is di splayed briefly if no failures

are detected.

3. Turn the UUT FUNCTION switch to the XPDR position. The Test Set will

automatically determine the transponder capability as being Mode S capable and

di splay the appropriate start page wit h the COMM A, B, C, & D capabilities also

listed. The Test Set will display if the transponder reports it is capable of

Enhanced Surveillance (EHS). The Test Set will display the Vertical Status

(Air/Gr ound) and displ ay the results of an Interrogation Identifier (14) test.

4. Toggle the AUTO/TEST/MANUAL switch to the MANUAL posit ion to begin the

sequence:

5. To adv anc e, toggle the AUT O/TEST/MANUAL switch to MANUAL. The next test

in sequence will commence:

Self Test

PASS

Capab Comm AB EHS

AIR Press A/M II:14

M A /

Testing . . .

M A 1234 100%

0.45–20.35– 0.45 PASS

M A Rply 3.11us P

M A Jitter 25ns P

M C /

Testing . . .

Mode A Test initialized.

Test Complete. Display indicates the UUT

4096 Octal Code (1234), Receiver

Efficiency as a percentage (100%),

Transponder Framing Pulse widths (0.45)

and separation measured in .05 µs

increments (20. 35 µs).

n alternati ng display indicates the Mode A

Reply Delay and Jitter with a P(ass) or

F(ail) indic ation for each measurement.

Mode C Test initializ ed.

** Deno tes a test only a vail able with

Software Revision 5.00 or

**

reater.

2-17

Page 35

Rev E TR-220 90 008 088-1

A

A

g

6. To adv anc e, toggle the AUT O/TEST/MANUAL switch to MANUAL. The next test

in sequence will commence:

7. To advance, toggle the AUTO/TEST/MANUAL switch to MANUAL. The next t est

in sequence will commence:

8. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

9. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

M C 6520 10000’ 100%

0.45-20.35-0.45 PASS

M C Rply 3.11us P

M C Jitter 25ns P

Mode A SLS /

Testing . . .

SLS P1>P2 100% PASS

P1=P2 0% PASS

M A All Call /

Testing . . .

M A All Call /

A02008 100%

M C All Call /

Testing . . .

M C All Call /

A02008 100%

Test Complete. Display indicates the UUT

ltitude Gray Code (6520=1000’), Rcvr.

Efficiency as a percentage (100%),

Transponder Framing Pulse widths (0.45)

and separation measured in .05 µs

increments (20. 35 µs).

n alternating display indicates the Mode

C Reply Delay and Jitter with a P(ass) or

F(ail) indic ation for each measurement.

Mode A SLS tests are initiated. The test

set makes alternating interrogations with

and without the SLS pul se.

When P1>P2 (S LS pulse at P1 - 9dB) the

transponder reply efficiency should be

greater than 99%. For P1=P3 (SLS) The

transponder repl y effi ciency should be l ess

than 1%

Mode A A ll Call Test initi alized. Transmits

an M A All Call.

Test Complete. Successful DF=11 reply

will display the decoded aircraft address in

Hexadecimal (A02008) and Receiver

Efficiency as a percentage (100%).

Mode 3C All Call T est initi alized. Tr ansmits

a Mode 3C All Call.

Test Complete. Successful DF=11 reply

will display the decoded aircraft address in

Hexadecimal (A02008) and Receiver

Efficiency as a percentage (100%).

** Denotes a test only available with

Software Revision 5.00 or

**

reater.

2-18

Page 36

Rev E TR-220 90 008 088-1

A

A

AIR

R

10. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

11. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

12. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

M A Only /

Testing . . .

M A Only /

PASS

M C Only /

Testing . . .

M C Only /

PASS

SI Lockout /

Testing . . .

SI Lockout

PASS 18 sec

M S Surv ID /

Testing . . .

M S Surv ID /

1234 FS: AIR 100%

Mode A ONLY Test initialized. Test Set

transmits an ATCRBS ONLY All-Call.

Mode S transpon der will not reply to an

ATCRBS Only All -Call. A “PASS” signifies

the Mode S transponder did not r espond.

Mode 3C ONLY Test initialized. Test Set

transmits an ATCRBS ONLY All-Call.

Mode S transpon der will not reply to an

ATCRBS Only All -Call. A “PASS” signifies

the Mode S transponder did not r espond.

The Test Set issues a SI Lockout

command (37) and verifies that UUT will

not respond f or mi nimum of 3 seconds and

maximum of 18 seconds.

Mode S Surveillance Identity Test

initialized. Test Set will transmit an UF=5

interrogation.

Test complete. A successful DF=5 Reply

will display the aircraft 4096 Octal code

(1234), Flight Status (Air), and Receiver

Efficiency as a percentage.

NOTE

Possible Fli ght Status Codes are

(Alert/Airborne), AL/GND (Alert/Ground), AL/SP (Aler t/SPI), and SPI.

(Airborne), GND (Ground), AL/A

2-19

Page 37

Rev E TR-220 90 008 088-1

p

13. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

14. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

NOTE

15. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

16. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

M S Surv Alt /

Testing . . .

M S Surv Alt /

10000’ 100%

M S Surv Srt /

Testing. . .

USA: N107PP /

A02008 VS:AIR 100%

USA: N107PP /

50020010 VS:AIR 100%

Appendix A list available country codes. If the Test Set can not locate the

country al gori thm, “??????” will be displayed.

M S Comm Id /

Testing . . .

M S Comm Id /

1234 yyyyyyyy 100%

Mode S Surveillance Altitude Test. Test

Set will transmi t an UF=4 interrogation.

Test complete. A successful DF=4 Reply

will display reported altitude (10000’) and

Receiver Efficiency as a percentage

(100%).

Mode S Short Ai r to Air Surveill ance Test.

Test Set transmits a special short UF=0

interrogation.

Test compl ete. A Mode S trans ponder

will reply in a DF=0 format. Alternating

display will indicate the Country code

(USA) and tai l number, aircraft address

in Hexadecimal (A02008) and Octal

(50020010).

Mode S Communi cation I dentity T est. Test

Set will transmi t a COMM A/B tr ansmission

utilizing the UF=5/RR:18 field. This tests

the transponders comm unic ation and datalink ca

Test complete. A successful DF=21 Reply

will display 4096 code (1234), Flight ID

(yyyyyyyy) and Receiver efficiency as a

percentage (100%).

abilities.

2-20

Page 38

Rev E TR-220 90 008 088-1

p

17. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

18. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

19. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

M S Comm Alt /

Testing . . .

M S Comm Alt /

10000’ 100%

Undesrd Rply /

Testing . . .

Undesrd Rply /

PASS

Squitter /

Testing . . .

ACQ: PASS 900 ms

ADD: A02008 II:0

EXT: NOT DETECTED

EXT: PASS 500 ms

ADD: A02008 II:0

Mode S Comm unicati on Alt itude T est. T est

Set will transmi t a COMM A/B tr ansmission

utilizi ng the UF=4/RR:18 form at. This tests

the transponders comm unic ation and datalink ca

Test complete. A successful DF=20 Reply

will display UUT Altitude (10000’) and

Receiver Efficiency as a percentage

Undesired Replies Test initialized. The

Test Set will make randomly addressed

interrogations.

Test complet e. If the UUT replies to any of

the random interrogations, “FAIL” will be

displayed. A “PASS” indicates the UUT did

not reply as req uired. The test set u ses a

minimum of 3 r andom addresses to comply

with FAR 43 App F.

The Test Set will not transm it interrogations

but receive and process DF=11 and DF=17

extended replies.

Test complete. Upon detection of the

replies, the Test Set will display the interval

time of the messages (if received) in

milliseconds (900 m s). If either a DF= 11 or

DF=17 extended m essage is not acquired,

NOT DETECTED will be displayed.

If and Ex tended Squitter “ IS” detected, the

following display indicating the interval time

and address.

abilities.

2-21

Page 39

Rev E TR-220 90 008 088-1

NOTE

20. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

21. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequence:

22. To advance, toggle the AUTO/TEST/MANUAL switch to MANUAL. The next test

in sequence will commence.

Max True Spd /

Testing . . .

Max True Spd /

GT 300 & LE 600 kts

Eight possibl e RI fi eld c odes are available.

1) NO Max airspeed dat a, 2) LE 75 knots , 3) GT 75 & LE 150 kts., 4) GT 150 &

LE 300 kts, 5) GT 300 & LE 600 kts, 6) GT 600 & LE 1200 kts, 7) GT 1200 kts,

8) Not Assigned.

GT denote “Greater Than”, LE denotes “Less than or Equal t oo”

Diversity /

Testing . . .

Diversity A02008 /

PASS 26 dB Attn

Sensitivity /

Testing . . .

A: -73.9dB C: -73.9dB

Mode S: -74.4 dB PASS

Test Set verifi es the UUT airspeed code by

transmitting an UF=0 interrogati on.

Test complete. The DF=0 will report the

aircraft maximum cruising airspeed in the

RI field of the DF=0 format.

Diversity Test i nitialized.

Test complete. A PASS indicates that

isolation relative to the active antenna is

greater than 20 dB. and t he actual isol ation

figure is displayed.

UUT Receiver sensitivity tests (MTL) for

modes A and C are initiat ed.

Test Completed. Displ ay indi cates the UUT

receiver sensitivity for mode A (-73.9db),

Mode C (-73.9dB) and Mode S (-74.4dB).

PASS is displayed when Mode A/C/S

sensitivities are within 1dB.

2-22

Page 40

Rev E TR-220 90 008 088-1

A

g

23. Toggle the AUTO/TEST/MANUAL switch to MANUAL to advance to the next

sequ enc e:

Mode S Width Ampl. /

Testing . . .

Rply Dlay 128.20us P

MS Jitter 50ns P

MS Ampl Var. PASS

MS Pulse Width PASS

Power, Frequency /

Testing

Power, Frequency /

54 dBm 1090.0Mhz

END OF MODE S MANUAL TESTS

Test Compl ete. Di splay i ndicat es the Mode

S Reply Delay , Mode S Jitt er, Mode S P6

mplit ude Variation, and Mode S P6 Pulse

Width with a P( ass) or F(ail) indic ation for

each measurem ent.

UUT Power and Frequency t ests for m odes

A and C are initiated.

Test completed. UUT transmitter power

(54dBM) (shown in dBm or WATTS as

selected in Set-up Menu) and UUT

transmitter frequency in MHz.

** Deno tes a test only a vail able with

Software Revision 5.00 or

**

reater.

2-23

Page 41

Rev E TR-220 90 008 088-1

2.13 Transponder Automatic Sequence of Tests

When conducti ng tests in the AUTO sequence, the operator i nitializes the sequence by t oggling

the AUTO/TEST/MANUAL switch to the AUTO positi on. The Test Set then comm ences a series

of tests without i nterrupti on (see fi gure 2-8) endi ng in the POWER, RECEIVER EFFICI ENCY and

FREQUENCY page. T est results will not be displayed unl ess a failure occ urs. The operator can

then overri de the f ailur e and c ontinue testing by toggli ng the TEST switch to the AUTO position.

NOTE

Before testi ng begins, ensure that you have read and f ully under stand the procedure s preceding

this section. By reviewing these sections, the operator can avoid erroneous and inaccurate

results.

2.13.1 ATCRBS, Mode A/C Automatic Testing

1. Turn the Test Set “ON” by toggling the ON/OFF switch to the ON position.

Ensure the green LED illuminates.

2. The Test S et commences the Self Test. “PASS” is displayed bri efly if no fail ures

are detect ed.

3. Utiliz e the procedures as outli ned in 2.9 to select the preferred ant enna method

for the following tests.

4. Turn the UUT FUNCTION switch to the XPDR position. The Test Set will

automatically determine the transponder capabili ty as being Mode A/C capable

and display the appropriate start page.

5. Toggle the AUTO/TEST/MANUAL switch to the AUTO position. The Test Set will

begin testing t he transponder, without inter ruption, IAW figure 2-4. Each test will

be displayed as “Testing . . .” but no results will be shown, until the Test Set as

completed all tests.

All illustr ations shown are for demonstrati on pur pose s. Though the test

results may be typic al, they are not meant to replace FAA guidelines and

manufacturer r ec ommendations.

Self Test

PASS

Capab Mode A/C

Press A/M

M A /

Testing . . .

2-24

Page 42

Rev E TR-220 90 008 088-1

p

6. If no failures are detected, the Test Set will cease testing and display the

following alternating display :

NOTE

7. If a f ailure is detected during any test in t he Automatic sequence, the Test Set

will “STOP” at that test and display the failure along with the Framing Pulses,

Pulse Width, and separation in µs.

8. The operator may ov er ride and advance to t he nex t t est in sequence by t oggl ing

the AUTO/TEST/MANUAL switch to the AUTO posit ion. It i s recomm ended that

the operator determ ine the cause of the f ailure before advancing. Subsequent

tests m ay be inaccurate or misleadi ng.

9. The operator may also elect to repeat the failed test by toggling the

AUTO/TEST/MANUAL switch to the MANUAL position.

Power, Receiver, Freq /

54dB -78dB 1090.0

Mode A: 1234

Mode C: 10000’

Power measurement s are measured in Watts or dBm. The Test Set only

displays dB due to display restrictions. To change the display to indicate

Watts, access the SETUP menu and toggle to the Power in Watts menu.

Use the UP/DOWN toggle to make a selecti on.

M C /

No Reply

M C

The final alternating display will indicate

the UUT power (54dB), Receiver

Sensitivity (-78dB), Frequency

(1090.0), 4096 O ctal Code (1234), and

the UUT Altitude (10000’) in 100 ft.

increments.

Illustrate a Mode C failure. The first

display indi c ates the f ailur e, t he second

screen displays the Framing Pulse

widths (0.45 & 0.35) and their

aration (20.3) in µs.

se

0.45-20.35-0.35 FAIL

END OF MODE A/C AUTOMATIC TESTS

2-25

Page 43

Rev E TR-220 90 008 088-1

A

y

2.13.2 Mode S Automatic Testing

1. Turn the Test Set “ON” by toggling the ON/OFF switch to the ON position.

Ensure the green LED illuminates.

2. The Test Set commences the Self Test. “PASS” is displayed bri efly if no failures

ar e detected.

3. Utiliz e the procedures as outli ned in 2.9 to select the preferred ant enna method

for the following tests.

4. Turn the UUT FUNCTION switch to the XPDR position. The Test Set will

autom atically determine t he transponder cap ability as being Mode S capable and

display the appropriate start page with the Communication capability of the

Transponder (COM M NO, COMM AB, COMM ABCD).

5. Toggle the AUTO/TEST/MANUAL switch to the AUTO positi on. The Test Set will

begin testing t he transponder, without inter ruption, IAW figure 2-7. Each test will

be displayed as “TESTING . . .” but no results will be shown until the Test Set

as completed all tests.

6. If no failures are detected, the Test Set will cease testing and display the

following alternating display:

Self Test

PASS

Capab Comm AB EHS

AIR Press A/M II:14

M A /

Testing . . .

FID: yyyyyyy 10000’

54dB 1090.0MHz

H: A02008 O:50020010

1234 USA:N107PP

The final alternating display will indicate

the transponder decoded Flight ID

Code (FID: YYYYYYY), Aircraft altitude

(10000’), UUT Power (54dB), Freq.

(1090.0), aircraft address in both

Hexadecimal and Octal (A02008,

50020010), and the Country code and

tail number (USA:N107PP) if available.

NOTE

ppendix A lists avail able count ry codes. If the T est Set can not locat e

the countr

algorithm, “??????” will be displayed.

2-26

Page 44

Rev E TR-220 90 008 088-1

7. If a f ailure is detected during any test in t he Automatic sequence, the Test S et

will “STOP” at that test and display the failure along with the Framing Pulses Pulse Width and separation in µs.

8. The operator m ay ov er ride and advance to t he nex t t est in sequence by t oggl i ng

the AUTO/TEST/MANUAL switch to the AUTO positi on. It i s recommended t hat

the operator determ ine the cause of the f ailure before advancing. Subsequent

tests may be inaccur ate or misleading.

9. The operator may also elect to repeat the failed test by toggling the

AUTO/TEST/MANUAL switch to the MANUAL position.

Squitter /

FAIL

END OF MODE S AUTOMATIC TESTS

Illustrat e a S quitt er failure

2-27

Page 45

Rev E TR-220 90 008 088-1

A

/

2.14 Testing a Transponders “IDENT” Function

NOTE

1. To test the “IDENT” feature of a transponder the operator may select the Mode A or

2. Allow the Test Set to complete the test.

3. Press the IDENT button or switch located on the transponder control panel or cockpit

4. IDENT will be displayed for approximately 20 seconds to verify the receipt of the SPI

5. The operator may now continue testing the transponder through the remainder of t he

tests.

The “IDENT” function c an only be tested in the Manual mode of Tests in

both Mode

the M C Test for the appropriate transponder (Mode A/C or M ode S ).

C and Mode S.

M A /

Testing . . .

M A 1234 100%

0.45–20.35– 0.45 PASS

interface.

pulse from the transponder.

M A 1234 IDENT 100%

0.45 ─ 20.35 ─ 0.45

END OF TRANSPONDER TESTS

2-28

Page 46

Rev E TR-220 90 008 088-1

2.15 TCAS Tests

The TR-220 Multifunction Test Set is capabl e of f ully testing ATCRBS and Mode S, ACAS, TCA S

I, and II system s (Traffi c Alert and Colli sion Avoi dance System ). T he operat or is able t o manuall y

select a scenario or utili ze the defaul t scenari o already preprogram med i n the Test Set Memory.

When properl y used, the T est Set will simulate an Intruder Aircraft conver ging on the posi tion of

the UUT. The operat or may then observ e the TCAS display to ensure t he correct TA’s (Traffic

Advisory) and RA’s (Resolution Advi sory) occur on their display.

The Simulati on is used with the Di rectional Ant enna. This giv es the operator the abi lity to mov e

the Test Set to differ ent locations and headings fr om the UUT.

2.15.1 Typical TCAS Concepts

NOTE

All illustr ations shown are for demonstrati on pur pose s. Though the test

results may be typic al, they are not meant to replace FAA guidelines and

manufacturer r ec ommendations.

TCAS i s a system, which prov ides situat ional awareness of t he surrounding ai rspace of

an aircraft to the pil ot and crew. A T CAS establishes a volume of airspace around the

aircraft. The size of the airspace is based on range, speed and altitude. By working in conjunction with the ai rcraft Transponder system, t he TCAS can determi ne the relative

threat of an aircraft, issue visual and audible advisories to assist the crew in locating

and/or take action to prevent a collision.

The per imeter of the CAUTION ARE A is approximat ely 20 to 48 seconds to t he tim e the

intruder would enter the WARNING AREA. Refer to Figure 2-9.

Caution, Warning, and Collision Areas for a TCAS I System

Figure 2-9

2-29

Page 47

Rev E TR-220 90 008 088-1

Typical TCAS I Display

Figure 2-10

A Solid Amber Circle indicates a TA (Traffic

Alert), signifying a possible collision threat to

your aircr aft. Acc ompanied by a audi ble warning

of “Traffic , Traffic”

A solid white diamond signifies a proximate

traffic. Aircraft that are within 4nmi and ± 1200

feet altitude.

An open white diamond signifies other traffic

within th e s el ect ed range.

Numbers repres ent the i ntruder aircrafts relativ e

altitude ± 100 ft levels from your aircraft.

The arrows indicate if the intruder aircraft is

ascending or descending from your relative

position.

T he perim eter of the WARNING AREA is approxim ately 15-35 second s fr om enteri ng the

COLLISION AREA (not depicted).

W hen an aircraft enters the CAUTION AREA, a “TA” (Traffic Advisory) is issued. This

would consist of an audi bl e and v isual warning in the cockpit.

When an int ruder enters the COLLISION AREA, the TCAS will issue a “RA” (Resoluti on

Advisory). “ RA ’s” consi st of audible and visual warnings and possible instruct ions to avoid

a collision.

A TCAS display will vary dependent on the manufacturer. T ypicall y, a TCA S I system , as

shown in figure 2-10, will display Traffic Advisories. A TCAS II System will be

incorporated wit h a Vertical Speed Indi cator (VSI), which will issue a RA, the pi lots VSI

will display a course of action to avoid a collision with an aircraft located in the

COLLISION AREA.

2.15.2 TCAS Scenario Selection and Setup

1. To TR-220 must hav e t he corr ect v alues entered t o properl y progr am an intruder

to converge with the UUT aircraft. If the intruder scenario is incorrectly

programmed, t he oper ator may not receive the antici pated resul ts.

2. Turn the Test Set “ON” and turn the UUT FUNCTION switch to SETUP.

3. Access the T CAS Scenario menu. The TR-220 has 10 preprogram med intruder

scenarios in its memory (see table 2-3). All TCAS Scenarios can be modified

2-30

Page 48

Rev E TR-220 90 008 088-1

and stored in the T est S et Memory. By toggling the UP/FWD-DOWN/REV switch,

the operator can sel ec t t he appr opr iate intruder scenario.

4. After selecting a suitable scenario, the operator needs only to turn the UUT

FUNCTION switch to the TCAS position t o begin an intr uder sim ulati on. Pr oceed

to paragraph 2.15. 5 to continue with TCAS T ests. If the operator desires different

parameter s, c ontinue with Step 5.

5. If the operator desires diff er ent parameters, Leave the UUT FUNCTION switch in

the SETUP position and toggle the AUTO switch. The Start Alt menu will be

displayed.

6. Toggle the UP/FWD-DOWN/REV switch to change t he intruder’s start altitude.

The Altitude can be changed from -1000 ft. to +99,900 ft. The altitude is

adjustable in 25 ft. increments between -1000 f t. and 50,175 ft. and i n 100 ft,

increments above 52, 000 ft. Hol d the toggle switch ei ther UP or Down f or more

than 5 seconds and the adjust speed will inc r ease.

TCAS Scenario: 1

Chg:Up/Dn Cont: AUTO

Scenario

#

1 5 nmi. 2500 ft 0 fpm. 250 Kts.

2 5 nmi. 2500 ft 0 fpm. 250 Kts.

3 5 nmi. 2500 ft 0 fpm. 250 Kts.

4 5 nmi. 2500 ft 0 fpm. 250 Kts.

5 5 nmi. 2500 ft 0 fpm. 250 Kts.

6 5 nmi. 2500 ft 0 fpm. 250 Kts.

7 5 nmi. 2500 ft 0 fpm. 250 Kts.

8 5 nmi. 2500 ft 0 fpm. 250 Kts.

9 5 nmi. 2500 ft 0 fpm. 250 Kts.

10 5 nmi. 2500 ft 0 fpm. 250 Kts.

TCAS

Start

Distance

Preprogrammed (default ) T CAS scenarios

Start

Altitude

(Intruder)

Table 2-3

Vertical Speed Velocity

Start Alt: 2500’

Chg:Up/Dn Cont: AUTO

Start Alt: 10000’

Chg:Up/Dn Cont: AUTO

2-31

Page 49

Rev E TR-220 90 008 088-1

7. Toggle the AUTO/TEST/MANUAL switch to the AUTO position to advance to

the Velocity menu. Utiliz e the UP/FWD-DOWN/REV switch to set the velocity to

the desired setting. The Velocity is adjustable from 120Kts t o 1200K ts.

8. Toggle the AUTO/TEST/MANUAL switch to the AUTO position to advance to

the Vert Speed m enu. Utilize t he UP/FWD-DOWN/REV switch to set the vertical

speed to the desired sett ing. The Vert Speed i s adj ustable from + 7,500 f pm. t o -

7,500 fpm.

9. Toggle the AUTO/TEST/MANUAL switch to the AUTO position to advance to

the TCAS dist menu. Set the di stance of the intruder to the UUT by toggli ng the

UP/FWD-DOWN/REV switc h to the desired range. The range i s adjustable fr om

1 nmi. to 50 nmi.

10. Toggle the AUTO/TEST/MANUAL switch to the Mode S Addr menu. The

operator m ay change the Mode S addr ess of t he intruder aircr aft. Switching t he