TIA Air Coffeeo 1601B-AC1P, Air Coffeeo 1601B-AC3P, Air Coffeeo 1601B-DC28, Air Coffeeo 1601A-AC3P, Air Coffeeo 1601B-DC28-B Maintenance Manual And Parts List

...

PLACE

8600

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

AIR COFFEE

MODEL 1601 SERIES

COFFEE BREWER

P/N 500-0521

P/N 500-0619

A division of The Richards Corporation

DESIGNERS AND MANUFACTURERS OF AIRCRAFT GALLEY PRODUCTS

44931 FALCON

WWW.TIAPRODUCTS.COM

PHONE: (703) 471-

l

STERLING VA 20166 USA

l

TIA@TIAPRODUCTS.COM

l

FAX (703) 481-5007

© Copyright 2005

The Richards Corporation

25-30-27

Page TP1

September 1, 2005

REV.

LEP1

103

303, 304

703, 704

NO.

PAGE

INSERTED

1 TP1,ROR1

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

RECORD OF REVISIONS

ISSUE

DATE

04-10-96

ISSUED

BY

REV.

NO.

PAGE

INSERTED

ISSUE

DATE

ISSUED

BY

LOl1, LP1

1,2

101, 102

301, 302

601,

602/603

604/605,

606/607

608/609,

610, 611

701, 702

1001, 1002

1003/1004

1005, 1006

1007/1008

1009, 1010

1011, 1012

1013, 1014

1015, 1016

1017

2 1005,1009

7-15-97

1012

3 Complete

03-01-01 TIA

Revision

4 Complete

09-01-05 TIA

Revision

Page ROR1/-ROR2

25-30-27

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

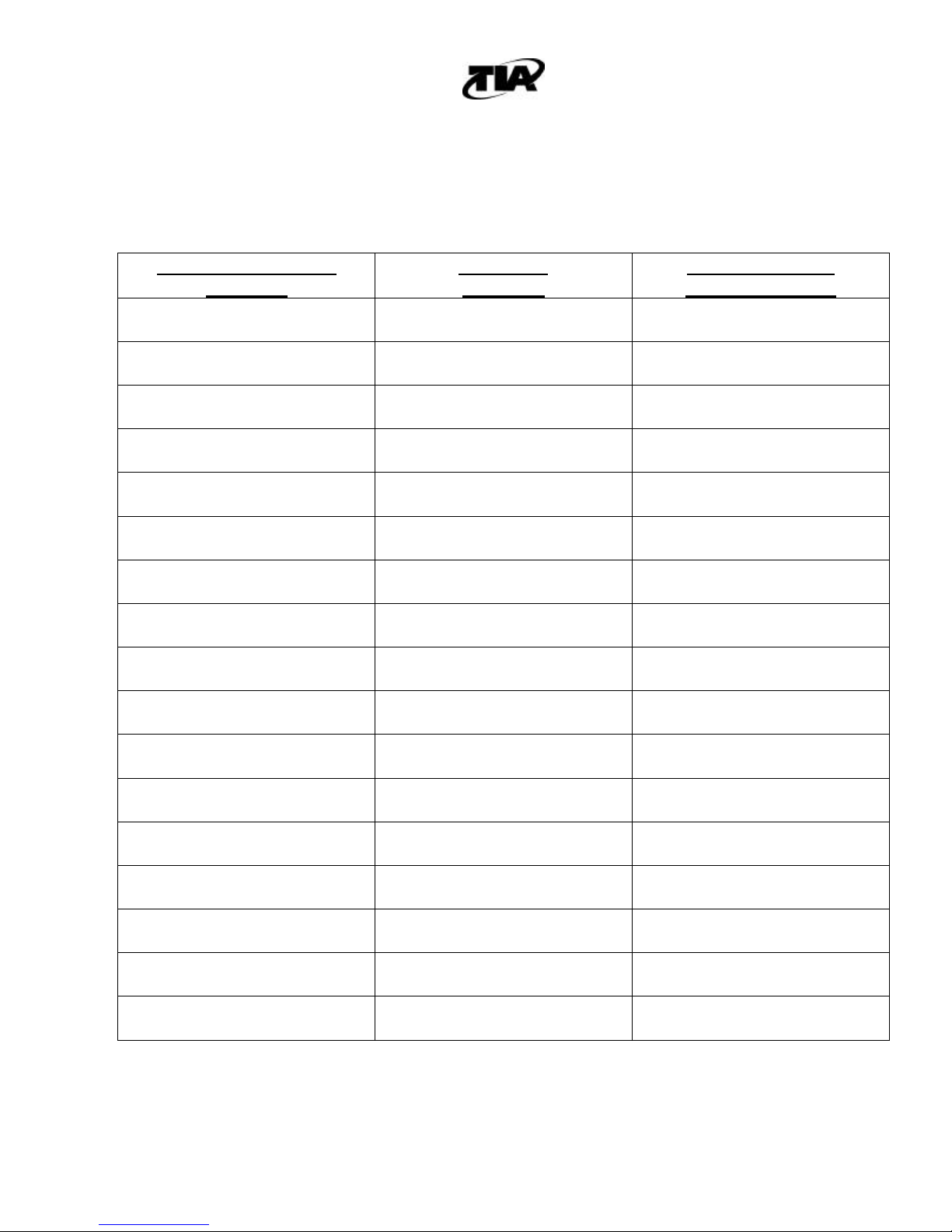

RECORD OF TEMPORARY REVISIONS

REV.

NO.

PAGE

INSERTED

ISSUE

DATE

INSERTED

BY

REMOVAL

DATE

REMOVED

BY

25-30-27

Page ROTR1/-ROTR2

September 1, 2005

SERVICE BULLETIN

NUMBER

SB-CB-011

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

SERVICE BULLETIN LIST

REVISION

NUMBER

A

DATE BULLETIN

INCORPORATED

9/01/05

25-30-27

Page SBL1/-SBL2

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE SUBJECT PAGE DATE

Title TP1 9/01/05 Inspection/Check 501 9/01/05

502 Blank

Record of Revisions ROR1 9/01/05

ROR2 Blank Repair 601 9/01/05

602 9/01/05

Record of Temporary ROTR1 9/01/05 603 9/01/05

Revisions ROTR2 Blank 604 9/01/05

605 9/01/05

Service Bulletin List SBL1 9/01/05 606 9/01/05

SBL2 Blank 607 9/01/05

608 9/01/05

List of Effective Pages LEP1 9/01/05 609 9/01/05

LEP2 9/01/05 610 9/01/05

611 9/01/05

Table of Contents TOC1 9/01/05 612 9/01/05

TOC2 Blank

Assembly 701 9/01/05

List of Illustrations LOl1 9/01/05 702 9/01/05

LOl2 Blank 703 9/01/05

704 Blank

Leading Particulars LP1 9/01/05

LP2 Blank Special Tools, Fixtures 901 9/01/05

and Equipment 902 Blank

Description and 1 9/01/05

Operation 2 9/01/05 Illustrated Parts List 1001 9/01/05

3 9/01/05 1002 9/01/05

4 9/01/05 1003 9/01/05

Testing and Fault 101 9/01/05 1005 9/01/05

Isolation 102 9/01/05 1006 9/01/05

103 9/01/05 1007 9/01/05

104 9/01/05 1008 9/01/05

105 9/01/05 1009 9/01/05

106 Blank 1010 9/01/05

Disassembly 301 9/01/05 1012 9/01/05

302 9/01/05 1013/1014 9/01/05

303 9/01/05 1015 9/01/05

304 9/01/05 1016 9/01/05

Cleaning 401 9/01/05

402 Blank

1004 9/01/05

1011 9/01/05

1017 9/01/05

25-30-27

Page LEP1

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

LIST OF EFFECTIVE PAGES – CONT.

SUBJECT PAGE DATE SUBJECT PAGE DATE

Illustrated Parts List 1018 9/01/05

1021 9/01/05

1022 9/01/05

1023 9/01/05

1024 9/01/05

1025 9/01/05

1026 9/01/05

1027 9/01/05

1028 9/01/05

1029 9/01/05

1030 9/01/05

1031 9/01/05

1032 9/01/05

1019/1020

9/01/05

25-30-27

Page LEP2

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

TABLE OF CONTENTS

PARAGRAPH TITLE PAGE

Description and Operation..................................................................... 1

Testing and Fault Isolation..................................................................... 101

Automatic Test Requirements ............................................................... N/A

Disassembly .......................................................................................... 301

Cleaning................................................................................................. 401

Inspection/Check................................................................................... 501

Repair.................................................................................................... 601

Assembly............................................................................................... 701

Fits and Clearances............................................................................... N/A

Special Tools, Fixtures and Equipment ................................................. 901

Illustrated Parts List............................................................................... 1001

25-30-27

Page TOC1/-TOC2

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

FIGURE NO. TITLE OF ILLUSTRATION PAGE NO.

1 Component Layout, 1601 Series 3

601 Wiring Diagram, 1601-AC3P 604

602 Wiring Diagram, 1601B-AC1P 605

603 Wiring Diagram, 1601A-AC3P 606

604 Wiring Diagram, 1601A-AC3P, 1601B-AC3P 607

605 Wiring Diagram, 1601-DC28 608

606 Wiring Diagram, 1601A-DC28 609

607 Wiring Diagram, 1601B-DC28, 1601B-DC28-B 610

608 Plumbing Diagram, Model 1601 611

609 Plumbing Diagram, Models 1601A and 1601B 612

1001 Illustrated Parts List, (P/N 500-0521)

Model 1601 Series Coffee Brewer 1013/1014

1002 Illustrated Parts List, (P/N 500-0619)

Model 1601A and 1601B Series Coffee Brewer 1019/1020

1003 Illustrated Parts List,

Heater Assembly 1026

1004 DELETED – See Figure 1003 1028

1005 DELETED – See Figure 1001 and 1002 1029

1006 DELETED – See Figure 1001 1030

1007 Illustrated Parts List,

Carafe Assembly 1031

Page LOI1/-LOl2

25-30-27

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

LEADING PARTICULARS

1. DIMENSIONS:

A. HEIGHT: 13.000 inches

B. WIDTH: 6.375 inches

C. DEPTH: 10.000 inches*

* Does not include pot handle. Depth including handle is 12 1/8” maximum.

2. ELECTRICAL:

MODEL

1601-AC3P 115 VAC, SINGLE PHASE,

1601A-AC3P

115 VAC, 3 PHASE

1601B-AC3P

1601B-AC1P 115 VAC, 3 PHASE

1601-DC28

1601A-DC28

1601B-DC28

1601B-DC28-B

3. WEIGHT:

A. 1601, EMPTY 11.00 Lbs.

B. 1601A, EMPTY 9.50 Lbs.

C. 1601B, EMPTY 9.50 Lbs.

4. BREW CHARACTERISTICS

A. Capacity: 48 oz. (10 cups)

B. Coffee Temperature: 170-180º F

C. Brew Temperature: 190º F

D. Brew Time: 8-10 Minutes

E. Recommended Filter Size: 2.75-Inch Base x 3 Inch Height*

*Recommended filter: BCF-100B

(V-25628, TIA P/N 124-0081)

Equivalent substitute may be use

INPUT

VOLTAGE

60 - 400 HZ

300 - 700 HZ

300 - 700 HZ

28 VOLTS DC

WATTAGE

1000 WATTS

1000 WATTS

1000 WATTS

1000 WATTS

25-30-27

Page LP1/LP2

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

DESCRIPTION AND OPERATION

1. General

TIA Model 1601 Series Coffee Brewer, shown in Figure 1, is an aviation quality,

general purpose top fill brewer capable of making 48 oz. (10 cups) of coffee every

brew cycle. The brew tray allows for the use of a standard coffee filter and loose

coffee, or a commercial pillow pack. An integral heater assembly both brews the

coffee and provides a heated surface to keep the coffee warm.

Temperature and overheat controls are provided independently by means of single

setpoint bi-metal thermostats for each to minimize maintenance and increase

reliability.

The coffee brewer is not designed to operate in a completely enclosed compartment.

Compartment doors should be open during operation to prevent a build-up of heat

and humidity.

2. Description

A. A single POWER switch operates the unit and, when in the ON position, allows

the water to be heated to a point (controlled by the control thermostat) at which

the heated water “percolates” up the brew pipe, over the coffee in the brew tray

and into the carafe.

B. A manually resettable overheat thermostat will deactivate the heater elements if

the temperature exceeds its set point. Activation of the overheat thermostat

indicates a fault. The overheat thermostat must be manually reset before

operation of the coffee brewer can resume.

3. Operation

NOTE: The primary cause of slow brew cycles is the buildup of mineral deposits in

the heater block.

A. Turn the brew basket retainer latch downward and remove brew basket. Insert

the new filter and load fresh coffee into the brew basket. Place the brew basket

back into the coffee brewer and latch into position.

25-30-27

Page 1

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

NOTE: Unit should be off and cool before filling it with water. Adding water to a hot

coffee brewer will create a puff of steam.

B. Fill the carafe with water and pour it into the water fill port located on the top of

the coffee brewer. Watch the water level indicator to avoid overfilling the water

tank.

OPERATING HINT: To prevent carafe overflow, make certain that the amount

of water poured into the coffee brewer does not exceed the capacity of the 54

oz. carafe. DO NOT add water during the brew cycle. Remember that the

carafe must be able to hold the amount of water poured into the coffee brewer

tank. Verify that carafe is empty prior to beginning brew cycle

NOTE: Only pour fresh water into the water tank. Do not pour coffee or other

premixed liquids into the water tank. Doing so will result in damage to the

coffee brewer.

C. Switch coffee brewer ON. The indicator light will illuminate on units equipped

with indicator lights (P/N 500-0521-01, -02 and 500-0619-01, 02 ONLY). After

approximately 30 seconds water will start percolating through the brew basket

and into the carafe.

D. When brew cycle is completed and coffee has ceased flowing into the carafe,

remove brew basket from coffee brewer and discard coffee grounds.

NOTE: Coffee may continue to drip from the brew basket after the completion of the

brew cycle. The dripping is from residual liquid in the brew basket and does

not indicate a fault with the Coffee Brewer.

E. Remove carafe from coffee brewer and serve coffee. Return carafe to coffee

brewer after serving coffee and latch into position. When finished serving

Coffee, turn the coffee brewer OFF.

CAUTION: DO NOT HEAT EMPTY CARAFE.

25-30-27

Page 2

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

Figure 1. Component Layout

1601B Series Shown

4. Cold Weather Precautions

CAUTION: IF FREEZING TEMPERATURES ARE EXPECTED AND COFFEE

BREWER WILL NOT BE IN USE, COFFEE BREWER WATER SYSTEM

MUST BE DRAINED TO PREVENT ICE DAMAGE. SEE “DRAINING

COFFEE BREWER”.

A. Draining Coffee Brewer

(1) There is no manual drain on the 1601 Series Coffee Brewer. To drain the

water from the coffee brewer, switch the coffee brewer ON and operate the

coffee brewer until the water tank is empty.

(2) Turn coffee brewer OFF.

25-30-27

Page 3

September 1, 2005

COMPONENT MAINTENANCE MANUAL

5. Storage Instructions

A. Preparation for Storage

(1) Ensure that all liquids have been drained from the coffee brewer and

components to prevent possible damage if the unit is exposed to freezing

temperatures.

(2) Store the coffee brewer upright in a clean, dry location where the unit will not

be subject to dents or other damage.

(3) Whenever possible, the unit should be stored in the shipping or packing

container originally provided by the manufacturer.

NOTE: Inserts may be stacked in accordance with standard warehouse

practices.

(4) If inserts are to be stacked, a separator of ¼ inch plywood, or similar

protective device, is to be placed between the units to insure against damage

to the finish or component parts.

B. Short Duration Storage

NOTE: No special protection is required if the units are to be stored less than

three months.

(1) If units are stored in excess of thirty days, complete test procedures should

be performed prior to placing the unit in service.

C. Extended Duration Storage

Wrap units in water repellant material (Federal Spec. VV-P-271 or equivalent) and

enclose silica gel packages to absorb moisture and retard corrosion.

MODEL 1601 SERIES COFFEE BREWER

WITH ILLUSTRATED PARTS LIST

25-30-27

Page 4

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

TESTING AND FAULT ISOLATION

1. General

A. This section consists of the following subsections: Testing and

Troubleshooting.

(1) The Testing subsection is a general functional test of the coffee brewer

to determine in which area a fault may have occurred.

(2) The Troubleshooting guide describes the most common possible faults

and their remedies. It is meant to serve as a general guide and

assumes that all internal wiring and power connections are correct.

B. The 1601 series coffee brewers have single setpoint thermostats. Brew

temperature calibration is not adjustable. The thermostat does not control

the brew temperature, it controls the temperature of the heater block.

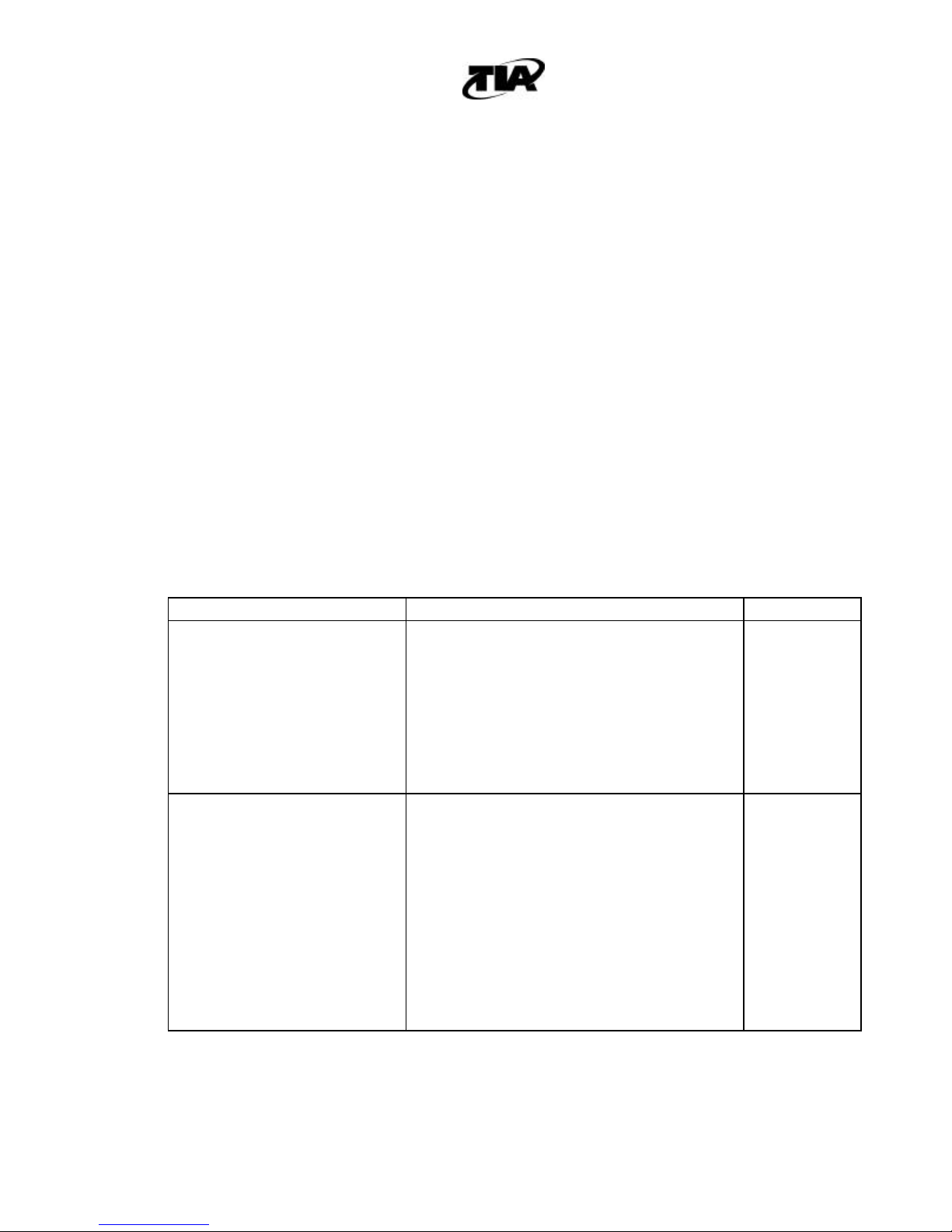

2. Testing

A. Functional Test Setup

The test bench will require the following:

(1) Power Requirements

MODEL

1601A-AC3P

1601B-AC3P

1601B-AC1P

1601-DC28

1601A-DC28

1601B-DC28

1601B-DC28-B

1601-AC3P

(2) A temperature measuring instrument capable of measuring ± 3° F.

115 VAC, 3-Phase, 300 - 700 Hz at 5 Amps

115 VAC, 3-Phase, 300 - 700 Hz at 10 Amps

28 VDC at 40 Amps

115 VAC, single phase, 60 - 400 Hz at 10 Amps

TEST BENCH REQUIREMENT

25-30-27

Page 101

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

B. Functional Test

(1) Ensure power switch is OFF and connect unit to applicable power supply.

(2) Fill carafe with water and then fill unit from top, observing water level sight

gauge in the back of the carafe cavity for Model 1601 or the LED’s on front

of the coffee brewer for Models 1601A and 1601B.

(3) Place carafe in the cavity and ensure that the brew tray is in place.

(4) Switch power switch ON and observe for the following:

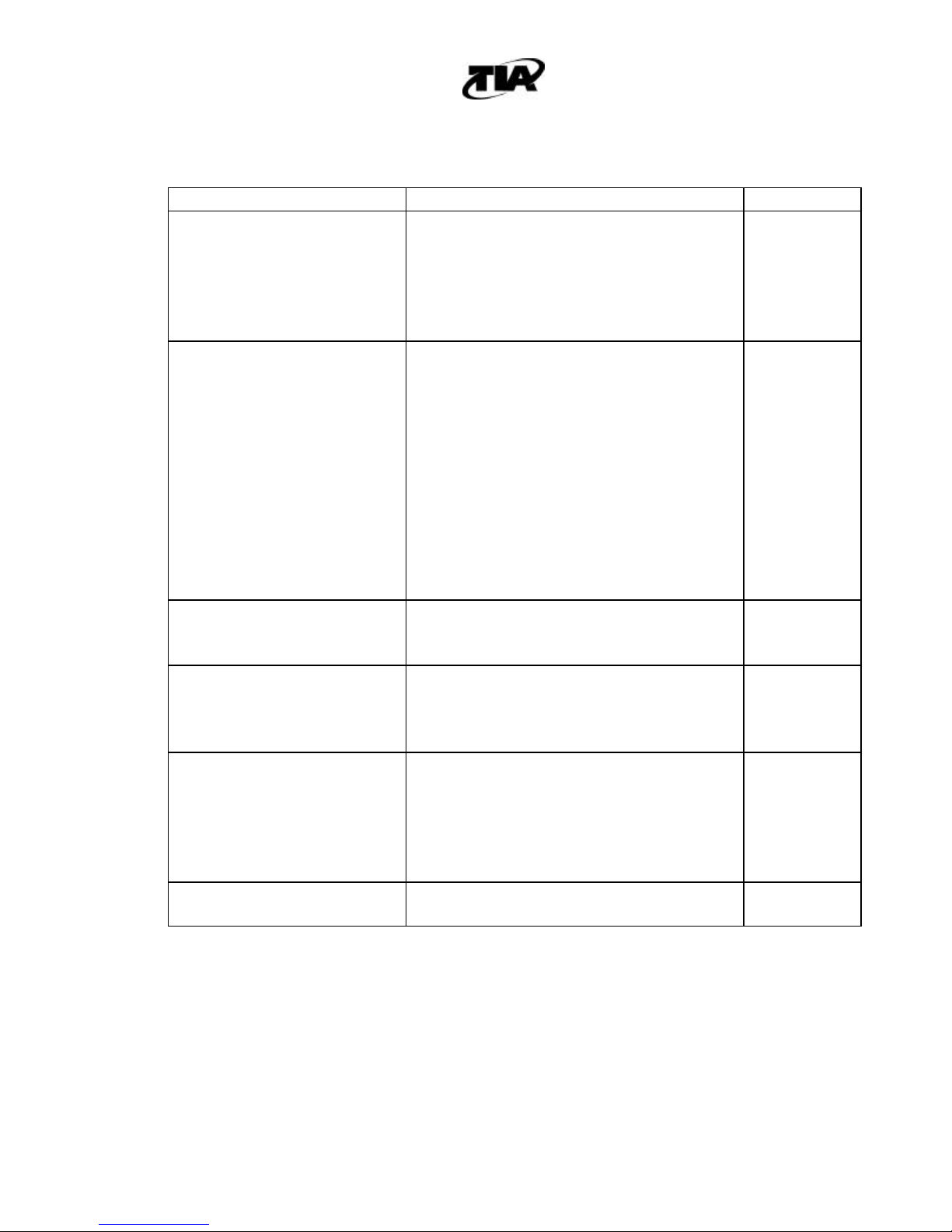

MODEL

1601-AC3P

1601A-AC3P

1601B-AC3P

1601B-AC1P

1601-DC28

1601A-DC28

1601B-DC28

1601B-DC28-B

(5) Water will now be heated and dispensed through the brew tray into the

carafe. The time to complete a brew cycle is approximately 8 - 10 minutes.

NOTE: In certain circumstances, coffee brewers equipped with 300°

thermostats can experience extended brew cycles if the heater

elements cycle during the brew cycle. This is acceptable as long as

the current draw is correct and there is no calcium build-up in the

heater block.

(6) Inspect the coffee brewer for leaks, pay special attention to the brewhead,

water tank, and hose connections.

(7) Remove carafe and measure the water temperature which should be

between 170° F and 180 ° F.

2.9 Amps ± 0.5 Amps

8.5 Amps ± 1 Amp

35 Amps ± 3 Amps

Normal Current Draw

25-30-27

Page 102

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

NOTE: This unit has a single setpoint thermostat. Temperature calibration is

not adjustable. The thermostat does not control the brew temperature,

it controls the temperature of the heater block.

(8) After the brew cycle has completed, remove the pot from the warmer tray

and observe that the control thermostat switches the Heater Elements OFF,

by observing the current draw. (This test may take several minutes)

(9) Place the pot back on the warmer tray and verify that the control thermostat

switches the heater elements back ON, by observing for normal current

draw. (This test may take several minutes)

3. Troubleshooting Guide

These guides address the most common potential problems associated with these models.

It is not intended to solve more in-depth faults.

A. All Model 1601 Series

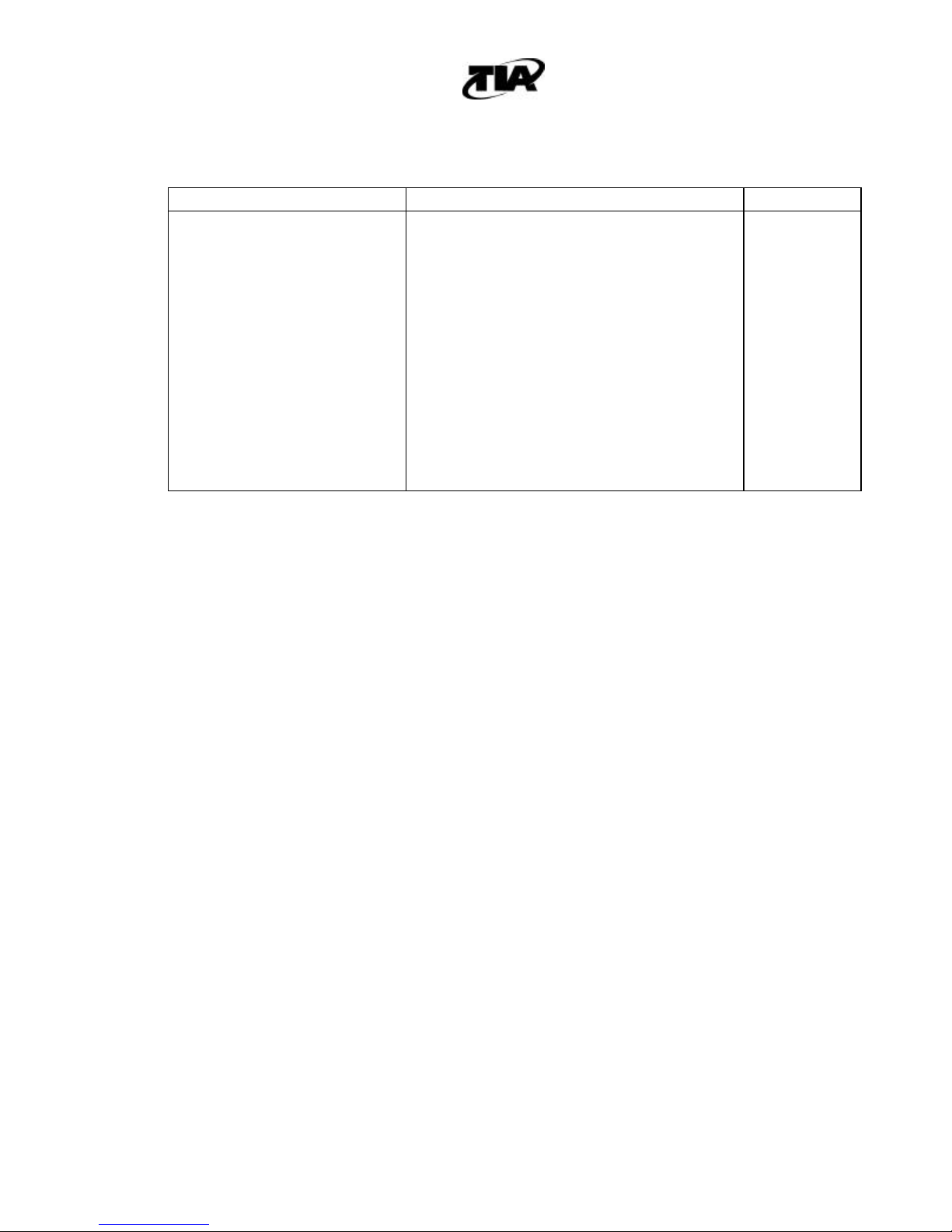

Fault Probable Cause Effectivity

(1) After the brew cycle

is completed and

carafe has been

sitting on the warmer

tray, unit switches off

and will not switch

back on.

(2) When unit operates,

steam rises.

(a) The overheat thermostat has

disconnected power from the

heaters. Allow unit to cool and

reset thermostat.

(b) Overheat thermostat may be

defective.

(c) The thermostat and/or its relay

have failed.

When the coffee brewer operates, the

normal functioning of the machine

generates some steam. If the steam

becomes “excessive”, remove the

brew basket from the coffee brewer

and observe the water flow for

consistency. A primary cause of

excessive steam is the build-up of

mineral deposits in the heater casting.

For cleaning details, refer to the

cleaning section of this manual.

All

All

25-30-27

Page 103

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

Fault Probable Cause Effectivity

(3) Carafe overflows

during brew cycle.

(4) Brew time is longer

than expected

(5) ON/OFF switch is

ON but unit will not

brew.

(6) Power Indicator on

ON/OFF switch does

not light. Brewer

works otherwise.

(7) When filling reservoir

for the second or

subsequent pots of

coffee, a puff of

steam emits from the

brew head.

(8) Brewbasket

overflows

Carafe can only overflow due to

overfilling water tank. Recommend

that carafe be used to fill the tank. Do

not add water to the water tank during

a brew cycle. Verify that carafe is

empty prior to beginning brew cycle.

(a) Unit has built up scale/mineral

deposits, which are constricting

flow. Clean unit in accordance

with cleaning section of this

manual.

(b) A heater element is defective.

Return to TIA for repair or

replace heater element.

(c) Water and/or unit was very cold

when starting brew. The water

took longer to heat resulting in a

longer brew time.

(a) The power relay is defective.

(b) Overheat thermostat has tripped.

Indicator lamp in switch is defective.

Replace switch.

Heater block is still warm enough to

“percolate” coffee. After first pot of

coffee, turn power switch to OFF and

allow heater block to cool before filling

tank for next pot.

Incorrect sized coffee filter being used

or too much coffee is being used.

All

All

All

500-0521-01

500-0521-02

500-0619-01

500-0619-02

All

All

25-30-27

Page 104

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

Fault Probable Cause Effectivity

(9) Display LEDs are

erratic and do not

function normally.

(a) Check source of water. If

water is distilled, display

may not work correctly

because of low mineral

content of water.

(b) Malfunctioning Display

PCB Assembly. Replace

assembly with a known

good PCB assembly and

retest.

(c) Faulty cold water tank

probe. Return to TIA for

repair or repair as necessary

500-0619

(Models Only)

25-30-27

Page 105

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

THIS PAGE INTENTIONALLY LEFT BLANK.

25-30-27

Page 106

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

DISASSEMBLY

1. General

A. Since complete disassembly is impractical and undesirable, only the following items

should be removed as required: Those which have been definitely established by

Check and/or Fault Isolation procedures as being defective, those which must be

removed to gain access to remove a defective part, and those which must be

removed in order to electrically isolate a part suspected of being faulty. Check

testing and Fault Isolation procedures determine those components which are

defective and, therefore, the extent of disassembly required.

B. This section consists of the following subsections:

a. Disassembly instructions for Model 1601

b. Disassembly instructions for Models 1601A and 1601B

NOTE: Observe proper ESD handling and storage procedures for PCB assemblies

after removing top cover. ESD Discharges may damage PCB assemblies.

2. Disassembly Instructions for Model 1601

A. Top Cover and Cold Water Tray Disassembly (Figure 1001)

1. Remove top cover (10) by removing screws (35).

2. Remove gasket (30) and cold water tray (25).

3. If required, remove receptacle (15) from top cover (10) by removing screws

(20).

B. Water Tank Disassembly (Figure 1001)

1. Remove brew tube (255) from barbed adapter (45). Pull brew tubing (255)

through the tank assembly (355). Remove tank washer (365).

2. Disconnect tubes (255) from heater casting (100).

3. Note correct orientation for later installation, and remove check valve (250)

from tubing (255).

4. Remove silicon tubing (200) from fitting (205).

25-30-27

Page 301

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

5. Remove screws (360) and remove water tank (355).

C. Brew Head Disassembly (Figure 1001)

1. Remove screws (55) to remove basket support (50) and hot water receptacle

(40) from chassis (5).

2. Remove barbed adapter (45) from the hot water receptacle (40).

D. Heater Assembly Removal (Figure 1001)

1. Remove bottom cover (285) by removing screws (290).

2. Disconnect electrical leads from the heater assembly (100) as necessary.

3. Remove locknuts (115), screws (110) and heater clamp (105).

4. Remove heater assembly (100) from chassis (5).

5. Remove tray (90) and gasket (95) from chassis (5).

E. Heater Disassembly (Figure 1003)

1. Remove screws (20) and washer (25) from heater casting (5). Remove

overheat thermostat (10).

2. Remove screws (40) and washer (45) from heater casting (5). Remove control

thermostat (30).

NOTE: Heater elements (50) are staked in place and should not be removed

except for replacement of a failed element. Replacement heater

elements should be securely staked into place.

25-30-27

Page 302

September 1, 2005

MODEL 1601 SERIES COFFEE BREWER

COMPONENT MAINTENANCE MANUAL

WITH ILLUSTRATED PARTS LIST

3. Disassembly Instruction for Model 1601A and 1601B

A. Top Cover and Cold Water Tray Disassembly (Figure 1002)

1. Remove top cover (10) by removing screws (25), and locknut (35).

2. Remove cold water tray (20).

B. Water Tank Disassembly (Figure 1002)

1. Remove tubes (290) from water tank (380) and heater assembly (260).

2. Note orientation for later installation, and remove check valve (295) from inlet

tube.

3. Remove screws (385) and remove water tank (380) from chassis (5). Liquid

Level sensor and ground wires will still be connected. Support water tank.

4. Remove ground and liquid level sensor leads from water tank (380) by

removing screws (390) and split lockwashers (395).

C. Brew Head Disassembly (Figure 1002)

1. Remove brew tube (290) from barbed adapter (55).

2. Remove brew head (40) from chassis (5) by removing screws (50).

3. Remove basket support (105) from chassis (5) by removing screws (110).

Clean RTV from both surfaces

D. Heater Assembly Removal (Figure 1001)

1. Remove bottom cover (280) by removing screws (285).

2. Disconnect heater assembly (260) electrical leads as required.

3. Remove locknuts (275), screws (265) and heater clamp (270).

25-30-27

Page 303

September 1, 2005

Loading...

Loading...