Thümler Z3, Z50, Z10, Z5, Z20 Operating Instructions Manual

...

1

Operating Instructions

Tensile Testers

Z3, Z5, Z10, Z20, Z50, Z100

Z3 Z5

Z10

Z20 Z50

5-2017

2

Table of Content

1: Introduction

2: Checking Contents and the Number of Machine

3: Power on checks

4: Control Display Unit

5 Menu Keypad

6: Configuration

7: Load Cell

8: Interface USB

9 Upload Hex file

10 Special Programs

11: Accessories, Maintenance

12 Windows-Software

13 Electric plan, Main board

14 Dimensions

15 Declaration of Conformity

3

1) Introduction

Danger Hints

Warning Danger of crushing!

By the accessible design of the machine there is a risk of crushing

Please make sure that during the adjustment and during

the test sequence no one comes to the area of the machine!

The device may only be operated by trained personnel.

Attention! The load cell can be destroyed by overload!

Especially upon moving the grips

or by lateral load is the danger that the load cell will be destroyed.

Install load cells carefully.

There must be no larger torque pull off the grips

pass through the load cell.

For smaller load cells, we recommend using pneumatic grips

4

Names

5

Notes

Limit

The limit switch must be set, so that the upper grip do not touch lower

grip.

Transport

Disassemble load cell.

Z3 Z5 and Z10 machines are provided for voltages 230 VAC or 115

VAC See back side of machine

Machine Z20 Z50 Z100 needs 3x 380 Volt

We can decline down to 260 Volt; if it is lower we need a Trafo

1) INTRODUCTION

1.01 This manual is to help the operator understand the operation

principle of the testing machine electronic panel.

These new testing machines represent a range of easy-to-use

compact devices for determining Tension, Compression, Shear,

Flexure and other mechanical and physical properties of materials.

Due to variations in international standards of force and extension

units, the tensile test machines enable the operator to select one of

the two standards for Force Units (Newton and Pounds) and either

Inches or Millimeters for the Extension Units.

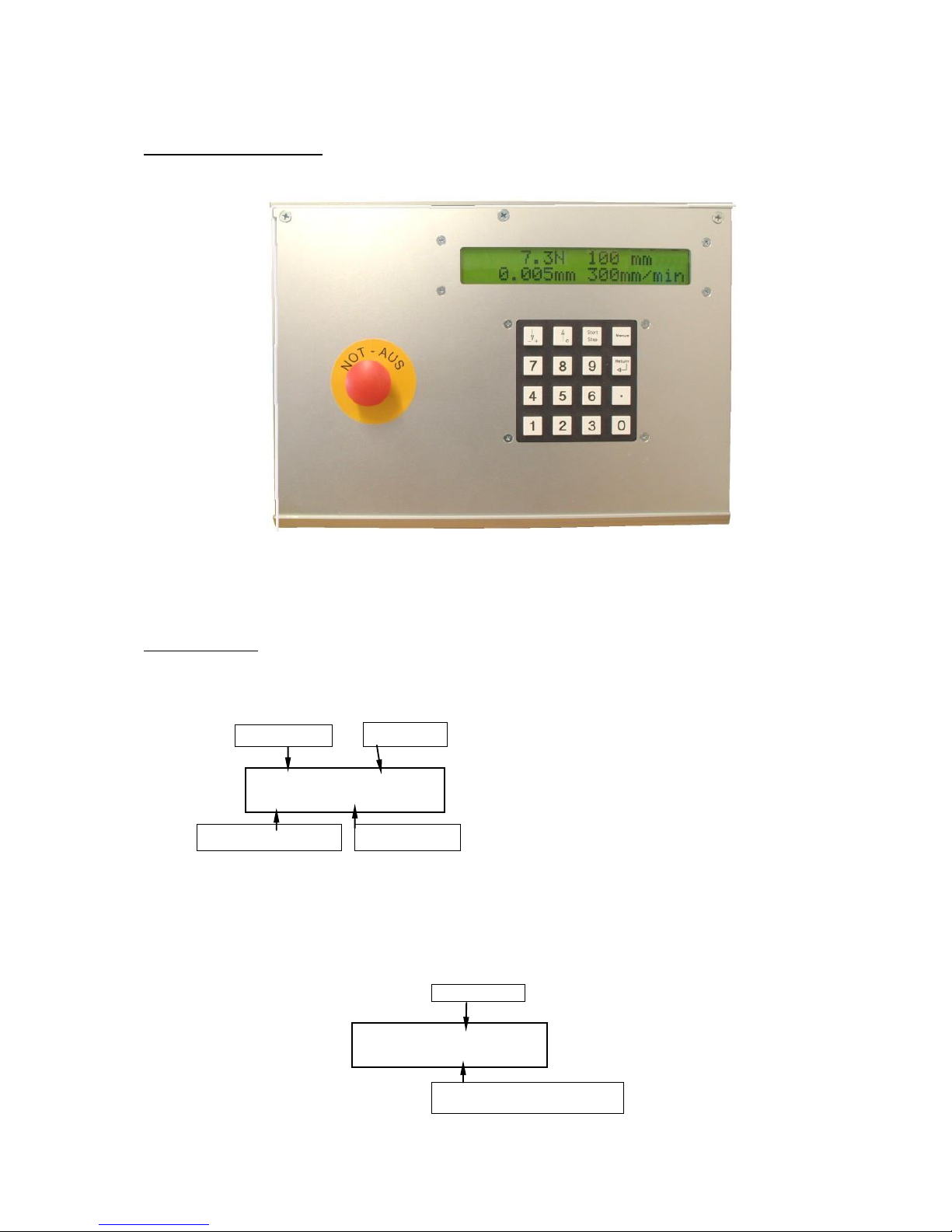

1.02 All the controls are located on the front panel, which has a large,

easy-to-read backlit 2-line LCD display and a numeric keypad. The

display unit shows the force and displacement values. Crosshead

control keys are provided for moving crosshead up or down, for

starting a test, or for getting access to various test parameters, such

as, for example, displacement or speed of crosshead. The numeric

keypad permits the inputting of test data.

1.03 There may be many aspects of material testing not covered in

this operation manual in particular the type of grips used and

additional optional equipment (for more information see our webpage

http://www.grip.de/ )

Operating Environment – All machines are designed to operate in

temperatures of 0 to 38°C (32 to 100°F) with a non-condensing atmosphere of

10 to 90% Relative Humidity.

6

2: CHECKING CONTENTS

The machines are shipped completely assembled except for the optional

accessories. The basic machines are supplied with the following items (please

insure that these are included for the installation):

- Z-Beam Load Cell at or below the maximum capacity of the load frame;

- Two Grip Pins (8 mm) for an adapter;

- operating instruction manual;

- load cell calibration certificate;

- One USB Serial Port Lead for external computer control;

- One 220 V cable.

The following diagrams are to help to identify each item:

Type Number of Machine:

On the backside of each machine you will find a type number (Type Nr.).

Please use it for future reference.

7

3) POWER ON CHECKS

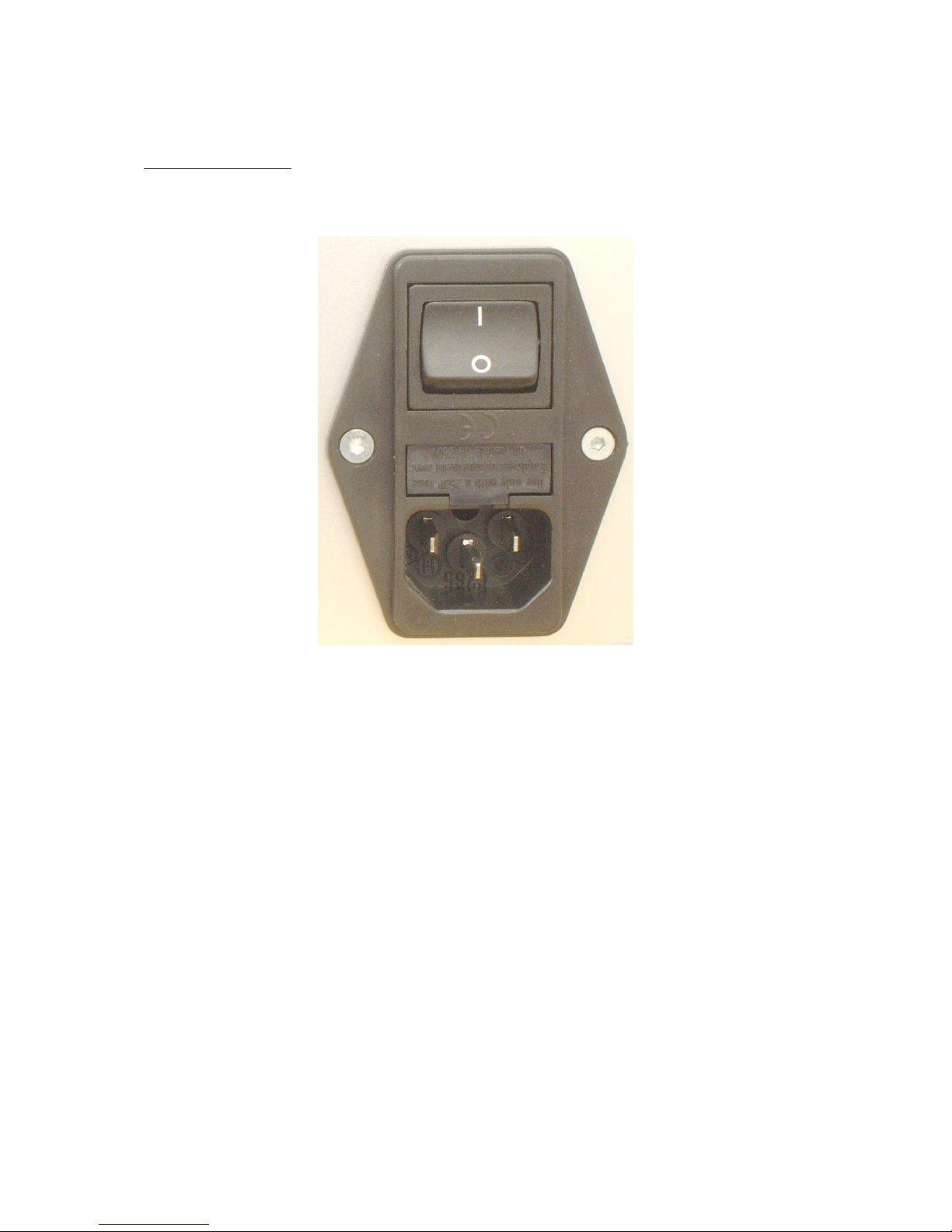

Power On / Off Switch.

The On (1) and Off (0) power switch is located on the back side of the machine and should be in the

Off (0) position before applying power to the machine.

The picture below indicates the location of the power switch:

1.3 Switching from 220 to 110 volts

Located on the back of the machine, Plug inside allows, that to switch to 110 Volt

8

Change 220Volt to 110Volt

How to switch power supply voltage to 110V

Tooling: You need a flat screwdriver.

Look at backside of your machine. Here is a Power Switch. It looks like this:

Voltage Mark indicates what voltage is selected. Here is 220-240V.

With screwdriver open fuse box:

Now rotate this, like it is shown on a picture below:

9

Now insert fuse box into switch. Also be attentive with voltage mark.

Now is selected to 110V. See Picture below. All done.

10

Emergency Stop Push-Button. The Emergency Stop push-button is located on the front panel of the

machine.

To activate the emergency stop you have to push the button. To deactivate the emergency stop turn

the button to the left and the button jumps out.

The picture below indicates the location of the emergency stop push-button:

11

Mechanical Limit Switches.

Before attempting to move the crosshead in either direction it will be required to set the mechanical

crosshead limit switches. The purpose of the limit switches is to reduce the travel of the crosshead

enabling a safe working area. A typical example is to protect the load cell and attachments for

unforeseen over travel and in doing so avoid a collision. These limit switches are located on the left

hand side of the machine.

The figure below shows the location of the mechanical crosshead limit switches:

The limit switches are held in position by a locking screw. To set the limit switch, unlock it by turning

the locking screw in the counterclockwise direction and slide to the required new position. To lock the

limit switch, rotate the locking screw in the clockwise direction. (Note: To eliminate slippage, re-tighten

locking screw securely).

The diagrams below indicate mechanical crosshead limit switches:

Release Upper Limit Switch, move Release Lower Limit Switch, move

crosshead to a new position, slide crosshead to a new position, slide

limit switch to crosshead striker, limit switch to crosshead striker,

Re-tighten. Re-tighten.

12

4) DISPLAY UNIT

Control Display Panel. This unit contains the LCD Display, the Numeric Keypad and

the Emergency Stop push-button.

LCD DISPLAY

When you switch on the machine, you get a message about the Firmware. You will

see the following:

When the test is finished (i.e. when the extension is reached, or the maximum force

is exceeded, or the break of the specimen is detected), you see the maximum force

of the last test.

1435.23 N 50 mm/min

327.12 mm 100 mm

actual force

crosshead displacement

test speed

test extension

F max = 1435.23 N

X max = 345.33 mm

Maximum force

Position where the maximum force

was reached

13

By pressing the [2] key the operator gets the information about the

force at break.

.

F break = 1435.23 N

X break = 345.33 mm

Force at break

Displacement at

break

14

5) Menu Keypad

Numeric Keypad: These keys are used for entering numeric values on the LCDDisplay (Speeds, Extension, etc.).

Crosshead Control Keys: There are two crosshead directional arrows:

The down arrow is used for lowering the crosshead

and for inputting negative values.

The Up arrow is used for raising the crosshead.

This key starts and stops a running test. If the [Start – Stop] key

is pressed during a test, the procedure is interrupted. The same

happens if you press any other key.

With the menu key, the operator can make settings for the next

test. The adjusted settings should be confirmed with the Return

key.

By pressing the [Return] key, the operator stops or returns the

crosshead to zero extension after the test.

This key will zero the Force and Extension display.

S

M

15

This key shows the maximum Force and the referring Extension

of the last test.

This key shows the Force and the Extension of the Rupture.

This key has no function.

This key has no function.

This key is used to enter the configuration menu. This menu is

protected with the password (09122).

This key has no function.

This key has no function.

This key allows switching to constant force mode.

This key has no function.

16

MENU

The [Menu] Key

With this key the operator can make settings for the next test.

The adjusted settings should be confirmed with the [Return] key.

If you press the [Menu] key, you will see the following:

ENDPOS - means “Test Extension”.

The range is possible from 1 mm to 540 mm (for the smallest

version of the machine), except for the length of grips and a

specimen. Positive values mean tensile test; negative values

mean compression test. In order to change from “–“to “+” you

have to press the [Down] key.

V means “Test Speed”.

The range is from 0,5 mm/Min to 500 mm/Min (only positive

values are possible).

F-LIMITS - means “Force Limit”.

The Force Limit can be used to protect tooling rated lower than

the load cell capacity, to end a test when that force is reached.

F-DELTA - means Force Delta.

Force Delta is the sensitivity for detecting the rupture of a

specimen, i.e. the value of 200N means, if during a tensile mode

the load decreases more than 200N/50ms, the rupture is

detected and the test is finished.

If the value is too low, rupture is not detected by the machine and

runs till the end of the set movement

Breaking force, the next interesting force after the maximum force it is difficult to recognize for the

small machine

Therefore, we recommend to setting F-delta to 5% of the maximum force

The expected minimum decline of load within 1/50 second after rupture.

(Between 2 measurement points we measured 50 times per second)

If F-delta is set correctly, the machine stand and the value is displayed

If it too large set the machine drives until the maximum test length is achieved

If it is too small set, the tensile strength will be detected too early - ie. The machine stops although

the candidate has not yet been reached

F-MAN - means Jog Speed.

The range is possible from 1 mm/Min to 500 mm/Min.

M

Loading...

Loading...