Battery Operated Systems (BOS)

Stair Lift

Installation and Service Manual

For Do It Yourself (DIY)

Warning!

STRICT ADHERENCE TO THESE INSTALLATION INSTRUCTIONS is required and will promote the safety of those

installing this product, as well as those who will ultimately use it for the purpose intended.

Any deviation from these instructions will void the LIMITED WARRANTY that accompanies the product.

Additionally, any party installing the product who deviates from the INSTALLATION INSTRUCTIONS shall be

taken to agree to INDEMNIFY, SAVE AND HOLD HARMLESS the manufacturer from any and all loss, liability or

damage, including attorneys fees, that might arise out of or in connection with such deviation.

Part #470280

Rev. A

1

This stair lift Installation and Service Manual has been written

to provide clear and precise instructions for proper installation

procedures of the Citia BOS stair lift.

Please refer to the Owner's Manual for warranty information and

operating instructions. The Owner's Manual must be given to

the owner of the lift before it is put into service.

Any alterations to the equipment without written authorization

Table of Contents

I. PRELIMINARY CHECKS ...........................................3

A. Installation site requirements ............................................. 3

B. Tools required .................................................................. 3

C. Shipment ........................................................................ 3

II. TYPICAL COMPONENTS ...........................................4

III. INSTALLATION PROCEDURES ..................................4

A. Time the gear rack ........................................................... 5

B. Determine where the track will be installed ........................... 6

An Introduction to T Bolts .................................................. 7

C. Install the Lower End Cap .................................................. 8

D. Install mounting hardware ................................................ 9

E. Mount the track to the staircase ........................................10

F. Install the chassis assembly into the track ..........................11

G. Installing the fuse ............................................................13

H. Test run the chassis .........................................................13

I. Level the seat hub ...........................................................14

J. Install the seat ................................................................14

K. Adjust seat height ...........................................................15

L. Remote control label ........................................................15

M. Charging the batteries ......................................................15

N. Changing the orientation of the pendant holster ..................15

by ThyssenKrupp Access may void the warranty.

If you have questions concerning the installation or service of

the Citia BOS please contact the Service Department:

ThyssenKrupp Access

4001 East 138th Street

Grandview, MO 64030

800-409-3349

xxIM0805-470251

2

IV. COMPLETION PROCEDURES ..................................16

A. Completion Checklist ............................................................16

V. E.T.L. REQUIREMENTS ...........................................17

VI. SERVICE INFORMATION ........................................18

A. General specifi cations ......................................................18

B. Standard equipment ........................................................18

C. Control Board Operation Notes ..........................................19

D. Control Board Diagnostics ................................................19

E. Charging Circuit ..............................................................20

F. Up/Down Logic ...............................................................20

G. Beep Alerts.....................................................................20

H. What to do if the lift is stuck on a fi nal limit switch ...............20

I. Troubleshooting Flowchart if lift won’t run ...........................20

Important! It is imperative that this manual be read and understood

prior to attempting installation of the stair lift. Also, please observe

all cautions and warnings in this manual, as well as labels on the

equipment.

I. PRELIMINARY CHECKS

C. SHIPMENT

A. INSTALLATION SITE REQUIREMENTS

Dedicated* 115 VAC, 60 Hz, 3-wire

grounded outlet within 13’ of the top or

bottom of the staircase.

Stair angle between 25° and 45°.

Must be installed INDOORS

* NEC requirement

B. TOOLS REQUIRED

Set of Phillips head screwdrivers

Tape measure

3/8” reversible drill with 3/8” hex socket and

a 6” extension

3/16” Allen wrenches

Torque wrench rated to at least 18ft.lbs. of

torque

Safety items: steel toe shoes, safety

glasses, gloves, etc.

Torpedo level

Tools for removing hand rail if it interferes

with the travel of the stair lift

13mm socket

1/2" combination wrench

Verify all components are included with the

shipment:

Seat Box:

• Seat assembly

Chassis Box:

• Chassis assembly (mounted to loading tool)

• (1) Power supply

• (2) Remote controls

• (2) 9 volt batteries for remote controls

• Unit small parts

- (1) Set of Velcro

®

- (1) Fuse

Track Box:

• Track pieces (quantity will vary) with gear rack

and splice bars

• Track brackets (quantity will vary)

• (1) Charging wire

• (2) Track end caps

• Small parts kit:

- (1) Tube of lubricant

- (1) 4” long piece of gear rack for splice timing

- Fasteners for track brackets and track end

caps

- Track bracket covers (quantity will vary)

- Splice bars (to be placed in track, quantity will

vary)

4mm Allen wrench (included)

3mm Allen wrench (included)

1/8" Allen wrench

Something heavy to hold track in place

during install.

Mallet and fl athead screwdriver

3

II. TYPICAL COMPONENTS

Swivel

Seat

Handle

Unit Control

Fixed or

Fold-Up Seat

(depends on

model)

Begin by laying out your track on the oor and

removing any plastic wrap that may be around

the track.

NOTE: While we begin laying out the track on the

oor, some people may nd it easier to lay out

the track on the staircase. If this is easier, you

may do it that way, however, make sure you have

something heavy to keep the track from sliding

down the stairs.

A stock unit may include as few as 1 or as many

as 4 custom cut sections of extruded aluminum

track. The track is cut at the factory. Make sure

the track is positioned so the bottom is facing up.

You may have extra gear rack in your track. Gear

rack should be installed on the SIDE of the track.

If you have any gear rack placed in the BOTTOM

of the track, use the supplied 3mm Allen wrench

and loosen, but do not rem

ove, the bolts from the

gear rack. Once loosened, slide the extra gear

rack out of the track.

Chassis

Folding

Footrest

Pictured above is a "Supreme" model. This line of stair

lifts features interchangeable seats. The seat on the

unit you are installing may not look exactly like this.

Regardless, the installation procedures are alike.

III. INSTALLATION PROCEDURES

Your stair lift will include three boxes:

Track Box

•

Chassis Box

•

Seat Box

•

IMPORTANT: The following instructions are for

building the track on the oor and then moving it

to the staircase. Keep in mind that with regard to

ceilings and doorways, a completed track, which

can easily exceed 10 feet long, can be very difcult to maneuver between rooms or doorways.

Some people may nd it easier to assemble the

unit directly on the staircase. This is perfectly

acceptable, however, please be advised of the

inherent danger of falling while working on a

staircase due to an uneven stance and smaller

working space.

Track with Gear Rack Installed

Top of track

Extra Gear Rack which

will need to be removed.

Bottom of track

Splice all the pieces of track together. With the

track laying so the bottom is facing up, line

up the sections of track you need to splice together.

Loosen the set screws in the splice bars with the

4mm Allen wrench.

Track

Set Screws

Track

4

Tip

If the splice bars do not slide in easily, use the

fl athead screwdriver and the mallet to gently tap

the splice bars into place.

Slide the two pieces of track together so that only a

hairline joint remains between them. Center the splice

bars on the joint as shown below and tighten the splice

bars onto the track.

Note the small, hair-line

joint between the two

pieces of track.

The splice bars are

centerd on the joint

between the two pieces

of track.

A. TIME THE GEAR RACK

Loosen the set screws in the top sections of gear

rack and slide them up until the gear rack in the

upper track section is 6' from the top.

Note: Multiple sections of gear rack need be slid into

the track. This may cause the gear rack to not

be fl ush with the bottom end of the track. This is

fi ne, as long as the gear rack stop no less than

5 ⅝ from the bottom of the track. Any longer

is fi ne.

The gear rack MUST be

6" from the top of the track.

Make sure this measurement is accurate.

6"

Track at top of

staircase

(side view)

Between each piece of gear rack, you will need to

"time" the teeth. To do this, use the short piece

of gear rack that comes in the small parts box.

Push the two pieces of gear rack close to each

other and then force the 4" piece of on top of

the gear splice, like this:

A short piece of gear rack

is provided in the small

parts kit to properly space

the gear rack splices.

Do not tighten gear rack until

the proper spacing has been

achieved.

The gear rack needs to

extend into this range for

correct installation.

5⅝"

Track at bottom of

(side view)

staircase

There may be a gap between two pieces of gear

rack when spacing the splice. This is acceptable

as long as the distance between the teeth is

consistent.

When the gear rack is timed, use the 4mm

Allen wrench to tighten the gear into place.

Note: There is not a top or bottom end of the gear

rack, however the gear rack will be needing to

face the wall, i.e., if it's a left hand installation,

the gear rack will need to face the left hand wall.

Make sure your track is oriented this way.

5

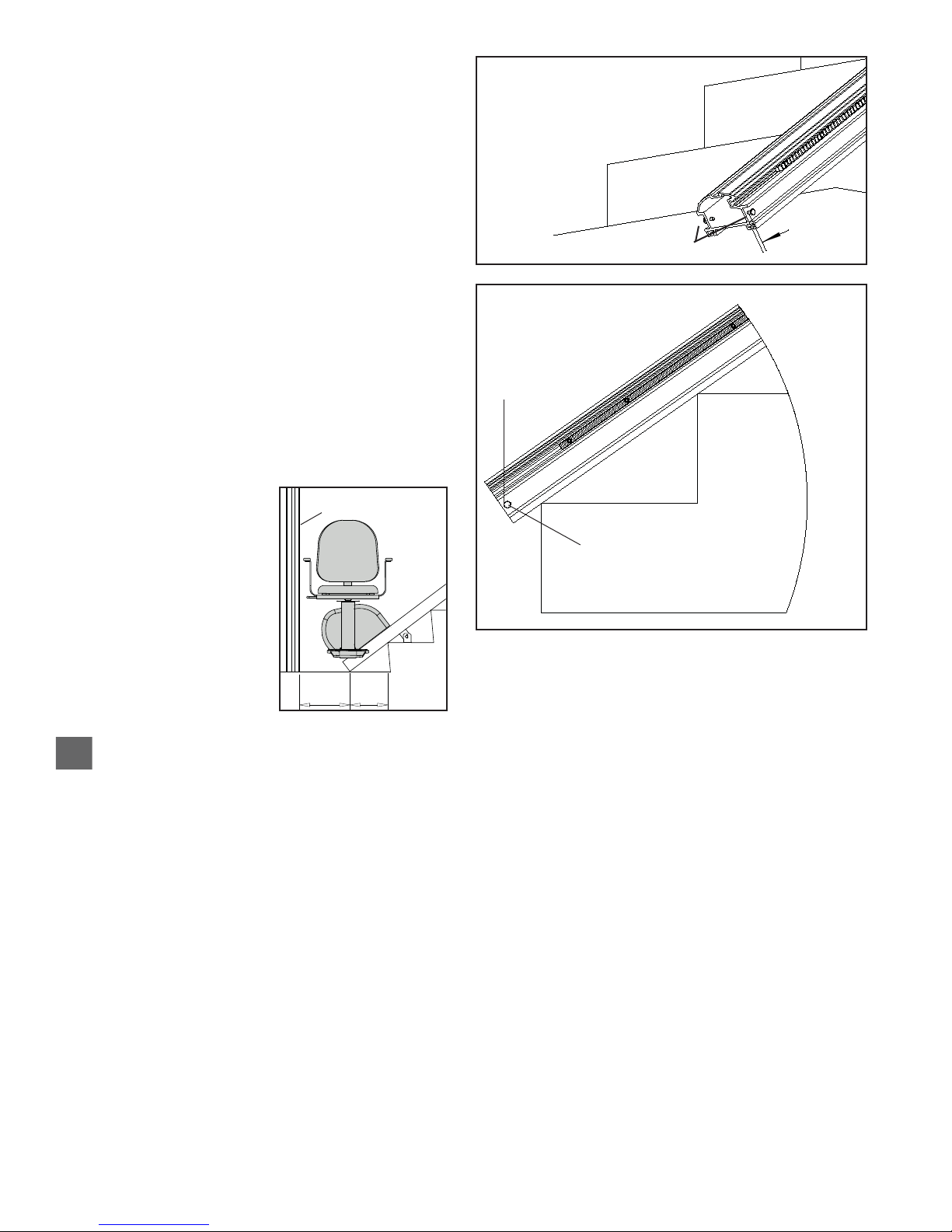

B. DETERMINE WHERE THE TRACK WILL BE

INSTALLED

Double check the orientation of your stair lift.

The chassis box of your stair lift will be marked as

either a Left Hand unit or a Right Hand Unit.

Optional Mounting (Angled View)

Stand at the bottom of the staircase on which you will

be installing the lift. A left hand unit will be traveling up

the left side of the staircase and a right hand unit will

be traveling up the right hand side of the staircase.

If the handedness of the unit is consistent with the lift

you ordered, continue the installation. If the handedness is wrong, please contact the authorized seller

fo the unit.

Verify there is adequate

clearance at the lower land-

Fig.1

Door jamb/other obstruction

ing for the track and seat.

Minimum clearance required

beyond the bottom step is

10" plus the depth of one

step (see Fig. 1).

3/8" [10mm]

1/4"-20NC Bolts

Optional Mounting Side View

Bolt is 3/8” from

end of track

1/4-20NC Bolt

Depth of

Step

10"

If you will be mounting the track so that it stops

at the bottom step instead of the lowest landing, you MUST drill a hole through the side of

the track and insert at least a 1/4"-20NC bolt

(supplied) on each side of end of the track to

act as a mechanical stop in case of complete

mechanical or electrical failure.

6

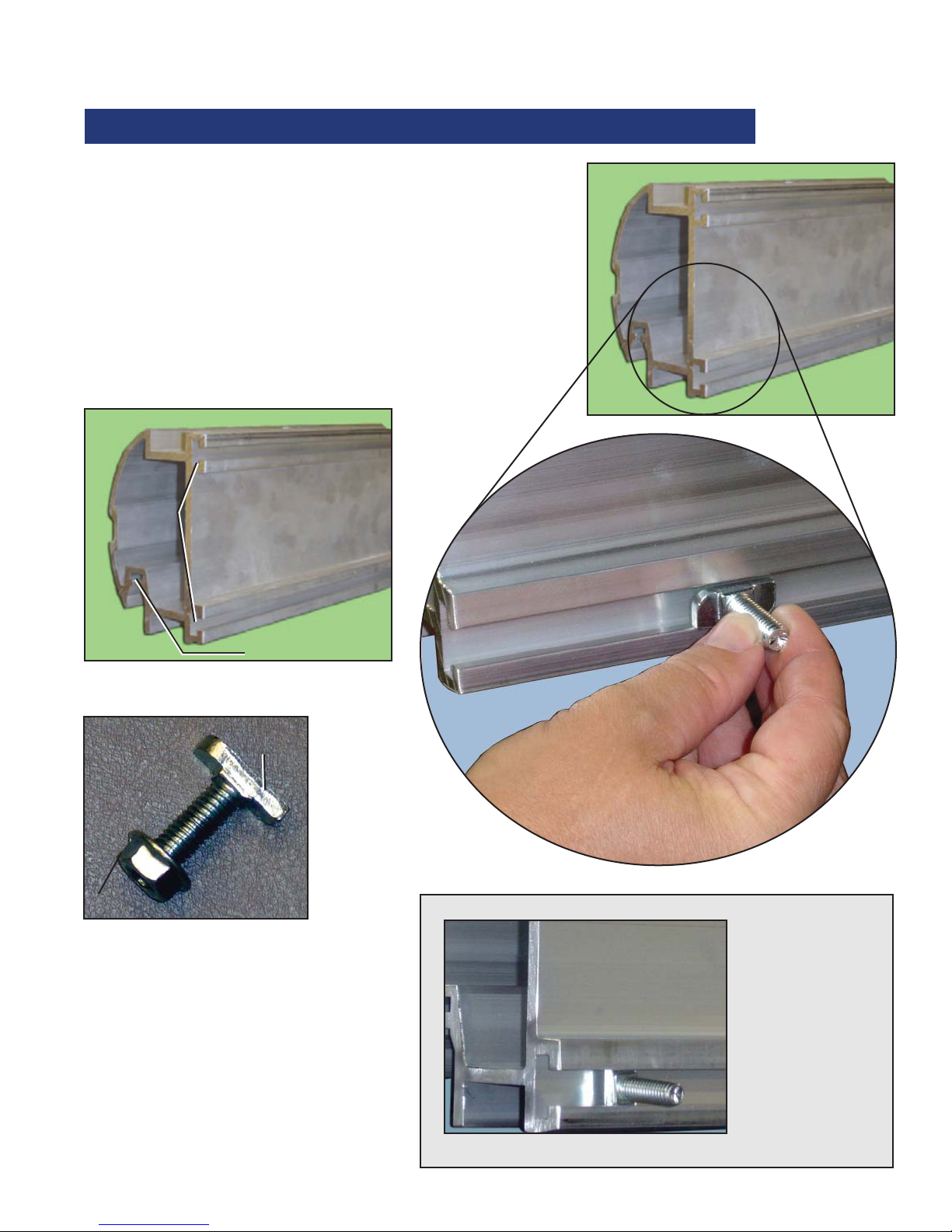

An Introduction to T-Bolts

T-bolts will

fit here

This is the

bottom of the

track

T-Bolt Nut

T-Bolt

The T head of

the bolt must be

placed parallel to

the channel in the

track. Push it into

the channel and

twist to lock in

place.

Throughout the installation of the track,

you'll be using T-bolts to attach track

brackets and a grounding bolt.

A T-bolt can be a tricky thing if you can't

see what you're doing, so we've included

this handy reference guide to walk

you through what should be going on

underneath the track.

This is the stair lift Track on its side:

This is the

T-bolts will

fit here

Gear Rack goes

in this channel

bottom of the

track

The T head of

the bolt simply

drops into the

channel on the

track. Once the

bolt is turned, the

T head catches

in the channnel

and a bolt can be

tightend down.

See pictures

below.

The T head of

the bolt must be

placed parallel to

the channel in the

track. Push it into

the channel and

twist to lock in

place.

Your T-Bolts look like this:

T-Bolt

T-Bolt Nut

The handy thing about a T bolt is that

even when the track is on the staircase,

you can reach to the underside of the

track, snap the bolt in place and screw

it in.

Now that the T

Bolt is locked in

the channel you

can apply the nut.

7

C. INSTALL LOWER END CAP

Feed the charging wire through the top of the track

to the bottom of the track.

Note: There is no up or down to the wiring har-

ness. Before putting the charging wire in the track,

decide where you will be plugging the stairlift unit

into the wall. Run the wire so that the end of the

charging wire with the extra plug and ring terminal

will be on the fl oor with the plug (see diagram on

page 9).

For instance, if you will be plugging the unit into an

outlet on the bottom fl oor, make sure the end of the

charging wire with the extra plug and ring terminal

are exiting the track on the bottom landing.

Tip

One of the

easiest ways

to feed the

charging wire

through the

track is to tape

the end of

the wire to a

tape measure

and feed the

tape measure

through the

track.

Plug the spade connector into the metal plug on

the inside of the end cap as shown below.

Slide the endcap on to the bottom of the track

Endcap

Fit this ridge into the track

Plug the Spade Connector

of the Charging wire here

Track (End View)

The dovetail portion of

the endcap fi ts into this

channel

Any extra wires will tuck

into this channel.

If your stairlift will be plugged into the wall at the

bottom of the staircase, you will have two extra

wires protruding from the lower endcap, one with

a ring terminal and one with a Molex® plug (see

diagram at right). Those other wires will need to

be routed to exit between the track and the end

cap and then tuck into the channel on the bottom

of the track (see illustration above). Take care to

make sure that the wires are not pinched.

NOTE: If the power supply will be on the top land-

ing you may skip this step and the next one, but

you will need to follow them when you install the

upper end cap, because you will have the extra

wiring at that end of the track.

8

A/C cord

Molex plug coming from transformer

Molex plug coming from track

Transformer

The harness is included with enough wire to cover

all installations. Most likely, you'll have more wire

than you need. DO NOT CUT THE WIRE. Simply

place excess wire inside the track.

If your track will not be resting on the lower

landing, but will be ending on the lowest step,

insert a second T bolt and bolt the endcap on

from the bottom (see below)

With the wires now routed out of the track you will

need to attach the grounding ring. Insert a T bolt

in the track, near the end cap. Slide the Grounding

Ring Terminal (see illustration at right) over the T

nut you just put in. Screw a nut over the T bolt to

tighten down the grounding ring.

Charging Wire

Spade Connector,

attaches to end

cap

Underside of track

End-

cap

Grounding

Wire

T nuts and

bolts

Track

Provide power to the unit by plugging the

molex plug from the track into the matching

plug from the transformer, then plug the A/C

cord into the other end of the transformer.

Finally, plug in the A/C cord to the wall.

Transformer

A/C cord

Spade

Connector,

attaches to

end cap

Power Supply

Ground Terminal

attaches to T bolt

Molex Plug

attaches to

Molex plug coming from track

Molex plug coming from transformer

D. ASSEMBLE MOUNTING HARDWARE

The track brackets come in 5 pieces: 1 riser,

2 feet and 2 covers for the feet. Assemble as

illustrated. When installing the T bolts into the

track bracket, make sure to thread the bolts

on, but do not tighten yet.

T bolts

Nut for cage bolt

Track Foot

5

/16-18 x ¾"

Cage bolts

(these will fi t into

the track)

Riser

9

E. MOUNT TRACK TO THE STAIRCASE

Track

T bolts holding track

bracket to track

Tip

Tread below the top landing

Tread above a track splice

Tread below a track splice

Center of each section of track

It's a good idea to put down a drop cloth during

your install so when y

the staircase you don't mark up carpet or scratch

hardwood stairs.

ou slide the track around on

Lay track along staircase. Make sure that:

The gear rack is facing the wall

•

The lower end cap is installed

•

The charging wire is oriented correctly

•

Tip

Note: These instructions are for mounting to a

standard wood staircase. For installation on

hard surface stairs, anchors may be needed

and different screws may be required. Consult

fl oor manufacturer for details

Place the

brackets on

the steps

where you

will be

installing

them.

Slide

each

bracket

under

the

track.

Once the track is laid on the stairs it will want

to slide down the staircase, so you will need

to put something to stop it, a toolbox or some

other heavy weight will work well.

Position the track in the middle of the staircase

with the underside of the track resting across the

stair nosings, and the lower track end cap resting

on the lower landing. With the track placed in the

middle of the staircase you'll have adequate room

to reach under and adjust the track brackets

The track brackets attach to the track with

the supplied T bolts. You will need to place 3

brackets per 8' section of track.

If you have spliced 2 pieces of track together,

you will need to place a track bracket on the

step directly above and the step directly below

the splice. A typical placement will have one

bracket at each of the following postions:

1st tread at the bottom of the

stair

10

Use the T nuts to attach the track to the

brackets.

Track

T bolts holding track

bracket to track

Underside view of the track bracket mounted to

the track. This side will be facing the steps.

For more specifi c help with T nuts refer to

pg. 7

Use a wrench to tighten everything up and

slide the track over 3½" from the wall.

Verify that both the bottom of the track and the

top are 3½" from the wall. If they are not, the

stairlift will not travel straight.

Note: This distance is needed for clearance of the seat

back in the riding and swivelled position.

Attach the track mounting brackets to the staircase.

Stair lift Chassis

Wooden Mounting Plank

Mounting Plates

Load Tool

The brackets attach to the stair treads with wood

screws.

The bottom of the track should be touching the

nose of stairs once the brackets are bolted down.

F. INSTALL THE CHASSIS ASSEMBLY INTO THE

TRACK

NOTE: If you will need to change remote frequencies

on the call/send remote controls do this PRIOR

to mounting the chassis on the track. With the

chassis close to the wall, it may become diffi cult

to remove the shroud and access the control

board. Refer to Step C of the Service Information

for instructions on changing the frequency of the

remote control.

Cut open the stair lift box, pull out the unit

which will be attached to a plank of wood.

Use the plank to support the unit, and

carefully transport the unit to the top of the

staircase.

Track Bracket installed.

Do not carry the unit by the plastic shroud!

Doing so could cause the unit to come away

from the shroud and cause serious injury!

Wooden Mounting Plank

Stair lift Chassis

Mounting Plates

Load Tool

Unbolt the mounting plates to free the stair

lift unit and load tool. There will be two bars

protruding from one end.

Track Bracket cover installed.

11

On The Track

Retaining Bolt

Tip

Ready To Load

Before loading the unit on the track, take the

power wires and lead them through the piece of

starter track the stair lift is mounted on, that way,

they won't fall down into the track.

Line up the splice bars of the starter track with the

top end of the track bolted to the staircase. Lift the

unit and insert the splice bars into the track.

Ready To Load

Grip the seat post and gently pull the chassis up

the track, not to move it, but just to take enough

pressure off the retaining bolt. Remove the bolt

from the starter track and gently slide the unit

down the track until the chassis is fully on the

mounted track and the gears have engaged.

Retaining Bolt

On The Track

Remove the starter track.

Install the top endcap by attaching the terminal of

the charging wire to the terminal on the inside of

the top end cap. Insert (1) T-bolt in each T-slot at

top of track, then fasten the end cap to the upper

end of the track with nuts provided.

12

Seat swivel switch

Seat Post

G. INSTALLING THE FUSE

Remove the front cover of the stairlift by removing

the screws located under the seat post

Install the fuse into the two spade connectors.

H. TEST RUN THE CHASSIS

Operate pendant control to verify that the stair lift

will go up and down properly, while holding the

seat swivel switch in. The seat swivel switch is

located on the back of the seat post (see illustration below) and the unit will not run if the switch

is not pressed in. Normally, the seat on the unit

will acctuate the switch, but because there is no

seat, you will need to do this manually.

Seat Post

Seat swivel switch

Fuse

Close up of fuse

Fuse

Chassis

NOTE: The green wire

is for diagnostic

purposes only,

and does not

need to attatch

to anything.

13

I. LEVEL THE SEAT HUB

Bolts

seat

Seat handle

Locking Mechanism

Seat Post

Seat Post

Seat Post Collar

Locking Mechanism

J. INSTALL THE SEAT

Loosen the three (3) bolts on the chassis behind

the footrest.

Place a torpedo level on either the seat hub or the

footrest.

Rotate mounting bracket on the bolts until the seat

mounting shaft is vertical and plumb.

Bolts

Footrest

Place the seat assembly onto the seat shaft.

Rotate the swivel seat handle and slide the seat

fully onto the shaft. Release the handle and make

sure the seat locks into position.

Rotate the swivel seat handle and check that the

seat locks in the loading, riding, and unloading

positions.

Locking Mechanism

seat

Seat handle

Note: If you run out of slot, remove the bolts and replace them

in different holes until the seat will plumb to vertical.

Tighten the bolts.

It is very important to torque the nuts to a mini-

mum of 18 ft. lbs. (24.4 Km) to lock the seat

hub into place.

Seat Post

Seat Post Collar

Locking Mechanism

Seat Post

14

K. ADJUST SEAT HEIGHT IF DESIRED

Pendant

Holster

Pendant Holster

with pendant

Loosen the Allen screws on the two seat

clamps.

O. CHANGING THE ORIENTATION OF THE PENDANT

HOLSTER

The stair lift comes with a Pendant Holster attached

under the armrest.

Slide the seat up or down as desired and

tighten the screws.

Install the front seat mounting cover into

position.

L. REMOTE CONTROL LABEL

Apply the appropriate directional label to the face

of the remote control, depending upon whether it

is a right hand or left hand installations. Confi rm

direction of remote buttons fi rst.

Note: Refer to Step C of the Service Information for

instructions on changing the frequency of the

remote control.

M. CHARGING THE BATTERIES

Connect the power supply to the charging

harness.

NOTE: The batteries come from the factory with a

small amount of charge already in them.

The pendant holster

comes from the factory

already attached, however,

you may need to change

which side the holster is

attached to for the comfort

Pendant Holster

of the user.

with pendant

The holster attaches in one

of two ways depending

on which model of stairlift

you're installing.

Option 1: There are two

screws under the armrest

which attach the armrest

to the chair arm. Undo

Pendant

Holster

these screws, remove

the holster, reattach the

armrest and install on the

other side.

Option 2: If there are no visible screws on the

bottom of the armrest, the armrest is most likely

snapped into place by the use some plastic, cone

shaped clips.

To change, gently pry up on the armrest carefully

as not to break the clips. Once detatched, slide the

pendant holster off and re-attach the armrest. Do

the same on the other arm to attach the pendant

holster (see illustration at right).

Plug the power supply into an electrical outlet.

Charge batteries for at least 12 hours.

N. VELCRO PENDANT CONTROL

Apply one side of Velcro to back of pendant control

and the other to the unit, so pendant will adhere

to the unit. Placement of pendant control is up to

the customer, The manufacturer recommends the

arm of the unit. Velcro will hold pendant to unit

when unit is not in use.

15

Right-Hand arm of stair lift

Armrest

Pendant Holster

IV. COMPLETION PROCEDURES

A. COMPLETION CHECKLIST

The following features must be verifi ed as operational

before the stair lift can be released for use:

Upper and lower limits: Verify the lift stops

automatically at the top and bottom of the

track.

Final limits: Verify the lift is inoperable in

both directions when each fi nal limit switch

is pressed.

Running Clearance: Verify the lift clears all

obstructions.

Track Mounting Brackets: Verify all track

mounting brackets are securely attached to

the stair treads, the track and at the pivot

points.

Pendant Holster

Right-Hand arm of stair lift

Armrest

Track Splice: Verify track joints are smooth

and free of burrs and gaps.

Gear Rack: Verify the gear rack is

suffi ciently lubricated.

Track End Covers: Verify the track end

covers are securely fastened to the track.

Track: Verify the inside of the track is free

of foreign objects.

Chassis Rollers: Verify the chassis roller

axles have been lubricated.

Footrest:

Verify the footrest clears all stair

nosings.

Verify the lift stops when the footrest

runs into an obstruction.

Verify the footrest folds up and stays

in the up position.

16

Verify the unit does not beep when it

stops at the upper and lower limits.

The unit will beep if stopped and not

on the charging strip

Seat:

V. E.T.L. REQUIREMENTS

Verify the seat is level.

Verify the seat swivels 70° towards

each landing and locks into position.

Verify the lift will not operate when

the seat is not locked in the riding

position.

For optional folding seat: Verify the

seat will fold up and stay in the up

position.

Verify the seat belt works properly.

Clean Up: Verify the lift is free of all grease,

dirt, etc.

This E.T.L. listed stairway lift must meet the latest

ASME A18.1a specifi cations for the E.T.L. listing to

be valid.

The following rules must be complied to at the installation site.

Rule 7.1.1

A free passage width of no less than 20 in. shall be

provided. If the seat and platform can be folded when

not in use, the distance shall be measured from the

folded position.

Rule 7.1.2

The structure on which the equipment is installed shall

be capable of safely supporting the loads imposed.

Rule 7.1.3

The installation of all electrical equipment and wiring

shall conform to the requirements ANSI/NFPA 70.

Rule 7.6.4

At no point in its travel shall the edge of the footrest

facing the upper landing be more than 24 in. above

the step or landing as measured vertically.

Rule 7.7.2

No lift shall be installed to operate on a greater incline

than 45 deg. as measured on the mean.

17

VI. SERVICE INFORMATION

A. GENERAL SPECIFICATIONS

Rated Load: 375 lbs. (170 kg)

Speed: 18-25 fpm (dependant on angle of install

and load)

Travel: 32’ max. (track length)

Power Supply: Dedicated* 115VAC, 60 Hz, 3-wire

grounded outlet

Incline Limits: 25° to 45°

ETL Listed when properly installed

B. STANDARD EQUIPMENT

Drive System: Rack and pinion

Motor: .5 hp, 24 VDC

Motor Controller: SoftStart/SoftStop

Brake: Self locking worm gear

Seat:

• Standard - 18” wide fi xed seat with two fi xed

arms OR

• Select - 18” wide fi xed, upholstered seat with

OR

• Excel - 19” wide folding seat with two fixed

arms

• Seat belt

• 70° locking swivel at upper and lower landings

Controls: Low voltage up-down hand-held control on

unit and two wireless remote controls

Safety Devices:

Footrest obstruction sensor

Swivel seat cut-off switch

Final limits

Warranty: Five years on drive train (motor and gear)

Two years on all component parts

Notes:

• The BOS model stair lifts are battery powered. Two

12V batteries are wired in series to provide 24V to

the control system. The batteries are charged by

a 33VDC power supply plugged into the 115 VAC

outlet. The batteries are charged only when the

lift is parked at the upper or lower landing.

• The call/send controls (transmitters) use infrared

signals. There are two infrared sensors located on

the chassis access cover. There is a combination

of 4 different frequencies the transmitters can be

set to (both transmitters must be set to the same

frequency).

• There is a half second delay after a control button

is pressed before the lift starts to move. After the

lift stops, the up/down controls are disabled for 3

seconds.

* ASME A18.1a / NEC Requirement

upper and lower fi nal limit

18

charge spring

upper and lower

stops

Caution!

The control board is sensitive to static charge. To avoid damage,

touch a metal surface on the lift to discharge yourself of static

charge. Never touch the chips on the control board.

Always disconnect the 115 VAC power and disconnect

the fuse when working on the lift.

D. CONTROL BOARD DIAGNOSTICSC. CONTROL BOARD OPERATION NOTES

The control board contains LED's that indicate various functions

or faults. A slow fl ash is 1 second on and 1 second off, a quick

fl ash is .25 seconds on and .25 seconds off.

Steady Green on PWR LED - Run Mode

Battery voltage is above 21 VDC and the lift is running. A green

test lead by the fuse allows the battery voltage to be measured

without removal of the shroud

First Power Up

To turn the controller board on after connecting the fuse, press

the unit controls Up or Down pendant switch. The seat must be

in the locked position and no obstructions can be in the way of

the footrest.

Once the controller board has been turned on, it will stay on as

long as the battery charger remains connected.

Remote Control (Transmitter) Frequencies

The standard wireless remote controls (transmitters) use infrared

signals. One button on the transmitter is UP and other button

is DOWN. There are two infrared sensors (receivers) located on

the chassis access cover.

A combination of 4 different transmitter frequencies allow for

more than one lift in a single home. The two transmitters must

be set to the same frequency (for each lift). For example 1 to

1, 2 to 2, etc.

To change a frequency:

Ensure the infrared receivers (in chassis cover) are connected

to the control board. Use the seat control to move the lift away

from the end of the track. Take the back off of the transmitters

and set the red jumpers (in each transmitter) to the same code.

Change the corresponding code in the control board J1 (see

chart). Press and hold the yellow "learn" button on the control

board, then press and hold one of the up/down buttons on one

of the transmitters. The controller board should beep and the

lift start to move after you release the transmitter button when

the frequency has been successfully changed.

Slow Flash Green on GRN LED - Stop Mode

Battery voltage is above 21 VDC and the lift is stopped.

Steady Yellow - Caution Low Battery

Battery voltage is between 11 VDC and 21 VDC.

Slow Flash Yellow - Under voltage

Battery voltage is below 11 VDC.

Quick Flash Yellow - Charging

Battery is charging. Charging begins approximately 2 minutes

after lift reaches upper or lower limit.

Slow Flash Red - Emergency Stop

Either the fi nal limit switch has been tripped, the swivel seat

switch is not in the operating position, or there is an obstruction

in the footrest path. If the fi nal limit switch has been reached the

stair lift must be manually moved using an 8mm socket.

Steady Red - Current Limit

Motor is loaded more than 120% of its rating. The motor will

continue to run in current limit for a preset time, however, the

speed will be reduced. The unit will sound 2 rapid beeps.

Note: Higher currents will allow for less run time.

Quick Flash Red - I2T

The motor has been overloaded for too long and the lift has timed

out. If the motor reaches 160% of full load for 6.0 seconds the

unit will time-out. To recover from this mode, the lift must be

put into stop mode. The unit will sound 2 rapid beeps.

Note that if the lift is on an upper or lower limit switch, the frequency may not be able to be changed.

To access the controller board the footrest support and shroud

must be removed. The footrest plug can be temporarily jumpered

out while changing frequencies.

Quick Flash Red/Yellow - Short Circuit

Short circuit is an unrecoverable fault and may only be reset by

disconnecting and reapplying the battery. Short circuit may be

caused by an excessive overload on the motor or failure of the

MOSFET power devices.

19

E. CHARGING CIRCUIT

F. UP/DOWN LOGIC

The charging circuit produces a DC voltage of 33 volts

plus or minus one volt. This must be read between

the charge strip on the charge (+DC) cam to the gear

rack on the track (-DC).

If you are not receiving 32 to 34 volts DC check the

following:

1. Verify that the power supply/charger is plugged

into the wall outlet. Check for 115 VAC at

outlet.

2. Verify that the charger is producing the 33

volts. This is done by checking voltage from B+

(pointed end of plug) to B- (fl at side of plug).

3. If this is all correct, verify the ring terminal B- is

mounted to a T-bolt on the track and tighten

down the nut to secure the ring terminal. This

will ensure that the proper ground is made

through the T-bolt or screw. Reconnect power

supply.

4. If you still do not get the 33 volts DC, verify

that your charging station is hooked up to one

of the white wires leading from the B+ wire.

Check voltage.

5. If you still do not get the 33 volts DC verify

that the gear rack screw on top and bottom

of each piece of gear rack is tight. This will

ensure proper grounding of the gear rack.

When the unit has been parked at the charge station

for three minutes, it should be receiving charge. If the

unit starts to beep while on the charge station, the unit

is still not receiving charge. Check the following:

When the lift is commanded to run, the controller board

will immediately sound a single beep and the lift will

pause momentarily before moving.

If the lift is commanded to stop by releasing a control

switch/button, the lift will decelerate to a stop in 1.5

seconds. However, if the switch/button is pressed

again, before the lift has reached a complete stop,

the lift will immediately start to accelerate.

The lift has a fi xed acceleration rate of 3.0 seconds.

The priority of the input signal to the lift for a direction

command is dependant on which input was received

fi rst.

G. BEEP ALERTS

The controller board will sound a single 0.35 second

departure beep upon receiving a signal to run.

The controller board will sound a 2.5 second beep

upon receiving a signal to run if the battery voltage is

low (11.0 VDC to 21.0 VDC) and will not run.

The control will sound two rapid beeps if current

overload occurs

The controller board will beep on and off for 20 seconds once every fi ve minutes when the charger is not

connected.

H. WHAT TO DO IF THE LIFT IS STUCK ON A FINAL

LIMIT SWITCH

(MANUALLY LOWERING THE LIFT)

1. Check that the charge springs are contacting

the tabs on the track.

2. Verify that all wires in the unit are connected

properly and that polarity is correct.

Remove the shroud to check DC voltage at charge

spring between 'charge +' and 'charge -' on board.

The unit should now be receiving the 33 volts DC

needed for proper charging of the batteries.

20

Remove the seat mount shroud.

Remove the fuse.

Note: Never perform manual lowering with the

stair lift circuit connected.

Insert an 8mm socket over the hex shaft located

at the end of the motor. Rotate the shaft to move

the stair lift off of the fi nal limit switch.

Install the fuse and cover

I. TROUBLESHOOTING FLOWCHART WHEN LIFT WON’T RUN

21

22

Loading...

Loading...