Page 1

Owner’s Manual

ThyssenKrupp Elevator

Americas Business Unit

TK

Page 2

This document for Internal Use Only.

Every attempt has been made to ensure that this documentation is as accurate and up-to-date as possible.

However, ThyssenKrupp Elevator assumes no liability for consequences, directly or indirectly, resulting

from any error or omission. The material contained herein is subject to revision, and ThyssenKrupp

Elevator makes every effort to inform its product users of these revisions as they occur. Please report any

problems with this manual to ThyssenKrupp Elevator, P.O. Box 2177, Memphis, TN 38101.

ThyssenKrupp Elevator S P.O. Box 2177 S Memphis, Tennessee 38101

E2010 ThyssenKrupp Elevator. All rights reserved.

Printed in the United States of America.

Published 2010

Firsth Edition February, 2010

Manual No.: TKE39673-A

P.O. Box 2177, Memphis, Tennessee 38101 Phone (601) 393-2110 Fax (601) 342-4309

Page 3

Owner’s Manual

Technical

Information

General Maintenance 2......................................

Sliding Guides 2............................................

Cabs 2...................................................

Gates and Doors 3..........................................

Motors 3..................................................

Power Unit 4..............................................

Controller 4...............................................

Jacks 4..................................................

Care and Cleaning of Architectural Metals 5......................

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Technical Information-1

Page 4

Owner’s Manual

General Maintenance Instructions

General Maintenance

Your ThyssenKrupp Elevator is the finest piece of equipment

of its type on the market today. It is designed, manufactured

and installed to minimize maintenance. However, maintenance must be provided to prolong the life of your equipment

and protect your investment.

A planned sequential procedure, regularly performed, will

keep your maintenance cost to an absolute minimum and

ensure realization of the long trouble free service the

equipment was designed to deliver. The procedure should

begin the day the elevator goes into service. Cleanliness of

the elevator’s components, machine room and hoistway

cannot be overstressed.

Every precaution should be taken

when servicing any elevator,

whether specifically mentioned here or not. Common

sense precautions should be followed making sure life

and limb of the person servicing the elevator and the public is not endangered.

Procedures listed in this manual that involve entering the

hoistway or machine room should only be carried out by

a trained elevator professional. Electrical and mechanical

hazards exist for untrained service personnel who are unfamiliar with this type of equipment.

Make certain ALL voltage is removedbefore touching any

parts of the electric controller or its peripherals. Due to

the nature of some internal controller power supplies,

voltage may be present on some components after the input power source has been removed. Always check for

voltage with a meter before servicing any component.

Sliding Guides

1. Check Guide Shoes at regular intervals for condition and

adjustment. Check the clearance between guide shoes

and the guide rails. Sliding shoes should be fitted to the

rail with approximately

theshoesinplaceshouldbetight.Checkthatthebolted

connections on the guide rail and brackets are securely

fastened.

2. For sliding guide shoes, check that guide rails are coated

with a film of approved lubricant (nameplate specified) to

ensure smooth operation. Guide rail lubricators, when

used, are located either at the top of the guide rails or on

the top guide shoes. The level of lubricant should be

checked regularly and refilled when low.

1

/32” clearance. All bolts holding

Cabs

1. Visually inspect the cab for burned out lamps, damaged

flooring or carpeting and damage to cab fixtures.

2. Check that all bolted connections on the cab are tightened securely.

3. Ensure that the car sill is clean at all times as trash in the

sill grooves can affect proper door operation.

4. Keep the car push button station clean and dry, as dirt or

moisture can cause electrical problems.

When access to the pit or hoistway is necessary, see that

safety measures are used to protect the public as well as

the servicing personnel.

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Technical Information-2

Page 5

Owner’s Manual

Gates and Doors

1. Check the car and hoistway doors and the door operator

for ease of operation. Any binding or dragging of the

doors indicates a need for alignment or adjustment.

2. Ensure that the doors are plumb and close completely.

Excessive looseness may constitute a safety hazard.

3. The guide grooves in the hoistway sills should always be

kept clean. NEVER sweep dirt or trash into the hoistway.

4. An experienced ThyssenKrupp serviceman should check

the power door operation, linkage and door hardware

regularly.

Checklist

S Ensure that all pivots in the linkage mechanism on the

doors have free operation and are lubricated sparingly.

S Inspect brushes regularly on DC motors and replace when

worn excessively.

S Check for proper operation of the switches and sensors

which governs acceleration and deceleration of the door

operator motor.

S Check that the pick-up rollers and clutch operate smoothly.

S Check the vee belts on the drive wheel and motor for ten-

sion, fraying or splitting.

Motors

1. Prevent dust accumulation by keepingthe machine room

and hoistway clean. Dust or dirt accumulated in thewindings will reduce the ability of the unit to dissipate heat and

impair efficiency.

S Should dust collect, blow it out, taking precautions to guard

against personal injury as well as to avoid damage to the

equipment.

2. Check the brushes of DC motors for wear and replace

where necessary, using only genuine ThyssenKrupp

brushes.

NOTE: Use of the wrong brushes may seriously damage the

commutator and/or interfere with the operation land adjustment of electrical components.

3. The spring tension of ThyssenKrupp brush holders is au tomatically maintained and never needs adjustment.

S Check to be sure the brush is free in its holder and the

spring is applying even pressure. ThyssenKrupp recommends that brush replacement be done by a qualified serviceman.

Failure to provide this regular maintenance, beginning when

the equipment is new, will eventually result in premature

failure of components with consequent equipment breakdowns. ThyssenKrupp Elevator strongly recommends that

maintenance be carried out by a member of their national

qualified service organization. There is no substitute for the

trained eye and hand of an experienced elevator serviceman.

Rotating electrical equipment.

Use strict safety precautions

when performing these tasks. Do not wear loose clothing,

jewelry or other items that can become entangled in the

moving parts of the machine or belts. Never place yourself physically in a position where unexpected motion of

the machine could be harmful.

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Technical Information-3

Page 6

Owner’s Manual

Power Unit

1. Check the following:

a. The machine room is well ventilated and properclear-

ance is provided around the Power Unit per local code

requirement.

b. Oil level is within the safe limits as shown on the

indicator. Only use hydraulic fluid that meets

ThyssenKrupp specifications. Contact your loca l

ThyssenKruppOffice for the fluid recommendedfor

your area.

c. Check that all belts, if used, are properly tensioned.

d. Ensure that any fluid leakage is cleaned and that all

coversareinplaceonthePowerUnit.

Controller

All maintenance and adjustment of the controller should be

done by qualified ThyssenKrupp personnel as they are best

qualified to safely and correctly perform the necessary steps.

Jacks

Jack inspection should only be made by qualified

ThyssenKrupp personnel.

1. Inspect jack head for cleanliness and leakage. Remove

any debris or oil that has accumulated.

Every precaution should be taken

when servicing any elevator.,

whether specifically mentioned here or not. Common

sense precautions should be followed making sure life

and limb of the person servicing the elevator and the public is not endangered.

Make certain ALL voltage is removedbefore touching any

parts of the electric controller or its peripherals. Due to

the nature of some internal controller power supplies,

voltage may be present on some components after the input power source has been removed. Always check for

voltage with a meter before servicing any component.

When access to the pit or hoistway is necessary, see that

safety measures are used to protect the public as well as

the servicing personnel.

2. Check that all bolts and connecting hardware between

the jack, platen and bolsters is securely fastened.

3. Replace seal(s) when leakage becomes excessive.

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Technical Information-4

Page 7

Owner’s Manual

Care and Cleaning of Architectural Metals

Listed below are suggested care and cleaning instructions

and typical products for use by building owners. Any cleaning

#4 Brushed and #7 or #8 Mirror Finished Stainless Steel

The use of chloride-containing cleaners must be avoided.

Surfae damage will occur from the use of such cleaners.

Routine cleaning with a mild dishwasher liquid will remove

fingerprints, smears and everyday liquids such as soda,

coffee and other beverages. Consumer type glass cleaners

#4 Brushed and #7 or #8 Mirror Finished Muntz (Bronze)

Only routine care and cleaning is recommended. The surface

should be waxed weekly with paste wax (or more often

depending on building traffic). This puts a protective coating

of wax over the lacquer and reduces scuffing. Do not use any

abrasives or chemical cleaners. This type of product will

ThyssenKrupp Baked Enamel Finishes

Routine cleaning with a mild detergent, soap and water will

remove fingerprints, smears and everyday type liquid spills

or refinishing, other than routine, should be handled by

qualified professions.

are also effective on fingerprints and beverage spills and a

good stainless steel cleaner can also be used. Do not use

abrasivessuch as scouring powders. Always finish with a light

rinse of warm clean water.

cause damage. Recommended cleaning is to remove spills,

smears and fingerprints with a soft cloth dampened with plain

tap water. If this recommendation is not followed, early failure

of the coating will occur.

such as coffee or soda. Do not use any abrasive powders or

harsh chemicals.

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Technical Information-5

Page 8

Owner’s Manual

This page

intentionally

left blank.

E2001, 2008 THYSSENKRUPP ELEVATOR Printed in USA September, 2008

Technical Information-6

Page 9

Owner’s Manual

Traditional

Signal Fixtures

Audible 2.....................................................

Car Braille 3...................................................

Emergency Light 7..............................................

Hall Braille 8...................................................

Hall Station 12.................................................

Lantern 12....................................................

Lantern Traditional 12...........................................

Phone 15.....................................................

Push Button 15................................................

Station Inspection 19............................................

Switch Push / Pull 19............................................

Switch Rotary 20...............................................

Switch Toggle 20...............................................

Traditional Faceplate 22..........................................

Traditional Hall Station 22........................................

Traditional Key Core 24..........................................

Traditional Key Switch 25.........................................

Traditional Key Switch 26.........................................

Traditional Push Button 26.......................................

Traditional Key Switch Selection Chart 27............................

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-1

Page 10

Owner’s Manual

Audible

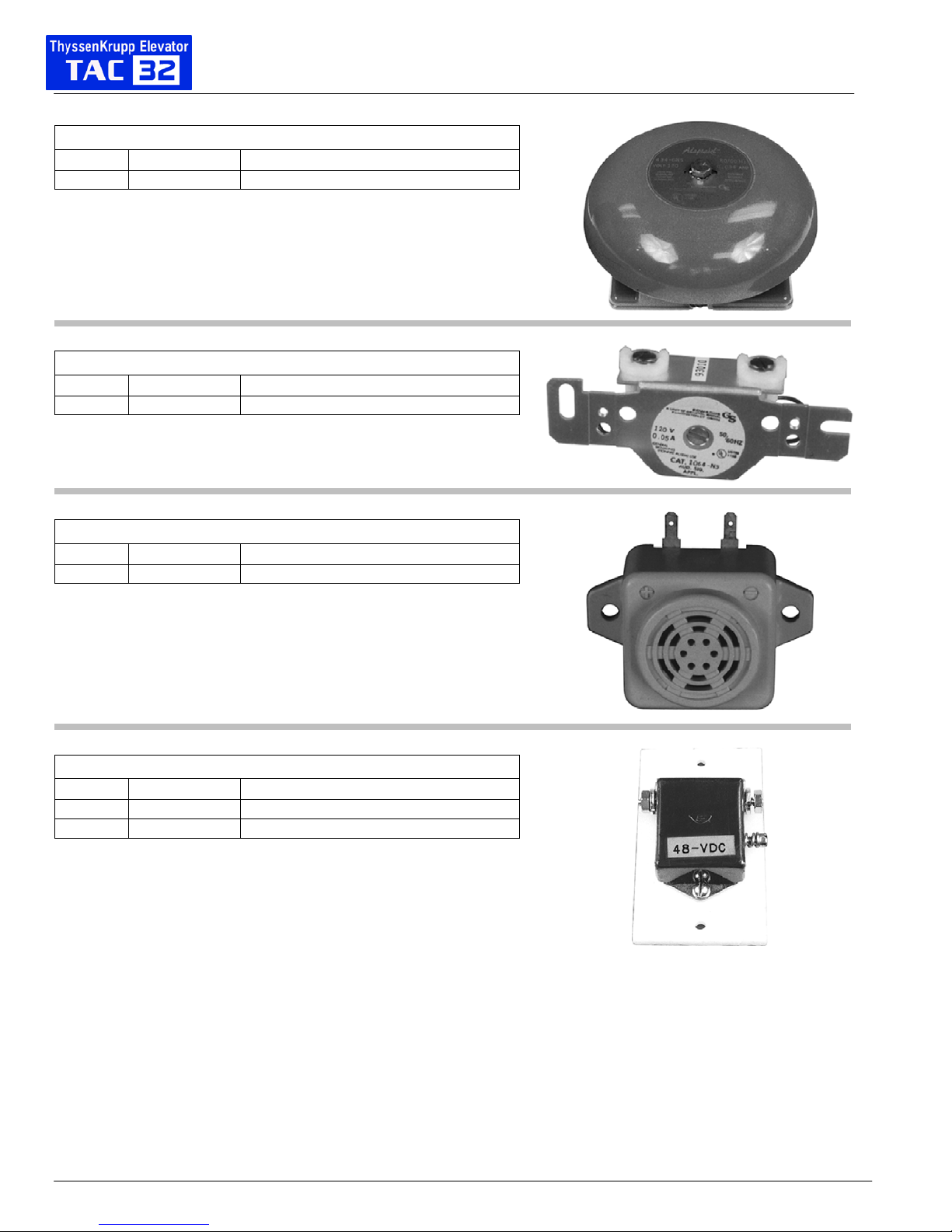

Part No. Print No. Description

9760593 76059 Bell, Alarm, 6” Dia X 2.625” Deep,120 VAC

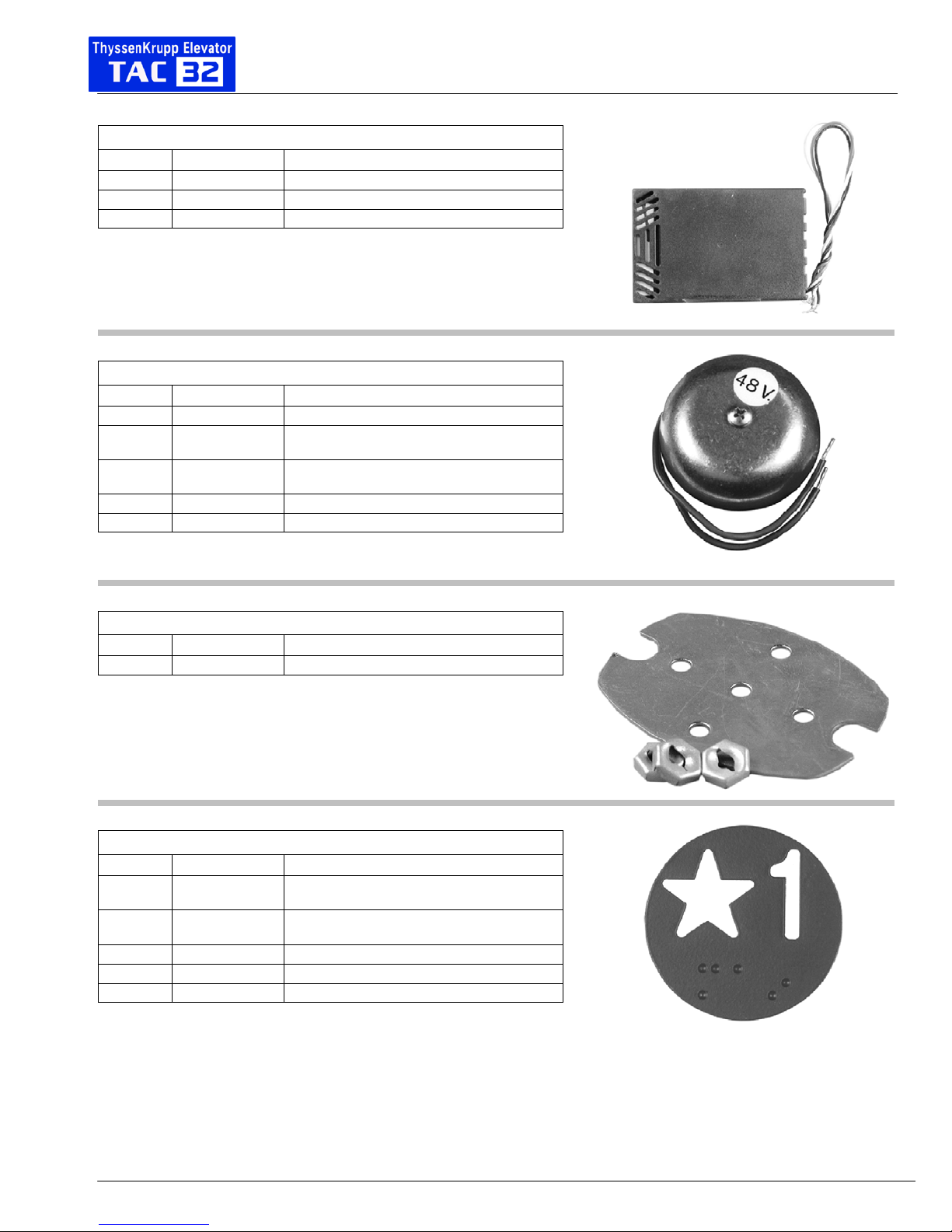

Audible

Part No. Print No. Description

9726603 32660 Buzzer, 120 V

Audible

Part No. Print No. Description

9882777 177AC1 Buzzer, 24 V, Audible, Fire Service

Audible

Part No. Print No. Description

9882765 68276 Buzzer, 24 VDC

9882753 68275 Buzzer, 48 VDC

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-2

Page 11

Owner’s Manual

Audible

Part No. Print No. Description

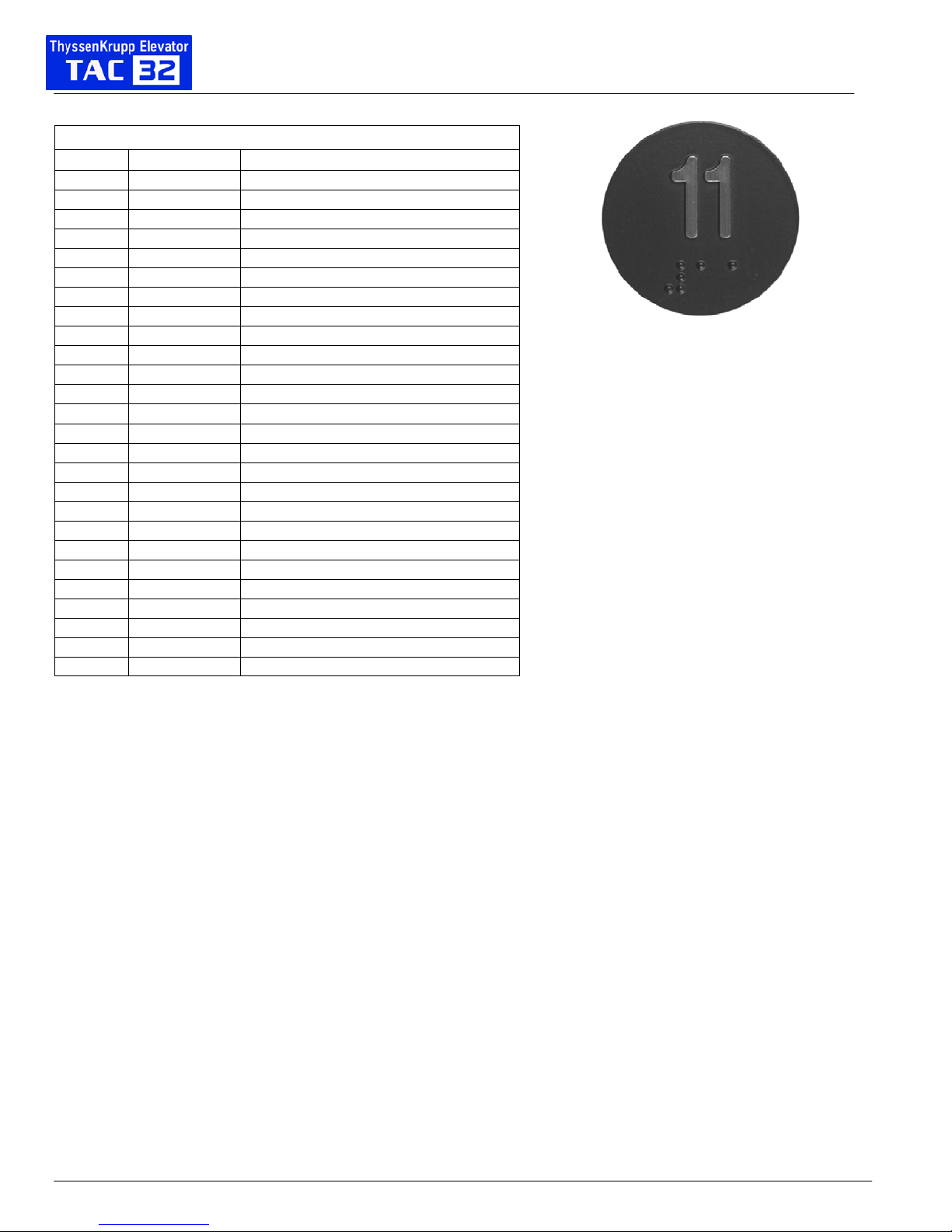

9780490 Chime,2DN,1UP,48VAC/DC

9780506 Chime, 2DN, 1UP, 115 V AC/DC

9780464 Chime, 2DN, 1UP, 24 V AC/DC

Audible

Part No. Print No. Description

9724394 32439 Gong Assy, Single Stroke, 115 VDC

9737194 107191

9737170 107190

9711818 111828 Gong Assy, Single Stroke, Steel, 24 VDC

9711820 111827 Gong Assy, Single Stroke, Steel, 48 VDC

Gong Assy, Single Stroke, Hall Lantern, Continuous

Duty Coil In Series W/ GE 161 Lamp, Brass, 24 V

Gong Assy, Single Stroke, Hall Lantern, Continuous

Duty Coil InSeries W/ GE 161 Lamp, Brass, 48 VDC

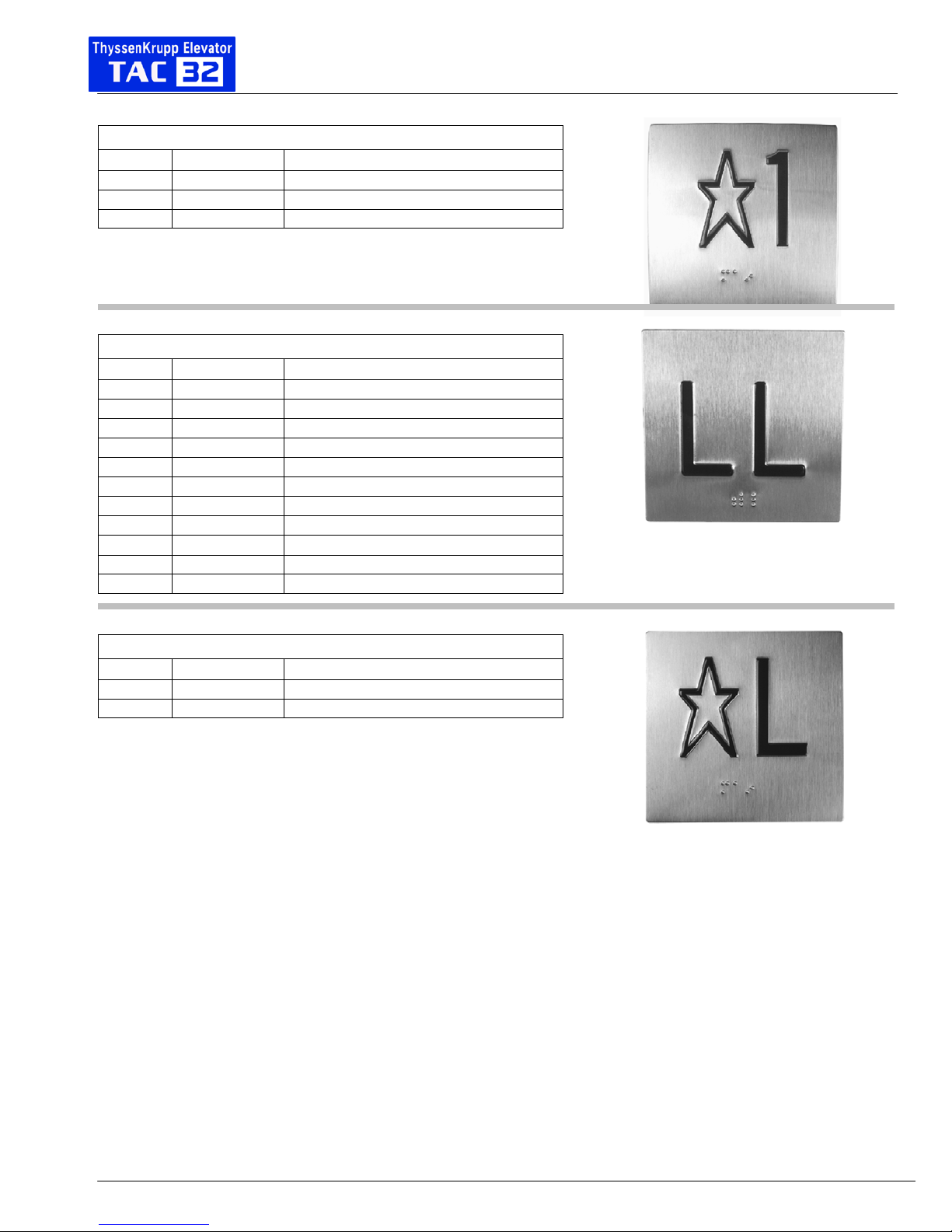

Car Braille

Part No. Print No. Description

9798262 Plate, Mounting Kit, for Car Braille

Car Braille

Part No. Print No. Description

9796046

9798237

9798225 Plate, Round, 1 1/2”, #4 SS, Rear Mount, ”4”

9798031 Plate, Round, 1 1/2”, #4 SS, Star 2

9797830 Plate, Round, 1 1/2”, #4 SS, Star L

Plate, Round, 1 1/2”, #4 SS, Door Close Rear

Symbol

Plate, Round, 1 1/2”, #4 SS, Door Open Rear

Symbol

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-3

Page 12

Owner’s Manual

Car Braille

Part No. Print No. Description

9797737 169BL41 Plate, Round, 1 1/2”, Rear Mount, ”* G”

9797920 169BL1 Plate, Round, 1 1/2”, Rear Mount, ”1”

9796435 169BL10 Plate, Round, 1 1/2”, Rear Mount, ”10”

9796538 169BL11 Plate, Round, 1 1/2”, Rear Mount, ”11”

9796630 169BL12 Plate, Round, 1 1/2”, Rear Mount, ”12”

9796733 169BL13 Plate, Round, 1 1/2”, Rear Mount, ”13”

9796836 169BL14 Plate, Round, 1 1/2”, Rear Mount, ”14”

9796939 169BL15 Plate, Round, 1 1/2”, Rear Mount, ”15”

9798020 169BL2 Plate, Round, 1 1/2”, Rear Mount, ”2”

9798122 169BL3 Plate, Round, 1 1/2”, Rear Mount, ”3”

9797932 169BL4 Plate, Round, 1 1/2”, Rear Mount, ”4”

9798328 169BL5 Plate, Round, 1 1/2”, Rear Mount, ”5”

9796034 169BL6 Plate, Round, 1 1/2”, Rear Mount, ”6”

9796137 169BL7 Plate, Round, 1 1/2”, Rear Mount, ”7”

9796230 169BL8 Plate, Round, 1 1/2”, Rear Mount, ”8”

9796332 169BL9 Plate, Round, 1 1/2”, Rear Mount, ”9”

9797038 169BL26 Plate, Round, 1 1/2”, Rear Mount, ”B”

9797439 169BL29 Plate, Round, 1 1/2”, Rear Mount, ”G”

9797130 169BL30 Plate, Round, 1 1/2”, Rear Mount, ”L”

9797531 169BL34 Plate, Round, 1 1/2”, Rear Mount, ”LL”

9797233 169BL31 Plate, Round, 1 1/2”, Rear Mount, ”M”

9797336 169BL32 Plate, Round, 1 1/2”, Rear Mount, ”P”

9797634 169BL39 Plate, Round, 1 1/2”, Rear Mount, ”UL”

9796149 169BL42 Plate, Round, 1 1/2”, Rear Mount, Alarm

9798330 169BL44 Plate, Round, 1 1/2”, Rear Mount, Door Close

9798134 169BL43 Plate, Round, 1 1/2”, Rear Mount, Door Open

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-4

Page 13

Owner’s Manual

Car Braille

Part No. Print No. Description

9796241 Plate, Round, 1 3/8”, #4 SS, ”1”

9797142 Plate, Round, 1 3/8”, #4 SS, ”10”

9797245 Plate, Round, 1 3/8”, #4 SS, ”11”

9797348 Plate, Round, 1 3/8”, #4 SS, ”12”

9797440 Plate, Round, 1 3/8”, #4 SS, ”13”

9797543 Plate, Round, 1 3/8”, #4 SS, ”14”

9797646 Plate, Round, 1 3/8”, #4 SS, ”15”

9769344 Plate, Round, 1 3/8”, #4 SS, ”2”

9769447 Plate, Round, 1 3/8”, #4 SS, ”3”

9796540 Plate, Round, 1 3/8”, #4 SS, ”4”

9796642 Plate, Round, 1 3/8”, #4 SS, ”5”

9796745 Plate, Round, 1 3/8”, #4 SS, ”6”

9796848 Plate, Round, 1 3/8”, #4 SS, ”7”

9796940 Plate, Round, 1 3/8”, #4 SS, ”8”

9797040 Plate, Round, 1 3/8”, #4 SS, ”9”

9797749 Plate, Round, 1 3/8”, #4 SS, ”B”

9797075 Plate, Round, 1 3/8”, #4 SS, ”G”

9797841 Plate, Round, 1 3/8”, #4 SS, ”L”

9796976 Plate, Round, 1 3/8”, #4 SS, ”LL”

9797944 Plate, Round, 1 3/8”, #4 SS, ”M”

9797178 Plate, Round, 1 3/8”, #4 SS, ”P”

9796873 Plate, Round, 1 3/8”, #4 SS, ”UL”

9798365 Plate, Round, 1 3/8”, #4 SS, Alarm

9796575 Plate, Round, 1 3/8”, #4 SS, Star 1

9796472 Plate, Round, 1 3/8”, #4 SS, Star 2

9796770 Plate, Round, 1 3/8”, #4 SS, Star G

9796678 Plate, Round, 1 3/8”, #4 SS, Star L

Car Braille

Part No. Print No. Description

9796071

9796174 Plate, Round, 1 3/8”, #4 SS, Door Close Symbol

9796277

9796370 Plate, Round, 1 3/8”, #4 SS, Door Open Symbol

Plate, Round, 1 3/8”, #4 SS, Door Close Rear

Symbol

Plate, Round, 1 3/8”, #4 SS, Door Open Rear

Symbol

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-5

Page 14

Owner’s Manual

Car Braille

Part No. Print No. Description

9716040 126496SP

Part No. Print No. Description

9796423 126047

9796526 126046

9796228 126041

9796320 126043

Plate, Square, Stick On, 1 1/4”, #4 Bronze, ”PH”

(Not Shown)

Car Braille

Plate,Square,StickOn,11/4”,#4SS,”*1”

Plate,Square,StickOn,11/4”,#4SS,”*2”

Plate,Square,StickOn,11/4”,#4SS,”*G”

Plate,Square,StickOn,11/4”,#4SS,”*L”

Car Braille

Part No. Print No. Description

9737078 124238

9737080 124239

9737091 124240

9737108 124241

9737110 124242

9737121 124249

9737017 33301

9737029 126049

9737133 124250

9737303 124248

9737285 124765

9737145 124762

9737030 124234

9737157 124247

9716051 126496

9737054 126050

9737005 124237

9737042 124236

Plate,Square,StickOn,11/4”,#4SS,”1”

Plate,Square,StickOn,11/4”,#4SS,”2”

Plate,Square,StickOn,11/4”,#4SS,”3”

Plate,Square,StickOn,11/4”,#4SS,”4”

Plate,Square,StickOn,11/4”,#4SS,”5”

Plate,Square,StickOn,11/4”,#4SS,”B”

Plate,Square,StickOn,11/4”,#4SS,”CALL”

Plate,Square,StickOn,11/4”,#4SS,”DN”

Plate,Square,StickOn,11/4”,#4SS,”G”

Plate,Square,StickOn,11/4”,#4SS,”L”

Plate,Square,StickOn,11/4”,#4SS,”LL”

Plate,Square,StickOn,11/4”,#4SS,”M”

Plate,Square,StickOn,11/4”,#4SS,”OPEN”

Plate,Square,StickOn,11/4”,#4SS,”P”

Plate,Square,StickOn,11/4”,#4SS,”PH”

Plate,Square,StickOn,11/4”,#4SS,”UP”

Plate,Square,StickOn,11/4”,#4SS,AlarmBell

Plate,Square,StickOn,11/4”,#4SS,EmergencyStop

Symbol

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-6

Page 15

Owner’s Manual

Car Braille

Part No. Print No. Description

9796927 124744 Plate, Square, Stick On, 1 1/4”, #4 SS, ”10”

9797026 124745 Plate, Square, Stick On, 1 1/4”, #4 SS, ”11”

9797129 124746 Plate, Square, Stick On, 1 1/4”, #4 SS, ”12”

9797221 124747 Plate, Square, Stick On, 1 1/4”, #4 SS, ”13”

9797324 124748 Plate, Square, Stick On, 1 1/4”, #4 SS, ”14”

9797427 124749 Plate, Square, Stick On, 1 1/4”, #4 SS, ”15”

9796629 124243 Plate, Square, Stick On, 1 1/4”, #4 SS, ”6”

9796721 124244 Plate, Square, Stick On, 1 1/4”, #4 SS, ”7”

9796824 124245 Plate, Square, Stick On, 1 1/4”, #4 SS, ”8”

9798043 124246 Plate, Square, Stick On, 1 1/4”, #4 SS, ”9”

9797520 124766 Plate, Square, Stick On, 1 1/4”, #4 SS, ”UL”

9737431 124743

Part No. Print No. Description

9797828

9797725

9797622

Plate, Square, Stick On, 1 1/4”, #4 SS, Door Close

Symbol

Car Braille

Plate, Square, Stick On, 1 1/4”, #4 SS, Door Close

Rear Symbol

Plate, Square, Stick On, 1 1/4”, #4 SS, Door Close

Symbol

Plate, Square, Stick On, 1 1/4”, #4 SS, Door Open

Rear Symbol

Emergency Light

Part No. Print No. Description

9880148 118412

9818420 118412 Card, Emergency Light And Alarm, Sub-Assy

Card, Emergency Light And Alarm, Repair,

Sub-Assy

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-7

Page 16

Owner’s Manual

Emergency Light

Part No. Print No. Description

9880719 108519 Emergency Light And Alarm Battery, 6 V

Emergency Light

Part No. Print No. Description

9787379 118414

Part No. Print No. Description

9796710 169BK19 Plate, 4” x 4”, B&W, ”* 1”

9796812 Plate, 4” x 4”, B&W, ”* 2”

9796915 Plate, 4” x 4”, B&W, ”* 3”

9796514 169BK54 Plate, 4” x 4”, B&W, ”*G”

9796617 169BK55 Plate, 4” x 4”, B&W, ”*L”

Lens, Emergency Light And Alarm Assy 5.44” x

1.50”

Hall Braille

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-8

Page 17

Owner’s Manual

Hall Braille

Part No. Print No. Description

9797014 169BK1 Plate, 4” x 4”, B&W, ”1”

9797117 169BK2 Plate, 4” x 4”, B&W, ”2”

9797210 169BK3 Plate, 4” x 4”, B&W, ”3”

9797312 169BK4 Plate, 4” x 4”, B&W, ”4”

9797415 169BK5 Plate, 4” x 4”, B&W, ”5”

9797518 169BK6 Plate, 4” x 4”, B&W, ”6”

9797610 169BK7 Plate, 4” x 4”, B&W, ”7”

9797713 169BK8 Plate, 4” x 4”, B&W, ”8”

9797816 169BK9 Plate, 4” x 4”, B&W, ”9”

9798316 169BK20 Plate, 4” x 4”, B&W, ”B”

9797919 169BK21 Plate, 4” x 4”, B&W, ”G”

9798018 169BK22 Plate, 4” x 4”, B&W, ”L”

9798110 169BK30 Plate, 4” x 4”, B&W, ”LL”

9796022 169BK23 Plate, 4” x 4”, B&W, ”M”

9796125 169BK24 Plate, 4” x 4”, B&W, ”P”

9798213 169BK65 Plate, 4” x 4”, B&W, ”UL”

Hall Braille

Part No. Print No. Description

9894196 169AX29 Plate, Black Plastic, ”0” (Zero) SUFFIX

9894469 169AX30 Plate, Black Plastic, ”1” SUFFIX

9894470 169AX31 Plate, Black Plastic, ”2” SUFFIX

9894482 169AX32 Plate, Black Plastic, ”3” SUFFIX

9894494 169AX33 Plate, Black Plastic, ”4” SUFFIX

9894500 169AX34 Plate, Black Plastic, ”5” SUFFIX

9894512 169AX35 Plate, Black Plastic, ”6” SUFFIX

9894524 169AX36 Plate, Black Plastic, ”7” SUFFIX

9894536 169AX37 Plate, Black Plastic, ”8” SUFFIX

9894548 169AX38 Plate, Black Plastic, ”9” SUFFIX

Hall Braille

Part No. Print No. Description

9761020 169AX20 Plate, Black Plastic, ”1” PREFIX

9761019 169AX21 Plate, Black Plastic, ”2” PREFIX

9761007 169AX22 Plate, Black Plastic, ”3” PREFIX

9760994 169AX23 Plate, Black Plastic, ”4” PREFIX

9760982 169AX24 Plate, Black Plastic, ”5” PREFIX

9760970 169AX25 Plate, Black Plastic, ”6” PREFIX

9760969 169AX26 Plate, Black Plastic, ”7” PREFIX

9894172 169AX27 Plate, Black Plastic, ”8” PREFIX

9894184 169AX28 Plate, Black Plastic, ”9” PREFIX

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-9

Page 18

Owner’s Manual

Hall Braille

Part No. Print No. Description

9894100 169AX1 Plate, Black Plastic, ”A”

9761070 169AX2 Plate, Black Plastic, ”B”

9894457 169AX3 Plate, Black Plastic, ”C”

9894550 169AX4 Plate, Black Plastic, ”D”

9894561 169AX5 Plate, Black Plastic, ”E”

9894573 169AX6 Plate, Black Plastic, ”F”

9761068 169AX7 Plate, Black Plastic, ”G”

9894585 169AX9 Plate, Black Plastic, ”L”

9761056 169AX9 Plate, Black Plastic, ”L”

9761044 169AX10 Plate, Black Plastic, ”M”

9894111 169AX11 Plate, Black Plastic, ”N”

9894597 169AX12 Plate, Black Plastic, ”O” ALPHA

9761032 169AX13 Plate, Black Plastic, ”P”

9894123 169AX14 Plate, Black Plastic, ”R”

9894135 169AX15 Plate, Black Plastic, ”S”

9894147 169AX16 Plate, Black Plastic, ”T”

9894159 169AX17 Plate, Black Plastic, ”U”

9894160 169AX18 Plate, Black Plastic, ”W”

9760957 169AX39 Plate, Black Plastic, STAR Symbol

Hall Braille

Part No. Print No. Description

9796502 139002 Plate, Square, 4” x 4”, #4 SS, ”1”

9796605 139003 Plate, Square, 4” x 4”, #4 SS, ”2”

9796708 139004 Plate, Square, 4” x 4”, #4 SS, ”3”

9796800 139005 Plate, Square, 4” x 4”, #4 SS, ”4”

9796903 139006 Plate, Square, 4” x 4”, #4 SS, ”5”

9797002 139007 Plate, Square, 4” x 4”, #4 SS, ”6”

9797105 139008 Plate, Square, 4” x 4”, #4 SS, ”7”

9797208 139009 Plate, Square, 4” x 4”, #4 SS, ”8”

9797300 139010 Plate, Square, 4” x 4”, #4 SS, ”9”

9797804 139013 Plate, Square, 4” x 4”, #4 SS, ”B”

9797403 139014 Plate, Square, 4” x 4”, #4 SS, ”G”

9797506 139012 Plate, Square, 4” x 4”, #4 SS, ”L”

9797609 139602 Plate, Square, 4” x 4”, #4 SS, ”LL”

9797907 139598 Plate, Square, 4” x 4”, #4 SS, ”M”

9798006 139011 Plate, Square, 4” x 4”, #4 SS, ”P”

9797701 139603 Plate, Square, 4” x 4”, #4 SS, ”UL”

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-10

Page 19

Owner’s Manual

Hall Braille

Part No. Print No. Description

9796204 Plate,Square,StickOn,4”x4”,#4SS,”*1”

9796307 Plate,Square,StickOn,4”x4”,#4SS,”*2”

9796400 Plate,Square,StickOn,4”x4”,#4SS,”*3”

Hall Braille

Part No. Print No. Description

9737169 124252 Plate,Square,StickOn,4”x4”,#4SS,”1”

9737182 124253 Plate,Square,StickOn,4”x4”,#4SS,”2”

9737200 124254 Plate,Square,StickOn,4”x4”,#4SS,”3”

9737212 124255 Plate,Square,StickOn,4”x4”,#4SS,”4”

9737224 124256 Plate,Square,StickOn,4”x4”,#4SS,”5”

9737236 124263 Plate,Square,StickOn,4”x4”,#4SS,”B”

9737248 124264 Plate,Square,StickOn,4”x4”,#4SS,”G”

9737297 124262 Plate,Square,StickOn,4”x4”,#4SS,”L”

9737273 124739 Plate,Square,StickOn,4”x4”,#4SS,”LL”

9737250 124735 Plate,Square,StickOn,4”x4”,#4SS,”M”

9737261 124261 Plate,Square,StickOn,4”x4”,#4SS,”P”

Hall Braille

Part No. Print No. Description

9796009 Plate, Square, Stick-On, 4” x 4”, #4 SS, ”* G”

9796101 Plate, Square, Stick-On, 4” x 4”, #4 SS, ”* L”

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-11

Page 20

Owner’s Manual

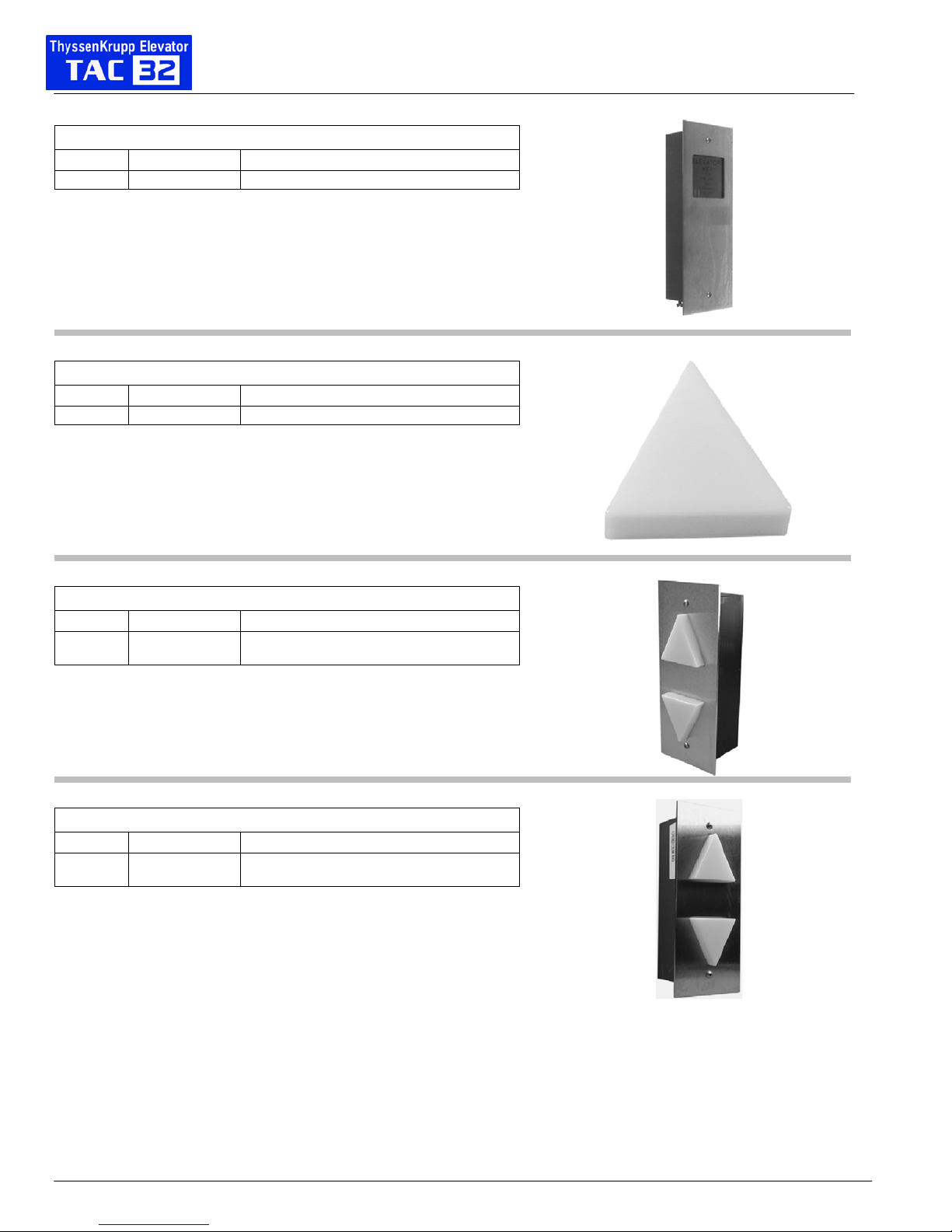

Hall Station

Part No. Print No. Description

9856456 35645 Station, Hall Emergency Key

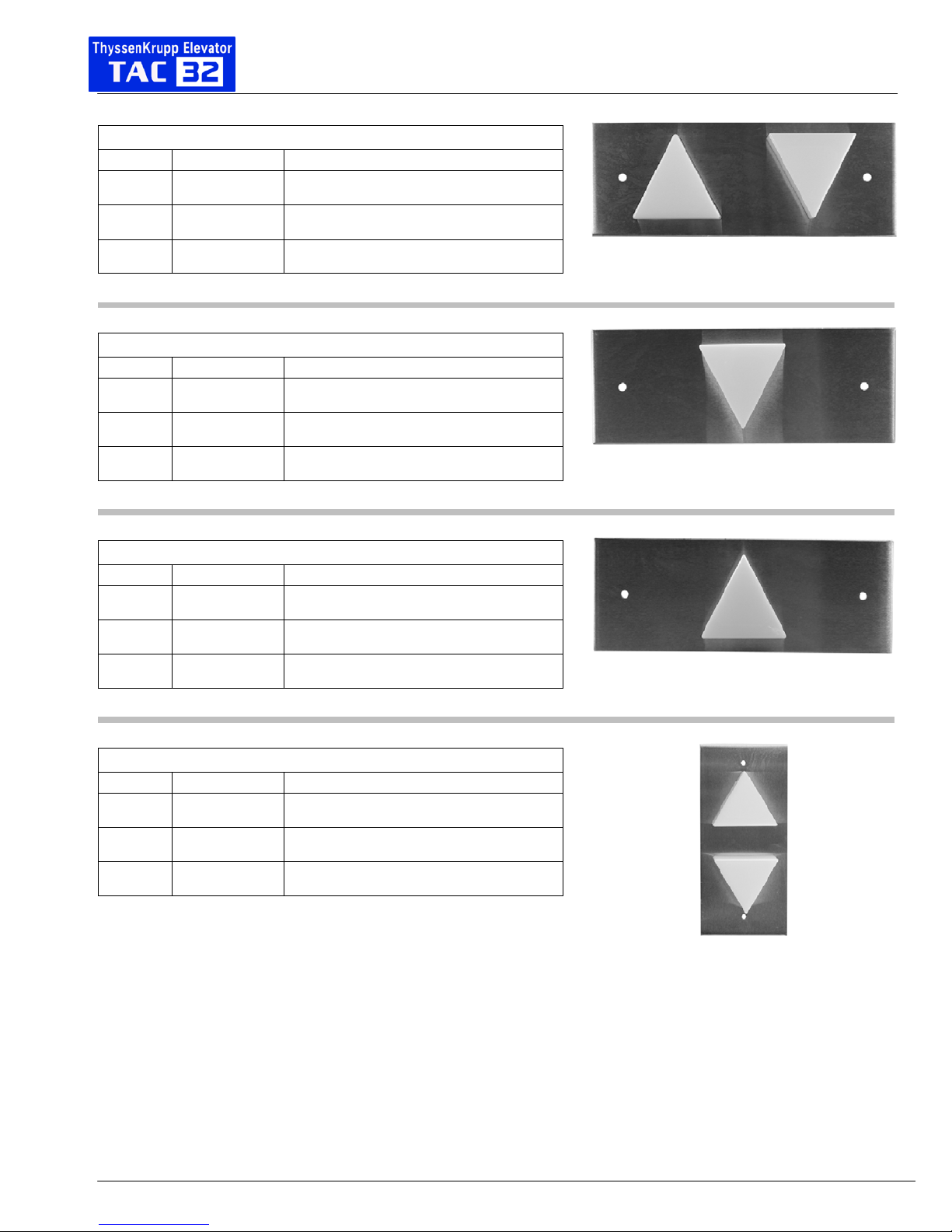

Traditional Lantern

Part No. Print No. Description

9722129 124081 Insert, Lantern

Traditional Lantern

Part No. Print No. Description

9753655 150080

Lantern, Car Riding, 24 V, Entrance Column

Mounting, 4” x 10”

Traditional Lantern

Part No. Print No. Description

9753667 150078

Lantern, Car Riding, 48 V, Entrance Column,

Mounting, 4” x 10”

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-12

Page 21

Owner’s Manual

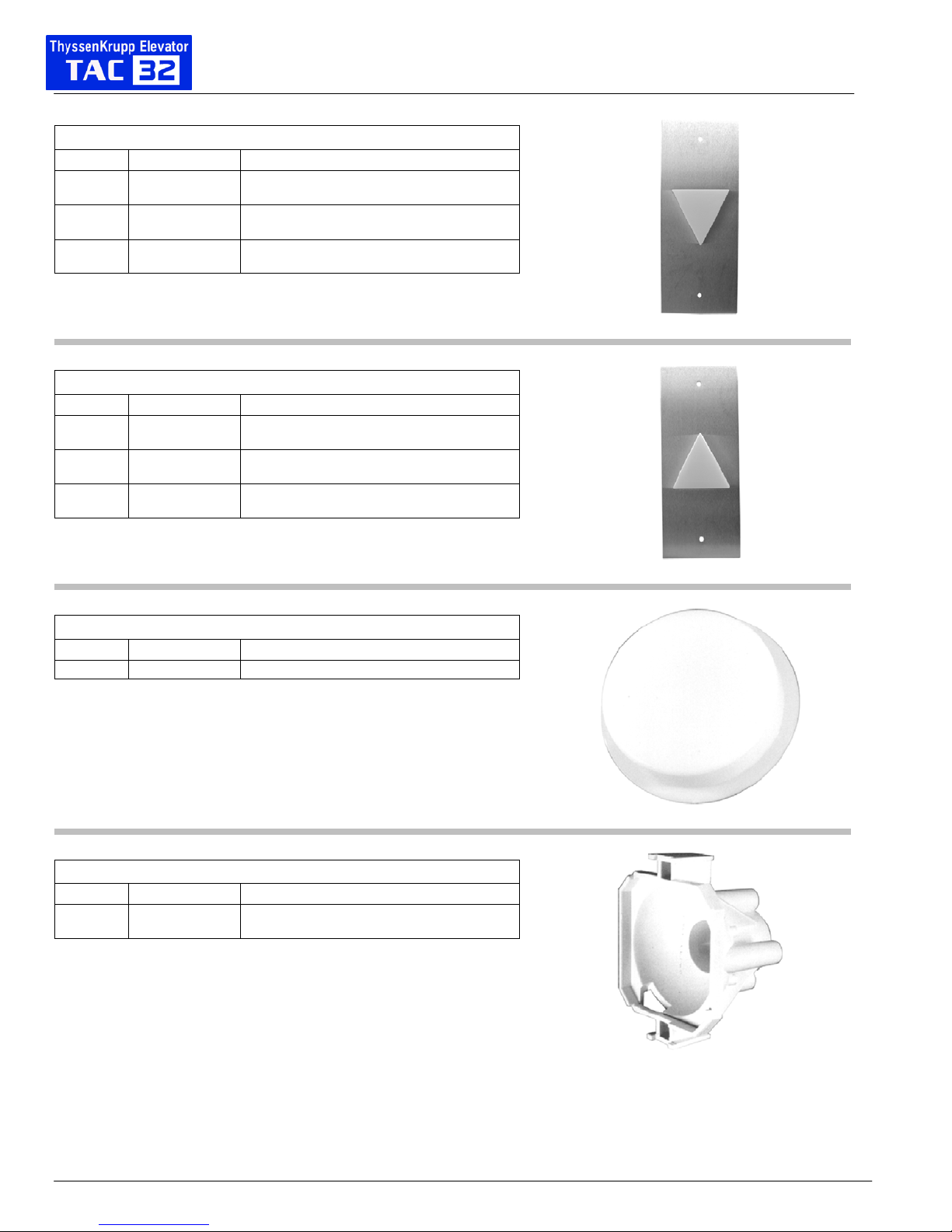

Traditional Lantern

Part No. Print No. Description

9797452 FEG12LTR4SHIB

9797350 FED24LTR4S1HB

9797257 FEF48LTR4S1HB

Part No. Print No. Description

9797154 FEG12LTR4SDHB

9797051 FED24LTR4SDHB

9796952 FEF48LTR4SDHB

Hall Lantern Assy W/ Box, Horizontal, Intermediate,

#4 SS, 110 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Horizontal, Intermediate,

#4 SS, 24 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Horizontal, Intermediate,

#4 SS, 48 V, 3 1/2” x 9”

Traditional Lantern

Hall Lantern Assy W/ Box, Horizontal, Terminal

Down, #4 SS, 110 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Horizontal, Terminal

Down, #4 SS, 24 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Horizontal, Terminal

Down, #4 SS, 48 V, 3 1/2” x 9”

Traditional Lantern

Part No. Print No. Description

9796850 FEG12LTR4SUHB

9796757 FED24LTR4SHUB

9796654 FEF48LTR4SUHB

Hall Lantern Assy W/ Box, Horizontal, Terminal Up,

#4 SS, 110 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Horizontal, Terminal Up,

#4 SS, 24 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Horizontal, Terminal Up,

#4 SS, 48 V, 3 1/2” x 9”

Traditional Lantern

Part No. Print No. Description

9796551 FEG12LTR4SIVB

9796459 FED24LTR4SIVB

9796356 FEF48LTR4SIVB

Hall Lantern Assy W/ Box, Vertical, Intermediate, #4

SS, 110 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Vertical, Intermediate, #4

SS, 24 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Vertical, Intermediate, #4

SS, 48 V, 3 1/2” x 9”

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-13

Page 22

Owner’s Manual

Traditional Lantern

Part No. Print No. Description

9796253 FEG12LTR4SDVB

9796150 FED24LTR4SDVB

9796058 FEF48LTR4SDVB

Part No. Print No. Description

9798341 FEG12LTR4SUVB

9798249 FED24LTR4SUVB

9798146 FEF48LTR4SUVB

Hall Lantern Assy W/ Box, Vertical, Terminal Down,

#4 SS, 110 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Vertical, Terminal Down,

#4 SS, 24 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Vertical, Terminal Down,

#4 SS, 48 V, 3 1/2” x 9”

Traditional Lantern

Hall Lantern Assy W/ Box, Vertical, Terminal Up, #4

SS, 110 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Vertical, Terminal Up, #4

SS, 24 V, 3 1/2” x 9”

Hall Lantern Assy W/ Box, Vertical, Terminal Up, #4

SS, 48 V, 3 1/2” x 9”

Traditional Lantern

Part No. Print No. Description

9730205 130204 Lens, Round, Hall

Traditional Lantern

Part No. Print No. Description

9872097 107208

Reflector, Combination Hall Lantern and Position

Indicator

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-14

Page 23

Owner’s Manual

Phone

Part No. Print No. Description

9738800 3019 Box, Phone, SRH/LH #4 SS (phone not included)

Push Button

Part No. Print No. Description

9840230 160644 Cap, Push Button, Clear, A D A

Push Button

Part No. Print No. Description

9806349 106349 Halo, Push Button, Black

Push Button

Part No. Print No. Description

9828230 42820 Halo, Push Button, White

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-15

Page 24

Part No.

9883710 106734

9890683 160645

9890014 160645

9890210 160645

9890233 160645

9890257 160645

9890270 160645

9890294 160645

9890312 160645

9890051 160645

9890075 160645

9890099 160645

9890117 160645

9890130 160645

9890154 160645

9890178 160645

9890191 160645

9883101 106734

9883113 106734

9883125 106734

9883137 106734

9883149 106734

9883150 106734

9883034 106734

9883046 106734

9883058 106734

9883060 106734

9883071 106734

9883083 106734

9883095 106734

9883381 106734

9883356 106734

9883447 106734

9883423 106734

9883344 106734

9883368 106734

9883393 106734

9883332 106734

9883400 106734

9883186 106734

9883174 106734

9883721 106734

9883162 106734

9883435 106734

Print

No.

Owner’s Manual

Push Button

Description

Jewel, White, Vertical, ”Fire Service”

PushButton,White,ADA,Horiz,”LOBBY”

PushButton,White,ADA,Vertical,”1”

PushButton,White,ADA,Vertical,”10”

PushButton,White,ADA,Vertical,”11”

PushButton,White,ADA,Vertical,”12”

PushButton,White,ADA,Vertical,”13”

PushButton,White,ADA,Vertical,”14”

PushButton,White,ADA,Vertical,”15”

PushButton,White,ADA,Vertical,”2”

PushButton,White,ADA,Vertical,”3”

PushButton,White,ADA,Vertical,”4”

PushButton,White,ADA,Vertical,”5”

PushButton,White,ADA,Vertical,”6”

PushButton,White,ADA,Vertical,”7”

PushButton,White,ADA,Vertical,”8”

PushButton,White,ADA,Vertical,”9”

Push Button, White, Ver tical, ”10”, replace W/ 9890210

Push Button, White, Ver tical, ”11”, replace W/ 9890233

Push Button, White, Ver tical, ”12”, replace W/ 9890257

Push Button, White, Ver tical, ”13”, replace W/ 9890270

Push Button, White, Ver tical, ”14”, replace W/ 9890294

Push Button, White, Ver tical, ”15”, replace W/ 9890312

Push Button, White, Vertical, ”3”, replace W/ 9890075

Push Button, White, Vertical, ”4”, replace W/ 9890099

Push Button, White, Vertical, ”5”, replace W/ 9890117

Push Button, White, Vertical, ”6”, replace W/ 9890130

Push Button, White, Vertical, ”7”, replace W/ 9890154

Push Button, White, Vertical, ”8”, replace W/ 9890178

Push Button, White, Vertical, ”9”, replace W/ 9890191

Push Button, White, Ver tical, ”Alarm”, replace W/ 9890440

Push Button, White, Vertical, ”B”, replace W/ 9890373

Push Button, White, Ver tical, ”CALL”, replace W/ 9890580

Push Button, White, Vertical, ”D”, replace W/ 9890520

Push Button, White, Vertical, ”Door Close”, replace W/ 9890350

Push Button, White, Vertical, ”Door Open”, replace W/ 9890397

Push Button, White, Vertical, ”G”, replace W/ 9890464

Push Button, White, Ver tical, ”L”, replace W/ 9890336

Push Button, White, Vertical, ”LL”, replace W/ 9890488

PushButton,White,Vertical,”P”

PushButton,White,Vertical,”R”

PushButton,White,Vertical,”Return”

PushButton,White,Vertical,”SB”

Push Button, White, Vertical, ”UL”, replace W/ 9890567

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-16

Page 25

Owner’s Manual

Push Button

Part No. Print No. Description

9890002 160645 PushButton,White,ADA,Horizontal,”1”

9890208 160645 PushButton,White,ADA,Horizontal,”10”

9890221 160645 PushButton,White,ADA,Horizontal,”11”

9890245 160645 PushButton,White,ADA,Horizontal,”12”

9890269 160645 PushButton,White,ADA,Horizontal,”13”

9890282 160645 PushButton,White,ADA,Horizontal,”14”

9890300 160645 PushButton,White,ADA,Horizontal,”15”

9890026 160645 PushButton,White,ADA,Horizontal,”2”

9890063 160645 PushButton,White,ADA,Horizontal,”3”

9890087 160645 PushButton,White,ADA,Horizontal,”4”

9890105 160645 PushButton,White,ADA,Horizontal,”5”

9890129 160645 PushButton,White,ADA,Horizontal,”6”

9890142 160645 PushButton,White,ADA,Horizontal,”7”

9890166 160645 PushButton,White,ADA,Horizontal,”8”

9890180 160645 PushButton,White,ADA,Horizontal,”9”

9890440 160645 PushButton,White,ADA,Horizontal,”Alarm”

9890373 160645 PushButton,White,ADA,Horizontal,”B”

9890580 160645 Push Button, White, ADA, Horizontal, ”Call”

9890520 160645 PushButton,White,ADA,Horizontal,”D”

9890350 160645 Push Button, White, ADA, Horizontal, ”Door Close”

9890397 160645 Push Button, White, ADA, Horizontal, ”Door Open”

9890464 160645 PushButton,White,ADA,Horizontal,”G”

9890336 160645 PushButton,White,ADA,Horizontal,”L”

9890488 160645 PushButton,White,ADA,Horizontal,”LL”

9890725 160645 PushButton,White,ADA,Horizontal,”LOBBY”

9890506 160645 PushButton,White,ADA,Horizontal,”M”

9890701 160645 PushButton,White,ADA,Horizontal,”RETURN”

9890427 160645 PushButton,White,ADA,Horizontal,”Send”

9890567 160645 PushButton,White,ADA,Horizontal,”UL”

9840229 160645 PushButton,White,ADA,Horizontal,Blank

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-17

Page 26

Owner’s Manual

Push Button

Part No. Print No. Description

9890439 160645 PushButton,White,ADA,Horizontal,”Alarm”

9890361 160645 PushButton,White,ADA,Horizontal,”B”

9890579 160645 Push Button, White, ADA, Horizontal, ”Call”

9890518 160645 PushButton,White,ADA,Horizontal,”D”

9893428 106734 PushButton,White,ADA,Horizontal,”D”

9890348 160645 Push Button, White, ADA, Horizontal, ”Door Close”

9890385 160645 Push Button, White, ADA, Horizontal, ”Door Open”

9894421 160645

9890452 160645 PushButton,White,ADA,Horizontal,”G”

9890324 160645 PushButton,White,ADA,Horizontal,”L”

9890476 160645 PushButton,White,ADA,Horizontal,”LL”

9890490 160645 PushButton,White,ADA,Horizontal,”M”

9890403 160645 PushButton,White,ADA,Horizontal,”Send”

9890555 160645 PushButton,White,ADA,Horizontal,”UL”

9840229 160645 PushButton,White,ADA,Horizontal,Blank

9893106 106734

9893118 106734

9893120 106734

9893143 106734

9893155 106734

9893090 106734

9893374 106734

9893430 106734

PushButton,White,ADA,Horizontal,”Fire

Service”, Jewel Button

Push Button, White, Horizontal, ”10”, replace W/

9890208

Push Button, White, Horizontal, ”11”, replace W/

9890221

Push Button, White, Horizontal, ”12”, replace W/

9890245

Push Button, White, Horizontal, ”14”, replace W/

9890282

Push Button, White, Horizontal, ”15”, replace W/

9890300

Push Button, White, Horizontal, ”9”, replace W/

9890180

Push Button, White, Horizontal, ”Send”, replace W/

9890403

Push Button, White, Horizontal, ”UL”, replace W/

9890555

Push Button

Part No. Print No. Description

9890658 160645 PushButton,White,ADA,Horizontal,DownArrow

9890592 160645 PushButton,White,ADA,Horizontal,UpArrow

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-18

Page 27

Owner’s Manual

Push Button

Part No. Print No. Description

9890671 160645 PushButton,White,ADA,Vertical,DownArrow

9890609 160645 PushButton,White,ADA,Vertical,UpArrow

Push Button

Part No. Print No. Description

9818431 171AP1

Part No. Print No. Description

9890531 140158 Inspection Station, Car Top

Switch, V7 Push Button, SPDT, 250 VAC, 10 A and

125 VDC, .5 A

Station Inspection

Switch Push / Pull

Part No. Print No. Description

9810857 108150 Switch Assy, Stop Horizontal, ”Push Stop, Pull Run”

9810845 108155

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Switch Assy, Stop Vertical, ”PUSH STOP, PULL

RUN”

Traditional Signal Fixtures-19

Page 28

Owner’s Manual

Switch Rotary

Part No. Print No. Description

9703019 32704

9703032 32706

Part No. Print No. Description

9737613 102761

Switch, Rotary Kit, Contains 3 Position Switch,

Bracket And Screws

Switch, Rotary Kit, Contains 4 Position Switch,

Bracket And Screws

Switch Rotary

Switch, Rotary, 3 Position, OFF-ON-ON, 0-45-90

deg, Hall Fire Service

Switch Rotary

Part No. Print No. Description

9777970 77797

Switch, Rotary, 4 Position, Off (12), On (3, 6, 9

O’Clock)

Switch Toggle

Part No. Print No. Description

9743637 76703 Switch, Light, Snap-in

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-20

Page 29

Owner’s Manual

Switch Toggle

Part No. Print No. Description

9758495 141208 Switch, Toggle, 3P, On-Off-On, 125 VAC, 15 A

Switch Toggle

Part No. Print No. Description

9826105 32610

9826671 32667

Toggle Switch Kit, Spring Return, Contains Cam,

Bracket,Switch and Screws

Toggle Switch Kit, W/ Bracket & Mounting Material

&Cam

Switch Toggle

Part No. Print No. Description

9826221 32622 Toggle Switch Kit, W/ Bracket & Mounting Material

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-21

Page 30

Owner’s Manual

Traditional Faceplate

Part No. Print No. Description

9830200 130104

9832609 32600 Faceplate, Intermediate, #4 SS, 3.50” X 9.00”

9830250 32600SP Faceplate, Intermediate, #8 SS, 3.50” X 9.00”

9830212 130103

9832610 32601 Faceplate, Terminal, #4 SS, 3.50” X 9.0”

9830248 32601SP Faceplate, Terminal, #8 SS, 3.50” X 9.0”

Part No. Print No. Description

9826919 32691 Faceplate, Terminal, #4 SS, Midwest, Hall Station

Faceplate, Intermediate, #4 Bronze, 3.50” X 9.00”,

1.25” Dia. Button Cutouts

Faceplate, Terminal, #4 Bronze, 3.50” X 9.00”,

1.25” Dia. Button Cutouts

Traditional Faceplate

Traditional Hall Station

Part No. Print No. Description

9954181 C718M4 Hall Fire Service

Traditional Hall Station

Part No. Print No. Description

9828369 130148

Hall Fire Service, Includes 1 Device Hall Station W/

9832610 Faceplate And 35053 Box

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-22

Page 31

Owner’s Manual

Traditional Hall Station

Part No. Print No. Description

9810020 110029

9810031 110031

Traditional Hall Station

Part No. Print No. Description

9856470 35647

Hall Station, Intermediate, W/ Illuminated Buttons,

#4 SS, 48 V, 3.5” x 9.0”

Hall Station, Terminal, W/ Illuminated Buttons, #4

SS, 48 V, 3.5” x 9.0”

Window, for Emergency Key Box 9856456, printed

”Elevator Key For Fire Department and Emergency

Use Only”

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-23

Page 32

Owner’s Manual

Traditional Key Core

Part No. Print No. Description

9821934 142193

9819629 130229 Core,Key,Black,LOBBY(12),ON(3),PARK(6)

9775626 117562

9775614 117561

9822987 108188 Core,Key,RotaryKeySwitch,Black,Blank

9823062 32743

9823025 32751 Core,Key,RotarySwitch,Black,FAN(12),OFF(9)

9823074 32744

9823037 32750 Core, Key, Rotary Switch, Black, LIGHT (12), OFF (9)

9823049 32741 Core,Key,RotarySwitch,Black,MG(12),OFF(3)

9822999 32758

9823013 32753 Core,Key,RotarySwitch,Black,ON(3)

9823001 32754

9823050 32742

9753412 35341

9832660 32665 Core, Key, Toggle Switch, Black, OFF (12), ON (3)

9822975 32665 Core,Key,ToggleSwitch,Black,ON(3)

Core,Key,3PositionCarFireServiceHorizontal,

HOLD (12) ON (3) FIRE (6) OFF (9)

Core, Key, Car Fire Service, Red, Off (12), ON (3),

Fire (6)

Core, Key, Hall Fire Service, Red, OFF-ON (12) to

(1), Fire (6), Bypass (9)

Core, Key, Rotary Switch, Black, EMERGENCY (12),

ON (3), POWER (6)

Core, Key, Rotary Switch, Black, LIGHT (12), FAN

(3), OFF (9)

Core, Key, Rotary Switch, Black, OFF (12) HI (3),

FAN (6), LOW (9), (2 Speed Fan)

Core,Key,RotarySwitch,Black,ON(3),SERVICE

(6), (Used For Out Of Service)

Core, Key, Rotar y Switch, Black, Photo-Eye (12),

OFF (9)

Core, Key, Toggle Key Switch, Black (Replaces

9822987)

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-24

Page 33

Part No.

9720029 138520

9720017 138521

9715952 138530

9715976 138526

9772613 138532

9772674 138537

9772595 138527

9772418 138514

9772558 138522

9719763 138519

9772583 138525

9772455 138533

9720637 138534

9772649 138535

9772650 138536

9772716 138538

9772431 138528

9772443 138529

9772728 138539

9772546 138518

9772522 138517

9772935 138511

9772492 138510

9772480 138512

9772560 138524

9772601 138531

9719775 138515

9772420 138516

9772467 138540

9772753 138543

9772479 138541

9772741 138542

Print

No.

Owner’s Manual

Traditional Key Switch

Description

Switch Assy, Key, V7, Horizontal, 1848, Car Call Register

Switch Assy, Key, V7, Horizontal, Hall Call, Terminal Register

Switch, Key, Micro Switch, 1846, ” In Car Stop”

Switch, Key, V7, H2389 Key, 3 Pos, ”Hall Fire Service,”

Horizontal ”Fire” ”Bypass” ”Off” ”On”

Switch, Key, V7, Horizontal, H1846, Hoistway Access for DMC-I,

TII

Switch, Key, V7, Horizontal, H1846, Hoistway Access for TIII

Switch, Key, V7, Horizontal, H1846, Hoistway Access for WCR

Switch, Key, V7, Horizontal, H1846, Inspection

Switch, Key, V7, Horizontal, H1848, Hall Call Registration,

Intermediate

Switch, Key, V7, Horizontal, H1848, Micro Switch, ”Car Call

Lockout”

Switch, Key, V7, Horizontal, H2389, Emergency Power

Switch, Key, V7, Horizontal, H2389, Impulse, California Car Fire

Service, ”Off”, ”On”, ”Fire””

Switch, Key, V7, Horizontal, H2389, Impulse, California Hall Fire

Service, ”Off”, ”On”, ”Fire”, ”Bypass”

Switch, Key, V7, Horizontal, H2389, Impulse, Chicago Car Fire

Service, ”Off”, ”On”, ”Fire”

Switch, Key, V7, Horizontal, H2389, Impulse, Chicago Hall Fire

Service, ”Fire”, ”On”, ”Service”

Switch, Key, V7, Horizontal, H2389, Impulse, Hall Fire Service,

”Off”, ”On”, ”Fire”

Switch, Key, V7, Horizontal, H2395, 2-speed Fan

Switch, Key, V7, Horizontal, H2395, Attendant Servic e

Switch, Key, V7, Horizontal, H2395, Code Blue

Switch, Key, V7, Horizontal, H2395, Door Hold Open

Switch, Key, V7, Horizontal, H2395, Emergency Service

Switch, Key, V7, Horizontal, H2395, Fan/Light

Switch, Key, V7, Horizontal, H2395, Light

Switch, Key, V7, Horizontal, H2395, Light/2-speed Fan

Switch, Key, V7, Horizontal, H2395, Lobby Park

Switch, Key, V7, Horizontal, H2395, Lobby Return

Switch, Key, V7, Horizontal, H2395, Micro Switch, ”Independent

Service”

Switch, Key, V7, Horizontal, H2395, Photo-Eye

Switch, Key, V7, Horizontal, H2395, Photo-Eye (front)

Switch, Key, V7, Horizontal, H2395, Photo-Eye (lower)

Switch, Key, V7, Horizontal, H2395, Photo-Eye (rear)

Switch, Key, V7, Horizontal, H2395, Photo-Eye (upper)

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-25

Page 34

Owner’s Manual

Traditional Key Switch

Part No. Print No. Description

9715990 138513

Traditional Push Button

Part No. Print No. Description

9822800 108301 Push Button Assembly, Marked ”1”

9822914 108310 Push Button Assembly, Marked ”10”

9822811 108302 Push Button Assembly, Marked ”2”

9822823 108303 Push Button Assembly, Marked ”3”

9822835 108304 Push Button Assembly, Marked ”4”

9822847 108305 Push Button Assembly, Marked ”5”

9822859 108306 Push Button Assembly, Marked ”6”

9822872 108307 Push Button Assembly, Marked ”7”

9822884 108308 Push Button Assembly, Marked ”8”

9822902 108309 Push Button Assembly, Marked ”9”

9822938 108335 Push Button Assembly, Marked ”B”

9822963 108339 Push Button Assembly, Marked ”G”

9822940 108333 Push Button Assembly, Marked ”L”

Switch, Key, V7, H2389 Key, Micro Switch, 3 Pos,

”Car Fire Service,” Vertical, ”Off” ”Hold” ”On”

”Fire”

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-26

Page 35

Owner’s Manual

Traditional Key Switch Selection Chart

PART NO

PRINT NO

9772443

138529

9772728

138539

9772546

138518

9772583

138525

9772522

138517

9772431

138528

DESCRIPTION BEZEL KEY KEY PLUG SPG

Attendant Service, H 138492

Code Blue, H 138508

Door Hold, H 138502

Emergency Power, H 138493

Emergency Service, H 138490

Fan, 2 spd, H 138507

9703135

H2395

9703135

H2395

9703135

H2395

9703196

H2389

9703135

H2395

9703135

H2395

9719519

660AC2

9719519

660AC2

9719519

660AC2

660AC1 N 2 90

9719519

660AC2

9719519

660AC2

KEY

POS

N 2 90

Y 2 45

N 2 45

N 2 90

N 3 180

DEG

ROT

9715990

138513

9772455

138533

9772649

138535

9715976

138526

9720637

138534

9772650

138536

9772716

138538

Fire Service, Car, ANSI,

Red, H

Fire Service, Car,

California, Red, H

Fire Service, Car,

Chicago, Red, H,

Fire Service, Hall, ANSI,

Red, H

Fire Service, Hall,

California, Red, H

Fire Service, Hall,

Chicago, Red, H

Fire Service, Hall, 2

position,Red,H

138487

138504

138504

138486

138486

138509

138504

9703196

H2389

9703196

H2389

9703196

H2389

9703196

H2389

9703196

H2389

9703196

H2389

9703196

H2389

660AC1 N 3 180

660AC1 N 2 45

660AC1 N 2 45

660AC1 N 3 135

660AC1 N 3 135

660AC1 N 2 45

660AC1 N 2 90

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-27

Page 36

Owner’s Manual

Traditional Key Switch Selection Chart (cont.)

PART NO

PRINT NO

9772613

138532

9772674

138537

9772595

138527

9772418

138514

9719775

138515

9772492

138510

DESCRIPTION BEZEL KEY KEY PLUG SPG

Hoistway Access, DMC,

T2, H

Hoistway Access, T3,

T4, H

Hoistway Access, WCR,

H

Hoistway Enable,

(Inspection), H

Independent Service, H 138489

Light, H 138496

138491

138491

138491

160504

9731064

H1846

9731064

H1846

9731064

H1846

9731064

H1846

9703135

H2395

9703135

H2395

9845641

660AD1

9845641

660AD1

9845641

660AD1

9845641

660AD1

9719519

660AC2

9719519

660AC2

KEY

POS

Y 3 90

Y 3 90

Y 3 90

N 2 90

N 2 90

N 2 90

DEG

ROT

9772935

138511

9772480

138512

9772560

138524

9772601

138531

9719763

138519

9719763

138523

9772420

138516

Light Fan, H 138497

Light 2spd Fan, H 138498

Lobby Park, H 138499

Lobby Return, H 138495

Lockout, Car Call, H

Lockout, Hall Call, H 138494

Photoeye, H

138494 9703391

138500 9703135

9703135

H2395

9703135

H2395

9703135

H2395

9703135

H2395

H1848

9703391

H1848

H2395

9719519

660AC2

9719519

660AC2

9719519

660AC2

9719519

660AC2

660AD2 N 2 90

660AD2 N 2 90

9719519

660AC2

N 3 180

N 4 270

N 2 90

Y 2 45

N 2 90

9772467

138540

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Photoeye Front, H

138505 9703135

H2395

Traditional Signal Fixtures-28

9719519

660AC2

N 2 90

Page 37

Owner’s Manual

Traditional Key Switch Selection Chart (cont.)

PART NO

PRINT NO

9772479

138541

9772753

138543

9772741

138542

9720029

138520

9772558

138522

9720017

138521

DESCRIPTION BEZEL KEY KEY PLUG SPG

Photoeye Rear, H

Photoeye Lower, H

Photoeye Upper, H

Registration, Car Call, H 138494

Registration, Hall Call,

Intermediate, H

Registration, Hall Call,

Terminal, H

138506 9703135

138545 9703135

138544 9703135

138501

138494 9703391

H2395

H2395

H2395

9703391

H1848

9703391

H1848

H1848

9719519

660AC2

9719519

660AC2

9719519

660AC2

660AD2 Y 2 45

660AD2 Y 3 90

660AD2 Y 2 45

KEY

POS

N 2 90

N 2 90

N 2 90

DEG

ROT

9715952

138530

Stop,Car,H

138503 9731064

H1846

9845641

660AD1

N 2 90

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Traditional Signal Fixtures-29

Page 38

Owner’s Manual

This page

intentionally

left blank.

E2001, 2008 THYSSENKRUPP ELEVATOR Printed in USA September, 2008

Traditional Signal Fixtures-30

Page 39

Owner’s Manual

Vandal Resistant

Signal Fixtures

Vandal Resistant Pushbutton Kit 2..................................

Pushbutton Assembly 3..........................................

Vandal Resistant Lantern and Position Indicator 4.....................

Vandal Resistant Lantern Intermediate 5.............................

Vandal Resistant Call Register Light 6...............................

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Vandal Resistant Signal Fixtures-1

Page 40

Owner’s Manual

Vandal Resistant Pushbutton Kit

Easyriser #3101

1

2

5

4

3

7

6

8

ITEM PART NO. PRINT NO. DESCRIPTION

1 161089 Contact Base Assembly

2 161072 Pushbutton, Vandal Resistant

3 161071 Shim, Metal

4 161085 Halo, Vandal Resistant

5 138594 Ring, Retaining, 1.25”

6 138593 Ring, Retaining, .875”

7 138590 Halo Ring, Pushbutton, Stainless Steel

8 138592 Pushbutton, Stainless Steel, Vandal Resistant w/jewel

138588 Pushbutton, Stainless Steel, Vandal Resistant wo/jewel

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Vandal Resistant Signal Fixtures-2

Page 41

Owner’s Manual

Vandall Resistant Pushbutton Assembly

#138585 Illuminated

#138586 Non-Illuminated

6

8

9

7

5

4

3

2

1

ITEM PART NO. PRINT NO. DESCRIPTION

1 138592 Pushbutton, Stainless Steel, Vandal Resistant w/jewel

138588 Pushbutton, Stainless Steel, Vandal Resistant wo/jewel

2 138590 Halo Ring Pushbutton, SS

3 138593 Ring, Retaining, .875”

4 138594 Ring, Retaining, 1.25”

5 130595 Halo, Pushbutton Vandal Resistant

6 129BC1 Base, Mounting

7 228AF2 Cam, Switch

8 292AA1 Cap, Switch

9 292AA1 Switch, SPDT

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Vandal Resistant Signal Fixtures-3

Page 42

Owner’s Manual

Vandal Resistant Lantern

and Position Indicator

1

2

3

4

ITEM PART NO. PRINT NO. DESCRIPTION

1 Faceplate (Custom Order for No. Landings)

2 160629 Bracket, Jewel Mounting

3 138316 Holder, Jewel

4 138313 Jewel, Red

138315 Jewel, Green

5 9727190 107189 Lamp, Wedgebase, 28V

6 9711065 110608 Lampholder, 24V

9778147 108149 Lampholder w/resistor, 48V (Uses 28V Lamp above.)

7 160591 Gong Assembly, 24V

160590 Gong Assembly, 48V

5 6

7

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Vandal Resistant Signal Fixtures-4

Page 43

Owner’s Manual

Vandal Resistant Lantern

Intermediate

Terminal

1

2

6

3

ITEM PART NO. PRINT NO. DESCRIPTION

1 160861 Faceplate, Terminal, #4 SS

160862 Faceplate, Terminal, #8 SS

160863 Faceplate, Terminal, #4 Muntz

160864 Faceplate, Terminal, #8 Muntz

2 160865 Faceplate, Intermediate, #4 SS

160866 Faceplate, Intermediate, #4 SS

160867 Faceplate, Intermediate, #4 Muntz

160868 Faceplate, Intermediate, #8 Muntz

3 160629 Bracket, Jewel Mounting

4 138316 Holder, Jewel

5 138313 Jewel, Red

138315 Jewel, Green

6 160511 Fastening Kit, #4 SS

160512 Fastening Kit, #8 SS

160513 Fastening Kit, #4 Muntz

160514 Fastening Kit, #8 Muntz

7 160591 Gong Assembly, 24V (Not Shown)

160590 Gong Assembly, 48V (Not Shown)

6

45

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Vandal Resistant Signal Fixtures-5

Page 44

Owner’s Manual

Vandal Resistant Call Register Light

#6300KJ1 24 VDC

#6300KJ2 48 VDC

#6300KJ3 115 VAC

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Vandal Resistant Signal Fixtures-6

Page 45

Owner’s Manual

Signa 4

2004 Fire Service Panel 176CL 2..................................

Fire Service Panel 176CF 6.......................................

Fire Insert Lens 130CL 7.........................................

Car Riding Lantern 556EB 9......................................

Telephone Kit 200AFA 11........................................

Button Assembly 680AX 12.......................................

P. I. and Emergency Light Panel 176CG 14...........................

Discrete Position Indicator Kit 200AFB 15............................

Discrete Position Indicator Display 178ME1 17........................

LON Electronic Position Indicator 178LP7 18.........................

CAN Position Indicator 178ME2 and LON Position Indicator 178ME4 19....

Fire Phone Jack with Bezel Assembly

(Hall or Car => 2004 Fire Code 128BW1 / 128BW3 20..................

2000 Fire Phone Jack with Bezel Assembly

(Car <= 2000 Fire Code) 128BW2 / 128BW4 20.......................

Light Fixture Assembly, Hall, Round Terminal and Intermediate 556DM 21..

Light Fixture Assembly, Hall, Arrows Terminal and Intermediate 556DM 23.

Hall Station Assembly 8503AN_1 25...............................

Hall Station Assembly 8503AN_2 27...............................

Hall Station Assembly 8503AN_3 29...............................

Hall Station Assembly 8503AN_4 31...............................

Hall Station Assembly 8503AN_5 33...............................

Trademark Panel Faceplate Assembly 141HV 35......................

Car Key Switches 36............................................

Hall Key Switches 43............................................

KeySwitchBezels 47............................................

Key Core Bezels 50.............................................

French Key Core Bezels 56.......................................

Push Button Inserts 58..........................................

DMG Contact Block Removal Procedure 61...........................

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-1

Page 46

Owner’s Manual

2004 Fire Service Panel

176CL

24

20

18

19

13

5

2

23

9

12

16

10

17

4

3

6

21

22

8

14

11

13

7

12

15

1

ITEM PART NO. PRINT NO. DESCRIPTION

1 168FH1 Frame Assembly, 2004 Fire Service

2 141KM2 Faceplate, Locked Compartment Door, ASME, LH, #4 SS

141KM51 Faceplate, Locked Compartment Door, ASME, LH, #4 SS, French

141KM31 Faceplate, Locked Compar tment Door, ASME, LH, #4 SS, No Smoking

141KM7 Faceplate, Locked Compartment Door, ASME, LH, #8 SS

141KM52 Faceplate, Locked Compartment Door, ASME, LH, #8 SS, French

141KM32 Faceplate, Locked Compar tment Door, ASME, LH, #8 SS, No Smoking

141KM8 Faceplate, Locked Compartment Door, ASME, LH, #4 Muntz Metal

141KM53 Faceplate, Locked Compar tment Door, ASME, LH, #4 Muntz Metal, French

141KM33 Faceplate, Locked Compar tment Door, ASME, LH, #4 Muntz Metal,

No Smoking

141KM9 Faceplate, Locked Compartment Door, ASME, LH, #8 Muntz Metal

141KM54 Faceplate, Locked Compar tment Door, ASME, LH, #8 Muntz Metal, French

141KM34 Faceplate, Locked Compar tment Door, ASME, LH, #8 Muntz Metal,

No Smoking

141KM10 Faceplate, Locked Compar tment Door, ASME, LH, Special Metal

141KM4 Faceplate, Locked Compartment Door, Mass.-LH, #4 SS

Front Opening AssemblyFront and Rear Opening Assembly

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-2

Page 47

Owner’s Manual

2004 Fire Service Panel

(continued)

ITEM PART NO. PRINT NO. DESCRIPTION

141KM36 Faceplate, Locked Compartment Door, Mass.-LH, #4 SS, No Smoking

141KM17 Faceplate, Locked Compar tment Door, Mass.-LH, #8 SS

2 141KM37 Faceplate, Locked Compartment Door, Mass.-LH, #8 SS, No Smoking

141KM18 Faceplate, Locked Compartment Door, Mass.-LH, #4 Muntz Metal

141KM38 Faceplate, Locked Compar tment Door, Mass.-LH, #4 Muntz Metal,

No Smoking

141KM19 Faceplate, Locked Compartment Door, Mass.-LH, #8 Muntz Metal

141KM39 Faceplate, Locked Compar tment Door, Mass.-LH, #8 Muntz Metal,

No Smoking

141KM20 Faceplate, Locked Compar tment Door, Mass.-LH, Special Metal

141KM40 Faceplate, Locked Compar tment Door, Mass.-LH, Special Metal,

No Smoking

141KM21 Faceplate, Locked Compartment Door, ASME, RH, #4 SS

141KM55 Faceplate, Locked Compartment Door, ASME, RH, #4 SS, French

141KM41 Faceplate, Locked Compar tment Door, ASME, RH, #4 SS, No Smoking

141KM22 Faceplate, Locked Compartment Door, ASME, RH, #8 SS

141KM56 Faceplate, Locked Compartment Door, ASME, RH, #8 SS, French

141KM42 Faceplate, Locked Compar tment Door, ASME, RH, #8 SS, No Smoking

141KM23 Faceplate, Locked Compar tment Door, ASME RH, #4 Muntz Metal

141KM57 Faceplate, Locked Compartment Door, ASME RH, #4 Muntz Metal, French

141KM43 Faceplate, Locked Compartment Door, ASME RH, #4 Muntz Metal,

No Smoking

141KM24 Faceplate, Locked Compar tment Door, ASME RH, #8 Muntz Metal

141KM58 Faceplate, Locked Compartment Door, ASME RH, #8 Muntz Metal, French

141KM44 Faceplate, Locked Compartment Door, ASME RH, #8 Muntz Metal,

No Smoking

141KM25 Faceplate, Locked Compartment Door, ASME RH, Special Metal

141KM45 Faceplate, Locked Compartment Door, ASME RH, Special Metal, No Smoking

141KM26 Faceplate, Locked Compar tment Door, Mass.-RH, #4 SS

141KM46 Faceplate, Locked Compartment Door, Mass.-RH, #4 SS, No Smoking

141KM27 Faceplate, Locked Compar tment Door, Mass.-RH, #8 SS

141KM47 Faceplate, Locked Compartment Door, Mass.-RH, #8 SS, No Smoking

141KM28 Faceplate, Locked Compartment Door, Mass.-RH, #4 Muntz Metal

141KM48 Faceplate, Locked Compar tment Door, Mass.-RH, #4 Muntz Metal,

No Smoking

141KM29 Faceplate, Locked Compartment Door, Mass.-RH, #8 Muntz Metal

141KM49 Faceplate, Locked Compar tment Door, Mass.-RH, #8 Muntz Metal,

No Smoking

141KM30 Faceplate, Locked Compar tment Door, Mass.-RH, Special Metal

141KM50 Faceplate, Locked Compar tment Door, Mass.-RH, Special Metal,

No Smoking

3 562AM1 Keyswitch, A17.1, Key No. 204

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-3

Page 48

Owner’s Manual

2004 Fire Service Panel

(continued)

ITEM PART NO. PRINT NO. DESCRIPTION

562AM2 Keyswitch, South Carolina

562AM4 Keyswitch, Arizona

562AM5 Keyswitch, Rhode Island

562AM6 Keyswitch, Ontario, Canada

562AM7 Keyswitch, Florida Region 1

562AM8 Keyswitch, Florida Regions 2

3 562AM9 Keyswitch, Florida Region 3

562AM10 Keyswitch, Florida Region 4

562AM11 Keyswitch, Florida Region 5

562AM12 Keyswitch, Florida Region 6

562AM13 Keyswitch, Florida Region 7

562AN3 Keyswitch, Massachusetts, New Hampshire, New Jersey, RH

562AN4 Keyswitch, Massachusetts, New Hampshire, New Jersey, LH (Shown)

4 700514 FS, Screw, MSPS. 164(#8) .375

5 580AED1 Marker, Overlay, 2004 Fire Service, Top Half

580AED3 Marker, Overlay, 2004 Fire Service, Top Half (French)

6 580AED2 Marker, Overlay, 2004 Fire Service, Lower Half

580AED4 Marker, Overlay, 2004 Fire Service, Lower Half (French)

7 9873537 393DK2 FS, Nut, Self-Threading

8 9734739 172CG2 Box

9 128BV2 Bezel, Red, Fire Service, Reset/Off/On, Massachusetts, New Hampshire,

New Jersey

128BP76 Bezel, Keycore, Red, Off/Hold/On, A17.1

128BY31 Bezel, Keycore, Red, Off/Hold/On, A17.1 (French)

128BP86 Bezel, Keycore, Red, Off/Hold/On, A17.1, Florida

10 See Keyswitch Parts Page

11 9852364 660BN1 Plug, Plastic, Black

12 9810845 108155 Stop Assembly, Stop/Run, Vertical

13 680AP3 Jewel, Assembly, Fire Hat

14 680AV45 Push Button Assembly, Open Door, Microban

680BD24 Push Button Assembly, Open Door, Microban (French)

15 680AV46 Push Button Assembly, Close Door, Microban

680BD25 Push Button Assembly, Close Door, Microban (French)

16 680AV47 Push Button Assembly, Close Door Front, Microban

680BD26 Push Button Assembly, Close Door Front, Microban (French)

17 680AV48 Push Button Assembly, Close Door Rear, Microban

680BD27 Push Button Assembly, Close Door Rear, Microban (French)

18 680AV49 Push Button Assembly, Open Door Front, Microban

680BD28 Push Button Assembly, Open Door Front, Microban (French)

19 680AV50 Push Button Assembly, O pen Door Rear, Microban

680BD29 Push Button Assembly, Open Door Rear, Microban (French)

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-4

Page 49

Owner’s Manual

2004 Fire Service Panel

ITEM PART NO. PRINT NO. DESCRIPTION

20 680AV53 Push Button Assembly, C all Cancel, Microban

680BD32 Push Button Assembly, Call Cancel, Microban (French)

21 297CE4 Contact, Push Button, Non-Illuminated

22 9741785 128BR1 Bezel, Keycore, Washer

128BR5 Bezel, Keycore, Washer, Massachusettes, New Hampshire, New Jersey

23 9752043 108288 Screw, # 10-24, 1.5” Lg, #4 SS

24 9752018 35402 Nut, # 10-24

(continued)

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-5

Page 50

Owner’s Manual

Fire Service Panel

176CF

3

1

2

4

8

6

7

9

5

ITEM PART NO. PRINT NO. DESCRIPTION

1 141HP1 Faceplate, Fire Frame

2 141HT2 Faceplate, Fire Insert, New York City

3 Lens, Fire Insert (See Fire Insert Parts Pages)

4 Key Switch (See Key Switch Parts Pages)

5 9873537 393DK2 Nut, Self Threading

6 6300RP4 Card, LED, Fire Hat, Red

7 812AH2 Speaker, Telephone

8 680AR6 Button, Call Cancel

9 297CF5 Contact, Push But t on, Non-Illuminated

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

141HT4 Faceplate, Fire Insert, Massachusetts, New Hampshire, New Jersey

141HR2 Faceplate, Fire Insert, A17.1, Arizona, Rhode Island, South Carolina

141HR3 Faceplate, Fire Insert, Chicago

141HR4 Faceplate, Fire Insert, French

680AR7 Button, California, White/White

Signa 4 Signal Fixtures-6

Page 51

Owner’s Manual

Fire Insert Lens

130CL

130CL2 130CL3

130CL4

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-7

Page 52

Owner’s Manual

Fire Insert Lens

(continued)

130CL

130CL5 130CL6

ITEM PART NO. PRINT NO. DESCRIPTION

1 130CL2 Lens, Fire Insert, A17.1, 2000 South Carolina, 2000 Massachusetts,

2000 B44

2 130CL3 Lens, Fire Insert, 1998 A17.1, 1998 Massachusetts, 1998 South Carolina,

Houston, Michigan, New York City

3 130CL4 Lens, Fire Insert, Chicago, Any with no Signage

4 130CL5 Lens, Fire Insert, 2000 French

5 130CL6 Lens, Fire Insert, 1996 A17.1

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-8

Page 53

Owner’s Manual

Car Riding Lantern

556EB

10

13

15

14

3

12

11

8

7

6

5

9

4

1

2

ITEM PART NO. PRINT NO. DESCRIPTION

1 396RC1 Screw, CSBHS, #10-24 x .750 B Mirror, Lacquered

144789 Screw, CSBHS, #10-24 x .750 B, Lacquered

396NP1 Screw, CSBHS, #10-24 x .750 SE, Mirror

9752031 35203 Screw, CSBHS, #10-24 x .750 SE

2 297CG1 Contact Blade, Ground

3 141KB9 Faceplate, Lantern, Arrow, #4 SS, Vertical

141KB10 Faceplate, Lantern, Arrow, #8 SS, Vertical

41KB11 Faceplate,Lantern,Arrow,#4Muntz,Vertical

41KB12 Faceplate,Lantern,Arrow,#8Muntz,Vertical

4 141HJ2 Faceplate, Frame

5 130CG2 Lens, Lantern Arrow, Flat

6 134AN1 Reflector, Round Lens, Hall Lantern

7 6300XC30 Card, Arrow, 24V, White

6300XC20 Card, Arrow, 24V, Red

6300XC1 Card, Arrow, 24V, Blue

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-9

Page 54

Owner’s Manual

Car Riding Lantern

(continued)

556EB

ITEM PART NO. PRINT NO. DESCRIPTION

8 9857426 6300WG1 Card, Breakout

9 177AK3 Chime, Audible, Adjustable, 24V, w/Plug-In

10 596BX2 Mount, PC Board

11 462MT1 Assembly, Harness

12 9752018 35402 Speed Nut

13 172AX1 Box, Faceplate Mount

14 701774 FS, Screw, MSRP .190 (#10)-24 x .500

15 9702210 700432 FS, Washer, LWET .190 #10 C

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-10

Page 55

Owner’s Manual

Telephone Kit

200AFA

6

11

5

4

10

9

1

7

8

12

2

3

ITEM PART NO. PRINT NO. DESCRIPTION

1 442AE1 Grill, Speaker-Charcoal

2 9873537 393DK2 Nut, Self-Threading

3 812AK2 Phone, Rath

4 128BJ2 Bezel, ADA, Help

5 680AV52 Push Button, Car, Help

680BD30 Push Button, Car, Help (French)

6 128BG2 Bezel, ADA, Jewel

128BG3 Bezel, ADA, Jewel (French)

7 392DG1 Washer

8 9873537 393DK1 Nut, Self-Threading

9 128BK1 Bezel, ADA, Microphone Mount

10 812AJ1 Microphone, Telephone, Rath

11 130CR1 Lens, ADA Jewel, Rath

12 297CF5 Contact, Push Button, Screw Connection

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-11

Page 56

Owner’s Manual

Button Assembly

680AX

3

3

1

4

Part of Item

3.

2

Note: To remove contact block

from the Push Button panel,

Contact Block Remov-

see the

al Procedure in this manual.

Hall Button Assembly Car Button Assembly

ITEM PART NO. PRINT NO. DESCRIPTION

1 9836214 128BH1 Bezel, Oblong, Gray

2 9858265 297CE2 Contact, Push Button, 4 Pin Connector, 1 Led, White, White, 24V (California)

297CE4 Contact, Push Button With Connector, Non- illuminated, 120V

297CE1 Contact, Push Button With Connector, Blue Illumination, 24V

297CE5 Contact, Push Button With Connector, Red Illumination, 12V

3 680AR6 Push Button, Black, Blank

680AR7 Push Button, White, Blank (California)

9739580 680AT6 Push Button, Black With White Arrow

680AT8 Push Button, White With Black Arrow (California)

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-12

Page 57

Owner’s Manual

Button Assembly

(continued)

680AX

ITEM PART NO. PRINT NO. DESCRIPTION

3 680AV45 Push Button, Black, Open Door

680BD24 Push Button, Black, Open Door (French)

680AV46 Push Button, Black, Close Door

680BD25 Push Button, Black, Close Door (French)

680AV47 Push Button, Black, Close Door Front

680BD26 Push Button, Black, Close Door Front (French)

680AV48 Push Button, Black, Close Door Rear

680BD27 Push Button, Black, Close Door Rear (French)

680AV49 Push Button, Black, Open Door Front

680BD28 Push Button, Black, Open Door Front (French)

680AV50 Push Button, Black, Open Door Rear

680BD29 Push Button, Black, Open Door Rear (French)

680AV51 Push Button, Black, Hold Door

680AV54 Push Button, Black, Hold Door Front

680AV55 Push Button, Black, Hold Door Rear

680AV56 Push Button, White, Open Door (California)

680AV57 Push Button, White, Close Door (California)

680AV58 Push Button, White, Close Door Front (California)

680AV59 Push Button, White, Close Door Rear (California)

680AV60 Push Button, White, Open Door Front (California)

680AV61 Push Button, White, Open Door Rear (California)

680AV62 Push Button, White, Hold Door (California)

680AV63 Push Button, White, Call Cancel (California)

680AV64 Push Button, White, Hold Door, Front

680AV65 Push Button, White, Hold Door, Rear

680AW6 Push Button, Black, Alarm

680BD31 Push Button, Black, Alarm (French)

680AW7 Push Button, White, Alarm (California)

4 169CB Sign, Car Pad Handicap, Front Mount Plastic

(See Push Button Inserts, Parts Pages)

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-13

Page 58

Owner’s Manual

P. I. and Emergency Light Panel

176CG

4

5

3

2

1

ITEM PART NO. PRINT NO. DESCRIPTION

1 141HK1 Faceplate, Position Indicator and Emergency Light

2 130BK1 Lens, Position Indicator, Emergency Light

3 6300RL12 Card, Emergency Light LED, 12V

4 9873537 393DK2 Nut, Self Threading, Palnut

5 580AAA1 Marker, Position Indicator, Emergency Light

6 196AFY1 Bracket, Emergency Light Battery (*Not Shown)

7 116AB2 Battery, SLA 12V (*Not Shown)

8 101275 Screw, #8 x .375” (*Not Shown)

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-14

Page 59

Owner’s Manual

Discrete Position Indicator Kit

200AFB

2

1

3

4

4

ITEM PART NO. PRINT NO. DESCRIPTION

1 130CW1 “1” Dot Film, .016 Clear Polycarbonate Film

130CW2 “2” Dot Film, .016 Clear Polycarbonate Film

130CW3 “3” Dot Film, .016 Clear Polycarbonate Film

130CW4 “4” Dot Film, .016 Clear Polycarbonate Film

130CW5 “5” Dot Film, .016 Clear Polycarbonate Film

130CW6 “0” Dot Film, .016 Clear Polycarbonate Film

130CW7 “6” Dot Film, .016 Clear Polycarbonate Film

130CW8 “7” Dot Film, .016 Clear Polycarbonate Film

130CW9 “8” Dot Film, .016 Clear Polycarbonate Film

130CW10 “9” Dot Film, .016 Clear Polycarbonate Film

130CW11 “⇑” Dot Film, .016 Clear Polycarbonate Film

130CW12 “B” Dot Film, .016 Clear Polycarbonate Film

130CW13 “C” Dot Film, .016 Clear Polycarbonate Film

130CW14 “D” Dot Film, .016 Clear Polycarbonate Film

130CW15 “F” Dot Film, .016 Clear Polycarbonate Film

130CW16 “G” Dot Film, .016 Clear Polycarbonate Film

130CW17 “H” Dot Film, .016 Clear Polycarbonate Film

E2010 THYSSENKRUPP ELEVATOR Printed in USA February, 2010

Signa 4 Signal Fixtures-15

Page 60

Owner’s Manual

Discrete Position Indicator Kit

(continued)

200AFB

ITEM PART NO. PRINT NO. DESCRIPTION

130CW18 “L” Dot Film, .016 Clear Polycarbonate Film

130CW19 “M” Dot Film, .016 Clear Polycarbonate Film

1 130CW20 “P” Dot Film, .016 Clear Polycarbonate Film

130CW21 “R” Dot Film, .016 Clear Polycarbonate Film

130CW22 “S” Dot Film, .016 Clear Polycarbonate Film

130CW23 “U” Dot Film, .016 Clear Polycarbonate Film

130CW24 “T” Dot Film, .016 Clear Polycarbonate Film

130CW25 “A” Dot Film, .016 Clear Polycarbonate Film

130CW26 “N” Dot Film, .016 Clear Polycarbonate Film