Page 1

Thurlby DSA524

digital storage adaptor

OPERATING MANUAL AN D TUTORIAL

V2.0

Page 2

1

INTRODUCTION

This manual is divided into four sections as follows:

Section 1 is the main reference section which contains a detailed

description of the operation of each function.

Section 2 is a tutorial for new users (or for existing users needing

examples of how functions operate).

The Appendices provide additional detail on some of the more

complex functions and on some of the theoretical aspects of digital

storage.

The Specifications give detailed technical specifications for the

instrument, plus service and warranty details.

N.B. The DSA524 can use either an oscilloscope or a personal

computer (IBM compatible) as the display device. This manual only

covers use with an oscilloscope. To use a PC as the display device

the "DS-PC Link" software package must be purchased, an additional

manual is supplied with this software.

FIRMWARE LEVEL

From time to time small revisions may be made to the

firmware of the DSA524 (the firmware is the ROM based

program code for the unit).

The firmware level is displayed briefly whenever the unit is

first switched on (and when SET 'SCOPE is used) as DSA524

X.XX, where X.XX is the firmware level.

This issue of the operating manual applies to units with a

firmware level of 2.71 and above.

IT IS VERY STRONGLY RECOMMENDED THAT NEW

USERS START BY FOLLOWING THE TUTORIAL.

INDEX

Title Section Page

REFERENCE SECTION

Connecting an Oscilloscope..................................... R1 ...............2

Setting up the Display .......................................... R2 ...............2

Front Panel Controls ............................................. R3 ...............2

Escape and Reset ................................................ R4 ...............2

Controlling Digitising ............................................R5 ...............2

Timebase Setting ................................................. R6 ...............2

CH1 and CH2 ....................................................... R7 ...............3

Digitising Memories .............................................. R8 ...............3

Trigger ................................................................ R9 ...............3

Trace A and Trace B ............................................. R10 ..............4

Memory Search (Comp, Scan, Mag) ........................ R11 .............5

Indexed Waveform Memories ................................. R12 ..............5

Display Update Rate .............................................. R13 .............5

Roll Mode Operation ............................................. R14 .............6

Repeat Mode Operation ......................................... R15 .............6

Cursor Measurement ............................................. R16 .............6

Program Mode ...................................................... R17 .............6

Sine Interpolation ................................................R18 .............7

Average ...............................................................R19 .............7

AxB (Trace Multiply) ............................................. R20 .............7

Line or Dots Display .............................................R21 .............7

Plot ..................................................................... R22 .............7

Print ...................................................................R23 .............8

Remote Control and Data Transfer ......................... R24 .............8

RS-423 Interface ................................................... R25 ............8

GP-IB (IEEE-488) Interface ................................... R26 ............8

Directly Acting Functions ...................................... R27 ............8

USERS TUTORIAL

Index to Tutorial .......................................................................9

APPENDICES

The Oscilloscope Display ........................................ Appendix A 16

Aliasing ............................................................... Appendix B 16

Bandwidth and Interpolation .................................. Appendix C 16

Analog Plotter Function ......................................... Appendix D 17

Connecting the Serial Interface .............................. Appendix E 18

Software Commands ............................................. Appendix F 18

SPECIFICATIONS

DSA524 Technical Specifications ............................ S1 ................20

Electrical Isolation ................................................. S2 ...............22

General Safety Considerations ............................... S3 ...............22

Fuse Replacement ................................................ S4 ...............22

Maintenance and Repair .......................................S5 ...............22

Updating the Firmware ......................................... S6 ...............22

Guarantee ........................................................... S7 ...............22

ADDENDA AND ERRATA .........................................................22

Page 3

2

REFERENCE SECTION

R1. CONNECTING AN OSCILLOSCOPE

Any conventional oscilloscope with an 8x10 division graticule can

be used with the DSA524. Only one input channel is needed and

a bandwidth of 5MHz is sufficient. The oscilloscope can be

connected using a single BNC to BNC cable. Alternatively two

cables can be used (see Appendix A).

Connect the rear panel socket marked "composite" to the vertical

input of the oscilloscope. If a two cable connection is preferred,

connect the rear panel socket marked "trigger" to the external

trigger input of the oscilloscope.

Set up the oscilloscope controls as follows:-

Vertical Input: DC coupling

100mV per division

Timebase: 50usec per division

No Sweep Hold-off

Trigger: Source — as input channel (single

cable connection)

— or external (two cable

connection)

Mode — normal (not bright-line auto)

Coupling — AC

Slope — negative

Level — negative

R2. SETTING UP THE OSCILLOSCOPE DISPLAY

Switch on the DSA524 (the power switch is at the rear) and wait

while the unit performs a brief selftest and initialisation. The

oscilloscope should then show a message as follows:"CENTRE ARROW TIP" alternating with "THEN PRESS ESCAPE"

Adjust the oscilloscope's horizontal and vertical position controls

until the tip of the arrow is exactly in the centre of the screen.

Two horizontal lines should be visible, one at three divisions

above the graticule centre and one at three divisions below.

Pressing the ESCAPE key on the DSA524 (top right-hand corner)

will remove this set-up display and start normal operation.

Once the display oscilloscope has been set up, no further use

need be made of its controls except for occasional re-centering of

the trace to correct for any warm-up drift. To re-centre the trace

press the two keys marked "SET 'SCOPE" (on the lower right of

the DSA) and adjust the oscilloscope's position controls to centre

the arrow tip. If problems occur when setting up the display read

Appendix A.

The oscilloscope setup

display.

R3. FRONT PANEL CONTROLS

All of the controls, including the rotary ones, are monitored by a

microprocessor which then performs the control. All of the

switches are of a momentary non-latching "key" type whose

status is indicated either by lamps under the panel or, where

appropriate, by text on the display. Each rotary control is enabled

or disabled by the key to its right. The control is enabled when

the lamp above the key is off, and is disabled when the lamp is

on.

The keys within the numeric keypad section (right-hand side of

unit) have up to three functions. The normal function is printed

in black above each key. After the SHIFT control is pressed the

function becomes as printed in green above the key. When a

function ending in (NN) is pressed (e.g. SAVE(NN)) the key will

enter the number printed alongside it.

Note that when SHIFT or a function ending in (NN) is pressed,

the lamp marked ENTER will flash to indicate that one or more

further key presses is required. Any function that causes the

ENTER lamp to flash can be cancelled by pressing that function

key again.

Note that some of the functions (including SET 'SCOPE)

automatically set the RUN/HOLD function to HOLD. If digitising

ceases unexpectedly check to see if you have unintentionally

set RUN/HOLD to HOLD.

All of the front panel settings are retained when the power is

turned off (except for RUN/HOLD which is always set to HOLD

at power-on).

R4. ESCAPE AND RESET

The ESCAPE key is used to terminate some of the functions of

the DSA such as "SET PLOT" and "SET AVG". At other times it

has no effect except after SHIFT has been pressed.

Pressing SHIFT followed by ESCAPE gives the RESET function.

RESET places the DSA into a known state. It cancels all of the

more complex functions and sets the DSA into a state which

makes it easy to display the input signals.

The main effect of RESET is to set up the unit as follows:-

RUN /HOLD RUN.

CH1 and CH2 Coupling: AC, Volts/div: 1V, Offset: ZERO,

On/off: ON.

TRIGGER Run/hold: RUN, Source: CH1, Mode: AUTO,

Level: ZERO, Slope: POS, Coupling: AC.

TRACES A Trace A source: CH1, Trace B source: CH2,

and B Gain variable: CAL, Position: HOME.

TIMEBASE Time/div: 20usec.

ALL OTHER

FUNCTIONS OFF.

After pressing RESET the DSA will be set such that the CH1

signal is displayed on trace A and the CH2 signal on trace B.

The display will be updated about three times per second. The

input sensitivity will be set at 1V per division. The timebase will

be set to 20usec/div. The input sensitivity and timebase speed

will need to be adjusted to suit the signal.

R5. CONTROLLING DIGITISING (DATA ACQUISITION)

The digitising of the input signals is controlled by the two keys

at the top of the TRIG section marked RUN/HOLD and SINGLE.

When RUN/HOLD is set to RUN, the DSA is automatically rearmed following each acquisition. Thus digitising is repeated

continuously provided that triggering is active (see Section R9

Trigger — Mode).

When RUN/HOLD is set to HOLD, digitising is stopped and the

contents of the digitising memories is frozen. When set to

HOLD, the DSA can be armed for a single acquisition using the

SINGLE key.

Digitising can be performed on both input signals

simultaneously, or on either signal individually. Each input

channel (CH1 and CH2) is enabled or disabled using the key

marked ON/OFF at the top of each channel section. When one

of the input channels is turned off, the digitising memory

associated with that channel is frozen and digitising takes place

on the other channel alone.

R6. SETTING THE TIMEBASE

The timebase of the DSA524 is somewhat different from that of

a conventional real-time oscilloscope. The time per division

keys, instead of setting a sweep speed, actually control the

Page 4

3

sampling rate of the digitiser. The shorter the time per division

the higher the digitising rate. After it has been stored, the

digitised data is displayed as 1024 samples across the screen

(100 samples per graticule division with 12 samples before and

12 samples after the graticule). Thus the time per division is

equal to 100 divided by the sampling rate.

The timebase should be set in much the same way as with a realtime oscilloscope but, unlike a real-time oscilloscope, the effect of

setting the timebase speed to too slow a rate can cause aliasing

effects on the display (see Appendix B). For this reason if the

signal frequency is unknown a fast timebase speed should be

selected initially.

Alternatively, if the signal is repetitive, the AUTOSET facility can

be used. It is fully described at the end of this section.

As well as setting the digitising rate, the time per division keys

also set the digitising mode. There are three modes:

NORMAL MODE: 100msec to 5usec per division (1KS/s to 20MS /s

sample rates) suitable for single or repetitive events. The screen

is updated after each digitising is completed.

ROLL MODE: 200msec to 200 minutes per division (500S/s to

8.3mS/s sample rate). Suitable for single or repetitive events. The

screen is updated continuously. As digitising takes place, new

data is written onto the right-hand side of the screen and old

data disappears from the left-hand side. Thus the waveform

appears to "roll" across the screen similarly to a strip chart

recorder. (See Section R14. Roll Mode Operation.)

REPEAT MODE: 2usec to 50nsec per division (50MS/s to 2GS /s

equivalent sample rate). Suitable for repetitive events only. The

screen is updated more slowly than in normal mode. The signal

must be repetitive and must be generating a trigger signal. Auto

free-run (trigger mode = AUTO) is not available in repeat mode,

neither is LINE trigger. (See Section R15. Repeat Mode

Operation.)

The time per division keys will autorepeat if held. When a change

in timebase speed causes a mode change a "beep" will be heard.

ROLL and REPEAT (RPT) modes are indicated by front panel

lamps.

When CH1 and CH2 are ON simultaneously the DSA524 uses a

single high speed digitiser to digitise both signals. For timebase

speeds of 20usecs per division and slower, both signals are

digitised together using a very high speed chopping technique.

For timebase speeds of 10usecs per division and faster the

signals are digitised separately on alternate trigger events. The

CHOP and ALT lamps show which mode is being used.

AUTOSET: The autoset function can be used to automatically set

the timebase speed so as to avoid aliasing effects. The input

signal must be repetitive and be generating a trigger signal

whose repetition rate is between 50Hz and 5MHz.

To initiate autoset press the two keys in the timebase section

marked AUTOSET simultaneously. If the trigger rate is between

50Hz and 1MHz the timebase will be reset to a position that gives

between 4 and 10 trigger events across the screen. The AUTO

lamp will illuminate for 3 seconds and the display will show the

message "AUTOSET SUCCESSFUL" for 3 seconds.

If the trigger rate was below 50Hz the timebase setting will

remain unchanged, the AUTO lamp will not illuminate and the

display will show the message "TRIGGER RATE TOO LOW" for 3

seconds.

If the trigger rate was above 1MHz the timebase will reset to

1usecs/div, the AUTO lamp will illuminate for 3 seconds, the

display will show the message "TRIGGER RATE ABOVE 1MHz"

and the DSA will "beep" to indicate that the timebase speed may

need to be set faster.

R7. CH1 AND CH2

The two input channels are identical. The input sensitivity is

variable between 10V and 2mV per division. The maximum

bandwidth is 35MHz down to 20mV/div, 20MHz at 10mV/div,

10MHz at 5mV/div and 5MHz at 2mV/div. The volts per division

keys autorepeat if held. The input coupling can be AC ( 3db =

5Hz) or DC.

When both keys are pressed simultaneously the unit enters an

AUTORANGING mode whereby the sensitivity is automatically

set to maintain a peak to peak signal amplitude between 2 and

4 divisions. The AUTO lamp is then illuminated. To leave autoranging mode press either key. Autoranging does not operate in

"roll" or "repeat" timebase modes.

The digitiser has an input dynamic range equivalent to ± 4.25

screen divisions. To maintain the input signal within this range

an OFFSET control is provided which has a range of ±8

divisions. OFFSET can be set to zero by pressing the

ZERO/(VAR) key. Press it again to return to variable offset.

If the signal goes outside the dynamic range of the digitiser

while digitising is taking place the AUTO/OVLD lamp flashes to

show that a signal overload is occurring. Signal values which

exceed the dynamic range will be digitised as either + 4.25 divs

or - 4.25 divs. Note that the lamp will continue to flash when

the waveform is "held" even if the signal overload is removed.

The input amplifiers have an automatic system for removing

offset errors. If the GND and AC/DC keys are pressed simultaneously an "autocalibration" takes place which re-checks and

removes offset errors from every volts/div position. AUTOCAL

should be used when the unit has warmed up, i.e. after about

20 minutes.

Each channel has an ON/OFF key. The operation of these keys

is explained in the next section (Digitising Memories).

R8. DIGITISING MEMORIES

Each channel has its own digitising memory of 4K words. When

both channels are turned ON (using the channel ON/OFF keys),

both memories are updated whenever digitising is performed.

When one channel is turned OFF, the contents of its digitising

memory is frozen and only the memory for the other channel is

updated.

The contents of the digitising memories is unaffected by the

settings of the trace controls. The digitising memories are nonvolatile i.e. their contents are not destroyed when the power is

turned off.

Note that if either of the digitising memories is storing a waveform which gave rise to an overload condition, the OVLD lamp

will continue to flash until the memory is overwritten with a

waveform which is within the dynamic range of the digitiser.

R9. TRIGGER

The trigger circuitry of the DSA is broadly similar to that of a

real-time oscilloscope. The trigger signal defines the exact

moment at which digitising takes place. Control of the trigger

circuit defines which part of a waveform will be stored.

Many functions are similar to those of a conventional oscilloscope:

SOURCE: Can be from CH1, CH2 or EXT (external

trigger BNC socket).

MODE: AUTO — similar to "Bright Line Auto", the

digitiser free runs if there is no trigger or if the

trigger repetition rate is below 20Hz. If the rate is

above 20Hz digitising takes place in synchronism.

NORM (Normal) — digitising is always in synchronism with the trigger signal. If there is no

trigger signal digitising stops.

LINE — digitising is in synchronism with AC line

rate (50 or 60Hz).

N.B. The trigger modes operate differently when

the timebase is set to "roll" mode (see Section

R14. Roll Mode Operation).

Neither Auto nor Line are available when the

timebase is set to "repeat" mode (see Section

R15. Repeat Mode Operation).

Page 5

4

LEVEL: Variable over ±4 divisions. Press ZERO/(VAR)

key to set zero level triggering, press again to

return to variable.

SLOPE: Can be POS (positive edge triggered) or NEG

(negative edge triggered).

COUPL: Can be AC, DC or HFREJ (high frequency

reject). With TV and video signals, use AC for Line

sync and HFREJ for Frame sync.

N.B. The lamp marked TRIG, to the right of the SINGLE key,

indicates the presence of a trigger signal.

Other functions are specific to the digital storage function:

RUN/HOLD: RUN — enables continuous digitising with

synchronism defined by the trigger mode control.

The previous contents of both digitising memories

are overwritten unless one has already been frozen

using the channel ON/OFF key.

HOLD — disables digitising. The contents of both

digitising memories are frozen.

SINGLE: Only operates when RUN/HOLD is set to

HOLD. Enables a single update of the digitising

memory with synchronism defined by the trigger

mode control.

EVENTS Sets a number of trigger events (0 to 15) which

DELAY: must occur before a trigger is sent to the digitiser.

This allows delayed triggering on complex single-event

waveforms, and can be used to avoid mis-triggering of complex

repetitive waveforms (similarly to Sweep Hold-off on a real-time

oscilloscope). Pressing either key shows the existing value on the

display for three seconds. Repeated pressing increments or

decrements the number, the keys auto-repeat if held. To rapidly

turn events delay off (i.e. to 00) press both keys simultaneously.

Note that when using AUTO trigger mode, events

delay will increase the minimum frequency at

which it can be used from 20Hz to (1 + 20Hz,

where n is the number of events.

TIME DELAY: Sets the time delay between the trigger event and

the start of the digitising process. The delay is

measured in screen divisions and can be positive

(POST TRIGGER DELAY) or negative (PRE

TRIGGER DELAY).

POST — this acts similarly to sweep delay on a

real-time oscilloscope. By adding time delay and

then selecting a faster timebase speed, a section of

a waveform occurring long after the trigger event

can be examined. For "normal" mode timebase

speeds (100msec/div to 5usec/div) the number of

divisions of post-trigger delay is automatically

increased or decreased to maintain a constant time

delay when the timebase speed is changed (within

a limit of 9,999 divisions maximum).

PRE — there is no equivalent to pre-trigger on a

real-time oscilloscope. Pre-trigger allows the part of

the waveform which occurred before the trigger to

be stored and observed. The maximum pre-trigger

delay is —40 divisions.

Pressing either key shows the existing value of

delay on the screen for three seconds. Repeated

pressing increments or decrements the number,

the keys autorepeat if held. To rapidly turn time

delay off (i.e. to 0000) press both keys

simultaneously.

N.B. Neither pre nor post trigger delay is available

in "repeat" mode. In "roll" mode only post trigger

delay is available. See Section R14. Roll Mode

Operation for an explanation.

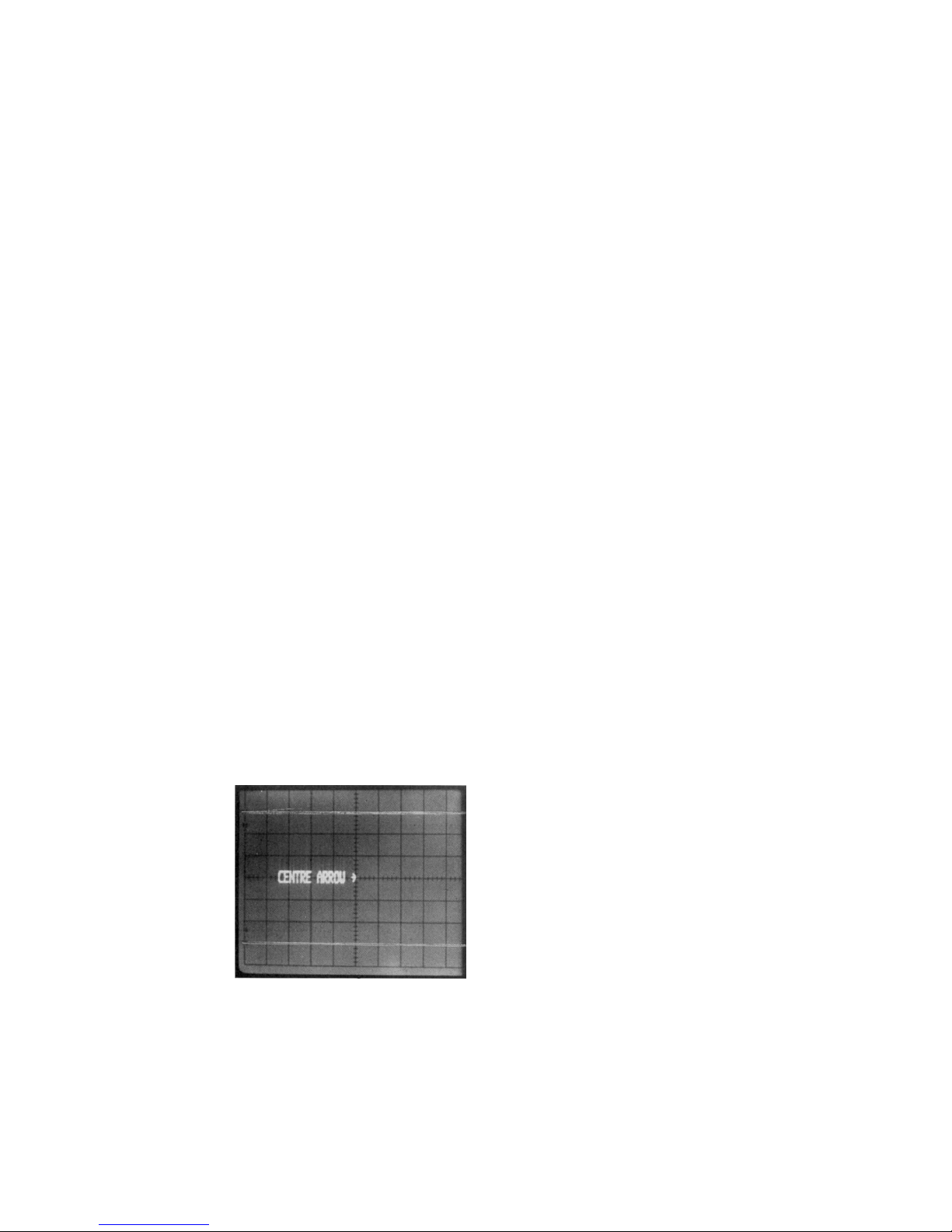

A waveform burst (4

cycles) captured with

no trigger time delay.

The same waveform

burst captured with 4

divisions of post

trigger delay.

The same waveform

burst captured with 9

divisions of pre

trigger delay.

R10. TRACE A AND TRACE B

The DSA524 can display two traces simultaneously, the traces

are called A and B. Each trace has its own 1K word memory

which can be loaded with data either from the corresponding

digitising memory (CH1 for trace A or CH2 for trace B) or from

an indexed waveform memory.

The trace controls operate on the waveform after it has been

digitised but before it has been 'displayed. Therefore they can

be used to modify waveforms recalled from a waveform store

as well as waveforms taken from the digitising memories of the

input channels.

POSITION: Enables the vertical position of the trace on the

display to be adjusted. Pressing the HOME/(VAR)

key toggles between fixed position (HOME) and

variable position.

GAIN Enable intermediate sensitivity levels to be set.

VARIABLE: Pressing the CAL/( UNCAL) key toggles

between calibrated gain (X1) and variable gain

(X1 to X0.2).

CH1 Pressing this key causes the trace to display the

(or

CH2): contents of the digitising memory for the

corresponding input channel.

RCL(NN): (Recall indexed waveform memory). Pressing

this key followed by a two digit number on the keypad

causes the trace to display the contents of the

corresponding waveform memory. It also sets RUN

/HOLD to HOLD.

OFF: Pressing the CH1 (or CH2) and RCL(NN) keys

simultaneously turns the trace off (the CH key should be

pressed first, otherwise RUN/HOLD will be set to HOLD).

Page 6

5

INV(Invert): Applies to Trace B only. Causes the waveform

to be displayed inverted.

ADD B: Applies to Trace A only. Displays the sum of

what is presently on Trace B and what was

previously on Trace A.

SAVE(NN): Pressing this key followed by a two digit number

causes the waveform presently displayed on that

trace to be stored in the corresponding waveform

memory. It also sets RUN/HOLD to HOLD.

R11. MEMORY SEARCH (COMP/SCAN/MAG)

Although the size of each trace memory is 1K words (equivalent

to 10.24 divisions across the screen) the size of each digitising

memory is 4K words (equivalent to 40.96 divisions). Normally

each trace memory is filled with the first 1K words from the corresponding digitising memory. (Note that in "roll" mode it is the

last 996 words — see Section R14. Roll Mode Operation.)

To enable all of the digitising memory to be viewed, a SEARCH

key is provided next to the timebase section. Pressing SEARCH

cycles through three states as detailed below. The actual mode is

indicated both by a corresponding front panel lamp and by a

diagram on the display which remains there for three seconds

after the mode has been changed.

COMP: Compresses all 4K words of the digitising

memory into the 1K words of the trace memory by

transferring every fourth word.

SCAN: Enables any 1K section of the digitising

memory to be transferred to the trace memory via

a moveable window. The window is moved using

the two keys marked SCAN/MAG. The position of

the window is shown graphically on the display for

three seconds whenever either key is pressed.

Repeated pressing of either key moves the window

left or right in one division (100 word) steps. The

keys autorepeat if held.

MAG: Digitally magnifies any 100 word section of the

trace memory by ten so that it fills the display. The

section is selected via a moveable window which is

moved using the two keys marked SCAN/MAG. The

position of the window is shown graphically on the

display for three seconds whenever either key is

pressed. Repeated pressing of the key moves the

window left or right in half division (50 word)

steps. The keys autorepeat if held.

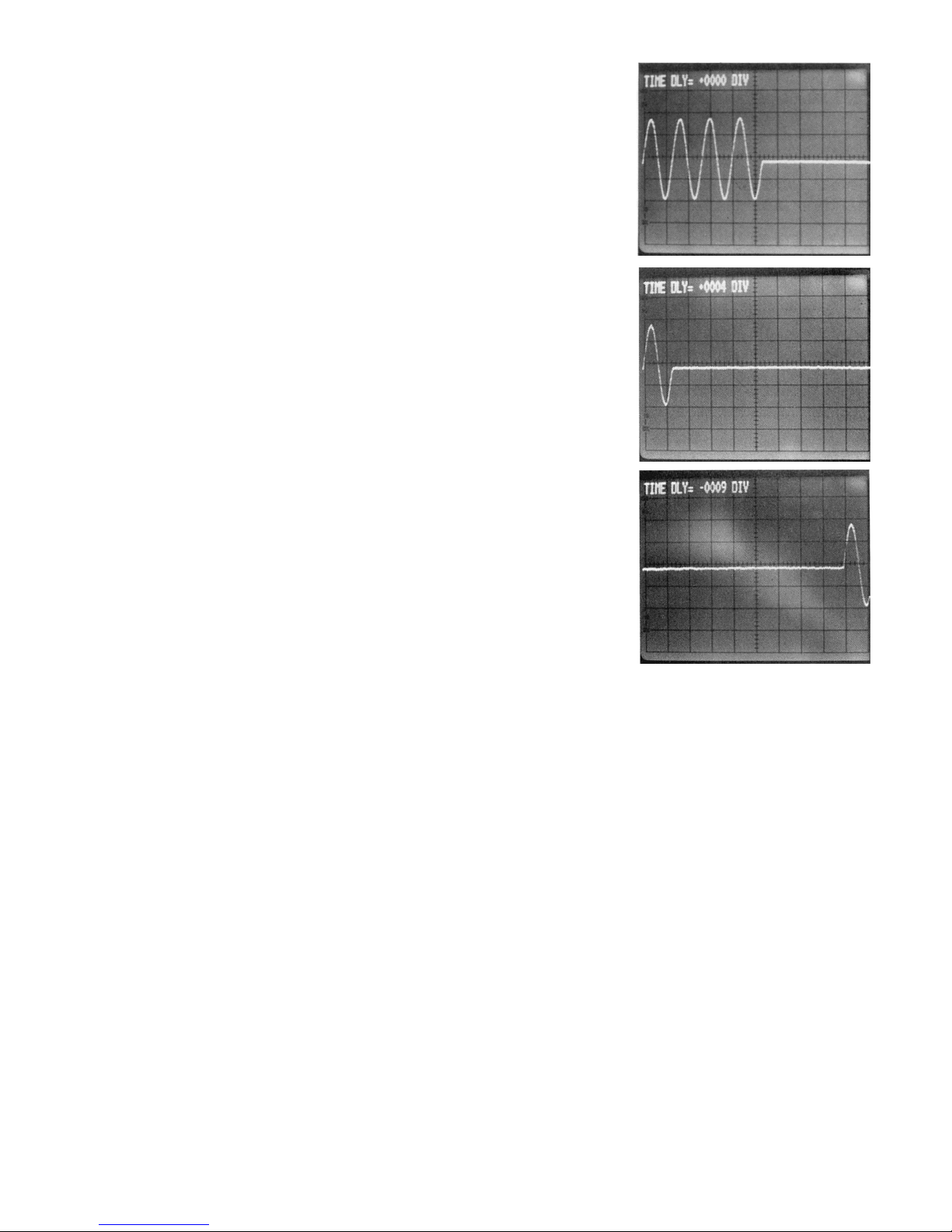

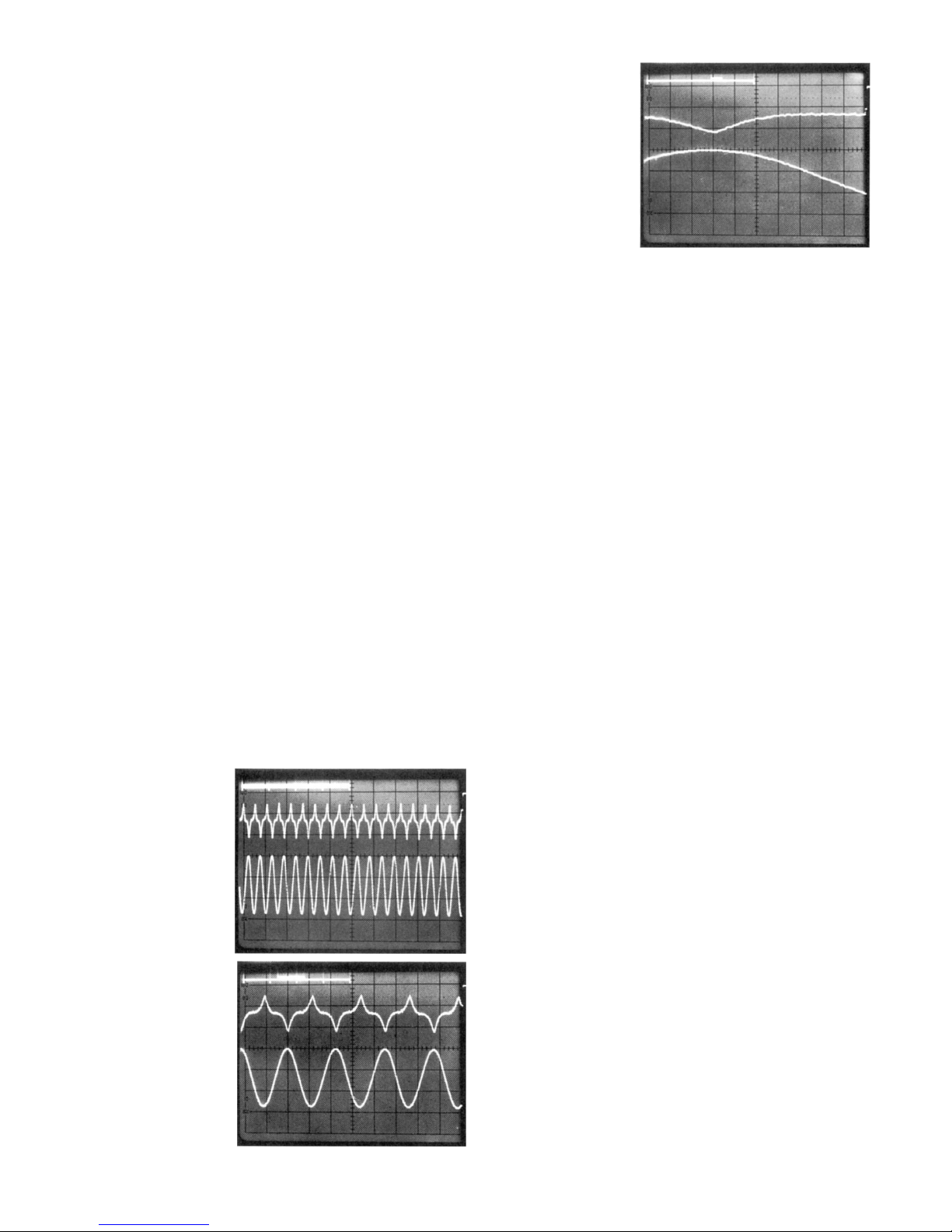

A captured waveform

displayed using Compress mode.

The same waveform

displayed using Scan

mode.

The same waveform

displayed using

Magnify mode.

To leave SEARCH mode and set the display mode back to

normal, press the two SCAN/MAG keys simultaneously.

If one of the traces is displaying a waveform recalled from an

indexed waveform memory when SEARCH is selected, the recalled waveform will remain unaffected.

R12. INDEXED WAVEFORM MEMORIES

The DSA524 has sixteen 1K word memories for temporary or

permanent storage of waveforms. Each memory is identified by

a two digit number from 01 through to 16. The memory is supported by trickle charged Ni-Cad batteries which will remain

charged for several months should the unit be left unpowered.

To store a waveform in an indexed memory, obtain the required

waveform on the display and press the SAVE(NN) key for the

appropriate trace. This will cause the ENTER lamp above the

numeric keypad to flash. Enter the two digits corresponding to

the required memory position, the display will show "MEMORY

NN = TRACE A (or B) for 3 secs.

Note that the waveform is stored exactly as it appears on the

display except for its vertical position which is stored as it would

be if the trace position control was at HOME.

To recall a waveform from an indexed memory, press the

RCLINN) key for the trace on which the waveform is to be displayed. This will cause the ENTER lamp above the numeric keypad to flash. Enter the two digits corresponding to the required

memory, the display will show "TRACE A (or B) = MEMORY NN"

for 3 secs.

When a waveform recalled from an indexed memory is being

displayed, the MEM lamp on the corresponding trace will be illuminated. The memory number from which it was recalled can

be checked by pressing the RCLINN) key twice.

Any trace recalled from a waveform store is temporarily suppressed when in "roll" mode RUN or SINGLE.

R13. DISPLAY UPDATE RATE

In "normal" mode (timebase speeds between 100msec and

5usec per division) the display update rate can be varied. This

is done with the key marked RATE (within the timebase

section).

The default update rate (NORM) re-starts the digitising process

about 300msecs after the completion of the previous one. This

gives a display update rate of about 3 per second for higher

timebase rates, slowing down as the timebase speed gets into

the tens of milliseconds (at 100msec per division digitising takes

4 seconds).

Pressing the RATE key once enters SLOW update mode. This

increases the delay from 300msec to 3secs giving more time for

each digitising of the waveform to be observed carefully. Pressing the key again returns to normal update rate.

Holding the RATE key depressed for two seconds enters FAST

update mode. This reduces the delay from 300msec to 20msec

giving a virtually instant update which mimics a real-time

oscilloscope. Pressing the key again returns to normal update

rate.

Entering FAST update mode reduces the acquisition memory

size to 1K words per channel and disables all of the trace

control functions except for trace position. Search mode

(COMP/ SCAN/MAG) and Average (AVG) are also disabled.

Page 7

6

When RUN/HOLD is set to HOLD, the remaining 3K words per

channel of the digitising memory are set to zeroes and the

disabled functions are restored. Pre-trigger time delay is limited

to 10 divisions in FAST mode.

In "roll" and "repeat" modes the RATE key is disabled.

R14. ROLL MODE OPERATION

In "roll" mode new data is written onto the right-hand side of the

display as digitising takes place. Thus the waveform appears to

roll across the screen. The operation of the DSA524 in "roll"

mode (timebase speeds of 200msecs and below) is different from

its operation in other modes in several respects:

a) Triggering and Display Update Rate

Because the waveform data is written continuously onto the display, it is not necessary to continually stop and restart the digitising process. Consequently when RUN /HOLD is set to RUN,

digitising takes place continuously and triggering is disabled. The

RATE key is disabled.

When RUN/HOLD is set to HOLD, triggering is enabled for

operation via the SINGLE key. Pressing SINGLE commences the

"roll" and the trigger event stops it, thus the waveform data

captured is entirely pre-trigger data. Consequently if a trigger

occurs immediately, no data will be captured unless some posttrigger time delay has been set. When the trigger mode is set to

AUTO, triggering occurs immediately. When the trigger mode is

set to NORM, triggering occurs synchronously with the trigger

signal.

Because in "roll" mode the trigger stops the digitising process

instead of starting it, all the data in the digitising memory is pretrigger data unless some post-trigger time delay has been set.

Pre-trigger time delay is therefore not needed and is disabled.

b) Display Window and Search mode

Because the waveform data is written continuously to the screen

as digitising takes place, the display shows the last part of the 4K

digitising memory instead of the first part. Because the left hand

edge of the display window is set in steps of 100 words, only 996

words are displayed and the remaining 28 words are set to zero.

SEARCH can only be selected in HOLD, and the scan window is

initially set fully to the right instead of fully to the left.

c) Trace Controls

When in roll mode, operation of any of the trace controls (e.g.

gain variable) will effect only the waveform data on the display

which was captured after the control was changed. However,

when the digitising process is stopped, the new trace control

values will be applied to the whole of the contents of the

digitising memory including waveform data captured before the

change was made.

R15. REPEAT MODE OPERATION

In normal mode the DSA524 can digitise a waveform at up to

20MS /s digitising rate, equivalent to 5usecs per division. If the

waveform is repetitive (as opposed to being a single event) it can

digitise the waveform repetitively, gradually building up the data

in the digitising memory. This mode of operation, known as

"repeat" mode, is used for timebase speeds of 2usecs and above

and provides equivalent digitising rates of up to 2GS /s (50nsecs

per div.). The operation of the DSA524 in repeat mode is

different from its operation in normal mode in several respects:

a) Triggering

Repeat mode requires a synchronously triggered waveform,

AUTO and LINE trigger modes are therefore disabled. Time delay

is not available (neither pre nor post trigger). The trigger event is

not captured, the first section of the waveform captured starts

350 nanoseconds after the trigger event.

b) Display Update Rate

Repeat mode involves complex manipulation of data which can

take several seconds per digitisation. The display update rate

varies between about one per second for a single channel at

2usecs/div to one every 10 seconds for both channels at

50nsecs/div. The Rate key is disabled in repeat mode.

R16. CURSOR MEASUREMENT

Moveable cursors allow accurate measurements of voltage and

time to be made on either Trace A or Trace B via an on-screen

digital readout.

To select cursor measurement, press the key marked ON/OFF

within the numeric keypad. Cursors will appear on Trace A, and

Trace B will be suppressed. Pressing the key marked A/ B

selects Trace B instead of Trace A. To turn cursor measurement

off press the ON/OFF key again.

Cursor measurement.

The cursors are flashing horizontal lines which each terminate

at a point on the waveform. The reference cursor is on the left

hand side of the screen, the delta cursor is on the right hand

side. The measurement is made between the two lines. The

readout shows the voltage and time difference between the end

of the reference cursor line and the start of the delta cursor

line. The cursors are moved using the arrow keys marked REF

CURS and ∆ CURS respectively.

R17. PROGRAM MODE

The DSA524 can operate as a fully programmable instrument. It

can "learn" individual or sequential front panel settings, store

them in non-volatile memory, and "replay" them on demand.

Up to 50 settings can be stored.

Each front panel setting includes the state of every key and

rotary control and the source of each trace waveform. Thus if a

setting is "learned" which includes a trace recalled from a waveform store, that same store will be recalled again when the setting is "re-played". Thus reference waveforms can be recalled

automatically within PROGRAM mode.

To "learn" one or more settings press the LEARN key, this turns

on learn mode. The display will show the message "NEXT

POSITION = NN" for 3 seconds where NN is a number between

01 and 50 corresponding to the position set when the unit was

last used.

To store a front panel setting in this position, ensure that the

front panel is set as required and press the SET/NEXT key. The

display will show the message "STORED IN NN" followed by

"NEXT POSITION = NN + 1". To store another front panel setting, reset the front panel as required and press the SET/NEXT

key again. To store the setting in any other memory position,

press the SET(NN) key followed by a two digit number between

01 and 50.

The next memory position can be checked at any time by

pressing the LEARN key again.

To "replay" one or more settings press the REPLAY key, this

turns on replay mode. The display will show "NEXT POSITION =

NN" as for learn mode. To replay the front panel setting corresponding to this position press the SET/NEXT key. The display

will show "REPLAYED FROM NN" followed by "NEXT POSITION

= NN + 1". Press the SET/NEXT key again to replay this next

position. To replay any other position press the SETINN) key

followed by a two digit number between 01 and 50.

The next memory position can be checked at any time by

pressing the REPLAY key again.

Whenever the front panel is set using the replay mode all the

rotary controls become inoperative. To make any rotary control

operative again press the key directly to its right. (Press once if

the lamp above the key is on, or twice if it is off.)

To exit either learn or replay modes press the LEARN and

REPLAY keys simultaneously.

Page 8

7

R18. SINE INTERPOLATION

When the display mode is set to MAG (magnify) the number of

true samples shown across the screen is reduced to 102. Although 1,024 samples are displayed, 9 samples out of each block

of 10 are mathematically calculated using linear interpolation.

Linear interpolation provides a good reconstruction of the original

waveform provided that either the number of samples per cycle

of the waveform is reasonably high (i.e. ten or more) or, if the

number of samples is low, that the original waveform is made up

mainly of linear elements (e.g. pulse, sawtooth, triangle

waveforms).

When the waveform is basically sinusoidal and the number of

samples per cycle is low, linear interpolation will not provide a

satisfactory reconstruction and sine interpolation should be used

instead. Sine interpolation uses a mathematical curve fitting algorithm and can provide a near perfect reconstruction of a sine

wave from only four samples per cycle. See Appendix C for a

detailed discussion of interpolation.

Pressing the SINE INTERPOLATE key toggles the function on or

off as indicated by the lamp above the key. Interpolation is only

active when the SEARCH mode is set to MAG. Sine interpolation

slows down the display update rate considerably.

R19. AVERAGE

The RUN AVERAGE function allows a number of digitisations of

the waveform to be summation averaged before being displayed.

This improves the signal to noise ratio of a noisy signal and can

often enable a signal to be observed that would otherwise have

been masked by large amounts of HF or LF noise. The average

function reduces the size of the digitising memories to 1K words

per channel.

The number of waveform digitisations which are averaged can be

Set to any number between 2 and 256. To change the number of

readings averaged press SHIFT (key 8) followed by SET AVG (key

4). The current averaging value is shown on the display and can

be incremented or decremented using the REF CURS keys (keys 2

and 3). When the required number is displayed, press ESCAPE.

Pressing the RUN AVERAGE key enables averaging, pressing the

key again disables it again, the status is indicated by the lamp

above the key. Acquisitions continue to be controlled by the

RUN/HOLD and SINGLE keys.

When the display update rate is set to NORM the display is

updated only whenever the total number of averages has been

completed. When the update rate is set to SLOW the display is

updated continuously as averaging takes place. The display

shows the number of averages currently accumulated.

Note that averaging slows down the display update rate. This is

particularly so at fast timebase speeds in "repeat" mode and slow

timebase speeds in normal mode.

R20. A= AXB (TRACE MULTIPLY)

This function provides a display of the Trace A waveform multiplied by the Trace B waveform. It is particularly useful for obtaining power waveforms.

Press SHIFT (key 8) followed by AxB (key 2). The two waveforms

will be multiplied together and displayed on Trace A (Trace B

continues to be displayed). To return to a normal display press

ESCAPE.

The multiplied waveform is scaled using units of one screen

division with the centre of the screen being zero. The traces are

multiplied exactly as they appear on the oscilloscope display including offsets introduced by the trace position controls. Thus at

a point where the position of Trace A is +2 divs and of Trace B is

—1.5 divs, the value of the multiplied waveform will be — 3 divs.

It should be noted that if either trace has values greater than ± 1

divs then overflows could occur on the multiplied waveform. The

displayed waveform is limited to ± 4.25 divisions and consequently —3 divs multiplied by —2.5 divs will be displayed as +

4.25 divs instead of + 7.5 divs.

The AxB function cannot operate while digitising is taking place.

Pressing the AxB key will set RUN/HOLD to HOLD. The function

multiplies the traces exactly as they appear at the moment that

the AxB key is pressed. When the function is enabled all of the

trace controls are inoperative with the exception of the Trace A

position control which can be used to adjust the position of the

multiplied waveform.

R21. LINE OR DOTS DISPLAY

In line display mode the 1,024 individual points of the display

are joined with angled lines to simulate one continuous line.

This gives a display which is easier to view and less subject to

visual aliasing than one made up of dots (see Appendix B).

Sometimes, however, it is desirable to see the exact points on

the waveform where samples have been taken, along with their

levels. Pressing SHIFT (key 8) followed by DOTS (key 7) causes

the points to be joined by right-angled lines which form a staircase. Since the horizontal lines are brighter than the vertical

ones, this gives an impression of dots and makes it easier to

see each sample point and its associated level.

Also the line display may reduce the amplitude of waveforms

where successive samples can have very large vertical

separations. Such a waveform will also appear brighter if a dots

display is used.

To return to a line display press LINE (key 7). The unit defaults

to a line display after RESET.

R22. PLOT

The waveforms shown on the oscilloscope display can be sent

either to a digital X-Y plotter (HP-GL compatible) using the RS423 interface; or to an analog X-Y plotter or Y-T chart recorder

using the analog plotter interface.

The plot function can be directed either to the RS-423 interface

for use with a digital plotter, or to the analog plotter interface.

The DSA is factory initialised for use with a digital plotter. To

change to use with an analog plotter key in "function 26" (press

FUNCTION NN, followed by 2 followed by 6). To return to use

with a digital plotter key in "function 27".

a) Digital Plotter

The digital plotter must be compatible with HP-GL plotting commands and must be fitted with a serial interface for connection

to the RS-423 interface socket of the DSA. For details of making

connections and of setting the baud rate see Section R25

’RS-423 Interface’. Alternatively, if the DSA has the IEEE-488

interface option fitted, a plotter with an IEEE-488 interface may

be used.

To commence plotting press PLOT (key 6), the time and voltage

per division and a graticule will be plotted followed by Trace A

followed by Trace B. If the plotter is a multi-pen plotter the text

and the graticule will be plotted using pen 1, Trace A will be

plotted using pen 2, and Trace B will be plotted using pen 3.

The entire plot fits onto an A4 sized sheet. To abandon plotting

at any stage press ESCAPE.

b) Analog Plotter

The analog plotter interface is mounted on the rear panel and

comprises five 4mm sockets marked X, YA, GND, YB, and PL

(pen lift).

The waveforms for Trace A and Trace B are sent simultaneously

to their separate output sockets along with an X axis signal for

use with X-Y plotters. The 10.24 divisions of the display are

plotted using a level of 100mV/div (for both Y and X) at a rate

selectable as 1, 2, 5 or 10 seconds per division. The pen-lift

signal is normally "low to lift" but can be inverted.

To set the plot rate, press SHIFT (key 8) followed by SET PLOT

(key 5)., The oscilloscope display will show the present plot

rate. Press one of the REF CURS keys (key 2 or 3) to select a

new value, then press ESCAPE.

Page 9

8

To commence plotting press PLOT (key 6). The oscilloscope display will show a series of prompts for setting the plotter. If RUN /

HOLD is at RUN it will be set to HOLD. To abandon plotting

before it is completed press ESCAPE.

A more complete description of the analog plotter PLOT function

is given in Appendix D.

R23. PRINT

The waveforms shown on the oscilloscope display can be converted to hard-copy using a dot-matrix printer. The printer must

be compatible with EPSON graphics commands (including quad

density bit mapping) and must be fitted with a serial interface for

connection to the RS-423 interface socket of the DSA. For details

of making connections and of setting the baud rate see Section

R25. Baud rates below 2400 are not recommended as the

printing time becomes excessive.

The waveforms are printed with an 8x10 graticule using the same

1:1 aspect ratio as the oscilloscope display. They are preceded by

several lines of text which detail the present settings of the DSA.

Line feeds are arranged so that two prints will fit onto one sheet

of 11 inch paper.

To commence printing, press SHIFT (key 8) followed by PRINT

(key 6). RUN /HOLD will be set to HOLD and printing will commence. To abandon printing before it is completed press ESCAPE.

R24. REMOTE CONTROL AND DIGITAL DATA TRANSFER

The DSA can be fully controlled via its RS-423 serial interface or

its IEEE-488 interface (if fitted). Anything that can be controlled

from the front panel can also be controlled via these digital interfaces. Waveform data can be sent to and from the DSA using the

interfaces, and a variety of other functions are also available.

The software commands for use on either of these interfaces are

listed in Appendix F. ‘Software Commands’.

R25. RS-423 INTERFACE

The DSA524 is fitted with an RS-423 serial interface which is fully

compatible with equipment fitted with an RS-232C interface. It

can be used for remote control of the DSA, for bidirectional data

transfers and for connection to a printer or a digital plotter.

The RS-423 interface is connected via the 9 pin female D

connector mounted on the rear panel. The connections are as

follows:

Pin No. Name Function

2 RXD Input line for sending data to the DSA

3 TXD Output line for sending data from the DSA

5 GND Signal ground line

7 RTS Output line for handshaking (Request to

Send)

8 CTS Input line for handshaking (Clear to Send)

The interface operates with 8 data bits, 1 start bit, 1 or more

stop bits, no parity. If hardware handshaking is not being used,

pin 8 (CTS) must be pulled permanently high, this can be done

by linking it to pin 7 (RTS) and forcing RTS permanently high by

using function 83 (see Section R27). X-on/X-off handshaking can

be used as an alternative to hardware handshaking.

The baud rate is adjustable in binary steps between 300 baud

and 38,400 baud. Once set, the baud rate is stored in nonvolatile memory and will remain set. As shipped from the factory

it is set to 9,600 baud.

To change the baud rate press SHIFT (key 8) followed by SET

BAUD (key 3). The display will show "baud rate = 9600" (for

example). Use the reference cursor keys (keys 2 and 3) to

increase or decrease the rate, then press ESCAPE. If the DSA is

not connected to an oscilloscope the baud rate may be set

directly using the FUNCTION NN key (see Section R27).

Note that as well as the options of 300 through to 38,400 there is

a further option of IEEE. This option is exclusively for use when

the optional IEEE-488 interface board is installed and enabled.

Note that the RS-423 interface cannot be used when the IEEE488 interface is enabled.

Further details of making connections to the RS-423 interface

are given in Appendix E.

A description of the software commands for remote control and

data transfer via the interface is given in Appendix F.

R26. GP-IB (IEEE-488) INTERFACE

An optional module is available which interfaces the DSA524 to

the General Purpose Interface Bus (GP-IB) using the IEEE-488

standard. This option makes all of the functions which are available via the RS-423 interface also available via the GP-IB interface. The interface can be used either with a controller or without a controller in "talker only" mode for connection to a printer

or digital plotter.

A full description of the fitting and operation of the GP-IB interface module is provided in the separate manual supplied with it.

A description of the software commands for remote control and

data transfer via the interface is given in Appendix F. ‘Software

Commands’.

R27. DIRECTLY ACTING FUNCTIONS

Some of the parameters of the DSA which are normally set

interactively using the text readout on the oscilloscope display

can also be set directly using the FUNCTION NN key. These

include setting the baud rate for the RS-423 interface and

setting the analog plotter rate.

A full list of these functions is given below:

Set Analog Plotter Rate 1sec /div 21

2sec/div 22

5sec/div 23

10sec/div 24

Select Analog Plotter Routine auto version 25

Select Analog Plotter Routine prompted version 26

Select Digital Plotter Routine 27

Set Baud Rate 300 30

600 31

1200 32

2400 33

4800 34

9600 35

19200 36

38400 37

IEEE-488 mode 38

Turn bandwidth limiting off 80

Turn bandwidth limiting on (factory default) 81

(a bandwidth limit of about 6MHz is applied

except in repeat mode)

Enable hardware handshaking via RTS (factory default) 82

Disable hardware handshaking via RTS 83

(disabling RTS handshaking forces RTS permanently high)

Note that the RESET function cancels the effect of Function 80.

The following functions are intended for use by Service Engineers only (in conjunction with the appropriate service manuals):

Start analog plotter calibration routine 20

Check display lamps 70

Check keyboard switches 71

Check rotary controls 72

Check DAC output waveform 73

Check RS-423 operation 74

Check Autocal values 75

Return bytes from RS-423 input buffer 76

Clear all set-up parameters 78

Function 78 can be used if the DSA appears to have suffered a

program corruption from which it cannot be made to recover

either by switching the DSA off or by using the RESET function.

Note that the contents of all the memories including the

indexed waveform stores and the PROGRAM memory will be

cleared. Function 78 restores the DSA to the same state as

when it left the factory.

Page 10

9

USERS TUTORIAL

The sophisticated facilities of the DSA524 have resulted in a fairly complex instrument. This "hands-on" tutorial takes the user through

most of the functions of the unit step by step, and provides an easy method of gaining familiarity with its operation.

New users should follow the tutorial exactly and resist the temptation to experiment with functions before they have been covered.

Existing users may find the tutorial useful for covering functions with which they are not yet familiar. Each section is complete in itself

and commences with the DSA being "reset" using SHIFT followed by RESET, and with the signal generator being set to SINE, 20kHz,

5V pk-pk.

INDEX TO THE TUTORIAL

Page

Equipment Required 10

Setting up the Equipment 10

First Steps 10

What to Expect 10

The Display Oscilloscope 10

Front Panel Controls 10

Getting out of Trouble 10

Part One The Basic Functions.

Controlling Digitising 10

Controlling the Input Channels 11

Controlling the Traces 11

Setting the Timebase 12

Normal Mode 11

Roll Mode 12

Repeat Mode 12

Triggering 12

Part Two More Advanced Functions.

More about Triggering 12

More about Roll Mode 13

Memory Search 13

Display Update Rate 13

Indexed Waveform Memories 14

Cursor Measurement 14

Averaging 14

Dot Joining and Interpolation 14

Trace Multiply 15

Program Mode 15

Hardcopy Output 15

Remote Interfacing 15

A Final Word 15

Page 11

10

Equipment Required

1. A conventional real-time oscilloscope for the display, the

minimum specification: 5MHz bandwidth, single channel,

8x10 division graticule.

2. A wide frequency-range signal source, preferably a

function generator. (The tutorial assumes that a function

generator is being used.)

3. Three BNC to BNC connecting cables.

Setting-up the Equipment

1. Connect the rear panel BNC socket of the DSA marked

"composite" to the CH1 input of the oscilloscope.

2. Set the oscilloscope as follows:

Mode: Single channel (CH1)

CH1 input coupling: DC

Sensitivity: 100mV/div

Timebase: 50usecs/div

Trigger source: CH1 (not vertical mode)

Trigger coupling: AC

Trigger slope: Negative

Trigger Level: Negative (slightly)

Sweep delay, sweep

hold-off etc: Zero or minimum

3. Connect the main output of the function generator to the

CH1 input of the DSA. Connect the Sync or TTL output to

CH2.

First Steps

1 Switch on the DSA (the power switch is at the rear). The

oscilloscope should then show the message "CENTRE

ARROW TIP" (alternating with "THEN PRESS ESCAPE").

Adjust the trigger level if necessary.

2. Adjust the vertical and horizontal shift controls of the os-

cilloscope until the arrow tip is in the centre of the

graticule.

3. Set the function generator to SINE, 20kHz, 5V pk-pk.

4. Press the ESCAPE key. Then press SHIFT followed by

RESET. This ensures that all of the more complex functions are cancelled, and that the DSA is put into a known

state as follows:

Both channels ON, 1V /div, AC coupled, 20usec/div AUTO

trigger from CH 1.

The display should now be showing a sine waveform and

a pulse waveform, each of around 5 divisions pk-pk amplitude and around 2.5 divisions period.

What to Expect

The unit is now operating as a digital storage oscilloscope. Both

input signals are being repetitively digitised by an analog to

digital converter (ADC), and stored in a memory the contents of

which is being converted back into analog signals by a digital to

analog converter (DAC) and then displayed on the screen via a

display multiplexer. This process takes a little time, introducing a

slight delay between a change occurring at the input and that

change appearing on the display.

The display multiplexer mixes together the two traces, the trigger

signal and, when needed, text. At the far left of the screen the

valid section of the trace is preceded by a very narrow negative

pulse followed by a horizontal line at the trace zero level (this can

be removed by using a two cable connection — see Appendix A).

Following the valid section, at the far right of the screen, the

trace is shifted up to the top of the display area.

When the display is correctly centred, the valid section of the

traces starts 0.12 divisions to the left of the graticule and ends

0.12 divisions to the right of it. If the timebase of the display

oscilloscope is not perfectly calibrated, the valid section may be

slightly longer or shorter than this.

Each trace is made up of 1024 samples across 10.24 horizontal

divisions of the screen (100 samples per division). Each sample

can be at any of 256 levels within 8.53 vertical divisions (30

levels per division).

Because the display is made up of discrete steps, waveforms do

not look quite the same as they do with an analog oscilloscope.

The minimum level change between samples is one thirtieth of

a division, and even where the input signal level is constant the

digitised level may vary slightly. This variation is caused by

noise on the signal, noise in the input amplifiers, or digitising

noise in the ADC (typically ± )bit) and results in the digitised

waveform looking slightly "ragged" when compared with an

analog oscilloscope. Noise on the waveform of an analog

oscilloscope is averaged out by the eye.

The Display Oscilloscope

Once the display oscilloscope has been set up, no further use

need be made of its controls except for occasional re-centering

of the trace to correct for any warm-up drift. To re-centre the

trace press the two keys marked "SET 'SCOPE" (on the lower

right of the DSA) and adjust the oscilloscope's position controls

to centre the arrow tip.

Front Panel Controls

The front panel of the DSA524 is completely "cold", that is to

say that there are no direct links between the front panel and

the circuitry. All of the controls, including the rotary ones, are

monitored by a microprocessor which then performs the control. All of the switches are of a momentary non-latching type

whose status is indicated either by lamps under the panel or,

where appropriate, by text on the display. This system enables

complete digital programming of the front panel when required.

The keys within the numeric keypad section (right-hand side of

unit) have up to three functions. Their normal function is

printed in black above each key. After the SHIFT key is pressed

the function becomes as printed in green above the key. When

a function ending in (NN) is pressed (e.g. SAVE(NN)) the key

will enter the number printed alongside it.

Note that when SHIFT or a function ending in (NN) is pressed,

the lamp marked ENTER will flash to indicate that one or more

further key presses is required. Any function that causes the

ENTER lamp to flash can be cancelled by pressing that function

key again.

Note that some of the functions (including SET 'SCOPE) automatically set the RUN/HOLD function to HOLD. If digitising

ceases unexpectedly check the condition of RUN /HOLD.

All of the front panel settings are retained when the power is

turned off (except for RUN /HOLD which is always set to HOLD

at power-on).

Getting out of Trouble

If at any stage you lose track of the operation of the DSA, it can

be reset to a known state by pressing SHIFT followed by RESET

(as in First Steps). Each section of the tutorial starts with the

DSA in the "reset" state and the generator set to SINE, 20kHz,

5V pk-pk. Thus it is easy to restart the tutorial at the beginning

of any section.

PART ONE — BASIC FUNCTIONS

The functions covered in this first part of the tutorial are the

ones necessary to operate the DSA524 as a basic digital storage

adaptor.

Controlling Digitising

(Start with the DSA reset and the generator set to SINE, 20kHz,

5V pk-pk.)

The digitising of the input signals is controlled by the two keys

at the top of the TRIG section marked RUN /HOLD and SINGLE.

1. When RUN/HOLD is set to RUN, digitising is repeated

continuously. Try changing the amplitude or frequency

of the generator and note how the display is updated

about three times each second.

Page 12

11

2. When RUN /HOLD is set to HOLD, digitising is stopped.

Press RUN /HOLD to set it to HOLD, then change the output of the generator, and note how the display remains

unchanged.

3. When RUN /HOLD is set to HOLD, pressing the SINGLE

key causes digitising to occur once. Press SINGLE and

note how the display is updated to the new amplitude/frequency of the generator.

Controlling the Input Channels

(Start with the DSA reset and the generator set to SINE, 20kHz,

5V pk-pk.)

The two input channels CH1 and CH2 are identical. They control

the levels of the input signals before they are digitised.

1. The input coupling switches (AC/DC and GND) perform

the same function as on a normal oscilloscope. Try

changing them. Note that when CH1 is grounded the

position of the CH2 waveform on the display becomes

random, this is because the trigger signal has been

removed. Set both channels back to AC.

2. The input sensitivity is variable between 10V/div and 2mV

/div. The key with a downwards arrow sets a lower

volts/div setting and the key with the upwards arrow a

higher one, the keys autorepeat if held depressed. Try

changing the CH1 sensitivity upwards and downwards.

Note that when the input exceeds approximately ± 4.25

divisions on the screen it becomes "clipped", this is

because the range of the digitiser is limited to ± 4.25

divisions. When the input signal is outside the range of the

digitiser, the AUTO/OVLD lamp flashes, this is to warn the

user that the signal is not being correctly digitised (no

damage is being done).

3. Autoranging input sensitivity can be selected on either

channel. Press both arrow keys simultaneously, the AUTO

lamp will come on. Try changing the amplitude of the generator output and note how the sensitivity is automatically

changed to maintain a screen amplitude of between about

1.5 and 3.5 divisions. To cancel autoranging press either

arrow key once.

4. If the DC level of the input signal is not zero, it may be

necessary to apply a DC offset to the signal before it is

digitised. This can be done with the rotary controls

marked OFFSET which can add up to ±8 divisions of

offset. Press the key marked ZERO(VAR) to enable

variable offset (it is enabled when the lamp is off). Try

rotating the offset control and note how the DC level of

the signal is changed. Press the key again to return to

zero offset.

5. The digitising for each channel can be controlled

individually by the keys marked "ON/OFF". These allow

one channel to be "held" while digitising continues on the

other channel. Try turning CH1 off and changing the frequency of the generator, note that the CH2 display continues to be updated but that the CH1 display is frozen.

Note that if both channels are turned off, RUN/HOLD will

be automatically set to HOLD.

Controlling the Traces

(Start with the DSA reset and the generator set to SINE, 20kHz,

5V pk-pk.)

The DSA524 can display two traces simultaneously, the traces are

called Trace A and Trace B. Whereas the input channel controls

(CH1 and CH2) operate on the input to the digitiser, the trace

controls operate on the output signals which are sent to the

display oscilloscope. Normally Trace A is used to display CH1, and

Trace B is used to display CH2, but the traces may alternatively

be used to display waveforms stored in the indexed memories.

1. The POSITION controls define the position of the traces

on the screen and provide ± 4.25 divisions of adjustment.

Press the key marked HOME(VAR) to enable variable position (it is enabled when the lamp is off). Try varying the

position of the traces, note that whereas OFFSET only

affects the waveform when digitising is taking place, POSITION affects it at all times whether RUN/HOLD is at

RUN or HOLD. Press the key again to "home" the trace

position.

2. The GAIN VARIABLE controls can reduce the amplitude

of each trace by any factor between one (fully clockwise)

and five (fully anti-clockwise). Press the CAL(UNCAL) key

to enable variable gain (it is enabled when the lamp is

off). Try varying the gain and note that, because it is

within the trace control section, it operates on the

waveform after it has been digitised and continues to

operate even when the waveform is "held". Press the

key again to return to calibrated gain.

3. Each trace is turned off by simultaneously pressing the

keys marked CH1 (or CH2) and RCL(NN). Try turning a

trace off (note that the CH key should be pressed first to

avoid setting RUN/HOLD to HOLD). To turn the trace

back on press the CH1 (or CH2) key. Do not try using

the RCL(NN) or SAVE(NN) keys at this stage.

4. Trace B has a key marked INV (Invert). Press this key

and note that the trace becomes inverted. Press it again

to turn inversion off.

5. Trace A has a key marked ADD B. Press this key and

note that Trace A then displays the sum of the Trace A

waveform and the Trace B waveform. Note that this can

also be used for subtraction when Trace B is set to

invert. Note also that because add and invert are trace

controls they can still be used when either or both

channels are "held".

Setting the Timebase

(Start with the DSA reset and the generator set to SINE, 20kHz,

5V pk-pk.)

The timebase is adjustable between 50ns/div and 200mins/div.

The timebase speed is set using the two TIME/DIV keys which

autorepeat if held depressed. Setting the timebase speed also

sets the DSA into one of three modes of operation:

1. Normal Mode

1a. Turn off CH2 and Trace B. Try changing the generator

frequency up and down and changing the timebase

speed to maintain a roughly constant period on the

screen (within the range 5us/div to 100ms/div). This is

the "normal" mode of operation whereby the display is

updated each time 40.96 divisions of the waveform have

been digitised. Note that at low timebase speeds the

display update rate becomes slower, this is because of

the increased digitising time (at 100ms/div digitising

takes 4.096 seconds).

1b. Now set a generator frequency of 100Hz and a timebase

speed of 5ms/div. Increase the generator frequency to

1kHz, note that the waveform is starting to become difficult to view. Increase to 2kHz, note that the waveform

can no longer be interpreted as a sine waveform and

appears to have random patterns superimposed onto it.

This is visual aliasing (caused by the vertical separation

between sample points being much greater than the

horizontal separation). Turn on the sweep magnifier of

the display oscilloscope to observe that the waveform is

roughly sinusoidal but is made up of only 10 samples per

cycle.

1c. Now increase the generator frequency to 20kHz and vary

it slightly, note that the waveform changes erratically as

the generator frequency is changed, and that waveforms

with an apparent frequency down to a few Hz can be

obtained. This is true aliasing, caused by the sampling

frequency being less than twice the signal frequency

(the sampling rate equals 100 divided by the time/div,

so at 5ms/div the sampling rate is 20kS /s).

Page 13

12

Aliasing effects are common to all digital storage instruments. Note that to avoid true aliasing the sampling rate

must be greater than twice the signal frequency (time/div

= 50/f) and to avoid visual aliasing the rate must be

greater than ten times the signal frequency (time/div =

10/f).

1d. The DSA524 incorporates a feature which automatically

sets the timebase to avoid aliasing effects and to provide

a sensible waveform period on the screen. Turn off the

sweep magnifier on the display oscilloscope. Press simultaneously the two keys marked AUTOSET within the

timebase section, note that the timebase is automatically

set to 20us/div.

1e. Try changing the generator frequency and using

AUTOSET, note how it sets the timebase to maintain

between 4 and 10 cycles of the waveform across the

screen. (AUTOSET can only operate when a trigger signal

of 50Hz or above is being generated.)

2. Roll Mode

For timebase speeds of 200ms/div and slower, the DSA

enters roll mode (indicated by an audible "beep" and

illumination of the ROLL lamp). In roll mode the waveform

data is written onto the screen continuously as it is being

digitised. This avoids the long delays that would occur if

the screen was only updated after digitising was

completed.

Set the timebase to 200ms/div and the generator to 2Hz,

note how the waveform appears to "roll" across the

screen. Try setting slower timebase speeds and lower

generator frequencies (DC coupling will be necessary for

lower frequencies). Set the timebase as slow as it will go,

note that below 500s/div the SEC and mSEC lamps illuminate together to indicate minutes (speeds as low as 200

minutes/div can be set enabling waveform capture over

many hours).

3. Repeat Mode

The maximum sampling rate of the DSA524 is 20MS /s

(which is obtained at 5us/div). This is the maximum rate

that can be used to capture single event signals. However,

if the signal is repetitive, repeat mode can be used. This

builds the waveform up by repeatedly digitising it, and can

provide equivalent sampling rates up to 2GS /s. For timebase speeds of 2us/div and faster the DSA enters repeat

mode (indicated by a "beep" and illumination of the RPT

lamp).

3a. Set the generator to 200kHz and set the timebase set to

2us/div (or press AUTOSET), note that the waveform is

being digitised at an equivalent rate of 50MS /s. Vary the

generator frequency slightly and note that the display

update rate is slower in repeat mode, and that the first

screen update after the signal is changed is invalid (this is

because the waveform is built up from multiple

digitisations).

3b. Ground the CH1 input and note that updating of the

screen ceases and a message "NO TRIGGER" appears on

the screen (this is because repeat mode requires a repetitive trigger signal to be able to operate). Un-ground the

input and increase the generator frequency. Increase the

timebase speed and note that waveforms up to 35MHz

can be captured (this is limited by the input amplifier

bandwidth of the DSA) using timebase speeds of up to

50ns/div (2GS /s equivalent sampling rate). Note also that

the update rate is slowest at the fastest timebase speeds

when in repeat mode.

4. Turn on CH2 and Trace B. Note that the repeat mode

update rate is slower when both channels are turned on.

Set the timebase speed down to 20us/div noting that

when both channels are on, the ALT lamp illuminates for

speeds of 10us/div and faster, and that the CHOP lamp

illuminates for speeds of 20us/div and slower. CHOP

indicates that both input channels are digitised together

(on opposite cycles of the sampling clock) while ALT

indicates that the input channels are digitised alternately

(CH2 followed by CH1). Thus if digitising is un-triggered,

or if the input signals do not have a constant relationship

to the trigger signal, phase relationships between the

signals will not be maintained above 20us/div.

Triggering

(Start with the DSA reset and the generator set to SINE, 20kHz,

5V pk-pk.)

The trigger controls for the DSA524 are broadly similar to those

on a conventional oscilloscope. The exceptions are EVENTS DLY

and TIME DLY.

1. SOURCE The source of the trigger signal can be CH1,

CH2, or EXT (external via the BNC socket below the

trigger controls). Note that only AC coupling is available

via the external input.

2. MODE The mode switch has three positions, AUTO,

NORM, and LINE. AUTO mode is similar to Bright-Line

Auto on a conventional oscilloscope. Digitising is performed in synchronism with the trigger signal but, if the

trigger signal ceases or the trigger repetition rate falls

below 20Hz, digitising continues but without synchronism. In NORM (normal) mode, digitising stops if the

trigger signal ceases. In LINE mode, digitising is

performed in synchronism with AC line (50 or 60 Hz).

Try removing the trigger signal by setting SOURCE to

external, note that digitising continues (without

synchronism) in AUTO mode, but ceases in NORM mode.

2.

LEVEL, SLOPE and COUPL (coupling) The function of

these controls should be self explanatory. To enable

variable trigger level, press the key marked ZERO(VAR

I (variable level is enabled when the lamp is off). Try

using all of the trigger controls, then return them to

their original settings.

PART TWO — MORE ADVANCED FUNCTIONS

The functions covered in the first part of the tutorial enable the

user to operate the DSA524 as a basic digital storage

oscilloscope. This second part covers the more advanced

features which would not be found on a basic DSO.

More about Triggering

(Start with the DSA reset and the generator set to SINE, 20kHz,

5V pk-pk.)

1. TIME DLY (time delay) With TIME DLY off, digitising

starts immediately following a trigger. Thus the left-hand

edge of the trace shows the waveform immediately after

the trigger point. TIME DLY shifts the point at which

digitising starts to allow the trace to show the waveform

either before the trigger (pre trigger delay) or after the

trigger (post trigger delay).

Set the generator to 5kHz; the trace should now show

about one cycle of the waveform starting at the trigger

point. Press the TIME DLY (minus) key, note that the

message "TIME DLY = +0000 DIV" is displayed. Press

the key again to decrement the number to —0001 (note

that the keys only increment or decrement when the

message is being displayed, on the first press they

merely cause the current delay value to be shown).

The trace should now start one division before the

trigger point. Try incrementing and decrementing the

delay using the + and — keys, note that the trace can

be positioned anywhere relative to the trigger point (in

steps of one division) and that the PRE and POST lamps

illuminate for negative and positive delays respectively.

The maximum pre trigger delay is —40 divs and the

maximum post trigger delay is + 9999 divs. Note that

the + and — keys autorepeat if held depressed, and that

the delay can be set back to zero at any time by

Page 14

13

pressing both keys simultaneously.

Post trigger time delay can be used to expand a small sec-

tion of a waveform (as in a sweep-delay oscilloscope). Set

a delay of +0002 so that the peak of the sinewave is

within the first division of the screen. Now increase the

timebase to 5usec/div, note that the delay is increased to

+0008 divs so as to maintain a constant time delay thus

keeping the sinewave peak within the trace area.

Note that time delay is not available in RPT mode, and

that only post trigger time delay is available in ROLL

mode. Time delay is automatically set to zero whenever

the timebase is set into RPT or ROLL.

2. EVENTS DLY (events delay) This function enables the

triggering of the digitising to be delayed by up to 15

trigger events. See the reference section of the manual for

a full explanation.

More about Roll Mode

(Start with the DSA reset and the generator set to SINE, 20kHz,

5V pk-pk.)

Because in roll mode the waveform data is written continuously

onto the display, it is not necessary to continually stop and

restart the digitising process. Consequently when RUN/HOLD is

set to RUN, digitising takes place continuously and triggering is

disabled.