Model 2900 System Manual

Thunder Scientific Corporation

Model 2900 Humidity Generation System

Document #OM2900 - Edition 2.0

OPERATION AND

MAINTENANCE MANUAL

Model 2900 Humidity Generation System

Thunder Scientific®

70% PROPYLENE GLYCOL 2 bottles for your system

Corporation

2900 Item Check List

1. Certificate of Calibration (In Chamber)

2. Quick Start Guide

3. HumiCalc® with Uncertainty Software Download

4. Chamber Port Plugs

5. Keyboard

6. Power Cable

7. Torx Driver with Screws

8. Reservoir Fluid Funnel

9. Chamber Fill Funnel

10. Plugs, ¼ Swagelok

11. Elbow, ¼ Tube x ¼ NPT

12. Communication Cable (DB9)

13. USB Serial Converter

14. Plastic Beaker 1000ML

15. 3/8" Plastic Elec Flex Conduit 36”

16. Velcro Straps 2 Ea.

17. Temp Probe or UT Cap Tool

18. Chamber Fluid

1. Optional Equipment – Air Compressor Power Cable

2. ACS2520 – Air Compressor System Manual

3. Air Hose – On Air Box

4. ACS Remote Control Cable

Thunder Scientific Corporation Web: www.thunderscientific.com

623 Wyoming Blvd. SE E-mail: support@thunderscientific.com

Albuquerque, NM 87123 Phone: 1-800-872-7728

IMPORTANT

NOTICE

IMPORTANT

NOTICE

DO NOT LOSE THIS FLYER

Go to this website to register your Model 2900 Humidity Generator and

download your software for FREE.

https://www.thunderscientic.com/product_registration

Once you have registered your Model 2900 Humidity Generator, click the link on the same page, labeled

Click here if you need to download your FREE software. Click here if you need to download your FREE software.

Or go to this URL https://www.thunderscientic.com/software/

Next, click on which software type you need, and go to that page, then click the Download Now button.

After downloading your software, open the ZIP le and install your software.

This is a trusted download link form Thunder Scientic, Thank You for your purchase.

For:

HumiCalc with Uncertainty Software Package Download

®

IMPORTANT CONTROLOG PASSWORD INFORMATION

User: 2900

Manager: 2900.1

Administrator: Contact Thunder Scientic Technical Support

(1-800-872-7728 or support@thunderscientic.com)

Humidity Generation and Calibration Equipment

®

The Humidity Source

Thunder Scientific Corporation

623 Wyoming Blvd SE

Albuquerque, NM 87123-3198

U. S. A.

Model 2900

www.thunderscientific.com

Suomi

English

Tämä tuote noudattaa WEEE-direktiivin (2002/96/EY)

merkintävaatimuksia. Kiinnitetty etiketti osoittaa, että tätä

sähkö-/elektroniikkalaitetta ei saa hävittää kotitalousjätteissä.

Tuoteluokka: Viitaten WEEE-direktiivin liitteessä I mainittuihin

laitteisiin, tämä tuote on luokiteltu luokan 9 “Tarkkailu- ja

ohjauslaitteet” -tuotteeksi.

Ei saa heittää kotitalousjätteiden mukana!

Palauta tarpeettomat tuotteet ottamalla yhteyttä valmistajan

websivustoon, joka mainitaan tuotteessa tai paikalliseen

myyntitoimistoon tai jakelijaan.

Dansk

Dette produkt er i overensstemmelse med kravene om afmærkning

i WEEE-direktivet (2002/96/EC). Det påhæftede mærkat angiver,

at du ikke må bortskaffe dette elektriske/elektroniske produkt via

husholdningsaffald.

Produktkategori: Med reference til kravene i WEEE-direktivets

bilag I klassificeres dette produkt som et produkt til “overvågning

og kontrolinstrumentering” i kategori 9.

MÂ ikke bortskaffes via husholdningsaffald!

Hvis du vil returnere uønskede produkter, skal du besøge

producentens websted, som vises på produktet, eller den lokale

forhandler eller distributør.

This product complies with the WEEE Directive (2002/96/EC) marking

requirements. The affixed label indicates that you must not discard

this electrical/electronic product in domestic household waste.

Product Category: With reference to the equipment types in the

WEEE Directive Annex I, this product is classed as category 9

“Monitoring and Control Instrumentation” product.

Do not dispose in domestic household waste!

To return unwanted products, contact the manufacturer’s web site

shown on the product or your local sales office or distributor.

Français

Ce produit est conforme aux normes de marquage de la directive

DEEE (2002/96/CE). La présence de cette étiquette indique que

cet appareil électrique/électronique ne doit pas être mis au rebut

avec les déchets ménagers.

Catégorie de EEE : Cet appareil est classé comme catégorie 9 parmi

les « instruments de surveillance et de contrôle » en référence aux

types d’équipements mentionnés dans l’Annexe I de la directive DEEE.

Ne pas éliminer avec les autres déchets ménagers !

Pour renvoyer les produits indésirables, contacter le site Web du

fabricant mentionné sur le produit, ou son distributeur ou bureau de

ventes local.

Español

Este producto cumple la Directiva WEEE (2002/96/EC) sobre

requisitos de las marcas. La etiqueta que lleva pegada indica

que no debe desechar este producto eléctrico o electrónico con

los residuos domésticos.

Categoría del producto: con referencia a los tipos de equipo

del anexo I de la Directiva WEEE, este producto está clasificado

como categoría 9 de “Instrumentación de supervisión y control”.

¡No lo deseche con los residuos domésticos!

Para devolver productos que no desee, póngase en contacto con

el sitio Web del fabricante mostrado en el producto, o con la oficina

de ventas o distribuidor local.

PN 2566073, 1/2006

Deutsch

Nederlands

Dieses Produkt stimmt mit den Kennzeichnungsanforderungen

der WEEE-Richtlinie (2002/96/EC) überein. Das angebrachte

Etikett weist darauf hin, dass dieses elektrische/elektronische

Produkt nicht in Hausmüll entsorgt werden darf.

Produktkategorie: In Bezug auf die Gerätetypen in Anhang

I der WEEE-Richtlinie ist dieses Produkt als Kategorie 9

“Überwachungs- und Kontrollinstrument” klassifiziert.

Nicht in Hausmüll entsorgen!

Zur Rückgabe von unerwünschten Produkten die auf dem

Produkt angegebene Website des Herstellers oder die zuständige

Verkaufsstelle bzw. den zuständigen Fachhändler konsultieren.

Italiano

Questo prodotto risponde ai requisiti sull’etichettatura stabiliti

nella Direttiva RAEE (2002/96/CE). Il simbolo apposto indica che

non si deve gettare questo prodotto elettrico o elettronico in un

contenitore per rifiuti domestici.

Categoria del prodotto: con riferimento ai tipi di apparecchiature

elencate nell’Allegato 1 della Direttiva RAEE, questo prodotto

rientra nella categoria 9 “Strumenti di monitoraggio e di controllo”.

Non gettare in un contenitore per rifiuti domestici.

Per restituire prodotti non desiderati, visitare il sito Web del

produttore riportato sul prodotto o rivolgersi al distributore o

all’ufficio vendite locale.

Dit product voldoet aan de merktekenvereisten van de AEEArichtlijn (2002/96/EG). Het aangebrachte merkteken duidt erop dat

dit elektrische/elektronische product niet met het huishoudelijk

afval mag worden afgevoerd.

Productcategorie: Met betrekking tot de apparatuurcategorieën

van bijlage I van de AEEA-richtlijn, valt dit product onder categorie

9 ‘meet- en controle-instrumenten’.

Niet afvoeren met huishoudelijk afval!

Om ongewenste producten te retourneren, neemt u contact op

met de website van de fabrikant die op het product staat vermeld,

of met uw plaatselijke verkoopkantoor of distributeur.

Svenska

Denna produkt uppfyller märkningskraven enligt WEEE Directive

(2002/96/EC). Märkningsetiketten anger att du inte får kassera denna

elektriska/elektroniska produkt tillsammans med vanliga hushållssopor.

Produktkategori: Med hänvisning till utrustningstyperna i

WEEE Directive Annex I, är denna produkt klassad som kategori 9

“Monitoring and Control Instrumentation” (Instrument för

övervakning och styrning).

Får ej kasseras tillsammans med vanliga hushållssopor!

Returnera ej önskvärda produkter genom att gå till tillverkarens

webbplats, vilken anges på produkten, eller till det lokala

försäljningskontoret eller distributören.

Português

Este produto está em conformidade com as exigências de rotulagem

da Directiva WEEE (2002/96/EC). O rótulo afixado indica que o

utilizador não deve deitar este produto eléctrico/electrónico fora

juntamente com o lixo doméstico.

Categoria do produto: No que se refere aos tipos de equipamento listados no Anexo I da Directiva WEEE, este produto está classificado como

produto da categoria 9, “Instrumentação de monitorização e controlo”.

Não deite fora juntamente com o lixo doméstico!

Para devolver produtos indesejados, contacte o fabricante através do

Website constante do produto ou contacte o seu representante de

vendas ou distribuidor local.

Norsk

Dette produktet oppfyller bestemmelsene ifølge WEEE-direktiv

(2002/96/EC) med krav til merking. Påsatt merke viser at det ikke

er tillatt å kassere dette elektriske/elektroniske produktet sammen

med husholdningsavfall.

Produktkategori: På grunnlag av utstyrstypene i WEEEdirektivet, vedlegg I, er dette produktet klassifisert i kategori 9,

“Instrumentering for overvåking og kontroll”.

Må ikke kastes sammen med husholdningsavfall!

Ved behov for returforsendelse av uønskede produkter må du gå

til produsentens nettside som er angitt på produktet, eller du må

kontakte det lokale salgskontoret eller den lokale forhandleren.

1 TABLE OF CONTENTS

2 Getting Started 6

2.1 About ....................................................................................................................................................... 6

2.2 Notice ....................................................................................................................................................... 7

2.3 Safety Information ................................................................................................................................... 7

2.3.1 Live Power Source ........................................................................................................................ 7

2.3.2 Electrostatic Discharge .................................................................................................................. 7

2.3.3 Compressed Gas ............................................................................................................................ 7

2.3.4 Personal Protective Equipment...................................................................................................... 7

2.3.5 Safety Symbols .............................................................................................................................. 7

2.4 Technical Support .................................................................................................................................... 8

2.5 License Agreement .................................................................................................................................. 8

2.6 Warranty ................................................................................................................................................ 10

2.7 Copyright ............................................................................................................................................... 10

2.8 Trademarks ............................................................................................................................................ 10

2.9 Specifications ......................................................................................................................................... 11

2.10 Uncertainty ............................................................................................................................................ 12

2.11 Facility Requirements ............................................................................................................................ 13

2.11.1 Environment ................................................................................................................................ 13

2.11.2 Floor Space .................................................................................................................................. 13

2.11.3 Power........................................................................................................................................... 13

2.11.4 Air Supply ................................................................................................................................... 13

2.11.5 Distilled Water Supply ................................................................................................................ 13

2.12 Installation.............................................................................................................................................. 14

2.12.1 Uncrating ..................................................................................................................................... 14

2.12.2 Positioning ................................................................................................................................... 14

2.12.3 Chamber Fluid ............................................................................................................................. 14

2.12.4 Reservoir Initial Filling Procedure .............................................................................................. 16

2.12.5 Setting Supply Pressure Regulator .............................................................................................. 16

2.13 Quick Start ............................................................................................................................................. 17

2.13.1 Power-Up .................................................................................................................................... 17

2.13.2 Loading Screen ............................................................................................................................ 18

2.13.3 ControLog Screen ....................................................................................................................... 19

2.13.4 Control Parameters ...................................................................................................................... 20

2.13.5 Control Modes ............................................................................................................................. 22

2.13.6 Generating and Shutting down .................................................................................................... 23

2.13.7 Power-Off .................................................................................................................................... 24

2.13.8 Set Date and Time ....................................................................................................................... 25

2.13.9 Help ............................................................................................................................................. 26

3 Principle of Operation 27

3.1 Pre-Saturation (T

3.2 Expansion Valve (T

3.3 Saturation Temperature (TS) .................................................................................................................. 28

3.4 Chamber Temperature (TC) .................................................................................................................... 28

3.5 Saturation Pressure (PS) ......................................................................................................................... 28

3.6 Chamber Pressure (PC) ........................................................................................................................... 28

3.7 Humidity Formulas ................................................................................................................................ 28

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

) .............................................................................................................................. 27

Psat

) ......................................................................................................................... 27

ExV

1

4 ControLog Interface 29

4.1 Menu Bar ............................................................................................................................................... 30

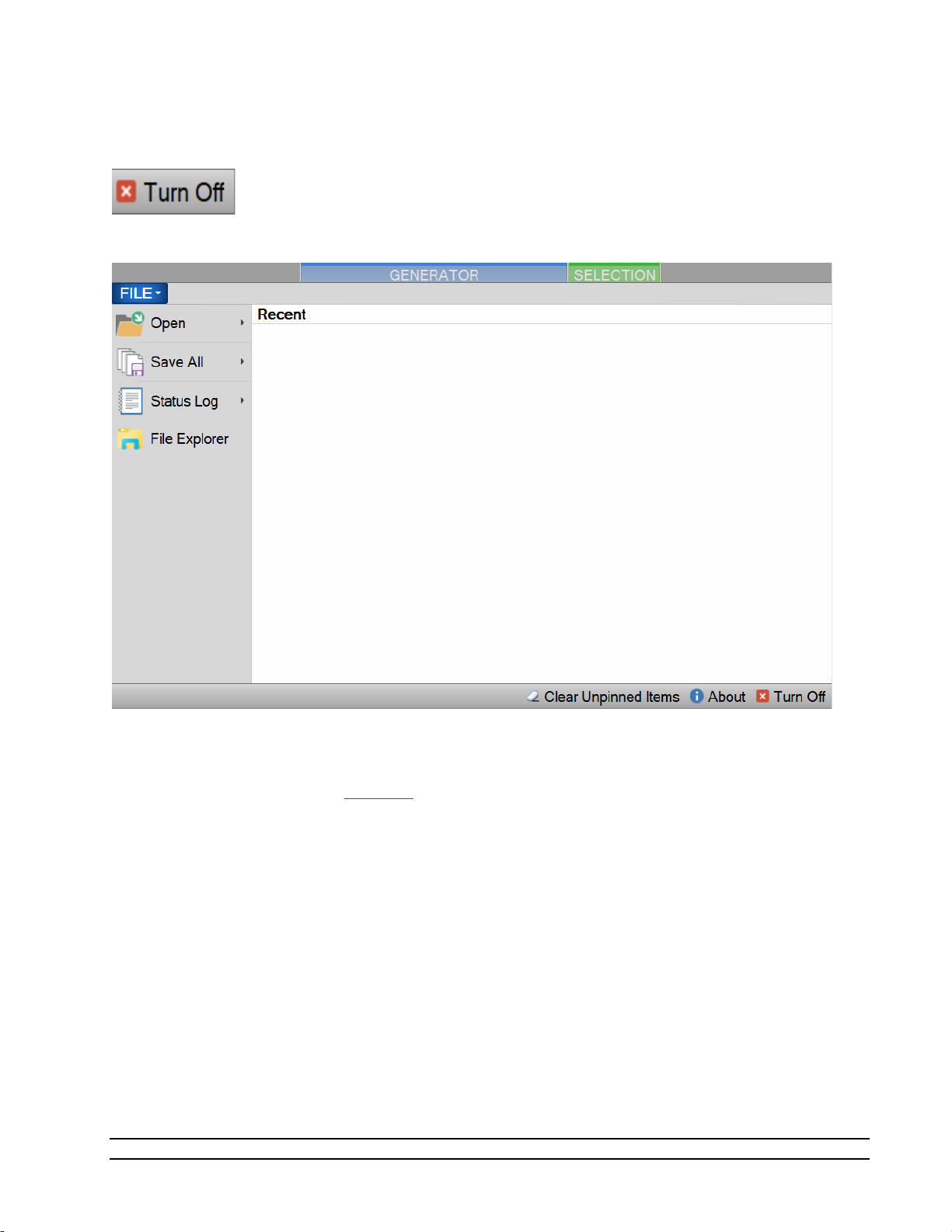

4.1.1 File Menu Tab ............................................................................................................................. 30

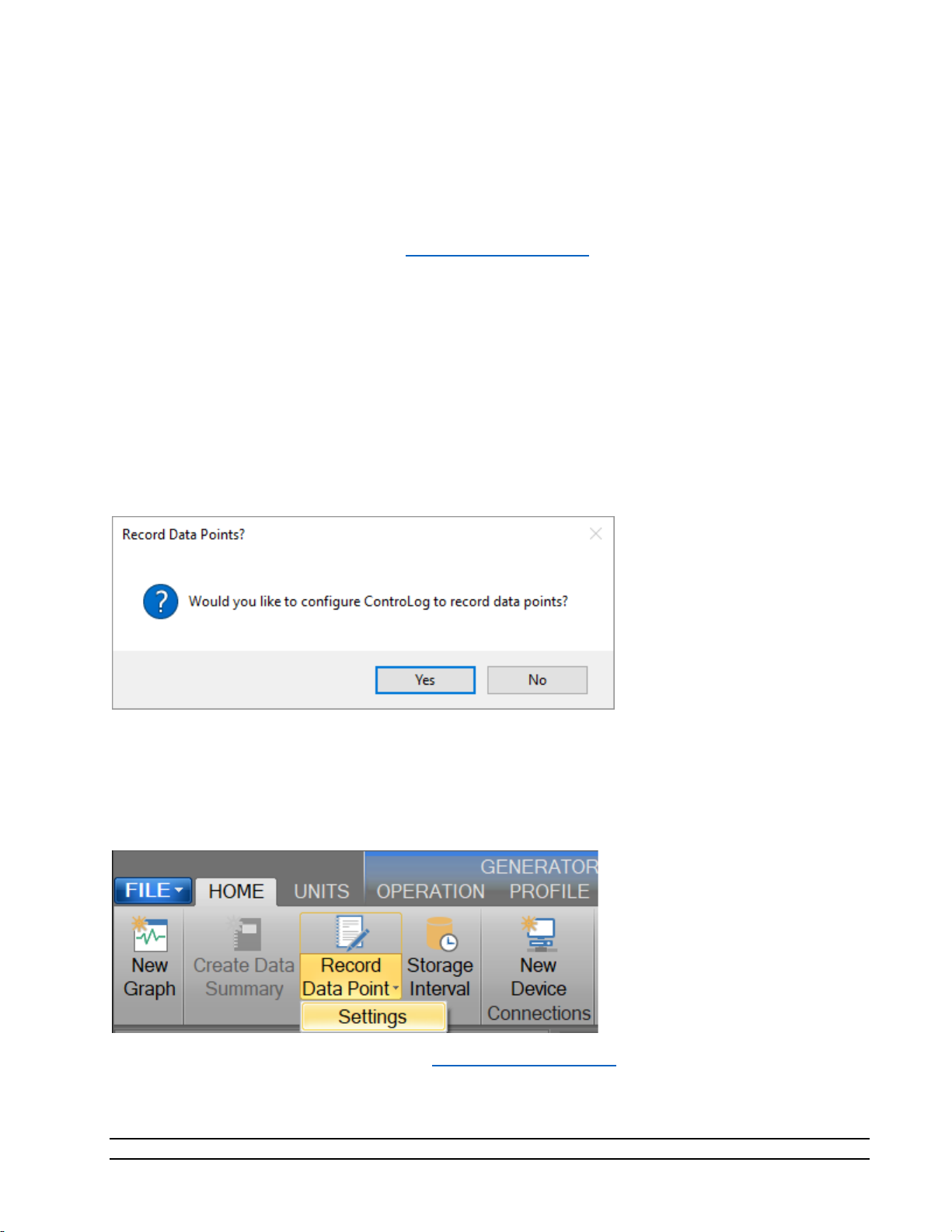

4.1.2 Home Menu Tab .......................................................................................................................... 34

4.1.3 Units Menu Tab ........................................................................................................................... 37

4.1.4 Operation Menu Tab ................................................................................................................... 38

4.1.5 Profile Menu Tab ........................................................................................................................ 41

4.1.6 Utilities Menu Tab ...................................................................................................................... 43

4.1.7 Graph Menu Tab ......................................................................................................................... 47

4.1.8 Data Menu Tab ............................................................................................................................ 49

4.1.9 Device Settings Menu Tab .......................................................................................................... 53

4.1.10 Help ............................................................................................................................................. 55

4.2 Parameters Tab Group ........................................................................................................................... 56

4.2.1 Tiles ............................................................................................................................................. 58

4.2.2 2900 Parameter Tab .................................................................................................................... 62

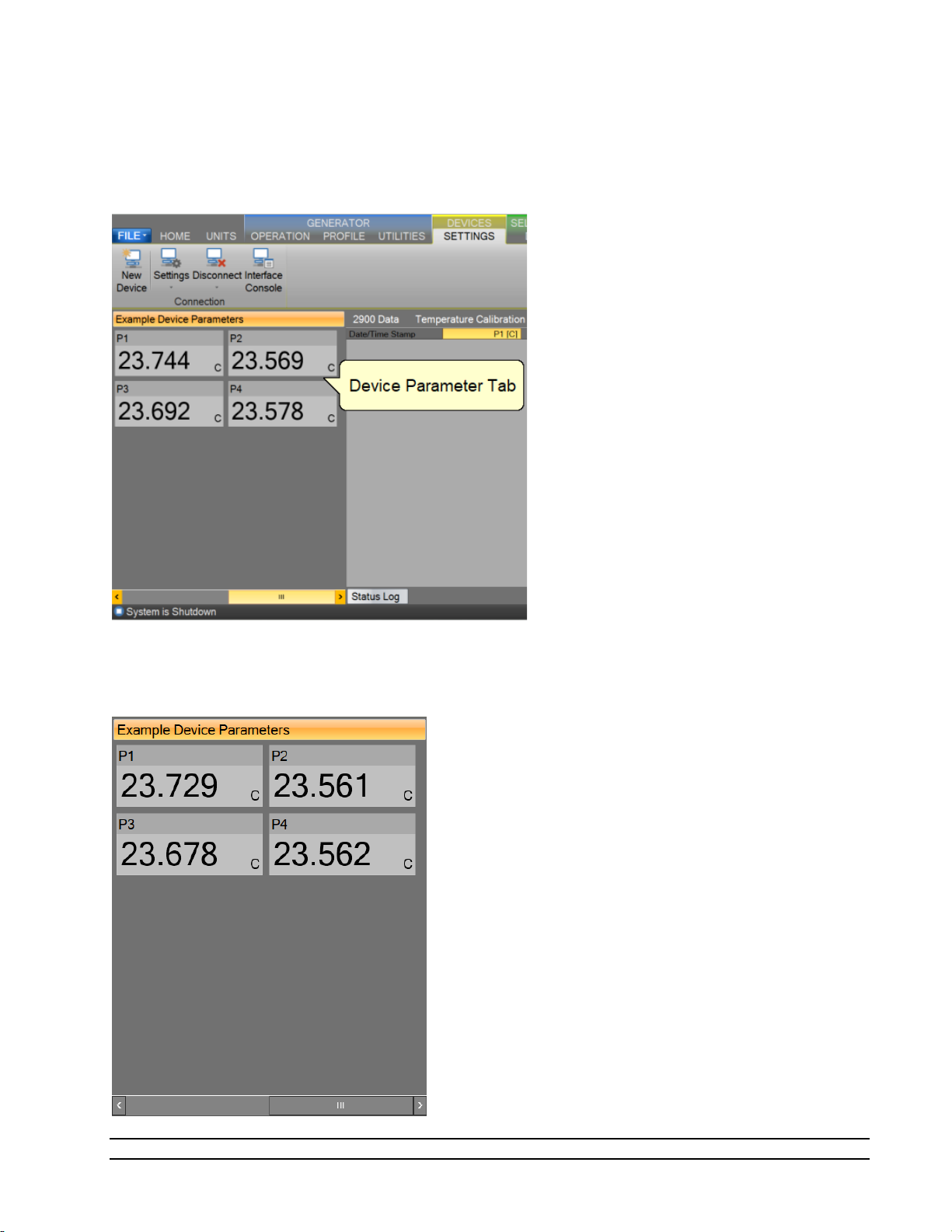

4.2.3 Device Parameter Tabs ................................................................................................................ 67

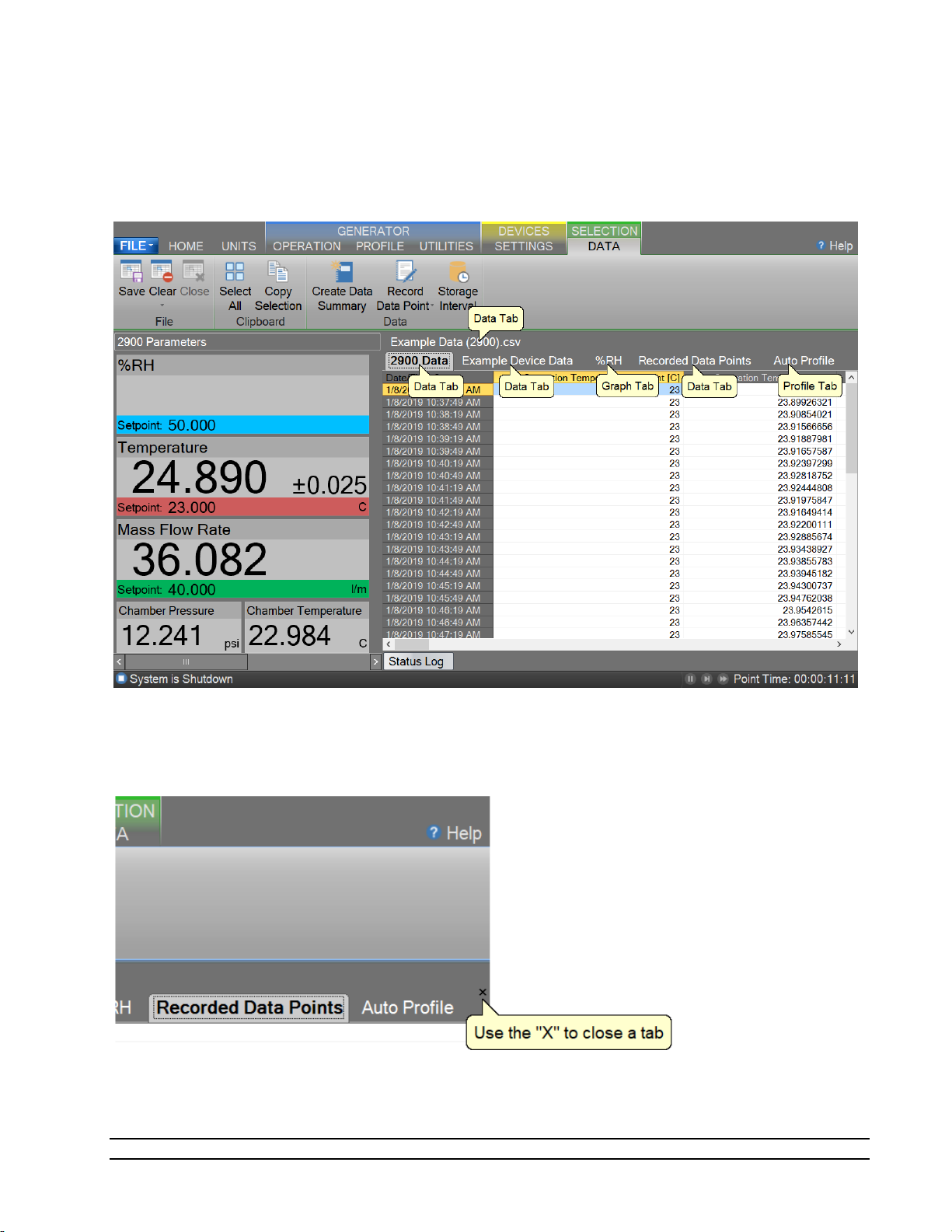

4.3 Data and Graph Tab Group .................................................................................................................... 68

4.3.1 Data Tabs .................................................................................................................................... 69

4.3.2 Graph Tabs .................................................................................................................................. 69

4.3.3 Profile Tab ................................................................................................................................... 69

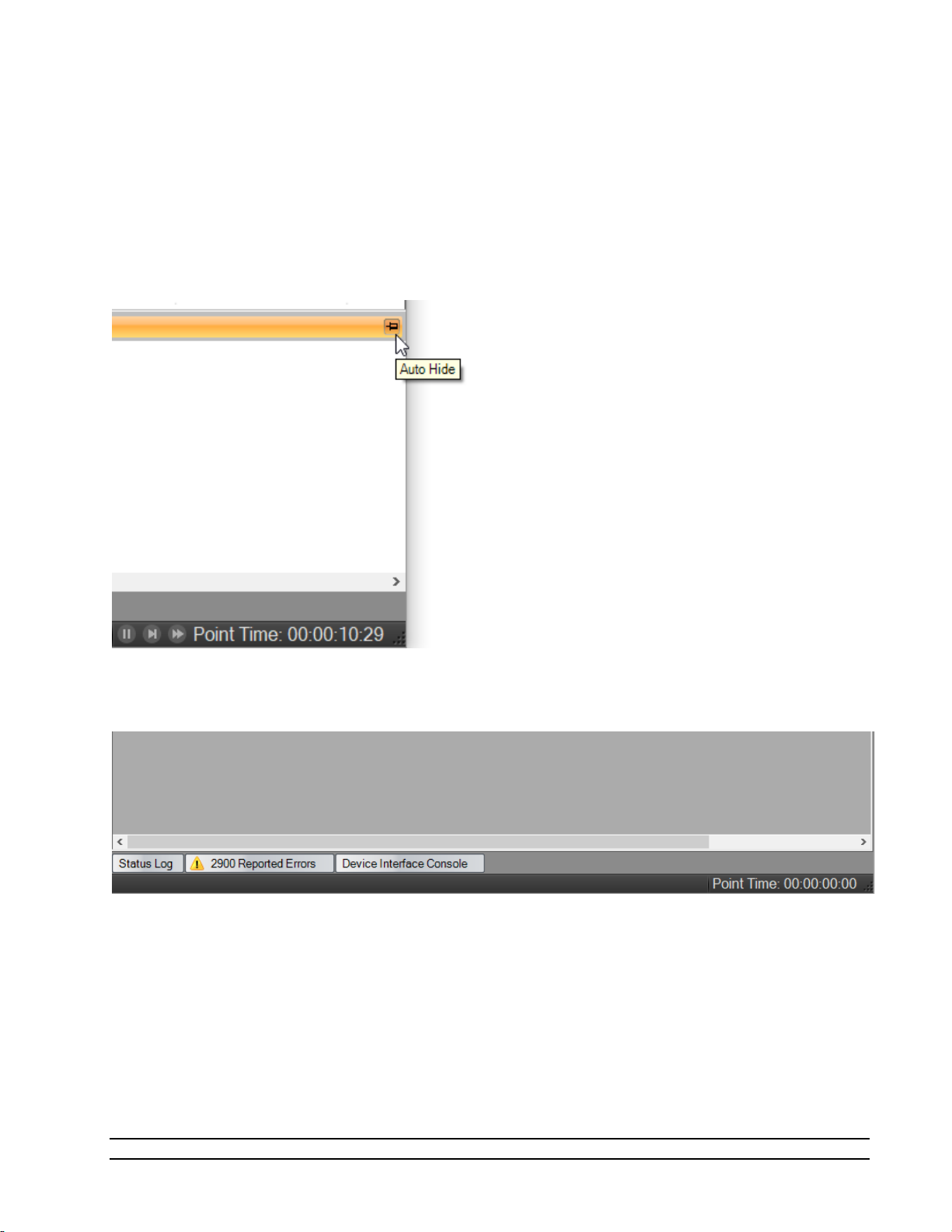

4.4 Information Tab Group .......................................................................................................................... 70

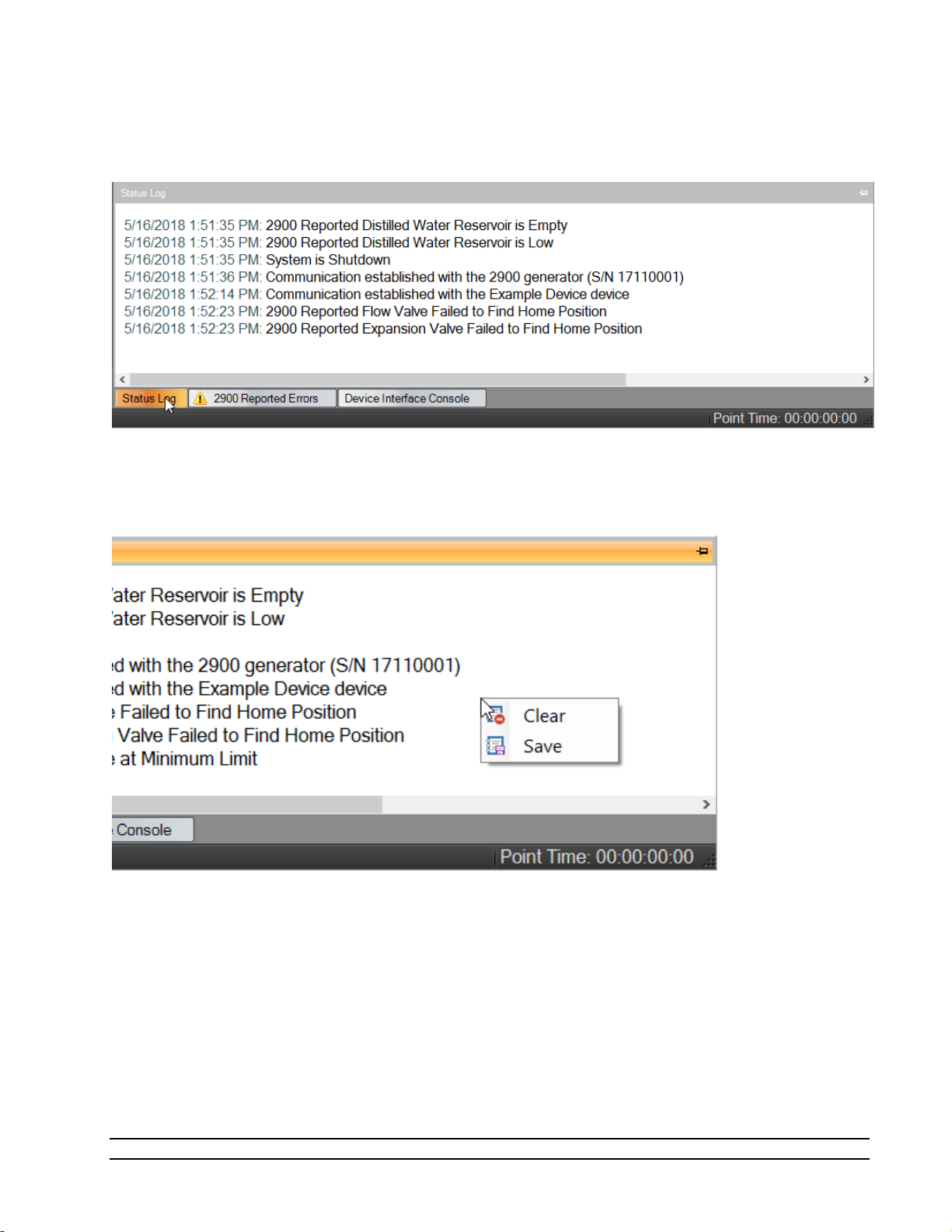

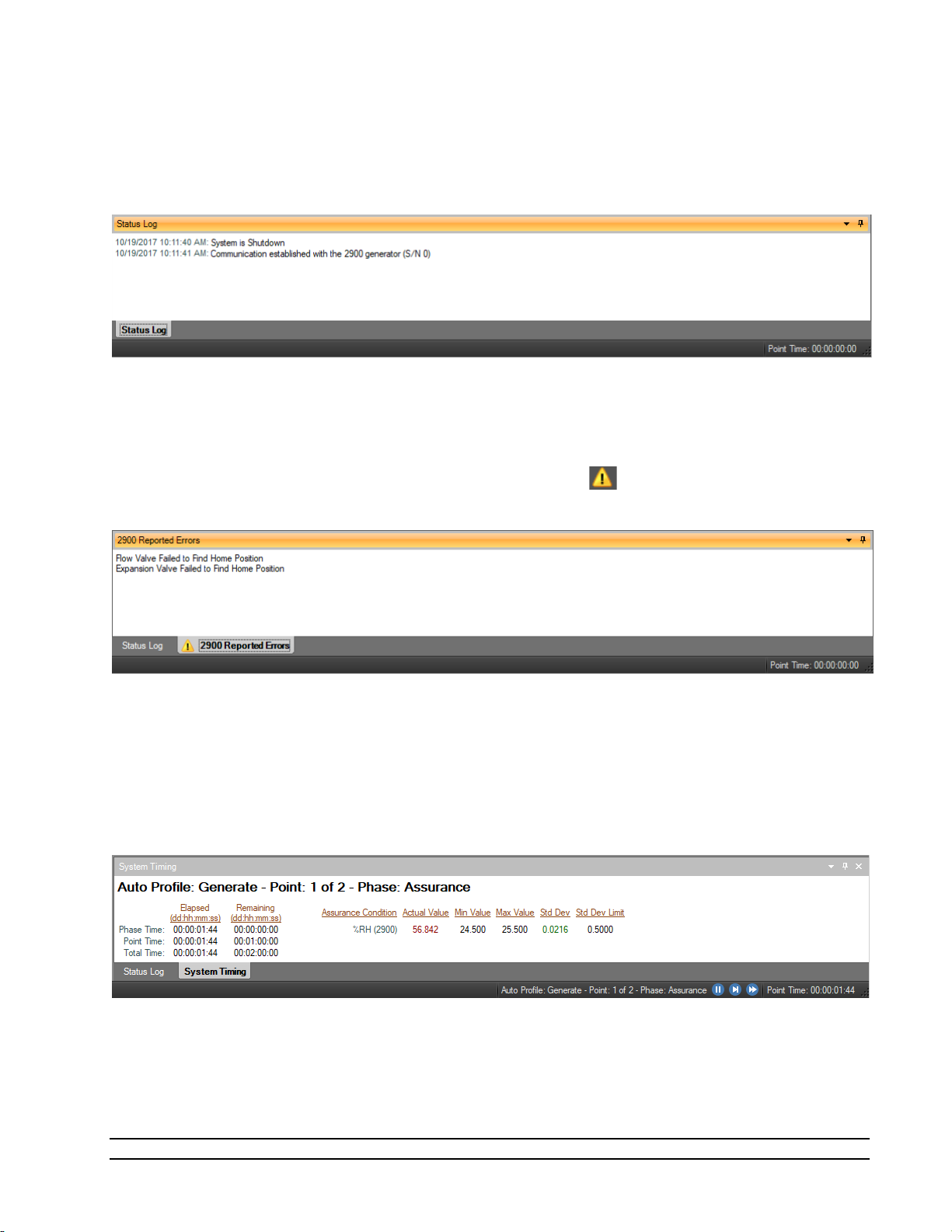

4.4.1 Status Log .................................................................................................................................... 72

4.4.2 2900 Reported Errors .................................................................................................................. 72

4.4.3 System timing .............................................................................................................................. 72

4.4.4 2900 Interface Console ................................................................................................................ 72

4.4.5 Device Interface Console ............................................................................................................ 73

4.5 Status Bar ............................................................................................................................................... 74

4.5.1 Connection and Run Status ......................................................................................................... 74

4.5.2 Auto Profile Controls and Status ................................................................................................. 75

4.5.3 Current Point Time ...................................................................................................................... 76

4.5.4 Set Date and Time ....................................................................................................................... 76

5 Fluid Levels 78

5.1 Water Reservoir Level ........................................................................................................................... 78

5.1.1 Fill Water Reservoir .................................................................................................................... 79

5.2 Liquid Level Sensors ............................................................................................................................. 80

5.2.1 Pre-Saturator Level ..................................................................................................................... 80

5.2.2 Flow Switch ................................................................................................................................ 81

6 Calibration 82

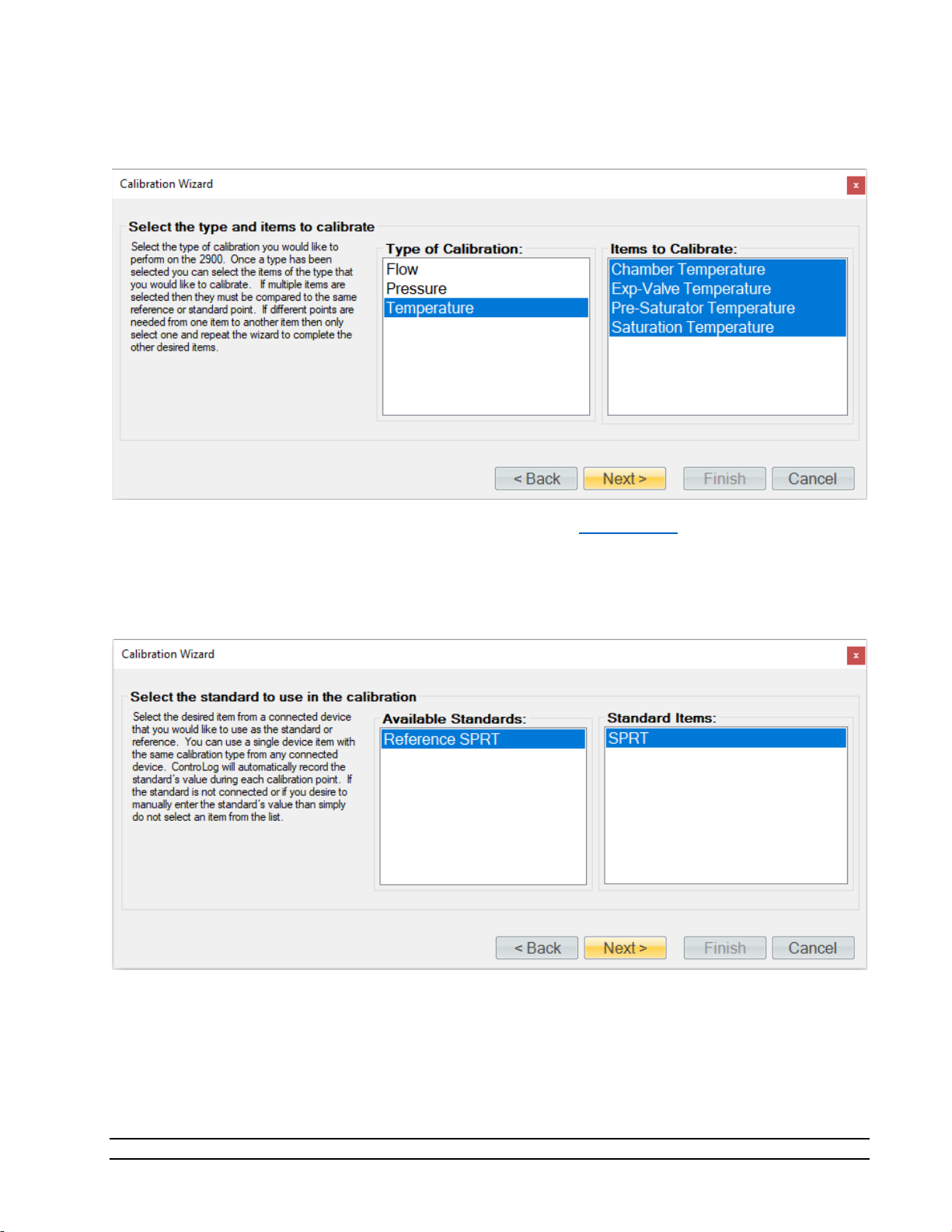

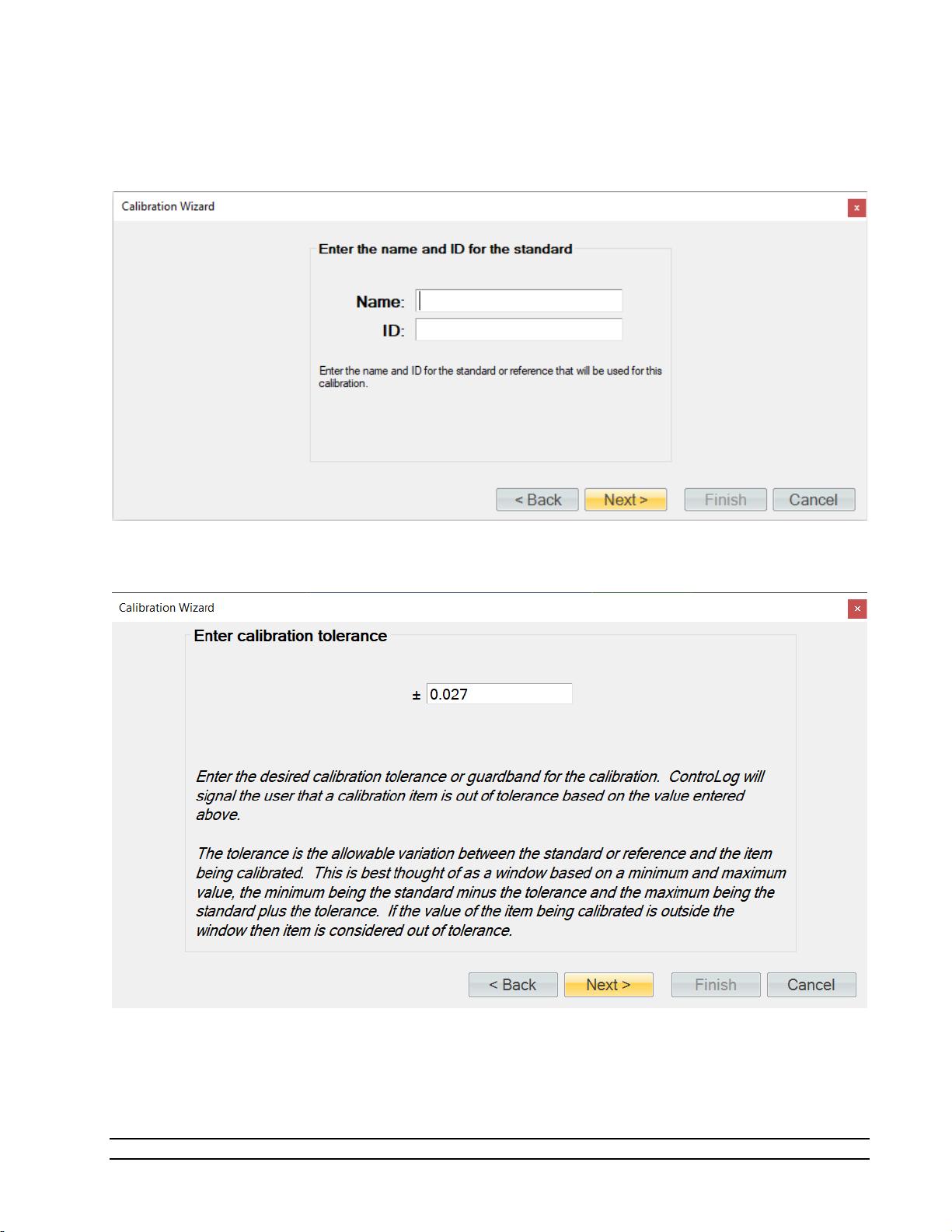

6.1 Temperature Calibration ........................................................................................................................ 82

6.1.1 Equipment Required .................................................................................................................... 83

6.1.2 Calibration Procedure .................................................................................................................. 83

6.2 Pressure Transducer Calibration .......................................................................................................... 103

6.2.1 Equipment Required .................................................................................................................. 103

6.2.2 Calibration Procedure ................................................................................................................ 103

6.2.3 Supply Pressure ......................................................................................................................... 121

6.3 Mass Flow Meter Calibration............................................................................................................... 122

6.3.1 Equipment Required .................................................................................................................. 122

6.3.2 Calibration Procedure ................................................................................................................ 122

6.4 Viewing and Editing Calibration Coefficients ..................................................................................... 139

7 Graphing 143

2

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

7.1 Creating a New Graph .......................................................................................................................... 144

7.1.1 Line Properties .......................................................................................................................... 146

7.1.2 Chart Properties ......................................................................................................................... 147

7.2 Customizing a Graph ........................................................................................................................... 148

7.2.1 Pan ............................................................................................................................................. 148

7.2.2 Zoom ......................................................................................................................................... 149

7.2.3 Zoom Graph’s X Axis ............................................................................................................... 150

7.2.4 Zoom Graph’s Y Axis ............................................................................................................... 151

7.2.5 Auto Scale ................................................................................................................................. 151

7.2.6 Scale .......................................................................................................................................... 151

7.2.7 Scale X Axis .............................................................................................................................. 151

7.2.8 Scale Y Axis .............................................................................................................................. 151

7.2.9 Graph Properties ........................................................................................................................ 152

7.3 Saving a Graph ..................................................................................................................................... 155

8 Data and Data Summary 157

8.1 Device Data Tabs ................................................................................................................................. 161

8.2 File Data Tabs ...................................................................................................................................... 162

8.3 Data Summary Tabs ............................................................................................................................. 165

8.3.1 Creating a Data Summary ......................................................................................................... 166

8.4 Recorded Data Points Tab .................................................................................................................... 173

8.4.1 How to Record a Data Point ...................................................................................................... 174

9 Auto Profiling 179

9.1 Creating a New Profile ......................................................................................................................... 181

9.2 Saving a Profile .................................................................................................................................... 193

9.3 Opening a Profile ................................................................................................................................. 195

9.4 Running an Auto Profile ...................................................................................................................... 197

9.4.1 Understanding Profile Phases .................................................................................................... 199

9.4.2 Manual Override of Profile ....................................................................................................... 202

10 Connections 205

10.1 Serial Connection ................................................................................................................................. 206

10.1.1 Serial Connection Example 1 .................................................................................................... 221

10.1.2 Serial Connection Example 2 .................................................................................................... 233

10.2 Analog Connection .............................................................................................................................. 250

10.2.1 Analog Connection Example ..................................................................................................... 260

10.3 Manual Connection .............................................................................................................................. 269

10.3.1 Manual Connection Example .................................................................................................... 273

10.4 Opening a Device Connection ............................................................................................................. 282

10.5 External Control ................................................................................................................................... 282

11 Data Backup 283

12 System 284

12.1 Control System ..................................................................................................................................... 284

12.1.1 Control Computer ...................................................................................................................... 284

12.1.2 HMI Computer .......................................................................................................................... 285

12.1.3 ControLog® Software ............................................................................................................... 285

12.1.4 HumiCalc with Uncertainty® Software ..................................................................................... 286

12.2 Electrical System.................................................................................................................................. 286

12.2.1 Solid State Relays ...................................................................................................................... 287

12.3 Pneumatic System ................................................................................................................................ 288

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

3

12.3.1 Pressure Measurement ............................................................................................................... 288

12.3.2 Mass Flow Rate Measurement .................................................................................................. 288

12.3.3 Pre-Saturator.............................................................................................................................. 289

12.3.4 Reservoir ................................................................................................................................... 289

12.3.5 Saturator .................................................................................................................................... 289

12.3.6 Flow Control Valve ................................................................................................................... 289

12.3.7 Expansion Valve ....................................................................................................................... 290

12.3.8 Chamber Pressure ...................................................................................................................... 290

12.3.9 Test Chamber ............................................................................................................................ 290

12.4 Fluid System ........................................................................................................................................ 290

12.4.1 Liquid Level Measurement ....................................................................................................... 290

12.4.2 Fluid Flow Measurement........................................................................................................... 290

12.4.3 Temperature Controlled Chamber Fluid.................................................................................... 291

12.4.4 Chamber Fluid Heating ............................................................................................................. 291

12.4.5 Chamber Fluid Refrigeration ..................................................................................................... 291

12.4.6 Temperature Measurement ........................................................................................................ 291

12.4.7 Fluid Jacket Door Option .......................................................................................................... 291

13 Maintenance 292

13.1 Drain Pre-Saturator .............................................................................................................................. 292

13.2 Chamber Fluid ..................................................................................................................................... 293

13.3 Air Input Filters (Mobile Cart) ............................................................................................................. 293

13.4 Circulation Pump Motor ...................................................................................................................... 293

13.5 Pre-Saturator Liquid Level Checkout .................................................................................................. 294

13.6 Reservoir Liquid Level Checkout ........................................................................................................ 294

13.7 Warning and Error Messages ............................................................................................................... 294

13.7.1 Saturation Temperature at Minimum Limit ............................................................................... 294

13.7.2 Saturation Temperature Over Range or at Maximum Limit ...................................................... 295

13.7.3 Pre-Saturation Temperature at Minimum Limit ........................................................................ 295

13.7.4 Pre-Saturation Temperature Over Range or at Maximum Limit ............................................... 295

13.7.5 Expansion Valve Temperature at Minimum Limit .................................................................... 295

13.7.6 Expansion Valve Temperature Over Range or at Maximum Limit ........................................... 295

13.7.7 Chamber Temperature at Minimum Limit ................................................................................ 295

13.7.8 Chamber Temperature Over Range or at Maximum Limit ....................................................... 295

13.7.9 Cabinet Temperature Over Range or at Minimum/Maximum Limit - Check Cabinet Fans ..... 295

13.7.10 Insufficient Supply Pressure to Generate .................................................................................. 296

13.7.11 Supply Pressure Over Range or at Maximum Limit ................................................................. 296

13.7.12 Saturation Pressure at Minimum Limit ..................................................................................... 296

13.7.13 Saturation Pressure Over Range or at Maximum Limit ............................................................ 296

13.7.14 Saturation Pressure Transducer Not Responding ...................................................................... 296

13.7.15 Chamber Pressure at Minimum Limit ....................................................................................... 296

13.7.16 Chamber Pressure Over Range or at Maximum Limit .............................................................. 296

13.7.17 Chamber Pressure Transducer Not Responding ........................................................................ 296

13.7.18 Mass Flow Rate at Minimum Limit .......................................................................................... 296

13.7.19 Mass Flow Rate Over Range or at Maximum Limit ................................................................. 297

13.7.20 Refrigeration Compressor Low Side Pressure at Minimum Limit ............................................ 297

13.7.21 Refrigeration Compressor Low Side Pressure Over Range or at Maximum Limit ................... 297

13.7.22 Refrigeration Compressor High Side Pressure at Minimum Limit ........................................... 297

13.7.23 Refrigeration Compressor High Side Pressure Over Range or at Maximum Limit .................. 297

13.7.24 Flow Valve Reported Error: ...................................................................................................... 297

13.7.25 Flow Valve Failed to Find Home Position ................................................................................ 297

13.7.26 Flow Valve at Minimum Limit.................................................................................................. 297

13.7.27 Flow Valve at Maximum Limit ................................................................................................. 297

13.7.28 Expansion Valve Reported Error: ............................................................................................. 298

13.7.29 Expansion Valve Failed to Find Home Position........................................................................ 298

4

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

13.7.30 Expansion Valve at Minimum Limit - Check for air leaks........................................................ 298

13.7.31 Expansion Valve at Maximum Limit - Reduce Mass Flow Rate .............................................. 298

13.7.32 Distilled Water Reservoir is Empty ........................................................................................... 298

13.7.33 Distilled Water Reservoir is Low .............................................................................................. 298

13.7.34 Unable to Fill Pre-Saturator ...................................................................................................... 298

13.7.35 No Fluid Flow ........................................................................................................................... 298

13.7.36 No Saturation Fluid Heat ........................................................................................................... 298

13.7.37 No Pre-Saturator Heat ............................................................................................................... 299

13.7.38 No Expansion Valve Heat ......................................................................................................... 299

13.7.39 System Failed to Vent Pressure on Shutdown ........................................................................... 299

13.7.40 Mass Flow Rate is being limited to achieve Humidity setpoint. ............................................... 299

13.7.41 Insufficient Supply Pressure to reach setpoint .......................................................................... 299

14 Drawings and Diagrams 300

14.1 18D29901-1 - Part List ........................................................................................................................ 301

14.2 18D29901-2 – 2900 Components ........................................................................................................ 302

14.3 18D29901-3 – 2900 Components (Back) ............................................................................................. 303

14.4 18D29901-4 – 2900 Components (Top) .............................................................................................. 304

14.5 18D29901-5 – Pneumatic Schematic ................................................................................................... 305

14.6 18D29901-6 – Fluid Schematic ........................................................................................................... 306

14.7 18D29901-7 – Refrigeration Schematic ............................................................................................... 307

14.8 18D29901-8 – Pneumatic Components................................................................................................ 308

14.9 18D29901-9 – Refrigeration Components ........................................................................................... 309

14.10 18D29901-10 – Electrical Components ............................................................................................... 310

14.11 18D29901-11 – Data Acq. Components .............................................................................................. 311

14.12 18D29908 – Chamber Fan Components .............................................................................................. 312

14.13 18D29909-1 – Chamber Fluid Filling Instructions .............................................................................. 313

14.14 18D29909-2 – Chamber Fluid Draining Instructions ........................................................................... 314

14.15 18D29910-1 – Cart / ACS Assembly ................................................................................................... 315

14.16 18D29910-2 – Exhaust Hose Assembly ............................................................................................... 316

14.17 18D29910-3 – Filter / Regulator Assembly ......................................................................................... 317

14.18 18D29910-4 – Cart Pneumatic System Schematic ............................................................................... 318

14.19 18S29911 – AC / DC Power Distribution ............................................................................................ 319

14.20 18S29912 – Temperature Probe Schematic ......................................................................................... 320

14.21 18S29913 – Pre Tran/Stepper Drive Schematic ................................................................................... 321

14.22 18S29914 – Transducer Schematic ...................................................................................................... 322

14.23 18S29915 – Pump / Comp / Flow Schematic ...................................................................................... 323

14.24 18S29916 – Exp. valve / Fluid Heater Schematic ................................................................................ 324

14.25 18S29917 – Pre Saturator Heater Schematic ....................................................................................... 325

14.26 18S29918 – Solenoid Valve Control Schematic .................................................................................. 326

14.27 18S29919 – Fan Control Schematic ..................................................................................................... 327

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

5

2 GETTING STARTED

This section will provide the user with information about the Model 2900 humidity generator, where to obtain

technical support, software license agreement, specifications, uncertainty, facility requirements and

installation. Following sections will provide further details on how to use and operate the Model 2900

generator using the ControLog software.

Note

- All pressures are absolute unless noted otherwise.

2.1 ABOUT

The Thunder Scientific Model 2900 Humidity Generator is capable of producing known humidity values using

the fundamental, NIST proven, "two-pressure" principle. The Model 2900 uses this fundamental “twopressure” principle to continuously supply a known relative humidity, dew point, frost point, parts per

million, or other calculated value for instrument calibration and evaluation as well as precision

environmental testing.

The Model 2900 humidity generator encompasses a high-performance stand-alone Data Acquisition

Computer that performs all functions required for humidity generation and control and a second dedicated

Human Machine Interface (HMI) computer that runs ControLog. ControLog is a software application that

fully automates the operation of the Model 2900 humidity generator and allows various device connections

through a number of different interfaces. Data from the generator and connected device or devices is

automatically retrieved and stored for viewing in either numerical or graphical format in real time or post

process. Data can be transferred off the system via a USB drive for further viewing, post processing and

printing. The ControLog software also provides the primary interface to the operator via the multi-point

touch LCD and keyboard.

Key features of the of the ControLog software are:

• ControLog stores data into individual data sheets (tab). Each data sheet contains a spreadsheet

type view that consists of a date/time stamp and the measured data items corresponding to that

date/time stamp. Data sheets consist of three similar but different types: Device Data, File Data

and Data Summary. Each type has the same spreadsheet type view and operation, but all three

have different data sources.

• Graphing is a powerful tool used to view previously recorded data or to monitor the current data in

real-time. The graph works hand in hand with the data sheets. While the generator is in operation,

data sheets store the most recent data points from the generator and or connected devices at the

desired interval. A graph can be used to create a visual picture of this stored data.

• The Auto Profiling feature is very similar to the Generate mode with the main exception that

profiling relies on a predefined list of setpoints referred to as a profile. The user configurable profile

is used as ControLog's road map during Auto Profile operation. It defines which setpoint values to

go to, at what rate to go from one setpoint to another, and how long to stay at a specific setpoint

before moving to the next setpoint.

• ControLog supports a customizable interface that works with most devices. ControLog will allow

the user to create a new device connection using the “Connection Wizard” or open previously saved

connections. The wizard will open a separate dialog window containing various steps that will guide

the user in defining the communication required to receive the desired data items from the

6

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

device. The user can create as many (up to 60) or as few data items as they see fit for any one

device. Each data item can be uniquely named and once connected will be recorded in its own data

sheet. ControLog also allows the user to save these interfaces for future use. The “Connection

Wizard” allows the user to step through the connection configuration. Using the “Next” and “Back”

buttons the user is allowed to progress through the connection configuration steps. At any time,

the user may cancel the new connection or opening of a connection by selecting the “Cancel”

button. Once the last step has been completed the “Finish” button will be available to complete

the new connection.

2.2 NOTICE

The specifications listed and the information contained in this document is subject to change without notice.

Screen shots shown in this document may differ slightly from the actual product and are given to show

functionality of the examples, procedures and program. Thunder Scientific Corporation makes no warranties,

either express or implied, regarding the examples, procedures and program, or the fitness of these examples,

procedures or program for a particular purpose. The examples, procedures and program are made available

solely on an "as is" basis and the entire risk as to their quality and performance rests with the user. Thunder

Scientific Corporation shall not be liable for any incidental or consequential damages in connection with or

arising out of the furnishing, use, or performance of the examples, procedures or program.

2.3 SAFETY INFORMATION

Important safety guidelines need to be observed when operating this equipment. Precautions are highly

advisable so that no personal injury will occur during the operation and maintenance of the system.

Observation of local and national regulations must be adhered to regarding safety standards.

2.3.1 Live Power Source

Warning! Make sure all power sources are turned off before making internal adjustments or replacing any

components. Only authorized technicians should perform any maintenance or repairs to equipment.

2.3.2 Electrostatic Discharge

Caution! Electrostatic discharge (ESD) could possibly damage or destroy solid-stat parts when exposed to

static electric discharges. Be aware because electrostatic discharges may not be seen, felt or heard at levels

less than 4,000 volts.

2.3.3 Compressed Gas

Compressed gas is used on this system and if not properly vented may create an environment where the

state of foreign matter may be propelled. Proper safety precautions must be fallowed when applying any

pressure to the system. Before applying any pressure to the system, ensure that all pneumatic connections

are properly secured and tightened. Make sure all pressure settings are set to the proper specifications

before operation, testing, calibration, or maintenance is performed.

2.3.4 Personal Protective Equipment

Safety glasses must be worn when preforming any maintenance, repairs, or calibration when system panels

have been removed. Gloves may be needed on some maintenance or repairs.

2.3.5 Safety Symbols

Symbols used in this manual for safety and other disciplines can be found in table 1-1.

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

7

Safety terminology used for identification of any safety conditions are as follows:

Symbol

Description

The equipment has this symbol displayed

directives.

This symbol is shown from the WEEE

This symbol means Caution should be

This symbol indicates a potential shock

This symbol means Earth Ground.

Warning indicates a potential hazard may exist and the user should be extremely careful.

Caution! identifies a condition or action that may cause damage to the system or the user.

and indicates that the equipment meets

the requirements of the European safety

directive and indicates do not dispose of

this product in any municipal waste area.

observed or important information.

hazard may exist.

Table 1-1

2.4 TECHNICAL SUPPORT

If the user requires assistance with any aspect of the 2900 Humidity Generating System or the ControLog

application, technical support can be obtained by contacting Thunder Scientific Corporation by any of the

following means:

Web: www.ThunderScientific.com

Email: support@thunderscientific.com

Tel : 1-505-265-8701

FAX : 1-505-266-6203

2.5 LICENSE AGREEMENT

THIS IS A LEGAL AGREEMENT BETWEEN YOU, THE END USER, AND THUNDER SCIENTIFIC

CORPORATION ("TSC"). THE ENCLOSED THUNDER SCIENTIFIC CORPORATION SOFTWARE PROGRAM

(THE "SOFTWARE ") IS LICENSED BY THUNDER SCIENTIFIC CORPORATION TO THE ORIGINAL

CUSTOMER AND ANY SUBSEQUENT TRANSFEREE OF THE PRODUCT FOR USE ONLY ON THE TERMS SET

FORTH HERE. PLEASE READ THIS LICENSE AGREEMENT. IF YOU DO NOT AGREE TO THESE TERMS,

RETURN THE FULL PRODUCT WITH PROOF OF PURCHASE WITHIN 30 DAYS FOR A FULL REFUND.

•GRANT OF LICENSE. TSC grants to you the right to use one copy of the enclosed SOFTWARE on a single terminal

connected to a single computer (i.e. single CPU) or to a network server. If you install the SOFTWARE on a network

s

erver, you must purchase a separate copy of the SOFTWARE for each computer terminal that will be used to operate the

SOFTWARE. If the anticipated number of users of the SOFTWARE will exceed the number of applicable Licenses, the

you

must have a reasonable mechanism in place to ensure that the number of persons using the SOFTWARE concurrentl

n

y

8

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

does not exceed the number of Licenses. If the SOFTWARE is permanently installed on the hard disk or other storage

device of a computer (other than a network server) and one person uses that computer more than 80% of the time, then

that person may also use the SOFTWARE on a portable or home computer.

• COPYRIGHT. The SOFTWARE is owned by TSC and is protected by United States copyright laws and international

treaty provisions. You may either (a) make two copies of the SOFTWARE solely for backup or archival purposes provided

that you reproduce all copyright and other proprietary notices that are on the original copy of the SOFTWARE provided

to you, or (b) transfer the SOFTWARE to a single hard disk provided you keep the original solely for backup or archival

purpose. You may not copy the written materials accompanying the SOFTWARE.

• OTHER RESTRICTIONS. You may not rent or lease the SOFTWARE, but you may transfer the SOFTWARE and

accompanying written materials on a permanent basis provided you retain no copies and the recipient agrees to the terms

of this Agreement. You may not reverse engineer, decompile, disassemble, or create derivative works from the

SOFTWARE.

SOFTWARE and written materials

• GOVERNMENT LICENSEE. If you are acquiring the SOFTWARE on behalf of any unit or agency of the United States

Government, the following provisions apply:

The Government acknowledges TSC's representation that the SOFTWARE and its documentation were developed at

private expense and no part of them is in the public domain.

The Government acknowledges TSC's representation that the SOFTWARE is "Restricted Computer Software" as that term

is defined in Clause 52.227-19 of the Federal Acquisition Regulations (FAR) and is "Commercial Computer Software" as

that term is defined in Subpart 227.471 of the Department of Defense Federal Acquisition Regulations Supplement

(DFARS).

The Government agrees that:

(i) If the SOFTWARE is supplied to the Department of Defense (DoD), the SOFTWARE is classified as

"Commercial Computer Software" and the Government is acquiring only "restricted rights" in the SOFTWARE

and its documentation as that term is defined in Clause 252.227-7013(c) (1) of the DFARS, and

(ii) If the SOFTWARE is supplied to any unit or agency of the United States Government other than DoD, the

Government's rights in the SOFTWARE and its documentation will be as defined in Clause 52.227-19 (c) (2) of

the FAR.

• RESTRICTED RIGHTS LEGEND. Use, duplication, or disclosure by the Government is subject to restrictions as set

forth in subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013.

Thunder Scientific Corporation, 623 Wyoming SE, Albuquerque, NM 87123.

• EXPORT LAW ASSURANCES. You acknowledge and agree that the SOFTWARE is subject to restrictions and controls

imposed by the United States Export Administration Act (the "Act") and the regulations thereunder. You agree and certify

that neither the SOFTWARE nor any direct product thereof is being or will be acquired, shipped, transferred or re-exported,

directly or indirectly, into any country prohibited by the Act and the regulations thereunder or will be used for any purpose

prohibited by the same.

• GENERAL. This Agreement will be governed by the laws of the State of New Mexico, except for that body of law

dealing with conflicts of law.

Should you have any questions concerning this Agreement, or if you desire to contact TSC for any reason, please write:

Thunder Scientific Corporation, 623 Wyoming NE, Albuquerque, NM 87123

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

9

2.6 WARRANTY

MADE IN USA

Thunder Scientific Corporation (TSC) warrants, to the Buyer, the Product manufactured by TSC to be free

of defects in material and workmanship under normal use and service and to be free from inadequate

mechanical design when operated within the specified design limitations for a period of one year from date

of acceptance. TSC's obligation under this warranty shall be limited to the following: The Product is

returned to TSC with transportation charges prepaid and that TSC's examination reveals the Product to be

defective. TSC, at its option, shall either refund to the Buyer the purchase price of the product or repair or

replace at TSC's plant, any part or parts of the Product which is or are defective. This warranty shall not

apply to any Product which has been maintained, handled, stored, repaired or altered in any manner, or by

anyone other than an authorized TSC representative, so as to affect adversely such Product or which has

been subject to improper installation, misuse, negligence, accident or corrosion. THIS WARRANTY IS

EXCLUSIVE AND IN LIEU OF ANY WARRANTY OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE OR ANY OTHER WARRANTY, WHETHER EXPRESS OR IMPLIED,

AND ALL OTHER LIABILITIES AND OBLIGATIONS ON THE PART OF TSC; TSC SHALL NOT

BE LIABLE FOR ANY OTHER CLAIMS OR DAMAGES, EITHER DIRECT OR CONSEQUENTIAL,

ARISING DIRECTLY OR INDIRECTLY OUT OF SUPPLYING THE PRODUCT. All warranties,

express or implied, with respect to any device or component not manufactured by TSC but incorporated

into its Product are the responsibility of the original manufacturer and shall not affect or apply to TSC.

2.7 COPYRIGHT

©2009-2022 Thunder Scientific Corporation

623 Wyoming Blvd. SE

Albuquerque, New Mexico 87123, USA

This document contains proprietary information which is protected by copyright. All rights are reserved. No

part of this document may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose without the prior written consent of

Thunder Scientific Corporation.

2.8 TRADEMARKS

ControLog is a trademark of Thunder Scientific Corporation.

HumiCalc is a trademark of Thunder Scientific Corporation.

THUNDER SCIENTIFIC is the registered trademark of Thunder Scientific Corporation

Microsoft Software License Terms Last updated July 2017

Follow this link to view Microsoft’s Software License Terms or scan this QR code to download your copy.

https://www.microsoft.com/enus/Useterms/OEM/Windows/10/UseTerms_OEM_Windows_10_English.htm

icrosoft Corporation 2022 - https://www.microsoft.com/en-us/

M

10

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

2.9 SPECIFICATIONS

Relative Humidity Range: ............................................................................ 10 to 95 %RH, 10 to 40 L/min

1

Relative Humidity Range:

Frost Point Temperature Range: ........................................................................................... -33.60 to 0 °C

Dew Point Temperature Range: ......................................................................................... -36.94 to 70 °C

Chamber Fluid Temperature Range:

Chamber Fluid Temperature Control Stability:

Chamber Temperature Uniformity:

Chamber Fluid Temperature Heating Rate: from -10 to 72 °C ....................... 0.5 °C per Minute (average)

Chamber Fluid Temperature Cooling Rate: from 72 to 0 °C ........................... 0.5 °C per Minute (average)

Chamber Fluid Temperature Cooling Rate: from 0 to -10 °C .......................... 0.2 °C per Minute (average)

Temperature Specification: ........................................................................................................... 0.027 °C

Gas Type: ............................................................................................................................. Air or Nitrogen

Gas Pressure Rating: (MAWP) ....................................................................................................... 175 psiG

Gas Flow Rate Range: ........................................................................................................... 10 to 50 L/min

Gas Flow Rate Specification: ................................................................................................ 5% of full scale

Saturation Pressure Range: ......................................................................................... Ambient to 160 psiA

Saturation Pressure Specification: ................................................................................. 0.02% of full scale

Test Chamber Pressure Range: ..................................................................................... Ambient to 17 psiA

Test Chamber Pressure Specification: .............................................................................. 0.02% of reading

Supply Pressure Range: ............................................................................................... Ambient to 150 psiG

Supply Pressure Specification: ......................................................................................................... ±1 psiG

Display Resolution: .............................................................................................................................. 0.001

Test Chamber Dimensions: ......................................... 12” x 12” x 10” (304.8 mm x 304.8 mm x 254 mm)

Physical Dimensions: ....................................... 22” H x 36” W x 23” D (558.8 mm x 432 mm x 584.2 mm)

.......................................................................... 95 to 98 %RH, 10 to 20 L/min

2

..................................................................................... -10 to 72 °C

3

........................................................................... 0.002 °C

4

............................................................................................. < 0.04 °C

1

The system will limit mass flow rate to 20 L/min for %RH greater than 95.

2

Only the glycol/water heat transfer fluid circulating around the chamber is controlled to setpoint via the saturation

temperature probe. Chamber temperature inside the chamber may vary depending on door configuration, setup, and

uniformity. Note: the 2900 can only operate for a finite amount of time at or below 0 °C.

3

Temperature Control Stability is defined as the standard deviation over a 10-minute period, as measured by the

saturation temperature control sensor after being at point for 60 minutes.

4

Chamber Temperature Uniformity is defined as the maximum temperature difference between any two locations at a

single point in time. Locations are within one inch of the chamber wall and within 2.5 inches of the chamber door.

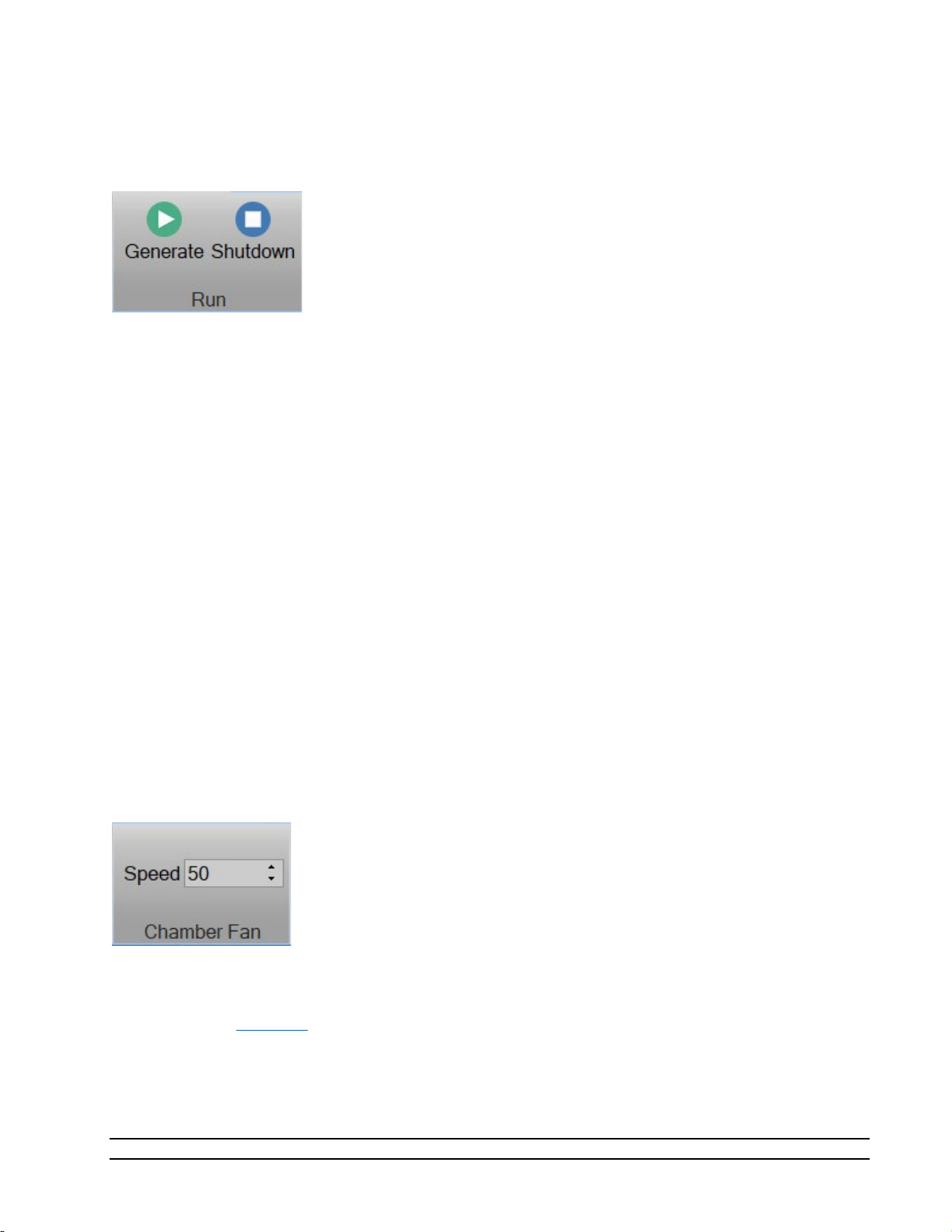

Using a minimum chamber fan speed of 25% for a temperature range of -10 °C to 72 ° when using fluid jacket door

option and ±10 °C from ambient when not.

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

11

2.10 UNCERTAINTY 5

RH Uncertainty: 10 to 95 %RH, 0 to 70 °C, 10 to 40 L/min ................................................. 0.5% of reading

RH Uncertainty: 95 to 98 %RH, 0 to 70 °C, 10 to 20 L/min ................................................. 0.5% of reading

Dew/Frost Point Uncertainty: < 0 °C, 10 to 40 L/min ...................................................................... 0.05 °C

Dew Point Uncertainty: 0 to 70 °C, 10 to 40 L/min .......................................................................... 0.08 °C

Temperature Uncertainty: -10 to 72 °C ......................................................................................... 0.031 °C

5

Chamber pressure at 1 atmosphere, Uncertainty values represent an expanded uncertainty using a coverage factor,

k=2, at an approximate level of confidence of 95%. Uncertainty is not specified at saturation temperatures below 0 °C

or at flow rates below 10 L/min. Uncertainty is based on the worst-case value from the 2900 uncertainty analysis.

12

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

2.11 FACILITY REQUIREMENTS

2.11.1 Environment

Operating Temperature: .......................................................................................................... 15 to 30 °C

Storage Temperature: ................................................................................................................ 0 to 50 °C

Humidity: ..................................................................................................... 5 to 95% RH Non-condensing

2.11.2 Floor Space

A bench and/or floor, capable of supporting approximately 300 pounds, with a minimum space of 27"

(0.686m) deep x 43" (1.09m) wide.

Allow an additional 20" (0.508m) in width for clearance, if possible, to allow complete opening of the

chamber door and access to the test ports.

Refer to drawings: 18D29901-2, 18D29910-1

2.11.3 Power

Electrical Power: ....................................................................... 200-230/210-240 V~, 10 A, 1 Ø, 50/60 Hz

Gas Supply Maximum Inlet Pressure: ...................................................................... 175 psiG @ 50 L/min

2.11.4 Air Supply

When not using the pneumatic cart, a clean, oil free instrument air supply operating at a @ 165 psiG and 50

L/m is required. The air supply should be filtered to a particle size of 0.5 microns or less, a hydrocarbon

content of 1 PPM or less, with a pressure dewpoint of 15 °C or less. Regulated supply pressure other than

recommended (175 psiG maximum) is acceptable but may limit the lowest humidity obtainable from the

generator and will require an internal pressure regulator (REG) adjustment.

Refer to section 2.12.5 Setting Supply Pressure Regulator for more information on adjusting the internal

pressure regulator (REG).

2.11.5 Distilled Water Supply

One gallon (3.8 liters) of double distilled water per fill. The one-gallon supply can last from 8 hours to more

than 500 hours of use depending upon the temperature and humidity at which the generator is operated

(reference section 13.3.4

for approximately 200 hours.

). During operation near ambient temperature and 50% RH, one gallon should last

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

13

2.12 INSTALLATION

2.12.1 Uncrating

Before uncrating, carefully inspect the crate and skid to be certain the unit was not subjected to damage. If

there is damage, proceed no further and notify your inspection department and the shipping agent.

If the crate appears satisfactory:

1. Remove steel strapping.

2. Using "Clip Removal Tool" or thin pry-bar, remove top cover clips then remove top panel.

3. One panel at a time, remove the panel clips then remove panel.

4. Remove polyethylene covering from unit.

5. Inspect for any visible damage.

6. Remove any/all accessory boxes.

7. Using forklift or another suitable lifting device, lift unit from skid and place on the 2900 cart or

instrument bench.

CAUTION!

BEFORE APPROACHING THE EQUIPMENT WITH THE FORKLIFT,

VISUALLY LOCATE ANY HARDWARE WHICH MIGHT PROJECT INTO

THE PATH OF THE FORKS. PLACE FORKS AS WIDE AS POSSIBLE TO

AVOID DAMAGE TO THE FRAME.

8. The unit may now be rolled to its point of installation.

2.12.2 Positioning

Position the system to have access to all sides of the console. Remove cover panels and inspect for any

visible damage that might have occurred during shipment.

CAUTION!

ALWAYS USE THE FILE>TURN OFF COMMAND TO PROPERLY EXIT THE SOFTWARE AND SHUTDOWN

THE COMPUTERS SO THAT THE MAIN POWER SWITCH CAN BE SWITCHED OFF.

2.12.3 Chamber Fluid

Temperature conditioning of the Model 2900 test chamber utilizes a mixture of propylene glycol and water

as a heat transfer fluid. This fluid is circulated by a magnetically coupled centrifugal pump through the

refrigeration and heating system and the fluid shell surrounding the test chamber.

2.12.3.1 Chamber Fluid Filling Procedure

1. Ensure main power switch is OFF.

2. Remove top console panel.

3. Locate fluid fill port (under insulation and labeled "Fluid Fill Port").

4. Remove "Red" cap and insert funnel into fluid fill port.

5. Add 2 gallons of 70% propylene glycol. Fill with water until level is approximately 1" (25.4 mm)

below the bottom of the fill port or until level touches funnel nozzle tip.

14

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

6. Remove funnel and replace fluid fill port cap and insulation.

7. Replace top console panel.

Refer to drawings: 18D29901-1, 18D29901-4, 18D29909-1

2.12.3.2 Chamber Fluid Draining Procedure

1. Ensure main power switch is OFF.

2. Remove rear console panel.

3. Locate drain hose in the lower left rear corner of the generator (when looking at the back of the

generator). It is the black hose with the yellow tip and brass cap.

4. Extend hose, remove drain hose cap and empty the chamber fluid into a clean container with a

minimum size of 4 gallons. Save the chamber fluid for refilling.

5. To restore hose: grasp hose and rotate counterclockwise ½ turn while pushing hose into left side

storage cavity.

6. Replace rear console panel

Refer to drawings: 18D29901-1, 18D29901-3, 18D29909-2

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

15

2.12.4 Reservoir Initial Filling Procedure

The reservoir requires an initial filling prior to first use, then periodic filling thereafter.

Refer to section 5.1 Water Reservoir Level

for detailed instruction on how to fill the reservoir.

2.12.5 Setting Supply Pressure Regulator

The supply pressure must be regulated to assure proper control and operation. The goal of the regulation is

to remove the spikes that occur during air supply generation.

– It is always recommended to double regulate the air supply; once at the supply and again at

Note

the 2900.

Adjust the 2900’s internal pressure regulator (REG) to 10 psiG below the supply pressure, but never above

150 psiG. For example, if the supply pressure indicates 165 psiG then adjust the internal pressure regulator

to 150 psiG. If the supply pressure indicates 155 psiG then adjust the internal pressure regulator to 145 psiG

(10 psiG below). For the best results operate the generator in run mode at the default flow rate to assure

the regulator adjustment corrects for any pressure drop caused by the flow rate.

1. Open the Supply Pressure Dialog by selecting “Supply Pressure” from the Utilities Menu Tab

2. Using a #6 or #8 straight blade screwdriver, rotate stem clockwise to increase pressure and

counterclockwise to decrease pressure while monitoring the supply pressure dialog window.

Refer to drawings: 18D29901-1, 18D29901-3, 18D29901-8

16

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

2.13 QUICK START

This section will provide the user a quick start on operating the generator. For detailed information on

operating the generator please refer to section 4 ControLog Interface

.

CAUTION!

DO NOT OPERATE THE GENERATOR WITHOUT CHAMBER FLUID.

2.13.1 Power-Up

To Power-Up the generator perform the following steps:

• Verify that the air supply connection has been made.

o If using the Series ACS2520 Air Compressor System (ACS)

The On/Off valve is open (handle inline).

The AC power cable is connected to the ACS box.

The remote air compressor control cable is connected from ACS box to generator.

The Remote/Manual switch on the left side of the ACS box is in the Remote position.

Toggle the power switch located on the left side of the ACS box to ON.

6

verify the following:

Note

– When the Remote/Manual switch is in the Remote position the ACS compressor will not run

when first switched to ON. The compressor is remotely controlled by the 2900 and will not start until

the user requests an operation that requires supply pressure.

o If using another air source, verify the following:

Supply is on and properly regulated.

• Verify that AC power cable is connected to the generator.

• Toggle the power switch located at the lower right rear of generator to ON. The generator will begin

to boot up.

6

Refer to Thunder Scientific’s website www.thunderscientific.com for the ACS2520 manual and more information on

the ACS2520.

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

17

2.13.2 Loading Screen

After the system boots the generator will show a loading screen which will indicate the status of the loading

process and will also show the software version of the generator.

18

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

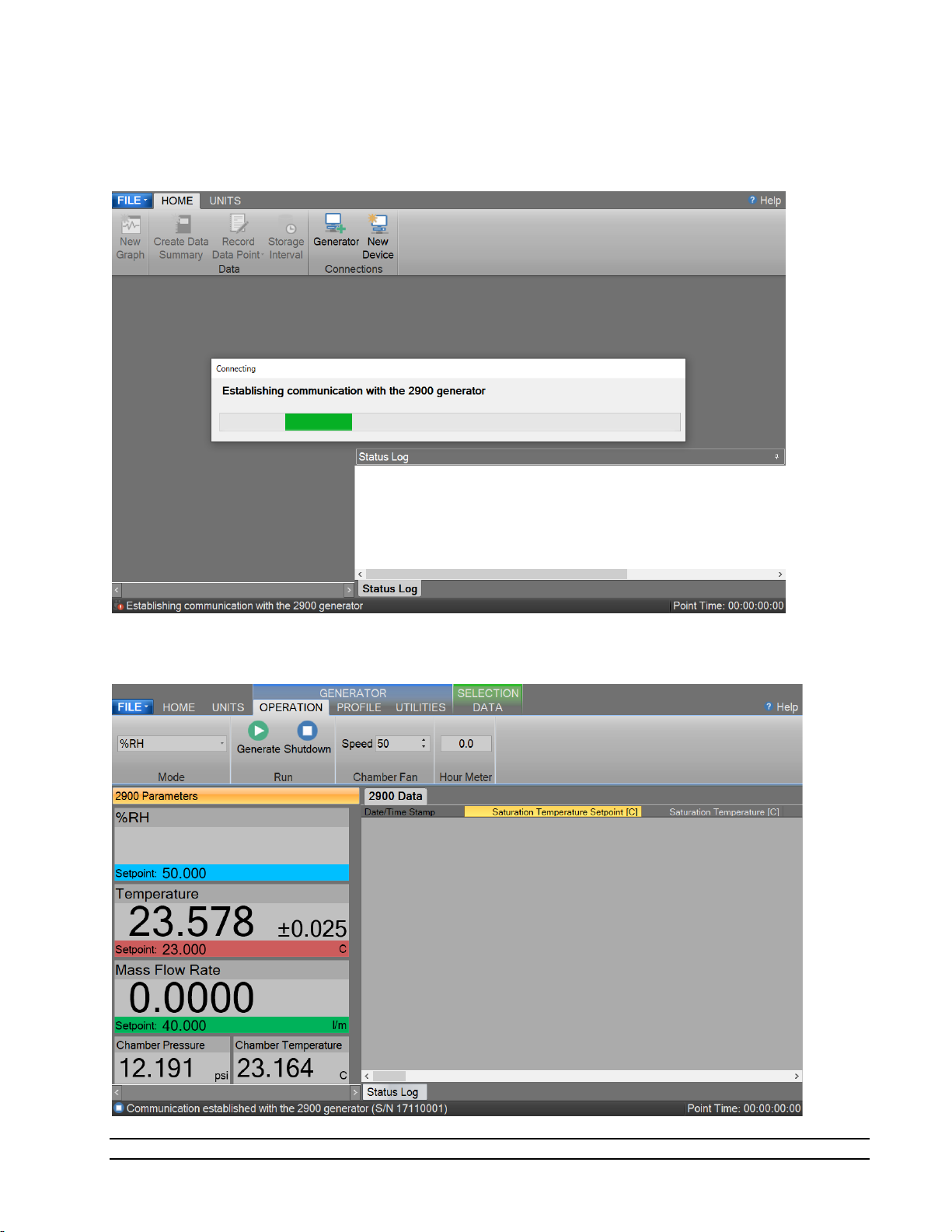

2.13.3 ControLog Screen

Upon completion of the loading process the generator will show the main ControLog page and a dialog

showing the status of establishing communication with the generator.

Once communication with the generator is established the generator’s parameter and data tabs will be

displayed.

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

19

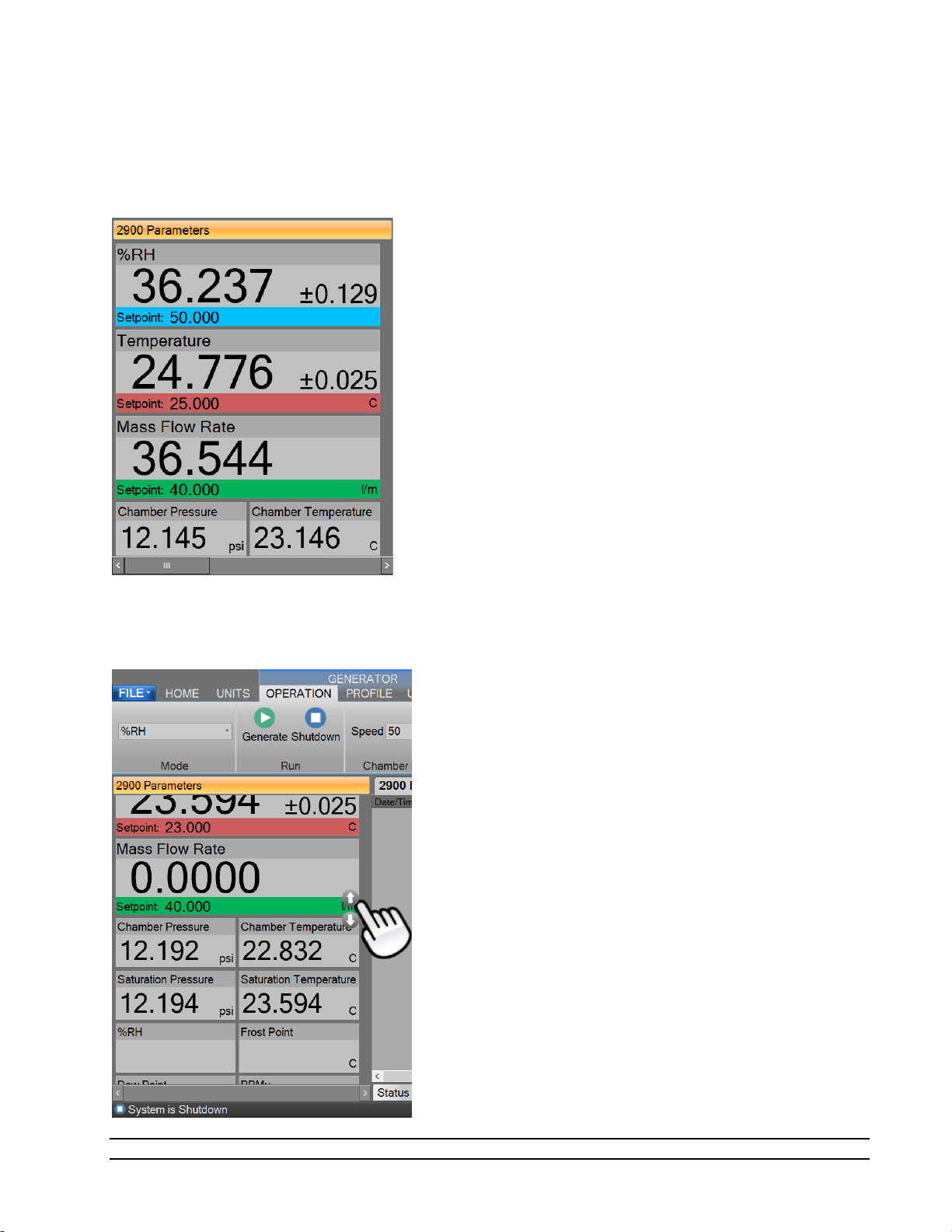

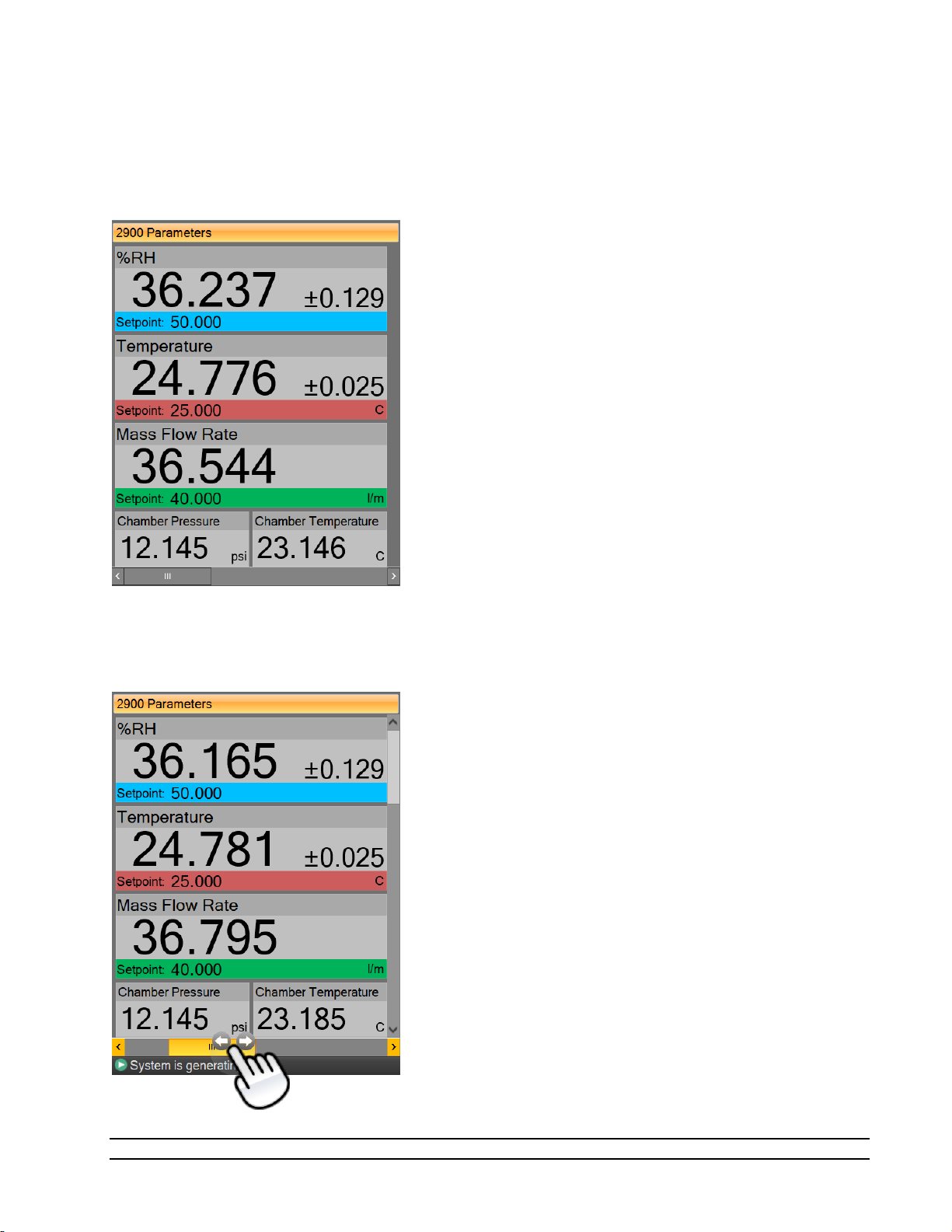

2.13.4 Control Parameters

The Parameter Tab Group is located on the left side of the application and contains a parameter tab for each

connected device. The 2900 Parameters contain all the control and measurement parameters critical to the

operation of

the humidity generator.

Scrolling the Parameters

Each Parameter Tab can be scrolled up and down to show additional parameters.

20

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

2.13.4.1 Setpoint Tile

The Setpoint Tiles allow the user to control the operation of the humidity generator by changing the desired

setpoint that the generator will control to. The Tiles contain 5 key parts; a header with the Parameter

Name, the Actual Value, the real-time Uncertainty Value, the Setpoint Value and the Unit the values are

displayed in. Each setpoint tile has a colored bar to allow quick indication of the what the tile is displaying

and in turn what the system is controlling. Blue is for the humidity that is being generated, red is for the

temperature that the system is controlling to and green is for the flow rate the system is generating at.

2.13.4.1.1 Changing Setpoints

To change a setpoint, click on the setpoint tile that you would like to change. A setpoint entry box will

appear. For example, to change the Percent Relative Humidity setpoint click on the %RH setpoint tile.

Enter the new value into the Setpoint Entry box and select Ok. Notice that the Percent Relative Humidity

setpoint value updates to the new value and the actual values begin moving toward the new setpoint.

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

21

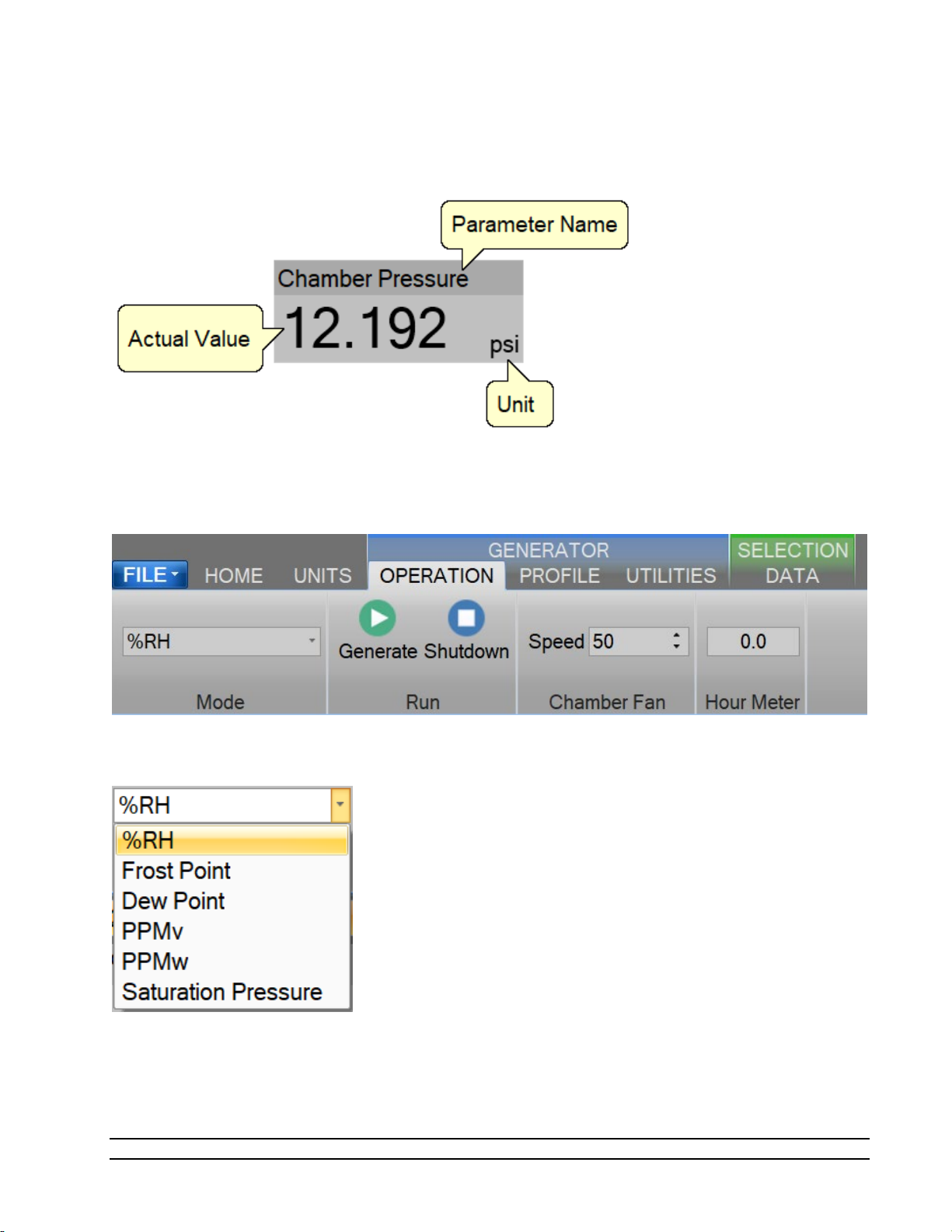

2.13.4.2 Value Tile

The Value Tiles display an actual value of a given parameter to the user. The Tiles contain 3 key parts; a

header with the Parameter Name, the Actual Value and the Unit the value is displayed in.

2.13.5 Control Modes

The user can change the operating mode of the 2900 by selecting from the drop-down menu within the

Mode group on the Generator’s Operation menu tab.

The drop-down allows the user to select between %RH, Frost Point, Dew Point, PPMv, PPMw, and Saturation

Pressure.

22

Model 2900 System Manual – Document #OM2900 - Edition 2.0 - June 2022

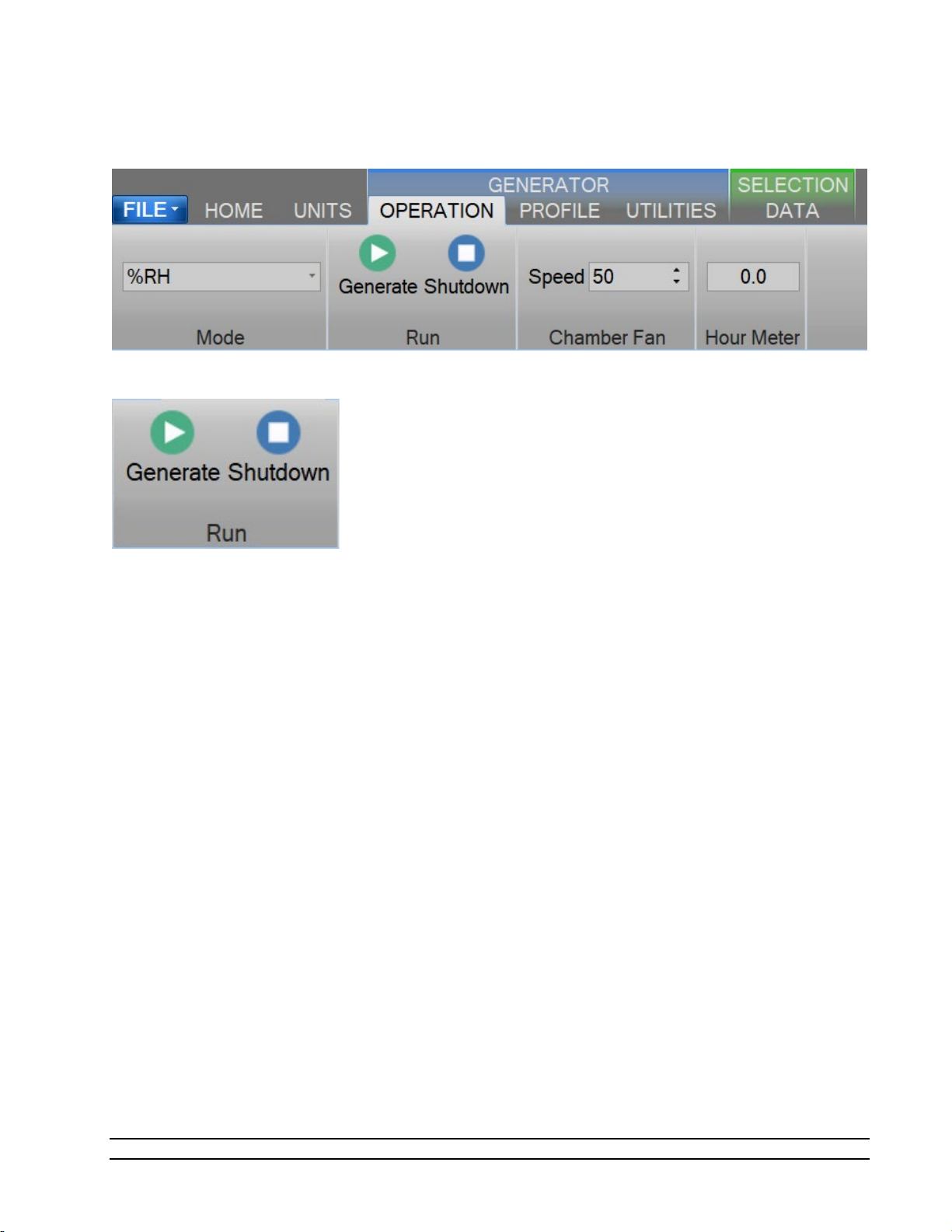

2.13.6 Generating and Shutting down

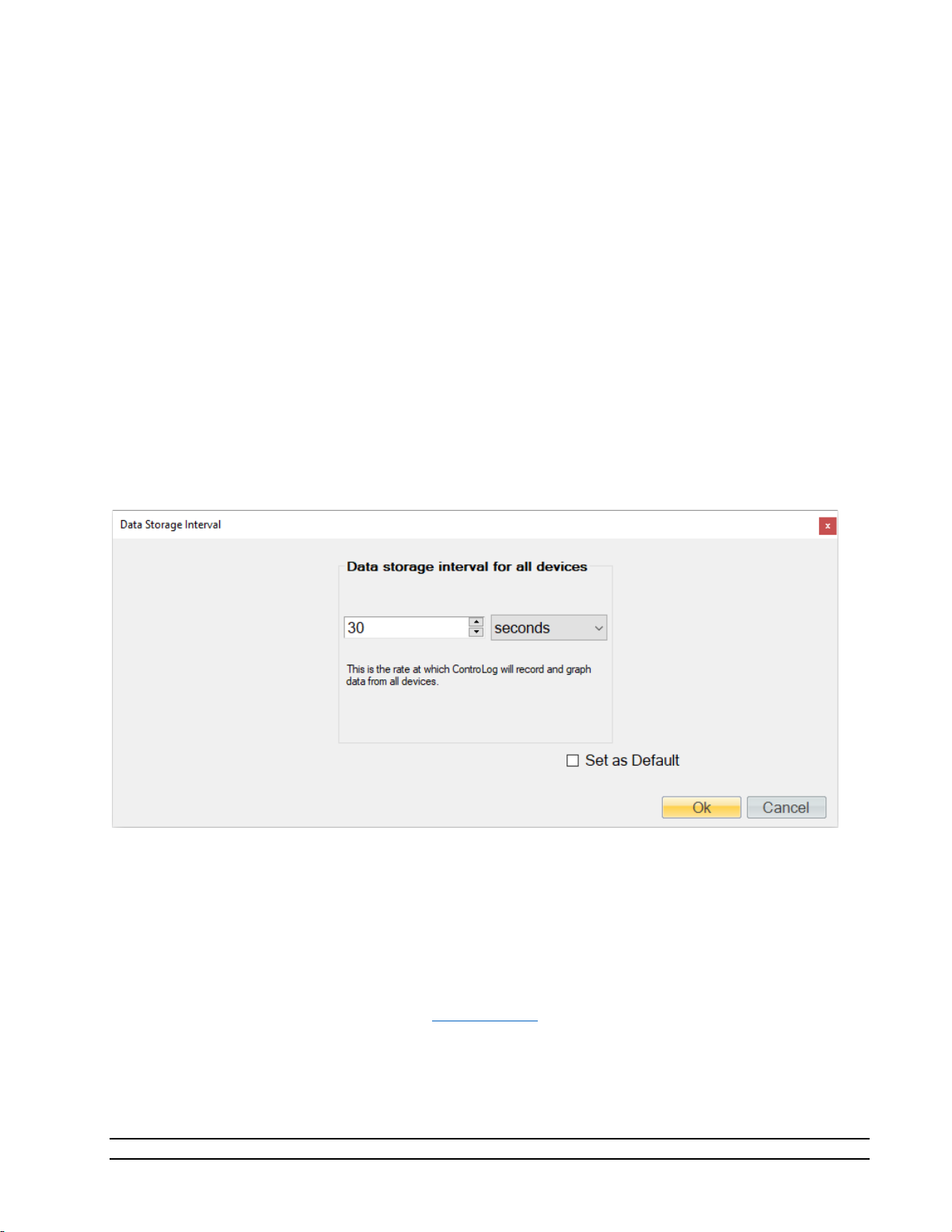

The Run Menu allows the user to run the 2900 manually.

The user can select to Generate or Shutdown.

2.13.6.1 Generate Mode

Selecting Generate from the run menu commands the 2900 into generate mode. When in the Generate

mode of operation, the system will control at the currently entered setpoints. Anytime a setpoint is

changed, the system immediately begins adjusting to that new value, and will control at the new point. The

Generate mode also allows you to change the humidity control mode at any time. For instance, the system

may be controlling %RH, then you may immediately switch to Dew Point control mode.

2.13.6.2 Shutdown

Selecting Shutdown from the run menu commands the 2900 to shutdown. The 2900 may be shutdown

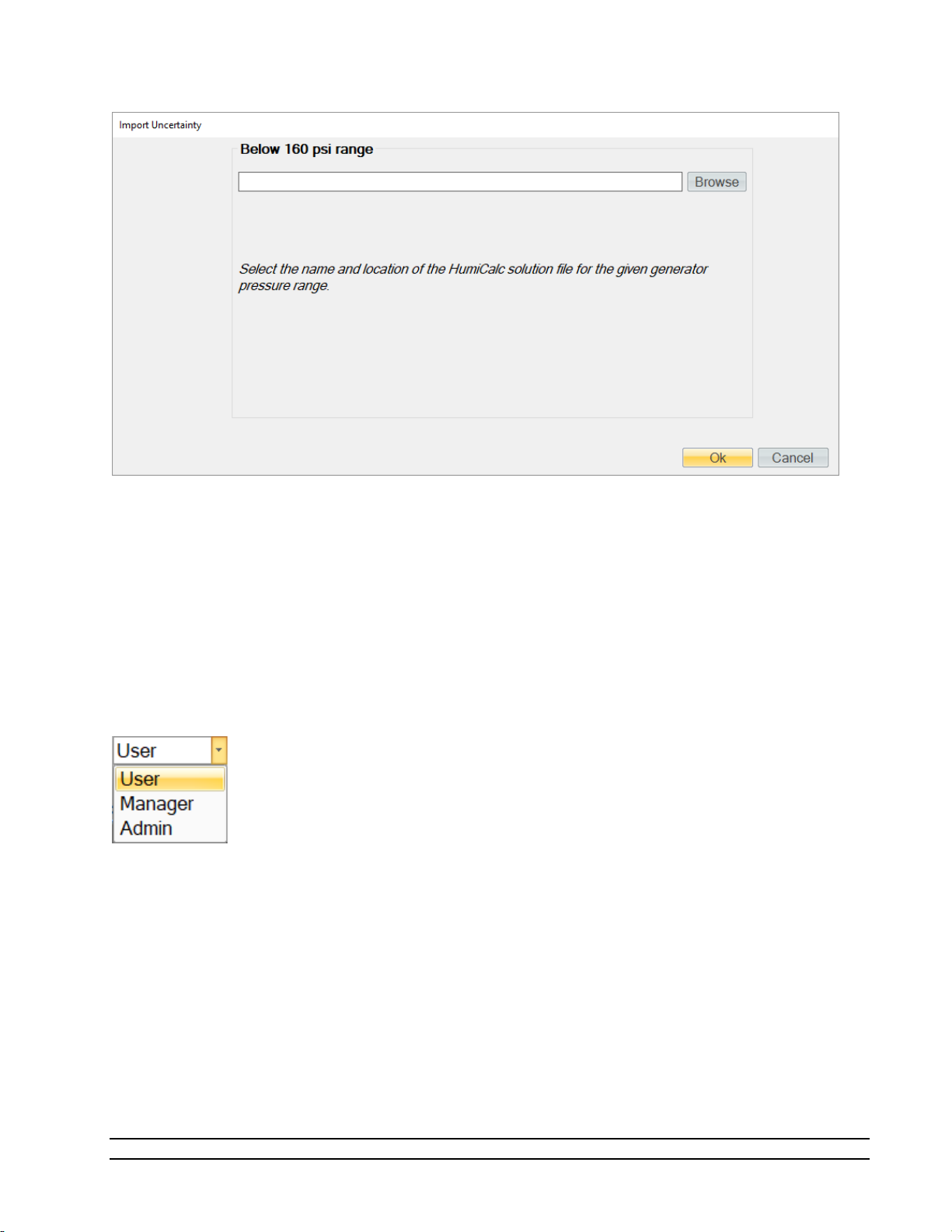

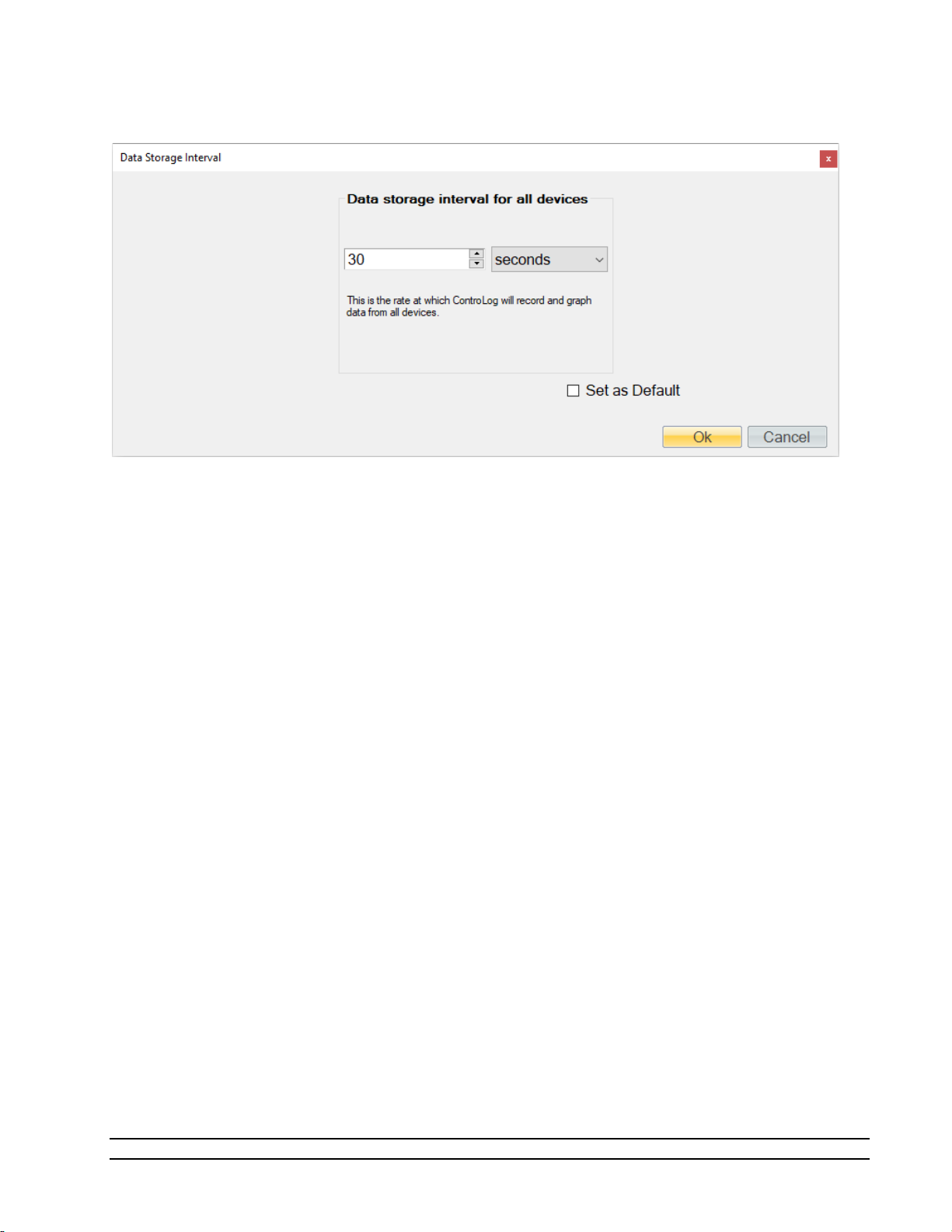

whenever it is generating. When stopped, all system functions shutdown, pressure is vented, and the idle