Page 1

Manual #9636-1220

Thrush Co.

Air Separators

AS & ASL

Manual # 9636-1220 Rev. A

Operation&MaintenanceManual

340West8thStreet

Peru,IN46970

PH:765‐472‐3351

FX:765‐472‐3968

www.thrushco.com

COPYRIGHTTHRUSHCO.,INC.2014

Page 2

Page 3

Manual #9636-1220

Thrush Co.

Table of Contents

Section No.

Description Page No.

1 General Product Information 1

2

3

Safety Information/Warnings

Component and Operational Information

2

3-6

4 Installation 7-8

5

Maintenance Procedure 9

6 Parts Ordering/Contact Information 9

COPYRIGHT THRUSH CO., INC. 2014

THIS DOCUMENT CONTAINS INFORMATION THAT THRUSH DEEMS CONFIDENTIAL AND PROPRIETARY.

THE BASIC THRUSH PRODUCT REVEALED IN THIS DOCUMENT IS PATENTED, AS ARE CERTAIN PRODUCT

COMPONENTS. IN CONSIDERATION FOR THE RECEIPT OF THIS DOCUMENT, RECIPIENT AGREES NOT TO

REPRODUCE, COPY, USE OR TRANSMIT THIS DOCUMENT OR THE INFORMATION CONTAINED HEREIN, IN

WHOLE OR IN PART, OR TO PERMIT OTHERS TO DO SO, FOR ANY PURPOSE WITHOUT FIRST OBTAINING

THE EXPRESS WRITTEN PERMISSION FROM THRUSH.

Page 4

Thrush Co.

Manual #9636-1220

Section 1

General Product Information

1.1 Overview

The Air Separator separates entrained air from flowing system water by the creation of a

vortex which will allow free air to rise in the center, the point of lowest velocity, to the air

collection chamber in the body of the air elimination valve.

The Thrush Co., Inc. (Thrush) Tangential Air Separator has been carefully assembled

and factory tested to provide years of trouble-free service. This manual provides

information to allow the installer/operator to install, operate, service and maintain the Air

Separator. In this manual the installer/operator will find that two Air Separator models are

covered. Visually these models will look very similar. The major difference between

models is the removable strainer option equipped only on the AS model. The model

number designates the size of the unit (Figure 1-1).

ModelDesignation

AS(L)‐8

}

Inlet/OutletSize(IN)

Less(without)Screen

AirSeparator

OptionalEquipment

Figure 1-1 Overview

Page 5

Section 2

Safety Information/Warnings

2.1 Safety Information and Warnings

Every practical safety feature has been incorporated into the design and manufacture of

the Thrush Co. Air Separator. If questions are not answered by this manual, or if specific

installation, operation, and/or maintenance procedures are not clearly understood,

contact your local representative before proceeding. Personnel must, at all times,

observe all safety regulations while performing maintenance or repairs.

All installation, operation, and maintenance procedures should be performed by

qualified, experienced and well trained personnel. The potential exists for severe

personal injury if proper procedures are not followed.

Thrush Co.

Manual #9636-1220

System water over 100°F can be very hazardous. Keep flow away from the body

when flushing the unit or removing the strainer. Failure to do so could result in

serious bodily injury or property damage.

4” and larger Air Separators have lift lugs to aid in lifting and locating the unit. The

lift lugs are not intended to be used to support the Air Separators during

operation. Adequately sized and spaced supports/hangers should be used to

prevent damage or strain on the system piping.

With any piece of equipment utilizing boiler water or high temperature water under

pressure, there is a potential for severe personal injury or death if proper

installation, operation and maintenance procedures are not followed.

Page 6

Thrush Co.

Manual #9636-1220

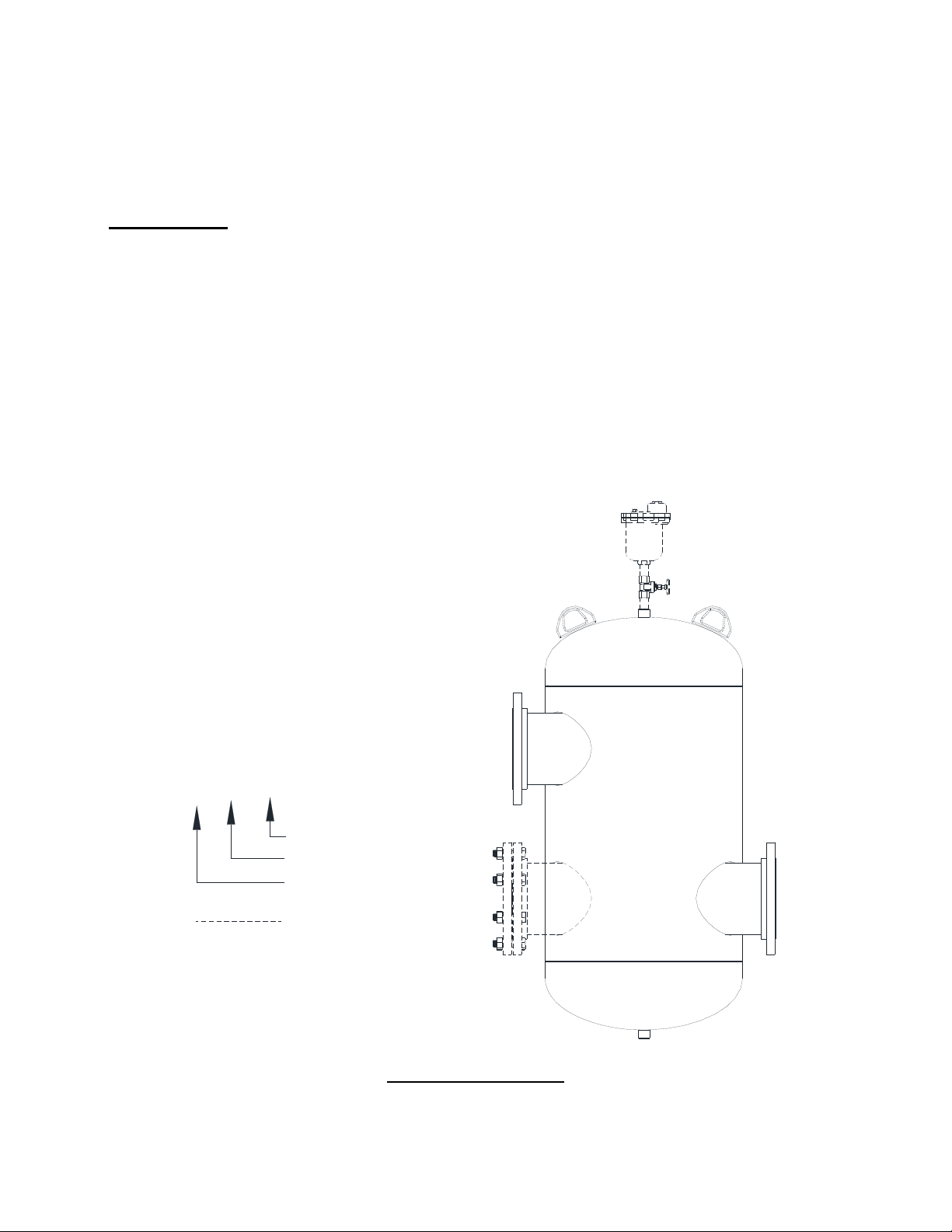

3.1 AS/ASL Component Identification

The major difference between the Air Separator AS/ASL models, is that the AS model

comes equipped with a removable strainer for maintenance.

Section 3

Component and Operational Information

OUTLET

INLET

STRAINER

304S.S.

51%OPEN

ASL

INLET

OUTLET

AS

Figure 3-1 AS/ASL Components

Page 7

3.1.1 Removable Strainer Option

The removable strainer option is a rolled 304 stainless perforated cylinder that allows the

user to easily remove the strainer for cleaning and /or inspection (Figure 3-2).

System water over 100°F can be very hazardous. Keep flow away from the body

when flushing the unit or removing the strainer. Failure to do so could result in

serious bodily injury or property damage.

Manual #9636-1220

Thrush Co.

Figure 3-2 Strainer

3.2 Optional Connections

The standard inlet and outlet flanged connections can be replaced with an alternate

grooved end pipe connection (Figure 3-3). This comes with or without strainer option.

FLANGEDNOZZLEFOR

ASMODELONLY

Figure 3-3 Grooved End Connection

Page 8

Thrush Co.

Manual #9636-1220

3.3 Suggested Equipment

Although the standard Air Separator is a simple design, a Thrush Model 720 Air

Eliminator is recommended to vent air from the system.

3.3.1 Model 720 Air Eliminator

The Model 720 Air Eliminator is a unique high capacity, air elimination device. It is

designed to eliminate air as fast as it can be separated from liquid. The valve will not

open if negative pressure occurs, preventing air from being drawn back into the system.

DRAINTAP

3

"NPT

8

CONTROLASSEMBLY

LEVERASSEMBLY

VALVETAP

1

"NPT

4

LID

5

7

"

8

3

"NPT

4

BODY

FLOAT

AIRCOLLECTION

CHAMBER

6"

Figure 3-4 Model 720 Air Eliminator

Operation

The air eliminator is designed to remove unwanted air that could reduce system

performance, increase operational cost, and support the damaging effects of

corrosion.

The collection of air in the body of the air eliminator causes the float to drop

allowing the air to be vented through an air eliminating orifice. As the liquid level

rises in the eliminator body, the float also rises shutting off the flow of vented air

(Figure 3-4)

Page 9

3.3.1 Model 720 Air Eliminator (Continued)

Installation Tips

1. The Model 720 Air Eliminator should be located in a clean, open area, where it is

easily accessible for inspection, service and repair.

2. The Model 720 Air Eliminator should be installed at the top of each air separator

(Figure 3-5), or it may be installed at the system piping highest point with a pipe

run from the air separator.

3. Additional Model 720 Air Eliminators are recommended for each component and

pipe locations where air could accumulate.

4. A shut off valve should be provided to simplify cleaning and replacement of float

and control assembly if necessary. Valve should remain open during normal

operating processes.

Manual #9636-1220

Thrush Co.

SHUTOFF

VALVE

DRAINLINETO

DRAIN/SINK/

ORCONTAINER

TOPUMP

FROM

SYSTEM

Figure 3-5 Model 720 Air Elimination Installation

(ASModelShown)

Page 10

Thrush Co.

Manual #9636-1220

4.1 Installation Tips

The following procedures are to aid the operator in installing the Air Separator. All

procedures are to be performed by experienced, trained, and certified personnel only.

4” and larger Air Separators have lift lugs to aid in lifting and locating the unit. The

Some considerations: Isolation valves are required to allow gasket changes and

inspection of strainer. Expansion joints and or flex connectors are recommended to

prevent pipe strain caused by thermal expansion or piping misalignment. System bypass piping is also recommended in the event of system service and or maintenance.

Section 4

Installation

lift lugs are not intended to be used to support the Air Separators during

operation. Adequately sized and spaced supports/hangers should be used to

prevent damage or strain on the system piping.

1. The Air Separator should be located in a clean, open area, where it is easily

accessible for inspection, service and repair. Installation of the unit in an area with

adequate drainage is recommended.

2. A standard Air Separator is installed in-line of the system piping. Adequately sized

and spaced pipe supports/hangers should be used to prevent damage or strain on

the system piping.

3. When placing the Air Separator (AS Model) with strainer in the system piping, be

aware of the clearance required for strainer removal for cleaning and replacement

4. When piping the unit into system piping, the pipe size should be sized to allow

adequate flow at a minimal head loss, and be, at minimum, the same size as the

Air Separator connections. The use of fittings (elbows, tees and couplings) should

be kept to a minimum as well.

With any piece of equipment utilizing boiler water or high temperature water under

pressure, there is a potential for severe personal injury or death if proper

installation, operation and maintenance procedures are not followed.

Page 11

Thrush Co.

4.2 Installation Tips (Continued)

Using the figure below as reference, follow the steps outlined to install piping for the Air

Separator (Figure 4-1, shown with AS Model). Before making any piping connections,

ensure that all piping is clean and free of any foreign material such as debris or scale.

Foreign material in the piping can cause damage to the unit and/or affect the

performance and operation. Manual shutoff valves should be installed

upstream/downstream from all connections to act as an isolation device. These valves

should be in the closed position and remain so until the installation is complete.

Expansion joints and/or flex connectors are recommended to prevent pipe strain caused

by thermal expansion or piping misalignment.

MODEL720AIRELIMINATOR

LIFTLUGS(2)

(4"&LARGER)

ISOLATIONVALVE

RETURN

INLET

ISOLATION

COLD

WATER

SUPPLY

AUTOMATIC

FILLVALVE

VALVE

DRAIN

DRAIN

OUTLET

Manual #9636-1220

AIRSEPARATOR

FLEXCONNECTOR(S)

SUPPLY

TRI‐FLOWVALVE

BOILER

TANK

SUCTIONDIFFUSER

Figure 4-1 Typical Piping Diagram

1. Connect the supply source to the inlet connection of the Air Separator. Be sure

the upstream manual shutoff valve is in the closed position (Figure 4-1).

2. Connect the suction piping of the pump to the outlet connection of the Air

Separator. Be sure the downstream manual shutoff valve is in the closed position

(Figure 4-1).

PUMP

Page 12

Thrush Co.

Manual #9636-1220

5.1 Maintenance Procedure

Because of the simple design of the Air Separator, minimal maintenance is necessary.

Periodical inspections by competent personnel for signs of corrosion, defects or cracks

are suggested. Examine the strainer (if applicable) for any debris, especially during initial

start-up period. Contact your representative for replacement gaskets and/or strainers.

6.1 Contact Information

Any additional information not supplied in this manual can be given by your

representative.

If your representative cannot be reached, please contact our customer service

department:

When calling or writing to place a parts order to your representative, it is recommended

to have the following items for reference:

Section 5

Maintenance Procedures

Section 6

Maintenance Procedures

Thrush Co., Inc.

PO Box 228

340 West 8th Street

Peru, IN 46970

Attention: Customer Service Group

Phone: (765) 472-3351

(800) 755-8110

Fax: (765) 472-3968

E-mail: customerservice@thrushco.com

1. Part number(s).

2. Description of product(s).

3. Quantity required.

4. National Board Number (if applicable).

Loading...

Loading...