Thrane&Thrane SB5006 Operation Manual

OPERATION MANUAL

SB5006 Service Tool

Introduction

The SB5006 is a service tool used for maintenance and configuration of the VHF 5000

equipment. The tool provides a standardized HTML based access from a PC to configuration

areas in the VHF radio and peripheral devices.

Note: The tool can be used for VHF 5000 series equipment only.

The service tool is delivered with the following components:

• The SB5006 Service box (part no.: 8050060007)

• A crossed Ethernet cable (part no.: 77.154)

• A SPARC II connection cable (part no.: 56.111)

Before using the service tool for the first time, it is strongly recommended to read this manual

and familiarize with the terms used in it

Notice: There may be some minor differences in the graphic layout of the product in the

manual compared to the actual physical unit.

Abbreviations used in this Manual

ATIS Automatic Transmitter Identification System

BI Channel mode when sailing on European rivers

CU Control Unit

DSC Digital Selective Calling

LAN Local Area Network

MMSI Maritime Mobile Service Identification

RX Receive/r

TX Transmit/ter

Please note

Any responsibility or liability for loss or damage in connection with the use of this product and

the accompanying documentation is disclaimed. The information in this manual is provided

for information purposes only, is subject to change without notice, may contain errors or

inaccuracies, and represents no commitment whatsoever. This agreement is governed by

the laws of Denmark.

Doc. No.: B5006COM Issue: C/0725

ii

Contents

Introduction .............................................................................................................................. ii

Abbreviations used in this Manual ...................................................................................... ii

1 The Devices that are Subject to Configuration and Maintenance with the SB5006

Service Tool ........................................................................................................................ 3

2 Physical Connection ......................................................................................................... 4

2.1 Physical Connection for CU5000 Software upload.................................................... 5

2.2 Alternative Connection ............................................................................................... 6

3 Using the Service Interface .............................................................................................. 7

4 Use Scenarios .................................................................................................................... 9

4.1 Configuration Level..................................................................................................... 9

4.2 Service Level ............................................................................................................ 19

4.3 Printer Configuration on an LB5007 LAN Box ......................................................... 21

5 Appendix – Troubleshooting .......................................................................................... 23

5.1 Preparing the Service PC .........................................................................................23

5.2 Connecting the PC.................................................................................................... 23

5.3 Logical Connection ................................................................................................... 23

5.4 Service Tool Software update .................................................................................. 29

6 Known Bugs and Limitations in the Service Tool ....................................................... 31

6.1 Physical Connection Issues ..................................................................................... 31

6.2 Logical Connection Problems................................................................................... 32

6.3 Use configuration scenarios ..................................................................................... 33

5

0546

1

2

0520

1 The Devices that are Subject to

Configuration and Maintenance with

the SB5006 Service Tool

This service tool is equally well suited for use in the workshop, as well as for on-board

configuration and maintenance of the VHF 5000 series products.

With the SB5006 it is possible to configure the devices described in the following:

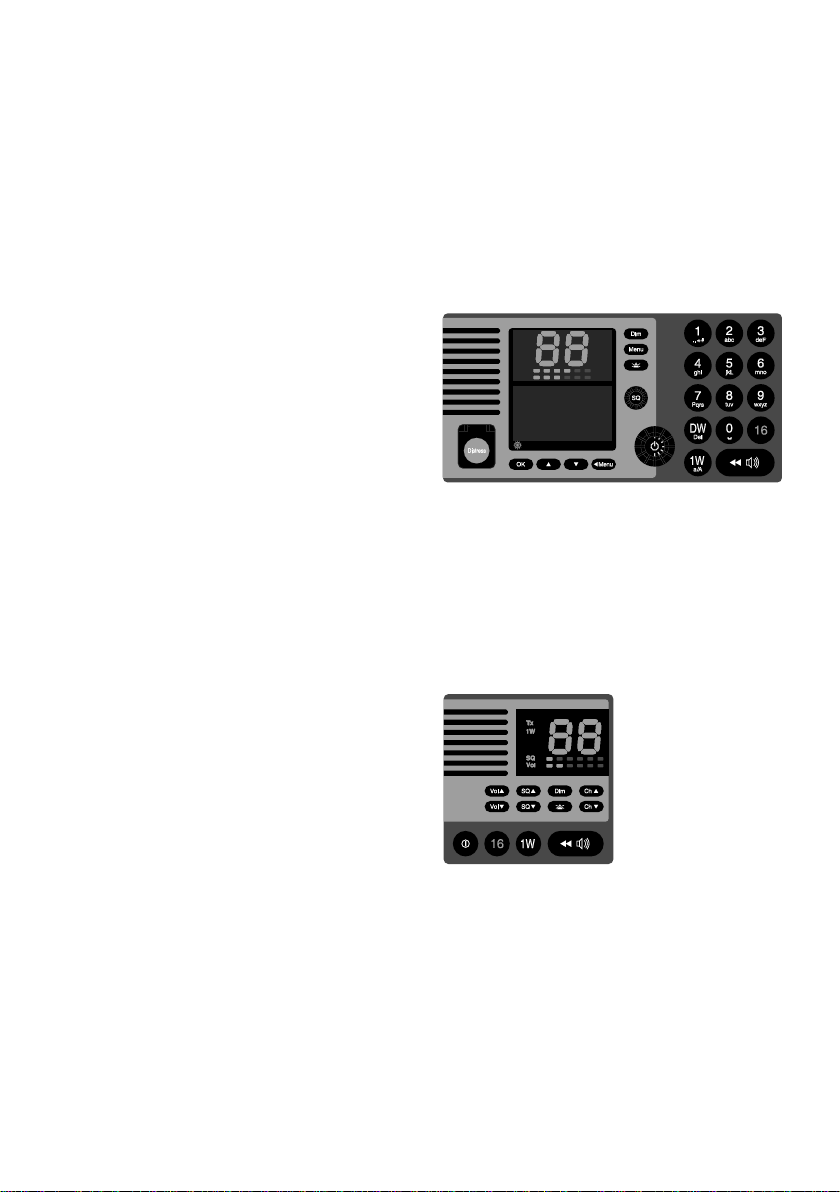

VHF 5000 series radio

• Updating to new software versions.

A single file containing everything is

distributed.

• Configuration

- Change MMSI number

- Change ATIS code

(inland waters only)

- Program channel mode for specific

regions (International, US, BI)

- Configure AUX relays

- Programming of private channels

- Program contact list

• Workshop Service/Maintenance

- Program scan behaviour

- Program serial number after repair

- Simplex or duplex profiling after repair

Alarm

Call

DW

1W

SQ

Vol

Int

US

BI

Tx

0191 - 05

CU5000 remote control unit

• The remote unit CU

may be updated with new software.

SB5006 Service tool

• The Service tool itself

can be updated with:

- New software

• The service tool may be configured with:

- New IP address

- Subnet address

- Default gateway address

- Ethernet speed

- IP assignment method

- SPARC II communication settings

- (Logical name settings)

0546

3

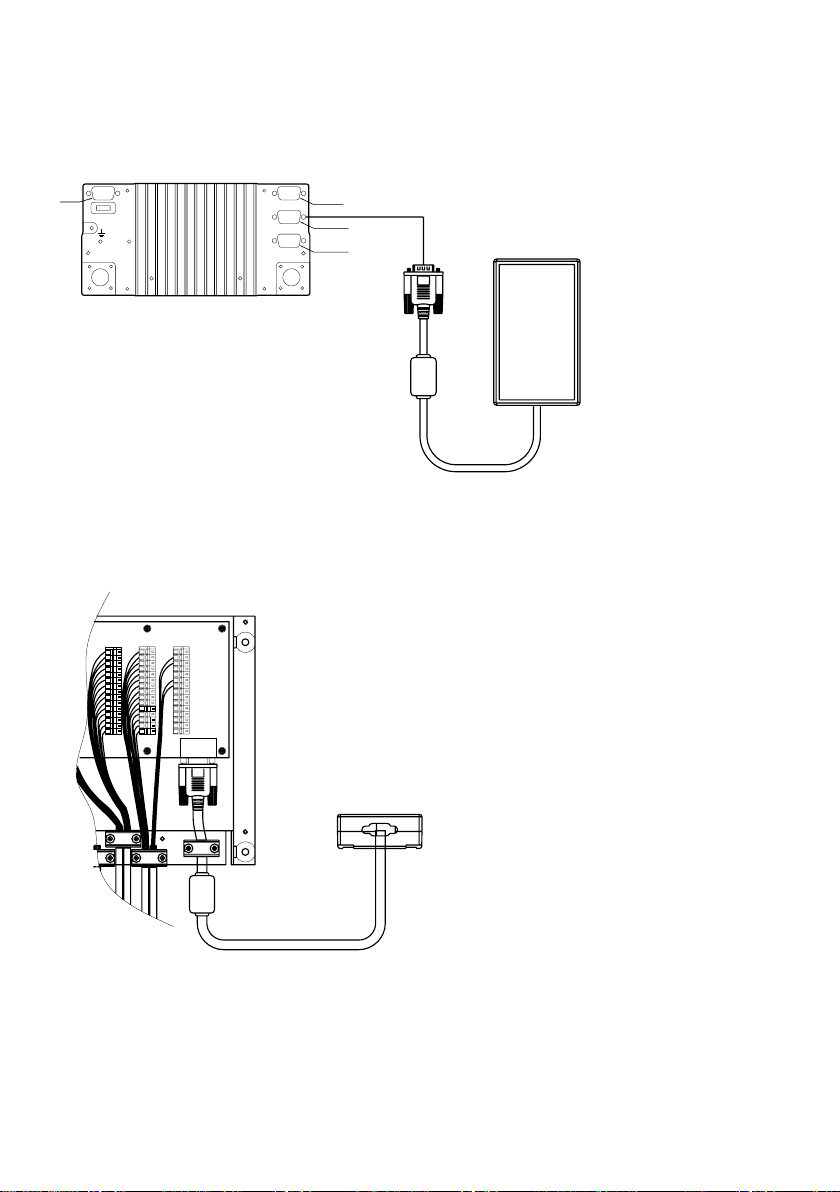

2 Physical Connection

The SB5006 is physically connected to the VHF equipment via the SPARC II bus. The VHF

radio is powering all components – including the SB5006 - via the SPARC II bus connection,

and must always be powered when operating the service tool.

RT5022/RT5020

Power

connector

FUSE

12-24V DC

Main Antenna DSC Antenna

40034A

Figure 2.1: The SB5006 service tool is connected to the VHF 5000 Series radio directly with the

The SB5006 may be connected directly to the SPARC II bus connector at the rear of the

VHF (see Figure 2.1).

SPARC II cable (15 pin Sub-D) delivered with the SB5006 service tool.

IF CU IS CONNECTED TO

EB/CU TERMINALS THEN

X5 X6

EXT /

1

CU LS

2

3

4

5

6

7

8

9

10

11

12

13

14

15

CONNECTIONS

EB/CU

REMOVE J1 & J2 FOR X4

AND J3 & J4 FOR X5

EXT

+12.5V

DATA+

DATA-

TX AF+

TX AF-

GND

+12.5V

RX AF+

RX AF-

+12.5V

EXT LS2

EXT LS2

GND

Line out+

Line out-

LAN

INTERFACE

X7

X4

EXT /

CU LS

SPARC II BUS

EB/CU

Option

Sparc II Bus

Handset

15-pin

sub D male

15-pin

sub D female

9 pin

sub D female

Sparc-bus

SB5006

SB5006

Sparc-bus

40035

Figure 2.2: The SB5006 service tool is connected to the VHF 5000 series in a fixed installation

using the connection box instead.

Alternatively the SPARC II bus is accessible at connector X7 in the connection box, if

installed (see Figure 2.2).

Note: Before connecting the SB5006 to the VHF system, power down the VHF radio.

4

0546

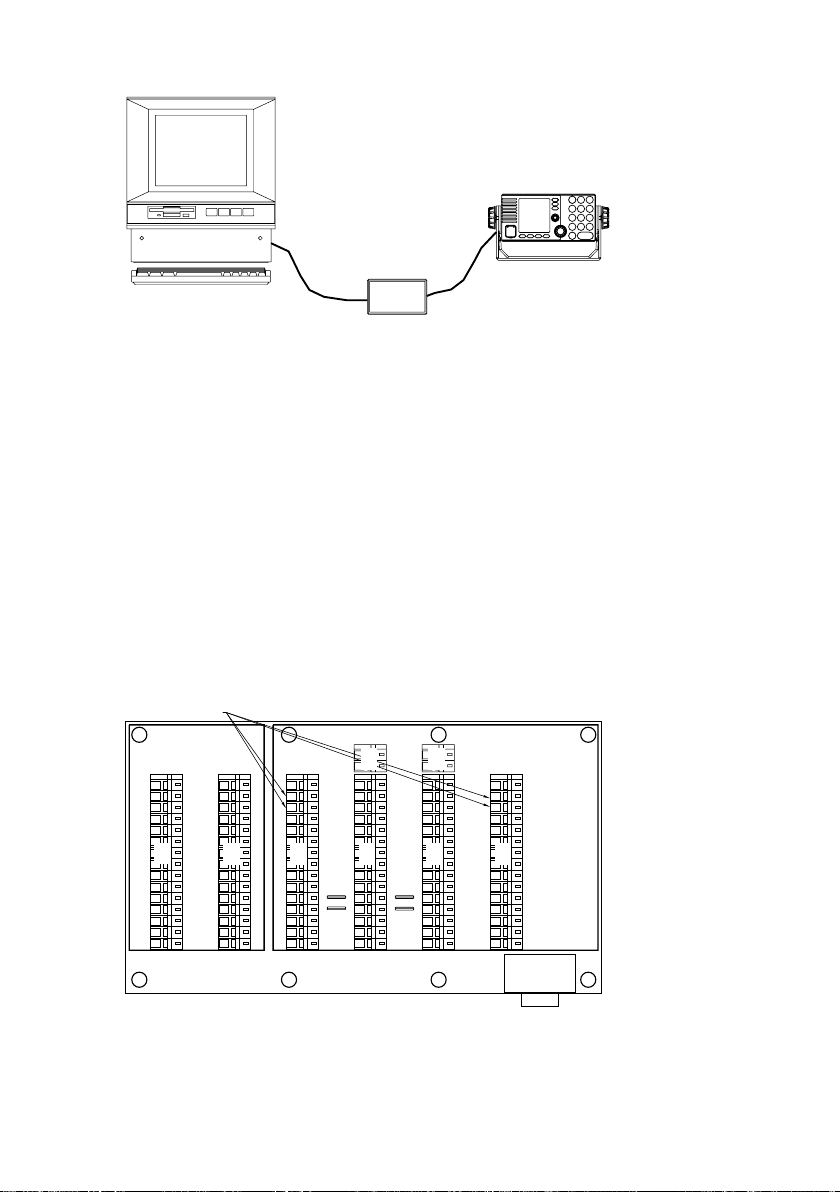

SB 5006

SPARC II

Ethernet

40253

Figure 2.3: A fully connected system with the service tool.

The connection of SB5006 to the service PC is done using the crossed Ethernet cable

(delivered with the SB5006).

2.1 Physical Connection for CU5000 Software

upload

Software upload to a CU5000 in an installation requires data connection to a particular

CU5000 being established exclusively, i.e. the SPARC II bus data lines for all other units on

the bus must be disconnected during this upload process. This includes the VHF itself, the

AP4365/AP1003 Alarm panel, if installed and a second CU5000, if installed (this second

CU5000 may simply be switched off during the upload process). See also fig. 2.4

Note: Remember to restore connection, after the uploads have been made and verify system

operation.

Disconnect

EB/CU

EB/CU

X8

X8

RT50XX

OPTIONS

X1

1

2

3

4

5

X1

6

7

8

9

10

11

12

13

14

15

OPTIONS

OPTIONS

X2

VDR+

VDR-

AUX2

AUX2

AUX1

X2

AUX1

INT LS+

INT LS-

CALL

CALL

GND

NMEA+

NMEA-

ALARM

ALARM

CONNECTIONS

EXT /

RT50XX

CU LS

SPARC II

1

1

2

2

3

3

4

4

5

5

X3

6

6

7

7

8

8

9

9

10

10

J1

11

J2

12

13

13

14

14

15

15

SPARC II BUS

EXT /

CU LS

X4X3

1

2

3

4

5

X4

6

7

8

9

10

J3

J4

13

14

15

CONNECTIONS

40036

Figure 2.4: Inside view of the CB5009 connection box. Lift/disconnect the lines DATA+ and DATA-

(X3 pin 2 and 3) in the terminal connecting any device not being part of the update e.g

the VHF radio and the optional Alarm Panel, as indicated.

IF CU IS CONNECTED TO

EB/CU TERMINALS THEN

X9

X9

REMOVE J1 & J2 FOR X4

AND J3 & J4 FOR X5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

X7

LAN

INTERFACE

EXT

X6

+12.5V

DATA+

DATA-

TX AF+

TX AF-

X6

GND

+12.5V

RX AF+

RX AF-

+12.5V

EXT LS+

EXT LS-

GND

Line out+

Line out-

X7

X5

X5

0546

5

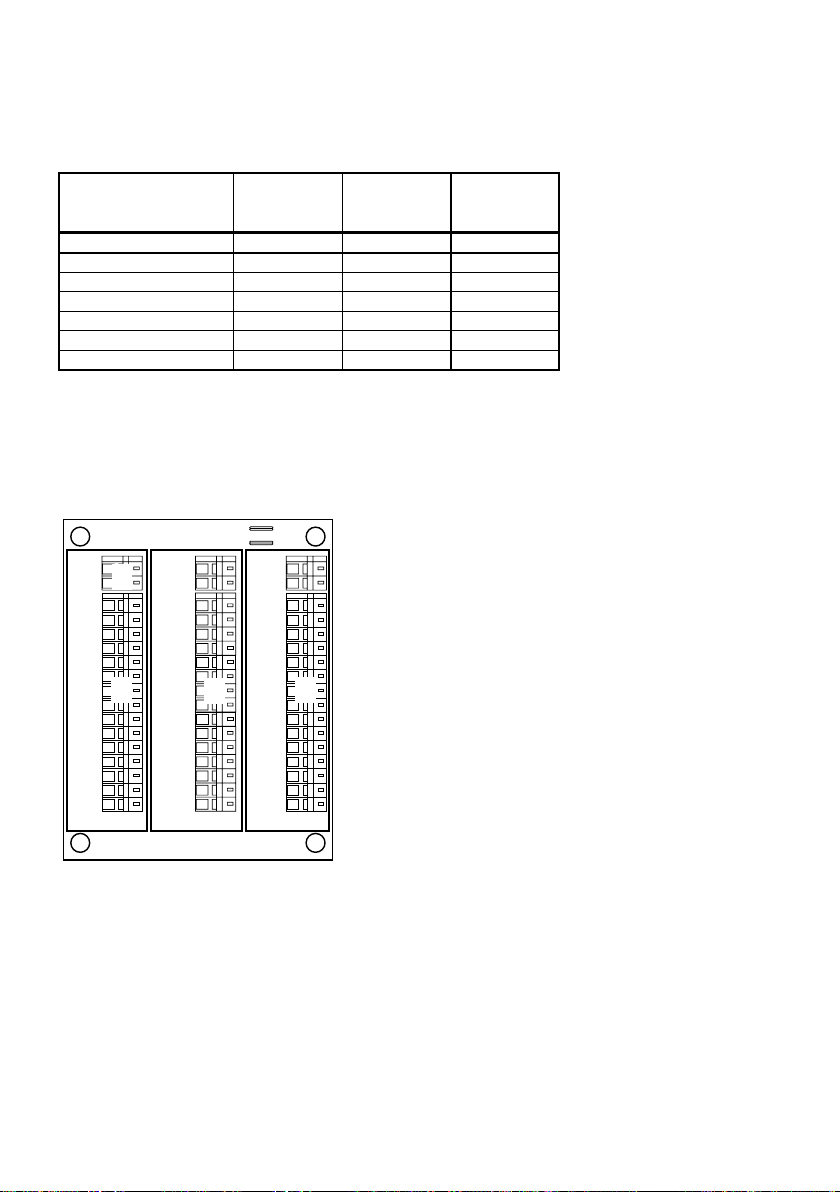

2.2 Alternative Connection

In fixed installations where only an extension box (EB5008) is used a cable may be made up

to provide access to the SPARC II bus through the EB5008 X2 terminals (refer to Tabel 1).

This cable is not part of the SB5006 service toolkit.

VHF SPARC-II

connector 15-pin D-sub

female

Pin1 12.5VDC+ Red/White X2-1

Pin 2 DATA_+ Yellow X2- 2

Pin 3 DATA_- Yellow/ Bla c k X2-3

Pin 6 GND Orange/Red X2-6

Pin 7 12.5VDC+ Orange/ W hite X2-7

Pin 10 12.5VDC+ Black/White X2-10

Pin 13 G ND Black X2-13

Tabel 1: If you do not have access to a 15 pole D-Sub SPARC II connector in the installation, a

cable can be created to get access to the terminals in the extension box. The table

shows only the necessary connections.

SPARC II cable P/N 56.114 may be used for this purpose cutting back wires not used (refer

also to Tabel 1).

Signal

Designation

Cable p/n

56.114

Extension box

terminals

X6:

J1 & J2 MOUNTED = EXT LS

J1 & J2 NOT MOUNTED = CU LS

X4

CU LS+

CU LS-

X1

1

2

3

4

5

X1

6

7

8

9

10

11

12

13

14

15

CU

39817B

X4

X5

EXT LS+

EXT LS-

X2

+12.5V

DATA+

DATA-

TX AF+

TX AF-

GND

+12.5V

RX AF+

RX AF-

+12.5V

EXT LS+

EXT LS-

GND

Line out

Line out

CB/RT50XX

J1

J2

X6

X5

X2

EXT/CU

LS+

EXT/CU

LS-

X3

X6

1

2

3

4

5

X3

6

7

8

9

10

11

12

13

14

15

EB/CU

Figure 2.5: Inside view of EB5008 extension box

6

0546

3 Using the Service Interface

Once the cable connections between the VHF equipment, the SB5006 Service tool and the

PC has been established, call up the HTML browser and type the IP address defined for the

Service tool (factory set default http://169.254.86.86 or lanbox) in the address field. The

Service Interface index page should appear (see Figure 3.1).

Figure 3.1: The index page is the common link for the service tool user interface. The index page

is the menu list in the left area, always available regardless of the page loaded.

The page shown is the front page that will always be displayed when “lanbox” or numeric IP

address is entered in the browser address field, or when the system reboots after a software

upload.

The “VHF Radio” field contains the following information of the VHF 5000 series radio:

• Line 1 – Software Main Release version

• Line 2 – Boot monitor version (only pre-programmable from factory)

• Line 3 – DSP code version (sub-version of the main release)

This information is also available from the menu system in the radio. If the version information does not appear in the “VHF Radio” field after 20 seconds, the connection may have

been lost. Please refer to Appendix – Troubleshooting.

0725

7

The “Service Tool” field contains the following information of the SB5006:

• Line 1 – Current logical name

• Line 2 – Current IP address

• Line 3 and 4 – Software version

The service tool user interface is created as a collection of individual HTML pages managed

by a HTTP server in the SB5006 service tool. The HTML pages that form the service tool

user interface are distributed between the SB5006 service tool memory and the VHF radio

memory.

The pages residing in the service tool are general pages. These pages can always be

reached even if the data connection to the VHF radio is lost.

Pages that are used for direct configuring of the VHF are physically placed in the VHF

memory. This is to ensure the pages always match the current version of the radio software.

No other components in the system (e.g. CUs) hold HTML service pages.

Selecting a page by clicking one of the available buttons/links on the current page, will

request the page from its physical location, request any parameter values that correspond to

the page, and display the page in the browser.

The physical communication interface between the SB5006 and the VHF radio is 9600 Baud

(some pages may take a while to load). While the page and values are fetched from the radio

the activity is indicated in the bottom of the browser window.

Note: It is recommended to wait for the currently requested page to appear, before another

page is request.

Figure 3.2: Activity indicators

8

0546

4 Use Scenarios

This section describes the users interactions required to configure the VHF 5000 series

system.

4.1 Configuration Level

The SB5006 service tool is only required for dealers/service workshops that are required to

do service and/or configuration of VHF 5000 series systems. The service tool is not compatible with other Sailor VHF products (such as VHF2000, VHF3000 and VHF4000 series).

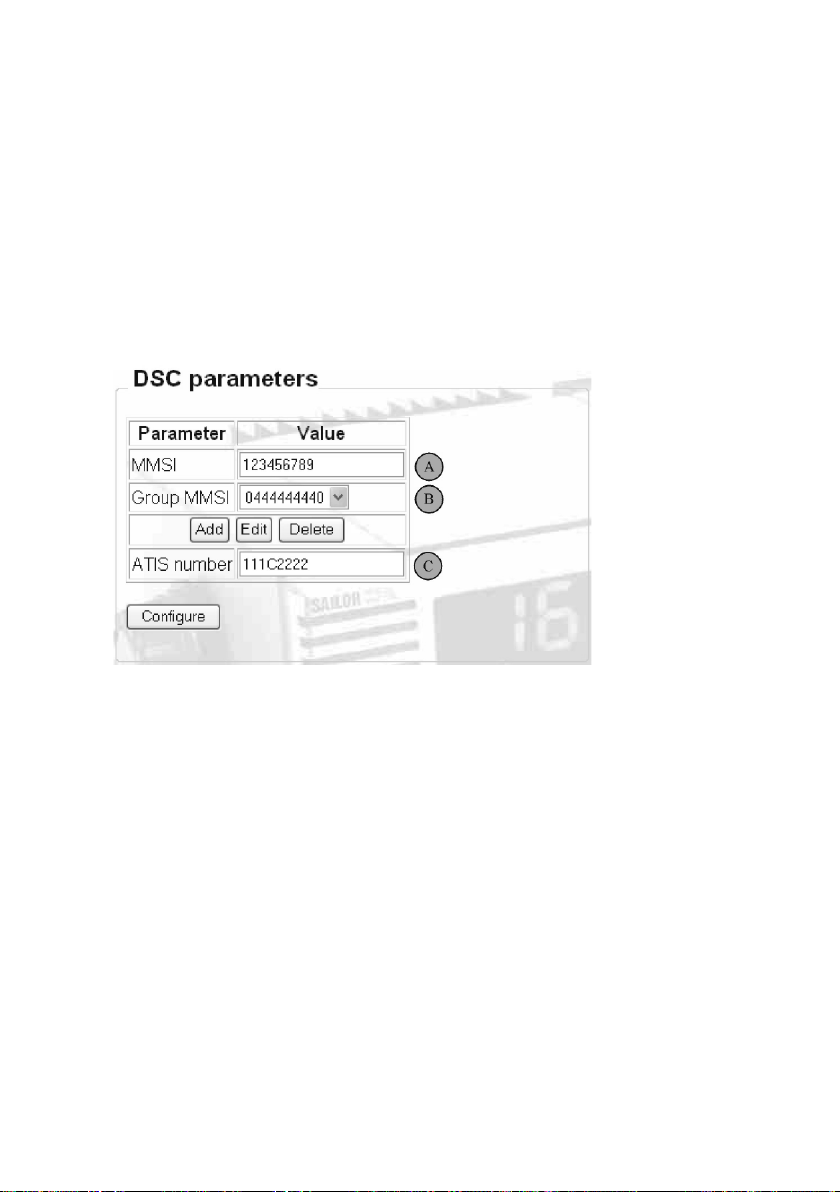

4.1.1 Setting DSC Parameters

Selecting the DSC Parameters menu item on the left side of the index page will bring up the

following page:

Figure 4.1: DSC relevant parameters.

A - The MMSI number can be changed any time just by entering a new number in the MMSI

field. The following values are valid for MMSI number entry:

• Enter the 9-digit MMSI number.

• Enter a 10-digit MMSI number, where the 10

used to distinguish between multiple radios on the same vessel (range: 0-9).

• Clear the MMSI by removing all digits. Allows the user to program a new MMSI

number one time only from the radio front.

B - Up to 10 MMSI group numbers can be programmed (added, edited or deleted) from the

Group MMSI section. The radio will respond to group calls addressed to one of these

numbers.

C - For radios configured to inland waters (BI) operation, an ATIS code must be applied. The

ATIS number is entered or cleared by simply typing or deleting it from the ATIS number field.

0546

th

digit is a sub-address digit that can be

9

Example: A Dutch (MID-number 244) ship with call sign SP1234, should be programmed

with the following number (letter digit must be capital):

244P1234

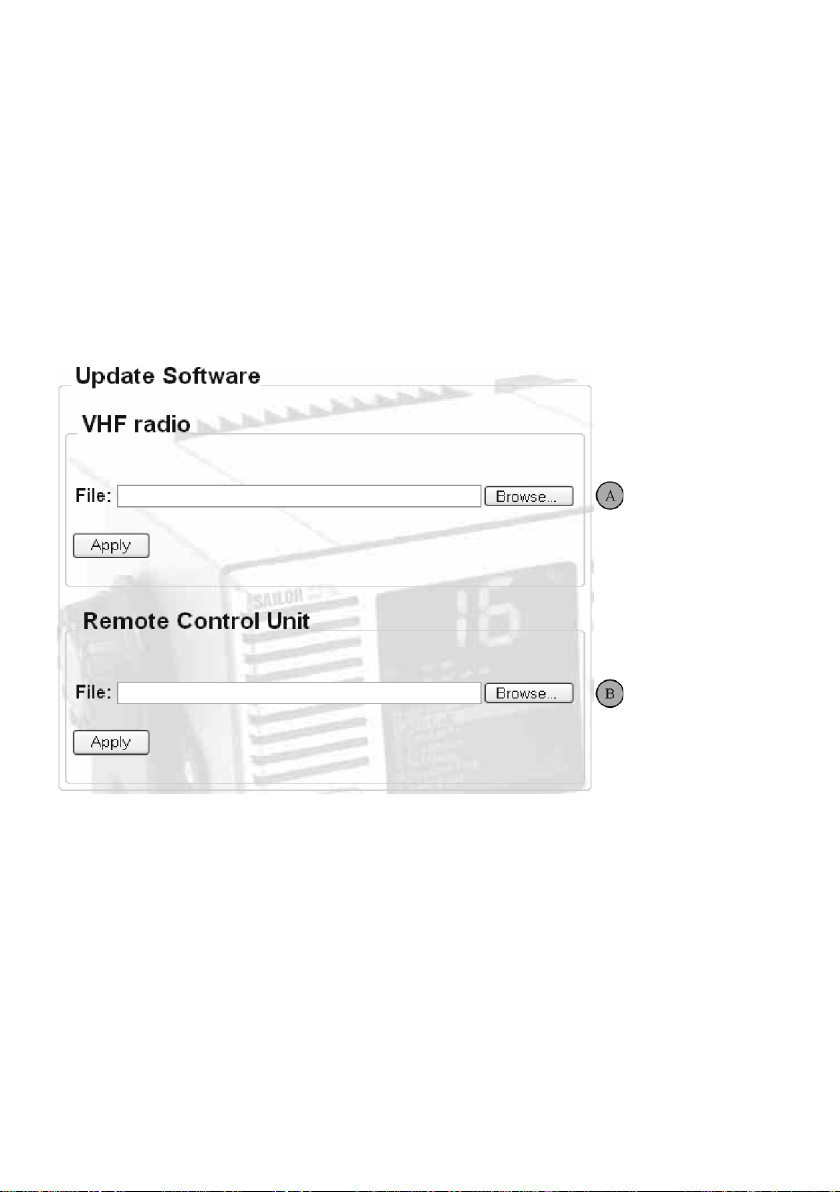

4.1.2 Software upload

If new software releases are made available from Thrane & Thrane for the VHF 5000 series

system, such a software file will be made available for download from the Thrane & Thrane

extranet.

To perform the software update the downloaded software file must be stored on the PC

connected to SB5006.

Click the Update software menu item in the left area of the index page.

Figure 4.2: The Update Software page is physically located in the SB5006.

A – The VHF software file is simply programmed by clicking the browse button, select the

acquired file and click on Apply.

Note: Any CU5000 in the system must be turned off during VHF software upload.

During the software upload sequence the VHF radio will indicate the software upload

progression by a pattern in the VHF channel display (Figure 4.3).

10

0546

Loading...

Loading...