Thornycroft 90, 108 Owner's Manual

BS 5514/1.

MARINE ENGINES

The Thornycroft 90 and 108 engines are both 4 cylinder, 4 stroke naturally

aspirated high speed diesel units, both engines having electrically operated heater

plugs to aid cold starting.

The cast iron crankcase with ribbed sidewalls houses a forged steel, fully

counterbalanced crankshaft carried in three or five bearings respectively.

A full pressure wet sump lubrication system is employed with a full flow

detachable element type oil filter and integrated lubricating oil cooler.

The cooling system is indirect and usually employs an engine mounted heat

exchanger with a belt driven raw water pump. This system is known as IFWC

(internal fresh water cooled).

An optional system is EFWC (external fresh water cooled.) This system utilizes the

engine fresh water pump and usually employs skin tanks attached to the hull to serve as heat

exchangers.

The single belt driven alternator and fresh water pump drive include a manual

belt tensioning arrangement for low maintenance completes the comprehensive

engine package.

90 108

4 Cylinder naturally aspirated 4 Cylinder naturally aspirated

Power intermittent at 3500rpm = 36BHP Power intermittent at 3500rpm = 47BHP

continuous at 3000rpm = 30BHP continuous at 3000rpm = 38BHP

Maximum torque at 2400rpm = 731bf ft

Maximum torque

Idle speed

at 2500rpm = 531bf ft

= 570rpm

Idle speed = 570rpm

Minimum full load speed = 1500rpm

ENGINE RATINGS

Minimum full load speed = 1500rpm

The type 90 Engine may be set to develop continuous outputs from 13.5 to 30 BHP according to

requirements

The type 108 Engine may be set to develop continuous outputs from 21 to 38 BHP

according to requirements.

For special applications where full power will not be required for periods in

excess of 1 hour in any 12 hours consecutive running the engine can be supplied at an

intermittent rating as shown above.

NOTE: All horsepower ratings quoted are at the engine flywheel. Due allowance must

be made for transmission losses which will depend on the type of gearbox fitted.

For tropical use it is necessary to derate the engine by 2% for each 5%°C (10°F)

above 30°C (85°F) air temperature at sea level. In some parts of the world

further derating for humidity is necessary in accordance with

INITIAL STARTING OF ENGINE

PAGE

_. Engine mounting and dipstick marking. Filling engine with oil.

2. Lubricant specification for engine and gearbox. Filling gearbox.

3. Coolant/Corrosion inhibitor specification. Filling cooling system.

4. Priming the engine oil system.

5. Bleeding the fuel system type 90 engines.

6. Bleeding the fuel system type 108 engines.

7. Initial start. Normal start. Running in.

8. Operating guidelines.

9. Operating guidelines.

MAINTENANCE

Maintenance schedule.

Engine oil and filter change

Engine oil and filter change

Fuel filter change. Cleaning

fuel lift pump. Gearbox oil

change. Cleaning air filter.

Alternator drive belt adjustment

and replacement. Raw water pump

adjustment and replacement.

Checking and setting valve

clearances. Procedure for

retorquing cylinder head nuts. Removal/Refitting

fuel injectors.

Changing coolant.

Draining raw water system.

External fresh water cooled engines.

Electrical system.

Fault finding.

Fault finding.

Laying up the engine.

Re-commissioning.

Notes.

10.

11.

12.

13.

14.

15.

16.

17.

Type 90 engines.

Type 108 engines.

18.

19

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

THORNYCROFT

Page 1

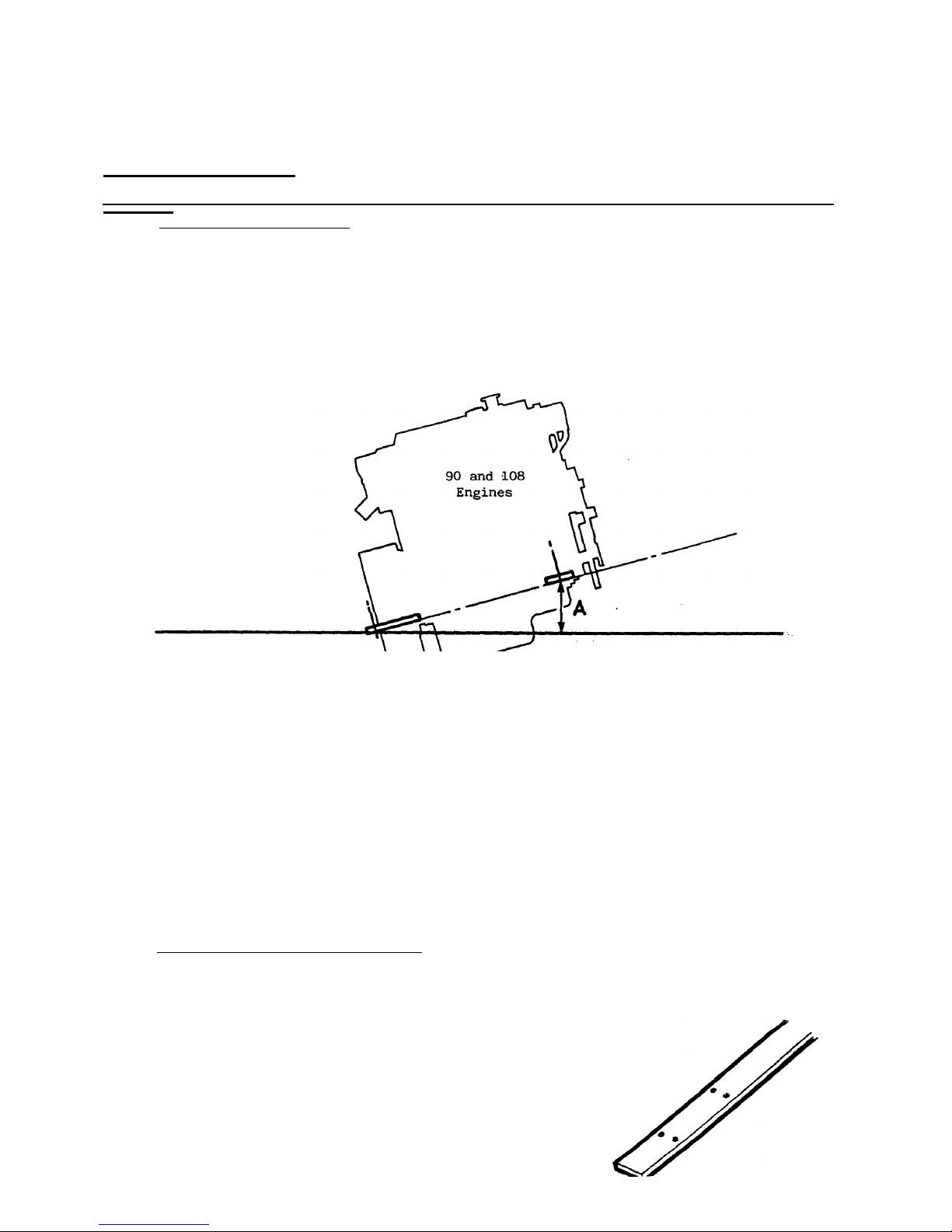

CHECKING ENGINE MOUNTING

The maximum installed angle of the engine is 15°, engine types 90/2, 108 and 108/2

(10° for engine type 90). This allows for a further rise of 4° when the craft is

moving. Check the angle of installation using the centreline of the mounting feet

bolts as a datum. Measure vertically on the centreline of the underside of the

front mounting foot bolt to find the angle of installation Fig. 1

Fig. 1

Horizontal Line

Type 90 Type 90/2 Type 108

A 93mm = 10° A 138mm = 150 A 136mm = 15°

46mm = 5° 93mm = 10° 91mm = 10°

46mm = 5° 46mm = 5°

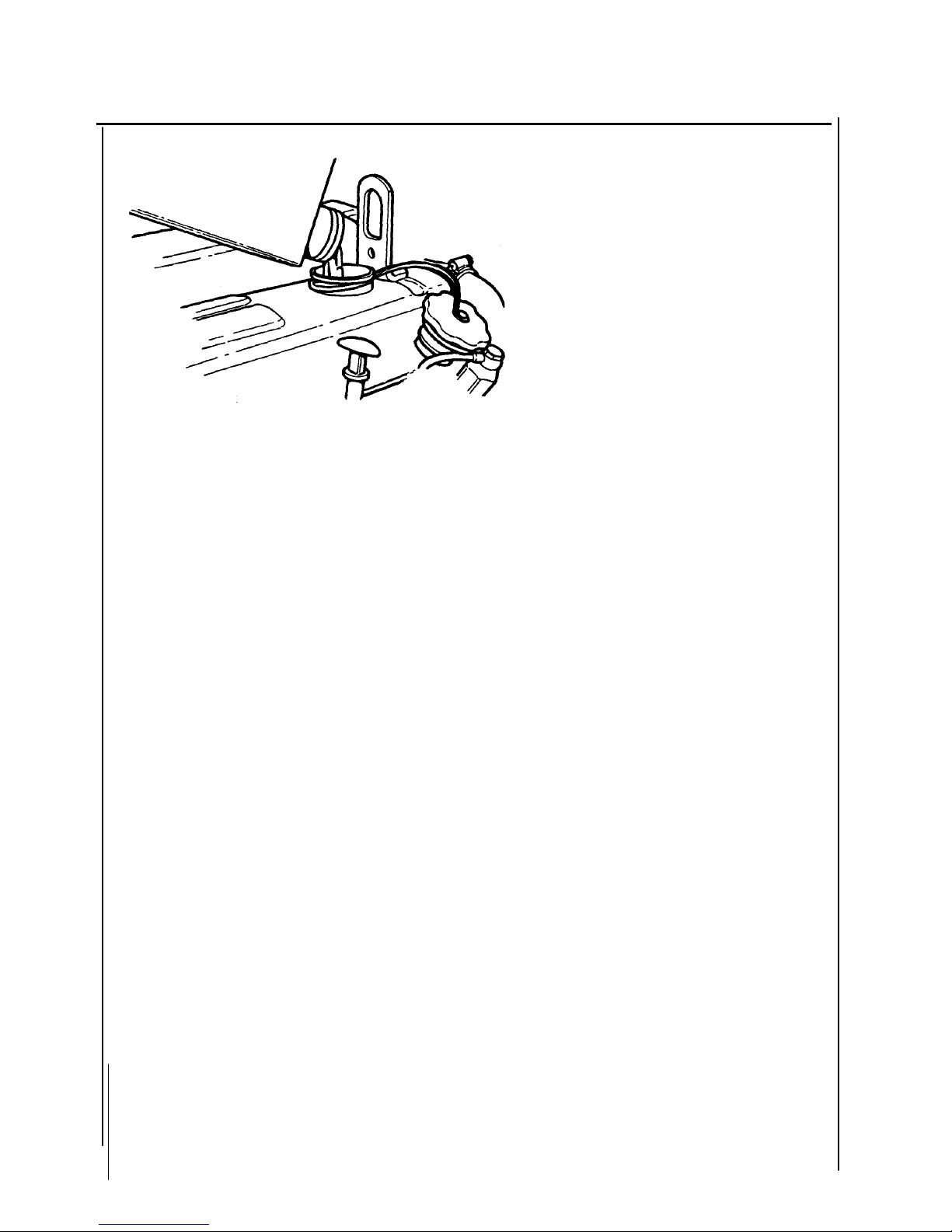

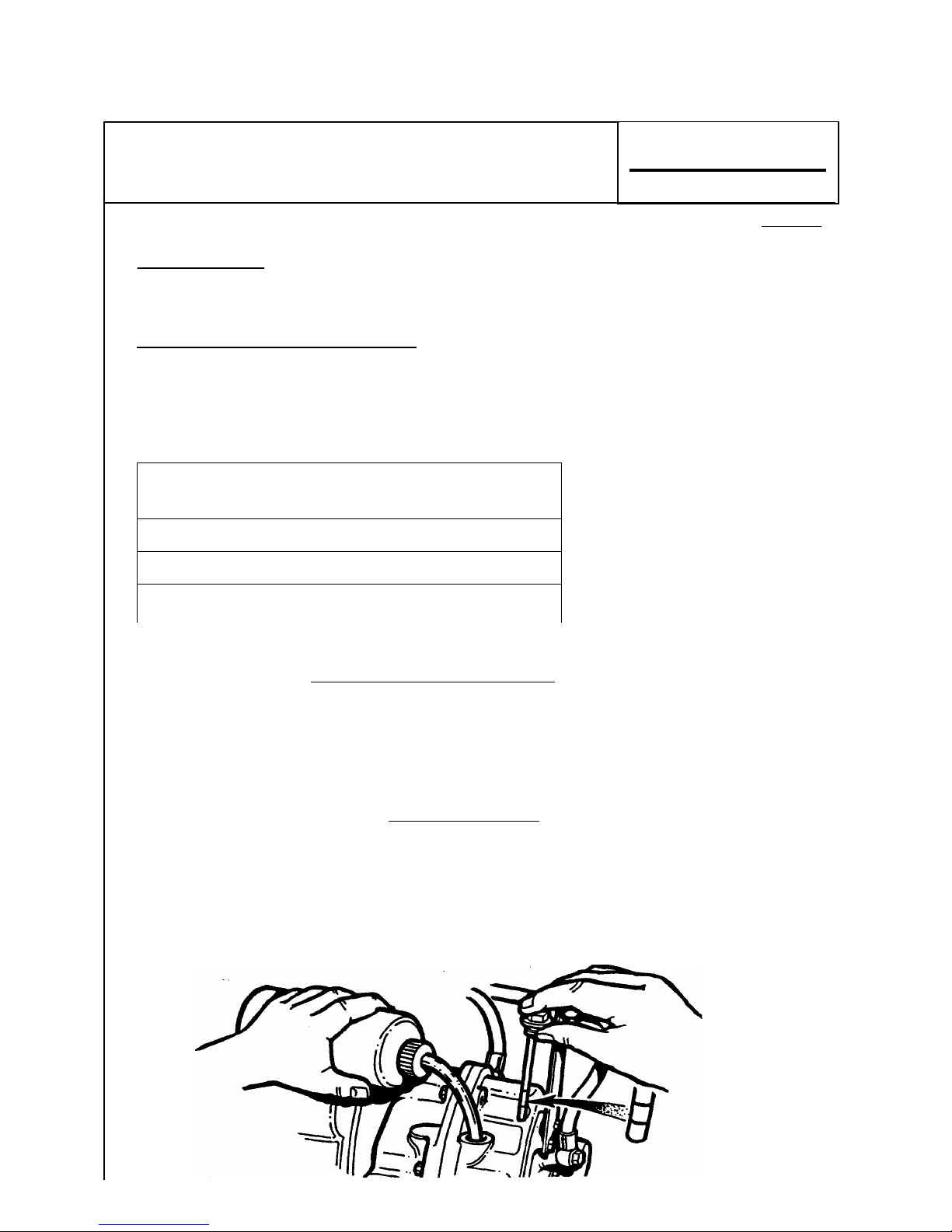

MARKING DIPSTICK, FILLING WITH OIL

Your engine is despatched from the factory without engine or gearbox oil and with an

unmarked engine dipstick. After the boat is launched, and is resting at

its normal trim angle, remove the oil filler cap from the rocker box Fig. 2 and pour 3.9

litres for type 90, 4.5 litres for type 90/2 or 4.8

litres for type 108 of specified lubricant through the filler

hole. Allow 5 minutes for .the oil to drain into the sump,

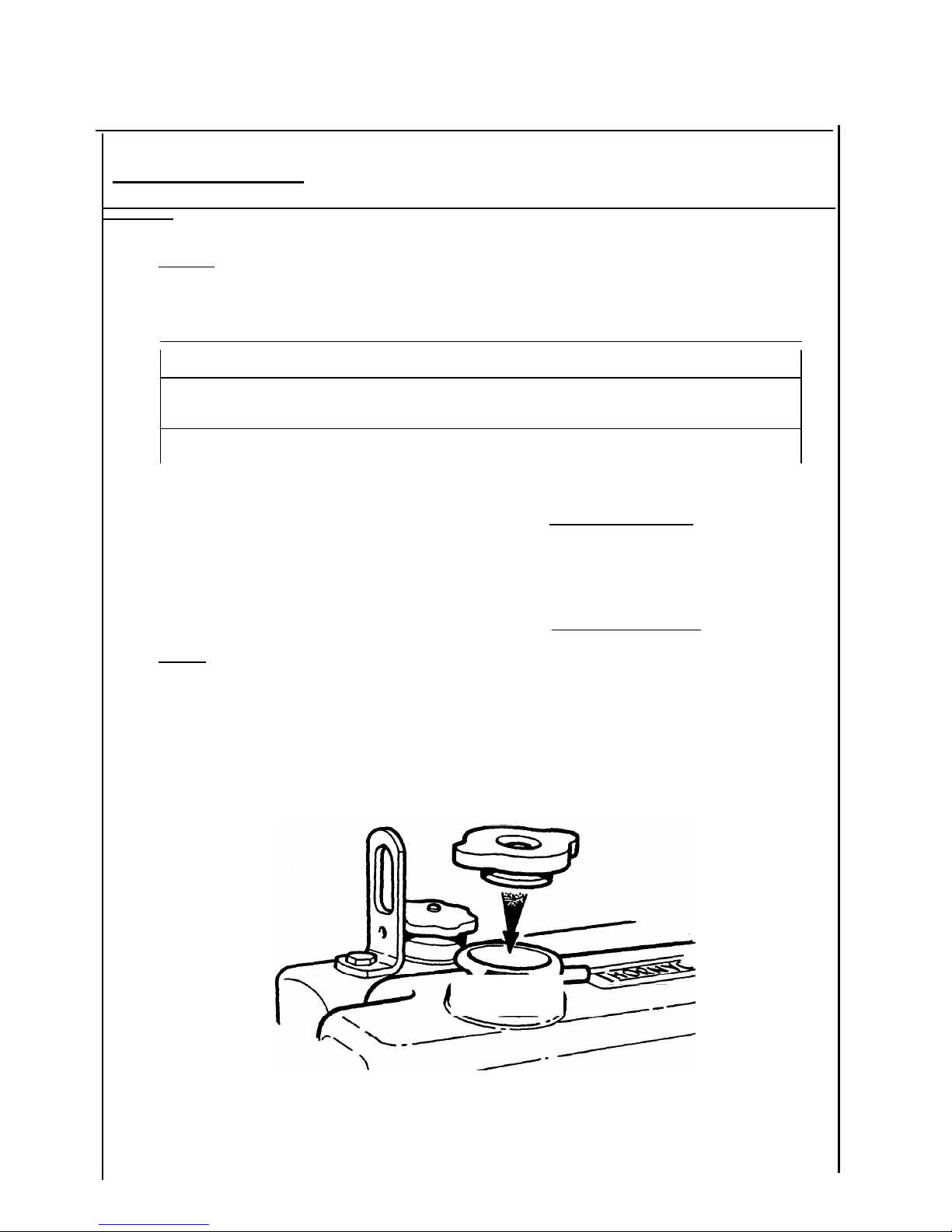

withdraw the dipstick and mark it for maximum oil level Fig.

3 (Use a centre punch for marking as filing a notch can

cause fatigue and eventual breakage while the engine is

running). Then mark dipstick using the same method 12.7mm

(%") below the maximum mark and this will be the minimum

level.

CHECKING ENGINE MOUNTING,

MARKING DIPSTICK, FILLING ENGINE WITH OIL

LUBRICANT ENGINE AND GEARBOX

`Page 2

ENGINE OIL

RUNNING IN OILS

Do NOT use special running-in lubricating oils for new or rebuilt engines. Use the

lubricating oils specified for normal engine operation.

ENGINE OIL VISCOSITY RECOMMENDATIONS

The use of a multi-graded lubricating oil has been found to improve oil

consumption and improve engine cranking in cold temperatures while maintaining

lubrication at high operating temperatures. A multi-grade oil conforming to

MIL-L-20104B is. recommended with the viscosity grades shown in Fig. 4. The use of

single grade lubricating oil is not recommended except for synthetic oils used

in arctic conditions.

Atmospheric Temperature Viscosity

Above -10°C 20W50

-20°C to 10°C 1OW30 or 1OW40

Below -10°C 5W30 or 5W40

Fig. 4.

GEARBOX OIL

Borg Warner

Automatic Transmission Fluid

(Type A)

Hurth

Automatic Trnamsission Fluid (Type A)

Newage PRM SAE 20 Engine Oil Minus 18°C to 0°C

SAE 30 engine Oil Above 0°C

FILLING THE GEARBOX

Remove the oil filler plug combined dipstick from the top of the gearbox. This is

in approximately the same position on Hurth, Newage PRM and Borg Warner. Using

a plastic bottle or funnel, fill the gearbox up to the maximum mark on the

dipstick. There is one level mark on the Hurth dipstick, the others have high

and low marks.

THORNYCRO

Fig. 5.

M Fig. 8

COOLING SYSTEM

Page 3

COOLANT

Use anti-freeze during all seasons to protect the engine cooling system from

corrosion as well as freeze damage. Using the following anti-freeze solution %.

25% 33% 50%

Solution Solution Solution

Complete protection lO°F(-12C) 3°F(-16C) - 4°F(-20°C)

Safe protection 1°F(-17C) -8°F(-22C) -18°F(-28°C)

In tropical climates where anti-freeze availability may be limited, corrosion

inhibitor to protect the engine cooling system.

NOTE: Corrosion inhibitor is NOT an anti-freeze. COOLANT QUANTITIES

Complete system including engine (IFWC) types 90 and 108 engines.

5.1 Litres

For external fresh water cooled engines (EFWC) See Page 23. FILLING THE COOLING

SYSTEM

Remove the filler cap from the heat exchanger Fig. 6 and fill the system

with coolant. This will take approximately 5 minutes as the system self

bleeds. Fill to 5mm below the filler neck level mark. Refit filler cap.

THORNYCROFT

use a

M Fig. 9

405i

l

I

Page 4

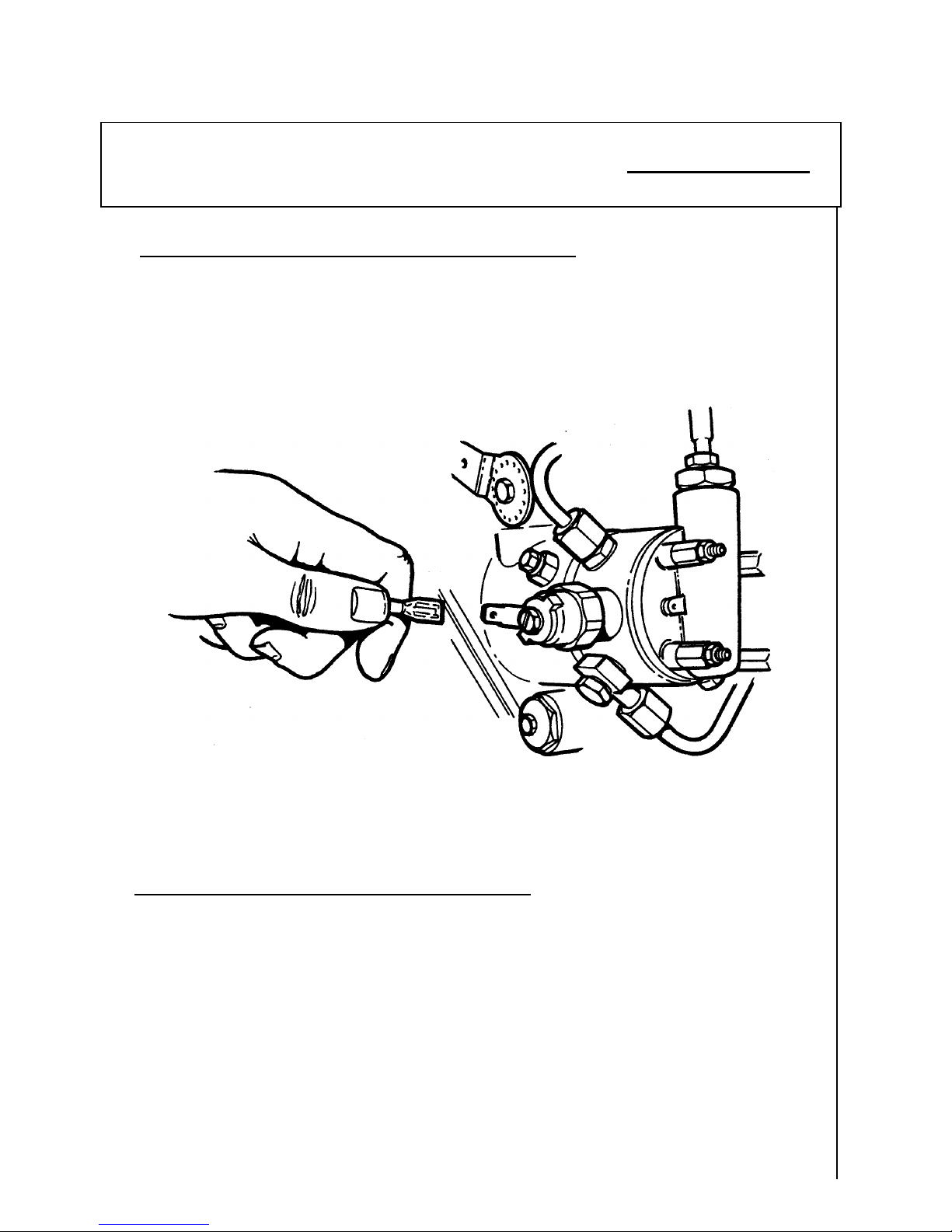

PRIMING THE ENGINE OIL SYSTEM (TYPE 90/2R ENGINES ONLY)

As only a residual amount of oil is present in the oil pump, filter and oil

galleries of the engine, it is therefore necessary to prime the system before the

engine is run. Connect the engine starter batteries disconnect power to the

fuel solenoid valve on the injection pump Fig. 7 and crank the engine over using

the key starter switch until pressure registers on the oil pressure gauge.

Stop cranking and check the engine and gearbox for oil or water leaks. Replace

power connector.

Fig. 7

PRIMING THE ENGINE OIL SYSTEM (TYPE 90 AND/108 ENGINES)

As only a residual amount of oil is present in the oil pump filter and oil

galleries of the engine it is therefore necessary to prime the system before the

engine is run. Connect the engine starter batteries, operate the key starter

switch with the stop control out, crank the engine over until pressure registers

on the oil pressure gauge. Stop cranking and check the engine and gearbox for

oil or water leaks.

PRIMING THE ENGINE OIL SYSTEM

THOMYCWFT

Page 5

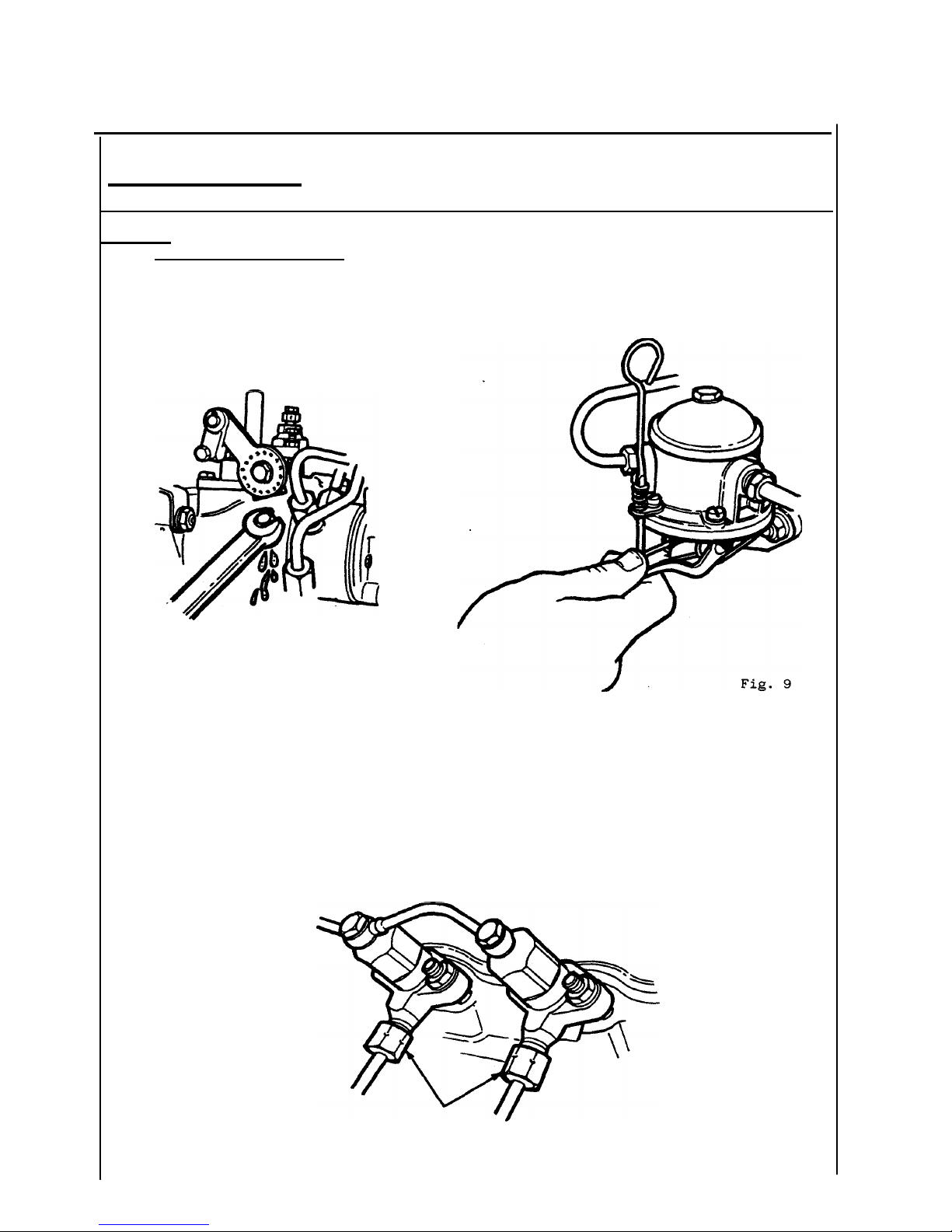

BLEEDING THE FUEL SYSTEM

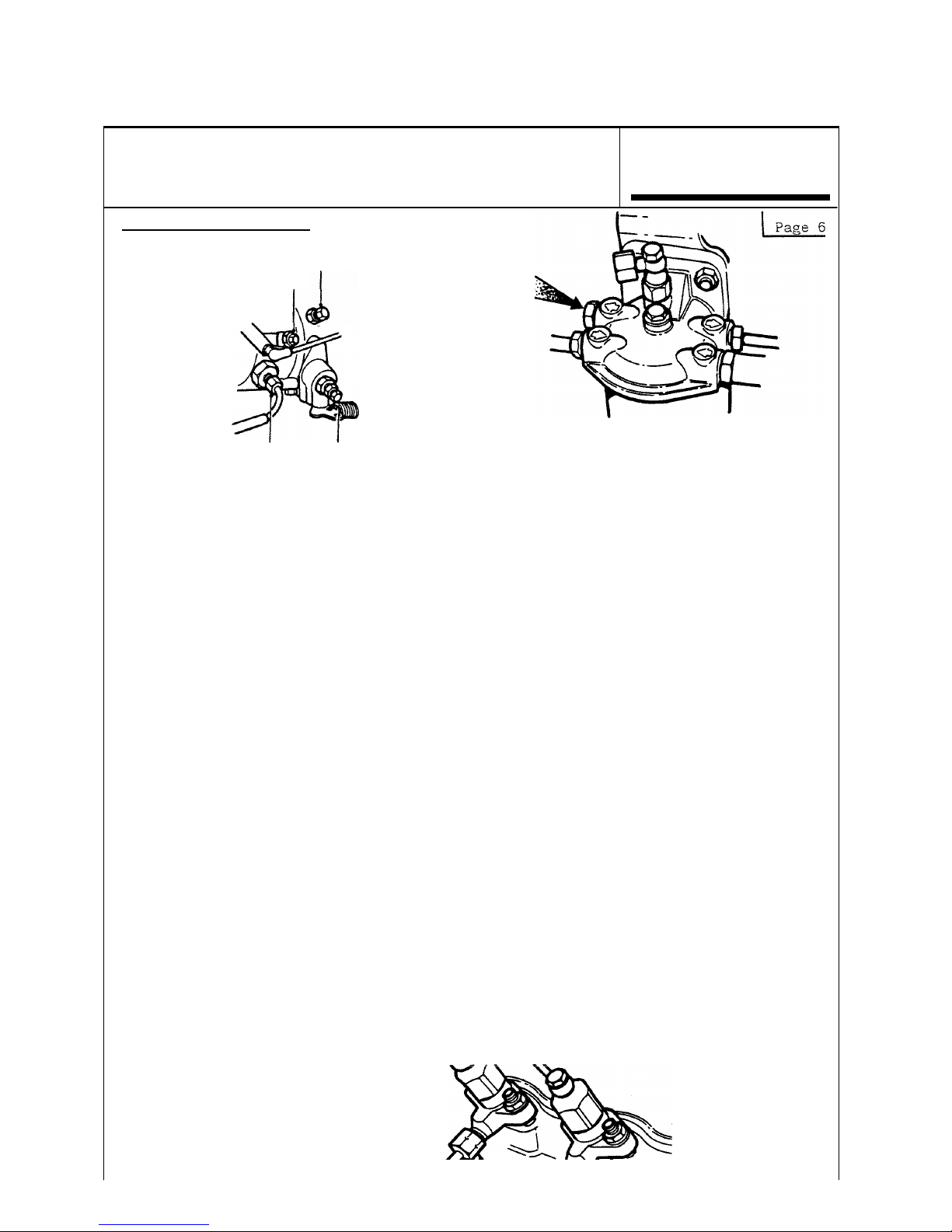

Slacken the bleed valve on the injection pump Fig. 8. Operate the lift pump

Fig. 9 and when the fuel coming from the valve is free of air bubbles, tighten the

valve.

Fig. 8

Slacken the unions at the

injector ends of any two high pressure pipes. Fig. 10. Ensure that the stop

control is in the run position and the engine speed control is in the fully

open position. Crank the engine until the fuel coming from both pipes is free from air

bubbles, then tighten the unions.

NB. After initial start procedure has been observed start the engine and allow it

to idle until it is running evenly on all four cylinders.

THORNYCROFT

BLEEDING THE FUEL SYSTEM TYPE 90 ENGINES

Fig. 10

Fig. 13

BLEEDING THE FUEL SYSTEM

5 3

Fig. 11 ~`

2 4,6

Note: After renewing the

fuel filter element it will only be necessary to bleed the fuel filter as

described in 1 and 2, provided that the engine has not been cranked while the

filter is dismantled.

1 Slacken the blanking plug in the unused outlet connection in the fuel

filter head Fig. 12. Operate the lift pump Fig. 9 (page 5) until the fuel

flowing from the plug is free of air bubbles, tighten the plug. NB. Numbers

2-6 refer to Fig. 11 bleed points.

2 Slacken the union nut at the injection pump end of the fuel feed pipe.

Operate the lift pump and when the fuel flowing from the union is free

from air bubbles, tighten the nut.

3 Slacken the air bleed screw on the injection pump body. Operate the lift pump

and, when the fuel flowing from the bleed screw is free from bubbles, tighten the screw.

4 Slacken the air bleed screw on the injection pump governor housing.

Operate the lift pump until the fuel flowing from the bleed screw is free

from air bubbles, leave the bleed screw slack.

5 Slacken the air bleed screw on the injection pump high pressure banjo bolt.

Operate the starter motor while operating the throttle control and, when the

fuel flowing from the high pressure bleed screw is free of air bubbles,

tighten the bleed screw.

6 Continue cranking the engine with the starter motor to expel any air

trapped in the governor and, when the fuel flowing from the governor

housing bleed screw is free of air bubbles, tighten the screw.

Slacken the unions at the injector ends of any two high pressure pipes. Fig.

13. Ensure that the stop control is in the run position and the engine

speed control is in the fully open position. Crank the engine until the fuel

comibng from both pipes is free from air bubbles, then tighten the unions. NB. After initial

start procedure has been observed start the engine and allow it to idle until it is

running evenly on all four cylinders.

BLEEDING THE FUEL SYSTEM TYPE 108 ENGINES

THORN

Fig. 12

Loading...

Loading...