Thornycroft 154 User Manual

r-

i

'

- -,.,:i

-iffii;

=:ii.:

'

-:r-a.

+t:.!

',..

l:

b

*

^

I

ïrf0RtïfYcR0FT

published

TECHNICAL

by

PUBLTCATIONS

DEPT.

Leyland

BRITISH

PO

Telephone

8ox

2. Hursl

LEYLAND

Lane, Íipron.

-557

021

Thornycroft

UK

LIMITED

StaÍís

Oy4

2881 Tetex

338026

9AD

Cabtes

Bean

Tipron

Teter

instructions

The

pages

operation

urged to

are

lubri-cation

aclvlce

without

who are

urged to consuft

Dealer

restricted

are

and

reconmendati-ons

given in

Certajn

use of

the

not equípped

or

Distributor.

maintenance

read

overhaul

INTRODUCTION

contained

to those

of the

them carefully,

ald.

Section

their

D about

operations

speci-al

undertake

to

Thornycroft

tools,

*-

.-*

within

necessary

engi:le;

to note

fuel clealliness.

are

the

for the

observe

to

and. those

najor

carefully

inpracticabl-e

repairs, are

or British-Leyiand

fol}owing

efficien:

operators

the

the

operators

Besides

nents,

fu11y equippecl

efficient

checked

this test

process.

process

and

50

ancl d.epeniiability

Dealers

All

gradually

hours nrani-ng.

befug

after-sales

diesel

perfornance on a test-bed

for

is ilsufficient

After

nust be continued

llforned

kept

and Distributors

r*orkshops

thus enabling

service.

RUNNING IN

engines

installilg

lncreasilg

nanufactured

to normql

This ri1l

throughout

of the

have skilled'

by the Comparry

but the

to conplete

engile'

the

by coromenciag

result

the

the

load durilg

i-a

life of the

latest

thera

the ruming-il

with a

greater

develop-

personnel

to naintairt

duration

ttrunnjlg-inrl

llght

the

efficlency

engine-

and

are

of

load

jlitial

LIST

PARAGRAPHS

OF

I

SECTION

Para,

It

I

tl

It

ll

It

tl

tl

SECTICE{

Para.

t'

t,

tt

r?

,t

C1

c2

a?

v)

11^

nE

c6

-

A

DATA & OPERATIOIL

Ger:ral

-n---t

a

i:le]lle lal]-ngs

'-l-et

i='

--;frrr

i -i-c-r'i

z:í'- a :p

:-c:;-.:

,:. =

C - d{GE{E

General

--

-:

:

s;arri-ng

i

LTBRICÀ:iO]{

description

Grade of lubricating

To check

To change

To change

Engine

oil

lescription

:^+-

and bilge

'.ni

the engifie

ston iho onoi no

the engile

nri-ntenance

engl-ne

the

engine

g

oi_1

oil

s s i oni-.::

engine

cooler

punp

suction

for

d.rlring lay

periods

and

oi-1

leveL

oil filter

strainers

the

first

up

element

time

SECIION

Para.

D1

tr

D2

tl

D1

tl

D4

tl

D5

tl

,o

tl

D7

$ECTIoN

Para.

E1

I

E2

ll

E3

tt

E4

tl

n5

It

-LO

tl

E7

*FUEL

D

SYSTN{

leanliness

C

Fuel handling

FueI lift

Fuel injectors

Fuel

filter

Bleeding

cleaner

Ai.r

-

E

C0oLING

l'lenerr'l docnri nl-i ^"

Frost

T)ra-inina end nlooni

SYSTH4

!

precautions

Routine

The sea

Heat exchalger

Bil-ge punp

and

purnp

the

system

uqÈua

r}JurUtl,

sdrrrng

mplntenance

water

pump

storage

the

of

the

water

sea

systems

water

system

SECTIO{

F - H,ECTRICÁI,

SYSTM{

Para.

Fl

ilF2

il

Ir3

ll

I1/t

SECTIOIi

Para

G]

VL

Alternator

Batteries

Starter

Ileater

-

REVIfiSE//REDIETION GEIRS

G

Sorg

motor

plugs

Warner Gear

TMP Gearbox

LIST

OF

ITTUSTRATTONS

Iig. i.

Fig.

2.

Fig.

l. cylinder

Fig.

4. Oil

Fig.

5.

Fig.

6.

Fig.

7. Fuel lift purap.

Fig.

8.

Fig.

9.

Fig.

10,

Fig.

11.

Fig.

l-2.

Fie.

15.

FÍg.

1{.

Fig.

15.

General view

Valve

0i-1

0i1

Fuel

Air

Water

Heat exchanger.

htiriag

Belt

Heater

Geexbox

rockers"

head

cooLer,

filler

filter

filter.

cl-eaner

adjustnent"

coolin6

diagran.

p1u6s.

oil

cap and

elenent.

.

cooler.

of engile.

nuts.

filter,

systern.

sump

dipstick.

draïn

prunp.

,',

.!

,\_

'

SECTION A - DATA

g!}{ERAI,

!isf

I

DESCRÏPTION

nê

&

OPERATIO]TI

The Thornycroft

based

4

(2)

Lubrication

}e lubrication

'*itn

-\ ^

j

I ;OC.-'E

lhe

upon

cylinder

exrernal-

S'r'Ste=,

sta::oarl

the British

diesel engine.

Systen

coo.t-rng

sJrs:er, :ierrostaticaily

assisted.

through

The

External

sJrstem,

assisted.

tank.

r'rateï

the

1íne

through

outside

where

immersion

It is

a heat

Keel

thermostatically

Pressure

Cooling

a

skin of the

it

is

of

these

marine

154

systen is a

ful-l- flow

system is

cooied by

exchange:.

Cooli-:cg

is maintained

is

achieved

series

cooied

pipes

diesel

engirre is

Leyland 2.52

pïessrtre

fuJ-L

oil- filter

a

fresh

controlled,

sea water passing

i_s

fresh

a

control l_ed

by

passilg

by

pipes

of

boat,

by

jn

mounted.

below

the

conti_nual

sea water,

Lítre,

and oil

water

pwp

nater

punp

and

a

header

the

on

the

water

systen

cool_er.

fresh

A

water

as

/ r r - t-

(

t(everqe7'Re(Lqqing

4/

FulI

for

jacketted

stand.ard.

detaiLs

the

Borg

gearboïes.

exhaust

Gears

given

are

Warner,

fMp

4.1

manifold

in

the

and

service

p.R.

is

fi_tted

nanuals

Motors

Á'2.

ÊES,EE4!-!48

/- \

(

L $nsule

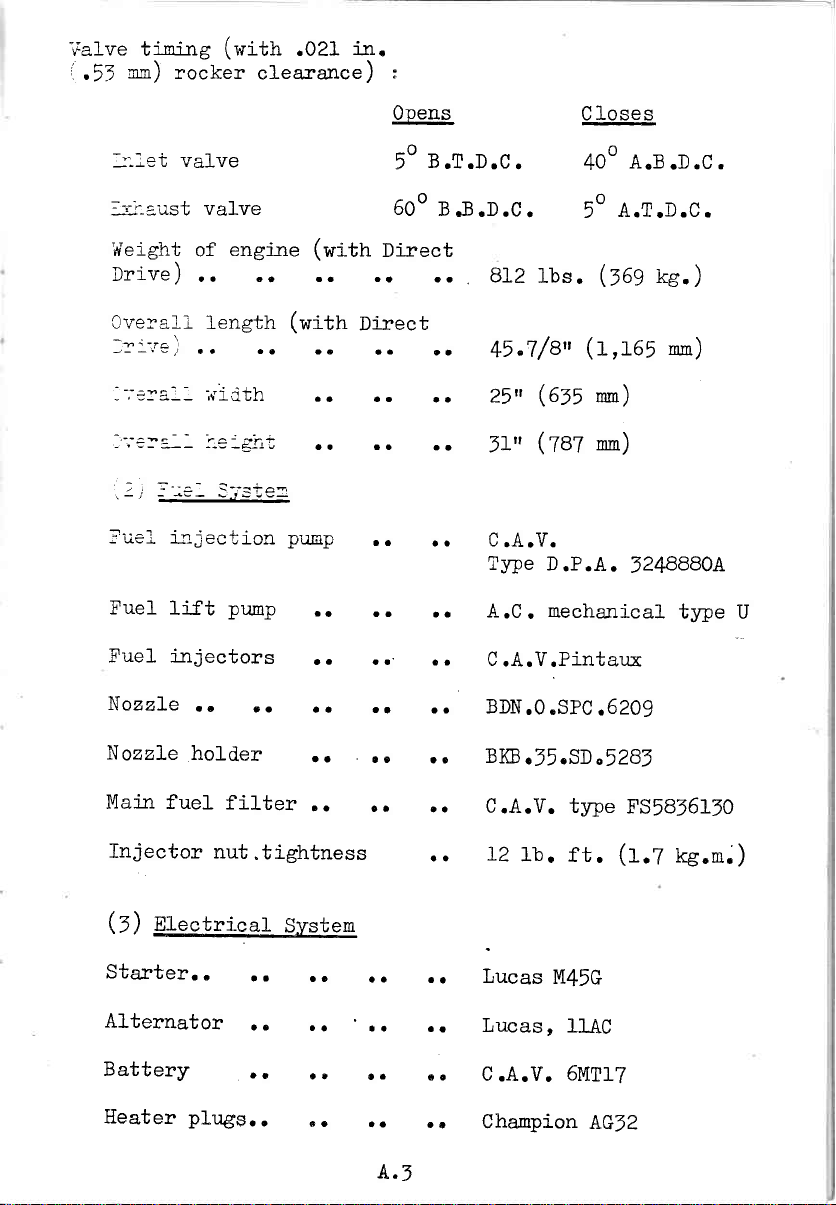

Nunber of

cylilders

?a

ec

4.

CyJ.ind.er

bore ..

Piston stroke

Swept

volume ..

Conpression

Cylilder

li:ner

Crankshaft..

Injection

pressure:

0i1

pressure

0i1

gOeS

order .o

OUt

at rr

..

ratio

..

.r

Idlirrg..

Normal

lÍarnirlg

oa

ta

at

aa

aa

running

light

.. .e

ca

oa

oa

o9

ac

aa

oo

5.5u

4,'

(88.9En)

(101.6nn)

154 cu.jn.

L9.5 : I

Dry, slip

bearing

J

on afl

crarkpjsso

It

15

(r,05

50

(3.52

5to

(ze

j

ournals and

4,

7,

Ib./sq.i-n.

kg/sq.cm.)

lb'/sq.in"

kg'/sq'en)

g

lb./sq.r4,

to

,65

(2"52

litres)

fit.

TUFTRIDED

2.

kg,/sq,cn)

oc

(

iacfuaiag

.. r.

0i1-

capaeity

filter)

Fresh

weter capacÍty

Valse rocker clesrsnee

Inlet oe 6o

firh;:ustoo 'n e{

€a

t'

.

cord,

\

a9

*o

l{ eë

t1

20

cu*'1

.015

pints

pirits

íJ:.

i.n.

\6,21

(tla|

(

"Jonm)

(.5so

l:.tres

litres)

sun)

)

i:alve tining

.>i

\,-\

rrl'm)

rocKer

(with

cleaSance/

.021

irr.

:':l-ei

:-iaust

t{ei-ght

Drive)

fve:ar

'!L'Í?,1

-;:Ia - ir'r

-,=--- --=-À1lr

._,'

li::'l

!

valve

valve

engile

of

.. .o .. ..

I

length

oo r.

Atl)

..^:

-..:

-- :---- ::---:^-

_ -=-

qEI

-i-!Ë:

irianiinn nr

--

---*

I4

U

PLUllp

Fuel i:rjectors

(with

f

(with

..

.

aa

rI?lP

f

..

..

.

ppens.

50

600

Direct

Direct

..

..

..

aa

ao

Closes

B.T.D.c.

r.B.D.c.

.. . Bl2

..

45.7/a"

.. 25,t

..

5L

. . C

.4.V.

?ype

lbs.

(AlS

(787

D.P.A.

À.8.D.c.

4oo

A.T.D.0.

io

(j}g

(rrr05

^

)

mn)

324ABB0A

.. A.C. nechanical

..

C.A.V.Pintaux

ts.)

mro)

type U

Nozzlg

NozzLe

Mairt fuel

fnjector

/-\ -.

trl

e+--.r-^-

uu4uglaa

Alternator

Rq**orrr

.,

hol-der

filter

nut

$feclTr_cal.

aa

..

J

a

Ileater plugs..

..

..

..

..

tightness

.

svsten

aa

..

a

at

,.

aa

ac

aa

la

aa

oa

aa

4.5

.. BDN.0.SPC

BIG.55.SD.5285

oo

..

C.A.V. type

12

..

ao

aa

co

at

Ib.

ft.

l,ucas

Lucas,

c.A.v.

Cha"npion

M45G

IIAC

6MTr7

AG12

.6209

FS5B36L30

(f

kg.n.)

.?

A,n7.

M.IJ

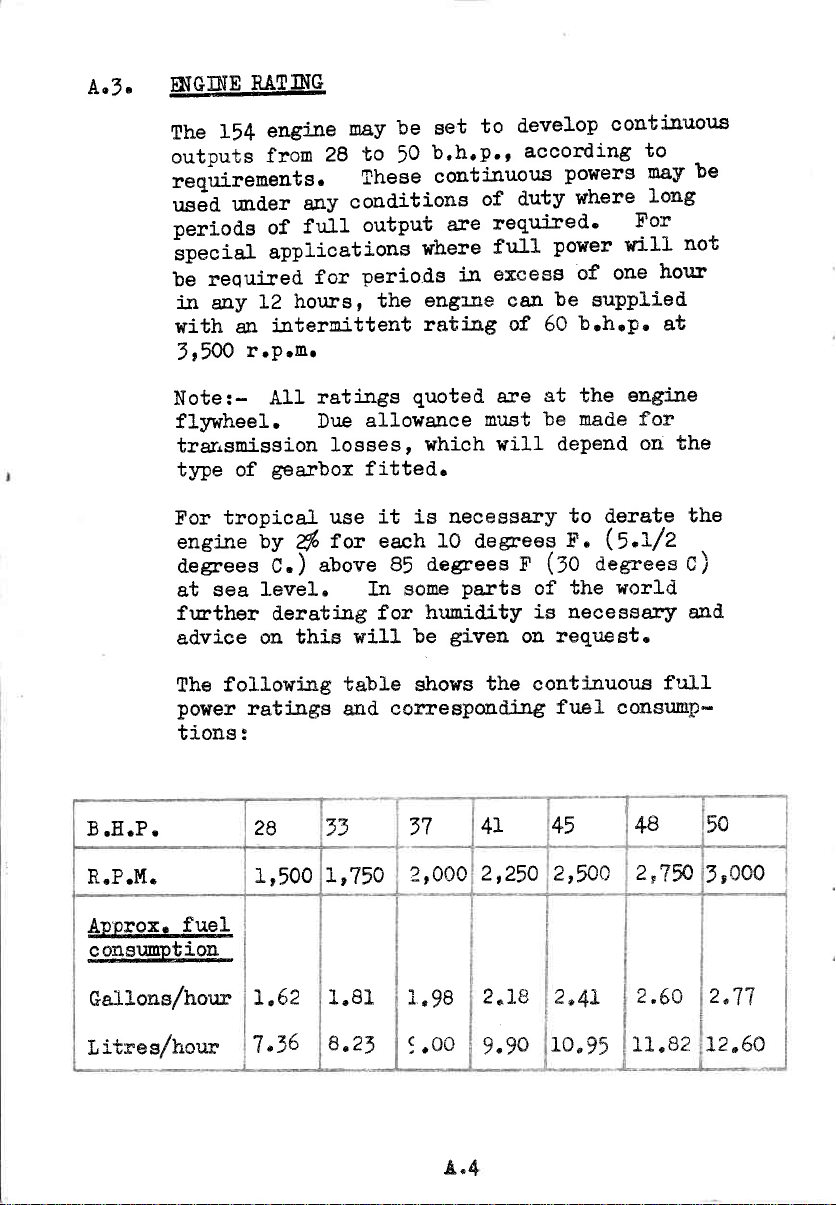

She

outputs

reqiuirenents.

usàd.

period.s

'special

be

in

with an

3r50O

ruÏr{G.

engjJle

154

fron

r.nd.er

of

eppiications

requi-red

12 hor.Es,

eny

jaternittent

r.Pellr

28

any

fuJ.l

for

be

nay

to

These

cond'itions

output

period's

6et

b.b.p.r

50

contiÍIuol:.s

where

engrlle ean

the

ratjng of

to

of

req-ujÍed'"

are

in

d'evelop

according

duty

power wiLL

fu1l

excees

be

60

conti$uou's

polÍers

where

of one

supplied

b.hnp.

to

ney

3'oag

For

be

not

hor:r

at

Note:-

flywheel,

trarrsmission

type of

Fcr tropical

engire

degrees C.)

at

frrther

advise on

The

polÍer

tions:

B

DDM

rrar

Áporox.

.E.P

auc

.

fuel

consunptioa

All

gBarbox

uv

Ievel. In

sea

d.eratiag

followi:*g

ratiags

2B

1

'500

rati.:ngs

Dr:e

losses,

use

for each

&

above

thig

table

ênd

3:"

1,75Q

quoted

allowsrrce

which will

fitted".

it is neeessery

85

some

for

be

will

shows

eorrespoiltèilÈg

77

?,00c

must

10

degreeq

d.egroe" F

perts

hunidi-ty

given

the continuous

+.L +5 48

2t25A 2'50c

et

are

be rnade f,or

depend

(30

of

is necessary ancl

reguesto

oa

fuel consunp*

engine

the

to d.erate

(5"I/2

F,

degrees

lrorLd

the

2u7fr

on the

the

C)

fulI

50

5,000

Gallonsfhorrr

Litresfhor"rr

r,62

't

zA

1.81

8.23

10Ê

9.oo

À.4

2"19

9.90

I

n4í

10,95

2,60

"r

1 0.j

ÁÀ.UÁ,

2"V7

12,60

!.4 SEA

ÏlfIET

Á]'TD

BTIGE

PWP

JJUCTION

STRÁINM.S.

Èani-ne

strai:rers

period.s

Before

with

the

(f)

Clean

applied

shouLd

coupl-i-ng

engi.:re

(Z)

Renove

roekers

(=)

Go

grJlrro

joiats

lubrieators

and

at

can

be

starting

following

off

to

be

is

the

and val_ve

over

both

Put

of

clean

the

regrrlar

set

up

with

alr brieht

paid.

faces

li-aed

vaJve gear

engiae

a little

control

and

sea inlet

i:rtervals.

d're

fo

the

engine

points

paraffin

to the

which

up"

nufrt

stems

and

oiI

gearsz

g€êsêTso

and

No

varyi:rg

for

-

the

rus,t

parts.

reverse

cover

pJr

particur-ar

be

cleaned

and

i:ritial

€iear

aceessories

i.:a

morriag

etcnl

bilge putrp

definile

local

the

conditioi.s,

first

preventative

and

before

give

al.l

feed

with

parts

and fill

suction

iaspection

time,

attention

tailshaft

the

of

oi.l.

an oil

si:ch

as

up

a1l

deal

(4)

Put

comect

by

high

(:)

By

at least

everSrbhi-ng

are

(6)

Drai'

sJrsten

Close

fj-Iler

head.er

pref,erably

anticipated',

s1rsten

into

the

dipsticks

grade

neans

elear

ered

-

the

sap

tqnk"

*

the

engine

quantity

lubri_eants.

of

a barr5r.g

two

eonplete

ie

free

of

obstruction,

fh:,sh

See

,Cooling

drain

oa

the

Use

soft

anti-frêeze

See

Cooting

sump

of

lubricating

and

and.

out

the

eock

top

c1ásn

Fater.

4"5

and

levelling

lever give

turs.s

that

fresh

Systen

aná

refíll

of

the

freeh

Where

shouJ-d

SSrsten,

reverse

p1ugs.

to

enswe

all novi:rg

water

oil

the

gear,

as

indieated

Use

engine

tËat

parts

coolixg

Section, para]g"]

tfrrolieh-ihe-

heat

erei.snser/

""tu*-o"6ï--'

freezingiis

be

para

adaód.

E.Z

to

the

only

(f)

the

(l\

\r/

T'ilt

vent

pump

the

the

e

tank with

fuel

pipe line,

the coreet

filters

and.

fuel

fueL a.nd.

injection

(e)

Examine

good

eorrectlY

(g)

Cheek

À.6. Í0 Sl_Ant:ëíD

.

r /- \

I

t

l!

To start the

(])

Open

(2)

Check

idl-ing

Operate

3)

prine

if the engine

(+)

Set the throttle

/-\

(5)

Turn

for

(

(,'t

Trrrn the starber.

\-/

nos'i ti on .-':o

!vv:v4v.r

/ -\

(7)

When

switch

normal idling

batteriesn Make

the

cond.iti-on,

wired.

terninals

all

S-!Q_lengine:

r+iCe the sea

that the

position

the

the

systenn fhis

__**___

topped

uPo

TïiE-

4qI,{8"

proceei.

inlet

engine

and

prÍnri-ng

has

been

ful1y opêïro.

and

that

iever on the Íuel

the staïter switch

secondse

J0

switeh to the

ê.err*.. i.lre s*":r.geI.

\v ei/v4*r'.

the englne

retu:Tj the throttle control

and

stuts,

posr'-tion

srire

up, fully

nake

srlre

as f ollolls

cocko

eontrol

gearbox

the

particularly

is

iÈle

for

key

to.

release the

"

they are

charged and

they

t-

lever

is i-n

is in neutral.

soice time.

the

heat

heat

and

nrot0f

starter

a.re

the

feeo

importani

position

stsrt

o

to

in

tight'

p'.rmp

its

to

(g)

{g)

Check

Cheek

the e:rg;i.::e L'rbr:lcating oil

the

uater fl-on and. the

sea

over-boafd"

/- - \ *

(tOj

F-enove the valve

lubrieatio& of the rockex

gpsr

À.6

eover

preseureó

dis*harge

anC eheek t1:e

gea.re

,

t.

a_L./

:

::a::e:

:-

t'*enty

-e;e-

:Ê3.1e:

:oi.leutes

:-

::-e

r:

í:esi

{.

iF.

c:l_

rater

nrnning,

:oo_er

i::

stop

a::d fllter")

the

heat

.1..f

p:,.:-ÊT::

--s:--ic::c:s

ï:;i

a uar=

to

eiop

the

tbrottle

?9

slof

of

the

.

!AÏ]ÏG

%

(r)

Run

engine.sump,

fitted)

(z)

Turn

d.isconnect

connection

sna11

side

quality

as

temporary

feeder pump

::e

el6::"

i:-)

eng-jae,

ihe

starter

does

the

engine,

governor

UP

THE

the

engine until

and re-filI

r

off

the mairl

ternporary

of

the feeder

low

She1l

Fusw

to

not

body.

nfG]NE

Teverse

the fuel

on the

viscosity

li:re

€r.tl

;r.subseguently

(9)

atove

horever,

switch

have

pu1l

the

m

to

stop

should

it

the

be

hot,

gear

rith

fuel

clean new

coek

srrction

fuel

feeder pump.

fuel

tank

puncp

corurected.

and. fill

eorrosion

(ft

A.

as

filter

is

essential_

described.,

in

the

started

be

observed..

will

not

the

be

position

opËrr.

on

oil

"heat,r

fully

lever

drai-n

and red.ucing

oil.

on

the fuel

pipe

fron

Rig

to

it

with

inhibitjag

to

so

as

to

circuit

)

froro

necessary

the

sid"e

fron

gear

tank

the

suction

up

the

suction

high

a

oi1 such

pipe

includ,e

cold,

the

(if

and

a

up

snd

the

the

3)

\,+)

R+n

the

15-20

the

the

Drain

the

mi:rutes

beerings,

injection

the

exhaust

exhaust

reverse

desiJable

jackets

engine

cooling

nanrfold

bend.s

gpar

to

in

the

at

about

to

circulate

and the

equipnento

systen

or

silencer,

oil

cooler

flush

sea

out rrith

rater

4.7

half

co:=osion

thoroughly,

jacket

and. the

jackets.

cireu:it.

speed

the

and

fresh

for

new

oi1

inhibitor

any

eng:ine

ït is

water

a firrther

thror:gh

thiough

includ.ing

jacketteti

aÍrd

any

off

Turn

suctron

suction

the

sea

connection

prpe

to the engine.

cock,

on

d.isconnect'the

the sea

inlet

water

and

d.rain

the

(l)

Remove

valve

the

(6)

Cl-ean

oit filter

Check

(Z)

Remove

the engine and store

place.

lrable

(B)

Rernove the

punp

(if

inpeller

wrth the uapellers removed

.

exterior of the

account

cause

(g)

Blank

outlet and

skin

of

valve

the

gear

axd

renew

oï

and

the electrical

Wrap

to

fitted). These

type

must

swelling and

off the

the

the

elements.

cfean

the conponents securely

get

dirty

engi-ne

and

the

engine

cooliag water d.ischarge

any

boat.

geaï

covers

valve

fuel fitter

the sea

sea

these

pump

inpellers be

consequent

springs

i:rlet

equipnent components from

them ashore

or dusty

water

pumps

should

kept in the

and

i:rtake

arr

wetl lubricate

and

wi-th

lubricati:rg

and

strainer

in

a

while ashore"

pump

and

and

are

of the

be

stored.,

tied up to the

oiled

failute.

and.

as

also

clean

(if

frtteO).

warra dry

if

they

the bilge

rubber

preferably

dark"

this will

the exhaust

pipes

oil.

are

no

0n

at the

(fO)

If the boat is to

(ff

)

,the

(re)

(r3)

grease

Wefr

or

cortode.

lisconnect the tailsiraft couphng

boat

out of

ïf the sterngear

exclud.erse

shaft frorn

when

the couplings are d.iscorurected,o

Cneck the

damage"

Open the sea

inlet"

propeller

parts

any

be hauled.

the water.

is equipped. with external

nust be ta.leen

ca.rê

slid3ng

coek

af

(if

of the engine liable to rust

out of

t noore

external

and

fitted)

the water for

before

prevent

to

I/2 i:."

than

sterngeax

to

ara:n the

haulÍag

the

(fZ

A.3

storase

sar.d

nnn)

for

sea

Loading...

Loading...