Page 1

1

PowerMon

Model: BT-DCPM

Bluetooth LE Enabled

Advanced Battery Monitor / DC Power Meter

– USER MANUAL –

Page 2

2

BRIEF

PowerMon (BT-DCPM) is a Bluetooth Smart (LE) Swiss-army knife tool that can be used in any DC circuit.

Its primary function is advanced battery monitor / DC power meter. PowerMon allows monitoring of important

electrical parameters: two voltages (0-75V), one current (0-60A using the integrated current shunt or up to

10,000A using an external current shunt), peak current, power (W), energy (Wh), battery charge (Ah) and

temperature. Many other parameters are computed: the battery state of charge (SOC) as a percentage,

remaining battery runtime, battery statistics (number of cycles, total discharged capacity, …). The current

measurement can be either unidirectional or bidirectional. In bidirectional mode, PowerMon senses current

flow in both directions (positive and negative). The device can drive a mechanical or solid-state relay which

allows it to function as a low voltage disconnect, high voltage disconnect, over-current disconnect, battery

isolator in multiple battery systems, remote on/off switch and timer. A mobile device running either Android or

iOS and the PowerMon app (available for free on Google Play Store and Apple App Store) are required for

operating this device.

Page 3

3

FEATURES

• Measures two voltages, one current

(unidirectional or bidirectional), peak

current, power (W), charge meter (Ah),

energy (Wh) and temperature

• Operates at up to 75V and 60A of

continuous current (75A peak current) using

the integrated current shunt

• Can sense up to 160mV of voltage drop

across an external current shunt allowing

current of up to 10,000A to be measured

• Full differential input for the current shunt,

allowing it to be mounted either on the

ground or positive wire

• Can control one relay or SSR (solid state

relay)

• Low / high voltage disconnect

• Over-current disconnect (circuit-breaker)

• Battery isolator for dual battery bank

systems

• Battery monitor (battery fuel gauge),

displays the state of charge in percentage

and the remaining time on battery

• Lithium iron phosphate battery charge

manager

• Timers

• Can use an external temperature sensor

• User / master password protection

• Very low power consumption (see

Performance Parameters)

• Bluetooth Smart (LE) radio with internal

antenna and long range

• 8-pole terminal block for connecting to the

system that will be monitored

• ABS plastic enclosure with mounting

flanges, completely enclosed in epoxy

potting compound

• Measures only 3.0” x 1.55” x 0.75” (76mm x

39mm x 19mm) including the mounting

flanges.

• Weatherproof

• Free PowerMon app available for Android

and iOS

• Most parameters can be configured,

allowing it to achieve top performance with

a variety of current shunts and batteries

TYPICAL APPLICATIONS

• RVs, boats, off-the-grid cabins

• Solar and wind alternative energy

• Vehicle batteries

• Backup electrical systems

• Lithium Iron-Phosphate battery charge manager

• Automatization: solar irrigation systems, solar street lights, general purpose DC timers

Page 4

4

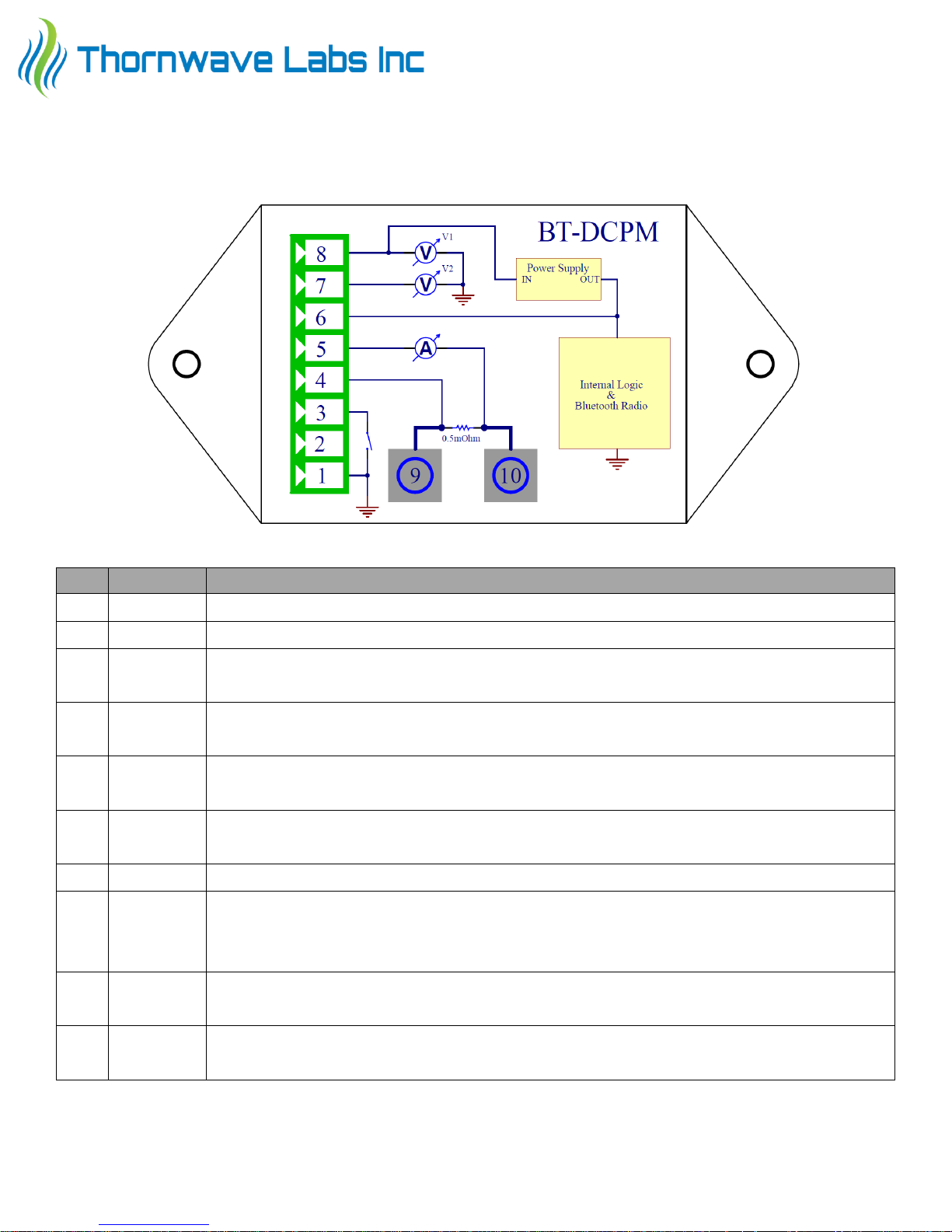

TERMINAL DESCRIPTION / INTERNAL DIAGRAM

No.

Name

Terminal Description

1

GROUND

System ground

2

MF

Multi-function (for hardware revision 2.2 and up) – call for details

3

RELAY

Relay output. It controls a mechanical or solid-state relay. This terminal is

connected to ground internally by the device when the power is turned ON.

4

ES+

External shunt connection. When using the internal current shunt connect

this terminal to ES- (terminal 5)

5

ES-

External shunt connection. When using the internal current shunt connect

this terminal to ES+ (terminal 4)

6

VS

Optional power supply. If available, connect this terminal to a power supply

of not more than 18V. This connection is optional.

7

V2

Second monitored voltage. Can measure the voltage of a second battery.

8

V1

Main power. This is the main voltage that will be monitored. The device

also draws its power form this terminal. If power is applied to terminal 6

(VS), the device will draw its power from VS instead of V1.

9

IS-

Internal shunt connection. The measured current is flowing from IS+ to ISor backwards. Do not connect if using an external shunt.

10

IS+

Internal shunt connection. The measured current is flowing from IS+ to ISor backwards. Do not connect if using an external shunt.

Page 5

5

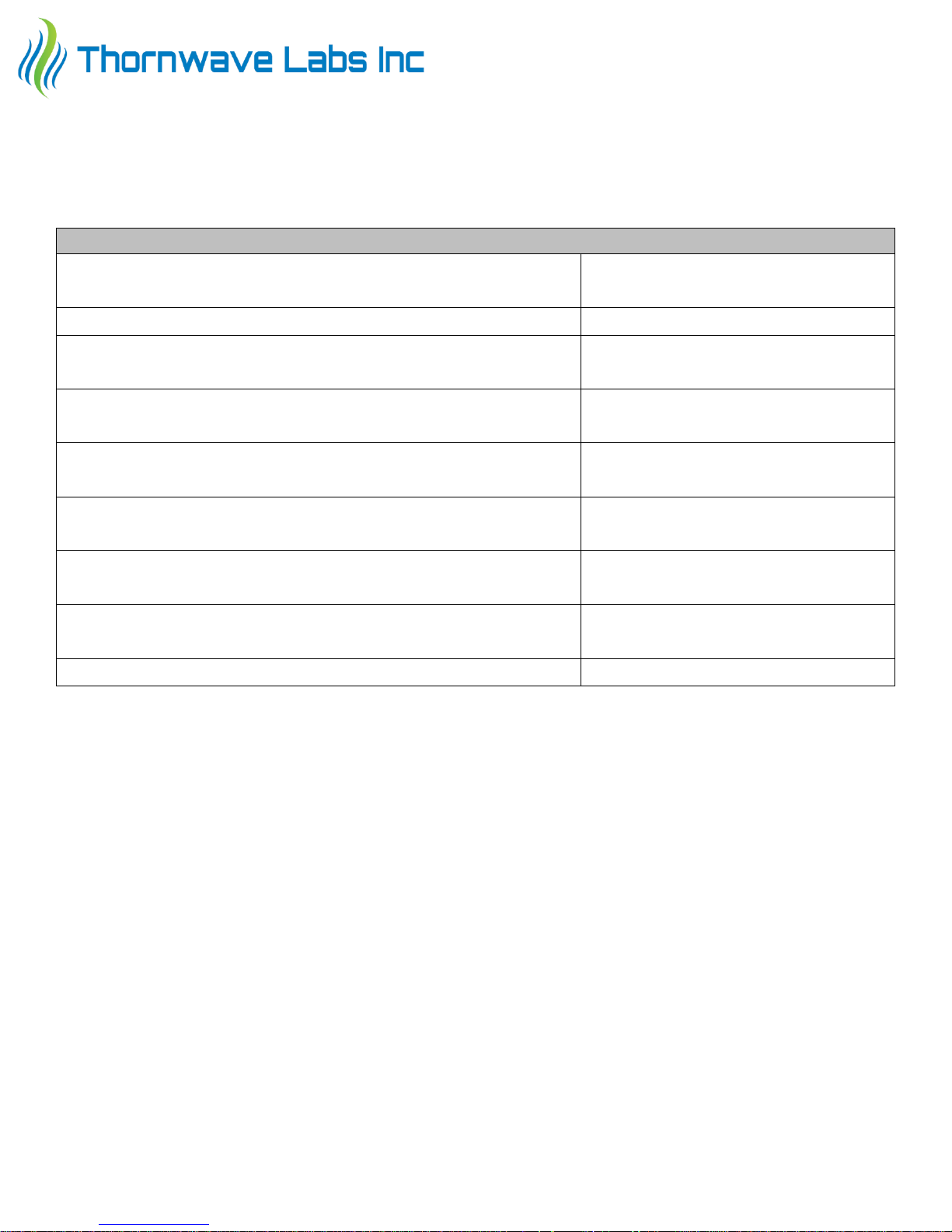

SPECIFICATIONS

Absolute Maximum Ratings

1,2

Maximum voltage at V1 and V2

+65V (hw rev 2.00)

+75V (hw rev 2.20)

Maximum voltage at VS

+18V

Maximum voltage at RELAY

+18V (hw rev 2.00)

+30V (hw rev 2.20)

Maximum current through RELAY terminal (maximum

relay coil current)

0.5A

Maximum current through IS+ and IS- (using the

integrated current shunt)

60A continuous, 75A peak

Maximum current (using an external current shunt)

depends on external shunt

(up to 10,000A)

Maximum differential input sense voltage ES+ to ES(using an external shunt)

-75V to +75V

Maximum common mode input sense voltage (ES+, ES-,

IS+, IS-)

-2V to +75V

Operating temperature

-30°C to +85°C

1. Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the device.

2. All voltages are referenced to ground unless otherwise specified.

Page 6

6

Performance Parameter

Value

Measured voltage (V1, V2)

0 to 60V (hw rev 2.00)

0 to 75V (hw rev 2.20)

Measured voltage accuracy

0.5%

Measured current (using integrated shunt IS+, IS-)

0 to 60A

Current monitoring accuracy (using integrated shunt)

2% - without calibration

1% - with calibration

Integrated current shunt resistance

0.5 mOhm / ±1%

Voltage at external shunt input (ES+ to ES-)

0 – 160mV / ~20µV resolution

Current monitoring accuracy (using external shunt)

depends on external shunt

precision, typically better than 1%

with calibration

Minimum external current shunt resistance

0.1 mOhm

Power (using integrated shunt)

max. 4500W

Power meter

more than 1000 MWh

Charge meter

more than 1000 MAh

Battery state-of-charge monitor

0% – 100%

Temperature

1°C / 1°F resolution

Current draw (current consumed by the device)

at 12V

at 24V

at 36V

at 48V

at 60V

at 75V

7.2 mA

7.5 mA

7.8 mA

8.1 mA

8.5 mA

8.9 mA

Page 7

7

COMPLIANCE STATEMENTS

FCC

ATTENTION: Changes or modifications not expressly approved by Thornwave Labs Inc could void the

user's authority to operate the equipment.

ATTENTION: This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference and (2) this device must accept any interference

received, including interference that may cause undesired operation.

ATTENTION: Cet appareil est conforme à la Partie 15 des règlements de la FCC. L'opération doit se

conformer aux deux conditions suivantes: (1) cet appareil ne peut causer d'interférences nuisibles et (2) cet

appareil doit accepter toute interférence reçue, y compris les interférences qui peuvent provoquer un

fonctionnement indésirable.

IC RSS-102 RF Exemption

This system has been evaluated for RF Exposure per RSS-102 and is in compliance with the limits specified

by Health Canada Safety Code 6.

L’exposition aux radiofréquences de ce système a été évaluée selon la norme RSS-102 et est jugée

conforme aux limites établies par le Code de sécurité 6 de Santé Canada.

IC RSS-Gen 8.4

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts

de licence. L'exploitation est autorisée aux deux conditions suivantes: (1) l'appareil ne doit pas produire de

brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

Page 8

8

SAFETY INSTRUCTIONS

Warning !

Read all the instructions and cautions before using the PowerMon device. Thornwave Labs Inc does not

assume responsibility for any injury or property damage caused by improper installation, bad wiring or use of

PowerMon outside of its intended purpose. The device should be installed by a professional.

Warning !

The PowerMon device should not be used for any medical purposes, life sustaining equipment, safety

applications or any application where equipment failure can cause injury, death, fires, or any other hazard.

Warning !

There are no serviceable parts or fuses inside the power meter! Do not disassemble or attempt to repair!

The unit operates with voltages up to 75V which can be lethal or cause serious and permanent injury.

Warning !

Do not submerge under water or other liquids. The device is weatherproof but not waterproof.

Warning !

The device is to be connected to DC circuits only, not exceeding 75V and 60A (using the integrated

current shunt). Failure to do so will result in equipment damage. Higher currents are supported when using an

external current shunt. Confirm that all connections are tight to avoid excessive heating and sparks. Never

connect the V1 or VS terminals to a power source without using a fuse or circuit breaker. A 0.1A to 5A fuse or

circuit breaker is required.

Warning !

Batteries are dangerous! Do not short-circuit a battery or the power meter. Batteries can produce

flammable and explosive gases and can generate very high currents that can lead to serious consequences

including explosion, fire, damage to equipment, personal injury and even death. It is the user’s responsibility to

operate the equipment in a safe manner. Do not charge batteries in an enclosed environment unless allowed

by the manufacturer of the battery. Never connect a load to a battery without using fuses or circuit breakers.

Page 9

9

FUNCTIONAL OVERVIEW

Device power. The PowerMon device is drawing its supply power from the V1 terminal and using an

internal voltage regulator it creates an internal supply voltage of 9V. This internal supply voltage is available at

the VS terminal but should not be used to supply any external load. Attempting to power external loads from

VS will damage the device. If a power supply of maximum 18V is available it is recommended to connect it to

the VS terminal. This will turn the internal regulator off and provide the power for the device, improving

efficiency (only if V1 is higher than 24V). When the device is used to monitor 12V batteries, V1 and VS can be

wired together to the positive side of the 12V battery. If an appropriate power supply voltage is not available

the VS input should be left unconnected.

Integrated current shunt. When using the integrated current shunt, the ES+ and ES- pins should be

connected together using a wire bent in a U shape and attached to the supplied terminal block. The current to

be monitored should be routed through the IS+ and IS- terminals. An internal current shunt of 0.5mOhm exists

in between these two terminals. The aluminum, hex screw terminal blocks (IS+ and IS-) can accept wires up to

6AWG in size. In order to minimize the voltage drop on wires and connections, use the thickest wires that can

support the required current. The common mode voltage at IS+ and IS- can be in between -2V and +75V relative

to ground, allowing the current shunt to be placed either on the positive side of the circuit or on the ground

wire. Current flowing from IS+ to IS- will display as a positive value and current from IS- to IS+ will display as a

negative value. The current sign can be flipped from the device configuration.

External current shunt. To monitor a large current or a very small current more accurately, an external

current shunt can be used. This method allows monitoring current up to 1,000A with reasonable resolution or

even higher current if resolution can be sacrificed. Using a higher resistance current shunt, current in the milliamp range can be measured accurately. The external current shunt resistor should be connected to the ES+ and

ES- inputs. To avoid noise the wires should be as short as possible. Twisting the sense wires reduces noise even

further. The IS+ and IS- terminals should be left unconnected. The common mode voltage at ES+ and ES- can be

in between -2V and +75V relative to ground, allowing the current shunt to be placed either on the positive side

of the circuit or on the ground wire. Current flowing from the ES+ to ES- sides of the external shunt will be

displayed as a positive value and current from ES- to ES+ will be displayed as a negative value. The current sign

can be flipped from the device configuration.

Operation. Once the device receives power it will start advertising its presence to other Bluetooth

devices. Using a cell-phone or tablet running the PowerMon app (found on the App Store / Play Store) the user

can scan for PowerMon devices and connect to one of them at a time (if multiple devices are present). Multiple

PowerMon devices can be distinguished after changing their Bluetooth name using the mobile app. This will be

displayed by the app upon scanning for Bluetooth devices. The factory default name is “DCPM”. Once the mobile

app is connected to a power monitor device, the app will display all the measured electrical parameters and

update them in real-time. Tapping on a measurement value for longer than 1 second will open a menu that

allows operations and configuration specific to that measurement.

Page 10

10

Radio performance. The device contains an internal Bluetooth Smart (LE) radio operating in the 2.4GHz

ISM band and an internal antenna. For best performance, the device should be installed in such a way to offer

a path for radio waves to reach it. Metal walls or enclosures can attenuate or completely shield the device.

Installation on non-metallic surfaces is preferred. The mobile device app displays the RSSI value (Received Signal

Strength Indication) in real-time.

Power relay control. PowerMon can control a power relay (either mechanical or solid-state) using the

RELAY output (terminal 6). When active (relay turned on), the RELAY terminal is internally connected to ground

by the device. The relay should be connected between its power supply and the RELAY terminal. The low/high

voltage disconnect and over-current disconnect functions require the use of a relay / SSR (Solid State Relay).

Low voltage disconnect. When this mode is enabled, and the battery voltage drops below a specified

value, the device disconnects the load, protecting the battery from over-discharge. In order to disconnect the

load, the voltage has to be below the set threshold for a configurable amount of time. This feature helps in

situations where cranking an engine or a short high current load causes the battery voltage to momentarily

drop. The device will re-engage the power relay a configured amount of time after the condition that caused it

to disconnect is removed. In this mode PowerMon can also operate as a battery isolator. The relay is used to

connect the house batteries in parallel with the starting battery. The LVD filter value should be set to 5000ms.

The disconnect threshold should be set to 13.2V and the connect threshold to 13.6V. When the engine is started

and the alternator starts charging the starting battery, the voltage will start increasing. When the voltage

reaches 13.6V (the connect threshold) the relay engages and connects the house batteries to the starting

battery, this way allowing all batteries to be charged. When the engine is stopped the voltage will quickly drop

below 13.2V (the disconnect threshold) and the relay disengages, isolating the house batteries from the starting

battery. The house batteries voltage can be monitored using the V2 input. Note that the thresholds (13.6V and

13.2V) are just an example. They can be configured to best fit the application.

High voltage disconnect. This function is similar to the low voltage disconnect, but as the name suggests

it will disconnect the load when the voltage goes above the disconnect threshold and will reconnect the load

when the voltage goes below the reconnect threshold. This mode can be used together with the low voltage

disconnect. Possible uses are to protect the load from high voltage conditions, start external chargers or

generators, connect to the grid and so on.

Over-current disconnect. PowerMon can operate as a circuit breaker. When this mode is enabled and

the measured current increases above a user specified trip value, the device disconnects the load, protecting

the batteries and load from over-current. The device will re-engage the power relay a configured amount of

time after the condition that caused it to disconnect is removed.

WARNING! Although PowerMon can disconnect power if an over-current condition occurs, it should not be

used to replace circuit-breakers. A properly rated circuit-breaker or fuse should be used to protect the load

and the wiring!

Page 11

11

Battery fuel gauge. PowerMon is a battery monitor so it can keep track of a battery state of charge. This

is accomplished by using coulomb counting. For the battery fuel gauge to work properly the current should be

sensed bidirectionally. Charging current should be positive and discharging current should be negative. Due to

the complex nature of chemical batteries, small errors in measurement and integrating current over long

periods of time will introduce errors in the state-of-charge estimation. This is normal and expected. For this

reason, the device will re-synchronize its SOC counter with the battery every time a full charge is performed. A

full charge is detected based on the chemistry of the battery but in general it requires a voltage higher than a

threshold while at the same time the charging current being lower than a threshold. The battery fuel gauge will

also take into consideration the Peukert effect. The next table shows the Peukert coefficients used for various

battery chemistries.

Battery Chemistry

Peukert Coefficient

Lead Acid - Flooded

1.25

Lead Acid – AGM

1.15

LiFePO4

1.02

Li-Ion/LiPoly

1.02

LiFePO charge manager. PowerMon can manage the charging of a lithium iron phosphate battery. This

function cannot be used together with the other disconnect functions. If enabled, the mobile app will

automatically disable the other functions. A relay must be placed in between the battery and the charger, or

power source used for charging (for example the vehicle alternator). The function of this relay is to disconnect

the charger from the battery if a full charge is detected or the power supply is turned off (for example the

engine is tuned off). To use the LiFePO charge manager, connect the V1 input to the battery positive and V2

input to the charger positive. The internal shunt and the relay should be wired in between the charger and the

battery. (see wiring diagrams at the end of the manual).

The user configures the number of LiFePO cells connected in series (4 for a 12V battery) and the total

capacity of the battery in Ah. These parameters are used to calculate a few thresholds as seen in the table

below. At least one disconnect condition has to be true for at least 2 seconds for the disconnect to take place.

The connect conditions must be true for time specified in “Connect Time” for the connect to take place

(default is 10 seconds).

The following table shows the conditions used by PowerMon to decide whether to connect or

disconnect the charger from the battery (turn the relay ON/OFF). V1 is connected to the battery and V2 to the

charger. Current refers to the current flowing in between the battery and the charger. “C” refers to the

battery capacity. Care should be exercised to ensure that the current is positive when the battery is being

charged and negative if it is being discharged. If wired backwards, use the “Flip Current Sign” option to fix it.

WARNING! PowerMon cannot be used as a charge current limiter or LiFePO cell balancer. A properly sized

battery charger is required to recharge LiFePO batteries. Thornwave Labs Inc. does not assume any

responsibility for expensive battery damage.

Page 12

12

Connect Conditions (10 sec. delay used)

Disconnect Conditions (2 sec. delay used)

battery voltage (V1) less than 3.32V / cell

AND

charger voltage (V2) at least 0.2V above the

battery voltage (V1)

battery voltage (V1) greater than 3.65V / cell

-

charging current (I) less than C/100 or 1 Amp,

whichever is greater

-

full charge is detected:

battery voltage (V1) greater than 3.5V /cell

AND

charging current (I) less than C/20

Time keeping. PowerMon keeps track of time internally. The internal clock can be set by tapping on

the Device Time tab for longer than one second. The internal date and time will be updated using the system

time provided by the mobile app.

Timer function. The device supports controlling the relay using a set of up to 16 timers. Each timer

contains a start time, stop time and repetition. The start time specifies the time of day (HH:MM) when the relay

turns on. Stop time specifies the time of day when the relay turns off. A timer does not need to have both a

start and stop time set. One of them can be disabled. This kind of timers should be used in pairs: one turns the

power on and the other one turns it off. Repetition controls when will the timer will trigger. This can be either

DOW (Day of Week) where the timer repeats on specific days of the week or DOM (Day of Month) where the

timer repeats on a specific day of the month.

Using multiple timers, users can create very complex time schedules.

Examples:

Timer1: START 4:50PM, STOP 5:10PM, REPETITION DOW Sun Mon Tue Wed Thr Fri Sat

This timer will run every day and turn the relay on for 20 minutes, from 4:50PM until 5:10PM

Timer2: START 8:00PM. STOP: disabled, REPETITION DOW Sun Mon Tue Wed Thr Fri Sat

Timer3: START disabled, STOP: 7:00AM, REPETITION DOW Sun Mon Tue Wed Thr Fri Sat

This set of timers used together will turn the relay on every day at 8:00PM and turn it off the following

day at 7:00AM.

Timer4: START 12:00AM. STOP: disabled, REPETITION DOM: 1

Timer5: START disabled, STOP: 12:00AM, REPETITION DOM: 8

This set of timers used together will turn the relay on every 1st of the month at 12:00AM and turn it off

7 days later on the 8th of the month at 12:00AM.

Page 13

13

Configuration. The following parameters can be configured using the PowerMon app:

Current Sense Voltage Range: The current shunt resistor voltage drop measurement range. This should be

adjusted to be higher than the maximum expected voltage drop across the current shunt.

Unidirectional (positive current only)

Bidirectional (positive and negative current)

+160mV

-

+150mV

-

+120mV

-

+90mV

±80mV

+60mV

±60mV

+30mV

±30mV

-

±15mV

-

±7.5mV

Current Shunt Resistance: The resistance value of the current shunt used (in milli-Ohms). By default, it is set to

0.5mOhm which is the integrated shunt resistance.

Flip Current Sign: Allows the current sign to be flipped by software. Can be used to correct a wiring mistake

without having to re-wire the device.

Peak Current Noise Filter: Enables or disables the peak current noise filter. If the filter is disabled, the peak

current detector will be more sensitive, but it will also pick up more noise. If enabled, the peak current detector

will react more slowly to current changes and may not catch a very short current peak.

Meter Voltage Source: The voltage used to calculate power and energy. V1 or V2 can be selected.

Initial Power Status: The default power status when powering the device. If set to on the relay will be turned on

automatically when the device receives power.

Trigger on RELAY: If enabled, the device will turn the power on as a response to the RELAY terminal being

temporarily pulled to ground using a push button.

Invert RELAY Logic: Enabling this option will invert the behavior of the RELAY terminal, when the power is on

the RELAY terminal will be floating and when the power if off it will be driven to ground.

Connect Filter (ms): The duration of time in milli-seconds the LVD (Low Voltage Disconnect), HVD and OCD (OverCurrent Disconnect) conditions have to be removed in order to re-engage the power relay.

MF Terminal Function: Selects the function of the MF terminal: Data Output or External Temperature Sensor.

The external temperature sensors is only available for hardware revision 2.2 or higher.

Page 14

14

Low Voltage Disconnect

LVD Voltage Source: The voltage used by the low voltage disconnect feature. V1 or V2 can be selected.

LVD Connect Threshold: The voltage in volts above which the power relay can re-engage (after the

connect filter time has passed). This must be higher than LVD Disconnect Threshold.

LVD Disconnect Threshold: The voltage in volts below which the power relay will disengage.

LVD Filter (ms): The duration of time the voltage has to be below the disconnect threshold for the relay

to disengage.

High Voltage Disconnect

HVD Voltage Source: The voltage used by the high voltage disconnect feature. V1 or V2 can be selected.

HVD Connect Threshold: The voltage in volts below which the power relay can re-engage (after the

connect filter time has passed). This must be lower than HVD Disconnect Threshold

HVD Disconnect Threshold: The voltage in volts above which the power relay will disengage.

HVD Filter (ms): The duration of time the voltage has to be above the disconnect threshold for the relay

to disengage.

Over-Current Disconnect

OCD Trip Threshold: The current in amperes above which the power relay disengages.

OCD Filter (ms): The duration of time the current has to be above the trip value in order to disengage

the relay. In order to function as a circuit breaker this should be set to a very low value between 0ms ..

20ms. Larger values will slow down the reaction to over-current. In some instances, this could be useful.

Auto-Off Timer: If enabled the power will turn off automatically after the specified time since it was turned on

has passed. This effectively becomes a turn-off timer.

Page 15

15

Battery Fuel Gauge

Battery Voltage Source: The voltage used by the battery fuel gauge feature. V1 or V2 can be selected.

Battery Chemistry: The chemistry of the battery used.

Number of Cells: Number of cells of the battery. 12V Lead Acid batteries have 6 cells. 12V LiFePO4 have

4 cells. If you have batteries connected in series, add the number of cells in each of them. If batteries are

connected in parallel the number of series cells does not change.

Battery Capacity: Battery capacity in Ah. If batteries are connected in parallel, add up their capacities. If

batteries are connected in series the capacity does not change. (only the number of cells in series does)

Disconnect on Fuel Gauge: The device will disconnect power (turn the relay off) when the battery state

of charge becomes lower than this threshold (in percentage). The “Invert RELAY logic” option can invert

this behavior.

Connect on Fuel Gauge: The device will re-connect power (turn the relay ON) when the battery state of

charge becomes higher than this threshold (in percentage). The “Invert RELAY logic” option can invert

this behavior.

LiFePO Charge Manager

Number of Cells: Number of cells of the battery. 12V LiFePO4 have 4 cells. If you have batteries connected

in series, add the number of cells in each of them. If batteries are connected in parallel the number of

series cells does not change.

Battery Capacity: Battery capacity in Ah. If batteries are connected in parallel, add up their capacities. If

batteries are connected in series the capacity does not change. (only the number of cells in series does)

Default Factory Settings. The default configuration for PowerMon is to use the integrated current shunt.

The device can always be reset to the default configuration using the PowerMon app. To do this, connect to a

device, tap the right corner menu (iOS) or right corner menu and then About (for Android). Tap on Factory Reset.

WARNING: When resetting to the factory defaults, all custom settings and timers will be erased,

including the device calibration and the battery fuel gauge internal state. The device Bluetooth name will not

be changed.

Page 16

16

Configuration example. Let’s suppose that current of up to 400A needs to be measured bidirectionally.

For this purpose, we will use a 500A / 50mV current shunt.

Ohm’s law states:

RIV =

This means that the voltage drop across a resistor is equal to the current passing through that resistor

multiplied by the resistance value. Rearranging that equation, we get:

I

V

R =

. Using this we can calculate the

resistance of the shunt:

mOhmOhm

A

mVV

1.00001.0

500

)50(05.0

==

In order to properly configure PowerMon we set the Sense Resistor to 0.1mOhm and Sense Voltage Range to

±60mV since this is the next higher range available that can be used for measuring up to 50mV. Using the

±60mV range allows a current up to ±600A to be measured but the 500A shunt rating should not be exceeded.

Page 17

17

MOBILE APPLICATION – POWERMON

The PowerMon device requires a mobile device running Thornwave Labs’ PowerMon app which is

available free of charge for both Android and iOS platforms and can be found on Google Play Store and Apple

App Store. The mobile device used needs to be equipped with a Bluetooth Smart (LE) adapter. The app will not

install on devices that are too old to support Bluetooth Smart (4.0).

PowerMon allows the following operations to be performed:

• scan for PowerMon devices and display a summary of measurements (voltage, temperature, battery

state of charge and power status)

• connect to devices and obtain real-time measurements

• set the device configuration (external shunt parameters, low voltage disconnect, high voltage disconnect

overcurrent disconnect, battery fuel gauge,… see the Configuration paragraph)

• zero the current reading offset

• calibrate the current reading

• rename the device

• reset the power and charge meters back to zero

• manually turn the power relay ON/OFF

• update the internal device clock from the mobile device current time and date

• create, edit and delete timers

• reset to factory defaults

• configure the password protection function

• update the device firmware (when new releases are published)

Scan for devices. The first screen that appears after PowerMon is launched is the scan screen. If the

mobile device Bluetooth adapter is not enabled PowerMon will prompt the user to enable it before continuing.

The app will then display all the PowerMon devices that are within range. Each advertisement packet contains

the device name, firmware version, two voltage readings (V1 and V2) and the device temperature. All this

information will be displayed by the app together with the device RSSI (Receiver Signal Strength Indication). The

RSSI value is a direct indicator of the signal strength received from a device. In most practical scenarios involving

Bluetooth, this is a negative number and is measured in dBm (decibel referenced to 1mV). Typical values range

from -110dBm being a very weak signal to -30dBm or better being a very strong signal. For a reliable connection,

an RSSI of at least -100dBm is required.

Page 18

18

Measurement limits. The app allows setting measurement limits. When a measurement value is in

between the specified limits it will be displayed with black. If the measurement is outside of the specified limits

(less than the low limit or more than the high limit) it will be displayed in red. This feature allows for easy

identification of parameters that are not within normal limits. In order to configure the limits, tap on the top

right corner menu button when on the scan screen. This menu also allows disabling of V2 measurement in case

it is not used. The voltage limits set here are also used in the main screen.

Connect to PowerMon devices. In order to connect to a device, tap on it in the scan list. The app will

switch to the main screen which can be used for all the interactions with a connected device. The main screen

displays the real-time electric parameter measurements. By long-tapping on a parameter tab, the user can

access a menu that is specific for that parameter. This will allow to set measurement limits, zero the current

offset, calibrate the current reading, reset the power and the charge meters and manually control the power

relay.

Zero the current offset. Due to the high sensitivity of the current measurement circuitry inside the

PowerMon device, the value displayed may have a small offset (measurement is different than zero even when

the actual current is zero). Typically, this is less than 0.1A. In situations where the measurement precision is

critical, the offset can be zeroed. To do this, disconnect the current wires from the device (or from the external

shunt) or make sure the actual current is zero. This can also be achieved by turning the power relay off from the

application (in case the system is wired with a relay). Tap on the “Current” tab and then “Zero Current”. The

operation will take 3 seconds to complete during which do not allow any current to pass through the device.

Also, do not zero the current offset if the actual current is greater than zero. Doing so will introduce a very large

offset.

Current calibration. Typically, the device can measure current with better than 2% precision. If higher

precision is required, the current measurement can be calibrated allowing for better than 1% precision. To

calibrate the current reading, a multimeter capable of measuring current with a precision better than 0.5% is

required. Connect the multimeter leads in series with the current to be measured and read the actual value of

the current. Tap on the “Current” tab, “Calibrate Current” and then type the actual value measured by the

multimeter. The sign of the current does not matter. Once calibrated, the only way to change the calibration is

to reset the device to factory defaults or re-calibrate. The device will not accept a calibration current more than

20% away from the current reading.

Renaming the device. Renaming the device can be achieved using the top right menu button and taping

on “About”. The maximum name length is 8 characters.

Timers. From the “timers” screen, users can create new timers, edit or delete them.

Page 19

19

Battery Fuel gauge. The device implements a fuel gauge functionality for lead-acid, LiFePO4 and other

lithium batteries. When the device is first powered on, the fuel gauge will display “-----” meaning that it is not

synchronized with the battery. A full charge is required to bring the SOC in sync with the battery. By tapping on

the Battery tab for longer than one second a few options relating to the fuel gauge will be shown. The user can

manually force a battery synchronization or retrieve the battery statistics. Do keep in mind that forcing the

battery synchronization can lead to an inaccurate battery state-of-charge indication until the first full charge

event occurs.

Password lock. The device can be locked using a master / user password scheme. Various functions

become unavailable when they are password locked. When the user attempts to use one of the locked functions,

the app will ask for the required password (user or master). If the master password is entered instead of the

user password all the functions become unlocked. The user password will not be accepted instead of the master

password. Once a correct password has been entered the device will unlock only the set of functions that apply

to that password. The user password will unlock only a sub-set of functions while the master password will

unlock all functions. If the master password is not set, the user password unlocks all the functions of the device.

Once a set of functions have been unlocked they will stay in this state until the device is disconnected, after

which they will revert back to the locked state (if any password has been set). This protection scheme allows

the device to still be operated by a user while allowing only the manufacturer or technician (the master) to make

configuration changes that may affect the proper or safe functioning of the system. The password lock function

can be accessed from the About page.

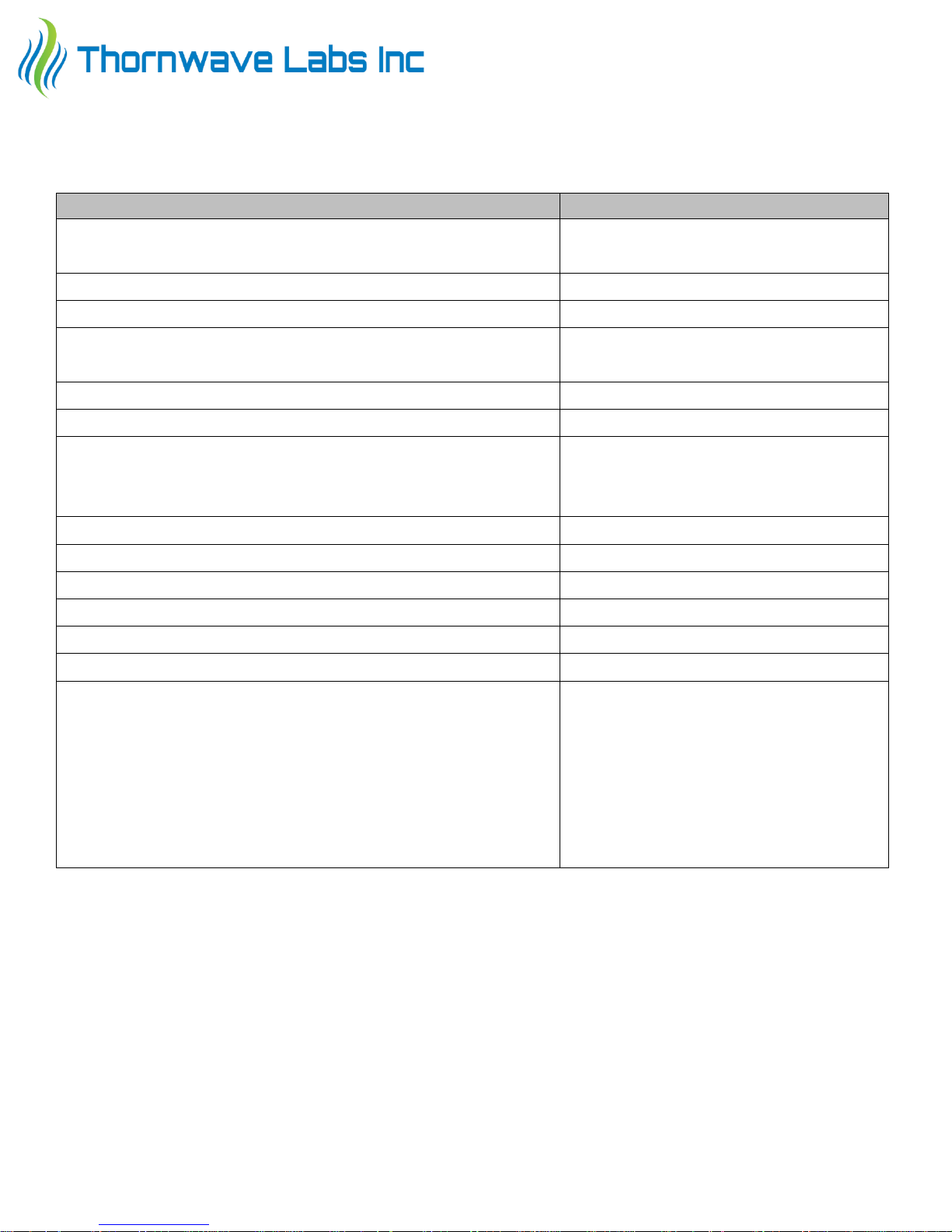

The next table describes which set of functions are affected by the master / user passwords.

Function

Master Password Required

User Password Required

View monitored data

Save configuration

YES

YES

Device rename

YES

YES

Reset to factory defaults

YES

YES

Zero current offset

YES

YES

Calibrate current

YES

YES

Reset peak current

YES

Reset power meter

YES

Reset charge meter

YES

Turn power ON/OFF

YES

Force fuel gauge sync.

YES

YES

Remove master password

YES

Remove user password

YES

Timers (add / edit / delete)

YES

Set time

YES

Firmware upgrade

YES

YES

Page 20

20

WIRING DIAGRAMS

Page 21

21

Page 22

22

Page 23

23

Page 24

24

Page 25

25

DIMENSIONS

Dimensions are in inch.

Page 26

26

ORDERING

Part Number

Description

BT-DCPM

PowerMon - Bluetooth smart DC power meter / battery monitor with

low/high voltage disconnect, over-current disconnect, timers and LiFePO

charge manager

Page 27

27

Changelog:

Date

Revision Description

8/1/2017

Initial preliminary version.

8/7/2017

Added FCC/IC required warnings.

8/9/2017

Revised FCC/IC required warnings.

7/17/2017

Added FCC required statement.

9/6/2017

Added details. Improved manual. Removed “preliminary” watermark.

9/10/2017

Added “Voltage Source” configuration parameter.

9/18/2017

Added “Mobile Application - PowerMon” section.

11/21/2017

Added “Timers” sections.

1/4/2018

Improved wiring diagrams. Added information about Auto-Off timer.

3/8/2018

Added new features implemented in the latest firmware release: peak current, high voltage

disconnect, battery fuel gauge

5/9/2018

Added new features implemented in the latest firmware release: password lock, disconnect on fuel

gauge.

6/11/2018

Added paragraph about master/user password locking.

10/12/2018

Added PowerMon brand name. Updated the device specifications. Improvements.

11/12/2018

Added LiFePO charge manager sections.

Loading...

Loading...