Thorn security TYCO T1216W-C Installation And Commissioning Manual

EQUIPMENT: T1216W-C

PUBLICATION: MARINEW-P-I

ISSUE No. & DATE: 1 11/12

© 2012 Thorn Security Ltd PAGE 1 of 39

Registered Company: Thorn Security Ltd. Registered Office: Dunhams Lane Letchworth Garden City Hertfordshire SG6 1BE

TYCO T1216W-C

Marine Fire Detection/Alarm Control Panel and Repeater

Installation and Commissioning Manual

T1216W-C

MARINEW-P-I

1 11/12

PAGE 2 of 39

List of Contents

1. LIST OF FIGURES ................................................... 3

2. LIST OF TABLES .................................................... 3

3. INTRODUCTION ...................................................... 4

4. INSTALLATION AND COMMISSIONING OVERVIEW ..... 4

5. INSTALLATION ....................................................... 4

5.1 ELECTRICAL SAFETY ...................................... 4

5.2 INSTALLATION INSTRUCTIONS ......................... 6

5.2.1 T1216W PANEL INSTALLATION

INSTRUCTIONS ........................................ 6

5.2.2 CONNECTION OF THE INCOMING AC

POWER SUPPLY ...................................... 8

5.2.3 T1200B-C BATTERY BOX INSTALLATION .. 8

5.2.4 BATTERY INSTALLATION .......................... 8

5.2.5 BATTERY CONNECTION ........................... 8

5.2.5.1 CONNECTING THE BATTERY BOX TO THE

PANEL PSU 9

5.2.6 INSTALLATION AND CONNECTION OF THE

C1631 REPEATER INTERFACE ................. 9

5.2.7 INSTALLATION AND CONNECTION OF THE

C1665 MUSTER INTERFACE .................... 9

5.3 MODIFICATIONS TO THE WATER MIST RELAY

CONTROL PANEL ......................................... 12

5.3.1 MODIFICATION 1 [SYSTEM ABNORMAL]: .. 12

5.3.2 MODIFICATION 2 [SYSTEM OPERATED]: .. 12

5.3.3 MODIFICATION 3: [FAULT INPUT FROM

T1216W-C] ......................................... 13

5.4 INTERCONNECTIONS WITH THE WATER MIST

RELAY CONTROL PANEL .............................. 13

5.4.1 FINAL CONNECTIONS BETWEEN THE

T1216W AND WMRCP ........................ 13

5.5 REPLACING THE DISPLAY INSERTS ............... 14

5.5.1 TO CHANGE THE INSERTS ...................... 14

5.5.2 TO FIT THE OPTIONAL DOOR STAY ........ 16

6. COMMISSIONING .................................................. 17

6.1 INTRODUCTION ............................................ 17

6.2 COMMISSIONING CHECKLIST ........................ 17

6.3 AN OVERVIEW OF THE COMMISSIONING

PROCEDURE................................................ 17

6.4 PRE-COMMISSIONING WIRING CHECK .......... 17

6.5 POWERING UP ............................................. 18

6.6 CONFIGURATION .......................................... 19

6.6.1 BASIC DEFAULT CONFIGURATION ........... 19

6.6.2 VESSEL-SPECIFIC CONFIGURATION ....... 19

7. OPERATING THE ENGINEER’S FUNCTIONS ............. 19

7.1 ENGINEER’S ZONE/OUTPUT CONFIGURATION

PROCESS: ................................................... 19

7.2 ZONE OR OUTPUT CONFIGURATION: ............. 19

7.3 TO RESTORE THE FACTORY DEFAULT

CONFIGURATION FOR ZONES & OUTPUTS: .... 20

7.4 ENGINEER’S ZONE/OUTPUT CONFIGURATION

TIME-OUT WARNING: ................................... 20

7.5 INVALID CONFIGURATION CONDITIONS: ......... 20

7.6 LIST OF CONFIGURATION DIL SWITCHES AND

THEIR FUNCTIONS: ....................................... 21

7.7 LIST OF LINK CONFIGURATION FEATURES ...... 23

7.8 DIL SWITCH SETTINGS ON THE REPEATER

INTERFACE BOARD: ..................................... 24

7.8.1 C1630 OUTPUT INTERFACE

CONFIGURATION ................................... 24

7.8.2 C1634 8 WAY VOLT FREE RELAY OUTPUT

MODULE CONFIGURATION ...................... 24

7.9 COMMISSIONING PROCEDURE ...................... 25

7.9.1 ALARM CIRCUITS .................................. 25

7.9.2 ZONES ................................................. 25

7.9.3 CLASS CHANGE INPUT .......................... 26

7.9.4 FIRE [ROUTING] OUTPUT....................... 26

7.9.5 FAULT [ROUTING] OUTPUT .................... 26

7.9.6 FIRE PROTECTION OUTPUT ................... 26

7.9.7 ANCILLARY INPUTS................................ 26

7.9.8 ANCILLARY OUTPUTS ............................ 26

7.9.9 REPEATERS [WHEN SUPPLIED] ............... 26

7.9.10 REPEATER MUSTER LINK [IF FITTED] ...... 27

7.9.11 POWER SUPPLY UNIT. .......................... 27

7.9.12 T1216W-C – WMRCP INTERFACE. ...... 27

7.9.13 FINAL DRESSING OF THE CABLES .......... 27

8. USER INDICATIONS .............................................. 29

9. USER CONTROLS ................................................ 30

10. PCB LAYOUTS ................................................. 31

11. INSTALLATION DETAILS ..................................... 34

12. WIRING DIAGRAMS ........................................... 35

13. WIRING DIAGRAM NOTES .................................. 39

EQUIPMENT: T1216W-C

PUBLICATION: MARINEW-P-I

ISSUE No. & DATE: 1 11/12

© 2012 Thorn Security Ltd PAGE 3 of 39

Registered Company: Thorn Security Ltd. Registered Office: Dunhams Lane Letchworth Garden City Hertfordshire SG6 1BE

1. List of Figures

FIGURE 1 – BULK HEAD MOUNTING DETAILS .............. 7

FIGURE 2 – BATTERY CLAMP DETAILS ...................... 10

FIGURE 3 – REPEATER CONNECTION DIAGRAM ......... 11

FIGURE 4 – MUSTER INTERFACE WIRING DIAGRAM ... 11

FIGURE 5– SYSTEM ABNORMAL MODIFICATION ........ 12

FIGURE 6– SYSTEM OPERATED MODIFICATION ......... 12

FIGURE 7– ADDITIONAL FAULT RELAY ...................... 13

FIGURE 8 – DISPLAY INSERT REPLACEMENT ............. 15

FIGURE 9– DOOR STAY ASSEMBLY .......................... 16

FIGURE 10 – C1627 MOTHERBOARD LAYOUT .......... 31

FIGURE 11 – REAR RIGHT HAND SIDE OF DISPLAY PCB

............................................................ 32

FIGURE 12 – C1634 RELAY OUTPUT MODULE ......... 32

FIGURE 13 – C1630 OUTPUT EXPANSION INTERFACE

............................................................ 33

FIGURE 14 – C1631 REPEATER INTERFACE BOARD . 33

FIGURE 15 – C1665 MUSTER INTERFACE BOARD ..... 33

FIGURE 16 – T1216W-C INSTALLATION DRAWING.... 34

FIGURE 17 – MAINS AC CHANGE-OVER UNIT

ELECTRICAL INSTALLATION DIAGRAM ..... 35

FIGURE 18 – T1216W-C INTERNAL LAYOUT DIAGRAM

............................................................ 36

FIGURE 19 – T1216W-C MOTHERBOARD, PSU &

REPEATER WIRING DIAGRAM ................. 37

FIGURE 20 – WATERMIST PANEL WIRING DIAGRAM .. 38

2. List of Tables

TABLE 1 – CONTENT OF SPARES BAG ......................... 6

TABLE 2 – C1631 SETTINGS FOR REPEATER QUANTITY

............................................................. 24

TABLE 3 – C1631 SETTING FOR REPEATER ADDRESSES

............................................................. 24

TABLE 4 – SETTING QUANTITY AND TYPE OF O/P

MODULES ON THE C1630 ...................... 24

TABLE 5 – SETTING C1634 BOARD ADDRESS ........... 24

TABLE 6 – SETTING C1634 ZONE RANGE ................. 24

TABLE 7 – SETTING C1634 TO FIRE PROTECTION

MODE ................................................... 25

TABLE 8 – ZONE AND ZONAL OUTPUT ALLOCATION ... 25

T1216W-C

MARINEW-P-I

1 11/12

PAGE 4 of 39

3. Introduction

This manual contains all the information necessary

for the installation, commissioning and maintenance

of the T1216W panel.

NOTE: It is important to read this manual fully

before commencing installation.

The following supporting documentation is also

available:

T1216W-C Application Guide

Related Documentation:

T1200-C Sales Literature

T1200-C Panel Application Guide

T1200-C User Manual

T1200-C Log Book

T1200-C Insert Template

Mains AC Changeover Unit Fixing

Instructions.

Note: References are made throughout this

document to “Fire Protection Output” and “Fire

Output”. These refer to particular outputs from the

T1216W panel and are provided for specific

purposes:

Fire Protection Output: An output used to

activate ancillary fire protection equipment or

systems. For example, fire doors or plant

shutdown.

Fire Output: An output used to send a

common fire warning signal to a remote fire

monitoring station.

References are also made to “Manual Fire Alarm”

and “Muster”. These relate to fire alarm sounder

operating modes which are activated manually from

the fire panel display. The panel is configurable to

one or other of the two modes.

Detailed descriptions of both outputs are provided

within the following text.

4. Installation and Commissioning

Overview

This section lists the steps that are taken in

installing and commissioning a T1216W system.

Reference should be made to the T1216W

Application manual for technical details and

description of panel features.

1. Install all field wiring and equipment

Refer to the Installation instructions in section

5.2. Refer to the field device installation

manuals.

2. Install the panel

Refer to the installation instructions in section

5.2. Do not connect the field equipment at this

stage.

3. Connect any repeaters (if applicable)

Refer to the installation instructions in section

5.2.

4. Commission the panel

Refer to section 6. Commissioning.

5. Installation

The control panel must be installed by suitably

qualified technicians familiar with the installation of

fire detection and alarm systems. In addition, it is

recommended to refer to the following information:

The Current edition of the relevant wiring

regulations for ships.

Any specific vessel requirements.

Any field device installation instructions.

Any data sheet provided for the installation of

Intrinsically Safe devices.

Notes:

The rating plate, containing essential electrical

information is located on the outside of the

panel, on the left side.

The mains supply cable should be a minimum

of 1mm2 copper protected by a 5A fuse.

An appropriate lockable double pole disconnect

device shall be provided as part of the vessel

installation. This device must have a minimum

contact gap of 3mm.

5.1 Electrical Safety

WARNING:

Prior to commencing installation of the

control panel, ensure that adequate

precautions are taken to prevent

damage to the sensitive electronic components on

the display board and the control board due to

electrostatic discharge. You should discharge any

static electricity you may have accumulated by

touching a convenient earthed object. You should

repeat the process at regular intervals during the

installation process, especially if you are required to

walk over carpets.

If possible, wear an anti-static wrist strap connected

to a suitable earth point when working on the panel.

The panel must be located in an area which

complies with the environmental specification

detailed in the T1200-C Application Manual and

should be at least 2 metres away from pager

systems or any other radio transmitting

equipment. The operating temperature range of

the panel & repeater is -10ºC to +55ºC. Batteries

are housed in a separate enclosure and are

rated as operational between -20ºC to +50ºC for

charging purposes. Maximum humidity is 95%

for panel, repeater & batteries.

EQUIPMENT: T1216W-C

PUBLICATION: MARINEW-P-I

ISSUE No. & DATE: 1 11/12

© 2012 Thorn Security Ltd PAGE 5 of 39

Registered Company: Thorn Security Ltd. Registered Office: Dunhams Lane Letchworth Garden City Hertfordshire SG6 1BE

IMPORTANT NOTES ON BATTERIES:

DANGER: Batteries are electrically live

at all times, take great care never to

short circuit the battery terminals.

WARNING: Batteries are often heavy;

take great care when lifting and

transporting batteries. For weights

above 24 kilos, lifting aids should be

used.

DANGER: Do NOT attempt to remove

the battery lid or tamper with the

internal workings of the battery.

Electrolyte is a highly corrosive

substance, and presents significant danger to

yourself and to anything else it touches. In case of

accidental skin or eye contact, flush the affected

area with plenty of clean, fresh water and seek

immediate medical attention.

Valve Regulated Lead Acid (VRLA) batteries are

“low maintenance”, requiring no electrolyte topup or measurement of specific gravity.

WARNING: Only clean the battery case with a cloth

that has been soaked or dampened with distilled

water. Do not use organic solvents (such as petrol,

paint thinner, benzene or mineral spirits) or other

materials that can substantially weaken the case.

Do not use a dry cloth as this will generate static

electricity, which in turn may lead to an explosion.

WARNING: Avoid operating temperatures outside

the range of -15C/5F to +50°C/122°F for

float/standby applications.

The recommended normal operating temperature is

20°C.

HIGH TEMPERATURE will reduce battery service

life. In extreme cases this can cause Thermal

Runaway, resulting in high oxygen/hydrogen gas

production and battery swelling. Batteries are

irrecoverable from this condition and should be

replaced.

LOW TEMPERATURE will prolong battery life but

reduce output capacity.

DANGER: Do not incinerate batteries.

If placed in a fire, the batteries may

rupture, with the potential to release

hazardous gases and electrolyte.

VRLA batteries contain substances

harmful to the environment.

Exhausted batteries must be recycled.

Return them to the battery

manufacturer or take them to your

Council waste disposal site for

appropriate disposal.

ELECTRICAL SAFETY:

The volt-free relay contacts provided within the

panel must not be used to directly switch any

voltage that exceeds 30V. (Please also refer to

relay rating data).

A 9V battery is supplied fitted to the inside of the

door. This battery provides power to the buzzer in

the event of total power failure or display ribbon

disconnection. The connecting lead of this battery is

disconnected from the display board during

shipping.

1. DO NOT short circuit the battery terminals or

the connecting lead.

2. DO NOT remove this battery unless it

measures 8V or less.

3. DISCONNECT THE LEAD from the display

board BEFORE replacing the battery to avoid

accidental polarity reversal which may damage

the display circuitry.

4. ALWAYS secure the battery in the battery

holder with a Tie-wrap.

5. DO NOT use rechargeable batteries as these

will gradually discharge due to internal

resistance.

Some of the panels covered by this manual

require a 110 or 230V AC supply. Refer to the

equipment rating plate and T1200-C Application

Manual for detailed information.

All installation work should be carried out in

accordance with the recommendations of the

current edition of the IEE regulations by

suitably qualified and trained personnel.

This is an IEC Class 1 electrical

appliance and therefore must have

the chassis connected to an

electrical earth.

T1216W-C

MARINEW-P-I

1 11/12

PAGE 6 of 39

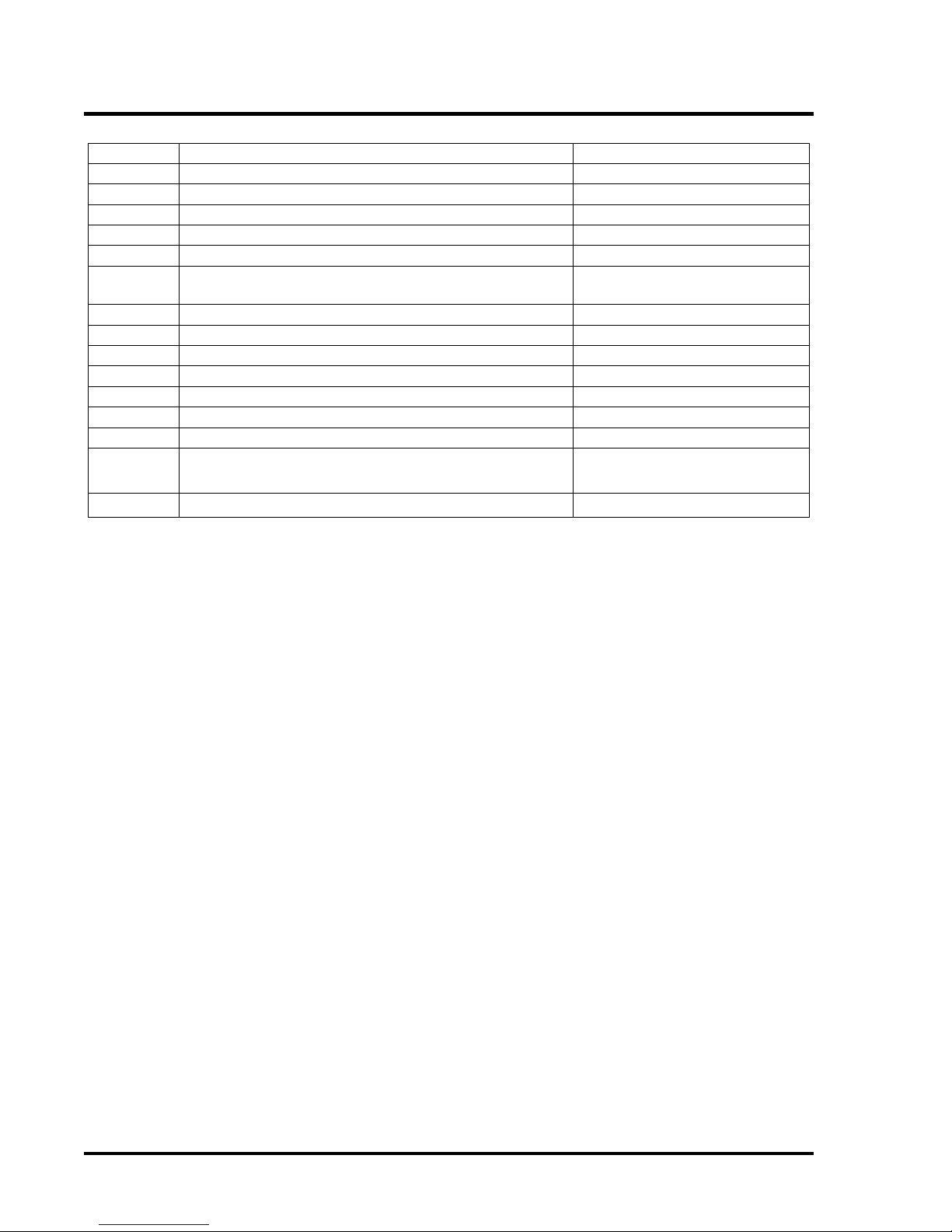

Table 1 – Content of Spares Bag

Quantity

Description

Type

1

Mains Fuse

T5AH250V 20mm

1

Battery Fuse

T8AH250V 20mm

16

End-of-Line resistors for zone circuits

10k 0.25W

4

End-of-Line resistors for alarm circuits

3k9 0.25W

3

End-of-Line resistors for monitored outputs

3k9 0.25W

2

Access Control key

Key Ref - 801

Part no 509.023.061

1

Positive battery lead

Red – 250mm

1

Negative battery lead

Black – 300mm

1

Battery coupling lead

Blue – 250mm

1

Tie wrap cable clip for securing mains lead

8

Neoprene washers for box fixing

Part no 2400174

1

Total power failure battery [PP3]

Supplied fitted

1

Alternative Button test insert

Panel - English

1 x THORN

1 x TYCO

TYCO & THORN Logo Labels

Self-Adhesive Label

1

T1200C Documentation CDROM

CDROM

5.2 Installation Instructions

1. Carefully remove the control panel from the

packing and lay the panel on a flat surface.

2. Locate the spares bag (either inside the

packing box or inside the panel) and check

that the items shown in Table 1 above are

present.

5.2.1 T1216W Panel Installation

Instructions

Note: The panel is supplied configured for bottom

cable entry. If top cable entry is required then the

door of the enclosure should be removed & fitted to

the opposite side of the enclosure. The installation

instructions below apply to top or bottom cable

entry.

1. Ensure that the panel is on a flat surface with

the door facing up.

2. Remove the panel door as follows:

3. Undo the two slotted screws that secure the

door shut. The screws will remain attached to

the door.

4. Open the door. Note that the door will open

past 180 degrees and will put tension on the

hinges if no support is provided underneath.

You may find it useful to place the packing box

underneath the door to provide support.

5. Locate the ribbon cable connecting the display

board to the main control board (motherboard).

Push the metal retaining clip off the connector

on the display and pull the ribbon cable out of

the connector.

6. Locate the earth strap connected to the door.

Pull the earth strap connector off the spade

terminal on the door.

7. Use a suitable flat blade screwdriver to

unscrew the hinges whilst supporting the door.

8. Place the door and hinge fixing screws

carefully to one side.

9. The chassis is fixed to the enclosure backbox

at five points. Three of these points are keyhole type; two are round holes for screws.

10. Remove the Chassis from the enclosure as

follows:

(a) Disconnect the chassis earth lead from

the spade terminal on the enclosure

backbox.

(b) Remove the two cross-head screws at the

bottom left & right corners of the chassis

(towards the gland plate).

(c) The three key-hole fixings do not have

screws.

(d) Slide the chassis free of the key-hole

slots.

(e) Lift the chassis out of the enclosure and

place carefully to one side. Note that the

chassis is heavy and caution should be

taken when lifting the chassis.

(f) Observe that there is a key-hole fixing in

the centre of the chassis which slides onto

a post. Care should be taken when

replacing the chassis that this key-hole

slides onto the post correctly.

NOTE: The door and chassis both contain

Control Boards with sensitive and fragile

EQUIPMENT: T1216W-C

PUBLICATION: MARINEW-P-I

ISSUE No. & DATE: 1 11/12

© 2012 Thorn Security Ltd PAGE 7 of 39

Registered Company: Thorn Security Ltd. Registered Office: Dunhams Lane Letchworth Garden City Hertfordshire SG6 1BE

electronic components on them. You must place

these items in a location where they will not be

damaged. Use the packing box to place these

items inside, ensuring that the door & chassis

remain separated. Store them in a safe place

which is clean, dry and dust-free.

Note: Do not allow the door & chassis to

come into contact with the packing foam as

this may hold a static charge.

11. Locate the earth lead connecting the gland

plate to the earth bar. Disconnect the earth

lead from the earth bar.

12. Remove the screws securing the gland plate to

the enclosure. Remove the gland plate.

13. Use a centre punch and hammer to remove

the required knock-outs by placing the centre

punch diagonally opposite the fixing point on

the knockout and striking the centre punch with

the hammer. DO NOT remove the knock-outs

from any unused cable entries.

14. Refit the gland plate ensuring that the seal is

correctly seated.

15. Re-connect the earth lead from the gland plate

to the earth bar.

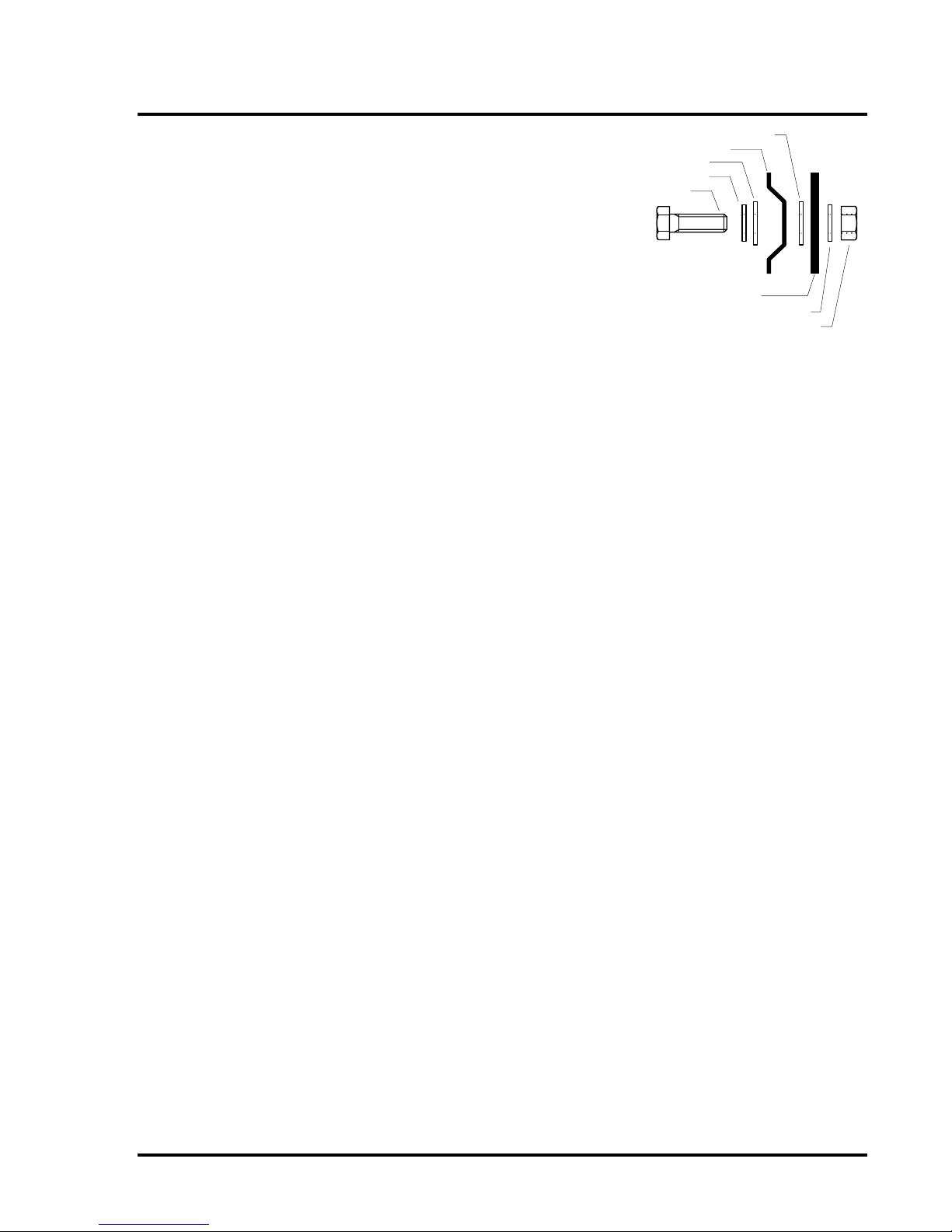

For Bulk Head mounting:

(a) Identify the four indented holes in the

back of the enclosure that are used to

mount the enclosure.

(b) Mark the location of one of the upper

fixing holes on the wall/bulkhead. Drill and

fix with a suitably plated or stainless steel

M5 nut, bolt and washers (fixings not

supplied). The fixing must be sealed using

two neoprene washers [supplied with the

panel fixing kit], one fitted between the

panel and the bulkhead and the other

fitted between the panel and the steel

washer inside the panel. See Figure 1 –

Bulk Head Mounting Details. Do not fully

tighten at this stage.

(c) Level the panel and fix the remaining

fixing points as above.

(d) Check that neoprene seals have been

fitted as shown in Figure 1 then fully

tighten all of the fixing nuts & bolts.

(e) Check that the enclosure is firmly seated

against the bulk head and is not deformed

in any way.

M5 STAINLESS STEEL BOLT

M5 STAINLESS STEEL WASHER

NEOPRENE WASHER

ENCLOSURE

NEOPRENE WASHER

BULKHEAD

M5 STAINLESS STEEL WASHER

M5 STAINLESS STEEL NUT

Figure 1 – Bulk Head Mounting Details

For Console mounting:

(a) Cut a suitable hole in the console to fit the

enclosure. Dimensions are shown in

section 11.

(b) Identify the four holes in the outer flange

of the enclosure that are used to mount

the enclosure in a console.

(c) Insert the enclosure into the console. Note

that the flange will not sit flush with the

console at this stage because of the four

bushes used for securing the door.

(d) Mark the centre positions of the four

bushes. Remove the enclosure and drill

suitable sized holes to accommodate the

bushes (13mm to 15mm diameter).

(e) Insert the enclosure into the console and

check that the flange now sits flush with

the console. Drill suitable mounting holes

in the console & fix with M5 counter sunk

screws.

16. Bring all field wiring into the enclosure through

suitable cable glands, ensuring that the cable

conductors are of sufficient length inside the

enclosure (at least 30cm). Waterproof glands

and seals should be used to maintain ingress

protection against water. Ensure that all

conductors are clearly labelled. Any unused

cable entries which are open must have

waterproof knockout seals fitted.

17. Connect the earth drain wires of the field

cabling to the earth bar(s) positioned at the

back of the back-box. Up to two drain wires

may be connected to each terminal.

18. Ensure that the electrical continuity of any

cable shield is maintained through to the last

device on the circuit. The shield must only be

connected to enclosure earth in the panel by

using the earth bars provided.

19. Clear any dust and debris from inside the

enclosure.

20. Reinstallation of the chassis is the reverse of

removal. Ensure that all keyholes on the

T1216W-C

MARINEW-P-I

1 11/12

PAGE 8 of 39

chassis are fully mounted onto the posts in the

back-box.

21. Reconnect all earth wires and ensure none are

trapped between the chassis and back-box. Do

not connect the field wiring at this stage.

22. Refit the door. The refitting procedure is the

reverse of removal. Ensure that the earth strap

and ribbon cable are reconnected correctly.

23. If a door stay is supplied then this should now

be fitted following the instructions in section

5.5.2.

24. Connect the incoming protective earth

conductor to the Earth terminal in the mains

terminal block. This is the primary earth point

and is labelled [Also labelled E]; see

section 12. Wiring Diagrams.

25. NOTE: When shutting the door of the panel,

DO NOT over tighten the thumb-screws.

Tighten until finger-tight and then turn another

quarter-turn using a screwdriver.

5.2.2 Connection of the incoming AC

Power Supply

Note: For installations requiring the Mains AC

switch-over unit, a 24Vdc supply will need to be

connected from the panel to the AC mains switchover unit to drive the LED indications. See Figure

17 for wiring details.

1. With both poles of the incoming power supply

safely isolated at the feeder end, connect the

Live [AC] conductor to the mains terminal

block [L terminal] as shown in section 12.

Wiring Diagrams.

2. Connect the Neutral [AC] conductor to the

mains terminal block [N terminal] as shown in

section 12. Wiring Diagrams.

3. Secure the incoming supply cable using the

cable tie supplied. NOTE: The cable tie should

be over the outer cable insulation.

5.2.3 T1200B-C Battery Box Installation

The T1200B-C battery box can only be bulk head

mounted. The incoming cable must have an in-line

fuse in the positive power supply (fuse type: T6.3A

HRC). The fuse must be mounted external to the

battery box, in a suitable terminal box which is

close-coupled to the battery box. See Figure 19 for

wiring details.

To mount the T1200B-C battery box:

(a) Identify the three indented holes in the back

of the enclosure that are used to mount the

enclosure.

(b) Mark the location of one of the upper fixing

holes on the wall/bulkhead. Drill and fix with

a suitably plated or stainless steel M5 nut,

bolt and washers (fixings not supplied). The

fixing must be sealed using two neoprene

washers [supplied with the fixing kit], one

fitted between the panel and the bulkhead

and the other fitted between the panel and

the steel washer inside the panel. See Figure

1 – Bulk Head Mounting Details. Do not fully

tighten at this stage.

(c) Level the enclosure and fix the remaining

fixing points as above.

(d) Check that neoprene seals have been fitted

as shown in Figure 1 then fully tighten all of

the fixing nuts & bolts.

(e) Check that the enclosure is firmly seated

against the bulk head and is not deformed in

any way.

(f) Mount the fused terminal box (not supplied)

adjacent to the battery box and fit a suitable

waterproof coupling to allow cable entry from

the terminal box to the battery box.

5.2.4 Battery Installation

The T1200B-C battery box will only hold 2 x 17Ah

PowerSonic SLA batteries.

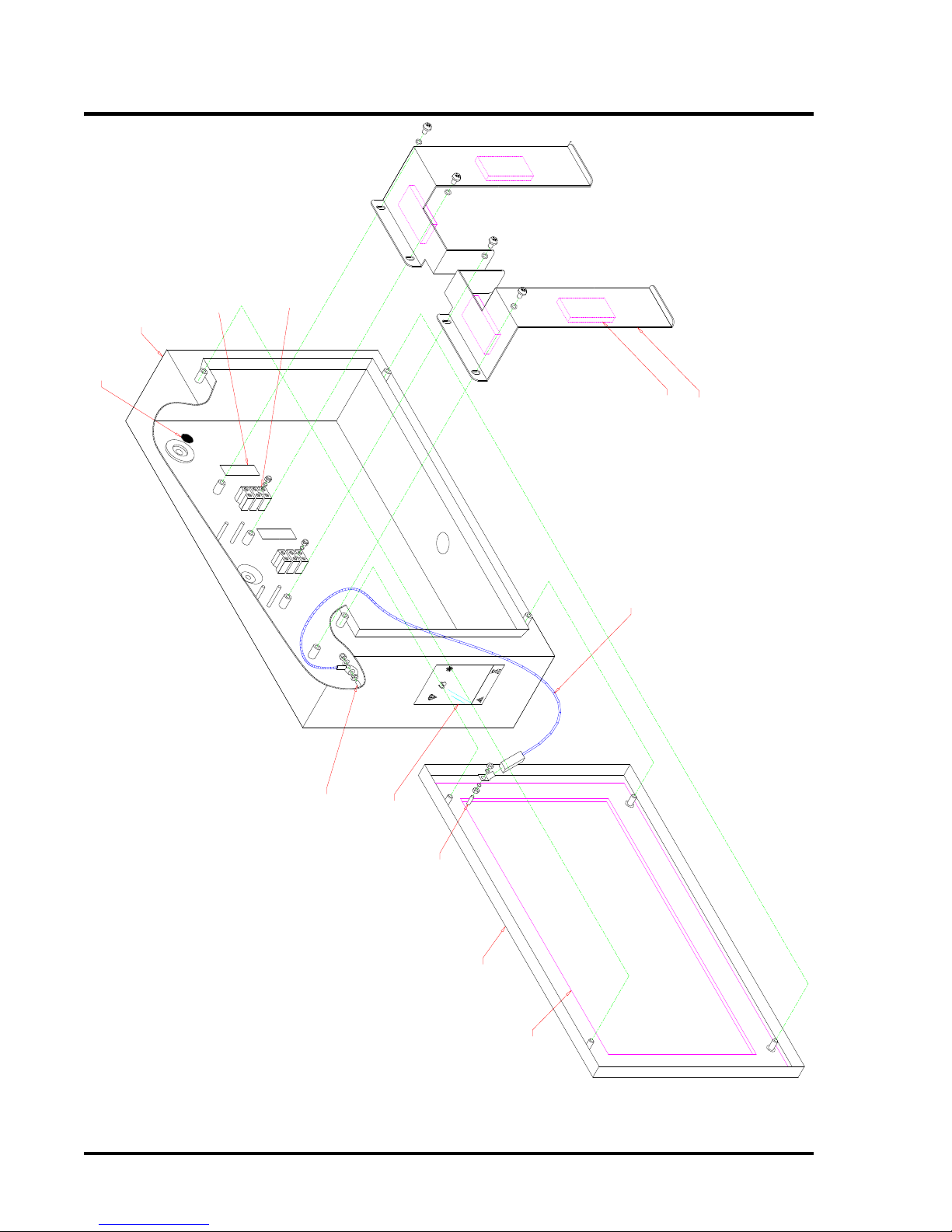

1. Remove the battery clamps from the battery

box before fitting the batteries.

2. Place the left-hand battery into the battery box.

The battery should be located toward the left

side of the enclosure, the battery terminals

should be positioned towards the front.

3. Place the right-hand battery into the battery

box. The battery should be located toward the

right side of the enclosure, the battery

terminals should be positioned towards the

front.

4. Fix the battery retaining clamps. [See Figure 2]

5.2.5 Battery Connection

1. Connect the black battery lead to the terminal

marked BAT-, connect the red battery lead to

the terminal marked BAT+.

2. The Thermistor assembly is supplied loose in

the fixing kit supplied with the T1216W-C

panel. Connect the Thermistor leads to the

terminals marked THERM.

3. Tie-wrap the Thermistor to one of the battery

leads so that when the battery leads are

connected, the Thermistor is located just

above one of the batteries.

4. The blue lead is used to connect the batteries

together. Do not connect this lead until you are

ready to power up the panel.

EQUIPMENT: T1216W-C

PUBLICATION: MARINEW-P-I

ISSUE No. & DATE: 1 11/12

© 2012 Thorn Security Ltd PAGE 9 of 39

Registered Company: Thorn Security Ltd. Registered Office: Dunhams Lane Letchworth Garden City Hertfordshire SG6 1BE

5.2.5.1 Connecting the battery box to

the panel PSU

1. Run a suitable 4-core shielded cable between

the panel and the battery box.

2. Label each core appropriately (BAT+, BAT-,

THERM, THERM).

3. Connect the negative battery conductor to the

“Batt -” [battery negative] terminal and connect

the positive battery conductor to the “Batt +”

[battery positive] terminal. Both terminals are

situated on the panel chassis.

4. Connect the Thermistor leads to the two

terminals marked “Therm” on the panel chassis.

5. Warning: Do not connect the leads to the battery

at this stage. Connection of the batteries will

power up the panel even if the mains supply is

off.

5.2.6 Installation and connection of

the C1631 Repeater Interface

Warning: Observe anti-static precautions

The C1631 interface board is not provided as

standard with the panel. It is included in the spares

kit of the repeater panel, to be fitted in the main fire

alarm panel when required.

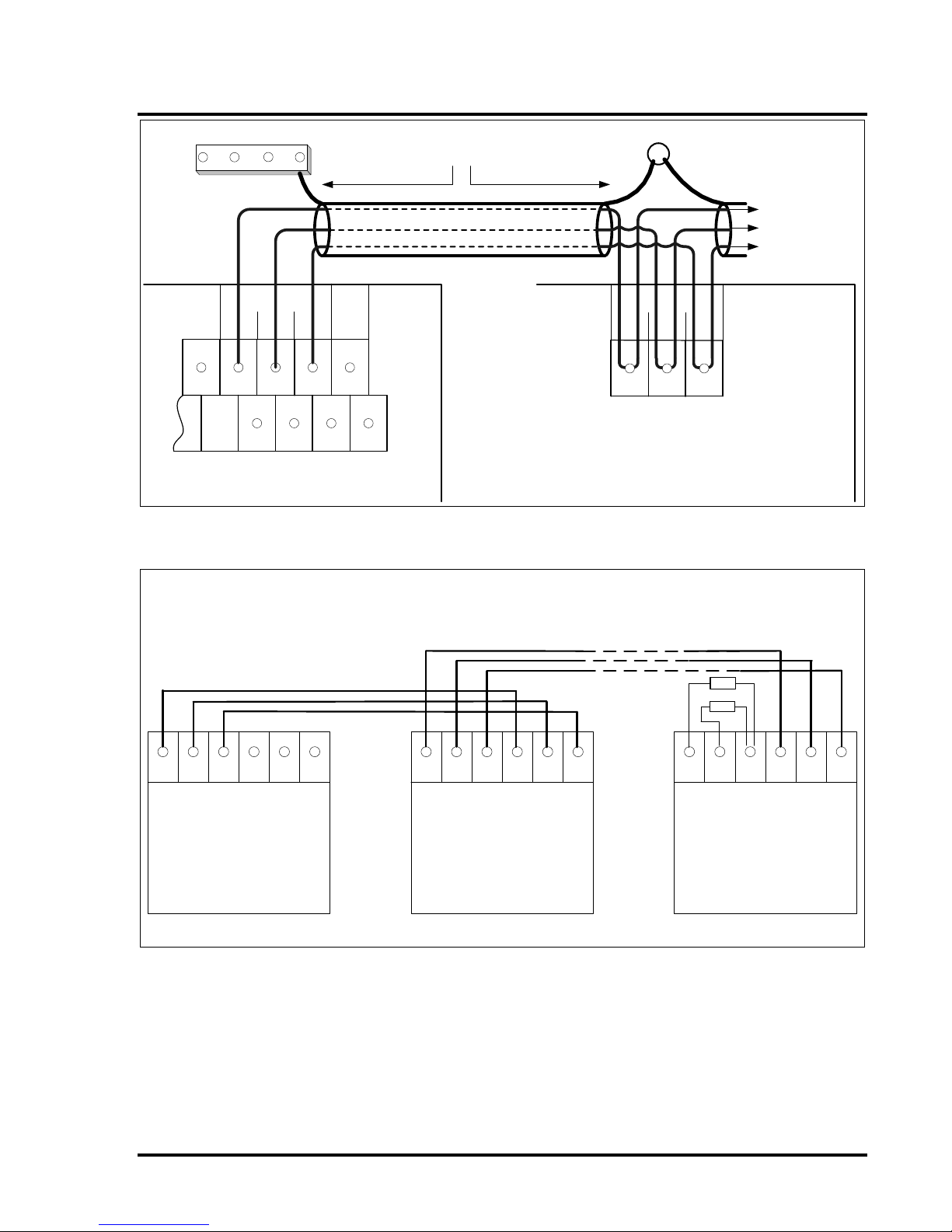

1. Ensure that the panel and repeaters are

powered down and the main and standby

supplies are disconnected.

2. On the fire alarm panel remove the jumper link

at J22 (adjacent to J9) and fit a C1631

repeater interface to connectors J13 and J9 on

the right-hand side of the C1627 motherboard.

The board should be held in place by the

12mm high plastic spacer provided. See

Figure 10.

3. The Repeater is supplied with the C1631

Interface Board fitted.

4. Connect the RS485 data cable as shown in

Figure 3.

5. Connect the Aux 24Vdc supply from the panel

to the repeater. You can use two cores in the

data cable for this purpose only if the voltage

drop between the panel and repeater is not

more than 2Vdc.

Notes:

One repeater will draw up to 75mA which means

that the total resistance of the cable should not

exceed 24 Ohms (12 Ohms in each core). The

T1216W-C Application Guide lists cable types with

their nominal DC resistance.

If more than one repeater is required or the cable

resistance is too great, then data cable is

unsuitable for supplying power and a separate

suitable 2-core cable must be used.

Use only Plenum rated screened data cable with at

least three core-pairs to accommodate repeater

communication & Muster Interface options. 4 pairs

will be required if power is also being provided

(subject to the limitations described above).

Connect the cable screen to earth at the fire alarm

panel and the repeaters.

5.2.7 Installation and connection of the

C1665 Muster Interface

Warning: Observe anti-static precautions

The C1665 interface board is not provided as

standard with the panel. It is an optional item that

can be ordered separately and used with repeaters

to provide Muster Alarm control from repeater

panels.

1. Ensure that the panel and repeaters are

powered down and the main and standby

supplies are disconnected.

2. On the C1627 motherboard in the fire alarm

panel and each repeater, identify link J23 and

connector J2 which are located on the left

hand side of the motherboard.

3. Remove link J23 and carefully plug the C1665

PCB into connectors J2 and J23.

4. Connect the field cable as shown in Figure 4.

5. Connect 2 off 3K9 monitoring resistors to the

C1665 in the last repeater as shown in Figure

4. [The resistors are supplied in the Muster

Interface fixing kit].

6. On the fire alarm panel display PCB fit link J2

to the lower position for Muster operation

Note:

Use three cores of the RS485 screened data

cable.

T1216W-C

MARINEW-P-I

1 11/12

PAGE 10 of 39

BACKBOX

DOOR

DOOR SEAL

'GORTEX' SEAL

EARTH POST

DOOR EARTH STRAP

EARTH POST

SELF ADHESIVE FOAM (4 PLACES)

Fuse:Input:Serial No:Part No:Product:Standards:Approval

:

0086

/

09

KM

95744

Fire Alarm System

Isolate Supply Before

0086

-

CPD

-

555921

Opening Cover

THIS UNIT MUST

BE EARTHED

RATING LABEL

Thorn Security Ltd

Made in Great Britian

3 WAY PSU TERMINAL

BLOCK (2 OFF)

TERMINAL BLOCK LABEL

BAT

+

BAT

-

N

/

C

THERM

THERM

N

/

C

BATTERY CLAMPS

Figure 2 – Battery clamp details

EQUIPMENT: T1216W-C

PUBLICATION: MARINEW-P-I

ISSUE No. & DATE: 1 11/12

© 2012 Thorn Security Ltd PAGE 11 of 39

Registered Company: Thorn Security Ltd. Registered Office: Dunhams Lane Letchworth Garden City Hertfordshire SG6 1BE

EARTH STUD

EARTH BAR

Repeater

A

B

GND

[Top right hand corner of C1627 motherboard]

Data Cable Screen

T1216W fire detection/alarm panel

Power Supply connections not shown.

Repeater

A

B

GND

T1200 repeater panel [max 5 off]

[Top right hand corner of C1626 motherboard]

Figure 3 – Repeater connection diagram

M in Sin GND GNDM out S out

C1665 Muster

Interface in Fire

Panel

M in Sin GND GNDM out S out

C1665 Muster

Interface in Repeater

Panel 1

M in Sin GND GNDM out S out

C1665 Muster

Interface in last

Repeater Panel

2 off 3k9

resistors

Wiring Optional Repeater Muster Interface[s]

These three cores should be contained within the Repeater RS485 communications cable, the cable

screen being connected to Earth at panel & repeaters. If a separate cable is used then the cable

screen should be connected to the Earth.

Figure 4 – Muster Interface Wiring Diagram

T1216W-C

MARINEW-P-I

1 11/12

PAGE 12 of 39

5.3 Modifications to the Water Mist

Relay Control Panel

Three modifications to the Water Mist Relay Control

Panel [WMRCP] are necessary to provide the

correct interface. See Modifications 1, 2 and 3 in

section 13.

These modifications should be carried out by

either the Engineer responsible for the WMRCP

or under their direct guidance and instruction.

5.3.1 Modification 1 [System Abnormal]:

Refer to Figure 5 for details.

On Relay R50/2, disconnect wires 313 and 314

from the normally closed contact pair and reconnect

to the normally open pair. [Contacts described with

RL50 de-energised – i.e. in the fault condition].

Remove the 6k8 monitoring resistor connected

between wires 313 and 314. Use two spare field

terminals to connect a 10K 0.25W resistor in series

with R50/2.

6k8

Resistor

TB5/3

TB5/4

313

314

R50/2

De-energised

(fault condition)

Before Modification

10k

Resistor

TB5/3

TB5/4

313

314

R50/2

De-energised

(fault condition)

After Modification

Wire

Link

WaterMist Control Panel

System Abnormal Output Signal

U3

U4

Site Wiring to

T1216W-C

Site Wiring to

T1216W-C

Figure 5– System Abnormal Modification

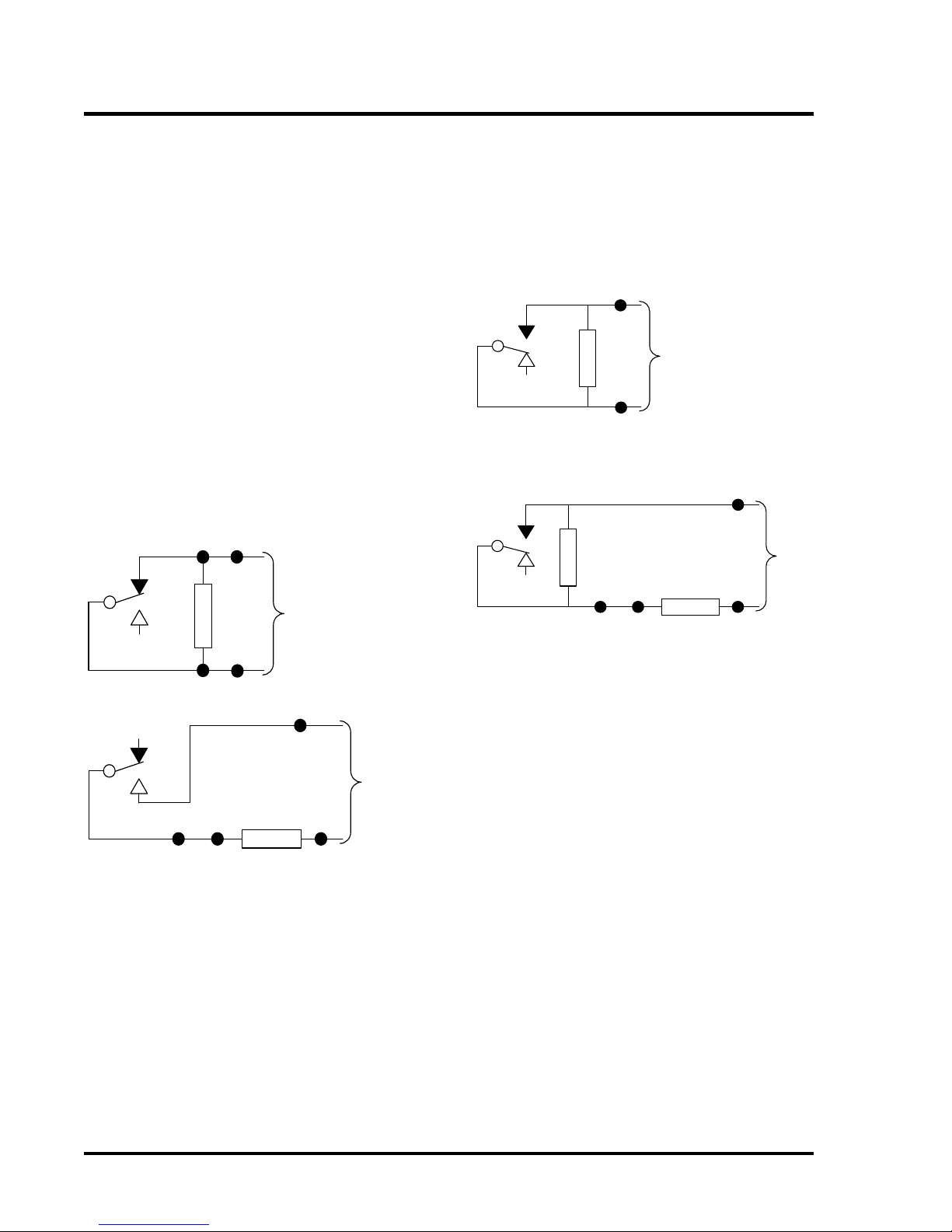

5.3.2 Modification 2 [System Operated]:

Refer to Figure 6 for details.

Replace the 6k8 monitoring resistor connected

between wires 315 and 316 with a 10k 0.25W.

Use two spare field terminals to connect 680 Ohm 1

Watt resistor in series with R44/3.

6k8

Resistor

TB5/1

TB5/2

315

316

R44/3

Relay shown in

quiescent

(non-alarm)

condition

Before Modification

680 Ohm

Resistor

TB5/1

TB5/2

315

316

R44/3

After Modification

Wire

Link

WaterMist Relay Control Panel

System Operated Output Signal

U1

U2

10k

Resistor

Relay shown in

quiescent

(non-alarm)

condition

Site Wiring to

T1216W-C

Site Wiring to

T1216W-C

Figure 6– System Operated Modification

Loading...

Loading...