Remote Control

User Guide

for the

MX / MBX / TLX Series

Remote Control User Guide for the MX / MBX / TLX Series

Table of Contents

Chapter 1

Chapter 2 Supported Commands ................................................................................................................... 4

Chapter 3 Remote Control Software ............................................................................................................ 14

Chapter 4 Thorlabs Worldwide Contacts ..................................................................................................... 20

Introduction ..................................................................................................................................... 1

1.1. Description ...................................................................................................................................... 1

1.2. Interfacing the Computer and the MX / MBX / TLX Instrument .................................................. 1

2.1. RF Amplifier Commands ................................................................................................................ 5

2.2. Laser Control Commands .............................................................................................................. 7

2.3. Mach-Zehnder EO Intensity Modulator Commands .................................................................... 9

2.4. System Commands ...................................................................................................................... 11

2.5. Variable Optical Attenuator (VOA) Commands ......................................................................... 12

3.1. Installing the Software and Opening a Connection with the Instrument ................................ 14

3.2. Using the Remote Control Application ...................................................................................... 15

3.3. Software Application Screenshots ............................................................................................. 16

3.4. Custom Application Development .............................................................................................. 19

Remote Control User Guide for the MX / MBX / TLX Series Chapter 1: Introduction

Chapter 1 Introduction

1.1. Description

The MX / MBX / TLX series of instruments may be remotely controlled via SCPI-type serial commands. This

requires connecting a computer running the Microsoft

instrument using a USB cable, or connecting a computer running any operating system to the RS-232 port on the

instrument. Serial commands are sent to the USB or RS-232 ports located on the back panel of the instrument.

The touchscreen interface remains active while the instrument is controlled remotely, and instrument functionality

remains accessible through the touchscreen interface.

This document describes the process of interfacing the instrument with the controlling computer, defines the serial

commands, and includes information about the remote control software tool that serves as an example and a

tutorial for sending the serial commands. To download the remote control software tool and supporting files for

your MX / MBX / TLX instrument, visit the following page and type in the instrument’s Item #:

https://www.thorlabs.com/manuals.cfm

®

Windows® 7 operating system, or later versions, to the

1.2. Interfacing the Computer and the MX / MBX / TLX Instrument

The following sections use the MX40G Electrical-to-Optical Converter as an example, but the procedure and

guidelines apply to all of the MX / MBX / TLX series of instruments. These instruments may be connected with a

computer via USB or RS-232 ports located on the back panel, as shown in Figure 1.

Please note that using both USB and RS-232 connections at the same time is not supported. If it is necessary to

change from a USB to a RS-232 connection, or vice versa, first power off the instrument, change the connection,

and then power on the instrument. This will ensure that the instrument recognizes the new connection.

B1

B5

B6

Figure 1 Back Panel of the MX40G

Label Description

B1

B2

B3

B4

B5

B6

B4

B3

B2

I/O Port (HDDB15 Connector)

Laser Interlock (2.5 mm Connector)

RS-232 Port (DB9 Connector)

USB Port (USB Type B Connector)

Power Connector

Power Switch

Supply On; Supply Off

Rev. D, September 29, 2017 Page 1

Remote Control User Guide for the MX / MBX / TLX Series Chapter 1: Introduction

Connecting to the USB Port on the Back Panel of the MX / MBX / TLX Instrument

A USB cable can be used to connect a computer running Windows 7, or later, with the port on the back panel of

the instrument as shown in Figure 2. The USB port is type-B. A USB cable with a type-B connector on one end

and a type-A connector on the other would allow connection with most computers.

USB Cable

RS-232

Port

USB Port

USB Port

Computer

Figure 2 Connecting the Computer and MX / MBX / TLX Instrument via the USB Ports

When discovered by the Windows PC, the MX / MBX / TLX instrument will appear as a human interface device

(HID), rather than as a virtual serial port. The HID class includes the computer mouse and keyboard. Please note

that PC terminal software, such as Tera Term, cannot be used to communicate with the MX / MBX / TLX

instrument via USB cable. This is due to PC terminal software requiring the connected instrument to be

recognized by the PC as a virtual serial port. The Thorlabs remote control application discussed in Chapter 3 can

scan for, discover, and open a connection with the connected MX / MBX / TLX instrument.

Connecting to the RS-232 Port on the Back Panel of the MX / MBX / TLX Instrument

If the controlling computer has an RS-232 port, or if a USB to RS-232 adapter is connected to the computer’s

USB port, an RS-232 cable can be used to make the physical connection between the computer and the RS-232

port on the back panel of the MX / MBX / TLX instrument. Any software capable of sending and receiving data

using serial ports can then be used to control the MX / MBX / TLX instrument. Configure the serial port of the

controlling computer for 115200 baud, 8 bits, no parity, 1 stop bit, and no flow control. The Thorlabs remote

control application discussed in Chapter 3 can also control the MX / MBX / TLX instrument via an RS-232

connection. The pin assignments for the DB9 connector on the back panel of the MX / MBX / TLX instrument are

described by Figure 3 and the table below.

1 2 3 4 5

6 7 8 9

Figure 3 RS-232 DB9 Connector on the

Back Panel of the MX / MBX / TLX

Instrument

Page 2 TTN116413-D04

Pin # Description

1

2

3

4

5

6

7

8

9

RS-232 Connector

Not Connected

RS-232 Input

RS-232 Output

Not Connected

Digital Ground

Not Connected

Not Connected

Not Connected

Not Connected

Remote Control User Guide for the MX / MBX / TLX Series Chapter 1: Introduction

Connecting to the MX /MBX / TLX Instrument Using the RS-232 Port on the Controlling Computer

Figure 4 illustrates the physical connection when the RS-232 ports on the MX / MBX / TLX instrument and the

controlling computer are used. The details of the connection depend on the controlling computer’s RS-232 port.

When it is a:

9-pin DB9 male connector, an option is to use a female-to-female 9-pin “null modem” cable. National

Instruments

http://digital.ni.com/public.nsf/allkb/1EE0DD8AF67922FA86256F720071DECF

25-pin DB25 male connector, a null modem cable that converts between 25 and 9 pins can be used.

In either case, if a null modem cable is not available, a null modem adapter could be used with a standard cable.

®

explains the difference between a standard and a null modem cable here:

Null Modem Cable

RS-232

Port

USB

Port

RS-232 Port

Computer

Figure 4 Connecting the Computer and MX / MBX / TLX Series Instrument via the RS-232 Ports

If the USB port on the controlling computer is used, a USB cable terminating in a USB to RS-232 adapter can be

can used to allow connection to a null modem cable. When the connector on the adapter is a 9-pin DB9 male, and

the null model cable has two 9-pin female DB9 connectors, it is possible to use the adapter and null modem cable

to make a connection between the computer’s USB and the MX / MBX / TLX instrument’s RS-232 ports. This is

illustrated in Figure 5.

Null Modem

USB Cable

Cable

USB to

RS-232

Port

USB

Port

RS-232

Adapter

RS-232 Port

Computer

Figure 5 Connecting the USB Port on the Computer to the RS-232 Port on the Instrument

Please note that the USB port on the MX / MBX / TLX instrument should not be connected to the RS-232 port on

the controlling computer; this configuration is not supported.

Rev. D, September 29, 2017 Page 3

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

Chapter 2 Supported Commands

This section describes the commands supported by firmware version V1.6.1. The commands are modeled on the

IEEE 488.2 standard commands for programmable instruments (SCPI) specification.

Following this convention, many commands in the “Syntax” columns of the following tables include both

uppercase and lowercase letters. Uppercase letters identify the shortest acceptable form of the commands. A

contiguous subset of the lowercase letters can be included in the command syntax as desired. (For example,

VOA:SET?, VOA:SETP?, and VOA:SETPO? are all acceptable variations of the single VOA:SETpoint?

command.)

The commands described below have been developed as a custom set, as no device in the SCPI standard is an

exact analogue.

Please note that not every command described in the following sections applies to every MX / MBX / TLX Item #.

In order for a command to apply to a specific instrument, the instrument must have the related built-in component.

For example, the Laser Control Commands do not apply to instruments that do not include an internal tunable

laser. The following table lists the commands supported by each instrument.

The command descriptions are grouped in the following sections:

Section 2.1: RF Amplifier Commands

Section 2.2: Laser Control Commands

Section 2.3: Mach-Zehnder EO Intensity Modulator Commands

Section 2.4: System Commands

Section 2.5: Variable Optical Attenuator (VOA) Commands

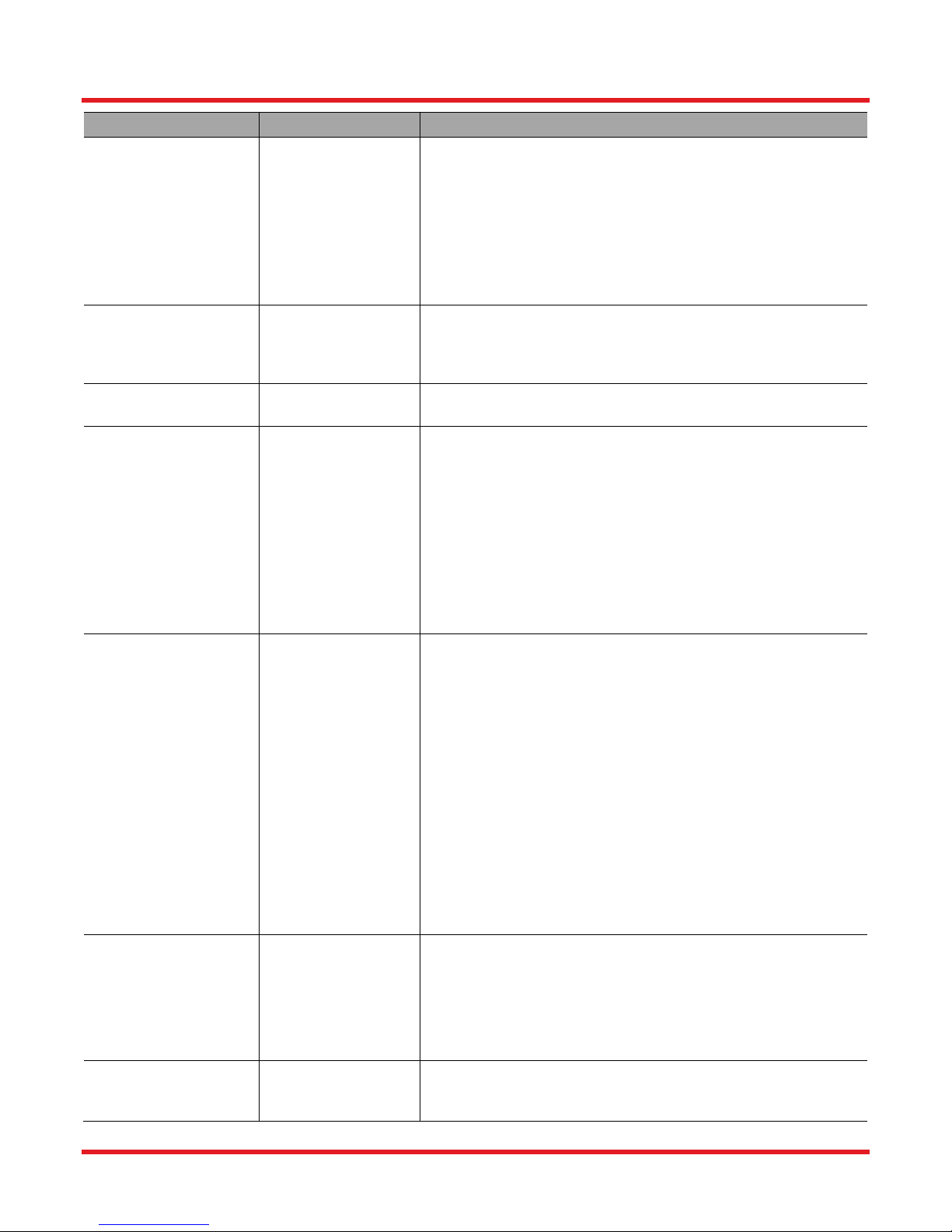

Item #

MBX

MX10A,

MX40A

MX10B,

MX40B

MX10C,

MX40C

MX35E

MX40G

TLX1,

TLX2

RF Amplifier

Commands

- -

-

-

Laser

Control

Commands

-

Mach-Zehnder Modular

Bias Control

Commands

System

Commands

-

-

Variable Optical

Attenuator

Commands

Figure 6 The Available Command Set for Each Instrument Corresponds to its Built-In Functionality

Page 4 TTN116413-D04

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

2.1. RF Amplifier Commands

The MX series of instruments include several that have a built-in RF amplifier, and the following commands apply

only to these instruments. The amplifier type is digital (limiting) in some of these products, such as the MX10A,

MX40A, MX10B, MX40B, MX10C, and MX40C. In other products, such as the MX35E, the amplifier type is linear

(analog). Only digital RF amplifiers have crossing point and swing settings, and only these RF amplifiers can operate

in either analog or digital modes. In contrast, the gain may be set only for linear RF amplifiers. Unless otherwise

noted, the following RF Amplifier commands apply to both amplifier types.

Command Syntax Description

Set Crossing

Point

(Analog Mode)

Get Crossing

Point

(Analog Mode)

Set Crossing

Point

(Digital Mode)

Get Crossing

Point

(Digital Mode)

Set Gain

Get Gain

AMP:CROSSing:ANAlog: N

AMP:CROSSing:ANAlog?

AMP:CROSSing:DIGital: N

AMP:CROSSing: DIGital?

AMP:GAIN: N

AMP:GAIN?

N is a floating point value between -1.0 and 1.0, inclusive.

This parameter applies to the digital amplifier operating in

analog mode and determines the location of the crossing

point. N has no units; -1.0 corresponds to the maximum

possible negative offset, and 1.0 corresponds to the maximum

possible positive offset. The available range, which depends

on the amplifier’s voltage limits and the current AMP:SWING

setting, may be smaller than this full -1.0 to 1.0 range. When

this is the case, N values within ±1.0 but exceeding the

currently available range will set the crossing point to the

closest permitted value. This command is not available for

instruments with linear (analog) amplifier types.

Returns a floating point value between -1.0 and 1.0, inclusive.

This value has no units and corresponds to the current

crossing point for the digital amplifier when it operates in

analog mode. This command is not available for instruments

with linear (analog) amplifier types.

N is a floating point value between -1.0 and 1.0, inclusive.

This parameter applies to the digital amplifier operating in

digital mode and determines the location of the crossing point.

Please see AMP:CROSS:ANA for additional information. This

command is not available for instruments with linear (analog)

amplifier types.

Returns a floating point value between -1.0 and 1.0, inclusive.

This value has no units and corresponds to the current

crossing point for the digital amplifier when it operates in

analog mode. This command is not available for instruments

with linear (analog) amplifier types.

N is a floating point value between 10.0 and 23.0 in decibels.

This values sets the gain of linear (analog) type amplifiers.

This command is not available for instruments with digital

(limiting) amplifier types.

Returns a floating point value between 10.0 and 23.0 in

decibels, which corresponds to the current gain of the linear

(analog) type amplifier. This command is not available for

instruments with digital (limiting) amplifier types.

Rev. D, September 29, 2017 Page 5

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

Command Syntax Description

Set Amplifier Mode

to Analog

AMP:MODE: 1

Sets the operation of the digital amplifier to analog mode. This

includes setting the crossing point to that currently specified

for analog mode operation (AMP:CROSS:ANA) and applying

the maximum possible swing. This command is not available

for instruments with linear (analog) amplifier types.

Set Amplifier Mode

to Digital

AMP:MODE: 0

Sets the operation of the digital amplifier to digital mode. This

includes setting the crossing point to that currently specified

for digital mode operation (AMP:CROSS:DIG) and applying

the current value of swing (AMP:SWING). The default value of

swing is the amplifier’s value for V

at 1 GHz, which is

determined at the factory and place in instrument memory.

This command is not available for instruments with linear

(analog) amplifier types.

Get Amplifier Mode

AMP:MODE?

Returns 0 if the amplifier mode is set to analog and 1 if the

amplifier mode is set to digital. This command is not available

for instruments with linear (analog) amplifier types.

Power Amplifier On

AMP:POWer: 1

Sets amplifier power to “on” and returns 1 on receipt of

command.

Power Amplifier Off

AMP:POWer :0

Sets amplifier power to “off” and returns 1 on receipt of

command.

Get Amplifier Power

Status

AMP:POWer?

Returns 0 if the amplifier power is set to “off” and 1 if the

amplifier power is set to “on.” This command returns the most

recent requested power state, which may differ from the

amplifier’s currently active power state. AMP:SET? can be

used to verify the last requested power state is active.

Get Amplifier Status

AMP:SETpoint?

A 1 is returned and a steady green dot shows in the AMP field

of the instrument’s touchscreen when the amplifier is fully

ready and has reached the requested settings. Otherwise, a 0

is returned and the green dot blinks. Amplifier settings are

updated quickly, typically within a second. However, it is

possible that an immediate query after sending a command to

adjust amplifier voltage will find the amplifier in a transient

state and return a zero.

Set the Amplifier

Swing

(Digital Mode)

AMP:SWING: N

N is a floating point value with a standard range of 3.0 to

7.0 V

. This command sets the swing of the digital amplifier

pp

when it operates in digital mode, and this value can be set

while operating in analog mode. Some factory-customized

units have an extended swing range. Use the touchscreen

GUI on the instrument to view the available range. The

AMP:SWING:N command is not available for instruments with

digital (limiting) amplifier types.

Get the Amplifier

Swing

(Digital Mode)

AMP:SWING?

Returns a floating point value with units of Vpp. This is the

swing setting applied when the digital amplifier operates in

digital mode. This value can be retrieved while operating in

analog mode. This command is not available for instruments

with linear (analog) amplifier types.

Set the Amplifier

Swing to V

(Digital Mode)

AMP:SWING:VPI

Sets the swing to the amplifier’s V

receipt of command. This V

instrument at the factory and saved to memory. It is the

“optimal swing” setting applied when the V

at 1 GHz and returns 1 on

value is found for each

button on the

touchscreen interface is pressed. This command is not

available for instruments with linear (analog) amplifier types.

Page 6 TTN116413-D04

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

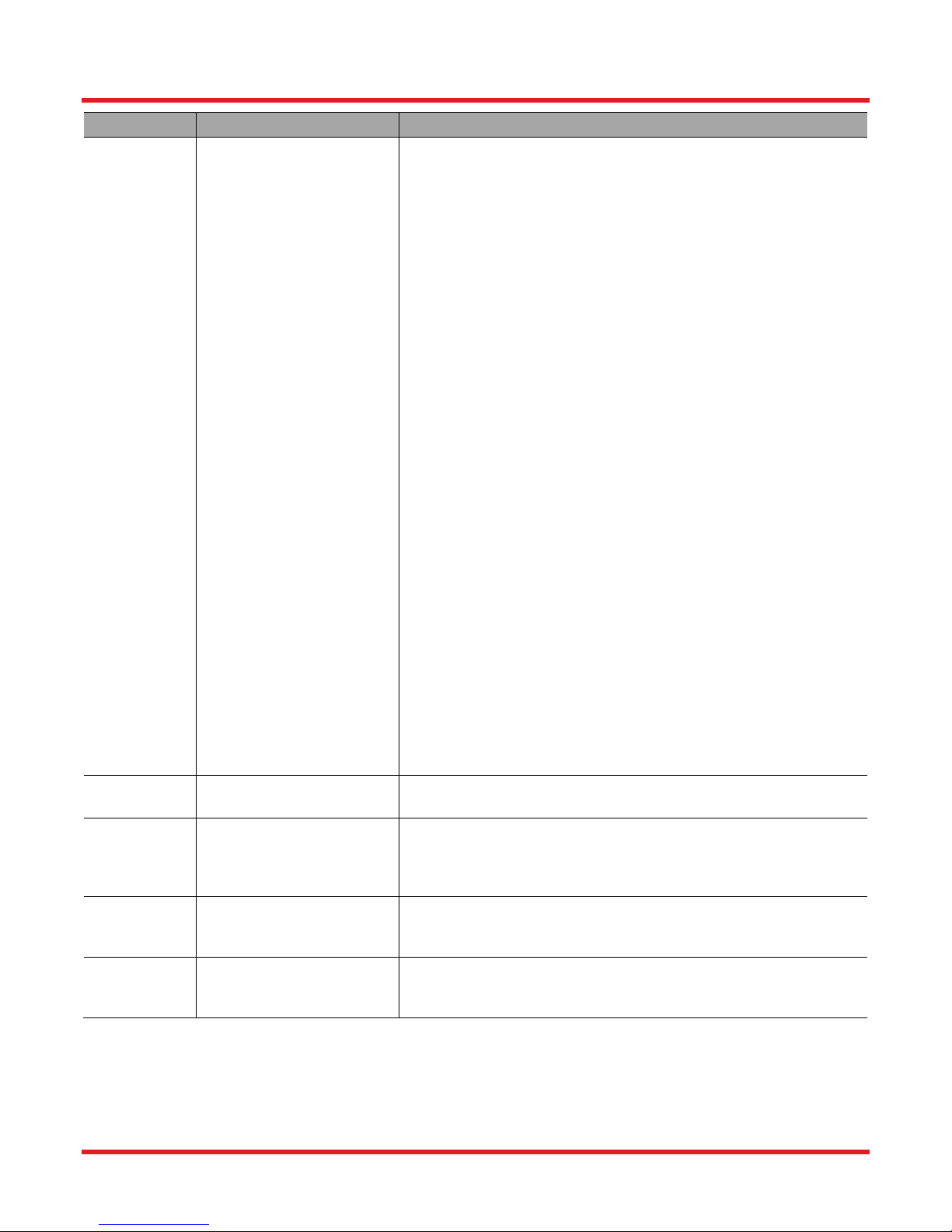

2.2. Laser Control Commands

These commands are available for the TLX series of instruments and those MX series products with a built-in

tunable laser, which include the MX10B, MX40B, MX35E, and MX40G. In the following, “Laser” refers to the builtin tunable laser, unless otherwise specified. Please note that the ITU channels are defined using a 50 MHz grid.

Be advised that there will be a delay between when requested laser state is specified in a “set” command and

when the requested state becomes the active laser state, as the instrument requires a finite period of time to

execute commands. Typical execution times are given in the following table for each relevant command. After

setting laser parameter(s), the LASER:SETpoint? command can be used to determine the laser’s active status.

Command Syntax Description

Set the ITU

Channel Number

Get the ITU

Channel Number

Turn Dither On

Turn Dither Off

Get Dither Status

Set Fine Tuning

Frequency Offset

Get Fine Tuning

Frequency Offset

Get Optical Laser

Frequency

LASER:CHANnel: N

LASER:CHANnel?

LASER:Dither: 1 Sets the laser dither to “on” and returns 1 on receipt of command.

LASER:Dither: 0 Sets the laser dither to “off” and returns 1 on receipt of command.

LASER:Dither?

LASER:FINE: N

LASER:FINE?

LASER:FREQ?

N is an integer from 1 and 96, inclusive, for the C-Band laser or

from 1 and 93, inclusive, for the L-Band laser. This command

sets the ITU channel of the laser and returns 1 on receipt of

command. While tuning to the desired channel, the laser’s optical

output may be temporarily reduced or turned off and then on.

Returns an integer value from 1 and 96, inclusive, for a C-Band

laser or from 1 and 93, inclusive, for an L-Band laser. This

command returns the most recent requested ITU channel, which

may differ from the currently active ITU channel due to a typical

channel set time duration of <10 s. The LASER:SET? command

can be used to verify the last requested ITU channel is active.

Returns 0 if dither is set to “off” and 1 if dither is set to “on.” This

command returns the most recent requested dither state, which

may differ from the currently active dither state due to a typical

dither set time duration of <10 s. The LASER:SET? command

can be used to verify the last requested dither state is active.

N is an integer between -30,000 and 30,000, inclusive. The

entered value is the frequency offset in MHz, and 1 is returned on

receipt of command. Sending this command causes the laser

frequency to be tuned to the sum of the current ITU channel

frequency and this specified fine tuning frequency offset. The

range of fine tuning frequency offsets spans the full frequency

range between ITU channels.

Returns an integer between -30,000 and 30,000, inclusive,

corresponding to the requested frequency offset in MHz. This

value may differ from the current frequency offset due to a typical

laser tuning time duration of <30 s. There is currently no accurate

way to determine, via remote control, whether a fine-tuning

operation has finished. However, other laser status information

can be obtained using:

LASER:FREQ?

LASER:SET?

LASER:OOP?

Returns a floating point value with unit of GHz. the reported

optical laser frequency, which is determined by the ITU channel

(LASER:CHAN:N) and fine offset (LASER:FINE:N). As the

resolution of the returned value is limited to 0.1 GHz (100 MHz),

the values of the intermediate frequencies set using the finetuning feature are reported rounded to the nearest 0.1 GHz.

Rev. D, September 29, 2017 Page 7

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

Command Syntax Description

Get Reported Optical

Output Power (OOP)

LASER:OOP?

Returns a floating point value with units of dBm. This value

corresponds to the optical output power from the laser module

measured by an integrated photodiode. A typical operating

value is 13.5 dBm. This is a different measurement than the

one reported in response to the LASER:TAP:DBM?

command, which measures the downstream optical power via

optical tap. The two measurements may differ slightly. Optical

output power will be unstable during laser warm-up and

frequency tuning.

Power Laser On

LASER:POWer: 1

Sets the laser power to “on” and returns 1 on receipt of

command. To ensure optimal stability and full optical output

power, allow the laser to warm up for 15 minutes after

powering on.

Power Laser Off

LASER:POWer: 0

Sets the laser power to “off” and returns 1 on receipt of

command.

Get Laser Power

Status

LASER:POWer?

Returns 0 if the laser power is set to “off” and 1 if the laser

power is set to “on.” This command returns the most recent

requested power state, which may differ from the laser’s

currently active power state. The LASER:SET? command can

be used to verify the last requested power state is active.

Additional laser status and setpoint information can be

obtained using:

LASER:SET?

LASER:OOP?

LASER:TAP:DBM?

LASER:TAP:MW?

Get Laser Status

LASER:SETpoint?

When the following conditions are all true, a 1 is returned and

a steady green dot shows in the laser field of the instrument’s

touchscreen. Otherwise, a 0 is returned.

The hardware key switch interlock on the front panel

is in the “on” position.

The instrument’s microcontroller, in response to

remote or touchscreen control, has commanded the

laser to power on.

The laser’s currently active dither state (on or off)

matches the last requested dither state.

The laser’s currently active ITU channel matches the

last requested ITU channel.

The laser currently reports it is in the “ready” state.

The laser currently reports it is in the “enabled” state.

The laser currently reports its optical output power is

greater than 12.0 dBm.

Get Measured

Optical Output

Power in dBm

LASER:TAP:DBM?

Returns a floating point value with units of dBm. This is a

measurement of the optical output power measured

downstream from the laser module using an optical tap. The

value returned by LASER:OOP is a measurement made by a

photodiode integrated into the laser module. The two

measurements may differ slightly. Optical output power will be

unstable during laser warm-up and frequency tuning.

Get Measured

Optical Output

Power in mW

LASER:TAP:MW?

Returns a floating point value with units of mW, with the

measurement details identical to those described for

LASER:TAP:DBM?.

Page 8 TTN116413-D04

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

2.3. Mach-Zehnder EO Intensity Modulator Commands

Several of the MX Series of instruments have built-in controllers for lithium-niobate-based, Mach-Zehnder EO

intensity modulators (MZMs). The following commands apply only to these instruments, which include the MBX,

MX10A, MX40A, MX10B, MX40B, MX35E, and MX40G.

Command Syntax Description

Get

Calibration

Status

Set Dither

Amplitude

Get Dither

Amplitude

Set Dither

Frequency

Get Dither

Frequency

Set Hold

Ratio

Get Hold

Ratio

Set Hold

Voltage

Get Hold

Voltage

MZM:CALibrating?

MZM:Dither:AMPLitude: N

MZM:Dither:AMPLitude?

MZM:Dither:FREQuency: N

MZM:Dither:FREQuency?

MZM:HOLD:Ratio: N

MZM:HOLD:Ratio?

MZM:HOLD:Voltage: N

MZM:HOLD:Voltage?

Returns a 0 if the MZM bias is not currently being calibrated and

a 1 calibration is currently in progress. The MZM bias is

calibrated automatically when the MZM Bias controller is turned

on for the first time or when recalibration is triggered manually

(MZM:RESET or using the RESET AUTO BIAS button on the

touchscreen GUI). Calibration data are maintained when the bias

controller is turned off and on without powering down the MX

instrument, but MZM calibration data are not stored upon

instrument shut-down.

N is a positive integer between 20 and 2,000, inclusive, with units

of mV

. It sets the dither amplitude for those MZM bias modes

pp

that reference this value. Not all MZM bias modes use dither.

Returns the current dither amplitude setting in mV

. as a positive

pp

integer between 20 and 2,000. This will return the stored dither

setting. It is not a measurement of the dither in the output from

the MZM. Not all MZM bias modes use dither.

N is a positive integer between 1,000 and 10,000, inclusive, with

units of Hz. Not all MZM bias modes use dither.

Returns the current dither amplitude setting in Hz as a positive

integer between 1,000 and 10,000, inclusive. This will return the

stored dither setting. It is not a measurement of the dither in the

output from the MZM. Not all MZM bias modes use dither.

N is a positive integer between 100 and 10,000, inclusive. It has

no units and represents the input power required to achieve the

desired input to output power ratio. Determine N by first choosing

the desired ratio of input to output powers, then multiply that ratio

by 100. (e.g. If desired input and output power values are the

same, their ratio is 1.0 and N = 100. If the input is 100.00 times

greater than the output power, N = 10,000.) This setting is used

only in Auto Power Ratio Positive and Auto Power Ratio Negative

MZM bias modes.

Returns a positive integer between 100 and 10,000, inclusive. It

has no units and represents the input power required to achieve

the desired input to output power ratio, as described in the entry

for MZM:HOLD:R:N. This will return the stored ratio setting. It is

not a measurement of the MZM bias output. It is only used in

Auto Power Ratio Positive and Auto Power Ratio Negative MZM

bias modes.

N is an integer between -10,000 and 10,000, inclusive, and has

units of mV. This setting is used only in Manual Voltage MZM

bias mode.

Returns an integer between -10,000 and 10,000, inclusive, and

has units of mV. This will return the stored ratio setting. It is not a

measurement of the MZM bias output. It is only used in Manual

Voltage MZM bias mode.

Rev. D, September 29, 2017 Page 9

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

Command Syntax Description

Set MZM

Bias Mode

MZM:MODE: N

N is a positive integer between 0 and 9, inclusive. Set this value

to select the MZM bias mode. The mode associated with each

value is:

0: Bias control is off. 0 V is applied to the MZM bias.

1: Auto Peak bias mode, which uses dither to maintain

operation at the peak of the modulation function.

2: Auto Null bias mode, which uses dither to maintain

operation at the lowest point (null) of the modulation function.

3: Auto Quad Pos bias mode, which maintains operation at

the positive quadrature position on the modulation function.

This is equivalent to using the touchscreen GUI to select

Quad Mode and positive slope, with dither on.

4: Auto Quad Neg bias mode, which maintains operation at

the negative quadrature position on the modulation function.

This is equivalent to using the touchscreen GUI to select

Quad Mode and negative slope, with dither on.

5: Hold Quad Pos bias mode, which holds the bias at the last

voltage found in Quad mode. It is equivalent to using the

touchscreen GUI to select Quad Mode and positive slope,

with dither off.

6: Hold Quad Neg bias mode, which holds the bias at the last

voltage found in Quad mode. It is equivalent to using the

touchscreen GUI to select Quad Mode and negative slope,

with dither off.

7: Manual Voltage bias mode, which is equivalent to using

the touchscreen GUI to select Manual Mode while the “bias”

setting is selected.

8: Auto Power Ratio Pos, which is equivalent to using the

touchscreen GUI to select Manual Mode while the “ratio”

setting and positive slope are selected.

9: Auto Power Ratio Neg, which is equivalent to using the

touchscreen GUI to select Manual Mode while the “ratio”

setting and negative slope are selected.

Trigger MZM

Calibration

Get MZM

Status

MZM:RESET

MZM:SETpoint?

Triggers a MZM bias calibration and returns a 1. While the

calibration is running, the MXM:CAL? command returns a 1.

A 1 is returned and a steady green dot shows in the Bias field of

the instrument’s touchscreen when the MZM bias is stable and at

setpoint. A 0 is returned and the green dot in the Bias field blinks

while the MZM is not at setpoint.

Get PostMZM Power

in dBm

Get PostMZM Power

in mW

MZM:TAP:DBM?

MZM:TAP:MW?

Returns the optical power, as a floating point value in dB, output

by the MZM. This value is the scaled optical power measurement

made at a tap located at the output of the MZM.

Returns the optical power, as a floating point value in mW, output

by the MZM. This value is the scaled optical power measurement

made at a tap located at the output of the MZM.

Page 10 TTN116413-D04

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

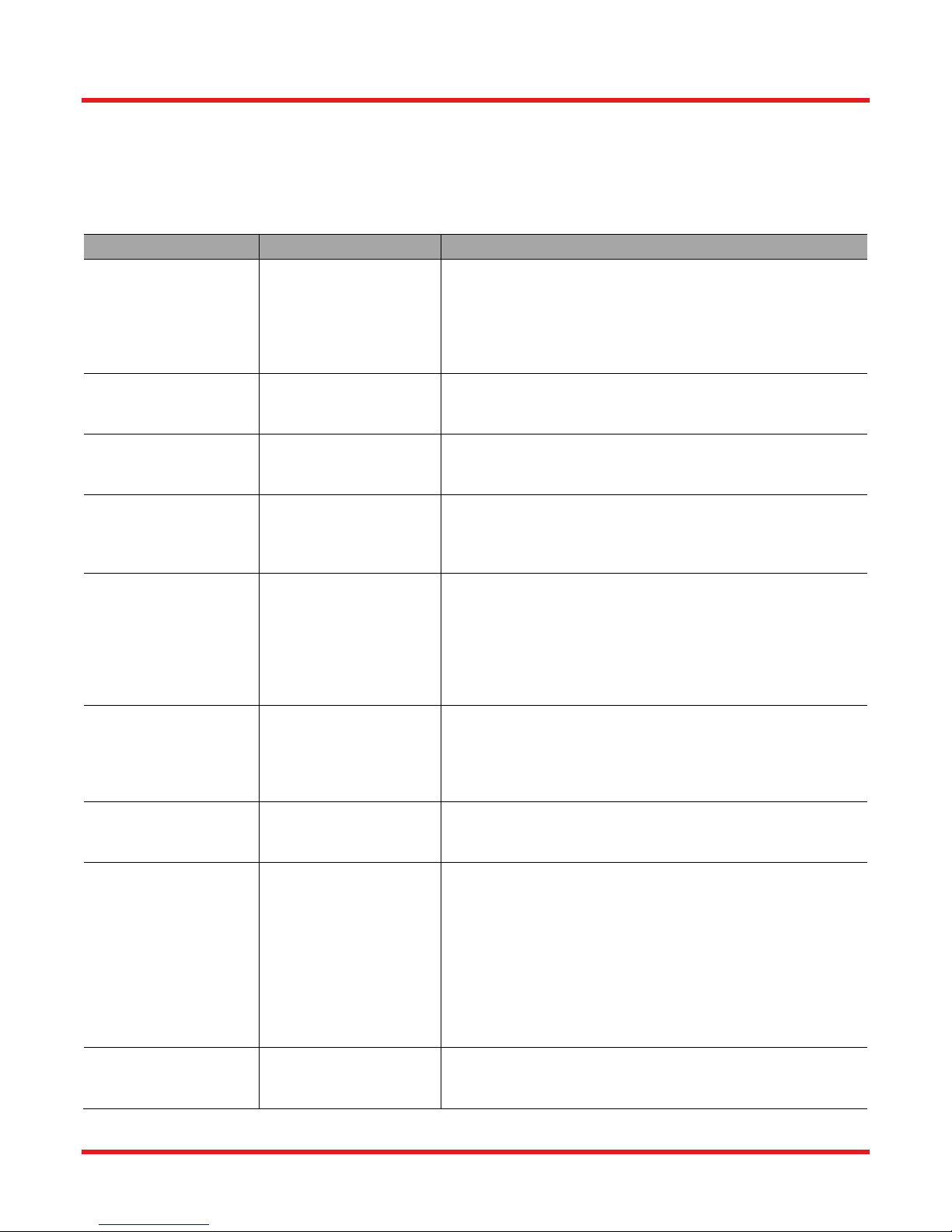

2.4. System Commands

The system commands described in this section apply to all MX / MBX / TLX instrument Item #s. The LED brightness

commands given below allow the user to individually set the brightness of the red, green, and blue LEDs that

contribute to the under-chassis lighting integrated into the housings of the these instruments. The brightness can

be set using a scale from 0.0 to 1.0, and the default combination is a value of 0.0 for the red LEDs, 0.0 for the green,

and 0.75 for the blue. These LEDs can be used to provide a visual indicator of a change in instrument status. For

example, the lighting could be changed to green to indicate the conclusion of a test driven by remote-control

commands.

Command Syntax Description

Set System

Wavelength

Get System

Wavelength

Set Red LED

Brightness

Get Red LED

Brightness

Set Green

LED

Brightness

Get Green

LED

Brightness

Set Blue

LED

Brightness

Get Blue

LED

Brightness

SYStem:WAVElength: N

SYStem:WAVElength?

RGB:RED: N

RGB:RED?

RGB:GREEN: N

RGB:GREEN?

RGB:BLUE: N

RGB:BLUE?

N is the positive integer value 1310, 1550, or 1590 with units of

nm. This command sets the system wavelength, which is used to

selected which calibration values to use when configuring the

VOA and when evaluating the power measurements made at the

taps. Setting the system wavelength optimizes the instrument for

use at that wavelength. Setting this value is equivalent to using

the touchscreen GUI to set the system wavelength.

Returns a positive integer value of 1310, 1550, or 1590 with units

of nm that correspond to the current system wavelength setting.

N is an integer value between 0 and 100, which is used to set the

brightness of the red LEDs that contribute to the under-chassis

accent lighting.

Returns an integer value between 0 and 100, indicating the

brightness of the red LEDs that contribute to the under-chassis

accent lighting.

N is an integer value between 0 and 100, which is used to set the

brightness of the green LEDs that contribute to the under-chassis

accent lighting.

Returns an integer value between 0 and 100, indicating the

brightness of the green LEDs that contribute to the under-chassis

accent lighting.

N is an integer value between 0 and 100, which is used to set the

brightness of the blue LEDs that contribute to the under-chassis

accent lighting.

Returns an integer value between 0 and 100, indicating the

brightness of the red LEDs that contribute to the under-chassis

accent lighting.

Rev. D, September 29, 2017 Page 11

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

2.5. Variable Optical Attenuator (VOA) Commands

The VOA commands described in this section apply to all MX / MBX / TLX instrument Item #s. These commands

are provided for controlling the VOA and determining its status are described in the following tables.

Command Syntax Description

Set the Optical

Attenuation Value

Get the Optical

Attenuation Value

Get Difference

between Actual and

Setpoint Attenuation

Get Measured

Attenuation Provided

by VOA

Set VOA Mode to

Constant Optical

Output

Set VOA Mode to

Constant Attenuation

Get VOA Mode

Set the Optical

Output Power Value

in dBm

Get the Optical

Output Power Value

in dBm

VOA:ATTen: N

VOA:ATTen?

VOA:ERRor?

VOA:MEASured?

VOA:MODE: 1

VOA:MODE: 0

VOA:MODE?

VOA:OUTput:DBM: N

VOA:OUTput:DBM?

N is a floating point value between 1.0 and 20.0, inclusive,

with units of dB. This command sets optical attenuation of

the VOA and returns 1 on receipt of command. If set while

operating in constant power mode, the operation of the

VOA will not be affected. Instead, the value will be cached

and applied when constant attenuation mode is activated.

Returns the attenuation setting of the VOA as a floating

point value between 1.0 and 20.0, inclusive, with units of

dB.

Returns the difference between the attenuation provided by

the VOA and the attenuation setpoint value as a floating

point value with units of dB.

Returns the value of attenuation provided by the VOA as a

floating point value with units of dB. The value of

attenuation is the calculated ratio of the optical power

measured before and after the VOA.

Sets the VOA mode to constant optical output power and

returns 1 on receipt of command. While operating in this

mode, the optical power measured after the VOA is

monitored and the VOA bias voltage is adjusted to maintain

the requested optical output power. Holding the optical

output power constant requires adequate optical power

input.

Sets the VOA mode to constant optical attenuation and

returns 1 on receipt of command. While operating in this

mode, optical power levels measured before and after the

VOA are monitored. The VOA bias voltage is adjusted to

maintain the specified ratio between the two.

Returns 0 if the VOA mode is set to constant optical

attenuation and 1 if the VOA mode is set to constant optical

output power.

N is interpreted as a floating point value between -20.0 and

20.0, inclusive, and the units are dBm. This command sets

optical output power of the VOA and returns 1 on receipt of

command. While this range exceeds the maximum power

output of the built-in laser, the entire range is supported to

accommodate the use of higher-power external laser

sources. If this value is set while operating in constant

attenuation mode, it will not affect the operation of the

VOA. In this case, the value will be cached and applied

when constant power mode is activated.

Returns the power setting of the VOA as floating point

value between -20.0 and 20.0, inclusive, with units of dBm.

Page 12 TTN116413-D04

Remote Control User Guide for the MX / MBX / TLX Series Chapter 2: Supported Commands

Command Syntax Description

Set the Optical

Output Power Value

in mW

VOA:OUTput:MW: N

N is a floating point value between 0.01 and 100.0,

inclusive, and the units are mW. This command sets optical

output power of the VOA and returns 1 on receipt of

command. While this range exceeds the maximum power

output of the built-in laser, the entire range is supported to

accommodate the use of higher-power external laser

sources. If this value is set while operating in constant

attenuation mode, it will not affect the operation of the

VOA. In this case, the value will be cached and applied

when constant power mode is activated.

Get the Optical

Output Power Value

VOA:OUTput:MW?

Returns the power setting of the VOA as a floating point

value between 0.01 and 100.0, inclusive, with units of mW.

in mW

Power VOA On

VOA:POWer: 1

Sets the VOA power to “on” and returns 1 on receipt of

command. When the VOA is powered on, an active and

automatic software control loop is engaged to vary the

VOA bias voltage. This maintains the requested

attenuation level, or optical output power, depending on the

VOA operating mode.

Power VOA Off

VOA:POWer: 0

Sets the VOA power to “off” and returns 1 on receipt of

command. As VOA is in-line with the optical path, there is

an insertion loss associated with it. When the VOA is

powered off, the VOA bias voltage is set to 0.0 V, which

minimizes the optical attenuation through the VOA.

Get VOA Power

Status

Get VOA Status

VOA:POWer?

VOA:SETpoint?

Returns 0 if the VOA power is set to “off” and 1 if the VOA

power is set to “on.”

A 1 is returned, and a steady green dot shows in the VOA

field of the instrument’s touchscreen, if the attenuation

provided by the VOA is within 0.1 dB of the attenuation

setpoint. The attenuation provided by the VOA is the

calculated ratio of the optical power measured before and

after the VOA. The attenuation setpoint references the last

requested power setting if operating in constant power

mode, and it references the last requested attenuation

setting if operating in constant attenuation mode. If the

difference between the attenuation provided by the VOA

and the attenuation setpoint is >0.1 dB, a 0 is returned.

This command returns a valid value whether or not the

VOA is powered on.

Get Optical Power

Output by the VOA in

VOA:TAP:DBM?

Returns the measured optical output of the VOA as a

floating point value with units of dBm.

dBm

Get Optical Power

Output by the VOA in

VOA:TAP:MW?

Returns the measured optical output of the VOA as a

floating point value with units of mW.

mW

Rev. D, September 29, 2017 Page 13

Remote Control User Guide for the MX / MBX / TLX Series Chapter 3: Remote Control Software

Chapter 3 Remote Control Software

Thorlabs provides a software tool for computers running Windows operating systems (Windows 7 and later). The

Remote Control application is primarily intended to be used as a reference example as well as a tool for exploring

the behavior of and interactions between the various remote control commands. Use it to experiment with all of

the currently supported laser and VOA commands, as well as to see examples of the outgoing commands and

replies from the MX / MBX / TLX instrument. This tool sends serial commands to the instrument, but this

application software is not intended for system integration, as it does not support running scripts or processes.

3.1. Installing the Software and Opening a Connection with the Instrument

Begin by downloading the application software by visiting the following link, typing in the Item # of the MX / MBX /

TLX instrument, and clicking on the Software Download Icon shown in the list of files available for download.

https://www.thorlabs.com/manuals.cfm.

Unzip the file whose name begins with “RCUP.” Keep the “Remote Control Utility Program.exe” file in the same

directory with the “platforms” folder and other supporting files, as the application will not run if these are

separated.

Before running the application, connect the MX / MBX / TLX instrument and the controlling computer using the

appropriate cabling as described in Section 1.2. Power on the instrument and ensure the power button on the

front panel is glowing green and the touchscreen is active. Wait until the computer discovers the instrument, and

then launch the application. The application window is shown in Figure 7. The actual application window does not

include the red, green, blue, and violet outlines shown in Figure 7, these outlines were drawn on an image of the

window for illustrative purposes.

Figure 7 Laser Tab of the Remote Control Tool’s Application Window

Page 14 TTN116413-D04

Remote Control User Guide for the MX / MBX / TLX Series Chapter 3: Remote Control Software

Select the “Connection Type” radio button corresponding to the utilized connector on the instrument. (The location

of the radios buttons is indicated by the red outline in Figure 7.) Then click the “Connect” button to open a

connection to the instrument.

After clicking the “Connect” button, the “Status” field, which is located at the bottom of the region enclosed by the

green outline, should show a number of lines of text. If the application established a connection with the

instrument, the text shown in the status field will conclude with “Device Opened Successfully.”

If a connection was not established between the computer and instrument, the text in the “Status” field will note

the failure. A common reason for a failure to connect is that the instrument has not been recognized by the

computer; the software cannot find the instrument unless it has been discovered by the computer. It may take up

to 30 seconds for the computer to recognize the instrument. If the device fails to open successfully, we

recommend closing the Remote Control application, waiting a few seconds, re- opening the application, and

attempting again to connect to the instrument. Other reasons the application may fail to successfully open a

connection to the instrument include the connection already being open or another copy of the application

running. If none of these are the source of the problem, and the problem persists when a different USB cable is

used, please contact Thorlabs’ Technical Support for assistance.

3.2. Using the Remote Control Application

When using the application, clicking the buttons located at the top of the application window sends serial

commands to the MX / MBX / TLX instrument. The results of clicking the buttons are logged in the three

rectangular text fields, which are bordered by the green outline in Figure 7. The commands sent by the computer

are written to the PC Output field, the data sent back from the instrument in response to the commands are

written to the Remote Instrument Output field, and the status of the software is written to the Status field.

The following examples illustrate the operation of the software and the interaction between the software and the

touchscreen interface on the front panel of the MX / MBX / TLX series instrument that includes a built-in laser,

such as the MX40G.

Example: Using the Application to Change the Laser’s ITU Channel

Adjust the “Channel” control (within the blue outline) to 5.

Click the “Set Channel” button (within the violet outline).

The text “LASER:CHAN 5”, which is the command sent to the instrument, is printed to the “PC Output”

field (within green outline).

After a short delay, the text “1” is printed to the “Remote Instrument Output” field (within green outline).

This indicates the command was received by the instrument.

The text printed to the “Status” field indicates the response was received.

Click the “Get Channel” button (within the violet outline).

The text “LASER:CHAN?” , which is the command sent to the instrument, is printed to the “PC Output”

field (within green outline).

After a short delay, the text “5”, which is the most recent ITU channel requested, is printed to the “Remote

Instrument Output” field (within green outline).

Rev. D, September 29, 2017 Page 15

Remote Control User Guide for the MX / MBX / TLX Series Chapter 3: Remote Control Software

Example: Using the Software Application with the MX40G’s Front Panel Touchscreen

Navigate to the Laser Settings Page, which is

shown in Figure 8, from the Home Screen

Use the Laser Settings Page to change the ITU

Chanel to 6.

Click the “Get Channel” button (within the violet

outline) in the Remote Control Application.

The text “LASER:CHAN?” , which is the

command sent to the MX40G, is printed to the

“PC Output” field (within green outline).

After a short delay, the text “6”, which is the ITU

channel entered using the touchscreen, is

printed to the “Remote Instrument Output” field

Figure 8 Laser Settings Page of the MX40G

(within green outline).

3.3. Software Application Screenshots

The functions in the Laser tab (Figure 9) correspond to the commands described in Section 2.2: Laser Control

Commands

Page 16 TTN116413-D04

Figure 9 Laser Tab

Remote Control User Guide for the MX / MBX / TLX Series Chapter 3: Remote Control Software

The functions in the VOA tab (Figure 9) correspond to the commands described in Section 2.5: Variable Optical

Attenuator (VOA) Commands.

Figure 10 VOA Tab

The functions in the Amp tab (Figure 11) correspond to the commands described in Section 2.1: RF Amplifier

Commands.

Rev. D, September 29, 2017 Page 17

Figure 11 Amp Tab

Remote Control User Guide for the MX / MBX / TLX Series Chapter 3: Remote Control Software

The functions in the MZM Bias tab (Figure 12) correspond to the commands described in Section 2.3: MachZehnder EO Intensity Modulator Commands.

Figure 12 MZM Bias Tab

The functions in the System tab (Figure 13) correspond to the commands described in Section 11: System

Commands.

Page 18 TTN116413-D04

Figure 13 System Tab

Remote Control User Guide for the MX / MBX / TLX Series Chapter 3: Remote Control Software

3.4. Custom Application Development

One option for users interested in developing custom software is to use our Remote Control application as a

reference and starting point. Please contact us to request the source code. Using this source code and a

development platform such as free version of the Qt

expanded.

When the computer is connected to the RS-232 port on the MX / MBX / TLX series instrument, commands are

sent directly to the instrument’s universal asynchronous receiver/transmitter (UART). This is not the case for

applications communicating with the instrument over USB. In this case, commands sent by the computer address

a Silicon Labs

®

USB to UART bridge chip built into the instrument. The UART is interfaced to the bridge chip. A

dynamic-link library (DLL) available from Silicon Labs’ website can be used to communicate with the bridge chip.

If you have questions or would like guidance as your develop a custom test configuration, please contact us. We

are happy to assist you.

®

software, our example application can be modified and

Rev. D, September 29, 2017 Page 19

5HPRWH&RQWURO8VHU*XLGHIRUWKH0;0%;7/;6HULHV&KDSWHU7KRUODEV:RUOGZLGH&RQWDFWV

Chapter Thorlabs Worldwide Contacts

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau / Munich

Germany

Tel: +49-(0) 8131-5956-0

Fax: +49-(0) 8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

Japan

Thorlabs Japan, Inc.

3-6-3 Kitamachi,

Nerima-ku, Tokyo 179-0081

Japan

Tel: +81-3-6915-7701

Fax: +81-3-6915-7716

www.thorlabs.co.jp

Email: sales@thorlabs.jp

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place

Ely CB7 4EX

Great Britain

Tel: +44 (0) 1353-654440

Fax: +44 (0) 1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

China

Thorlabs China

Room A101, No. 100, Lane 2891,

South Qilianshan Road

Putuo District

Shanghai 200331

China

Tel: +86 (0) 21-60561122

Fax: +86 (0) 21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

Page 0 771'

www.thorlabs.com

Loading...

Loading...