Thermoelectric Temperature

Controller

TED200C

Operation Manual

2015

Version:

Date:

3.3

02-Jul-2015

Copyright © 2015 Thorlabs

Contents

Foreword

2

1 General Information 3

2 Getting Started 7

3 Operating Instruction 10

103.1 External Connections

103.1.1 TEC Output

113.1.2 Connecting the TEC element

113.1.3 Control LED for TEC ON mode

123.1.4 Connecting a temperature sensor

41.1 Protection of the TEC element

41.2 Safety

61.3 Ordering Codes and Accessories

72.1 Parts List

72.2 Preparation

82.3 Operating elements

92.4 First Operation

143.1.5 Analog Temperature Tuning Input

143.1.6 Analog Temperature Output

153.2 Operation

153.2.1 Setting the TEC current limit

163.2.2 Adjusting Temperature Control Loop

173.2.3 Over-Temperature Protection

173.2.4 Disabling the Beeper

4 Maintenance and Service 18

184.1 Line Voltage Setting

194.2 Replacing Mains Fuses

204.3 Troubleshooting

5 Appendix 21

215.1 Technical Data

235.2 Declaration of Conformity

245.3 Warranty

255.4 Exclusion of Reliability and Copyright

265.5 Thorlabs 'End of Life' Policy (WEEE)

275.6 Thorlabs Worldwide Contacts

We aim to develop and produce the best solution for your application

in the field of optical measurement technique. To help us to live up to

your expectations and improve our products permanently we need

your ideas and suggestions. Therefore, please let us know about

possible criticism or ideas. We and our international partners are

looking forward to hearing from you.

Thorlabs GmbH

Warning

Sections marked by this symbol explain dangers that might result in

personal injury or death. Always read the associated information

carefully, before performing the indicated procedure.

Attention

Paragraphs preceeded by this symbol explain hazards that could

damage the instrument and the connected equipment or may cause

loss of data.

Note

This manual also contains "NOTES" and "HINTS" written in this form.

Please read these advices carefully!

2

© 2015 Thorlabs

1 General Information

1 General Information

The Thorlabs TED200C Thermoelectric Temperature Controller is a precise temperature

controller for laser diodes and detectors.

The TED200C is excellently suited for:

· wavelength stabilization of laser diodes

· noise reduction of detectors

· laser diode's wavelength tuning by regulating the temperature

· modulation of wavelength by tuning the temperature

The TED200C is easy to operate via the operating elements on the front panel. Operating

parameters are shown on a 5-digit LED display. UP-DOWN keys allow to select the parameter

to be displayed.

The P, I and D shares of the temperature control loop can be set independent of each other.

The TED200C operates with different temperature sensors - NTC thermistors and IC

temperature sensors are supported. With a thermistor, the temperature is displayed in kW, with

a temperature sensor IC - in °C.

The output for the TEC current can be switched on or off via front panel key.

The temperature sensor and the TEC element are connected to a 15-pin D-SUB jack at the

rear of the unit.

At the TE OUTPUT jack a control signal is available to drive an external LED to indicate TEC

ON mode when the TEC current is activated.

The set value of the temperature can be changed with a knob at the front panel or via an

analog input at the rear panel.

For monitoring purposes, an DC voltage proportional to the actual temperature is available at

the rear panel (CTL OUT).

The TED200C controller is cooled by an internal fan, which protects the unit against

overheating in case of high environmental temperatures. With free air circulation a safe

operation of the unit is guaranteed up to 40 °C ambient temperature.

Warning

Do not obstruct the air ventilation slots in the housing!

Note

In order to prevent damages to the laser diode, it is recommended to mount the laser into a

suitable Thorlabs laser diode mount (e.g., LM14S2, LDM21 or TCLDM9) and connect it to the

TED200C using the supplied Thorlabs CAB420-15 cable. This ensures the utmost protection of

the laser diode from damage by wrong connection.

In case of overheating, the output is switched off automatically in order to avoid damages. The

LED "OTP" (Overtemperature Protection) indicates the overtemperature. After a temperature

drop for about 10°C the LED "OTP" extinguishes and the output current can be switched on

again by pressing the key "ON".

If an error occurs (OTP or OPEN) the corresponding LED lights up and a short warning beep is

heard.

The installed mains filter and the careful shielding of the transformer provide a low ripple at the

output.

© 2015 Thorlabs

3

TED200C

1.1 Protection of the TEC element

· Limit of the TEC current in all operating modes

Protection against thermal destruction.

· Protection of the sensor

Protection against use of incorrect temperature sensors; protection against interrupted

connection of the temperature sensor.

· Contact protection of the TEC element (open circuit)

Protection against cable damage, bad contact or TEC element with too high resistance.

· Control LED for TEC current on

Protection against accidental turning off the cooling.

· Overtemperature protection

Protection against malfunction caused by internal overheating of the controller.

· Line failure protection

The TEC current is switched off immediately if a power failure or line interruption occurs. In

this case, same as after turning on the controller, the TEC current remains switched off and

can be switched on manually only.

1.2 Safety

Attention

All statements regarding safety of operation and technical data in this instruction manual will

only apply if the unit is operated correctly as it was designed for.

All modules must be operated with proper shielded connection cables only.

Only with written consent from Thorlabs may changes to single components be carried out or

components not supplied by Thorlabs be used.

This precision device is only serviceable if properly packed into the complete original packaging

including the plastic foam sleeves. If necessary, ask for a replacement package.

Prior to apply power to the TED200C controller, make sure that the protective conductor of the

3 conductor mains power cord is correctly connected to the protective earth contact of the

socket outlet!

Improper grounding can cause electric shock with damages to your health or even death!

Also make sure that the line voltage setting of the fuse holder at the rear panel agrees with your

local supply and that the corresponding fuses are inserted. If not, please change the line

voltage setting (see section Line voltage setting ) and the mains fuses (see section Replacing

the mains fuses ).

19

The TED200C controller must not be operated in explosion endangered environments!

18

Do not obstruct the air ventilation slots in housing!

Do not remove covers!

Refer servicing to qualified personnel!

Attention

Use only duly shielded connection cables for laser, photodiode and control input/output

connections.

Mobile telephones, cellular phones or other radio transmitters must not be used within the

© 2015 Thorlabs4

1 General Information

range of three meters of this unit since the electromagnetic field intensity may then exceed the

maximum allowed disturbance values according to IEC61326-1.

This product has been tested and found complying with the limits according to IEC 61326-1 for

using connection cables shorter than or equal to 3 meters (9.8 feet).

Attention

The following statement applies to the products covered in this manual, unless otherwise

specified herein. The statement for other products will appear in the accompanying

documentation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules and meets all requirements of the Canadian

Interference-Causing Equipment Standard ICES-003 for digital apparatus. These limits are

designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

· Reorient or relocate the receiving antenna.

· Increase the separation between the equipment and receiver.

· Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

· Consult the dealer or an experienced radio /T.V. technician for help.

Thorlabs is not responsible for any radio television interference caused by modifications of this

equipment or the substitution or attachment of connecting cables and equipment other than

those specified by Thorlabs. The correction of interference caused by such unauthorized

modification, substitution or attachment will be the responsibility of the user.

The use of shielded I/O cables is required when connecting this equipment to any and all

optional peripheral or host devices. Failure to do so may violate FCC and ICES rules.

© 2015 Thorlabs

5

TED200C

1.3 Ordering Codes and Accessories

Ordering code Short description

TED200C thermoelectric Temperature Controller, TEC current 0 ... 2 A,

working with thermistors and IC temperature sensors (AD590, AD592,

LM135 and LM335) as temperature sensor, 5-digit LED-display

Shielded cable:

CAB420-15 Cable to connect the temperature controller TED200C to a Thorlabs Laser

Diode Mount.

Note

The cable should not be manipulated as it serves multiple devices and therefore does not have

the standard pin assignment as described for TED200C.

Laser diode mounts for different laser diode packages:

TCLDM9 Temperature controlled lase r d io de mount for 3- and 4-pin TO18-packages

(9 mm CD, 5.6 mm CD)

LDM21 Miniature sized temperature controlled laser dio de mount for 3- and 4-pin

TO18-packages (9 mm CD, 5.6 m m CD)

LM14S2 laser diode mount for lase r modules in a 14-pin butterfly-package

(programmable pinning)

Please visit our homepage http://www.thorlabs.com for further information.

© 2015 Thorlabs6

2 Getting Started

2 Getting Started

2.1 Parts List

Inspect the shipping container for damage.

If the shipping container seems to be damaged, keep it until you have inspected the contents

and you have inspected the TED200C controller mechanically and electrically.

Verify that you have received the following items within the package:

1. 1 TED200C controller

2. 1 power cord, connector according to ordering country

3. 1 operation manual

4. 1 connection cable CAB420-15

2.2 Preparation

Prior to operate a TED200C controller, check if the set line voltage matches with your local

power supply and if the appropriate fuses are inserted. (See sections Line Voltage Setting

and Replacing the Mains Fuses )

19

18

Connect the unit to the power line using the supplied cable. Turn the unit on by pressing the

line switch (F11) .

8

If required, the chassis ground can be connected to ground potential via the connector jack R4.

© 2015 Thorlabs

7

TED200C

2.3 Operating elements

Front Panel

F1 - 5-digit LED display

F2 LED "°C" Temperature display in C

F3 LED "kΩ" Resistance display in k

F4 LED "A" Current display in A

F5 LED "OTP" Over temperature protection is active

F6 LED "OPEN" TEC element is not conne ct ed or too high resistance

F7 LED "NO SENSOR" Temperatu re sensor is wrong or not connected

F8 LED "TEC ON" TEC output is switched on

F9 Key "TEC ON" On / Off switch for the TEC output

F10 - Knob for adjusting the set temperature / resistance

F11 - Line switch (ON / OFF)

F12 LIM I Potentiometer for sett in g the TEC current limit

F13 LED "TACT" Display shows the actual temperature / resista nce

F14 LED "ITEC" Display shows the TEC current

F15 LED "TSET" Display shows the set temperature / resistance

F16 LED "ILIM" Display shows the current limit

F17 Key “DOWN” Select the parameter to be displayed

F18 Key “UP” Select the parameter to be displayed

F19 LED "AD590" Selected sensor is AD 590, AD 592, LM 135 or LM 335

F20 LED "TH 20 0kW" Selected sensor is thermistor in the 2 00 kW range

F21 LED " TH 20 kW" Selected sensor is thermistor in the 2 0 kW range

F22 P Potentiometer for sett in g P- (gain) share of control loop

F23 I Potentiometer for setting I- (integral) share of co ntrol loop

F24 D Potentiometer for sett in g D- (derivative) share of co ntrol loop

F25 Key “SENSOR” Select sensor / disable I-share (press for more than 1 sec.)

© 2015 Thorlabs8

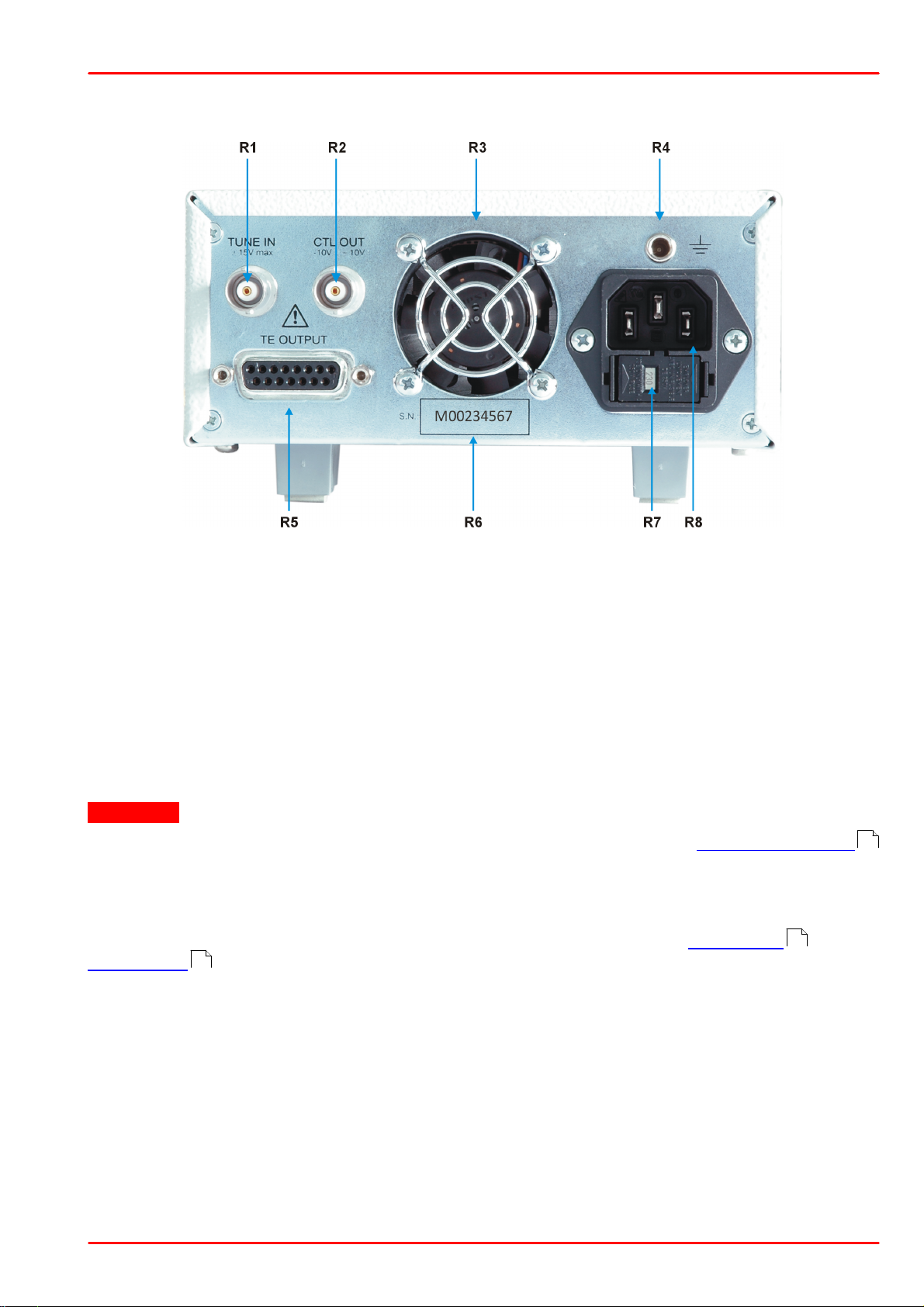

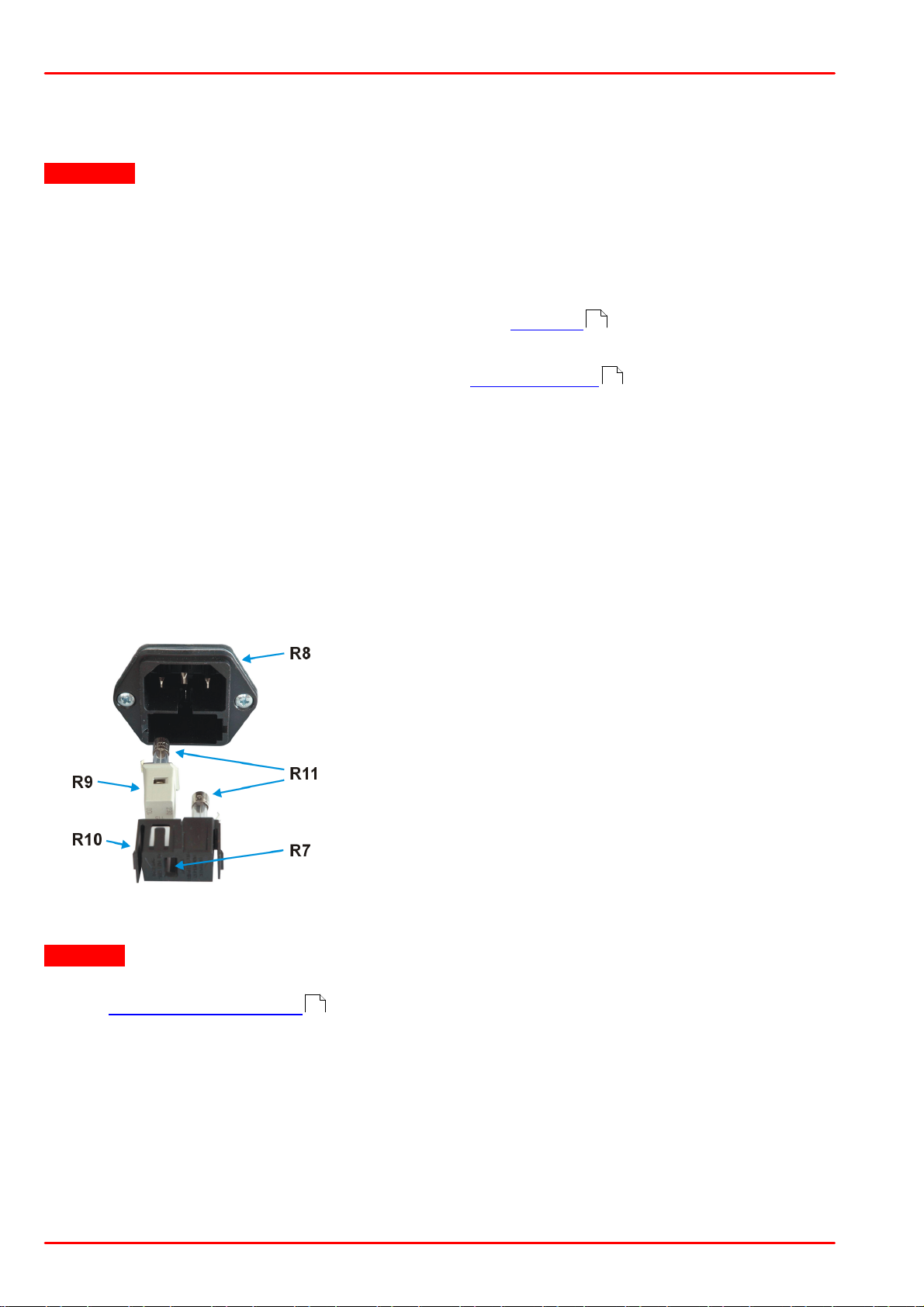

Rear Panel

2 Getting Started

R1 Analog temperature control input "TUNE IN", -10 ... +10 V

R2 Analog temperature control output "CTL OUT" , -1 0 … +10 V

R3 Fan

R4 4 mm banana jack for chassis ground

R5 15-pin D-SUB jack for the TEC element and the temperature sensor

“TE OUTPUT”

R6 Serial number of the unit

R7 Indicator / switch for line voltage (included in fuse holder)

R8 Mains connector and fuse holder

2.4 First Operation

Attention

Prior to switch on your TED200C controller, please make sure that the line voltage setting

corresponds to your mains voltage! Mismatching may lead to damage of the controller!

Turn the unit on by pressing the line switch F11.

After switching on the unit, the LED display F1 and a LED, indicating the selected

measurement value (F13 ... F16), light up, otherwise please check the line voltage and the

mains fuses .

19

18

By using F17 and F18 keys, the displayed measurement value can be selected.

18

A TED200C controller is immediately ready to use after turning on. The rated accuracy is

reached, however, after a warming-up time of approx. 10 minutes.

© 2015 Thorlabs

9

TED200C

Pin #

Connection

TEC element, status indication:

5

TEC (+)

6

TEC (+)

7

TEC (+)

13

TEC (-)

14

TEC (-))

15

TEC (-)

1

Status LED (+) for TEC ON/OFF indication

Temperature sensor:

4

Thermistor (+)

3

Thermistor (-), ground

10

Transducer AD 590/592 (-), LM135 / 335 (+)

11

Transducer AD 590/592 (+), LM135/ 335 (+)

2

N.C.

9

N.C.

12

N.C.

8

AGND LM135/335 (-), Status LED (-)

3 Operating Instruction

3.1 External Connections

Prior to switch on the TED200C controller, all required external connections must be made

properly. Please read the following sections carefully.

3.1.1 TEC Output

The Thorlabs TED200C controller can drive all thermoelectric coolers up to a current of 2 A.

The voltage drop across the TEC must not exceed the TED200C compliance voltage (6V)

If a Thorlabs laser mount is used, just connect the 15-pin D-SUB jack "TE OUTPUT" (R5) of

the TED200C controller to the 9-pin plug "TEC DRIVER" of the Laser Diode Mount using the

supplied shielded cable CAB420-15.

Note

The cable should not be manipulated as it serves multiple devices and therefore does not have

the standard pin assignment as described for TED200C.

If a Thorlabs laser mount TCLDM9 or LDM21 is used, in addition the polarity of laser diode and

photodiode must be set using the two slide switches at the laser mount. Please refer to the

individual operation manual of the laser diode mount.

If other laser diode fixtures are used, connect the TE cooler and the temperature sensor using

shielded cables to "TE OUTPUT" (R5) according to the pin assignment as shown below:

9

© 2015 Thorlabs10

3 Operating Instruction

3.1.2 Connecting the TEC element

Connect the thermoelectric cooler between pin 5, 6, 7 (TEC anode) and pin 13, 14, 15 (TEC

cathode) of the 15-pin D-SUB jack .

Attention

A mispoled TEC element may lead to thermal runaway and destruction of the connected

components.

Check the TEC polarity

· Turn on the Temperature Controller TED200C

· Connect the temperature sensor to the jack "TE OUTPUT" (R5)

(refer to "Connecting a temperature sensor ").

· Select the appropriate sensor type with the key (F25).

· Select a suitable current limit "ILIM" for the TEC element

(refer to “Setting the TEC current limit ").

· Switch the display to "TSET" and set the desired set temperature using the tuning knob.

· By pressing the key "ON" switch on the TED200C outpu t current. The LED "ON" (F8)

lights up.

· Switch the LED display to "TACT".

10

12

15

If the TEC module is connected with correct polarity, the difference between the set

temperature "TSET" and the actual temperature "TACT" will decrease. If the control loop

parameters are set well (see section Adjusting Temperature Control Loop ), the actual

16

temperature approximates the set temperature within a short time.

If the TEC module is connected with wrong polarity, the difference between set temperature

and actual temperature will increase continuously. Switch off the TEC current by pressing key

"ON" (F9) and change the TEC module wiring at the D-SUB plug connected to the jack “TE

OUTPUT” (R5).

3.1.3 Control LED for TEC ON mode

If a LED is connected between pin 1 and pin 8 as shown to the

left, this LED lights up when the TEC current output is switched

on.

© 2015 Thorlabs

11

TED200C

3.1.4 Connecting a temperature sensor

The TED200C is compatible with a number of temperature sensor types:

· NTC (standard thermistor)

· AD590/AD592

· LM135/LM335

The temperature sensor is selected at the front ( key SENSOR - F25 ). The LED F19 to F21

8

indicate the selected sensor.

Temperature Ranges

· NTC (thermistor): 2 measu re ment ranges - 0 to 20kW and 0 to 2 00kW

· AD590/AD592/LM135/LM335): the measurement range -45°C to +145°C.

· The actual temperature control range depends on the sensor ratings and the individual

thermal setup.

If no temperature sensor is connected or if the temperature sensor does not correspond to the

selected sensor type, the LED “OPEN” (F6) lights up and the display (F1) indicates overflow

when "TACT" measurement value is selected.

The temperature sensor is connected to the 15-pin D-SUB jack "TE OUTPUT" (R5) at the rear

of the TED200C depending on the used sensor type.

Note

If LM135/LM335 is used as temperature sensor, select "AD590" (key F25). The LED

"AD590" (F19) lights up.

Thermistor

A thermistor is a resistor with a Negative Temperature Characteristic, that's why it is also known

as NTC. It's resistance decreases exponentially with the temperature.

A thermistor must be connected between pin 3 and pin 4 of the 15-pin D-SUB

jack (R5) . The polarity is not relevant, so far the thermistor is floating. If one

10

pin of the thermistor is grounded (for example in a laser module), this pin has to

be connected to pin3.

If the TED200C is operated with a thermistor temperature sensor, the "TSET"

and "TACT" temperature is displayed as resistance in kW.

The NTC measurement current is 100µA in 20kW range and 10µA in 200kW

range.

To describe the dependency of resistance vs. temperature, several algorithms

are known. A simplified method, giving good results within a range relatively close to the

reference temperature, is the exponential formula:

© 2015 Thorlabs12

3 Operating Instruction

with: R0: Thermistor nominal resistance at temperature T

T0: Nominal temperature (usually 298.15 K = 25°C)

B

Energy constant

val

For R0 and B

please refer to the data sheet of the thermistor; T and T0 are given in K (Kelvin)

val

If using a thermistor, the resistance for a given temperature TSET T

0

must be calculated first. If

0

the thermistor characteristic R(T) is given in the data sheet, the thermistor resistance can be

read directly. Then select "TSET" (key F18 or F19) to display the resistance set value. Adjust the

value using the tuning knob (F10).

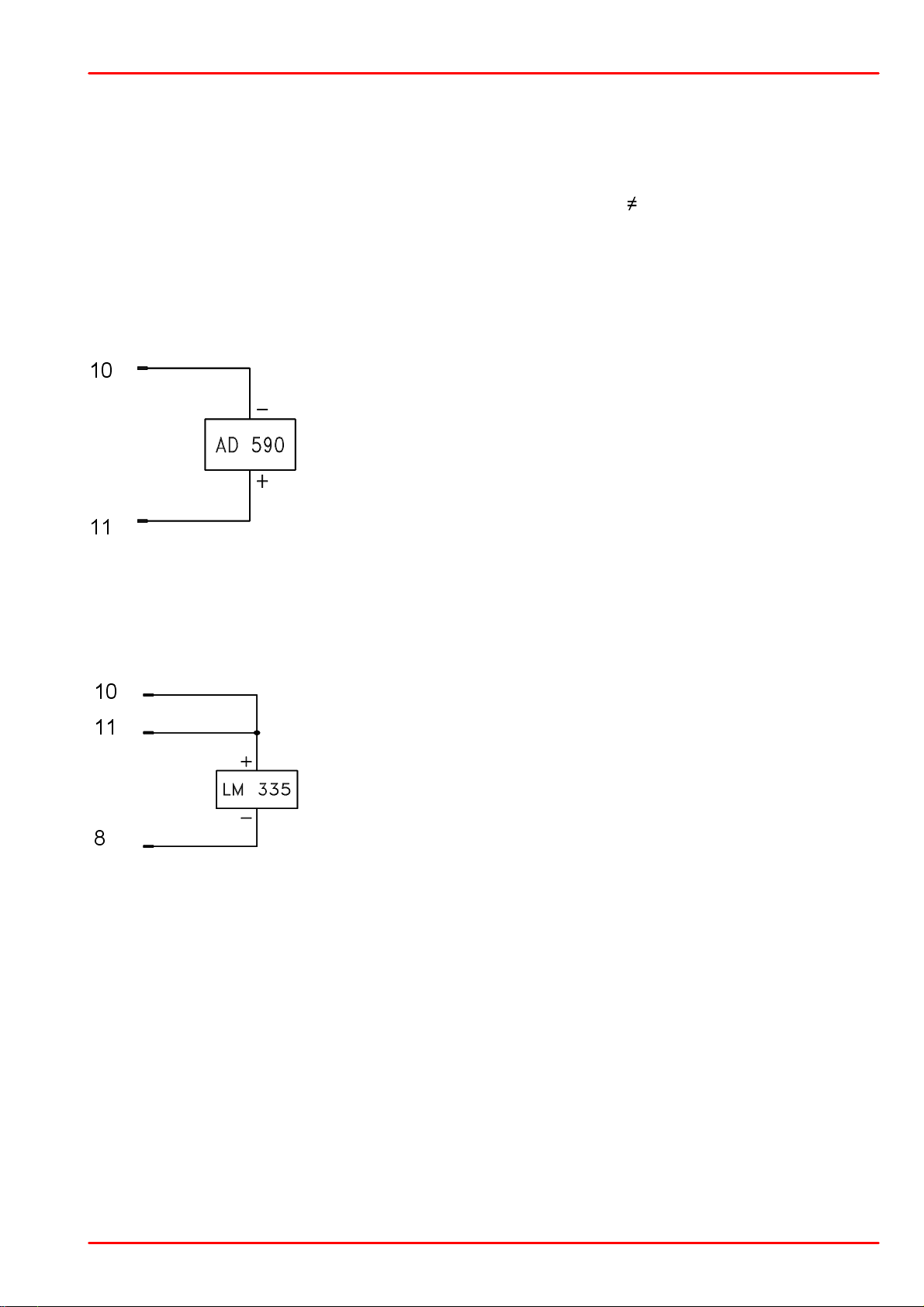

AD 590/AD 592 Temperature sensor

AD590/592 are IC transducer type temperature sensors that

produce an output current linearly proportional to the absolute

temperature.

These devices act as current source, delivering 1µA/K within a

wide supply voltage range. They are calibrated to 298.2µA output

current at 298.2K (25°C).

An AD590/592 is connected between pin 10 (-) and pin 11 (+) of

the 15-pin D-SUB jack "TE OUTPUT" (R5)

The accuracy of the displayed temperature depends on the

tolerance of the used transducer.

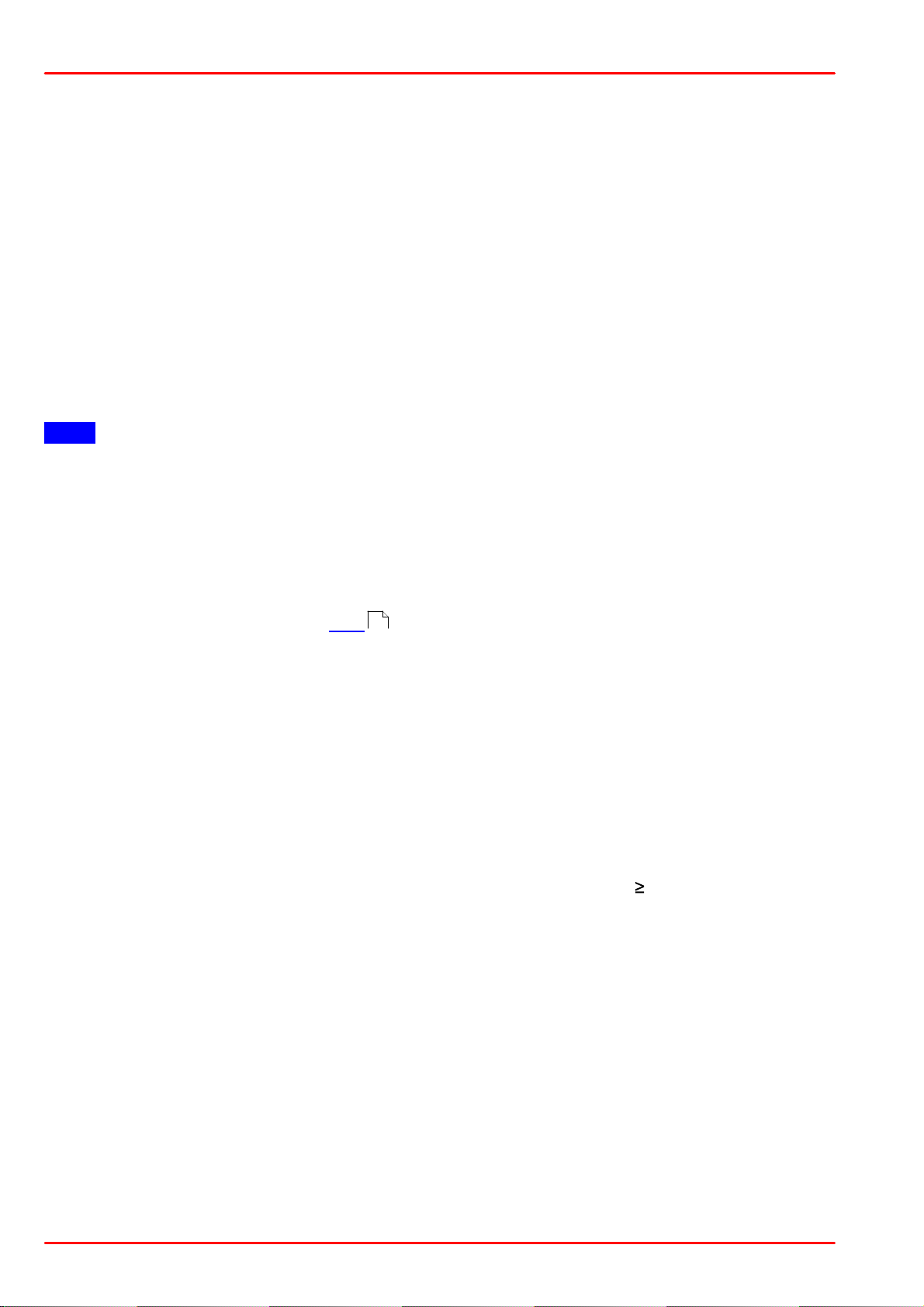

LM135/LM335 Temperature sensor

The LMx35 Temperature Transducer Sensors operate as a zener

diode (inverse current direction) with a breakdown voltage linearly

proportional to absolute temperature at +10 mV/K. They operate

over a current range of 400 µ A to 5 mA.

A LM135/LM335 is connected to pin 10 (+), pin 11 (also +) and pin

8 (AGND) of the 15-pin D-SUB jack "TE OUTPUT" (R5) at the rear

of the unit.

The accuracy of the displayed temperature depends on the

tolerance of the used transducer.

© 2015 Thorlabs

13

TED200C

Sensor

Control Range

TUNE IN voltage

range

Conversion Coefficient

TH 20 K

0 ... 20 kW

0 ... 10 V

2 kW/V

TH 200 K

0 ... 200 kW

0 ... 10 V

20 kW/V

AD590/592;

LM135/335

-45 °C...+145 °C

- 2.25 V...+7.25 V

20 °C/V

Sensor

Control Range

TUNE IN voltage

range

Conversion Coefficient

TH 20 K

0 ... 20 kW

0 ... 10 V

2 kW/V

TH 200 K

0 ... 200 kW

0 ... 10 V

20 kW/V

AD590/592;

LM135/335

-45 °C...+145 °C

- 2.25 V...+7.25 V

20 °C/V

3.1.5 Analog Temperature Tuning Input

The set temperature "TSET" can be tuned by applying a voltage to the input "TUNE IN" (R1) at

the rear panel of the TED200C. The temperature set value is proportional to the sum of the

signal at input "TUNE IN" (R1) and of the value set with the adjustment knob (F10).

The tuning range for the analog control input "TUNE IN" depends on the connected sensor:

Note

Only slow variations of the temperature set value (<< 1 Hz) are possible via the analog control

input "TUNE IN".

The actual temperature "TACT"can be observed at the temperature monitor output "CTL

OUT" (R2).

3.1.6 Analog Temperature Output

The analog output "CTL OUT" (R2) delivers a DC voltage, proportional to the actual

temperature "TACT". The output voltage range depends on the used temperature sensor:

To the analog output "CTL OUT" any measurement equipment can be connected directly.

Devices connected to these outputs should have an input resistance of 10 kW.

This monitor output is convenient to use for temperature monitoring e.g. during adjustment of

PID loop parameters.

9

© 2015 Thorlabs14

3 Operating Instruction

3.2 Operation

· Connect the jack "TE OUTPUT" (R5) at the rear panel of the TED200C to the input "TEC

DRIVER" of the Thorlabs Laser Diode Mount using the supplied cable CAB420-15. If a

different laser diode fixtures is used, the output jack “TE OUTPUT” (R5) must be connected

according to the TEC Output pin assignment , see also "Connecting a temperature sensor”

12

.

· Switch on the Temperature Controller TED200C.

10

· Select a suitable current limit "I LIM " for the TEC element

15 15 15

· Select the used temperature sensor with key (F25).

Note

The TEC output can be switched on only if a temperature sensor is connected "TE

OUTPUT" (R5) and the sensor type is selected correctly. If the connected temperature sensor

does not correspond to the selected sensor type, the LED "OPEN" (F6) lights up. In this case

check the connection and the type of the temperature sensor.

· Select "TSET" to display the set temperature (keys F17 or F18)

· Set the desired temperature "TSET" using the tuning knob (F10).

· If a thermistor is used, the instead of temperature (°C) the resistance is set (kW). If an

AD590/AD592 or LM135/LM335 is used as temperature sensor, the set temperature is

entered in °C.

· Switch on the TEC current output by pressing key "ON" (F9). The LED "ON" (F8) lights up.

Note

The TEC output cannot be switched on as long as the LED "OPEN" (F6) lights up. In such case

check the connection of the temperature sensor and the selected sensor type.

During operation between the displayed values for "TSET", "TACT", "ILIM" or "ITEC" can be

switched at any time by pressing (F17) or (F18).

3.2.1 Setting the TEC current limit

The Temperature Controller TED200C delivers a maximum TEC current of 2 A. Prior to switch

on the TEC output, an appropriate TEC current limit "ILIM" should be set using the

potentiometer "LIM I" in order to avoid damage of the TEC element.

A limitation of the maximum TEC current can be helpful to optimize the settling time in case of

a low thermal load (laser with low output power, set temperature close to environmental

temperature etc.)

Select the display parameter "ILIM" with the key (F17) or (F18).

Use a screwdriver to set the desired TEC current limit "ILIM" with the 12-turn potentiometer "LIM

I" (F12).

Note

The current limit can be displayed at any time by selecting the parameter "ILIM".

© 2015 Thorlabs

15

TED200C

3.2.2 Adjusting Temperature Control Loop

Temperature controllers are used to manage the temperature of thermo-electrically heated/

cooled components in experimental setups, independent of external influences. To adapt a

controller to different thermal loads, and to optimize the controller’s response characteristics,

the controlling parameters of the system’s feedback loop must be optimized. All Thorlabs’

temperature controllers provide a PID control loop whose shares (P, I and D share) must be

matched with the thermal load of the device under test. For an optimum adaptation, these

parameters have to be adjusted separately and independent of each other. This section

describes how to optimize the PID parameters in order to get optimum performance from the

TED200C temperature controller.

· The P share (proportional, gain) can be adjusted with potentiometer "P" (F22).

· The I share (integral, off set control) can be adjusted with potentiometer "I" (F23).

· The D share (derivative, rate control) can be adjusted with potentiometer "D" (F24).

Preparation

1. Select "TACT" to display the actual temperature or thermistor resistance (keys F17 or F18).

2. Turn the three potentiometers "P" (F22), "I" (F23) and "D" (F24) completely counterclockwise.

3. Switch off the I share to ease the setting of P and D shares: Press key (F25) for at least one

second to switch off the I share. The sensor LED (F19/F20/F21) is flashing to indicate the "I

share off" state.

4. Set the temperature "TSET" to a value around room temperature and switch on the TEC

current output (switch "ON" F9).

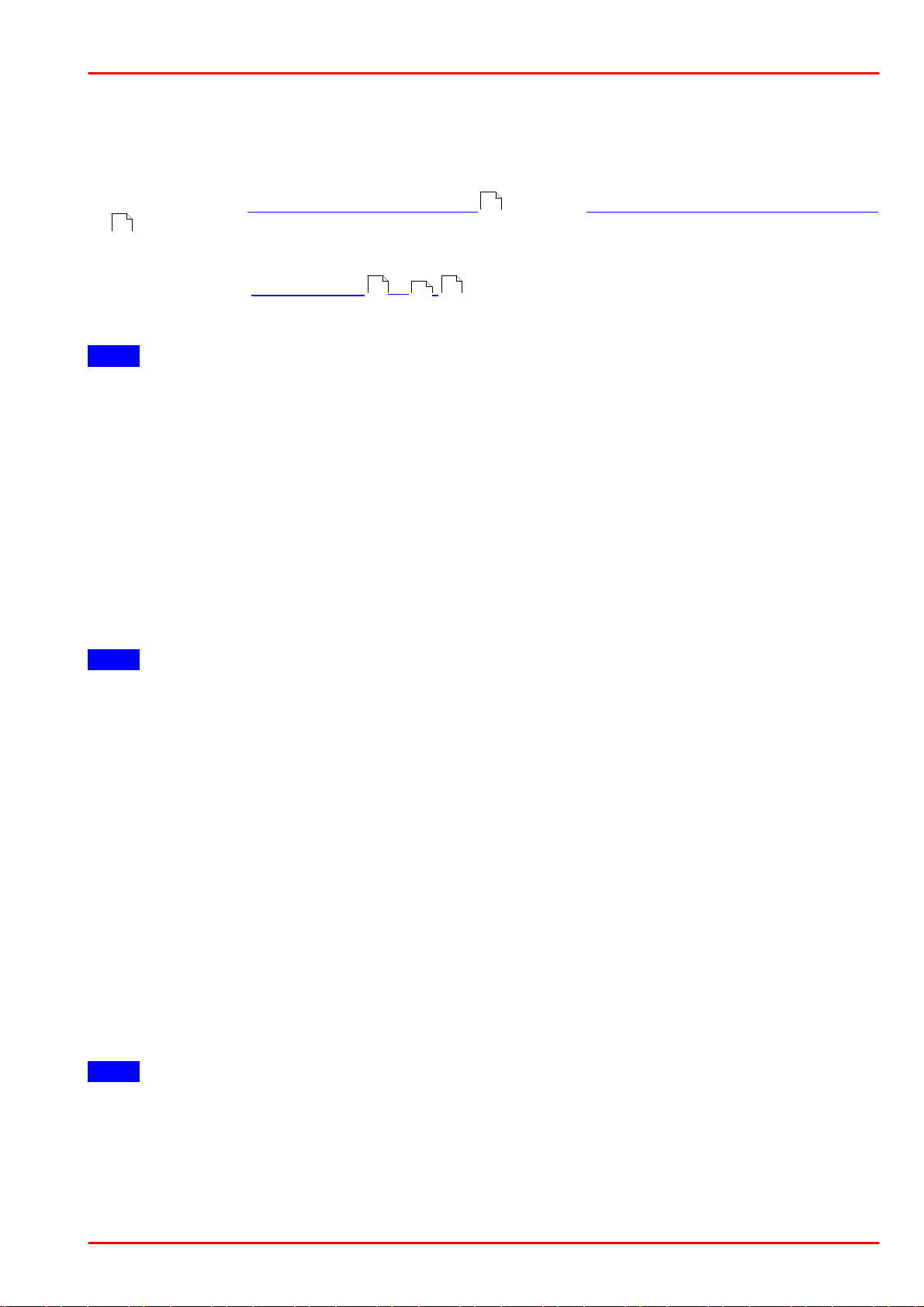

Adjust P share

Repeatedly increase and decrease the set temperature for about ± (1...2)°C around room

temperature using the tuning knob (F10) or by applying a suitable slow, square-wave signal to

the analog control input "TUNE IN" (R1) at the rear panel. Watch the settling behavior of the

actual temperature "TACT".

Note

The settling behavior can be observed at the "CTL OUT" output (R2).

Increase the P-share gradually by turning potentiometer (F22) clockwise.

Higher values will increase the settling speed. Too high values will increase the amplitude and

number of overshoots or will even make the system instable (continuous oscillation).

The P share is set correctly if the actual temperature remains stable near the set temperature

after only 2 … 3 overshoots.

Adjust D share

Change set temperature again repeatedly for ± (1...2)°C around room temperature while

observing the settling behavior of the actual temperature.

Increase the D share gradually by turning potentiometer (F23) clockwise.

Higher values will decrease the amplitude and number of overshoots. Too high values will

increase again the amplitude and number of overshoots or will even make the system instable.

The D share is set correctly if the actual temperature remains stable at a value near the set

temperature after a minimum of overshoots.

© 2015 Thorlabs16

3 Operating Instruction

Adjust I Share

Turn on the I share, if it was if disabled, by pressing key (F25) for at least one second. The

sensor LED (F19/F20/F21) stops flashing if the I-share is enabled.

Change set temperature again repeatedly for ± (1...2)°C around room temperature while

observing the settling behavior of the actual temperature.

Increase the I share gradually by turning potentiometer (F24) clockwise.

Higher values will accelerate the settling to the set temperature. Too high values will increase

the amplitude and number of overshoots. The I share is set correctly when the actual

temperature reaches the set temperature in short time with at most one overshoot.

3.2.3 Over-Temperature Protection

The TED200C controllers come with an internal over-temperature protection. If the internal heat

sink is overheated, the output of the controller is disabled automatically. The LED "OTP" (F5)

lights up and a short beep is heard. The TEC current is switched off immediately. Pressing the

key "TEC ON" (F9) has no effect in this case.

After the internal heat sink's temperature decreased for about 10°C, the LED "OTP" (F6)

extinguishes and the laser current output can be switched on again.

3.2.4 Disabling the Beeper

If audible signals are unwanted, the beeper can be disabled in this way:

· Press and hold the key “UP” (F18).

· Press the key “Down” (F17). Now the beeper state is displayed:

· “Sd.ON” - Sound ON

· “Sd.OFF” - Sound OFF

To change the beeper state, hold the key “UP” pressed and toggle the beeper state by pressing

"DOWN" key.

© 2015 Thorlabs

17

TED200C

4 Maintenance and Service

Protect the TED200C from adverse weather conditions. The TED200C is not water resistant.

Attention

To avoid damage to the instrument, do not expose it to spray, liquids or solvents!

The unit does not need a regular maintenance by the user. If necessary the unit and the display

can be cleaned with a cloth dampened with water. A mild 75% Isopropyl Alcohol solution can

be used for more efficient cleaning.

TED200C Controllers do not contain any modules and/or components that could be repaired by

the user himself. If a malfunction occurs, please contact Thorlabs for return instructions.

Do not remove covers!

27

To guarantee the specifications given in section Technical Data over a long period it is

21

recommended to have the unit factory calibrated every two years.

4.1 Line Voltage Setting

The TED200C operates at fixed line voltages of

100 V +15% / -10% ( 90 V … 115 V)

115 V +15% / -10% (104 V … 132 V)

230 V +15% / -10% (207 V … 264 V)

line frequency 50 … 60 Hz.

The line voltage setting can be changed from the rear without opening the unit.

1. Turn off the controller and disconnect the mains cable.

2. The fuse holder (R10) is located below the 3-pole power

connector of the mains jack (R8). Release the fuse holder

by pressing its plastic retainers with the aid of a small

screwdriver. The retainers are located on the right and left

side of the holder and must be pressed towards the center.

3. Unplug the white line voltage switch/indicator (R9,

containing the left fuse) from the fuse holder (R10), rotate it

until the appropriate voltage marking (100V, 115V, or 230V)

is on target for the cutout (R7) of the fuse holder, and plug

it back into the fuse holder. Press in the fuse holder until

locked on both sides. The appropriate line voltage marking

must be visible in the cutout (R7) of the fuse holder.

Attention

If you have changed to or from 230 V, also change the mains fuses to the correct value given in

section Replacing Mains Fuses .

19

© 2015 Thorlabs18

4 Maintenance and Service

100 V

500 mA, time-lag, 250V

T0.5A250V

115 V

500 mA, time-lag, 250V

T0.5A250V

230 V

250 mA, time-lag, 250V

T0.25A250V

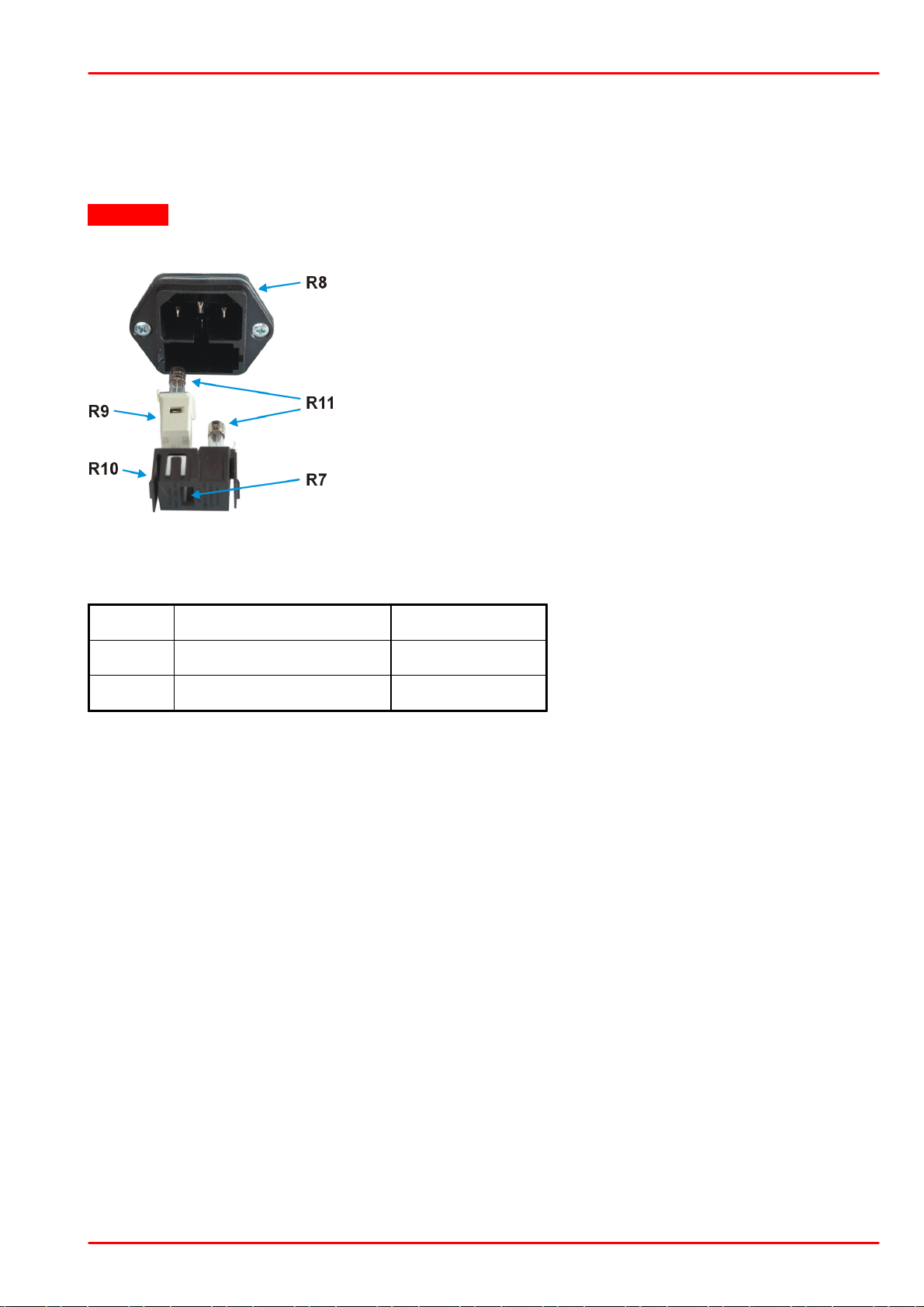

4.2 Replacing Mains Fuses

The two power input fuses are externally accessible. If they blew due to line distortions,

incorrect line voltage or other causes, they can be replaced from the rear without opening the

unit.

Attention

To avoid risk of fire only the appropriate fuses for the corresponding line voltage must be used

1. Turn off the TED200C and disconnect the mains cable.

2. The fuse holder (R10) is located below the 3-pole power

connector of the mains jack (R8). Release the fuse holder by

pressing its plastic retainers with the aid of a small screwdriver.

The retainers are located on the right and left side of the holder

and must be pressed towards the center.

3. Replace the defective fuses (R11) and press in the fuse

holder until locked on both sides. Take care to maintain the

correct rotation of the white line voltage indicator / switch (R9)

which contains the left fuse and is plugged into the fuse holder.

The appropriate line voltage marking must be visible in the

cutout (R7) of the fuse holder.

Fuse types

All fuses must meet IEC specification 60127-2/III, time characteristic: time-lag (T), 250V AC,

size 5 x 20 mm.

© 2015 Thorlabs

19

TED200C

4.3 Troubleshooting

In case that your TED200C Controller shows malfunction please check the following items:

q Unit does not work at all (no display at the front):

o TED200C connected properly to the mains?

§ Check the power cord and the line voltage setting

o TED200C turned on?

§ Turn on your TED200C Controller (button "LINE" F1 1).

18

o Check the fuses at the rear panel.

19

§ If blown, replace the fuses with the correct type.

q The display works but you don’t get the desired op eration temperature

o Is the hardware current limit ILIM set to 0?

§ Adjust the hardware limit "LIM I" (F12) on the f ro nt panel to an appropriate value.

o Is the TEC con nected properly to the TEC output?

11

15

§ Check all cab le s.

§ Check the correct polarity

o Is the temperature sensor connected properly and is the sensor type selected

12

correctly?

§ Check the corresponding connections and pola rities of the temperature sen sor.

§ Select the corresponding temperature senso r b y pressing key F25.

§ Adjust the right set value for TSET

q After pressing “TEC ON” the unit bee ps and the error LED “OPEN” lights up

o Is the TEC con nected properly to the TEC output?

11

§ Check all cab le s.

q The operation temperature is oscillating

o Are the control loop parameters of the PID control loop adjuste d correctly ?

16

§ Set th e P share, D share and I share appropriate to the thermal load

q The unit switches on, but display shows error message (e.g., “Err06”)

o This indicates a malfunction of the TED200C. In such case, the controller n eeds to be

returned to Thorlabs for maintenance. Please contact Thorlabs with the information of

27

the error code number and the serial number of your TED200 C in order to receive the

RMA (Return Material Authorization) instructions accordingly.

If you don’t find the error source by means of the trouble shooting list please contact Thorlabs

27

for advise and/or return instructions

© 2015 Thorlabs20

5 Appendix

TEC Current Output

Control Range

0 to ±2 A

Compliance Voltage

>6 V

Maximum Output Power

12 W

Measurement Resolution

1 mA

Measurement Accuracy

±10 mA

Noise and Ripple (typ.)

<1 mA

TEC Current Limit

Setting Range

0 to >2 A

Resolution

1 mA

Accuracy

± 20 mA

Thermistor Sensors 2)

Control Range

10 W to 20 kW

100 W to 200 kW

Resolution

1 W

10W

Accuracy

±10 W

±100 W

Temperature Stability 24 hours 3)

<0.5 W

<5 W

IC Sensors (Transducers)

Supported Sensors

AD590, AD592, LM135, LM335

Control Range with AD590, LM135

-45 °C to +145 °C

Control Range with AD592

-25 °C to +105 °C

Control Range with LM335

-40 °C to +100 °C

Resolution

0.01 °C

Accuracy

±0.1 °C

Temperature Stability 24 hours

<0.002 °C

Temperature Control Input

Input Resistance

10 kW

Control Voltage

-10 V to +10 V

Transmission Coefficient Thermistor

2 kW/V ± 5 %

20 kW/V ± 5 %

Transmission Coefficient IC-Sensors

20 °C/V ± 5%

Temperature Monitor Output

Load Resistance

>10 kW

Transmission Coefficient Thermistor

500 mV/kW ± 5 %

50 mV/kW ± 5 %

Transmission Coefficient IC-Sensors

50 mV/°C ± 5 %

5.1 Technical Data

5 Appendix

© 2015 Thorlabs

21

TED200C

General Data

Safety Features

TEC Current Limit

Short Circuit when TEC off

Missing Sensor Protection

Open Circuit Detection

Over Temperature Protection

Display

LED, 5 Digits

Connector for Sensor, TE Cooler, TEC On

Signal:

15-pin D-Sub Jack

Connectors for Control Input / Output

BNC

Chassis Ground Connector

4mm Banana Jack

Line Voltage

100 V

115 V +15% / –10%

230 V

Line Frequency

50 to 60 Hz

Mains Supply Overvoltage

Category II (Cat II)

Maximum Power Consumption

60 VA

Operating Temperature Range 1)

0 °C to +40 °C

Storage Temperature Range

-40 °C to +70 °C

Relative Humidity

Max. 80% up to 31 °C, decreasing to 50% at 40 °C

Pollution Degree (Indoor Use only)

2

Operation Altitude

<2000 m

Warm-up Time for Rated Accuracy

10 min

Dimensions (W x H x D)

w/o Operating Elements

with Operating Elements

146 x 66 x 290 mm³

146 x 77 x 320 mm³

Weight

<3.1 kg

1

)non-condensing

2

)Temperature Control Values for thermistors are given in W since the controlled parameter is the resistance, not

the temperature

3

)Due to the nonlinear conversion from W to °C the stability in °C depends on the operating conditio ns and the

characteristics of the thermistor. E.g. for a typical thermistor at a set point of 10kW (25°C), a 0.5W stability

translates into about 1mK temperature stability. At a set point of 5kW (38°C), the stability is about 2mK.

All technical data are valid at 23 ± 5°C and 45 ± 15% rel. humidity (non condensing)

© 2015 Thorlabs22

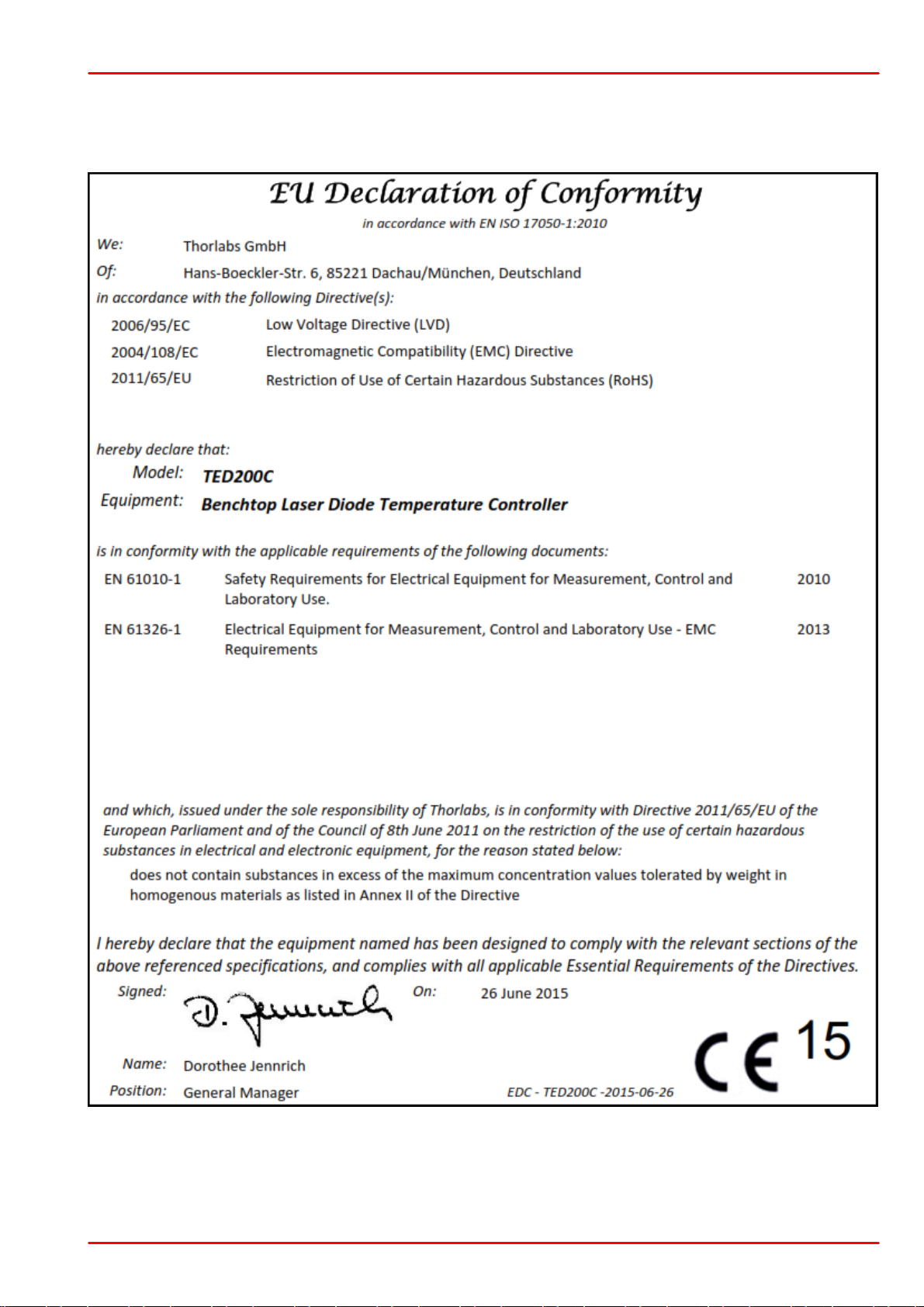

5.2 Declaration of Conformity

5 Appendix

© 2015 Thorlabs

23

TED200C

5.3 Warranty

Thorlabs warrants material and production of the TED200C for a period of 24 months starting

with the date of shipment. During this warranty period Thorlabs will see to defaults by repair or

by exchange if these are entitled to warranty.

For warranty repairs or service the unit must be sent back to Thorlabs. The customer will carry

the shipping costs to Thorlabs, in case of warranty repairs Thorlabs will carry the shipping costs

back to the customer.

If no warranty repair is applicable the customer also has to carry the costs for back shipment.

In case of shipment from outside EU duties, taxes etc. which should arise have to be carried by

the customer.

Thorlabs warrants the hard- and software determined by Thorlabs for this unit to operate faultfree provided that they are handled according to our requirements. However, Thorlabs does not

warrant a fault free and uninterrupted operation of the unit, of the software or firmware for

special applications nor this instruction manual to be error free. Thorlabs is not liable for

consequential damages.

Restriction of warranty

The warranty mentioned before does not cover errors and defects being the result of improper

treatment, software or interface not supplied by us, modification, misuse or operation outside

the defined ambient stated by us or unauthorized maintenance.

Further claims will not be consented to and will not be acknowledged. Thorlabs does explicitly

not warrant the usability or the economical use for certain cases of application.

Thorlabs reserves the right to change this instruction manual or the technical data of the

described unit at any time.

© 2015 Thorlabs24

5 Appendix

5.4 Exclusion of Reliability and Copyright

Thorlabs has taken every possible care in preparing this Operation Manual. We however

assume no liability for the content, completeness or quality of the information contained therein.

The content of this manual is regularly updated and adapted to reflect the current status of the

software. We furthermore do not guarantee that this product will function without errors, even if

the stated specifications are adhered to.

Under no circumstances can we guarantee that a particular objective can be achieved with the

purchase of this product.

Insofar as permitted under statutory regulations, we assume no liability for direct damage,

indirect damage or damages suffered by third parties resulting from the purchase of this

product. In no event shall any liability exceed the purchase price of the product.

Please note that the content of this User Manual is neither part of any previous or existing

agreement, promise, representation or legal relationship, nor an alteration or amendment

thereof. All obligations of Thorlabs result from the respective contract of sale, which also

includes the complete and exclusively applicable warranty regulations. These contractual

warranty regulations are neither extended nor limited by the information contained in this User

Manual. Should you require further information on this product, or encounter specific problems

that are not discussed in sufficient detail in the User Manual, please contact your local Thorlabs

dealer or system installer.

All rights reserved. This manual may not be reproduced, transmitted or translated to another

language, either as a whole or in parts, without the prior written permission of Thorlabs.

Copyright © Thorlabs 2015. All rights reserved.

© 2015 Thorlabs

25

TED200C

Crossed out

"Wheelie Bin" symbol

5.5 Thorlabs 'End of Life' Policy (WEEE)

As required by the WEEE (Waste Electrical and Electronic Equipment Directive) of the

European Community and the corresponding national laws, Thorlabs offers all end users in the

EC the possibility to return “end of life” units without incurring disposal charges.

This offer is valid for Thorlabs electrical and electronic equipment

· sold after August 13th 2005

· marked correspondingly with the crossed out “wheelie bin” logo (see figure below)

· sold to a company or institute within the EC

· currently owned by a company or institute within the EC

· still complete, not disassembled and not contaminated

As the WEEE directive applies to self contained operational electrical and electronic products,

this “end of life” take back service does not refer to other Thorlabs products, such as

· pure OEM products, that means assemblies to be built into a unit by the user (e. g. OEM

laser driver cards)

· components

· mechanics and optics

· left over parts of units disassembled by the user (PCB’s, housings etc.).

Waste treatment on your own responsibility

If you do not return an “end of life” unit to Thorlabs, you must hand it to a company specialized

in waste recovery. Do not dispose of the unit in a litter bin or at a public waste disposal site.

WEEE Number (Germany) : DE97581288

Ecological background

It is well known that waste treatment pollutes the environment by releasing toxic products

during decomposition. The aim of the European RoHS Directive is to reduce the content of

toxic substances in electronic products in the future.

The intent of the WEEE Directive is to enforce the recycling of WEEE. A controlled recycling of

end-of-life products will thereby avoid negative impacts on the environment.

© 2015 Thorlabs26

5.6 Thorlabs Worldwide Contacts

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-579-7227

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place, Ely

Cambridgeshire CB7 4EX

United Kingdom

Tel: +44-1353-654440

Fax: +44-1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau

Germany

Tel: +49-8131-5956-0

Fax: +49-8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Mölndalsvägen 3

412 63 Göteborg

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33-970 444 844

Fax: +33-811 38 17 48

www.thorlabs.com

Email: sales.fr@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

Japan

Thorlabs Japan, Inc.

Higashi Ikebukuro

Q Building 2nd Floor 2-23-2

Toshima-ku, Tokyo 170-0013

Japan

Tel: +81-3-5979-8889

Fax: +81-3-5979-7285

www.thorlabs.jp

Email: sales@thorlabs.jp

China

Thorlabs China

Room A101, No. 100

Lane 2891, South Qilianshan Road

Putuo District

Shanghai 200331

China

Tel: +86-21-60561122

Fax: +86-21-32513480

www.thorlabs.com

Email: chinasales@thorlabs.com

5 Appendix

© 2015 Thorlabs

27

Loading...

Loading...