S1FC405, S1FC635, S1FC637,

S1FC660, S1FC675, S1FC780,

S1FC785, S1FC808, S1FC980,

S1FC1060, S1FC1310, S1FC1550

Fiber-Coupled Laser Source

User Guide

Fiber-Coupled Laser Source

Table of Contents

Chapter 1 Warning Symbol Definitions..............................................................................................1

Chapter 2 Safety....................................................................................................................................2

Chapter 3 Description...........................................................................................................................3

Chapter 4 Setup.....................................................................................................................................4

4.1. Setting the AC Line Voltage and Installing Fuses ........................................................ 4

4.2. Initial Set-up ..................................................................................................................... 4

Chapter 5 Operation..............................................................................................................................6

5.1. Front and Back Panel Overview ..................................................................................... 6

5.2. Turning On the Source ................................................................................................... 7

5.3. Adjusting the Laser Output Power ................................................................................ 7

5.4. Turning the Laser Off ...................................................................................................... 7

5.5. Modulating the Laser Output ......................................................................................... 7

Chapter 6 Making the Safety Interlock Connections........................................................................8

Chapter 7 General Maintenance..........................................................................................................9

7.1. Cleaning ........................................................................................................................... 9

7.2. Connector Cleaning ........................................................................................................ 9

Chapter 8 Specifications.....................................................................................................................10

Chapter 9 Mechanical Drawing...........................................................................................................12

Chapter 10 Regulatory...........................................................................................................................13

Chapter 11 Thorlabs Worldwide Contacts..........................................................................................14

2298-D11, Rev S March 23, 2017

Fiber-Coupled Laser Source Chapter 1: Warning Symbol Definitions

Chapter 1 Warning Symbol Definitions

Below is a list of warning symbols you may encounter in this manual or on your device.

Symbol Description

Direct Current

Alternating Current

Both Direct and Alternating Current

Earth Ground Terminal

Protective Conductor Terminal

Frame or Chassis Terminal

Equipotentiality

On (Supply)

Off (Supply)

In Position of a Bi-Stable Push Control

Out Position of a Bi-Stable Push Control

Caution: Risk of Electric Shock

Caution: Hot Surface

Caution: Risk of Danger

Warning: Laser Radiation

Rev T, June 7, 2018 Page 1

Caution: Spinning Blades May Cause Harm

Fiber-Coupled Laser Source Chapter 2: Safety

Chapter 2 Safety

All statements regarding safety of operation and technical data in this instruction manual will only apply when the

unit is operated correctly.

SHOCK WARNING

High voltage inside. To avoid electrical shock, before powering unit, make sure that the protective

conductor of the 3-conductor power cord is correctly connected to the protective earth contact of

the socket outlet. Improper grounding can cause electric shock resulting in severe injury or even

death. Do not operate without cover installed.

WARNING

This unit must not be operated in explosive environments

Thorlabs provides the proper power input cable for use in the United States. If using this unit anywhere else, the

user will need to supply a properly grounded power cable to power the unit.

Do not obstruct the air-ventilation slots in the housing!

Make sure that the line voltage rating marked on the rear panel agrees with your local supply and that the

appropriate fuses are installed. Changing of the mains fuse can be done by the user (see Setting the AC Line

Voltage and Installing Fuses).

With the exception of the mains fuses, there are no user serviceable parts in this product.

This device can only be returned when packed into the complete original packaging, including all foam packing

inserts. If necessary, ask for a replacement package.

Mobile telephones, cellular phones or other radio transmitters should not to be used within the range of three

meters of this unit since the electromagnetic field intensity may exceed the maximum allowed disturbance values

according to EN50082-1.

LASER RADIATION

Class 1 Laser Product

1550 nm <5 mW

AVOID EXPOSURE TO THE BEAM

CLASS 3B LASER PRODUCT

405 - 1064 nm <50 mW

LASER RADIATION

Class 1 Laser Product

1310 nm <5 mW

AVOID DIRECT EYE EXPOSURE

CLASS 3R LASER PRODUCT

600 - 700 nm <5 mW

Page 2 2298-D11

Fiber-Coupled Laser Source Chapter 3: Description

Chapter 3 Description

The Thorlabs Fiber Coupled Laser Sources provide easy coupling and simple control of laser diode driven fiber

optics. These laser sources are available in two versions, Fabry-Perot and Distributed Feed Back (DFB). The

Fabry-Perot version comes in five available wavelength choices from 405 nm to 1550 nm with standard single

mode fiber or polarization maintaining fiber output. The DFB version comes equipped with a thermo-electric

cooler to stabilize the output wavelength, and a 40 dB optical isolator to eliminate frequency jitter due to backreflections. The DFB is available in 1310 nm and 1550 nm wavelengths.

Rev T, June 7, 2018 Page 3

Fiber-Coupled Laser Source Chapter 4: Setup

Chapter 4 Setup

4.1. Setting the AC Line Voltage and Installing Fuses

Your S1FC Series Laser Source has been shipped from Thorlabs configured for 115 VAC operation. If you are

planning to operate your unit using a 220/230 VAC input, or need to replace an open fuse, you must perform the

following procedure.

Remove the AC power cord if it is connected to the unit.

Remove the cover of the unit by removing the two 4-40 Philips head screws located on the bottom rear of

the unit and slide the cover off. Refer to Figure 1 on page 5.

Locate the AC Line Select Switch and Fuse Holder. They are located near the AC Input Module towards

the back of the unit. Refer to Figure 1.

Using a flat blade screwdriver turn the Line Select Switch to the appropriate setting to match the AC input

voltage you will be using.

Remove the cover to the fuse holder. You will find the fuse installed in the cover. Remove the existing

fuse and install the appropriate fuse for the line voltage you will be using:

o For 115 VAC operation use 250 mA

o For 220/230 VAC operation use 160 mA

o In all cases use only 5 mm x 20 mm 250 VAC Type T Fuses (IEC 60127-2/III, low breaking

capacity, slow blow)

Reinstall the cover and replace the two 4-40 Philips head screws.

Remove the small cap head screw indicating the previous voltage configuration located on the rear panel,

above the AC input housing. Place the screw in the threaded hole indicating the new AC input

configuration, see Figure 2.

4.2. Initial Set-up

Determine the AC line voltage the unit will be connected to (either 115 VAC or 230 VAC) and set the AC

Line Voltage Selector Switch to the appropriate position and install the proper fuse.

Place the unit on a dry, level working surface.

Make sure the POWER key switch on the front of the unit is in the OFF position (key perpendicular to

working surface).

Plug the female end of the AC line cord provided into the AC Input Receptacle on the rear of the unit.

Plug the male end into a properly grounded AC socket.

Connect a Fiber Optic cable to the LASER APERTURE on the front panel of the unit.

Page 4 2298-D11

Fiber-Coupled Laser Source Chapter 4: Setup

Line Select Switch

Set to either 110 or 220 V

Fuse Holder

Fuse is installed in the cover

Figure 1 Locations of Line Select Switch and Fuse Holder

Rev T, June 7, 2018 Page 5

Fiber-Coupled Laser Source Chapter 4: Setup

Chapter 5 Operation

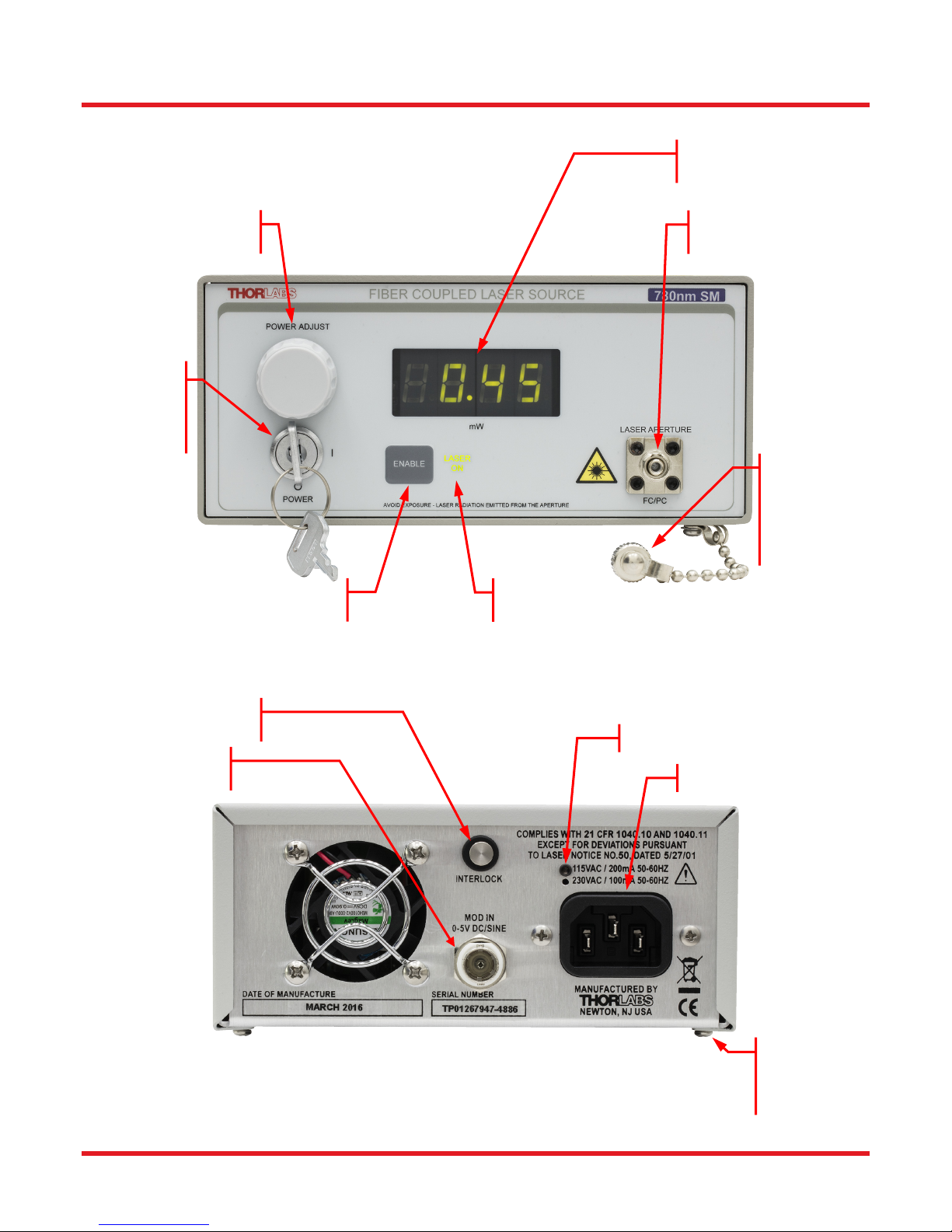

3½ Digit Display

5.1. Front and Back Panel Overview

Power Adjust Knob

Keylock Power

Switch

Turn on power to

the unit. Key only

removes when off

Laser Aperture

FC/PC fiber optic connector

Laser Output

Cover

Cover should be

installed on FC

connector when

fiber removed

Laser Enable Switch

Press to activate laser

Remote Interlock Input

Modulation Input

0 to 5 V Max, 50 Ω

Laser Emission Indicator

Lights up 5 seconds before laser turns on

Voltage Type Cap Screw Indicator

AC Power Cord Connector

Figure 2 Front and Rear Panels of Laser Source

Page 6 2298-D11

Cover Screws (2)

Remove to access

line voltage switch

and fuse

Fiber-Coupled Laser Source Chapter 4: Setup

5.2. Turning On the Source

Turn the POWER key switch clockwise. The unit is ON when the display lights up.

Make sure the Interlock Input is short-circuited, see page 8 for more details..

Press and release the ENABLE switch to turn ON the laser. The LASER ON indicator will light up and

after a delay of approximately 5 seconds, the source will begin to emit light.

5.3. Adjusting the Laser Output Power

Use the PWR ADJUST knob to adjust the output power to the desired level.

The power shown on the display is the optical power at the laser aperture. The actual power at the end of

your fiber optic cable may be less, depending on the quality of the connection.

Note, each unit is calibrated internally to limit the maximum operating power of the laser diode to a safe operating

range.

5.4. Turning the Laser Off

The Laser output should be turned off by pressing and releasing the ENABLE switch.

When completely powering down an enabled unit, first press and release the ENABLE switch and then

turn the POWER key switch counterclockwise, which will turn OFF the entire unit. Anytime the unit is

turned OFF and then turned back ON, the Laser will be disabled until the ENABLE switch is pressed.

5.5. Modulating the Laser Output

The MOD IN input can be used to modulate the laser output, or set the laser output remotely using a +5 V power

source. The 5 V maximum input corresponds to the maximum calibrated power of the laser source. Each unit is

calibrated to achieve the maximum power for the particular laser diode used in the device. Due to variations in the

coupling process no two units will have the same maximum power.

Connect a signal generator or +5 V power source to the unit using a BNC type connector.

Set the PWR ADJUST knob to its full counter clockwise setting.

Press the ENABLE switch to turn on the laser.

Apply the appropriate signal to the MOD IN input. Signals above approximately 5.5 V will be clamped by

internal circuits.

Adjusting the PWR ADJUST knob will allow for a DC offset on the modulated output. Adjust the input

signal accordingly to avoid clipping the output waveform, which will occur if the unit is driven to its current

or power limits.

Caution!

DO NOT apply TTL or square wave modulation to the MOD IN input.

Due to response delays of the constant power control loop, damage to the integrated fiber

coupled laser may occur!

Rev T, June 7, 2018 Page 7

Fiber-Coupled Laser Source Chapter 6: Making the Safety Interlock Connections

Chapter 6 Making the Safety Interlock Connections

The S1 series laser sources are equipped with a remote interlock connector located on the rear panel, see Figure

2 on page 6. All units have this feature regardless of their FDA and IEC classifications. In order to enable the

laser source, a short circuit must be applied across the terminals of the Remote Interlock connector. In practice

this connection is made available to allow the user to connect a remote actuated switch to the connector (i.e. an

open door indicator). The switch (which must be normally open) has to be closed in order for the unit to be

enabled. Once the switch is in an open state the laser source will automatically shutdown. If the switch returns to

a closed condition the laser source must be re-enabled at the unit by pressing the ENABLE switch.

All units shipped from Thorlabs are configured with a shorting device installed in the Interlock connector. If you

are not going to use this feature then you can leave the shorting device installed and the unit will operate normally

as described in the procedures above.

If you wish to make use of the Interlock feature you will need to acquire the appropriate connector mate and wire

it your remote interlock switch. Next, remove the shorting device by pulling it out with a pair of needle nose pliers

and install the connector into the interlock input.

The interlock input only accepts a 2.5 mm mono phone jack. This connector is readily available at most

electronics stores.

The electrical specifications for the interlock input are shown in the following table.

Specification Value

Type of Mating Connector

Open Circuit Voltage

Short Circuit Current

Connector Polarity

Interlock Switch

Requirements

Figure 3 Remote Interlock Connector

2.5 mm Mono Phone Jack

+5 VDC with Respect to Chassis

Tip is +5 V, Barrel is Ground

Must be N.O. Dry Contacts

Under no circumstances should any

external voltages be applied to the

Ground

0.5 mA DC

Interlock input

Ground

+5 Volts

Page 8 2298-D11

Fiber-Coupled Laser Source Chapter 7: General Maintenance

Chapter 7 General Maintenance

Aside from the AC Input fuse there are no user serviceable parts in this product. If you suspect something has

failed on the unit, please contact Thorlabs for advice on returning the unit for evaluation.

7.1. Cleaning

The unit can be cleaned using a soft, slightly damp cloth. Avoid using any solvents on or near the unit.

7.2. Connector Cleaning

Always clean the ferrule end of your fiber patch cable prior to inserting it into the output FC Adapter. Your

benchtop source comes with a fiber-cleaning card (FCC-CLN4-1). This should be used before inserting the fiber

connector into the mating barrel.

Figure 4 Fiber Cleaning Card (FCC-CLN4-1)

To use the card, peel back and tear away one small blue strip. Holding the connector firmly, swipe the connector

tip across the exposed cleaning strip. The connector tip should be flush to the card surface for FC-PC connectors

and at a slight angle with the key straight up for FC-APC connectors.

Rev T, June 7, 2018 Page 9

Fiber-Coupled Laser Source Chapter 8: Specifications

Chapter 8 Specifications

Item # S1FC405 S1FC635 S1FC637 S1FC660 S1FC675 S1FC780

Wavelength

Min Full Output Power

Laser Class

Stability

Display Accuracy

Setpoint Resolution

Adjustment Range

Stability

Setpoint Accuracy

Setpoint Resolution

Adjustment Range

Operating Temp

405 nm 635 nm 637 nm 660 nm 675 nm 785 nm

8.0 mW 2.5 mW 8 mW 15.0 mW 2.5 mW 10 mW

3B 3R 3B 3B 3R 3B

15 min: ±0.05 dB, 24 hr: ±0.1 dB

(After 1 hr Warm-up at 25 ± 10 °C Ambient)

±10%

0.01 mW

~0 mW to Full Power

TEC

n/a

n/a

n/a

n/a

Environmental

15 to 35 °C

Storage Temp

AC Input

Modulation Input

Modulation Bandwidth

Fiber

S405-XP SM600 SM600 SM600 SM600 780HP

115 VAC / 230 VAC (Switch Selectable) 50 - 60 Hz

0 - 5 V = 0 - Full Power, DC or Sine Wave Input Only

5 kHz Full Depth of Modulation

30 kHz Small Signal Modulation

0 to 50 °C

Page 10 2298-D11

Fiber-Coupled Laser Source Chapter 8: Specifications

Item # S1FC785 S1FC808 S1FC980 S1FC1060 S1FC1310 S1FC1550

Wavelength

Min Full Output Power

Laser Class

Stability

Display Accuracy

Setpoint Resolution

Adjustment Range

TEC

Stability

Setpoint Accuracy

Setpoint Resolution

Adjustment Range

Environmental

Operating Temp

785 nm 808 nm 980 nm 1064 nm 1310 nm 1550 nm

20 mW 15.0 mW 13.0 mW 20.0 mW 1.5 mW 1.5 mW

3B 3B 3B 3B 1

15 min: ±0.05 dB, 24 hr:±0.1 dB

(After 1 hr Warm-up at 25 ± 10 °C Ambient)

±10%

0.1 mW 0.01 mW 0.1 mW 0.01 mW

~0 mW to Full Power

n/a

n/a

n/a

n/a

15 to 35 °C

Storage Temp

AC Input

Modulation Input

Modulation

Bandwidth

Fiber

0 to 50 °C

115 VAC / 230 VAC (Switch Selectable) 50 - 60 Hz

0 - 5 V = 0 - Full Power, DC or Sine Wave Input Only

5 kHz Full Depth of Modulation

30 kHz Small Signal Modulation

780HP SM800-5.6-125 SM980-5.8-125 HI1060 SMF-28-J9 SMF-28-J9

Rev T, June 7, 2018 Page 11

Fiber-Coupled Laser Source Chapter 9: Mechanical Drawing

Chapter 9 Mechanical Drawing

5.76"

(146.3 mm)

3.07"

(78.0 mm)

11.43"

(290.3 mm)

Figure 5 Mechanical Drawing

Page 12 2298-D11

Fiber-Coupled Laser Source Chapter 10: Regulatory

Chapter 10 Regulatory

As required by the WEEE (Waste Electrical and Electronic Equipment Directive) of the European Community and

the corresponding national laws, Thorlabs offers all end users in the EC the possibility to return “end of life” units

without incurring disposal charges.

This offer is valid for Thorlabs electrical and electronic equipment:

Sold after August 13, 2005

Marked correspondingly with the crossed out “wheelie bin” logo (see right)

Sold to a company or institute within the EC

Currently owned by a company or institute within the EC

Still complete, not disassembled and not contaminated

As the WEEE directive applies to self-contained operational electrical and electronic products, this end of life take

back service does not refer to other Thorlabs products, such as:

Pure OEM products, that means assemblies to be built into a unit by the user (e. g. OEM laser driver

cards)

Components

Mechanics and optics

Left over parts of units disassembled by the user (PCB’s, housings etc.).

If you wish to return a Thorlabs unit for waste recovery, please contact Thorlabs or your nearest dealer for further

information.

Wheelie Bin Logo

Waste Treatment is Your Own Responsibility

If you do not return an “end of life” unit to Thorlabs, you must hand it to a company specialized in waste recovery.

Do not dispose of the unit in a litter bin or at a public waste disposal site.

Ecological Background

It is well known that WEEE pollutes the environment by releasing toxic products during decomposition. The aim of

the European RoHS directive is to reduce the content of toxic substances in electronic products in the future.

The intent of the WEEE directive is to enforce the recycling of WEEE. A controlled recycling of end of life products

will thereby avoid negative impacts on the environment.

Rev T, June 7, 2018 Page 13

Fiber-Coupled Laser Source Chapter 11: Thorlabs Worldwide Contacts

Chapter 11 Thorlabs Worldwide Contacts

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau

Germany

Tel: +49-(0)8131-5956-0

Fax: +49-(0)8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

Japan

Thorlabs Japan, Inc.

Higashi-Ikebukuro Q Building, 2F

2-23-2, Higashi-Ikebukuro,

Toshima-ku, Tokyo 170-0013

Japan

Tel: +81-3-5979-8889

Fax: +81-3-5979-7285

www.thorlabs.jp

Email: sales@thorlabs.jp

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place, Ely

Cambridgeshire CB7 4EX

Great Britain

Tel: +44 (0)1353-654440

Fax: +44 (0)1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

China

Thorlabs China

Room A101, No. 100

Lane 2891, South Qilianshan Road

Putuo District

Shanghai

China

Tel: +86 (0) 21-60561122

Fax: +86 (0)21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

Page 14 2298-D11

www.thorlabs.com

Loading...

Loading...