Compact Polarimeter

PAX1000

Operation Manual

2019

Version:

Date:

1.2

26-Feb-2019

Copyright © 2019 Thorlabs GmbH

Contents

Foreword

1 General Information 1

2 Getting Started 5

142.6 First Steps

3 Graphical User Interface (GUI) 15

153.1 General

163.2 GUI Overview

173.3 Menu File

11.1 Safety

31.2 Ordering Codes and Accessories

41.3 Requirements

52.1 Parts List

62.2 Operating Principle

72.3 Operating Elements

82.4 Mounting

92.5 Installing Software

203.4 Menu Device

223.5 Menu View

223.6 Menu Tools

223.7 Menu Help

233.8 Status Bar

4 PAX1000 Settings 24

5 Operating Instruction 25

255.1 Alignment Assistance

265.2 PAX1000 Measurements

275.2.1 Measurement Value Table

295.2.2 Polarization Ellipse

295.2.3 Poincaré Sphere

315.2.4 Scope Mode

345.2.5 Long Term Measurement

345.2.5.1 Settings

355.2.5.2 Measurement

365.2.6 Extinction Ratio Measurement

385.2.6.1 ER Measurement Wizard

415.2.6.2 ER Measurement Tool

435.2.7 Virtual Device

435.2.8 Multiple Devices

6 Write Your Own Application 45

466.1 32 Bit Operating Systems

486.2 64 Bit Operating Systems

7 Maintenance and Service 50

507.1 Version Information

517.2 Troubleshooting

8 Tutorial 53

538.1 Polarization of Light

538.1.1 The Nature of Polarization

548.1.2 Handedness of Polarization

588.1.3 Mathematical Representation of an Electromagnetic Wave

608.1.4 Polarization Ellipse

628.1.5 Poincaré Sphere

638.1.6 Polarization in Fibers

658.1.7 Polarization Parameters - Definitions

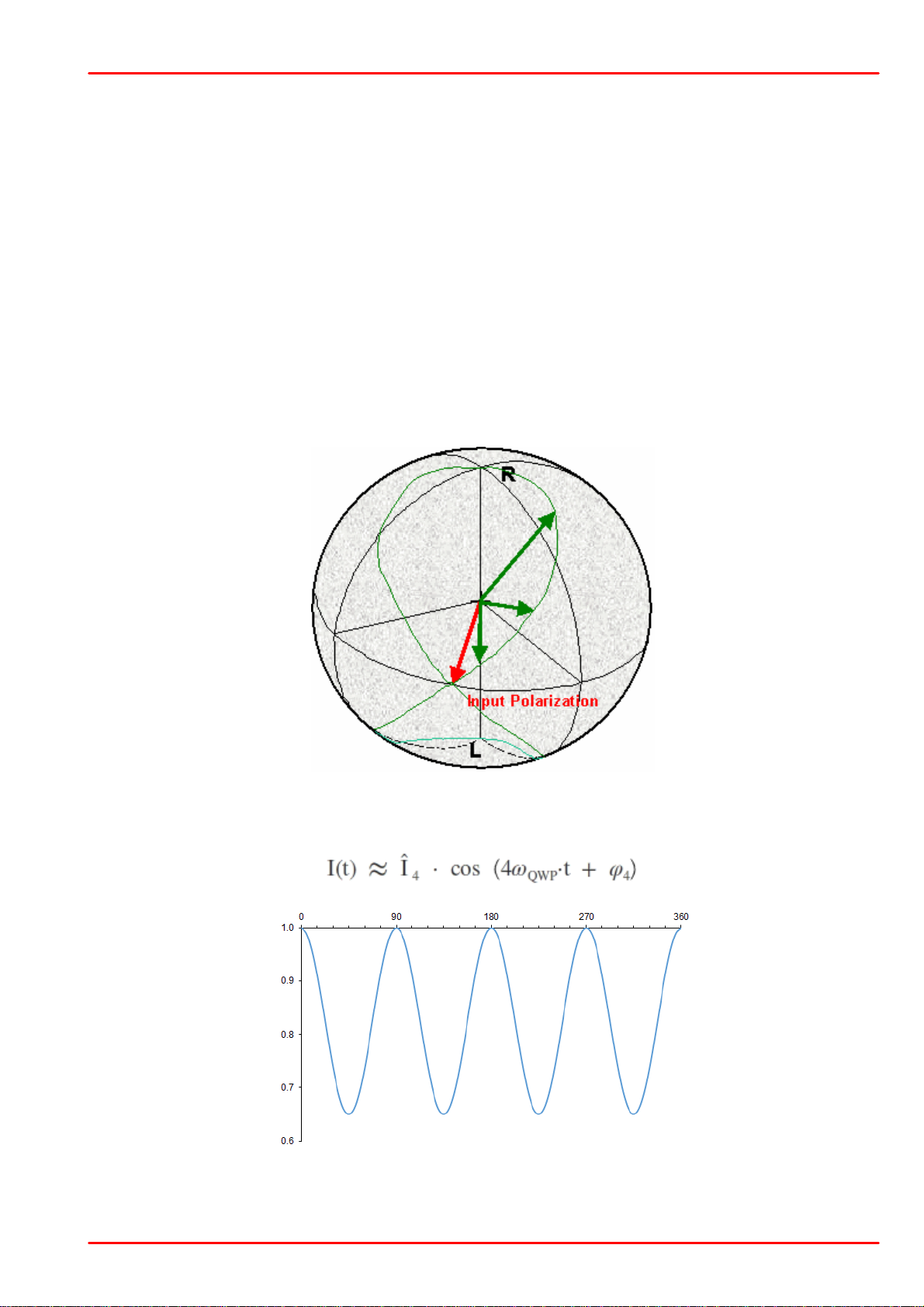

678.2 Polarization Measurement Technique

678.2.1 Rotating Waveplate Technique

718.3 Polarization Control and Transformation

718.3.1 Bulk Optics

718.3.2 Fiber Polarization Controllers

728.3.3 Fiber Polarization Scrambler

738.4 Extinction Ratio Measurement on PM Fibers

738.4.1 Definition

738.4.2 Measurement

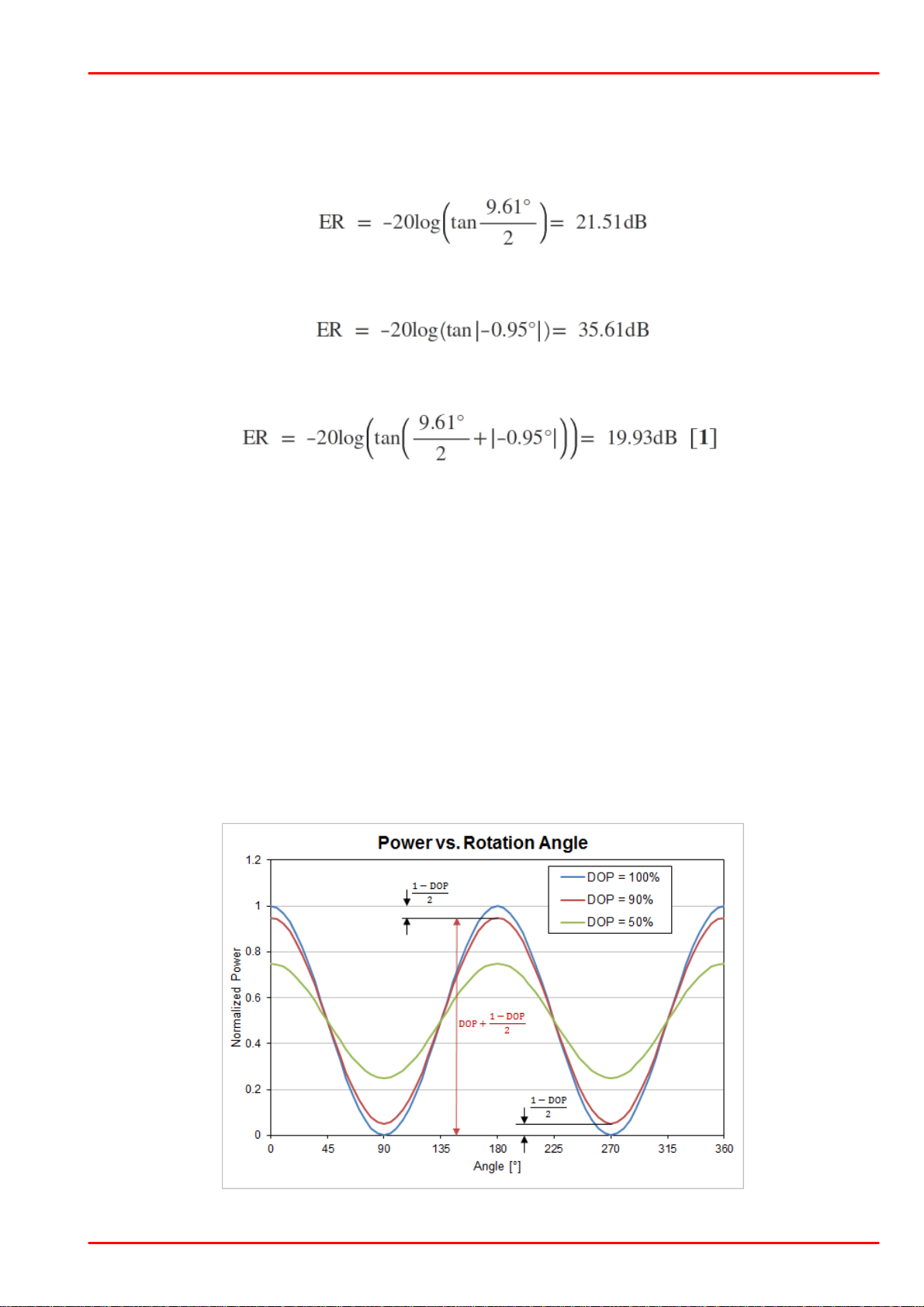

758.4.3 Correction of the Polarimeter ER Measurements

9 Appendix 79

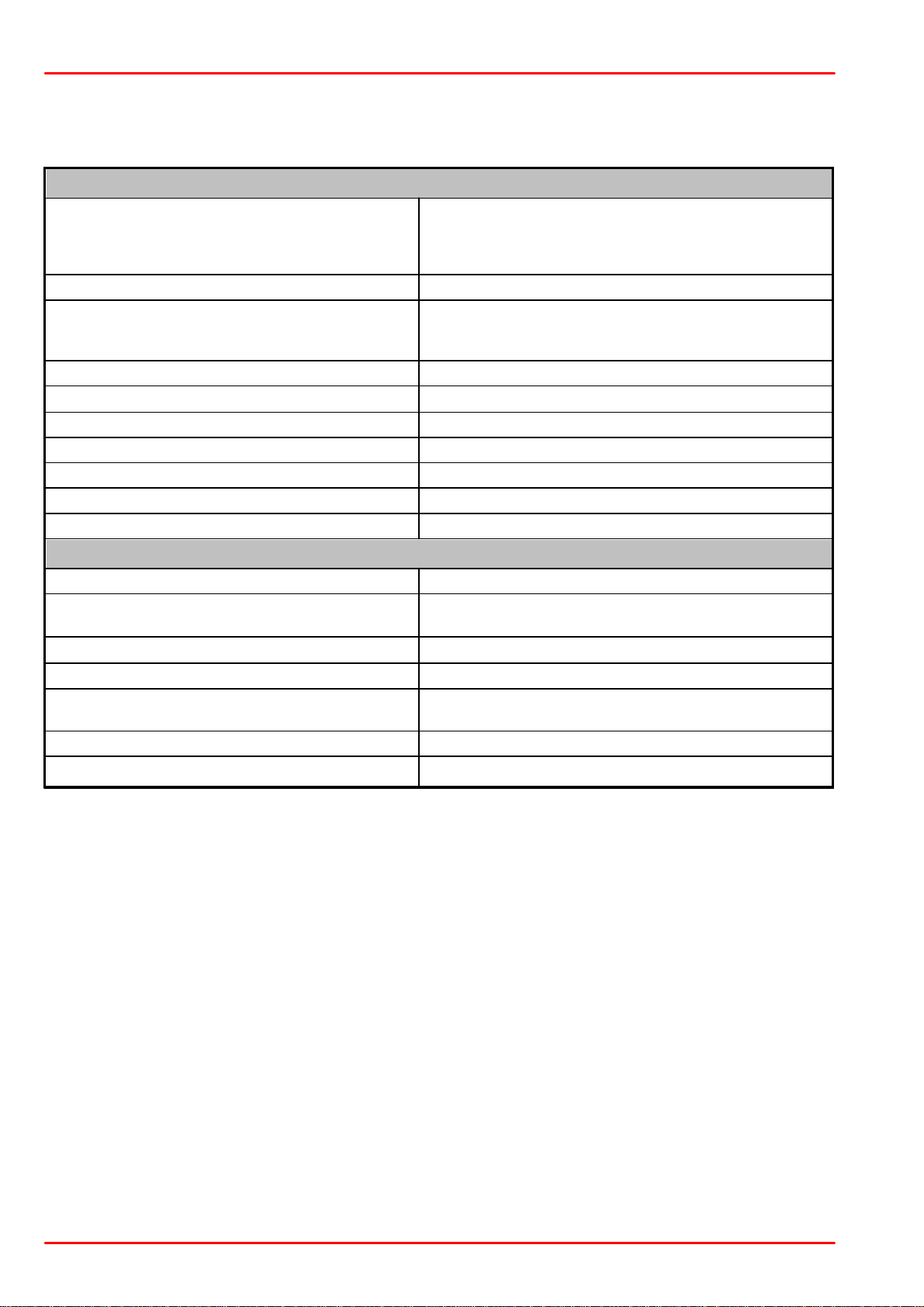

799.1 Technical Data

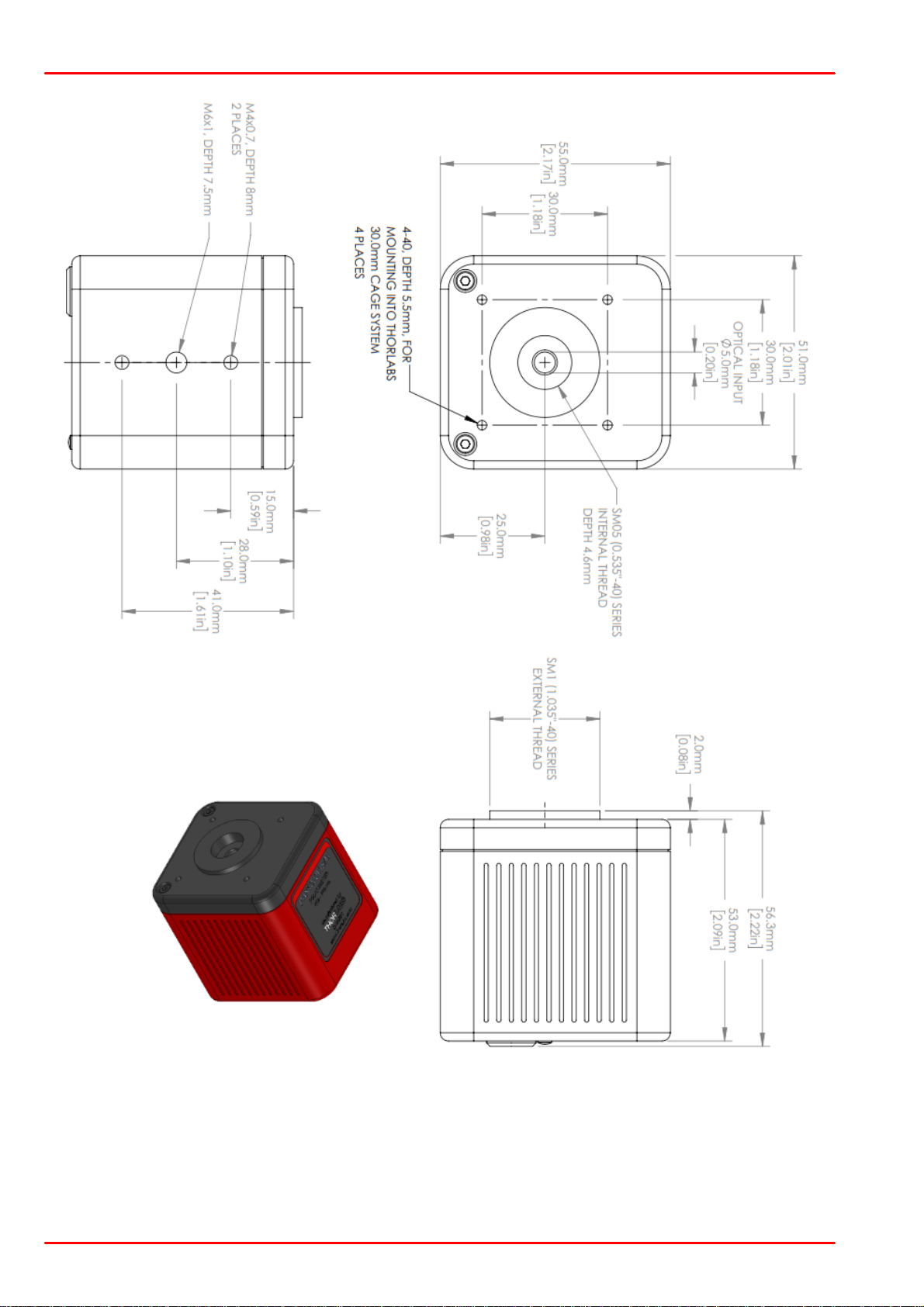

809.2 Dimensions

829.3 Certifications and Compliances

839.4 Warranty

849.5 Copyright and Exclusion of Reliability

859.6 Thorlabs 'End of Life' Policy

869.7 List of Acronyms

879.8 Literature

889.9 Thorlabs Worldwide Contacts

We aim to develop and produce the best solution for your application

in the field of optical measurement. To help us to live up to your

expectations and constantly improve our products we need your

ideas and suggestions. Therefore, please let us know about possible

criticism or ideas. We and our international partners are looking

forward to hearing from you.

Thorlabs GmbH

Warning

Sections marked by this symbol explain dangers that might result in

personal injury or death. Always read the associated information

carefully, before performing the indicated procedure.

Attention

Paragraphs preceded by this symbol explain hazards that could

damage the instrument and the connected equipment or may cause

loss of data.

Note

This manual also contains "NOTES" and "HINTS" written in this form.

Please read this advice carefully!

© 2019 Thorlabs GmbH

PAX1000

1 General Information

Thorlabs polarimeters are terminating, wave-plate-based modules for free-space and - with installed fiber collimator - fiber-based measurements of the state of polarization (SOP). Their high

dynamic range of 70 dB, three models covering the visible to near-infrared range, and accuracy

of ±0.25° on the Poincaré sphere opens a wide spectrum of application possibilities.

Each measurement sensor is calibrated at different wavelength points. These base points are

interpolated.

The PAX1000 is basically powered via the USB port. For a measurement speed higher that 50

samples per second, an additional power supply is required - please connect the DS15 power

supply to your mains outlet and to the PAX1000.

Note

Polarization measurements with the PAX1000 are possible only for monochromatic coherent

light (e.g., laser emission)!

1.1 Safety

Attention

The safety of any system incorporating the equipment is the responsibility of the assembler of the system.

All statements regarding safety of operation and technical data in this instruction manual

will only apply when the unit is operated correctly as it was designed for.

Use for external power supply of the PAX1000 only the supplied by Thorlabs GmbH

power adapter.

The PAX1000 must not be operated in explosion endangered environments!

Do not open the cabinet, there are no parts serviceable by the operator inside!

Refer servicing to qualified personnel!

Only with written consent from Thorlabs GmbH may changes to single components be

made or components not supplied by Thorlabs GmbH be used.

This precision device is only serviceable if properly packed into the complete original

packaging. If necessary, ask for a replacement package prior to return.

Attention

The following statement applies to the products covered in this manual, unless otherwise specified herein. The statement for other products will appear in the accompanying

documentation.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules and meets all requirements of the Canadian

Interference-Causing Equipment Standard ICES-003 for digital apparatus. These limits

are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Thorlabs GmbH is not responsible for any radio television interference caused by modifications of this equipment or the substitution or attachment of connecting cables and

© 2019 Thorlabs GmbH1

1 General Information

equipment other than those specified by Thorlabs GmbH. The correction of interference

caused by such unauthorized modification, substitution or attachment will be the responsibility of the user.

The use of shielded I/O cables is required when connecting this equipment to any and all

optional peripheral or host devices. Failure to do so may violate FCC and ICES rules.

Attention

Mobile telephones, cellular phones or other radio transmitters are not to be used within

the range of three meters of this unit since the electromagnetic field intensity may then

exceed the maximum allowed disturbance values according to IEC 61326-1.

This product has been tested and found to comply with the limits according to

IEC 61326-1 for using connection cables shorter than 3 meters (9.8 feet).

© 2019 Thorlabs GmbH

2

PAX1000

PAX1000VIS

Polarimeter, Wavelength Range 400 to 700 nm

Included Accessories:

· F240FC-A Fiber Collimator

· KAD12F SM1 Threaded Adapter for the Fiber Collimator

· SM1M10 SM1 Lens Tube

· End Cap (Laser-Engraved Cross-Hair)

PAX1000VIS/M

Same as PAX1000VIS, but with metric mounting threads

PAX1000IR1

Polarimeter, Wavelength Range 600 to 1080 nm

Included Accessories:

· F240FC-B Fiber Collimator

· KAD12F SM1 Threaded Adapter for the Fiber Collimator

· SM1M10 SM1 Lens Tube

· VRC2SM1 alignment disk with mounting adapter

PAX1000IR1/M

Same as PAX1000IR1, but with metric mounting threads

PAX1000IR2

Polarimeter, Wavelength Range 900 to 1700 nm

Included Accessories:

· F240FC-C Fiber Collimator

· KAD12F SM1 Threaded Adapter for the Fiber Collimator

· SM1M10 SM1 Lens Tube

· VRC2SM1 alignment disk with mounting adapter

PAX1000IR2/M

Same as PAX1000IR2, but with metric mounting threads

1.2 Ordering Codes and Accessories

© 2019 Thorlabs GmbH3

1 General Information

1.3 Requirements

These are the requirements for the PC intended to be used for remote operation of the

PAX1000.

Hardware Requirements

CPU: 2.4 GHz or faster

RAM: min. 2 GB

Graphic card Min. 1024x768 pixel graphic resolution

Hard disc Min. 1 GB of available free space (32 bit operating system)

Min. 2.3 GB of available free space (64 bit operating system)

Interface free USB2.0 port, USB cable according the USB 2.0 specification

Mouse A mouse is required for access to graphic options in the GUI

Software Requirements

The PAX1000 software is compatible with the following operating systems:

· Windows® 7 (32-bit, 64-bit)

· Windows® 8.1 (32-bit, 64-bit)

· Windows® 10 (32-bit, 64-bit)

For operation of the PAX1000, the following software is required as well:

· NI-VISA® Runtime (Version 5.4 or later)

· Microsoft® .Net (Version 4.6.1 or later)

· DirectX9® or higher

Above mentioned software is included with the Thorlabs GmbH PAX1000 installation package,

and will be installed automatically, if the required minimum versions are not recognized.

© 2019 Thorlabs GmbH

4

PAX1000

2 Getting Started

2.1 Parts List

Inspect the shipping container for damage.

If the shipping container seems to be damaged, keep it until you have inspected the contents

and you have inspected the PAX1000 mechanically and electrically.

Verify that you have received the following items within the package, depending on the ordered

item:

1. PAX1000VIS (PAX1000VIS/M) Polarimeter, Wavelength Range 400 – 700 nm

2. F240FC-A Fiber Collimator

3. KAD12F SM1 Threaded Adapter for the Fiber Collimator

4. SM1M10 SM1 Lens Tube

5. SM1CP1 End Cap (Modified: Laser-Engraved Cross-Hair)

6. Cable USB 2.0, A to Mini-B, 1.5 m length

7. Power Supply DS15

8. Quick Reference Manual

or

1. PAX1000IR1 (PAX1000IR1/M) Polarimeter, Wavelength Range 600 to 1080 nm

2. F240FC-B Fiber Collimator

3. KAD12F SM1 Threaded Adapter for the Fiber Collimator

4. SM1M10 SM1 Lens Tube

5. VRC2SM1 with mounting adapter

6. Cable USB 2.0, A to Mini-B, 1.5 m length

7. Power Supply DS15

8. Quick Reference Manual

or

1. PAX1000IR2 (PAX1000IR2/M) Polarimeter, Wavelength Range 900 to 1700 nm

2. F240FC-C Fiber Collimator

3. KAD12F SM1 Threaded Adapter for the Fiber Collimator

4. SM1M10 SM1 Lens Tube

5. VRC2SM1 with mounting adapter

6. Cable USB 2.0, A to Mini-B, 1.5 m length

7. Power Supply DS15

8. Quick Reference Manual

© 2019 Thorlabs GmbH5

2 Getting Started

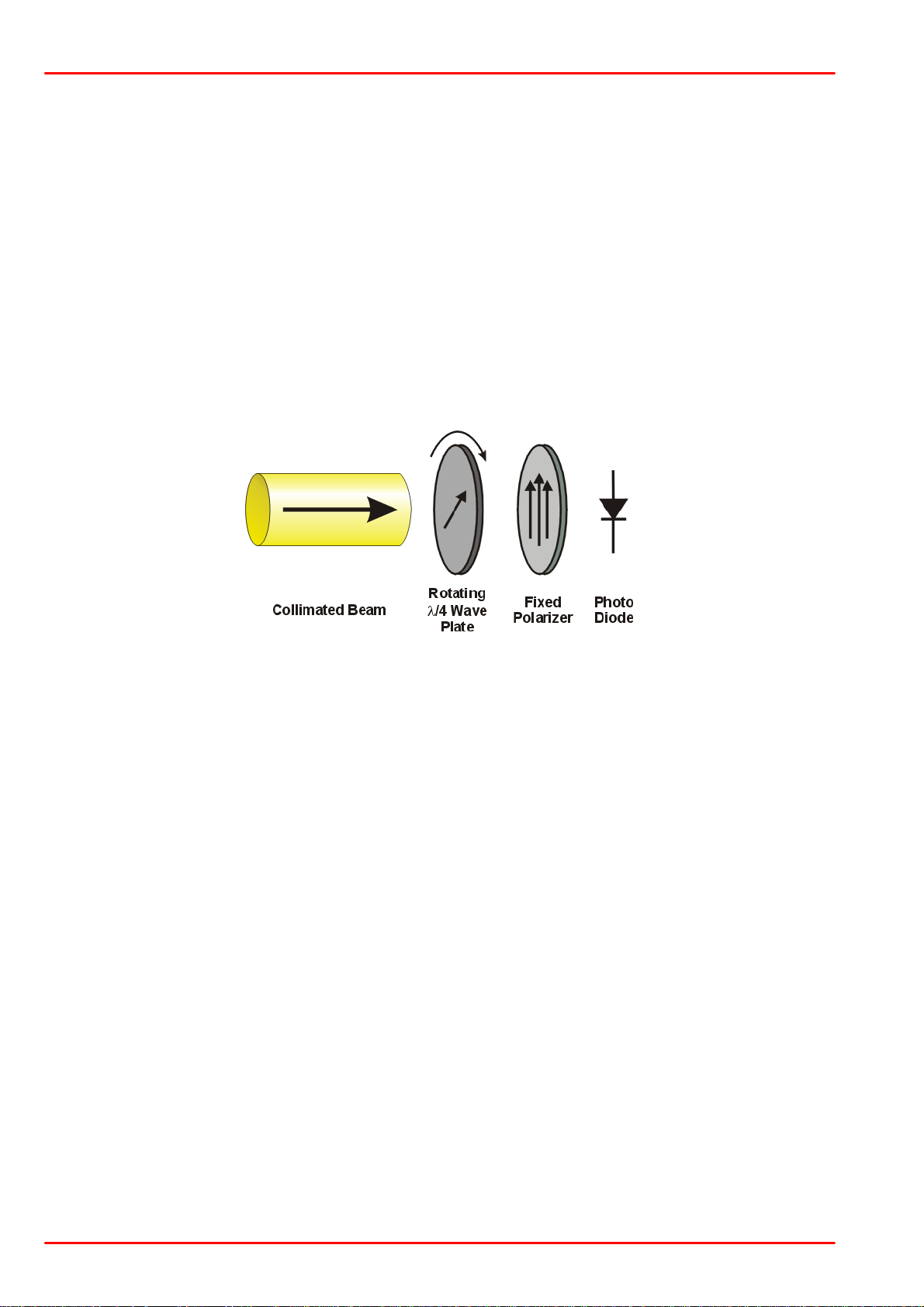

2.2 Operating Principle

The PAX1000 is based on the rotating quarter waveplate technique.

The l/4 true zero order waveplate is mounted to a hollow shaft that is driven by a low vibration

DC motor. By this rotation, the waveplate modulates the input polarization. This polarization

modulation is converted by the fixed polarizer into an amplitude modulation of the light intensity

incident to the photo diode. This way, the photo current is modulated as well. A Fast Fourier

Transformation (FFT) analysis allows then to calculate the 3 normalized Stokes vectors s1, s2

and s3, the polarized power and degree of polarization DOP. These parameters are sufficient

to completely describe the polarization state of the light incident on the PAX1000 polarization.

Please see section Rotating Waveplate Technique for detailed explanation.

67

© 2019 Thorlabs GmbH

6

PAX1000

Operating Elements Front

1

Mounting hole for Thorlabs 30 mm cage system (4-40, depth 5.5 mm), 4 places

2

Input aperture with Thorlabs SM1 (1.035"-40) external thread

3

Input aperture with Thorlabs SM05 (0.535"-40) internal thread

PAX1000 Operating Elements (Rear)

Operating Elements Rear

4

External power supply connector

5

LED "Ready"

6

USB Mini B connector

2.3 Operating Elements

© 2019 Thorlabs GmbH7

2 Getting Started

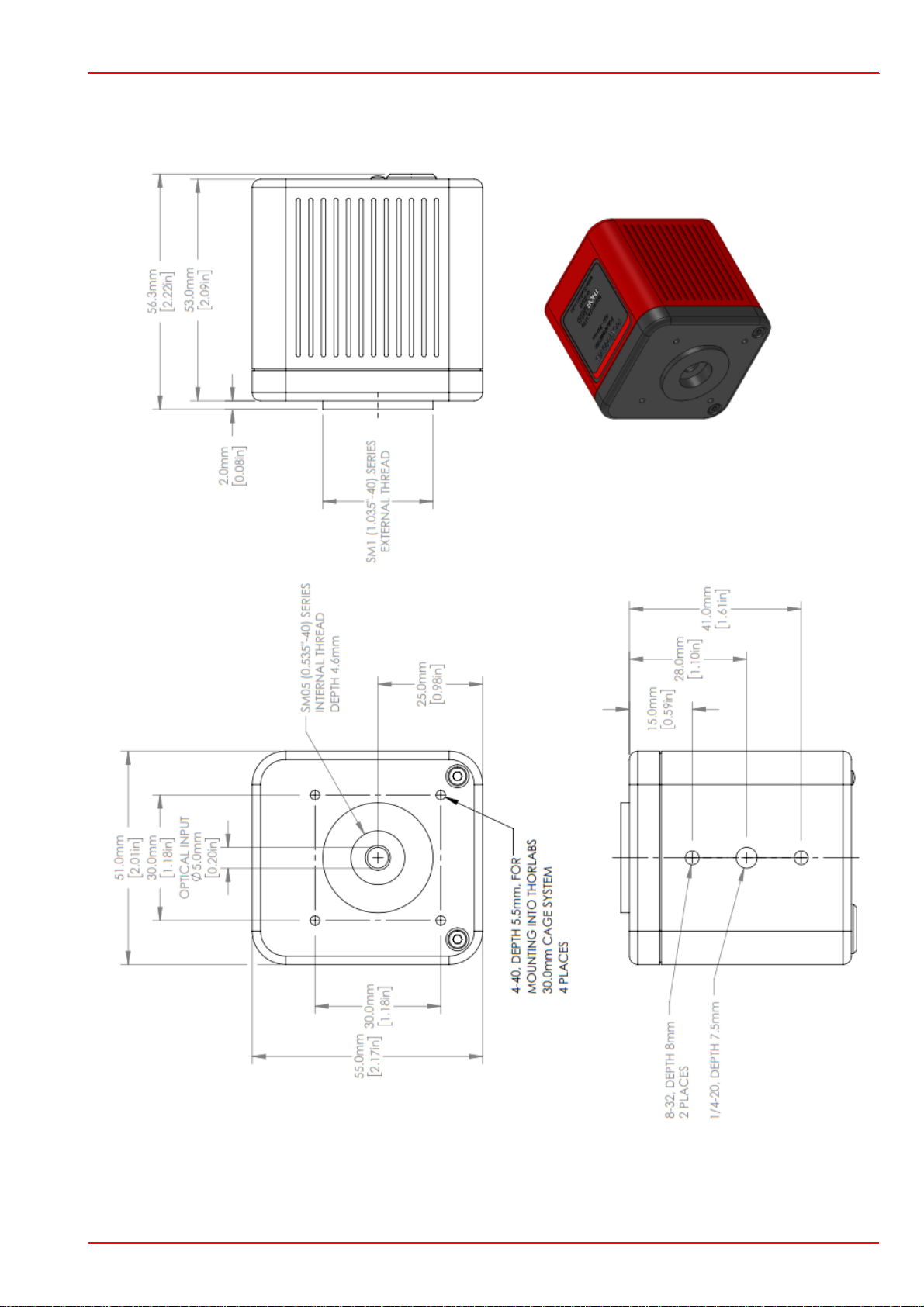

2.4 Mounting

Mounting the PAX1000 for Open Beam Applications

The PAX1000 can be mounted in two different ways to your optical setup:

1. On the bottom there are three mounting holes:

· One M6 x 1 (metric version) or 1/4-40 (imperial version) threaded mounting hole

· Two M4 x 0.7 (8-32) threaded holes

Use these holes for post mounting.

2. On the front are four threaded mounting holes 4-40 for mounting into the standard Thorlabs

30 mm cage system.

For details, please see the dimension drawings in the Appendix.

80

Note

It is important to align the incident beam perpendicularly to the front surface of the PAX1000

and centered to its input aperture.

The centering can be easily aligned by using the delivered protection cap - the PAX1000VIS

comes with an cross-hair engraved end cap (in the picture left), the PAX1000IR1 and

PAX1000IR2 come with a mounted viewing target.

The right-angled alignment of the beam with respect to the front surface is important as well.

The PAX1000 software offers a tool, the Alignment Assistance .

25

Setting Up the PAX1000 for Fiber-Coupled Applications

To enable the PAX1000 to accept fiber-based input, screw the SM1M10 lens tube onto the external SM1 threads on the front of the housing. Insert the F240FC series fiber collimator into

the KAD12F adapter, and tighten the set screws to hold the fiber collimator securely. Screw this

assembly into the open end of the SM1M10 lens tube. With the assistance of the Alignment

Tool in the software, optimize the alignment of the fiber collimator using a 5/64" [2.0 mm] hex

key (not included) to rotate the pitch and yaw adjustment screws on the adapter.

© 2019 Thorlabs GmbH

8

PAX1000

2.5 Installing Software

Note

Do not connect the PAX1000 to the PC prior to software installation!

For software installation, you need administrator privileges on your computer!

Attention

Exit all running applications on your PC as the installer may require a reboot of your PC

during installation!

Thorlabs is breaking new ground in saving our environment. We decided to refrain from shipping an installation CD ROM and to offer a download of the software from our website instead.

As an additional advantage to this distribution method, the most recent version of the software

will always be available online.

The PAX1000 software package contains beside the PAX1000 software a NI VISA Runtime

and the Thorlabs DFU Wizard. The latter is required to enable the user to install future firmware

updates to the PAX1000. The software package can be downloaded from the website

https://www.thorlabs.com/software_pages/ViewSoftwarePage.cfm?Code=PAX1000x

Note to Windows 8.1 and Windows 10 users

The NI VISA installer might require disabling the Windows Fast Startup feature. This feature

was introduced with Windows 8 and is enabled by default. The Fast Startup may interfere with

correct hardware recognition by NI VISA, so it is strongly recommended to disable the Fast

Startup as the installer requests.

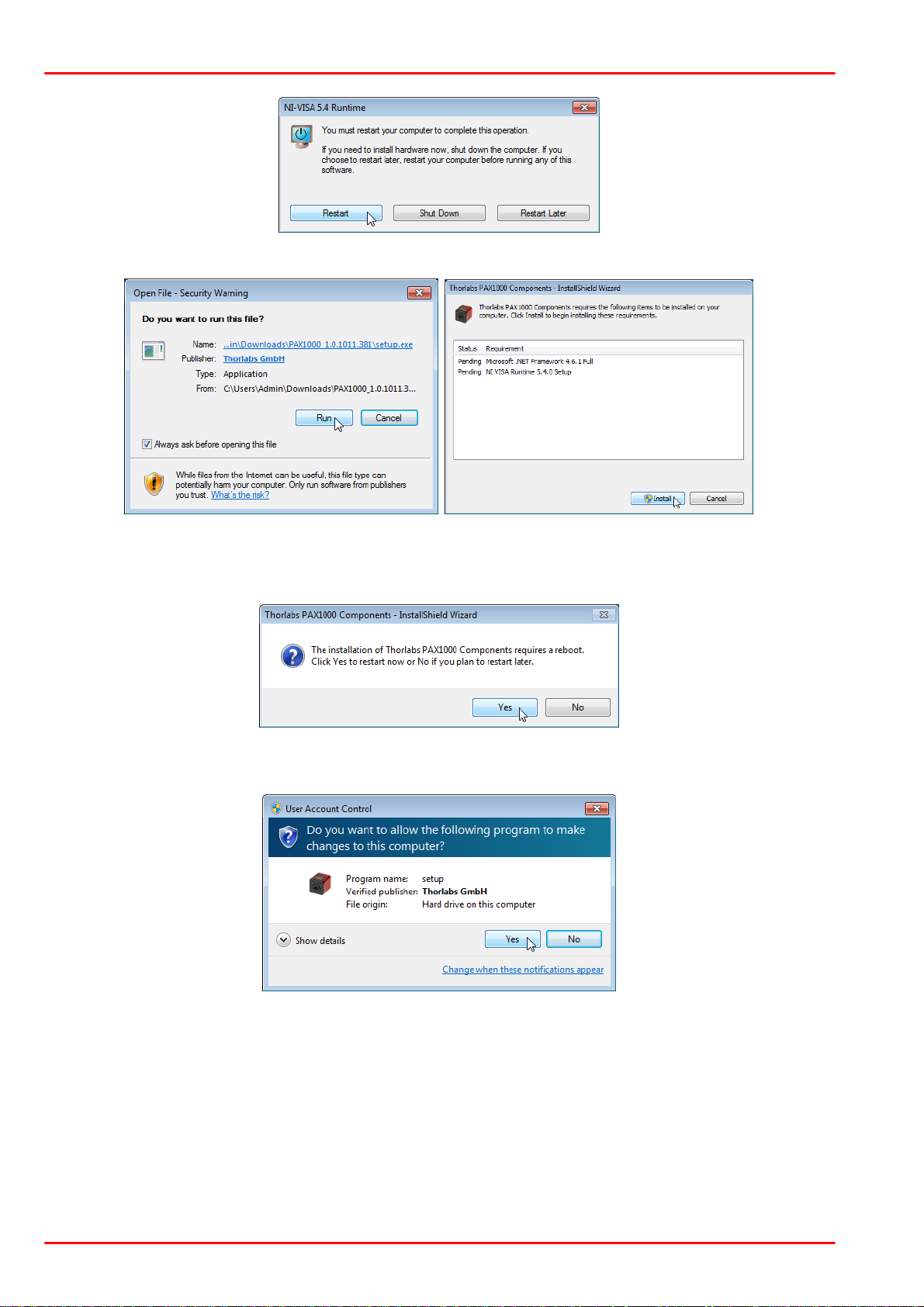

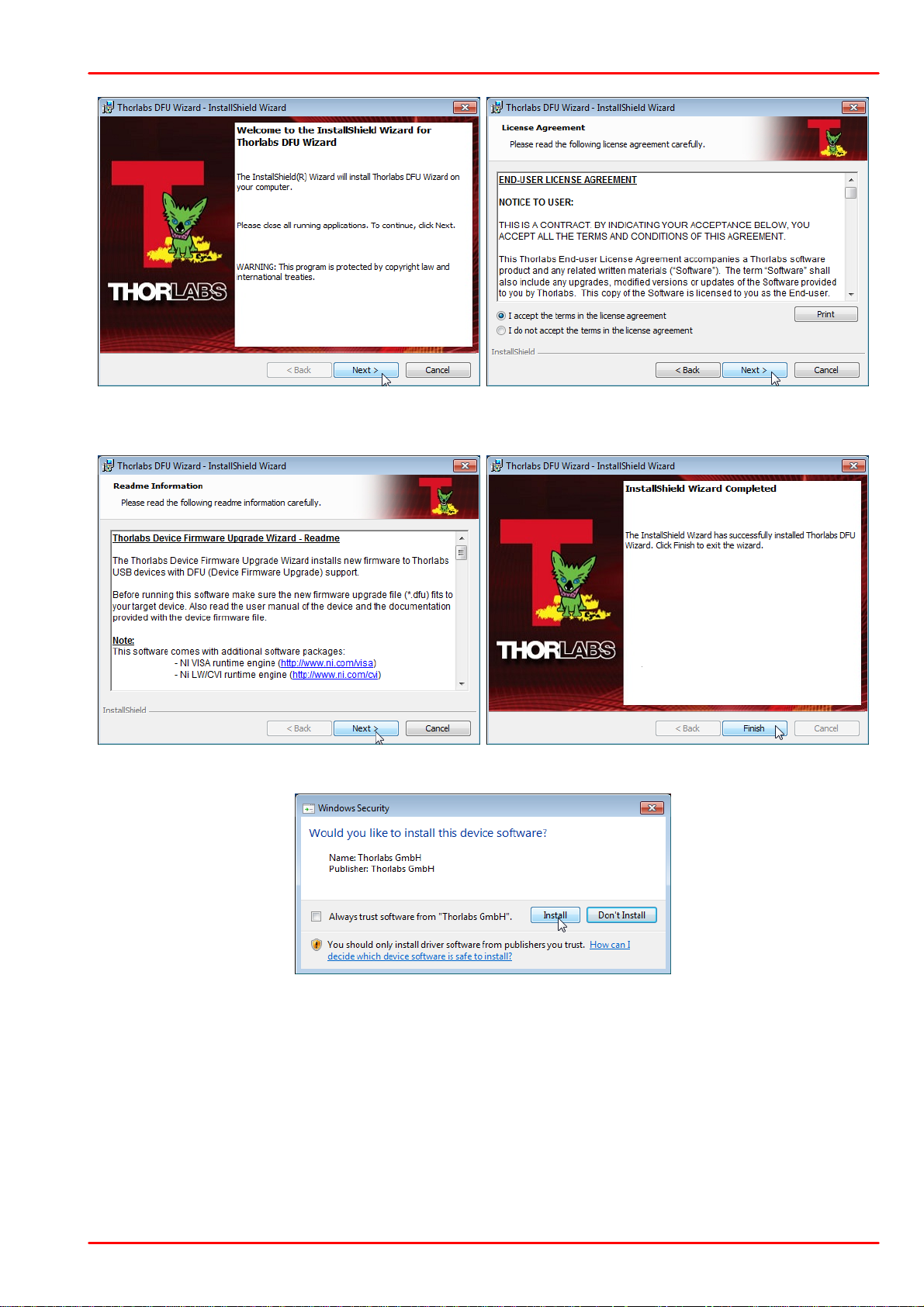

In the following, an installation to an Windows 7 64 bit operating system is described, including

the installation of NI VISA Runtime 5.4.0 and Microsoft.NET Framework 4.5.1.

Download the software package to your computer, unzip it and execute the setup.exe:

© 2019 Thorlabs GmbH9

2 Getting Started

Click 'Install' to proceed. Windows Security might require your confirmation to install the

software, depending on the security level settings - please hit the appropriate button:

The installer starts the NI-VISA 5.4.0 installation. This will take some minutes and usually require a

reboot.

Click 'Next' to continue. In the subsequent dialog windows, follow the instructions. Accepting

the proposed settings is recommended..

If you are prompted to restart your computer, please do so to avoid installation issues.

© 2019 Thorlabs GmbH

10

PAX1000

After restarting the computer, the installer automatically resumes the installation process:

As a next step, the Microsoft .NET Framework will be installed. This installation procedure may

take several minutes, please do not interrupt the installation process. When you are prompted

again to restart your computer, please do so to avoid installation issues.

After restarting the computer, the installer automatically resumes the installation process and

installs the Thorlabs DFU Wizard:

© 2019 Thorlabs GmbH11

2 Getting Started

Click 'Next' to continue. In the subsequent dialog windows, follow the instructions. Accepting

the proposed settings is recommended.

As a next step, the installer continues with installation of the PAX1000 software:

© 2019 Thorlabs GmbH

12

PAX1000

Click 'Next' to continue. In the subsequent dialog windows, follow the instructions. Accepting

the proposed settings is recommended.

The Readme screen contains important information, please read it carefully. Then click 'Next'.

Click 'Finish' to finalize the installation of the software package.

© 2019 Thorlabs GmbH13

2 Getting Started

2.6 First Steps

Mount your PAX1000 to the optical setup.

Note

Do not connect the PAX1000 to the PC prior to software installation! Please make sure that the

installation was carried out completely, including the reboot requests. This is essential for a

proper operation.

Power supplied via the USB2.0 port (max. 500 mA) is sufficient for waveplate rotation speeds

up to 100 Hz. For faster measurements, please use in addition the supplied DS15 wall plug adapter.

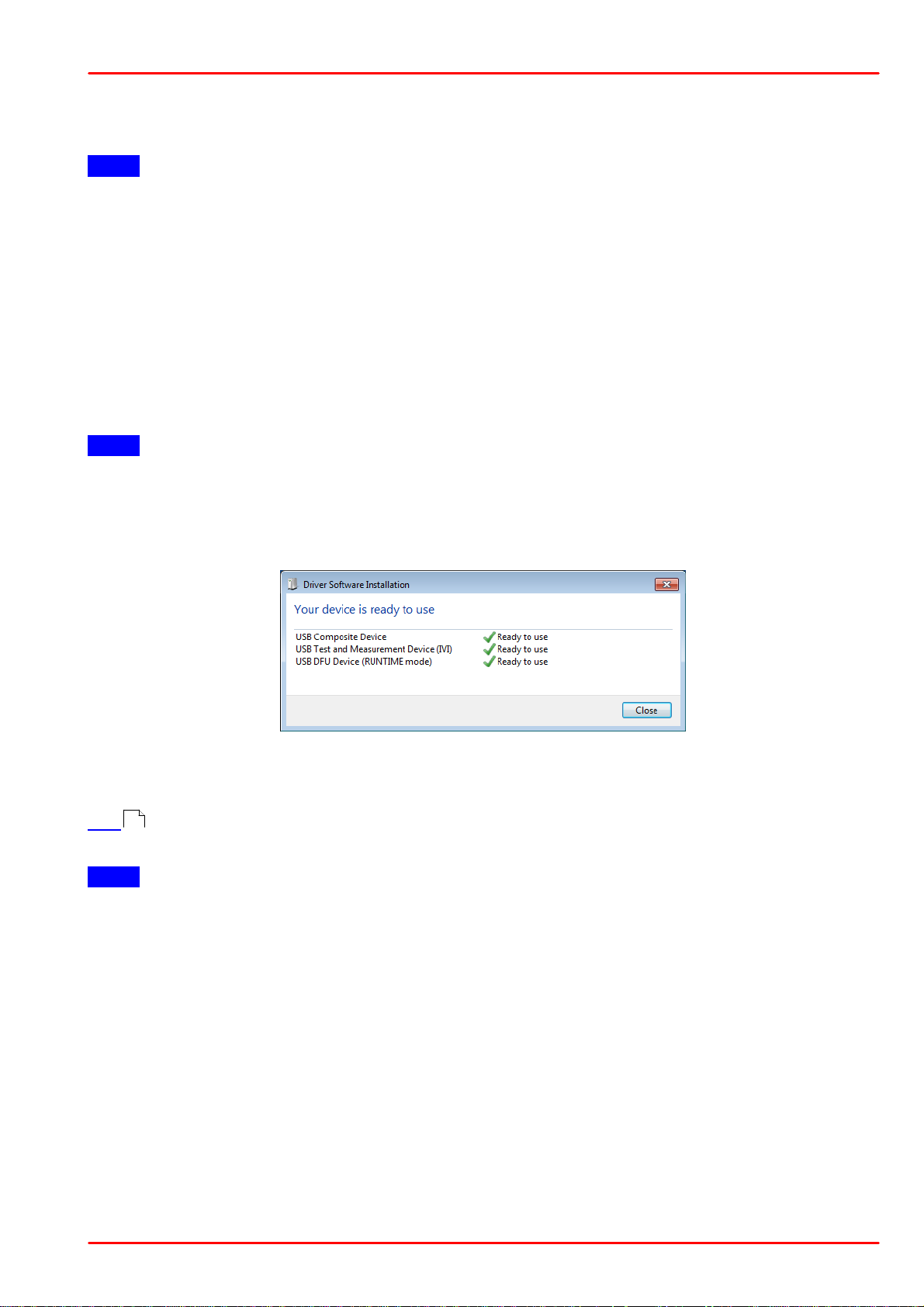

Connect the PAX1000 using the supplied USB2.0 cable to your computer.

After connection of PAX1000xxx to your PC, the green LED on the back of the PAX1000xxx

lights up green and blinks during the booting phase of the device.

Please take into account an initial warm up time of the PAX1000xxx.

Note

The supplied USB cable is certified for use with the PAX1000. The use of other and / or longer

cables may lead to degradation of performance, data loss or even malfunction of the PAX1000.

A pop-up window confirms the PAX1000 is recognized by the computer, and it shows the installation status of the appropriate driver software.

It is recommended to skip the search for driver software in Windows Update, because no

drivers will be found there and the installation process will consume longer time.

After the driver software was installed successfully, click to PAX1000 icon on your desktop. The

15

GUI (Graphic User Interface) comes up, scans the USB for installed devices and connects

automatically the recognized PAX1000.

Note

Up to five PAX1000 instruments can be connected at a time and displayed in a single software

instance. If more that one PAX1000 is connected and recognized, the software will connect to

the first recognized device any time the software is started.

© 2019 Thorlabs GmbH

14

PAX1000

3 Graphical User Interface (GUI)

3.1 General

Prior to explaining the GUI in detail, there are some general comments to make about the interactions between the PAX1000 hardware and the control software. Please read these comments carefully as this information is important to understanding the functionality.

The PAX1000 calculates the polarization parameters (power, degree of polarization and the

three normalized Stokes vectors) in its firmware. These 5 parameters are transferred as a data

set to the GUI via the USB connection.

Note

It is important to establish the USB connection prior to starting the software. Only this way the

correct drivers can be installed and the PAX1000 can be recognized.

When the GUI starts for the first time, factory default settings for the GUI and default settings

for the recognized PAX1000 are applied.

Upon exit, the software automatically saves the most recent workspace to an XML-type file that

is located at

C:\Users\[user name]\AppData\Local\Thorlabs\PAX1000

This file contains

· the recent GUI appearance

· all measurement settings

· all PAX1000 devices that ever were connected, with their individual settings

This file is automatically updated any time the GUI is closed by the user. Please see section

Menu File for detailed information about the workspace.

Note

When powered via USB, a 50 to 100 Hz sample rate can be set. With connected external

power supply, it can be set between 50 and 400 Hz.

18

© 2019 Thorlabs GmbH15

3 Graphical User Interface (GUI)

3.2 GUI Overview

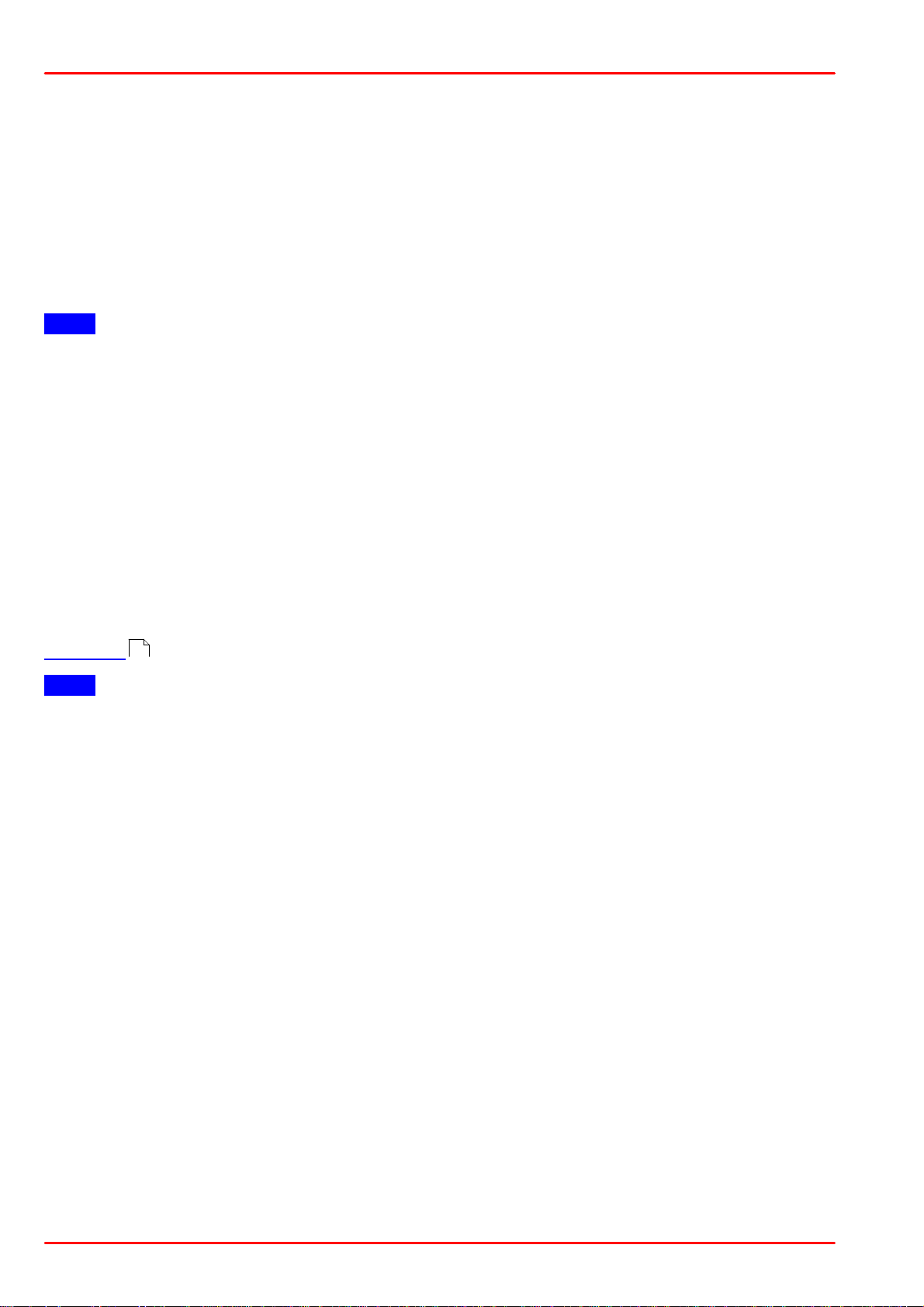

The GUI consists of a Tool Bar , several Ribbons , selectable Views (e.g. and )

and the Status Bar ( ). The ribbons can be minimized and restored using the small icon

to the right of the Thorlabs logo. Click to an area of the screenshot below to be directed to the

appropriate section for detailed information.

Functions in View panels

Each View panel has a header with five options:

· Save opens a dialog to save the content of the appropriate panel as a JPG, PNG or BMP

image file.

· Print creates a screenshot of the appropriate panel in order to print it out to any installed

system printer.

· Help opens the appropriate section in the PAX1000 software online help.

· The Pin allows to temporarily unpin the appropriate view from the GUI. Click the pin

and the Polarization Ellipse view collapses and appears like a bookmark on the left, while

the other active view (here: Poincaré Sphere) is expanded over the entire GUI:

© 2019 Thorlabs GmbH

16

PAX1000

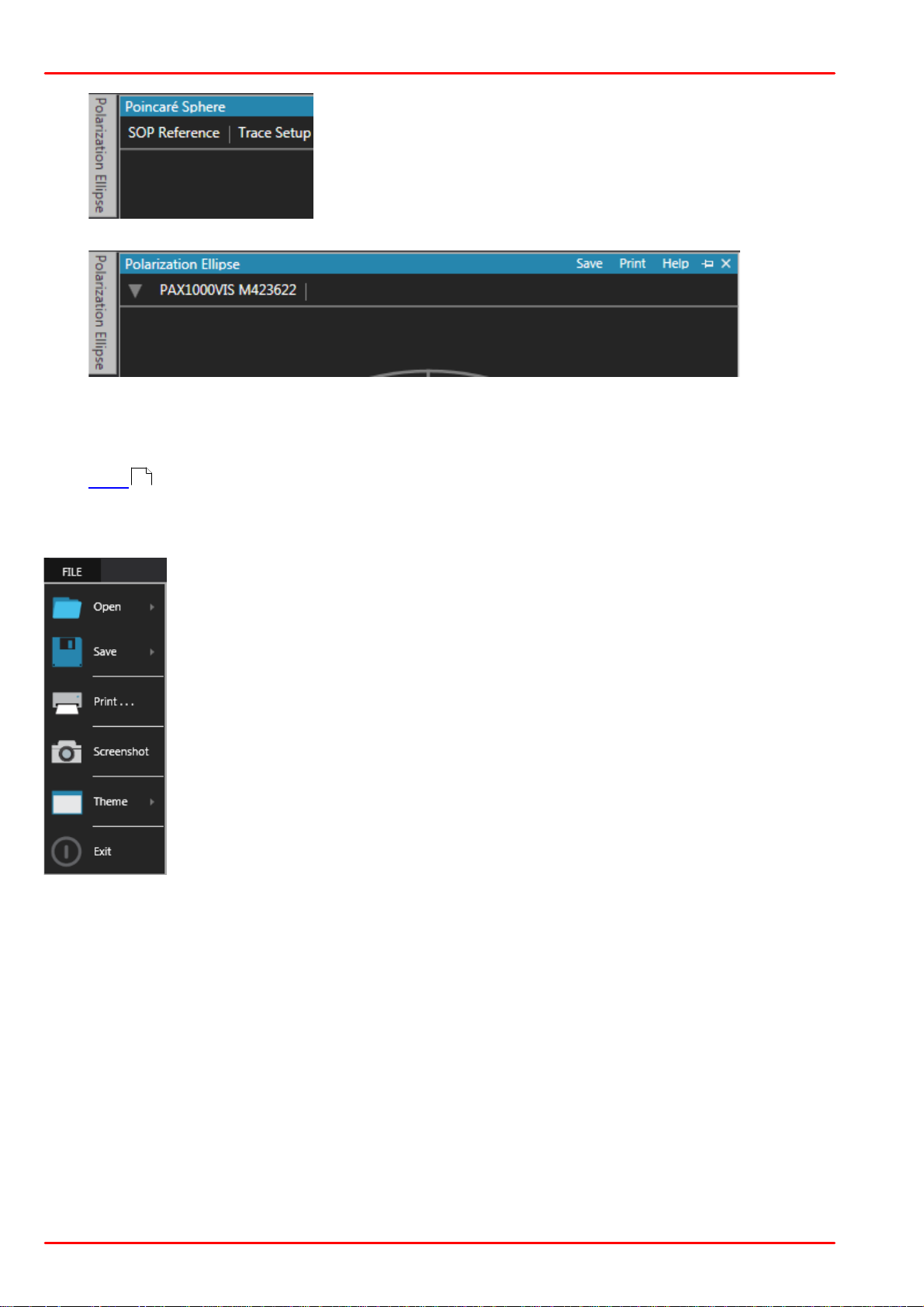

Open / Save Here you can open or save either a configuration or a measurement results file. For a detailed explanation, please see below.

Print... opens a new window with a screenshot of the actual GUI. This screenshot can be sent to any of your system printers, including PDF driver.

Screenshot creates a screenshot of the actual GUI and opens a dialog for saving this screenshot as JPG, PNG or BMP file.

Theme allows to toggle between a light or dark design of the GUI.

Exit closes the application. You can use the X icon in the upper right corner of

the GUI as well.

To recover the collapsed view, click to the bookmark and then the pin:

The collapsed view is recovered.

As all active views share the GUI area, the pin/unpin function is helpful to keep the GUI

clearly arranged and ensure a quick access to desired or often used view panels.

· The X in upper right corner allows to close the active view. They can be recalled in the

View menu by clicking the appropriate icon.

22

3.3 Menu File

© 2019 Thorlabs GmbH17

3 Graphical User Interface (GUI)

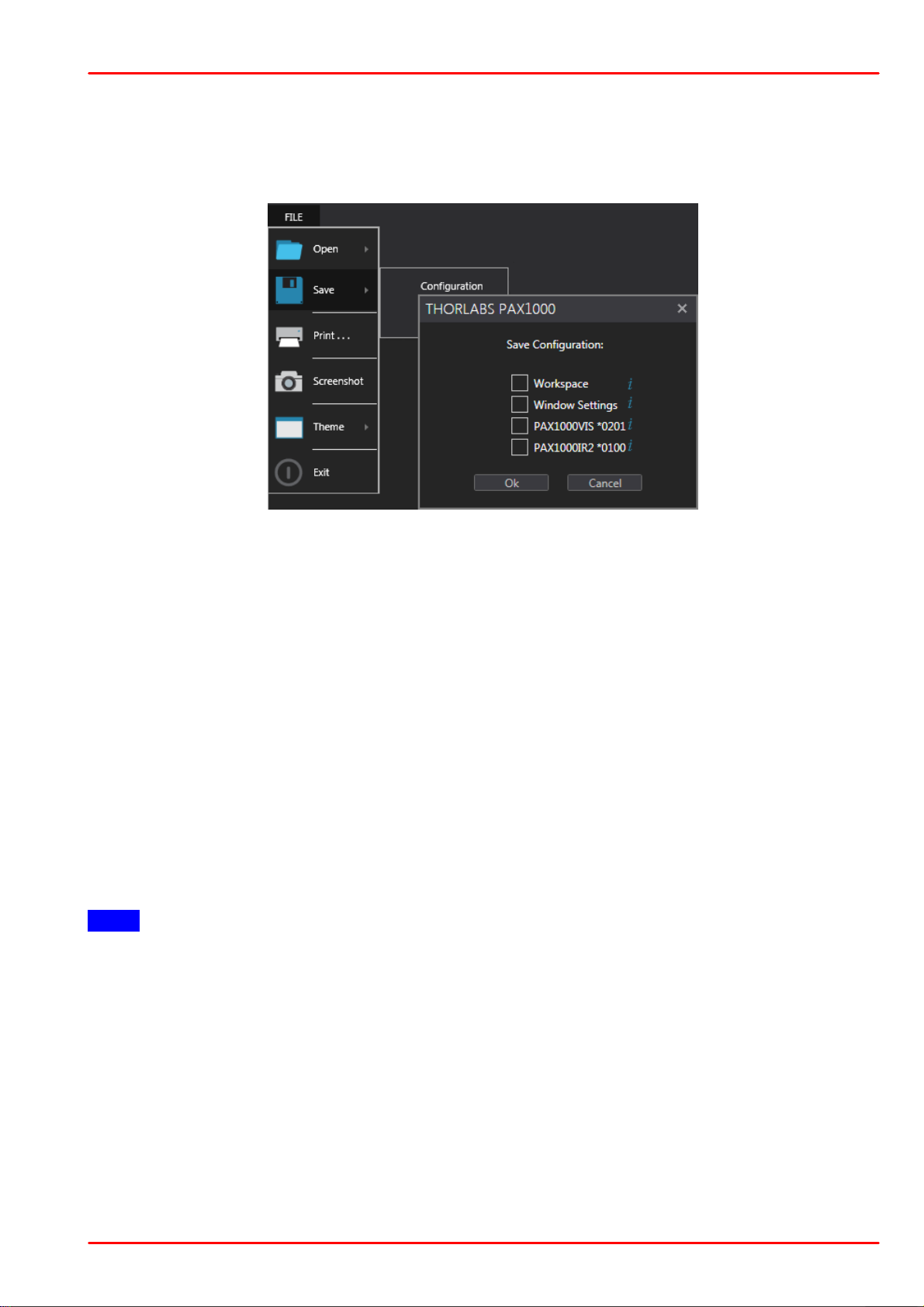

Save Configuration

This option allows the setup of the GUI and/or the connected PAX1000 polarimeters to be

saved. The saved configuration can be loaded later for use in future experiments, or with a different optical setup, or copied to and loaded into the software running on a different computer.

A configuration is an XML file, that may contain a selectable set of information and that is

saved by default to ["My Documents"]\Thorlabs\PAX1000.

From the list in the Save Configuration dialog you can select:

· Workspace saves the configuration of the GUI view, i.e., which sub-panels are displayed,

how they are located and sized.

Example: If the GUI displays only the Scope, with a single diagram expanded, selecting

Workspace will save this view.

· Window Settings saves the size, position and color theme of the GUI main window.

Example: You are using two monitors in extended mode, and you the GUI was placed to

the extension monitor with a certain size. Using the Window Settings, this arrangement

will be saved.

· PAX1000xxx saves:

- Device settings and device information of the connected PAX1000.

- All actual settings of the Measurement Value Table, Polarization Ellipse, Poincaré

Sphere, Scope Mode and ER Measurement.

After selecting any of above options, a dialog opens to save the configuration file.

Note

Please assign an appropriate file name that tells you about the file content, because you can

load afterwards just the entire configuration file, without any option to select workspace, window

setting or device setting!

© 2019 Thorlabs GmbH

18

PAX1000

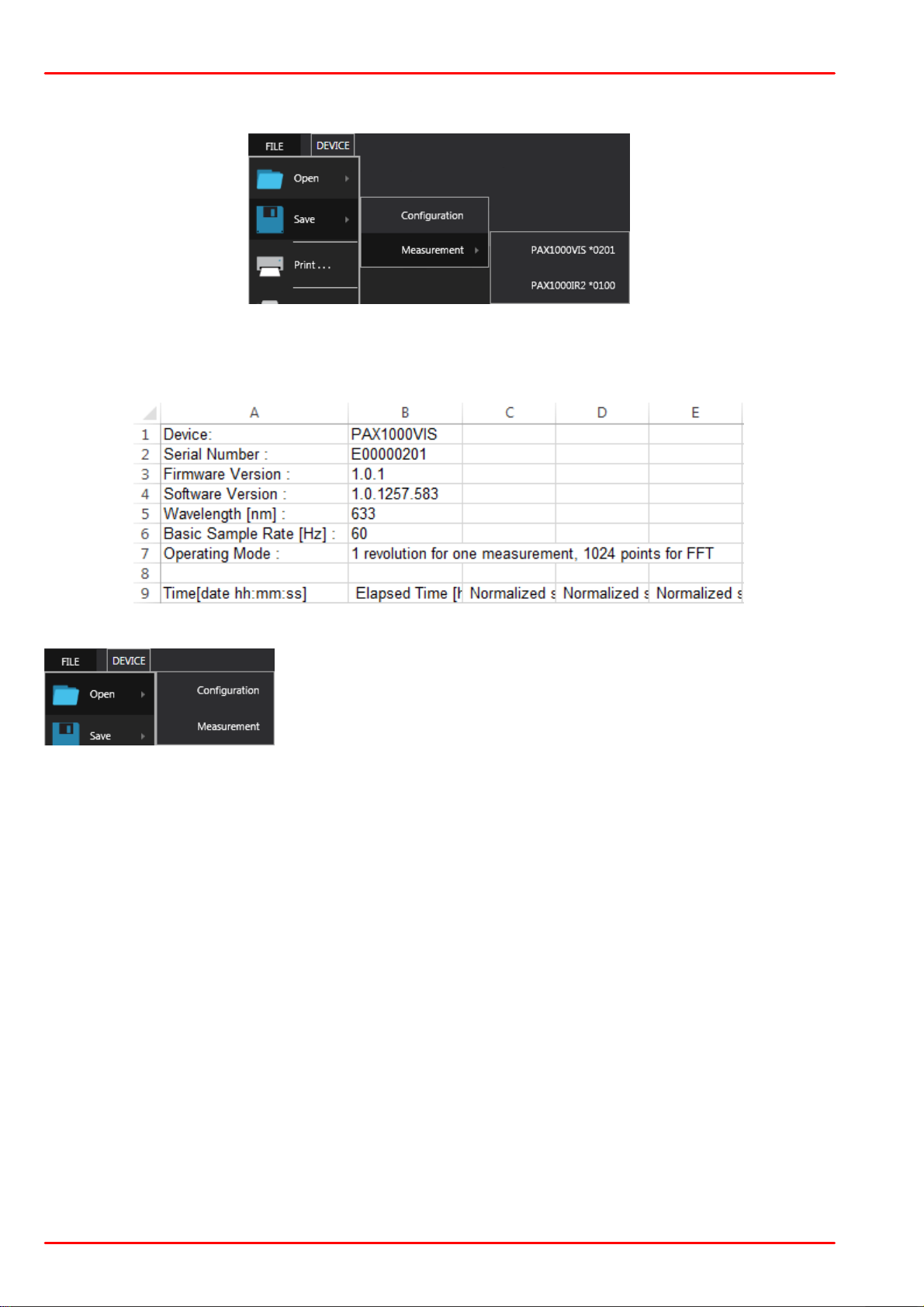

Save Measurement

The Measurement file is an CSV file that contains:

· Device settings and device information of the PAX1000 that was used for measurement.

· The most recent 1000 measurement results with time stamp.

Open

Here you can open a previously save configuration or a measurement results file.

© 2019 Thorlabs GmbH19

3 Graphical User Interface (GUI)

3.4 Menu Device

Scan USB

Use this button to rescan all USB Ports in the case the connection was interrupted or an

additional PAX1000 was connected during the session.

Note The PAX1000 software is able to connect up to five PAX1000 device per session, see

also Multiple Devices .

Add Virtual Device

43

Virtual devices can be used to test the software features without a PAX1000 hardware

43

connected, for example for evaluation purposes.

Devices & Measurements

A dialog opens that shows presently connected PAX1000 instruments

and opened long-term measurement files. This way, an instrument can

be disconnected and/or a measurement can be closed - just click on

the entry.

Device Settings (Polarimeter)

This dialog lists the PAX1000 device information (read-only)

and adjustable settings (within framed boxes).

The icon in the header shows information about connected

devices and loaded measurements and allows a selection.

Device Information

Model version, serial number, firmware version and external

power supply status.

Settings

The Basic Sample rate is based on the rotation speed of the

waveplate, while the Operating Mode defines measurement

averaging and resolution. Please see section PAX1000 Set-

tings for detailed explanations of the parameters Basic

24

Sample, Sample Rate and Operating Mode.

Wavelength: Enter the operating wavelength to the best

known accuracy. This is mandatory for correct measurements. The allowed value range is

shown when hovering the mouse over the icon.

Power Range: The PAX1000 has a large input power dynamic range of 70 dB. To achieve a

high measurement accuracy, a switchable gain amplifier is used. Each gain value corresponds

© 2019 Thorlabs GmbH

20

PAX1000

to a certain maximum input power. By default, the gain is switched automatically (box "Auto

Power Range" is checked). In particular cases it might be useful to fix the power range - uncheck the box and set the power range then manually.

Device Color: Select a color for the selected PAX1000 instrument. This color will be used for

Polarization Ellipse and Poincaré Sphere display of the measurement data. For each connected and active PAX1000 a different color is assigned that can be changed individually.

Button Default

This button resets the device settings of the selected PAX1000 to default:

· Operating wavelength depending on the device type:

PAX1000VIS: 633 nm

PAX1000IR1: 980 nm

PAX1000IR2: 1550 nm

· Basic Sample Rate to 60 Hz

· Operating Mode to 1 (1024 pts FFT)

· Power Ranging to Auto

· Device Color to Blue

· Power Unit to dBm.

Device Settings (Measurement)

This dialog lists the settings of the PAX1000 device when the loaded measurement was executed.

Only the settings within the framed boxes can be changed, these

are Device Color and Power Unit.

Reset All

Resets both the GUI and the active PAX1000 settings to default:

The GUI shows the ribbon device with the Polarization Ellipse and the Poincaré Sphere

pane, while the PAX1000 device settings are reset to factory defaults .

21

Pause / Run

This toggle icon allows to pause and resume the current data acquisition from the

PAX1000 with the displayed below serial number.

© 2019 Thorlabs GmbH21

3 Graphical User Interface (GUI)

3.5 Menu View

Click to an icon in the above shown screenshot to view the appropriate manual section.

Reset Layout

This button resets only the GUI layout:

· Polarization ellipse with numerical values for azimuth and ellipticity

· Poincaré sphere in default view (H (horizontal SOP) in front); clears all traces, clears

marker circle

There is no impact on device settings (e.g., wavelength) and measurement settings (e.g., SOP

references remain).

3.6 Menu Tools

Click to an icon in the above shown screenshot to view the appropriate manual section.

3.7 Menu Help

Troubleshooting

Contact Technical Support opens Thorlabs' web site

with the list of world-wide contacts.

Save Logfile: This file logs the most recent 5 software

sessions. It might be helpful to attach this file to a Tech

Support request.

System Info: Displays the Windows System Information about the used PC.

PAX1000 Help

Click this button to open the online help. When pressing the F1 key, the online help opens with

the section of the currently active view (context sensitive help).

© 2019 Thorlabs GmbH

22

PAX1000

Product License

Opens the License.rtf file.

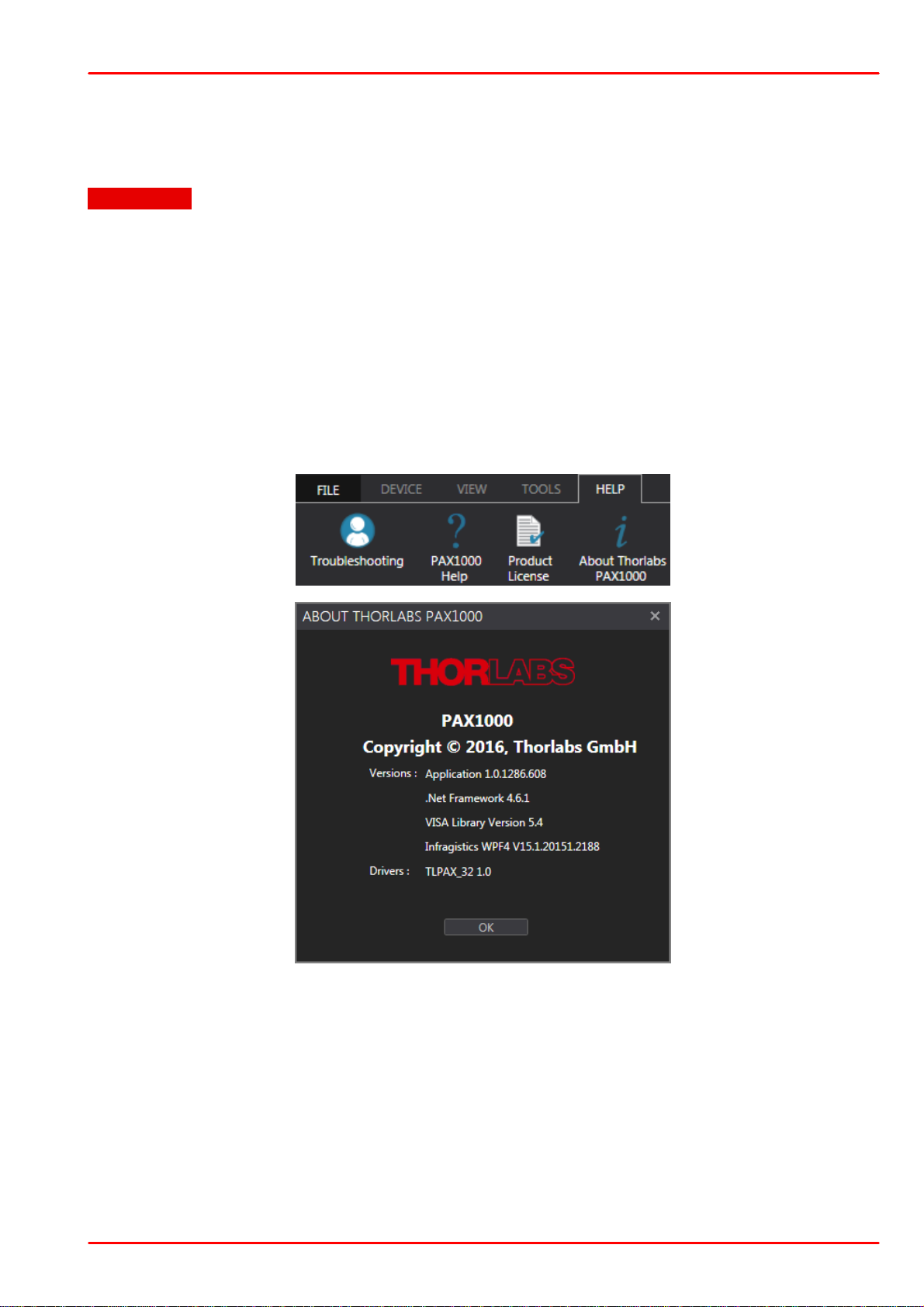

About Thorlabs PAX1000

Displays information about the current PAX1000 software.

3.8 Status Bar

By default, the status bar displays only the actual date and time:

It is used to indicate common errors as well as information about long-term measurement (LtM)

progress and errors that were observed during the current LtM session:

Please see section Error Messages for detailed explanations.

51

© 2019 Thorlabs GmbH23

4 PAX1000 Settings

4 PAX1000 Settings

Prior to explain PAX1000 Setting, lets shortly recapitulate the

measurement procedure that is discussed in detail in section

Rotating Waveplate Technique :

The PAX1000 uses a rotating quarter waveplate for polarization analysis.

A half turn of the waveplate is sufficient to uniquely determine

the state of polarization. The parameter Basic Sample rate is

always related to this half-turn.

The photo current measured during this half turn is analyzed

by a Fast Fourier Transformation (FFT). By default, the FFT

"splits" the data into 512 measurement points (ADC values).

In order to increase the measurement accuracy:

· the number of FFT points can be set to 1024 or 2048;

· the FFT can be carried out over a full turn or over 2 full turns

of the waveplate.

The parameter Operating Mode reflects that:

67

For example, the operating mode "1/2 (512 pts FFT)" means, that the data for calculation are

collected per 1/2 revolution of the waveplate (number of basic periods = 1/2), and the FFT is

carried out on 512 points (number of AD converter values) within this half turn. So, the resulting

sample rate or measurement speed can be written

Mathematically, the number of points used for FFT does not impact the measurement speed.

The more FFT points are used, the higher the measurement accuracy, but the higher is also

the workload of the microcontroller. Particularly, at high measurement speed and high FFT resolution, measurement data might be not captured because the microcontroller is busy with FFT

calculation.

Recommendations

For fast measurements use a high basic sample rate, a small operating mode value and fewer

FFT calculation points. At this setting, measurement accuracy might be impacted.

When measuring an optical signal at low power power or with significant noise, decrease the

basic sample rate, increase the operating mode and use more FFT points.

Note

When the PAX1000 is powered via USB only, the Basic Sample Rate can be set between 50

and 100 Hz. With external power supply, the maximum Basic Sample Rate is 400 Hz.

© 2019 Thorlabs GmbH

24

PAX1000

5 Operating Instruction

5.1 Alignment Assistance

For accurate measurements, it is essential to align the incident beam so that it is centered in

the input aperture and is normally incident on the rotating l/4 waveplate.

The beam centering is particularly important in the case of large incident beam diameters, close

to the aperture diameter ( Ø 3.0 mm). In such cases the correct centering is essential to avoid

beam cutting and reflections from the inner surface of the hollow shaft that holds the waveplate.

The beam centering can be achieved by using the protection cap with engraved cross-hair

(PAX1000VIS) or with a viewing target (PAX1000IR1 and ~IR2).

The angular alignment is critical for another reason: As explained in the section Rotating Wave-

plate Technique , the photo current is analyzed by a Fast Fourier Transformation and ideally

consists only of even-numbered components (harmonics). If the beam hits the waveplate not

exactly perpendicular, unwanted odd-numbered harmonics will appear in the photo current. The

same happens, if the incident beam consists reflected from the inner surface of the hollow shaft

light components. These unwanted components have a significant impact on the measurement

accuracy. The Alignment Assistance tool can be used to align the beam, which will minimize

the contribution from unwanted components.

67

Click the icon in the Tools ribbon. A new screen comes up.

22

The Alignment graph shows the fraction of wanted components in the photo current. The green

portion of the scale defines the range of acceptable alignment values. Click the Start Alignment

button.

Adjust the alignment of the beam with respect the PAX1000 beam. When the best alignment is

achieved, click Stop Alignment and close the window.

© 2019 Thorlabs GmbH25

5.2 PAX1000 Measurements

Note

5 Operating Instruction

Prior to starting a measurement, please make sure that the device settings are entered prop-

20

erly. Particularly, the correct wavelength and power ranging (preferred setting: Auto Range) are

essential for accurate measurement results.

The PAX1000 software provides several polarization measurement views that can be called

from the View ribbon. If this ribbon is hidden, please click the small arrow next to the Thorlabs

logo (marked yellow):

These views are described in detail in the subsequent sections:

· Measurement Value Table

· Polarization Ellipse

· Poincaré Sphere

· Scope Mode

31

29

29

· Long Term Measurement

· Extinction Ratio Measurement

27

34

36

The Reset Layout button resets the GUI layout to:

· Polarization ellipse with numerical values for azimuth and ellipticity

· Poincaré sphere in default view H (horizontal SOP) in front; clears all traces, clears

marker circle

There is no impact on device settings (e.g., wavelength) and measurement settings (e.g., SOP

references remain).

© 2019 Thorlabs GmbH

26

PAX1000

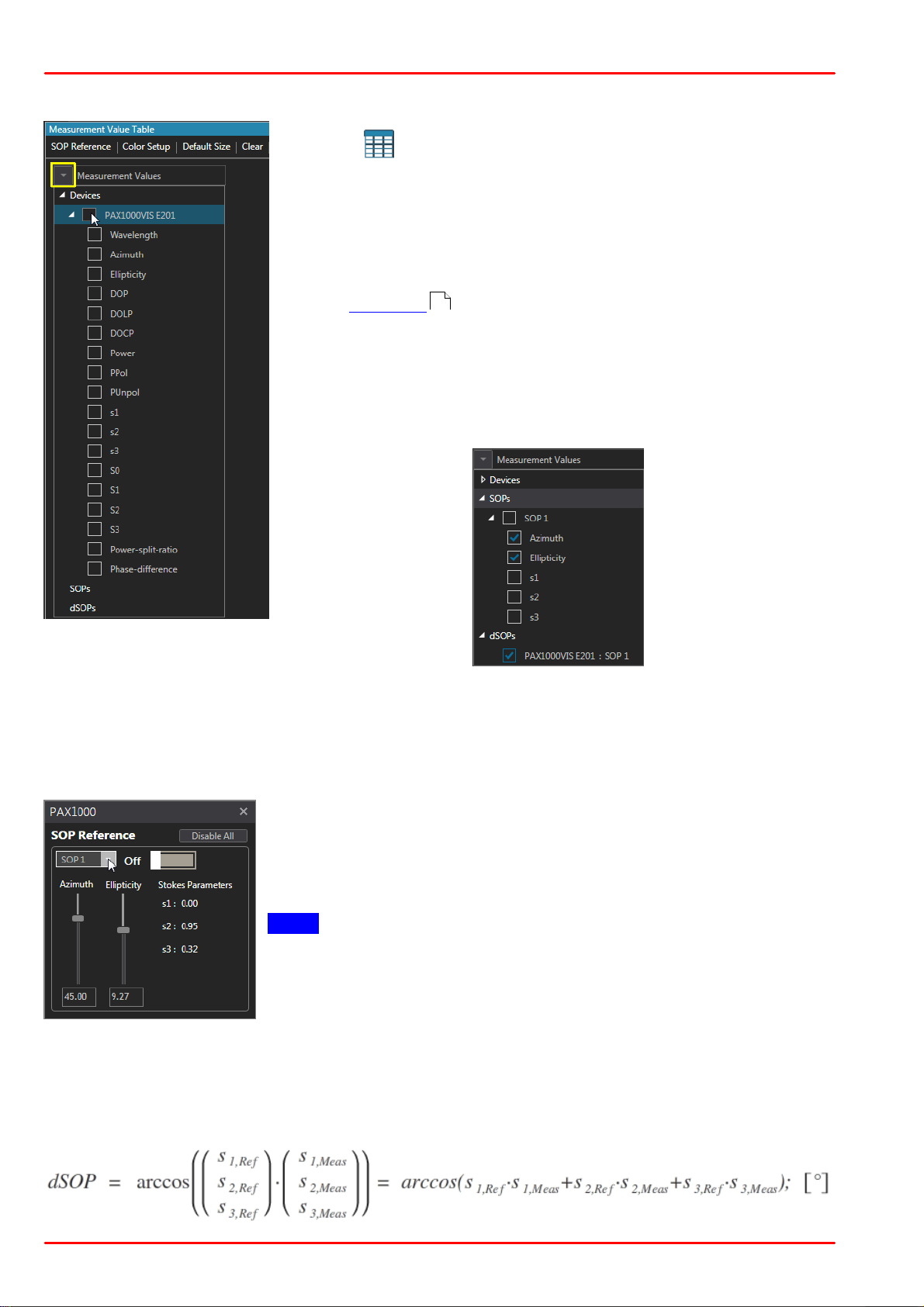

5.2.1 Measurement Value Table

Click the icon to show the Measurement Value Table. It displays a selectable number of polarization parameters numerically

in a list. Click the drop-down arrow (marked yellow) to expand the

list and select the desired parameters. When checking the box of

the active PAX1000, all parameters will be enabled, with the possibility to disable any of them.

For detailed explanation of the polarization parameters, please

see the Appendix .

If more than one PAX1000 is connected and active, this selection

can be made for each of these devices.

If at least one SOP Reference is enabled, you can select the polarization parameters of the reference that shall be displayed numerically, as well as the dSOP:

65

A SOP reference is a certain, user-configurable state of polarization that can be used as a reference point. In combination with the dSOP parameter, this allows to measure the polarization

shift of the actual state of polarization from the reference point.

Up to 20 reference SOPs can be defined.

Click to the menu item SOP Reference. A dialog opens:

Select from the drop-down menu one of SOP 1 to SOP 20.

Define the azimuth and ellipticity for this reference point, either by

using the slider or by entering the desired value numerically. The

software automatically calculates the appropriate normalized Stokes

vectors.

Note The Stokes vectors cannot be entered by the user.

Set the switch from Off to On to enable the actual SOP reference.

The Disable All button disables all SOP references at once.

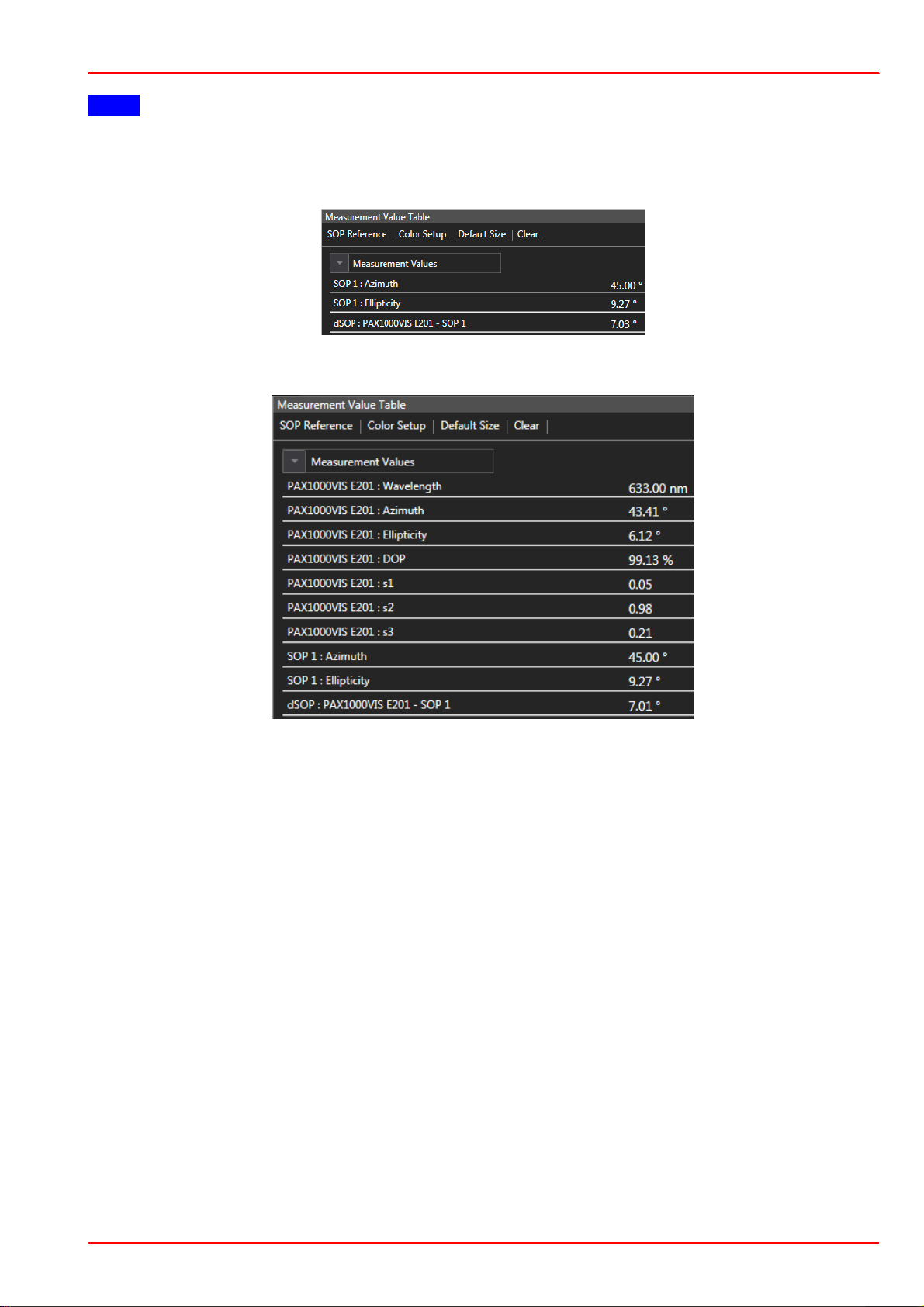

dSOP

dSOP is the difference between the actual measured SOP and a SOP reference, in degree.

This is the angle between the two polarization vectors on the Poincaré sphere. Using the normalized Stokes vectors, this can be written mathematically as:

© 2019 Thorlabs GmbH27

5 Operating Instruction

Note

Above formula takes into account that the normalized Stokes vectors with an absolute value

=1 are used for calculation.

The dSOPs will be displayed in Measurement Value Table this way:

By clicking to the area outside the parameter selection window, the parameter selection panel

closes and in the GUI will be displayed the table with measurement results:

© 2019 Thorlabs GmbH

28

PAX1000

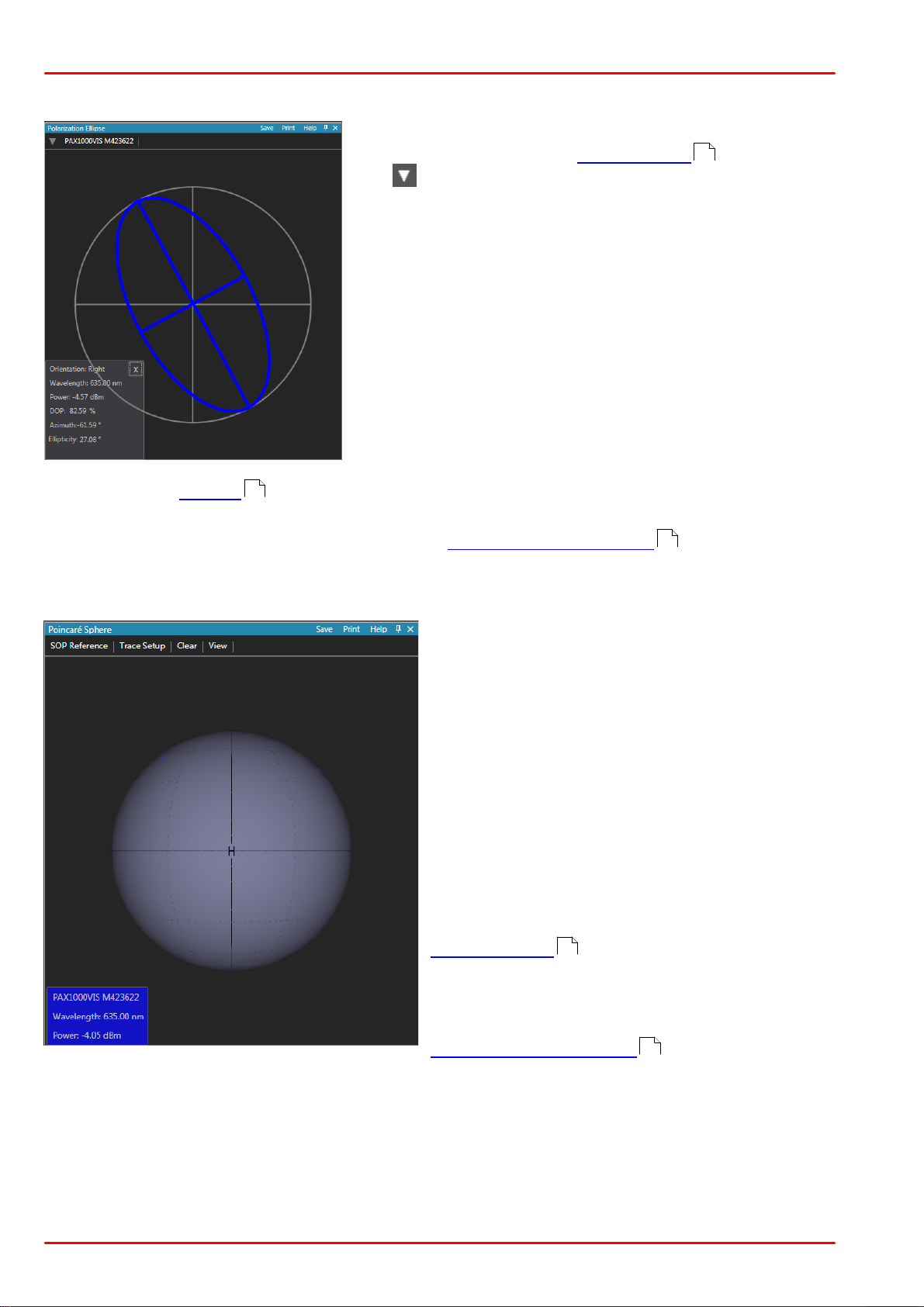

5.2.2 Polarization Ellipse

In this view, the polarization ellipse is displayed. The ellipse color depends on the device setting .

21

The icon in the left upper corner allows to select one

of the connected polarimeters for display.

Below the ellipse, a box with numerical parameters is

shown. The first four parameters

- orientation (handedness)

- wavelength

- total power

- DOP (degree of polarization)

are shown at any time.

By clicking to the grey area, the display of the additional

parameters can be changed:

- azimuth and ellipticity, or

- power split ratio and phase difference, or

- the 3 normalized Stokes vectors s1, s2 and s3.

Please see the Tutorial for detailed information on these parameters. The numerical para-

53

meters can be hidden (X); then the small i icon will restore them.

For functions in the blue header line, please see Functions in View panels .

16

5.2.3 Poincaré Sphere

The default view of the Poincaré sphere is

shown in the screenshot.

Viewing options

· Click the colored box to show the current

SOP in front. If you have more than one

PAX1000 connected, the click shows the current

SOP of the selected device.

· Hold the left mouse button and drag to rotate

the sphere.

· Scroll the mouse wheel or press + (-) to zoom

the view.

· To move the sphere, press A (left), D (right),

W (up) or S (down).

· Press Ctrl and left mouse button to create a

SOP reference .

29

· Press Ctrl, hold down right mouse button and

drag to create a circular marker on the sphere.

For functions in the blue header line, please see

Functions in View panels .

16

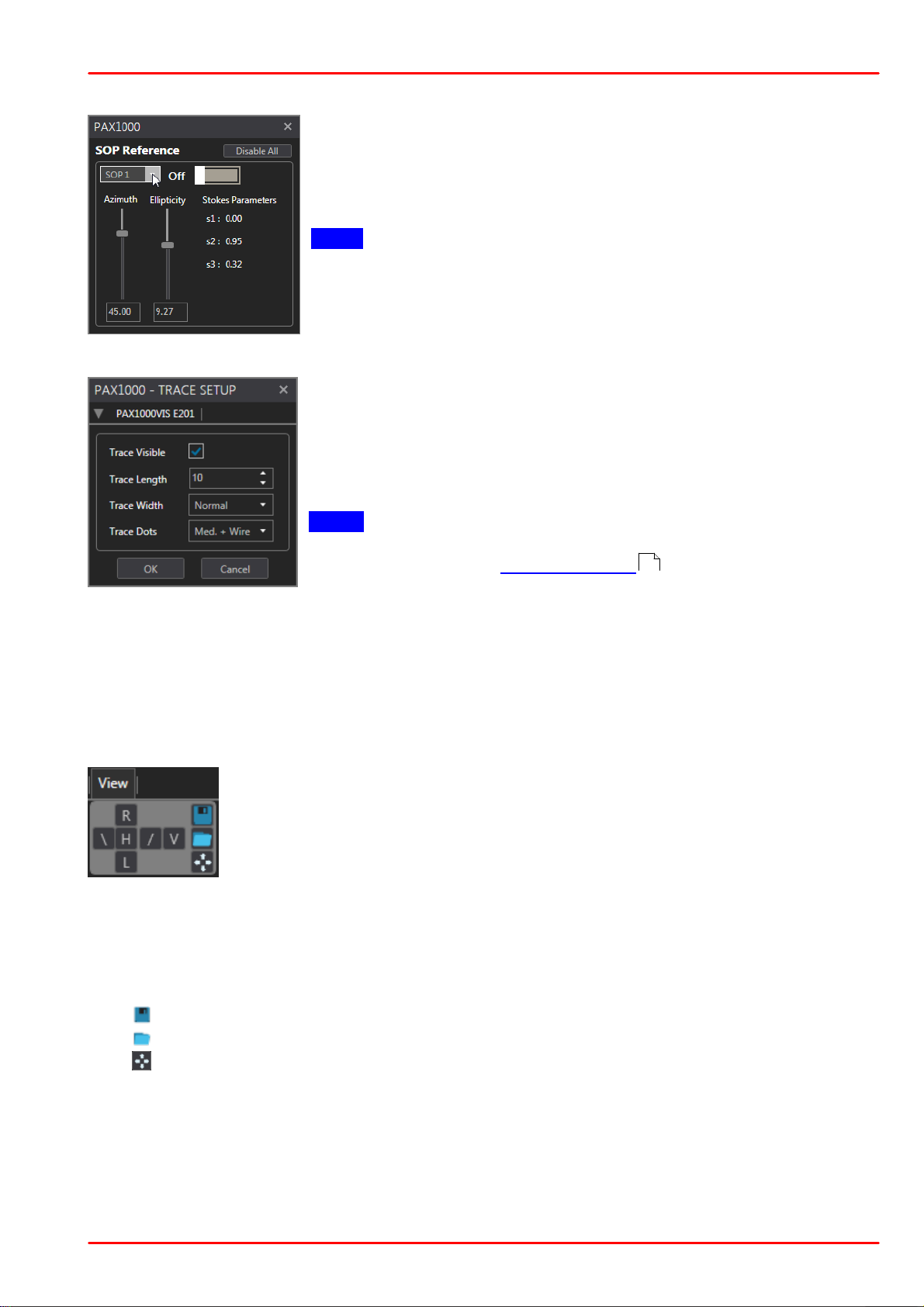

Menu SOP References

A SOP reference is a certain, user-configurable state of polarization that can be used as a reference point. In combination with the dSOP parameter, this allows to measure the polarization

shift of the actual state of polarization from the reference point.

Up to 20 reference SOPs can be defined.

© 2019 Thorlabs GmbH29

Click to the menu item SOP Reference. A dialog opens:

Select from the drop-down menu one of SOP 1 to SOP 20.

Define the azimuth and ellipticity for this reference point, either by

using the slider or by entering the desired value numerically. The

software automatically calculates the appropriate normalized Stokes

vectors.

Note The Stokes vectors cannot be entered by the user.

Set the switch from Off to On to enable the actual SOP reference.

The Disable All button disables all SOP references at once.

Menu Trace Setup

In this menu you setup the SOP trace on the Poincaré sphere.

When enabled, each SOP measurement point is added to the trace

until the selected trace length is reached. The dwell time of a trace

this way depends on the trace length and the measurement speed.

Trace Visible enables/disables the trace display.

Trace Length Values between 1 and 50,000 can be entered.

Note : The maximum trace length is limited for memory load reas-

ons and it is available only in case of a single device is connected.

Please refer to section Multiple Devices .

Trace Width can be selected to thin, normal and bold.

Trace Dots Select the shape of the trace:

- small, medium or large dots only

- small, medium or large wired dots, or - wire only.

5 Operating Instruction

43

Click OK to apply settings and close the panel.

Menu Clear Clears the trace. SOP references remain.

Menu View

Adjust, how you want to look at the Poincaré sphere.

H and V rotate the sphere to bring the equatorial points corresponding to the

linear horizontal and vertical polarizations, respectively, to the front.brings the

horizontal resp. vertical point (linear horizontal/vertical polarization) on the

sphere's equator to the front.

R and L rotate the sphere to bring the polar points corresponding to the right or left handed circular polarizations, respectively, to the front.

Finally, \ and / rotate the sphere to bring the points corresponding to an azimuth of -45° and

+45°, respectively, to the front.

The 3 buttons to the right provide the following functions:

· Saves the current Poincaré sphere orientation and zoom factor as user view..

· Recalls the saved user view.

· Resets the zoom to default, all other view settings are not impacted.

© 2019 Thorlabs GmbH

30

PAX1000

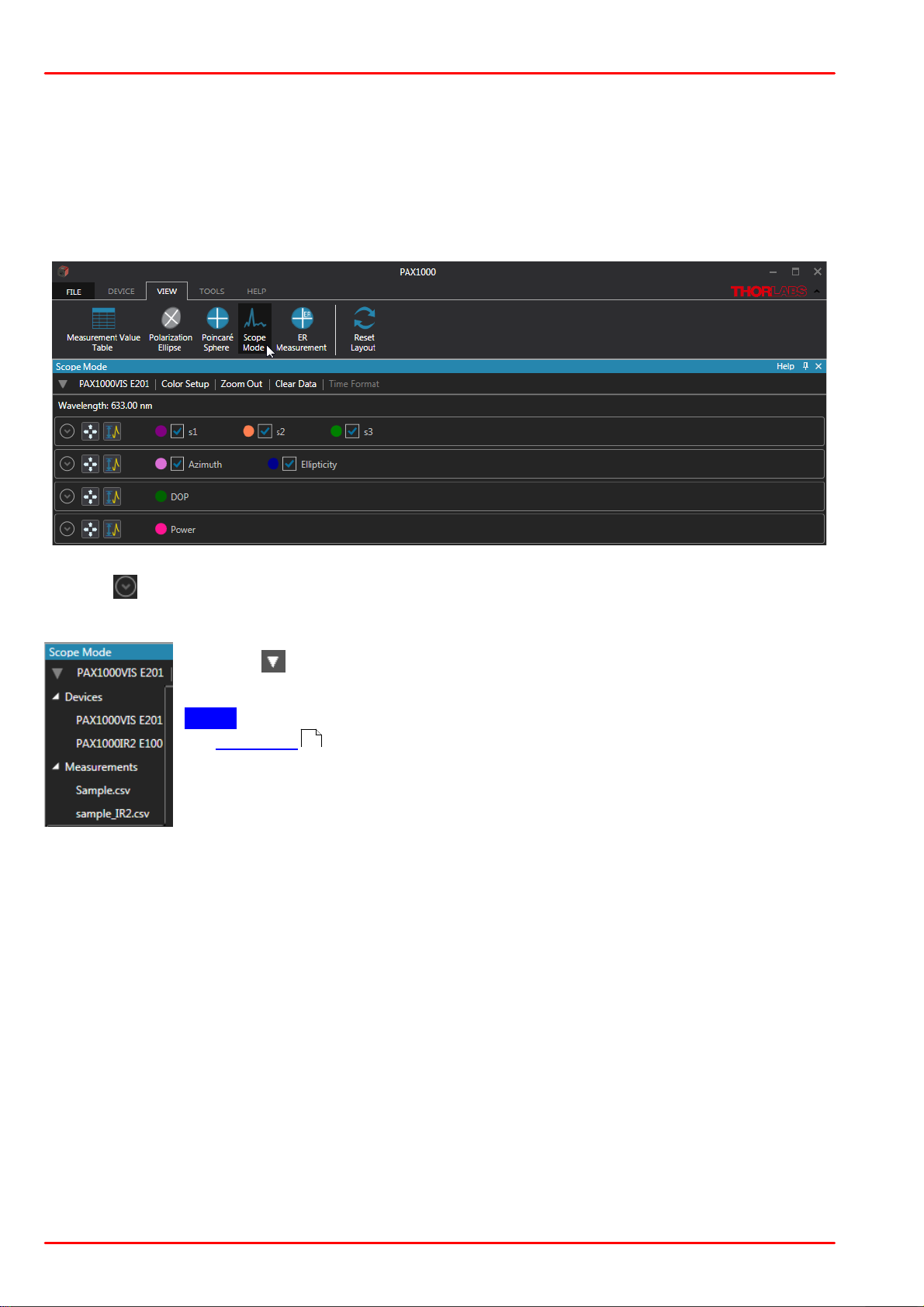

5.2.4 Scope Mode

In Scope Mode, the 1000 most recently measured polarization parameters are shown plotted

to a graph. The graph can be continuously updated as values are acquired. The data logging

· starts with the connection of a PAX1000 device

· restarts after pressing the Clear Data button.

Select from the View ribbon the item Scope Mode.

In the initial view shows four parameter groups, with the display of the scope graphs collapsed.

Use the icon to show the desired diagram.

Select Data Source

Click the icon and expand Devices and/or Measurements to select a data

source.

Note In order to select a saved measurement, it must be opened first from

the File menu !

17

Color Setup This menu assigns the color to the individual graphs. Select your preferred color.

Clear Data deletes the accumulated measurement value and restarts the display. The time axis

is then zoomed until the maximum of 1000 measurement values is reached. After reaching

1000 samples, the diagram shows the most recent 1000 samples, i.e., with each new sample,

the oldest is discarded, and the times axis shifts.

Time Format: If a measurement is loaded and selected for display, the time format can be

toggled between time stamp and elapsed time. For running measurements (a PAX1000 is selected), only the time stamp is used.

© 2019 Thorlabs GmbH31

5 Operating Instruction

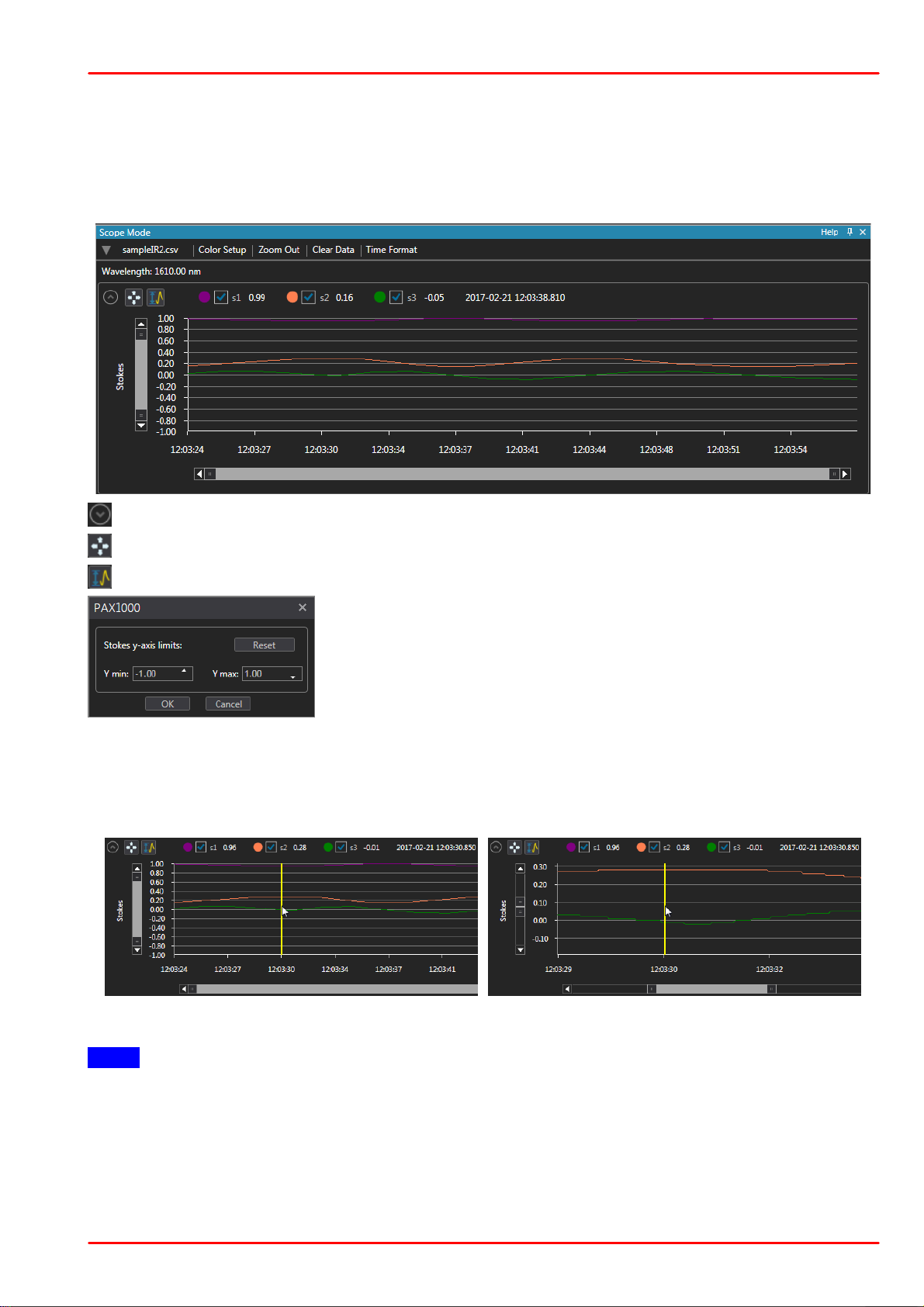

Hover the mouse pointer over the diagram area ...

... and scroll the mouse wheel

Diagram Options

Each of the four diagrams can be modified for the best view. Additionally, for the first two diagrams (normalized Stokes vectors; ellipticity/azimuth) you can select the parameters to be displayed. The diagram options are explained below using the example of the Stokes vectors diagram with a saved measurement loaded from a file.

Toggle the diagram view between expanded and collapsed.

Expand the diagram over the entire GUI window by hiding the other 3 charts.

Set the upper and lower limits of the Y scale:

Set the desired limits either by entering numerically or using the

up/down arrows.

Click OK to apply changes.

Click Reset to restore the scale limit to the maximum in accordance with the actual parameter.

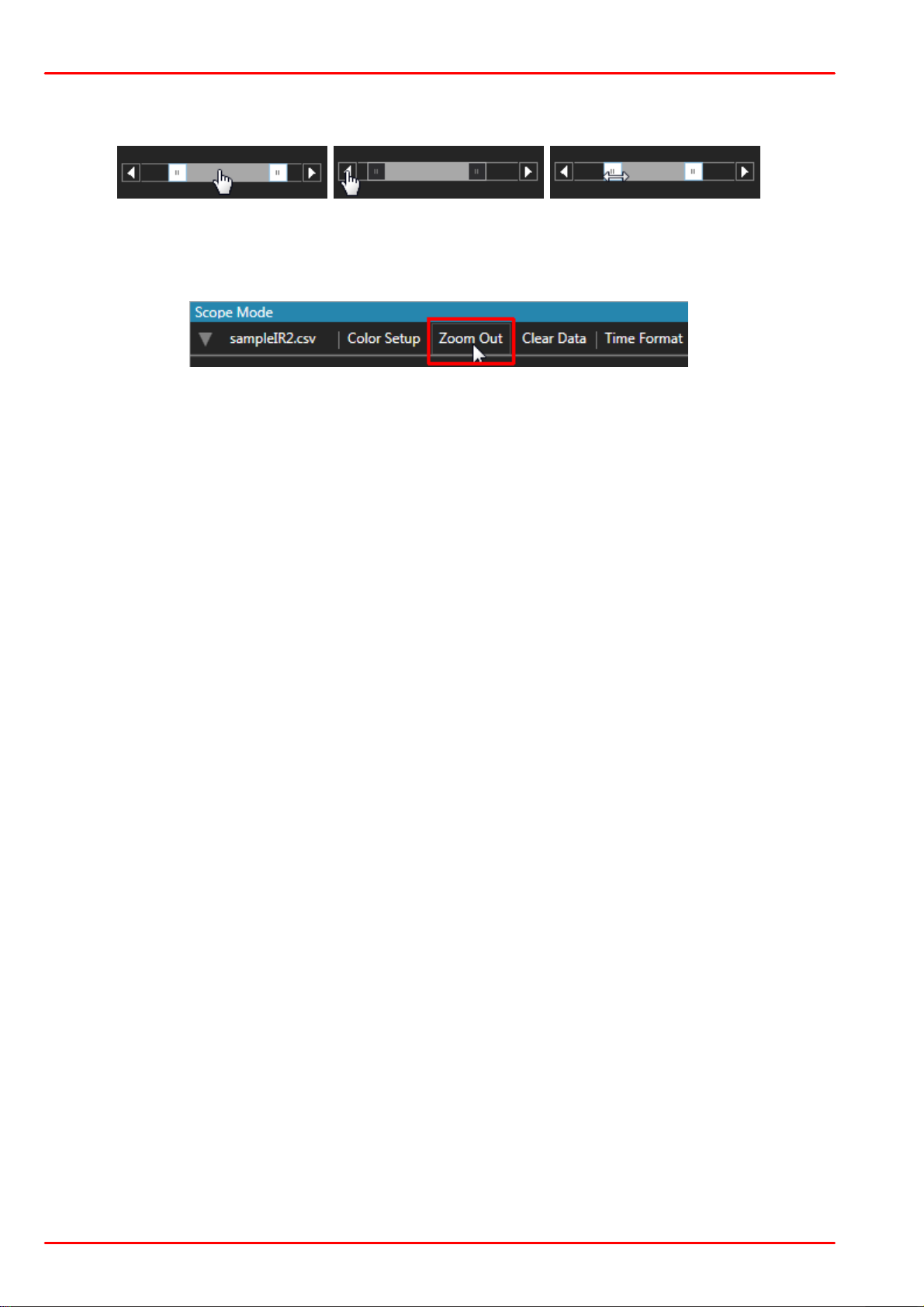

Zoom and Pan

Place the mouse pointer to the point in the diagram that you want to zoom in. A yellow marker

appears. Scroll the mouse wheel and the diagram will be zoomed in around the moose pointer

in both the Y and time scale directions:

Note

The yellow marker appears instantly when hovering the mouse over the diagram only if a loaded measurement is displayed.

In live mode, when the measurement of a PAX1000 is displayed, the yellow marker appears

only after the mouse wheel was rotated. Then the display of the current measurement is

paused and the diagram can be zoomed.

© 2019 Thorlabs GmbH

32

PAX1000

Pan Diagram

Pan Diagram

Zoom Diagram

Another way to zoom and pan the diagram is the use of the zoom-pan-sliders to the left and below the chart:

Using the Zoom Out button in the diagram header, you can instantly return to the full diagram

view:

© 2019 Thorlabs GmbH33

5.2.5 Long Term Measurement

The LTM buttons can be found in the Tools ribbon.

The long-term measurement tool records the following parameters:

· Stokes vectors S0, S1, S2 and S3 [mW]

· Normalized Stokes vectors s1, s2 and s3

· Azimuth [ ° ]

· Ellipticity [ ° ]

· Degree of polarization [ % ]

· Degree of linear polarization [ % ]

· Degree of circular polarization [ % ]

· Total power [ mW / dBm ]

· Polarized power [ mW / dBm ]

· Unpolarized power [ mW / dBm ]

· Power split ratio

· Phase difference

5 Operating Instruction

Each set of above listed parameters is provided with the exact time stamp (dd.mm.yyy

hh:mm:ss) and the elapsed time with millisecond resolution (d.hh:mm:ss:msec). The recorded

file format is *.csv and can be easily imported to Microsoft Excel. Alternatively, the data can be

saved as a *.txt file.

5.2.5.1 Settings

Prior to starting a long-term measurement, open the LTM

Settings panel and enter the measurement conditions.

1. Select a folder, the file name and file format.

2. Select the sampling frequency.

Options:

· Set the sample acquisition time interval to a value from

50 ms to 60 s in increments of 1 ms.

· Specify which measurements to record to file, with a value of 1 recording every measurement and a maximum value of 10000 recording every 10000th measurement.

3. Select the Stop criteria:

· after reaching a file size between 0.1 and 1000 MB

· after reaching a record time 10 sec and 365 days

23:59:59 hours

· after recording 1 to 10000 measurement data sets

© 2019 Thorlabs GmbH

34

PAX1000

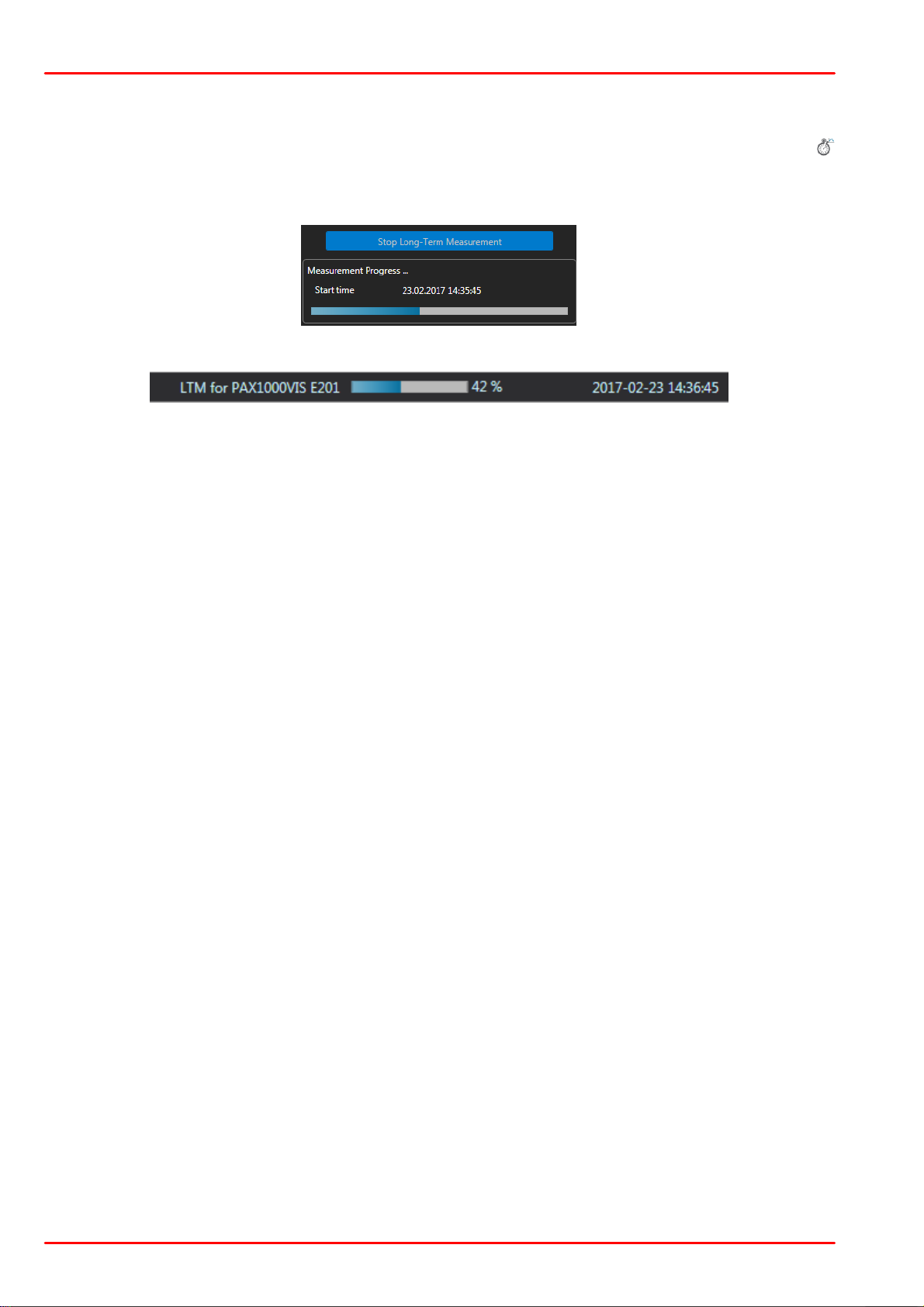

5.2.5.2 Measurement

After completing the desired settings for your long-term measurement, the recording can be

started by pressing the Start Long-Term Measurement button in the settings panel or the

button in the ribbon Tools.

The measurement progress is shown in the settings panel

and in the status bar on the bottom of the GUI:

© 2019 Thorlabs GmbH35

5 Operating Instruction

5.2.6 Extinction Ratio Measurement

The PAX1000 allows the measurement of the Extinction Ratio (ER) of polarization maintaining

fibers (PMF). Please see the section Extinction Ratio Measurement on PM Fibers for theory

and basics.

Measurement Setup

For correct ER measurements, a linearly polarized light source is mandatory. This can be a pigtailed laser diode with a PMF output fiber, or a free space laser combined with a fiber coupler

and a Thorlabs Fiber-To-Fiber U-Bench or a manual fiber polarization controller.

The DOP (degree of polarization) of the light source should be as close to 100% as possible.

Also, the operating wavelength must be well known, and the optical power must not exceed the

specification of the PAX1000.

It is important to couple the linearly polarized light parallel to the slow axis of the fiber under

test.

The output of the fiber under test is connected to the PAX1000 using the supplied fiber collimator with the SM1 adapter.

Note

73

The F240FC-x collimator is designed for FC/PC connectors. If your fiber under test has an

angled connector (FC/APC), please purchase a Thorlabs F240APC-x collimator.

"x" stands for the operating wavelength range of the anti-reflective coating and must match with

your PAX1000 and the operating wavelength of your setup.

The fiber under test must be dynamically stressed while the ER measurement is performed.

Below, an example of an ER Measurement Setup is shown:

The optical test signal is generated by a DFB laser diode. Its output is connected to a Thorlabs

GmbH PL100S deterministic polarization controller. The PMF under test (fiber with blue jacket)

© 2019 Thorlabs GmbH

36

PAX1000

is connected to the output of the polarization controller and the input of the polarimeter (the discontinued polarimeter model PAX5720 is shown).

The fiber is heated when the filament bulb in the center of the looped fiber is turned on, which

stresses the fiber. However, the stress can also be applied mechanically, e.g. by pulling the

fiber manually.

Note

The mentioned above stress methods are applicable only to PMF without tubing!

During measurement, i.e., when the fiber is stressed, the PMF output SOP (State of Polariza-

tion) describes a circle on the Poincaré Sphere. For reliable ER Measurement results, at least a

full circle must be drawn (i.e. the stress must vary enough during the test to result in this minimum change in polarization state).

© 2019 Thorlabs GmbH37

5 Operating Instruction

5.2.6.1 ER Measurement Wizard

The ER Measurement Wizard guides you through the preparation and measurement step by

step.

Note

If you are already familiar with this measurement, you may use the ER Measurement tool

41

directly.

Open the ER Measurement Wizard from the Tools menu.

The Start Window summarizes how to set up the measurement. Additional details are given in

the previous section .

36

If necessary, select the PAX1000 for measurement, then click .

© 2019 Thorlabs GmbH

38

PAX1000

Enter the operating wavelength of your light source and select the desired measurement time.

Select the option Stop on Circle Completed, which will terminate the measurement as soon

as the SOP change reached a full circle.

When done, click .

The current SOP is displayed on the Poincaré Sphere. Click to proceed.

© 2019 Thorlabs GmbH39

5 Operating Instruction

Save the numeric test results and the Poincaré Sphere screenshot to a PDF file.

Return to the previous window.

Close the ER Measurement Wizard and return to the PAX1000 GUI.

After finishing the measurement, above final screen appears.

Please see the Tutorial in the appendix for detailed explanation of the options Compensate El-

lipticity and Compensate DOP .

Please see next section for detailed explanations of the numerical results.

If a warning or an error message appears, please see section Troubleshooting for possible

75 76

42

52

reasons and solution proposals.

© 2019 Thorlabs GmbH

40

PAX1000

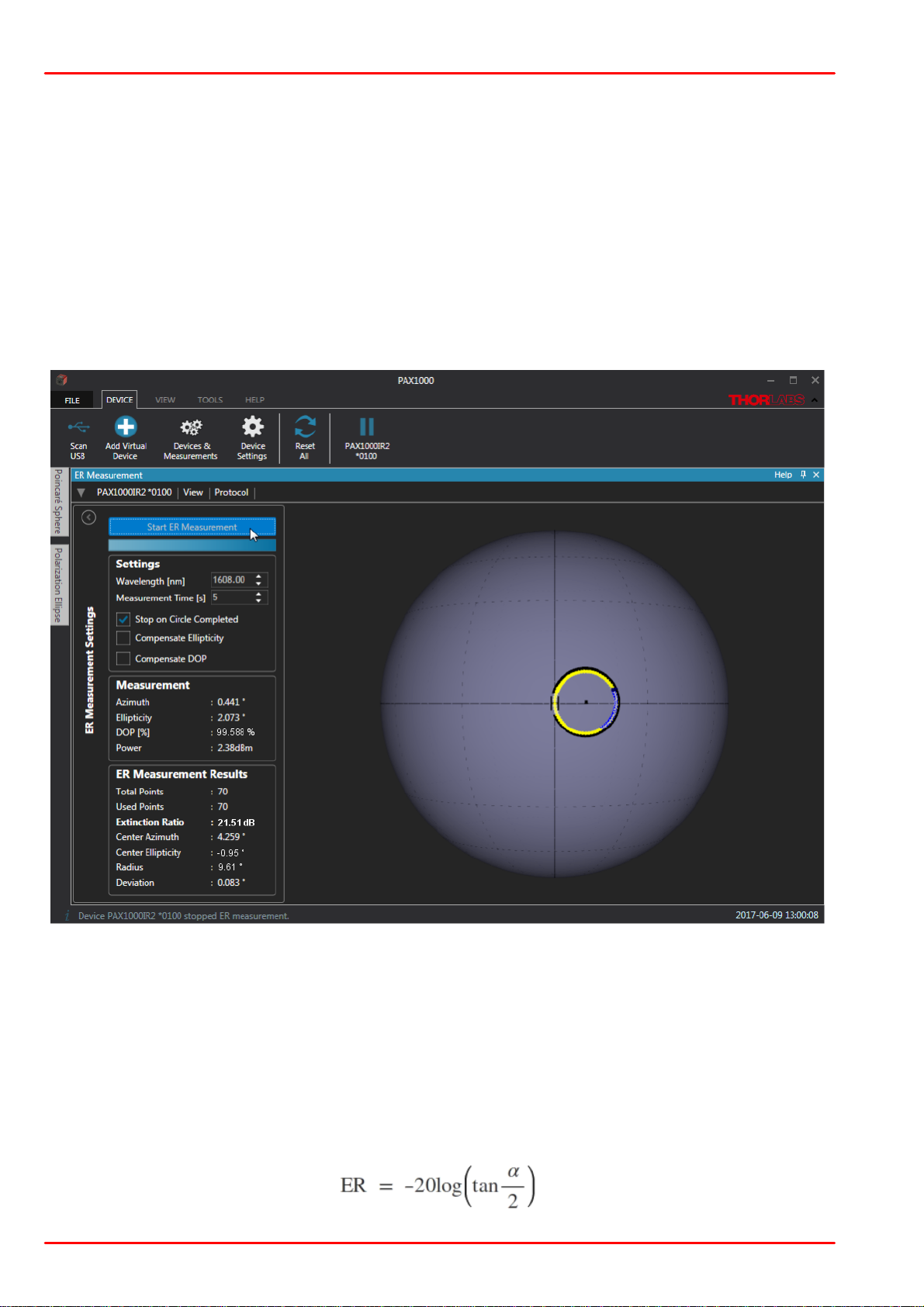

5.2.6.2 ER Measurement Tool

The tool ER Measurement allows the easy measurement the Extinction Ratio of PM fibers.

During the measurement, the fiber must change enough to cause at least a change of polarization that describes a circle on the Poincaré Sphere: The smaller the circle diameter, the higher

the ER value.

1. Prepare your setup . Ensure a correct coupling of the light signal into the fiber - the dot on

36

the Poincaré Sphere representing the SOP out of the fiber should lay as close as possible to

the H mark. Azimuthal deviations from the Horizontal polarization are not critical, whereas a

position towards the poles indicates an ellipticity that is caused by miscoupling of the light

into the fiber under test.

2. Start the ER Measurement tool from the appropriate button in the view ribbon:

3. Enter the operating wavelength of your light source.

Note : An exact wavelength value is essential for minimum measurement errors.

4. Select the measurement time between 3 and 10 s. During measurement, the fiber stress

must cause at least a full circle on the Poincaré Sphere. The higher the stress applied to the

fiber, the shorter the time to achieve this.

You may select for a first try the maximum time of 10 s and check the box Stop on Circle

Completed.

5. Start the fiber stress and the ER measurement.

© 2019 Thorlabs GmbH41

5 Operating Instruction

Total Points

This is the total number of measured points (SOPs).

Used Points

The software has an internal algorithm that excludes points located too

close to each other from the total number of measured points. The remaining points are used for circle approximation and subsequently for ER calculation.

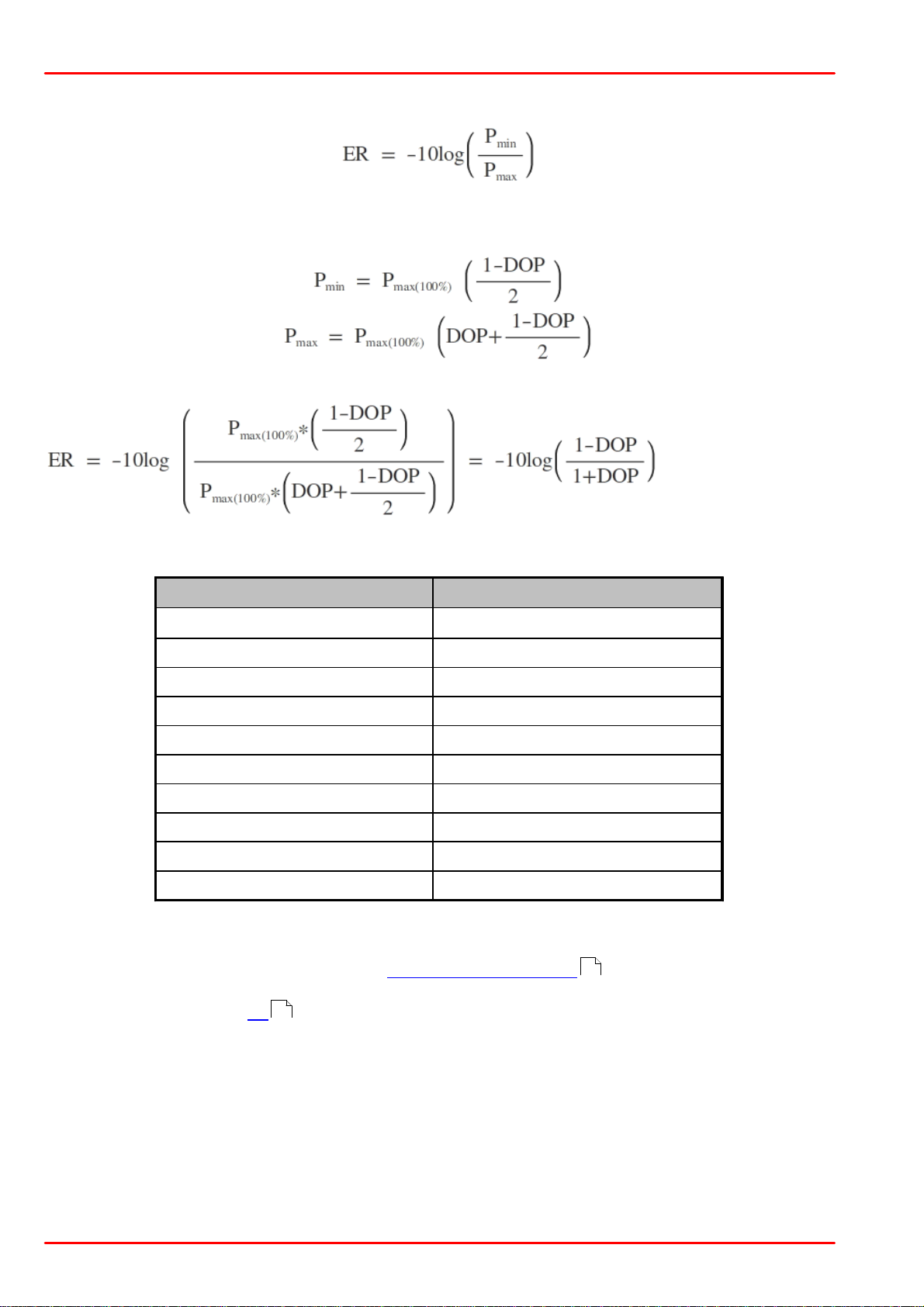

Extinction Ratio

Measurement result is displayed with respect to the state of the check

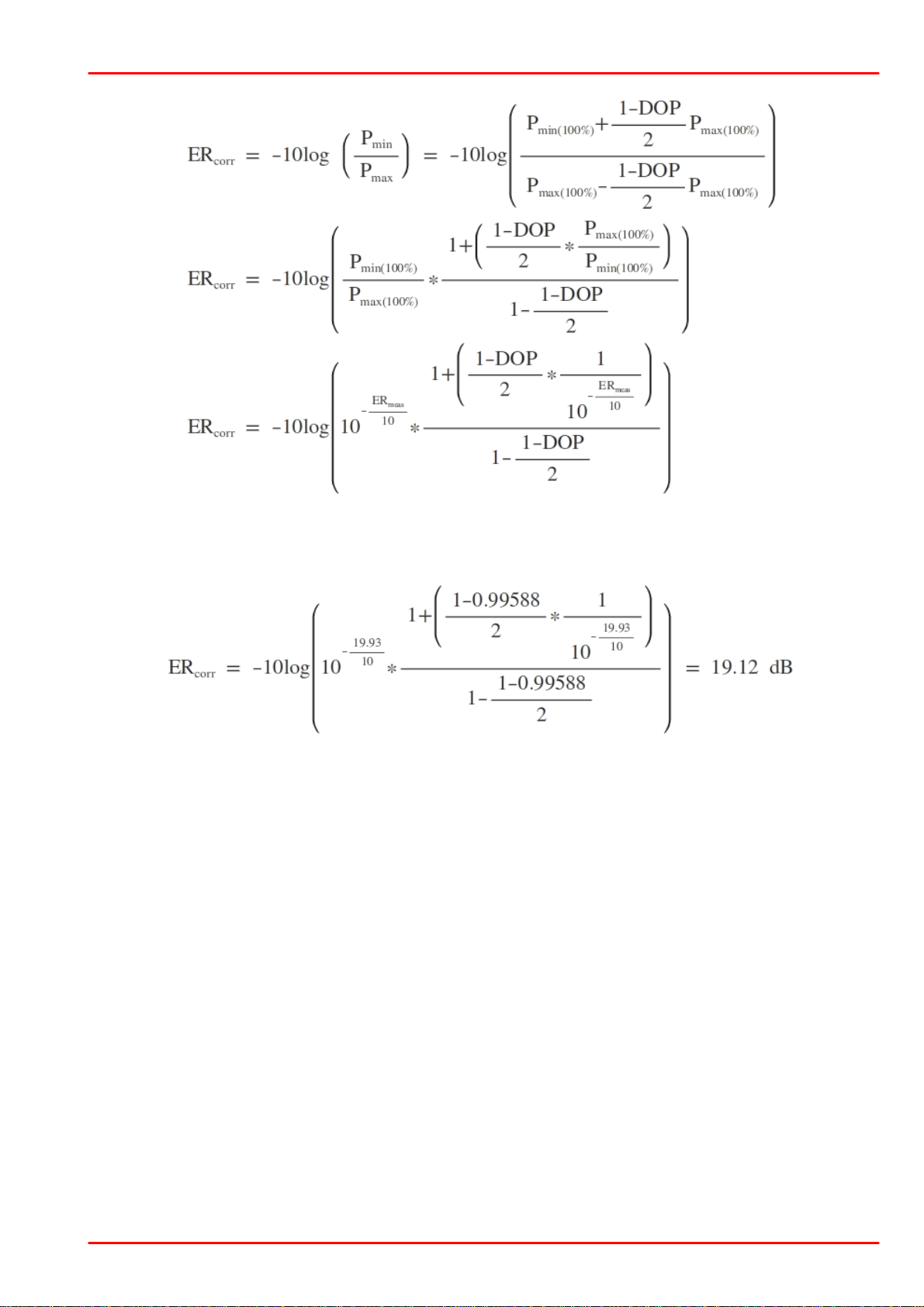

boxes Compensate Ellipticity and Compensate DOP. For detailed explanations and examples of these compensations, please see section Cor-

rection of the Polarimeter ER Measurements in the Tutorial.

Center Azimuth

Azimuth angle of the center of the calculated circle.

Center Ellipticity

Ellipticity angle of the center of the calculated circle.

Radius

Radius of the calculated circle in ° on the Poincaré Sphere.

Deviation

Standard deviation of the Used Points from the approximated circle.

6. After finishing the measurement, the GUI will display the measurement results:

7. The yellow circle represents the measured states of polarization, while the black circle is the

approximation that is used for calculation of the ER.

Measurement Results

The box Measurement displays the parameters that were measured at the end of the ER

Measurement.

The box ER Measurement Results displays several parameters:

75

If a warning or an error message appears, please see section Troubleshooting for possible

reasons and solution proposals.

© 2019 Thorlabs GmbH

52

42

PAX1000

5.2.7 Virtual Device

A virtual PAX1000 can be connected. This is an easy way to evaluate the PAX1000 software

without the hardware. This device is based on a PAX1000IR1 with its default settings . These

21

settings cannot be changed.

The virtual device delivers random measurement values that can be used to test all measure-

ment functionality, except the ER measurement on PM fibers.

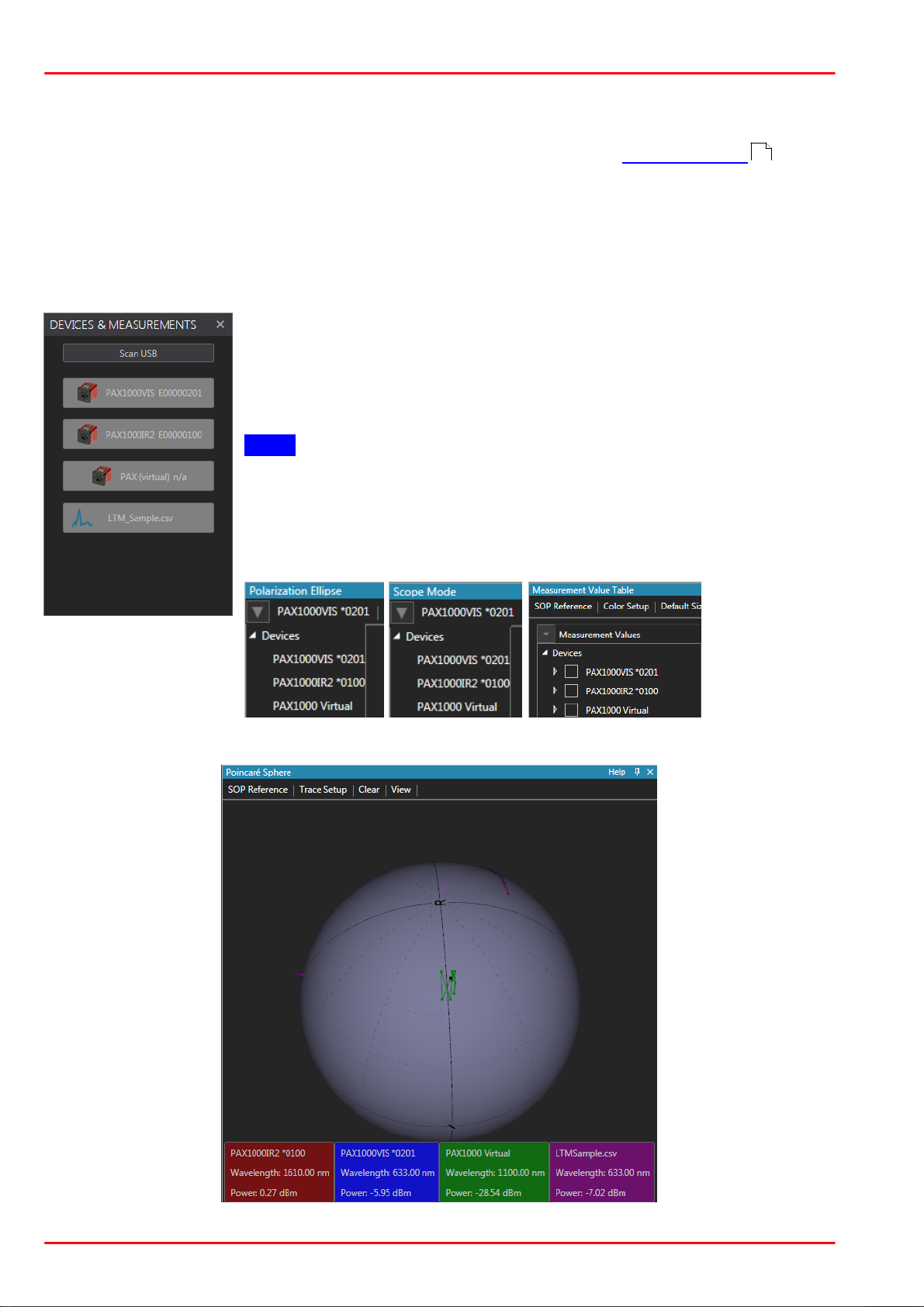

5.2.8 Multiple Devices

The PAX1000 software allows up to five PAX1000 devices, including

live devices and measurement files, to be simultaneously connected.

Connect the PAX1000. Open menu Devices & Measurements in the

DEVICE ribbon - all connected and recognized PAX1000 devices are

listed here, along with loaded measurement files.

Note

If you do not see the device that your want to connect, please make

sure that the USB connection is made properly. Click Scan USB force

recognition.

Each view of the GUI allows a selection of the device to be displayed

from a drop-down menu:

In the Poincaré sphere view all connected devices are displayed at the same time:

© 2019 Thorlabs GmbH43

5 Operating Instruction

Note

A total of 50,000 measurement values can be displayed on the Poincaré sphere. This limitation

was set in order to save system resources. This limitation affects the maximum trace length. If

more than one PAX1000 is connected, the maximum number of points that can be displayed

on the Poincaré sphere, equal to the maximum trace length, will be shared:

1 PAX1000: max. 50,000 points

2 PAX1000: max. 25,000 points

3 PAX1000: max. 15,000 points

4 PAX1000: max. 12,500 points

5 PAX1000: max. 10,000 points

For any loaded measurement file, a maximum of 1000 most recent points will be displayed on

the Poincaré sphere. However, in the Scope Mode, all measurement data of a loaded file will

be displayed.

Please note also, that in the case of large trace lengths and multiple device operation, the software performance may degrade significantly, depending on the computer's resources.

© 2019 Thorlabs GmbH

44

PAX1000

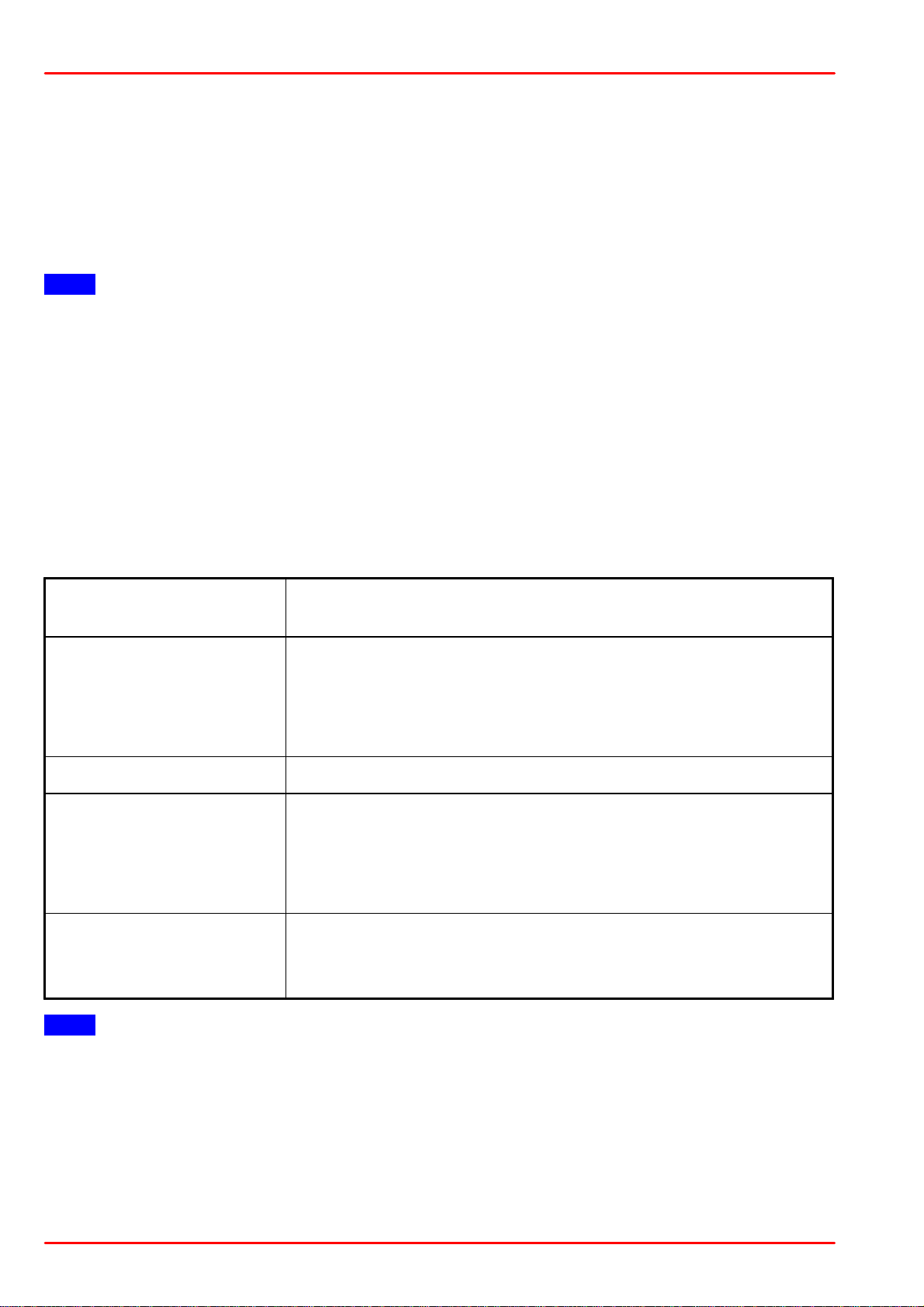

Programming environment

Necessary files

C, C++, CVI

*.fp (function panel file; CVI IDE only)

*.h (header file)

*.lib (static library)

*.dll (dynamic linked library)

C#

.net wrapper dll

Visual Studio

*.h (header file)

*.lib (static library)

or

.net wrapper dll

LabView

*.fp (function panel) and NI VISA instrument driver

Beside that, LabVIEW driver vi's are provided with the *.llb con-

tainer file

6 Write Your Own Application

In order to write your own application, you need a specific instrument driver and some tools for

use in different programming environments. The driver and tools are included in the installer

package and cannot be found as separate files on the installation CD.

In this section the location of drivers and files, required for programming in different environments, are given for installation under Windows 7, Windows 8.1 and Windows 10 (32 and 64

bit)

Note

PAX1000 software and drivers contains 32 bit and 64 bit applications.

In 32 bit systems, only the 32 bit components are installed to

C:\Program Files\…

In 64 bit systems the 64 bit components are being installed to

C:\Program Files\…

while 32 bit components can be found at

C:\Program Files (x86)\…

In the table below you will find a summary of what files you need for particular programming environments.

Note

All above environments require also the NI VISA instrument driver dll !

During NI-VISA Runtime installation, a system environment variable VXIPNPPATH for including

files is created. It contains the information where the drivers are installed to, usually to

C:\Program Files\IVI Foundation\VISA\WinNT\.

This is the reason, why after installation of a NI-VISA Runtime a system reboot is required: This

environment variable is necessary for installation of the instrument driver software components.

In the next sections the location of above files is described in detail.

© 2019 Thorlabs GmbH45

6 Write Your Own Application

6.1 32 Bit Operating Systems

Note

According to the VPP6 (Rev6.1) Standard the installation of the 32 bit VXIpnp driver includes

both the WINNT and GWINNT frameworks.

VXIpnp Instrument driver:

C:\Program Files\IVI Foundation\VISA\WinNT\Bin\TLPAX_32.dll

Note

This instrument driver is required for all development environments!

Header file

C:\Program Files\IVI Foundation\VISA\WinNT\include\TLPAX.h

Static Library

C:\Program Files\IVI Foundation\VISA\WinNT\lib\msc\TLPAX_32.lib

Function Panel

C:\Program Files\IVI Foundation\VISA\WinNT\TLPAX\TLPAX.fp

Online Help for VXIpnp Instrument driver:

C:\Program Files\IVI Foundation\VISA\WinNT\TLPAX\Manual\TLPAX.html

NI LabVIEW driver (including an example VI)

The LabVIEW Driver is a 32 bit driver and compatible with 32bit NI-LabVIEW versions 8.5 and

higher only.

C:\Program Files\National Instruments\LabVIEW xxxx\instr.lib\TLPAX…

…\TLPAX.llb

(LabVIEW container file with driver vi's and an example. "LabVIEW xxxx" stands for actual

LabVIEW installation folder.)

.net wrapper dll

C:\Program Files\Microsoft.NET\Primary Interop Assemblies…

…\Thorlabs.PAX1000.Interop.dll

C:\Program Files\IVI Foundation\VISA\VisaCom\Primary Interop…

…Assemblies\Thorlabs.PAX1000.Interop.dll

Example for C

Source file:

C:\Program Files\IVI Foundation\VISA\WinNT\TLPAX\Examples\CSample\…

…sample.c

(C program how to communicate with a PAX1000 Series polarimeter)

Example for C#

Solution file:

C:\Program Files\IVI Foundation\VISA\WinNT\TLPAX\Examples…

…\CSharp\Thorlabs.PAX_CSharp_Demo.sln

© 2019 Thorlabs GmbH

46

PAX1000

Project file:

C:\Program Files\IVI Foundation\VISA\WinNT\TLPAX\Examples…

…\CSharp\Thorlabs.PAX_CSharp_Demo\Thorlabs.PAX_CSharp_Demo.csproj

Executable sample demo:

C:\Program Files\IVI Foundation\VISA\WinNT\TLPAX\Examples…

…\CSharp\Thorlabs.PAX_CSharp_Demo\bin\Thorlabs.PAX_CSharp_Demo.exe

Example for LabView

Included in LabVIEW llb container.

© 2019 Thorlabs GmbH47

6 Write Your Own Application

6.2 64 Bit Operating Systems

Note

According to the VPP6 (Rev6.1) Standard the installation of the 64 bit VXIpnp driver includes

the WINNT, WIN64, GWINNT and GWIN64 frameworks. That means, that the 64 bit driver includes the 32 bit driver as well.

In case of a 64 bit operating system, 64bit drivers and applications are installed to

“C:\Program Files”

while the 32 bit files - to

“C:\Program Files (x86)”

Below are listed both installation locations, so far applicable.

VXIpnp Instrument driver:

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\Bin\TLPAX_32.dll

C:\Program Files\IVI Foundation\VISA\Win64\Bin\TLPAX_64.dll

Note

This instrument driver is required for all development environments!

Header file

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\include\TLPAX.h

C:\Program Files\IVI Foundation\VISA\Win64\include\TLPAX.h

Static Library

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\lib\msc…

…\TLPAX_32.lib

C:\Program Files\IVI Foundation\VISA\Win64\Lib_x64\msc\TLPAX_64.lib

Function Panel

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\TLPAX\TLPAX.fp

Online Help for VXIpnp Instrument driver:

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\TLPAX\Manual…

…\TLPAX.html

NI LabVIEW driver (including an example VI)

The LabVIEW Driver supports 32bit and 64bit NI-LabVIEW2009 and higher.

32 bit NI-Labview version

C:\Program Files (x86)\National Instruments\LabVIEW xxxx\instr.lib…

…\TLPAX\TLPAX.llb

64 bit NI-Labview version

C:\Program Files\National Instruments\LabVIEW xxxx\instr.lib…

…\TLPAX\TLPAX.llb

(LabVIEW container file with driver vi's and an example. "LabVIEW xxxx" stands for actual

LabVIEW installation folder.)

© 2019 Thorlabs GmbH

48

PAX1000

.net wrapper dll

C:\Program Files (x86)\Microsoft.NET\Primary Interop Assemblies…

…\Thorlabs.PAX1000.interop.dll

C:\Program Files (x86)\IVI Foundation\VISA\VisaCom\…

…Primary InteropAssemblies\Thorlabs.PAX1000.Interop.dll

C:\Program Files\IVI Foundation\VISA\VisaCom64\…

…\Primary Interop Assemblies\Thorlabs.PAX1000_64.Interop.dll

Example for C

Source file:

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\TLPAX\Examples\…

…CSample\sample.c

(C program how to communicate with a PAX1000 Series polarimeter)

Example for C#

Solution file:

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\TLPAX\Examples…

…\CSharp\Thorlabs.PAX_CSharp_Demo.sln

Project file:

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\TLPAX\Examples…

…\CSharp\Thorlabs.PAX_CSharp_Demo\Thorlabs.PAX_CSharp_Demo.csproj

Executable sample demo:

C:\Program Files (x86)\IVI Foundation\VISA\WinNT\TLPAX\Examples…

…\CSharp\Thorlabs.PAX_CSharp_Demo\bin\Thorlabs.PAX_CSharp_Demo.exe

Example for LabView

Included in LabVIEW llb container.

© 2019 Thorlabs GmbH49

7 Maintenance and Service

7 Maintenance and Service

Protect the PAX1000 from adverse weather conditions. The PAX1000 is not water resistant.

Attention

To avoid damage to the instrument, do not expose it to spray, liquids or solvents!

The unit does not need regular maintenance by the user. It does not contain any user-repairable modules or components. If a malfunction occurs, please contact Thorlabs GmbH for return

instructions.

Do not remove covers!

7.1 Version Information

The software version information can be found in the About dialog (ribbon HELP):

© 2019 Thorlabs GmbH

50

PAX1000

ADC underrun during last measurement.

ADC overflow during last measurement.

TIA gain switching is in progress.

An one-time TIA auto ranging is in progress.

An out-of-sync condition occurred during the last measurement.

Motor speed too low (too high).

PAX operating temperature is below (above) limit.

USB power supply voltage is too low.

7.2 Troubleshooting

Common Error Messages

The incident optical power was too low.

ð The PAX1000 is set to a fixed gain.

ð Set the instrument to Auto Power Range or select an appropriate power range man-

ually.

The incident optical power was too high.

ð The PAX1000 is set to a fixed gain.

ð Set the instrument to Auto Power Range or select an appropriate power range man-

ually.

ð This is a status message during the automatic adjustment of power range.

ð No action required.

20

20

ð This is a status message during the automatic adjustment of power range.

ð No action required.

ð If this message appears, the measurement results are not reliable. The PAX1000

should resolve this error automatically.

ð If the error message persists, please contact Thorlabs.

ð This is a status message when the measurement speed was changed.

ð If this message appears frequently or permanently, please contact Thorlabs.

ð This error message may appear in the case of too low (too high) environmental temper-

ature.

ð If this message appears at normal operating temperature, please contact Thorlabs.

ð The PAX1000 requires a higher operating current than the standard USB2.0 port can

deliver, e.g. at hing measurement speed.

ð Connect the external power supply.

© 2019 Thorlabs GmbH51

7 Maintenance and Service

Incomplete circle due to insufficient number of measurement values. Increase fiber

stress or extend measurement time.

Circle completed, but the distance between adjacent measurement points is too

large for accurate measurement. Decrease fiber stress and increase measurement

time.

Eigenmodes of the fiber under test are not strictly linear or measurement is noisy.

ER cannot be calculated.

The circle on the Poincare sphere is too small. The calculated ER is above the theoretical maximum accuracy. Please check if stress was applied to the fiber during

the measurement.

The ellipticity of some points is bigger than |25°|. Eventually there is a problem on

the coupling into the fiber or there is constantly stress on the fiber.

Extinction Ratio Warnings Error Messages

The change of polarization during the measurement was insufficient to draw a full circle on

the Poincaré Sphere.

ð Increase the fiber stress during measurement.

ð Alternatively, increase the measurement time.

The change of polarization during the measurement was sufficient to draw a full circle on

the Poincaré Sphere, but the number of measurement points was insufficient to approximate a circle with the necessary accuracy.

ð Decrease the fiber stress during measurement and increase the measurement time.

The change of polarization led to a non-circular trace on the Poincaré Sphere.

ð The optical power is too low, so that noise interfered the measurement.

Check your setup for possible power loss, or increase the optical power of your laser

source.

ð The fiber under test behaved not like a PM fiber.

Check if the fiber as specified as a PMF.

If so, check if the operating wavelength of your PM fiber matches with the measurement wavelength.

The measured ellipticity change is close to or less than the PAX1000 measurement accuracy.

ð Was the fiber Increase the fiber stress during measurement?

The output SOP was of a too high ellipticity.

ð Check your setup for proper coupling of the light source into the fiber under test. The

light must be coupled in parallel to the slow axis of the fiber.

ð Check your light source for strictly linear polarization.

ð Check if your fiber under test is exposed to a permanent stress due to extreme bending

or squeezing. Also, the connectorization of the fiber might be not stress-less.

© 2019 Thorlabs GmbH

52

PAX1000

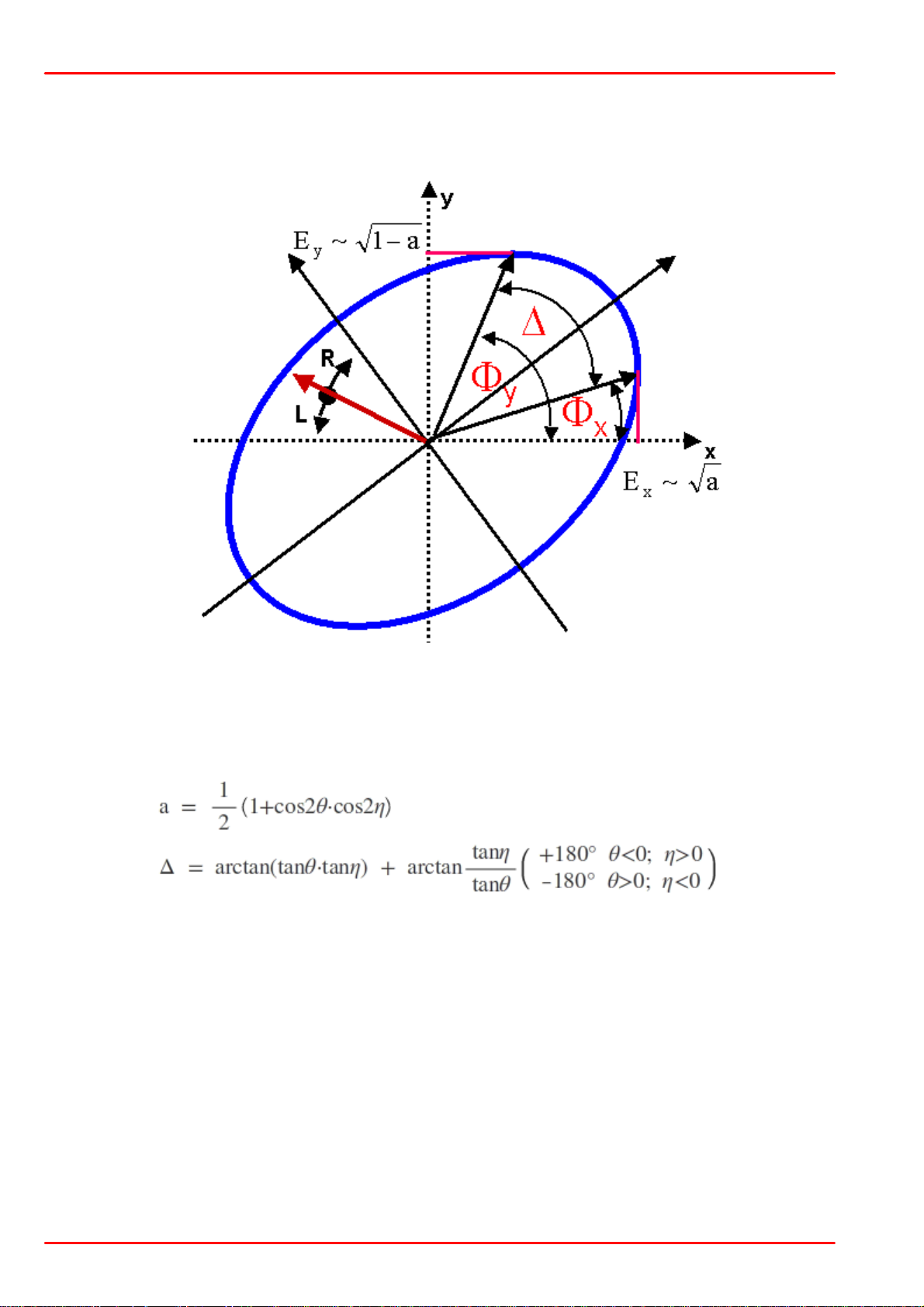

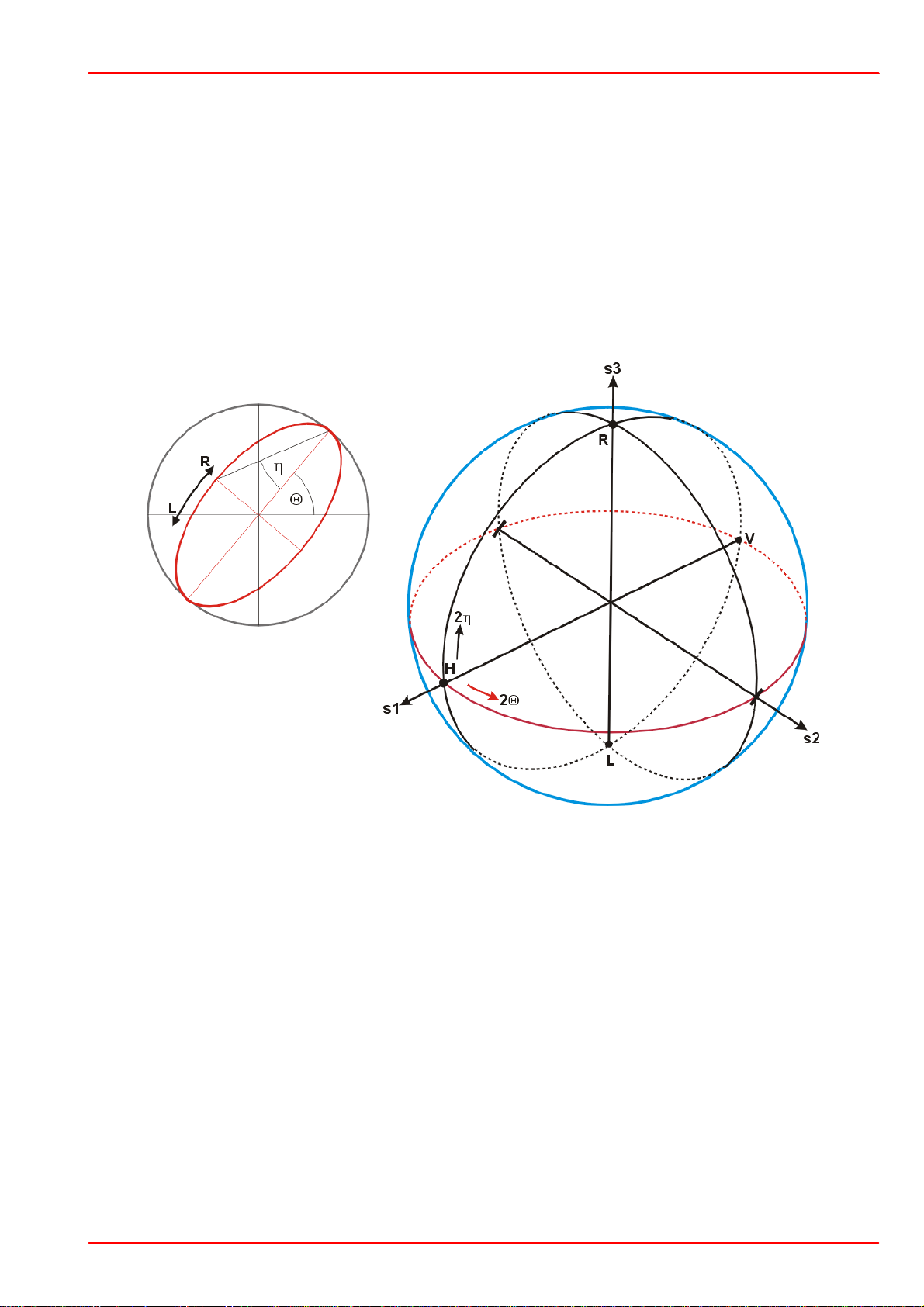

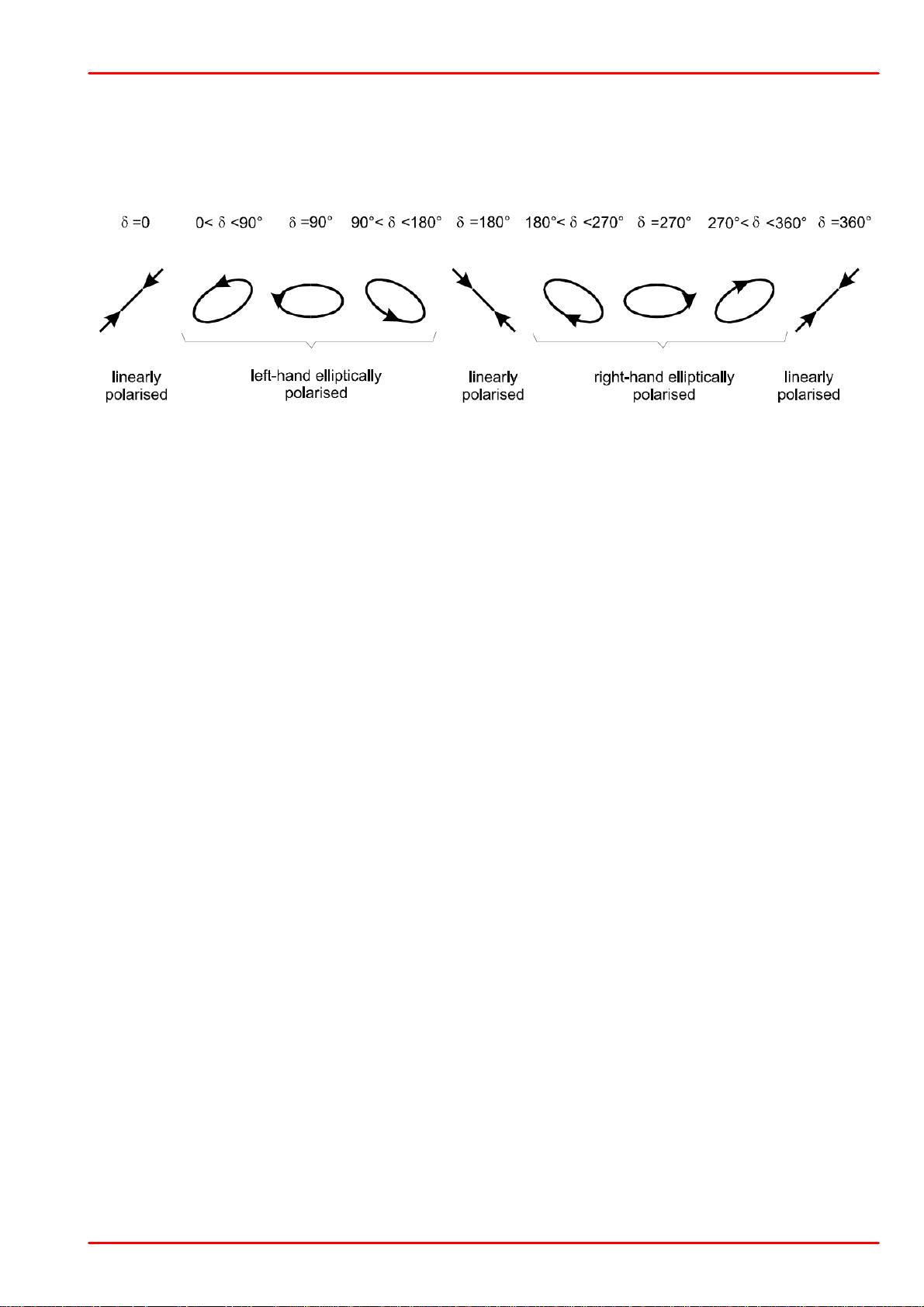

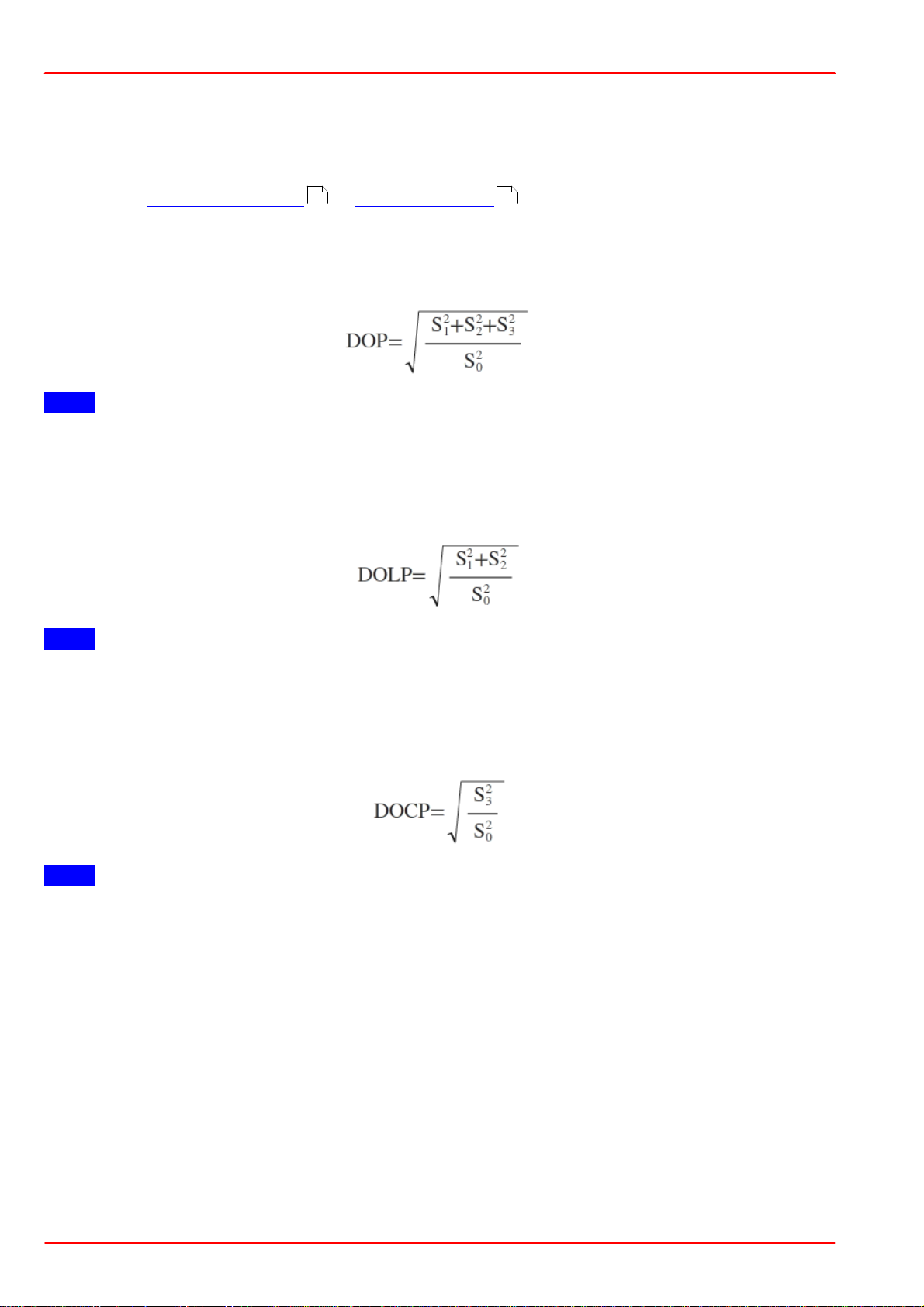

Linear Polarization

Elliptical Polarization

Circular Polarization

8 Tutorial

8.1 Polarization of Light

8.1.1 The Nature of Polarization

When talking about polarization, light is considered as an electromagnetic wave. It oscillates

perpendicular (transverse) to the direction of the propagation of the light beam. Such a transverse electromagnetic wave can be divided into an unpolarized and polarized part. The plane of

polarization of unpolarized light, also called natural light, fluctuates arbitrarily around the direction of propagation, so that in average no direction is favored.

All field components of polarized light have a fixed phase difference to each other. Each state

of polarization (SOP) can be split into any two orthogonal states. The following pictures illustrate different states of polarization:

The first example is linear polarized light. The phase difference between the two orthogonal

states is 0° or 180°, and superposition results in a total electric field that is always oriented in

the same direction when viewed in the transverse plane.

The second diagram shows an elliptical polarization state. The phase difference between the

orthogonal states is >0° and <=90°. The projection results in an ellipse with a right or left direction of rotation.

A special case of elliptical polarization is circular polarization (3rd example), where the phase

difference between the orthogonal states is 90°. Then the amplitude of the rotating vector is

constant over the entire 360° rotation.

Common light sources except lasers emit natural light. Helium Neon lasers or DFB laser diodes

normally feature linear polarization. However, if this laser light is launched into a single mode

standard fiber (SMF), the linear polarization is transformed into an arbitrary polarization.

Even if a polarization maintaining fiber is used, the linear polarization has to be coupled into

one of the main axes to prevent the loss of linearity.

A multimode fiber allows a propagation of numerous modes. The state of polarization of each

mode at the end of the fiber is arbitrary. The superposition of the polarization of all modes results in unpolarized light.

The spectral width of the emitted light needs to be considered as well. If the spectral line width

of the emission is narrow enough, then the light is polarized. An example is a DFB laser diode

with a linewidth of about 3MHz.

Light sources with a broad spectrum like LEDs are generally unpolarized. A polarizer can be

used to polarize light with a large spectral width.

© 2019 Thorlabs GmbH53

8 Tutorial

Right-Circularly Polarized Light

Left-Circularly Polarized Light

8.1.2 Handedness of Polarization

Convention

When light is elliptically polarized, the electric field (E field) vector rotates with respect to a

Cartesian coordinate system as it propagates. The software of the PAX1000 and the predecessor, the PAX57xx Polarimeter System, plot the E field vector with respect to a right-handed

coordinate system with x, y, and z axes. The light wave propagates in the +z direction, and the

(virtual) observer looks along the -z direction towards the light source. The handedness of the

elliptically polarized light describes the direction of rotation of the E field vector as seen by this

observer. This convention is common in the technical literature.

Each state of polarization can be split into two linearly polarized orthogonal components, in

which one is oriented in the x direction and one in the y direction. If both components have

equal magnitudes and the phase shift of the y component relative to the x component is +p/2 or

-p/2, the light is circularly polarized. The sign of the phase difference determines the handedness of the rotation. A clockwise rotation corresponds to a right-hand circular polarization state

and a phase shift of -p/2, while a counterclockwise rotation refers to left-hand circular polarization state and a phase shift of +p/2.

In above figures, the projection of the rotating E field vector on a virtual screen generates a

circle over time as the E field vector rotates clockwise (counterclockwise) representing right

(left) circular polarization.

Generation of Circularly Polarized Light

A circular polarization state can be generated using linearly polarized light and a quarter waveplate. When the E field vector of the incident linearly polarized light is oriented at a 45° angle to

the slow and fast axes of the quarter waveplate, the output light is circularly polarized. It is convenient to mathematically describe this transformation using matrix algebra, with Jones vectors

representing the polarized light and a Jones matrix representing the quarter waveplate.

The Jones matrix, describing a quarter waveplate with its slow axis oriented along the x (horizontal) axis is:

The phase factor e

© 2019 Thorlabs GmbH

ip/4

can be omitted in almost all cases.

54

PAX1000

The Jones vector of a linear polarization state oriented at + 45° is written as:

When this linearly polarized light travels through a quarter waveplate, the Jones vector of the

output light can be calculated as follows:

The output polarization is right-hand circular. The figure below illustrates this case:

The slow axis of the quarter waveplate are aligned with the x axis, and the fast axis of the QWP

is aligned with the y axis of the coordinate system. The input polarization is +45° linear and it is

transformed into a right-hand circular polarization.

The purple vector at the origin indicates the orientation of the incident +45° linearly polarized

light, while the red and blue vectors represent this E field decomposed into its orthogonal components. These two components are in phase. The x axis component, which is represented by

the blue vector, is aligned with the slow axis of the waveplate and travels at a slower velocity

through the waveplate than the y axis component, which is aligned with the fast axis and represented by the red vector. Propagating through the waveplate, the phase of the x axis component is retarded with respect to the phase of the y axis component. The amount of the retardation is determined by the thickness of the waveplate. A quarter waveplate is designed to into-

duce a phase shift of -p/2. This retardation results in a right-hand circularly polarized output

light, and its E field vector rotates clockwise when it propagates along the z axis.

© 2019 Thorlabs GmbH55

When the incident beam has a -45° linear polarization, its Jones vector is:

The output polarization state is then expressed:

The output light is left-hand circularly polarized.

8 Tutorial

Above illustrates this case.

Again, the slow axis of the quarter waveplate are aligned with the x axis, and the fast axis of the

QWP is aligned with the y axis of the coordinate system. The input polarization is -45° linear

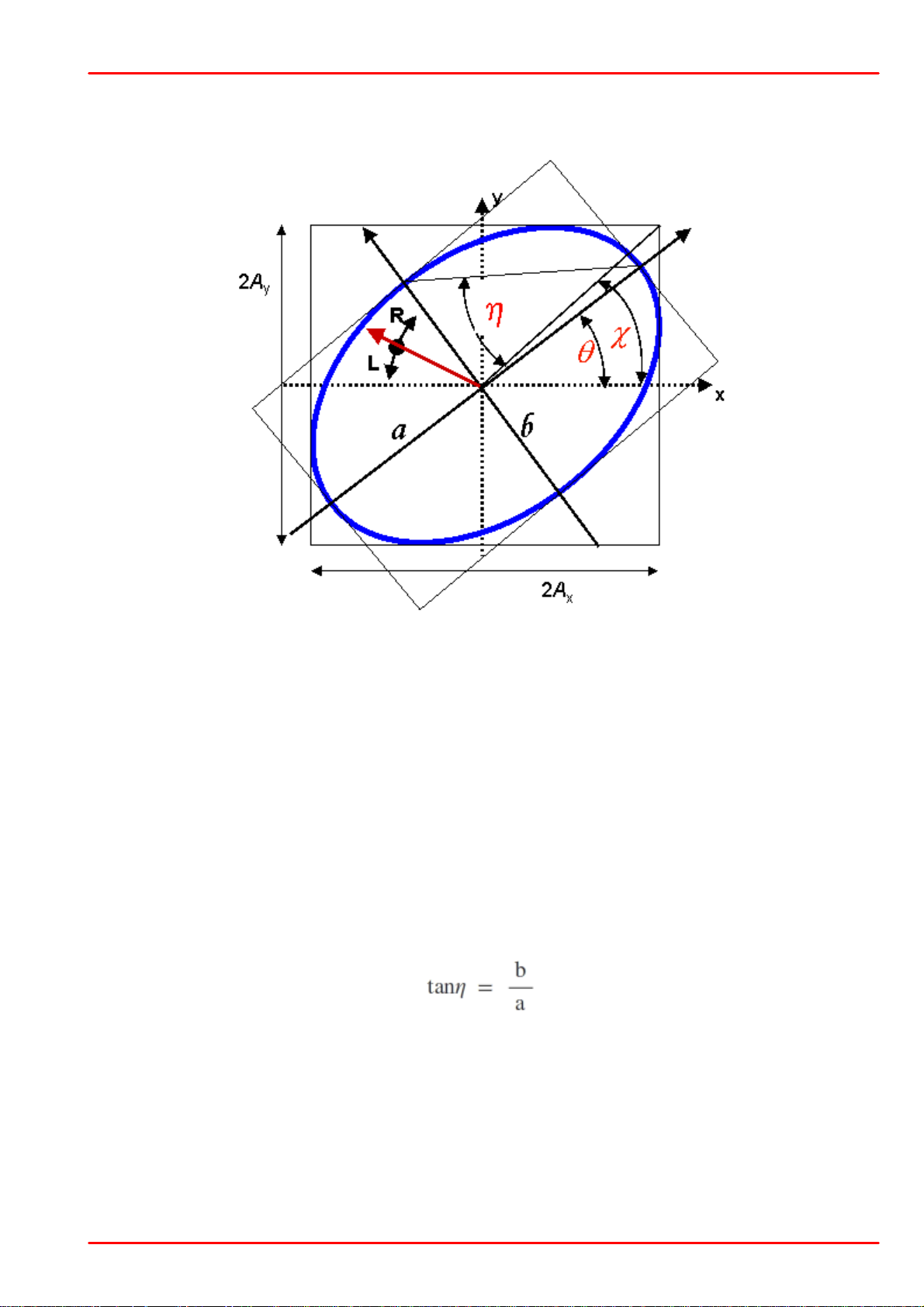

and it is transformed into a left-hand circular polarization.