OCTG Series,

OCT-LKx, and OCT-RAx

OCT Standard Scanner,

Scan Lens Kit,

and Standard Scanner

Reference Arm Adapter

User Manual

Original User Manual – not translated

Table of Contents

Chapter 1 Warning Symbol Definitions ....................................................................................... 1

Chapter 2 Introduction .................................................................................................................. 2

2.1. Safety ........................................................................................................................ 2

2.2. Care and Maintenance ............................................................................................. 3

2.2.1. Optical Cleaning .............................................................................................................. 3

2.2.2. Service ............................................................................................................................ 3

2.2.3. Accessories and Customization ...................................................................................... 3

Chapter 3 Scanner Compatibility ................................................................................................. 4

Chapter 4 Installation .................................................................................................................... 5

4.1. OCTG Mounting ....................................................................................................... 5

4.2. OCTG Connections .................................................................................................. 6

4.2.1. Connecting the Electrical Control Interface ..................................................................... 6

4.2.2. Connecting the Optical Fiber........................................................................................... 7

4.3. Integration ................................................................................................ ................ 8

Chapter 5 Description ................................................................................................................... 9

5.1. Theory ...................................................................................................................... 9

5.1.1. Signal Generation ........................................................................................................... 9

5.1.2. Limitations ....................................................................................................................... 9

5.2. Optical Design ....................................................................................................... 10

5.2.1. Common Path Setup ..................................................................................................... 10

5.2.2. Dual Path Setup (OCTG-NR) ........................................................................................ 10

5.2.3. Realization..................................................................................................................... 11

5.3. Components ........................................................................................................... 12

5.3.1. OCTG Base Module ...................................................................................................... 13

5.3.2. OCTG Reference Module ............................................................................................. 15

5.3.3. OCT Scan Lens Kit (Accessory) ................................................................................... 16

5.3.4. Reference Arm Adapter (Accessory) ............................................................................ 17

5.3.5. Dove Tail Mount ............................................................................................................ 18

5.4. Dimensions ............................................................................................................ 19

Chapter 6 Troubleshooting ......................................................................................................... 20

Chapter 7 Certifications and Compliance ................................................................................. 21

Chapter 8 Specifications ............................................................................................................. 22

8.1. Reflectivity Scanning Mirror ................................................................................. 23

Chapter 9 Warranty ...................................................................................................................... 24

9.1. Imaging Systems ................................................................................................... 24

9.2. Non-Warranty Repairs ........................................................................................... 24

9.3. Warranty Exclusions ............................................................................................. 24

Chapter 10 Regulatory .................................................................................................................. 25

10.1. Waste Treatment is Your Own Responsibility ..................................................... 25

10.2. Ecological Background ......................................................................................... 25

Chapter 11 Thorlabs OCT Support Contact ................................................................................ 26

Chapter 12 Thorlabs Worldwide Contacts .................................................................................. 27

OCTG Series Scanner Chapter 1: Warning Symbol Definitions

Rev C, April 06, 2016 Page 1

Chapter 1 Warning Symbol Definitions

Below is a list of warning symbols you may encounter in this manual or on your device.

Symbol

Description

Direct Current

Alternating Current

Both Direct and Alternating Current

Earth Ground Terminal

Protective Conductor Terminal

Frame or Chassis Terminal

Equipotentiality

On (Supply)

Off (Supply)

In Position of a Bi-Stable Push Control

Out Position of a Bi-Stable Push Control

Caution: Risk of Electric Shock

Caution: Hot Surface

Caution: Risk of Danger

Warning: Laser Radiation

Caution: Spinning Blades May Cause Harm

OCTG Series Scanner Chapter 2: Introduction

Page 2 MTN004419-D02

Chapter 2 Introduction

2.1. Safety

Please read this manual carefully before operating the OCTG standard scanner. Please also read any

manuals for the systems being connected to the OCTG.

All statements regarding safety and technical specifications will only apply when the unit is operated correctly.

ATTENTION

This equipment is intended for laboratory use only and is not certified for medical

applications, including, but not limited to, life support situations.

WARRANTY WARNING

There are sensitive electronic and optical parts in the OCTG.

Any modification or servicing of this system by unqualified personnel renders Thorlabs free of

any liability.

Any modification or the galvanometer scanners or the camera may cause loss of the factory

optical alignment.

This device can only be returned for service when it is packed into the complete original

packaging, including all foam packing inserts. Please contact Thorlabs’ OCT support

(see Chapter 11) for replacement packaging if the original packaging has been lost.

LASER RADIATION WARNING

When a light source (e.g. SLD, laser) is being coupled into the OCTG, please observe the

appropriate laser safety precautions for your own protection. The appropriate laser safety

precautions depend on the light source coupled into the OCTG.

During normal operations, laser light will be present within the scanner and will also be

emitted from the scanner. Also laser light may be emitted from unexpected locations, such as

if the fiber has been disconnected from the body or if the reference arm has been

disconnected.

In addition, the OCTG is an optical system that can influence the divergence of the beam. This

can cause a change of laser class of the light source, especially if the OCTG is used without

an objective.

Always turn off the light source before changing or adjusting the OCTG configuration or

accessories as the objective, lens kit, reference arm adapter, or sample z-spacer. For Thorlabs

OCT base units, turn off the OCT base unit main power to turn off the light source.

OCTG Series Scanner Chapter 2: Introduction

Rev C, April 06, 2016 Page 3

2.2. Care and Maintenance

The system should be treated with care, particularly during transportation and unpacking. Hitting or dropping

the system can damage the unit and lower system performance. If mishandling occurs, misalignment of the

optical components may occur, leading to a decrease in image quality. In this situation, the system should be

realigned by qualified personnel. Do not store or operate in a damp, closed environment.

Do not store or operate on surfaces that are susceptible to vibrations.0

Do not expose to direct sunlight.

Do not use solvents on or near the equipment.

Keep the unit away from dust, dirt, and airborne contaminants, such as cigarette smoke. The system

is not designed for outdoor use. Protect the equipment from rain, snow, and humidity.

Do not subject the equipment to mechanical and thermal extremes. Protect the equipment from rapid

variations in temperature.

Handle all electrical and fiber connectors with care. Use of excessive force to form electrical or fiber

connections may damage the connectors.

2.2.1. Optical Cleaning

The most common cause of low signal intensity is dirtying of the fiber due to airborne contaminants. To

minimize the fiber’s exposure to air, avoid unnecessary disconnections of the optical fiber patch cable. Ensure

that the connection is tight, and keep the fiber as straight as possible without placing it under tension. It is

also advisable to check the fiber when making other adjustments to the optical system, such as changing the

objective.

Thorlabs’ Fiber Inspection Scope (Item # FS200) can help determine when the fiber needs cleaning. We

recommend our Fiber Connector Cleaner (Item # FCC-7020) for quickly cleaning the fiber tips.

2.2.2. Service

Only trained and approved Thorlabs personnel are allowed to service the system. Please contact Thorlabs’

OCT support (see Chapter 11) for more information.

2.2.3. Accessories and Customization

The OCTG series standard scanners are Thorlabs-qualified accessories for Thorlabs’ OCT Systems (i.e., our

CALLISTO, GANYMEDE, VEGA and TELESTO). We strongly suggest using Thorlabs’ OCT-LKx scan lens

kits as well as OCT-RA reference arm adapter kits with the OCTG as they were specifically designed to work

together.

In order to achieve the intended performance, this scanner should only be used with qualified parts. Please

hold a conversation with Thorlabs’ OCT support (see Chapter 11) to determine if other parts you wish to use

are compatible. Any modification or servicing of this system by unqualified personnel renders the warranty

null and void, leaving Thorlabs free of any liability.

OCTG Series Scanner Chapter 3: Scanner Compatibility

Page 4 MTN004419-D02

Chapter 3 Scanner Compatibility

The OCTG standard scanner is a standalone, preassembled, integrated scanner intended for the use together

with a Thorlabs OCT base unit such as the CALLISTO, VEGA, GANYMEDE or TELESTO series.

This scanner is available in two different setups

The OCTG-xxxNR standard scanner is designed for dual path setups using a dedicated external

reference to create the interferometric signal.

These scanners does NOT comprise an interferometer.

The other OCTG-xxx scanner is designed for common path setups and comprise an interferometer

consisting of a beam splitter and a reference arm creating the interferometric signal. The OCTG-xxx

is available in two versions for different wavelength ranges.

o The OCTG-900 for OCT systems working in the 900 nm regime.

o The OCTG-1300 for OCT systems working in the 1300 nm regime.

In this manual we will use abbreviation for the OCTG scanner as follows:

OCTG OCTG-900; or OCTG-1300

For common statements the abbreviation “OCTG” is used for both setups.

The OCTG scanners are fully compatible with all Thorlabs OCT base units of the CALLISTO, VEGA,

GANYMEDE, and TELESTO series.

The table below gives a short overview of the different standard scanners, their usable wavelength range and

lists preferred OCT base units.

Standard Scanner

Wavelength Range

OCT Base Unit

OCTG-900

850 nm – 1000 nm

CALxxx

GANxxx

OCTG-1300

1200 nm – 1400 nm

TELxxx

OCTG-1300NR

1200 nm – 1400 nm

VEGxxx

Table 1 Usable Wavelength Range of OCT Scanner

The most selective optical component is a mirror mounted on the Y galvanometric scanner of the scanner

set.

A reflectivity graph of the scanning mirror is given in Figure 21.

Detailed information about the spectral performance of the different mirrors are available upon request.

Please contact Thorlabs’ OCT support (see Chapter 11) for details

OCTG Series Scanner Chapter 4: Installation

Rev C, April 06, 2016 Page 5

Chapter 4 Installation

The OCTG standard scanner is a standalone, preassembled, integrated accessory to an OCT base unit. It

should be securely mounted to an optical table or breadboard with minimal vibrations. We recommend

mounting the OCTG to a Thorlabs OCT-Stand.

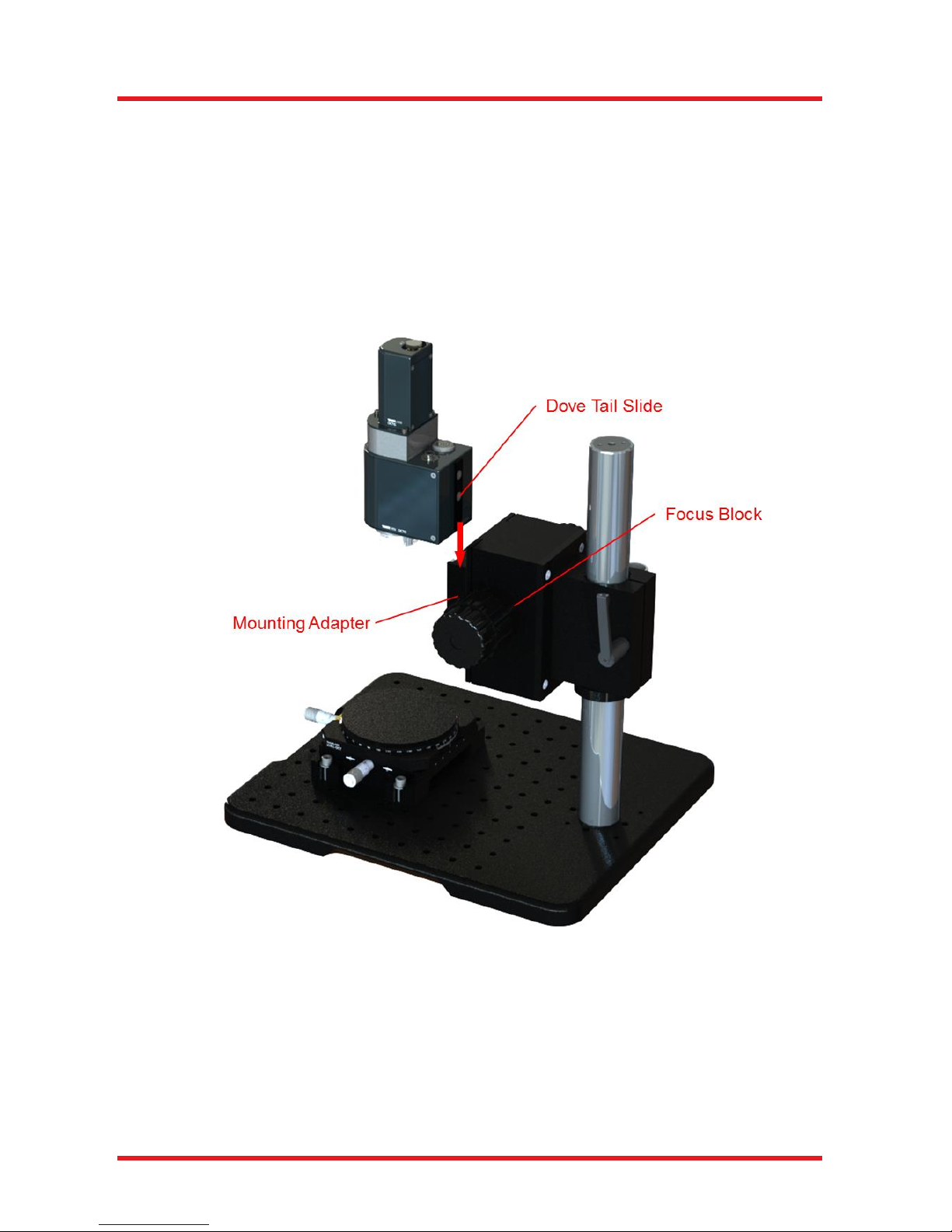

4.1. OCTG Mounting

To mount the OCTG in the OCT-Stand, gently slide the dovetail of the OCTG into the slide of the OCT-Stand.

Figure 1 Mounting the OCTG in the OCT-Stand

OCTG Series Scanner Chapter 4: Installation

Page 6 MTN004419-D02

4.2. OCTG Connections

4.2.1. Connecting the Electrical Control Interface

Attach the included electrical control cable to the OCTG. You may use either side of the cable since the plugs

are identical. The OCT scanner’s electrical control interface is located at the top of the OCTG base module.

Align the red dot of the plug to the alignment mark of the port.

Push the connector into the receptacle until a “click” sound is heard. This click indicates that the connector is

locked.

Figure 2 Installation of the Control Cable Connector at the OCTG

The remaining plug of the electrical control cable will be attached to the OCT base unit. Make sure that the

base unit is switched off.

The connection is located at the rear of the base unit. For installation, align the red dot, facing the alignment

mark in the base unit. Push the connector into the receptacle marked “Control” until a “click” sound is heard.

This click indicates that the connector is locked.

OCTG Series Scanner Chapter 4: Installation

Rev C, April 06, 2016 Page 7

4.2.2. Connecting the Optical Fiber

ATTENTION

When installing the fiber, make sure that the fiber tip does not get contaminated by dust.

Thorlabs’ Fiber Inspection Scope (Item # FS200) and Fiber Connector Cleaner (Item # FBC1)

are useful for keeping the optical path clean.

Do not touch the fiber tip!

Attach the optical fiber to the OCTG, as illustrated in Figure 3 below. Either end of the fiber patch cable may

be used to connect to the OCTG. Remove the dust cap from each fiber end and store them with the system

packaging. The FC/APC fiber connection is located at the top of the OCTG base module side by side with the

electric interface. Insert the fiber tip into the center bore of the fiber connection, than secure the tip by gently

rotating the locking cap clockwise.

The fiber connector needs to be oriented such that alignment key slides into the key slot of the fiber

connector (as shown in Figure 3 below). If the key is NOT properly aligned with respect to the key slot, you

will still be able to screw in the fiber connector, but significant light intensity loss and focal shift will result from

this incorrect connection.

Figure 3 Installation of the Fiber at the OCTG Standard Scanner

OCTG Series Scanner Chapter 4: Installation

Page 8 MTN004419-D02

4.3. Integration

For the full integration into such a system, please refer to the user manual of the OCT base unit.

Figure 4 Fully integrated Callisto System with 900 nm Standard Scanner (Item # OCTG-900) Mounted on a

Stand (Item # OCT-Stand) with Translation Stage (Item # OCT-XYR1) operated by a Base Unit (Item # CAL110)

OCTG Series Scanner Chapter 5: Description

Rev C, April 06, 2016 Page 9

Chapter 5 Description

5.1. Theory

5.1.1. Signal Generation

Spectral domain optical coherence tomography (SD-OCT) generates cross-sectional images up to several

millimeters deep into tissue. The images are assembled by performing a series of scans at adjacent,

increasing depths, allowing 2D and 3D reconstruction of the specimen.

Therefore the interference between the light coming back from the specimen and from a reference is sampled

for a broad range of different wavelengths. This is performed either by using a broadband light source divided

into separate wavelength using a spectrometer or by a laser with small bandwidth quickly tuned over a broad

wavelength range.

The phase delay of the back-reflected and back-scattered light (with respect to the stationary reference) is

recorded as a function of wavenumber, and a Fast Fourier Transform (FFT) yields the cross-sectional images

as a function of sample depth.

5.1.2. Limitations

The spatial resolution and sensitivity of the OCTG scanner depends on several parameters, including the

following:

Wavelength Range: The optical components within the OCTG are optimized for a specific

wavelength range, depending upon the model. For the usable wavelength range please refer to Table

1.

Optical Power: The sensitivity of the OCTG is directly related to the intensity of the light returning

from the sample. Factors that can reduce the collected light intensity from the sample fiber include:

dirty fibers, blocked/cropped beams, and condensed water in the environment.

Physical Movements: OCT systems use a camera to detect the phase relation of the light returning

from the sample. Even small movements of the specimen in relation to the optical reference arm can

”wash out” the wavenumber-resolved phase contrast, affecting the image.

Imaging: In a fiber-based OCT setup, the light returning from the sample is focused into the core of

an optical fiber. Hence, the fiber can be thought of as a spatial filter for the light. This filter has an

effective diameter, referred to as the “mode field diameter. For single mode propagation, mode field

diameter is larger than the fiber core diameter. Poor focusing, caused by optical aberration or

misalignment, therefore leads to loss of contrast and sensitivity.

OCTG Series Scanner Chapter 5: Description

Page 10 MTN004419-D02

5.2. Optical Design

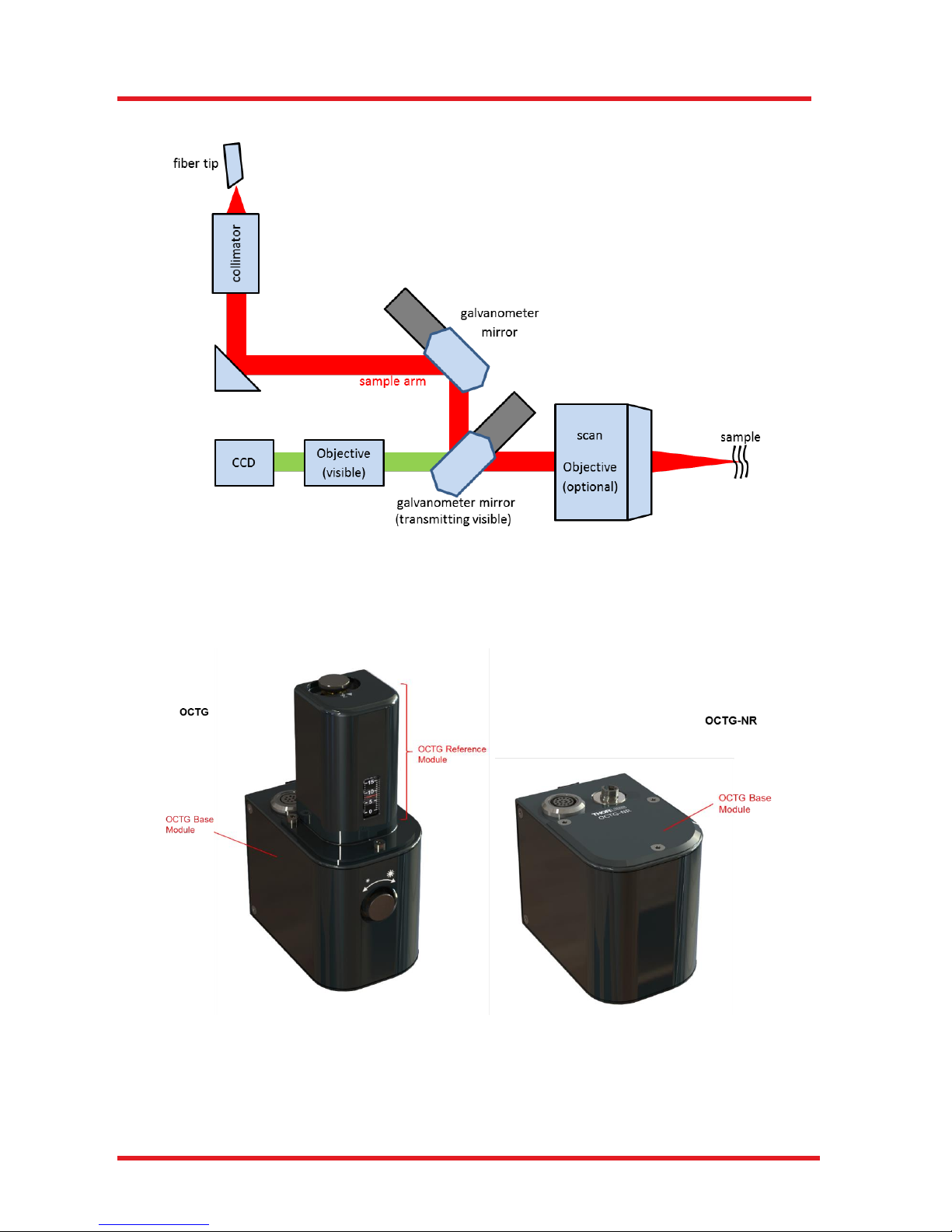

5.2.1. Common Path Setup

As shown below in Figure 1, in this configuration, the scanner is factory-configured such that the sample

beam and reference beam are generated after the beam leaves the fiber. This allows you to use single-mode

optical fiber to transport the beam into the scanner while minimizing the use of free-space propagation.

This approach avoids problems that can degrade image quality, related to optical phenomena like polarization

mode dispersion (PMD) and birefringence, and makes the performance of the system independent from the

length of the single-mode fiber.

Figure 5 Diagram of the Common Path Setup

5.2.2. Dual Path Setup (OCTG-NR)

Shown below in Figure 6 is the beam geometry when the scanner is ordered in a special configuration without

reference. The sample beam and reference beam are generated within different fibers, before the beam exits

into free space. In this configuration, the scanner becomes the sample arm of the interferometer. By using

two different fibers, the beamsplitter cube used in the Common Path Setup is no longer needed.

This configuration allows single mode optical fiber to be used to a greater extent within the setup. While this

approach is able to provide greater sensitivity due to the absence of the beamsplitter cube (which reduces

the intensity of the light that returns to the fiber), it is significantly more sensitive to the optical phenomena

mentioned before. Please contact Thorlabs’ OCT support (see Chapter 11) for details.

Figure 6 Diagram of the Dual Path Setup

OCTG Series Scanner Chapter 5: Description

Rev C, April 06, 2016 Page 11

5.2.3. Realization

The basic optical layout of the OCTG scanner in common path layout is illustrated below in Figure 7.

Figure 7 Optical Layout OCTG

The output of an FC/APC fiber is collimated and routed to a beam splitter cube. Here the beam is divided

into a sample beam and a reference beam, similar to a Michelson interferometer. The sample beam is

routed over two galvanometer actuated mirrors to allow for scanning in two axes. The scan objective then

focuses the beam in the sample. Back-scattered and back-reflected light is collected by the scan objective

again and travels back to the fiber. The light reflected into the reference arm is retro-reflected back into the

fiber. There is an optimum intensity for the reference light that can be adjusted using the reference intensity

adjustment knob which will open or close the variable aperture inside the OCTG.

OCTG Series Scanner Chapter 5: Description

Page 12 MTN004419-D02

In the dual path configuration of the OCTG-NR, the reference path components are not included.

Figure 8 Optical Layout OCTG Common Path

5.3. Components

The OCTG Standard Scanner are to be used in combination with Thorlabs’ OCT base units.

Figure 9 OCT Modules OCTG and OCTG-NR

OCTG Series Scanner Chapter 5: Description

Rev C, April 06, 2016 Page 13

The major components of the OCTG Standard Scanner are an OCTG base module and a

Reference Arm Module if applicable. We recommend also considering other accessories like the OCT-LKx

scan lens kit and the OCT-RAx reference arm adapter.

The following sections describe the two modules and possible accessories in detail.

ATTENTION

Always turn off the light source before changing or adjusting OCTG configuration or

accessories such as the objective, scan lens kit, reference arm adapter, or sample z-spacer.

For Thorlabs OCT base units, turn off the OCT base unit main power to turn off the light

source.

Please contact a member of the Thorlabs’ OCT support team to determine if other parts you wish to use are

compatible (see Chapter 11). Any modification or servicing of this system by unqualified personnel renders

the warranty null and void, leaving Thorlabs free of any liability.

5.3.1. OCTG Base Module

The OCTG base module provides high-speed, two-dimensional (X and Y) raster scans of the specimen. The

clear aperture of the scan mirrors used within is Ø 6 mm. The module also contains a high-resolution video

camera for recording the sample during the measurement.

Figure 10 OCT Base Module

The electrical control interface hosts the included Thorlabs electric control cable to connect the scanner with

a Thorlabs OCT base unit. Please contact Thorlabs’ OCT support (see Chapter 11) for information regarding

the pin configuration.

The optical fiber port is a FC/APC receptacle.

The optical output to the reference arm is equipped with a circular iris aperture which is manipulated using

the reference adjustment knob. In order to adjust the reference intensity, it may be necessary to rotate the

reference length adjustment knob. Rotating clock-wise increases the reference intensity, rotating counter

clock-wise decreases it.

OCTG Series Scanner Chapter 5: Description

Page 14 MTN004419-D02

ATTENTION

The iris aperture might be damaged by inadequate torque. In positions “open” and “closed”

an enlarged mechanical resistance indicates the limit of the travel range.

In order to adjust the reference intensity adjustment knob, pull the knob approximately 5 mm outwards until

you feel the knob coming to a rest.

Figure 11 Reference Intensity Adjustment

As a qualitative indication, observe the reference intensity bar in the OCT software. Please refer to the

Software Manual for additional guidance.

OCTG Series Scanner Chapter 5: Description

Rev C, April 06, 2016 Page 15

5.3.2. OCTG Reference Module

The reference module contains a mounted mirror (i.e., retro reflector) that reflects the beam from the light

source back into the OCT interferometer.

Figure 12 OCTG Reference Module

In order to match the optical path length in this reference arm to the optical path length of the light from the

sample, it may be necessary to translate the mirror along the axis of the optical system. Length adjustments

can be performed by rotating the reference length adjustment knob.

Figure 13 Reference Length Adjustment

Rotating clock-wise increases the reference path length, rotating counter clockwise reduces it.

The position of the mirror can be monitored using the reference length indicator on the front side of the module.

The full adjustment range of the reference module is >12 mm while the intended standard position is around

3 mm giving an adjustment range of -2 mm / +10 mm.

locked

unlocked

OCTG Series Scanner Chapter 5: Description

Page 16 MTN004419-D02

5.3.3. OCT Scan Lens Kit (Accessory)

The OCT scan lens kit from Thorlabs are specially designed accessories to support telecentric scanning over

a wide range and to compensate the dispersion mismatch of the scanner. The OCT-LKx are fully compatible

with the OCTG.

If you ordered a scan lens kit and reference adapter with the OCTG, these items are pre-installed.

If not already installed the installation procedure follows these three steps.

Insert the included OCT scan lens by screwing it in,

Inserting the illumination module

Secure the illumination module using the four included M2.5x6 cap screws

Figure 14 Installation of Scan Objective and Illumination

Another part of the lens kit is the dispersion compensation set. This has to be inserted into the

reference adapter OCT-RAx

Figure 15 Dispersion Compensation Set

ATTENTION

Optics are sensitive components!

When handling the objective lens take care to avoid touching or harming the optical surfaces.

Changing the objective of the OCTG requires changing the probe configuration data in the software package

ThorImage OCT as well.

This is performed automatically using the calibration procedure built-in the ThorImage OCT Software package

version 4.1.4 and higher. A detailed description of this procedure is given in the ThorImage OCT Operating

Manual.

OCTG Series Scanner Chapter 5: Description

Rev C, April 06, 2016 Page 17

5.3.4. Reference Arm Adapter (Accessory)

The match the required optical path length and the dispersion for the used OCT scan lens kit the installation

of the reference arm adapter OCT-RAx is strongly suggested.

If you ordered a reference arm adapter with the OCTG, this item is pre-installed.

If not already installed the dispersion compensation kit provided with the lens kit and must be installed

Insert the dispersion compensation kit, which is part of the lens kit, into the reference adapter

Fix it using the SM05 retaining ring

Figure 16 Installation of Dispersion Compensation Set

For the installation procedure of the OCT-RAx follow these steps.

Remove the OCT reference module by loosen the three fixed M3x6 cap screws

Insert the reference arm adapter onto the OCT base module

Inserting the OCT reference module onto the reference arm adapter

Secure the assembly using the three included M3 cap screws

Figure 17 Installation of Reference Arm Adapter

OCTG Series Scanner Chapter 5: Description

Page 18 MTN004419-D02

5.3.5. Dove Tail Mount

The OCTG ships with a dovetail mount at the back side (as seen in Figure 18 below). This accessory allow

the scanner to be mounted in standard Thorlabs OCT-Stand.

Figure 18 OCTG-1300 with Dove Tail Mount

The OCT-Stand is a dedicated stand for OCTG scanners.

The OCTG scanners are attached to the focus block of the OCT-Stand using a spring loaded mount accepting

the dove tail mount of the OCTG. The focus block can be rotated 360° around the Ø1.5” rod, and features

30 mm of travel with fine and coarse adjustment knobs.

Figure 19 OCT Stand with OCT-XYR1

OCTG Series Scanner Chapter 5: Description

Rev C, April 06, 2016 Page 19

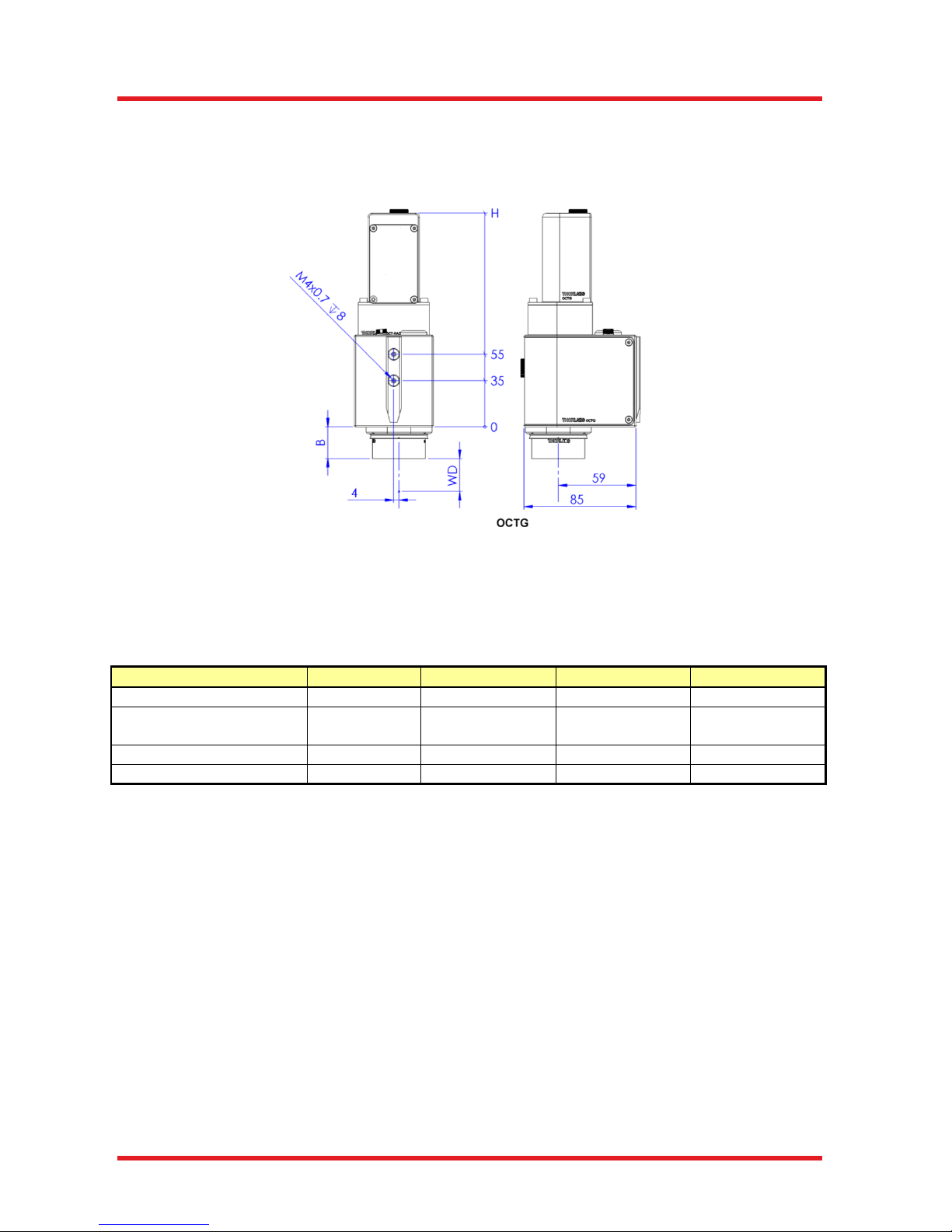

5.4. Dimensions

The dimensions of the OCTG series standard scanners are given in the following drawing. All dimensions are

in mm.

Figure 20 Drawing showing Dimensions,

Mounting Options, and Focal Plane

The opto-mechanical specifications of the OCT scan lens kits are listed in the table below.

Scan Lens Kit #

No OCT-LK

OCT-LK2 (-BB)

OCT-LK3 (-BB)

OCT-LK4 (-BB)

Field of View

-

6 mm x 6 mm

10 mm x 10 mm

16 mm x 16 mm

Mechanical Height (H)

OCTG

139 mm /

71.5 mm

142.5 mm /

71.5 mm

162 mm /

71.5 mm

189 mm /

71.5 mm

Barrel Height (B)

-

25.5 mm

24.0 mm

37.0 mm

Working Distance (WD)

-

3.4 mm

24.9 mm

41.6 mm

Table 2 Data for OCT Scan Lens Kits

Changing the objective of the OCTG requires changing the probe configuration data in the software package

ThorImage OCT as well.

This is performed automatically using the calibration procedure built-in the ThorImage OCT software package

version 4.1.4 and higher. A detailed description of this procedure is given in the ThorImage OCT operating

manual.

OCTG Series Scanner Chapter 6: Troubleshooting

Page 20 MTN004419-D02

Chapter 6 Troubleshooting

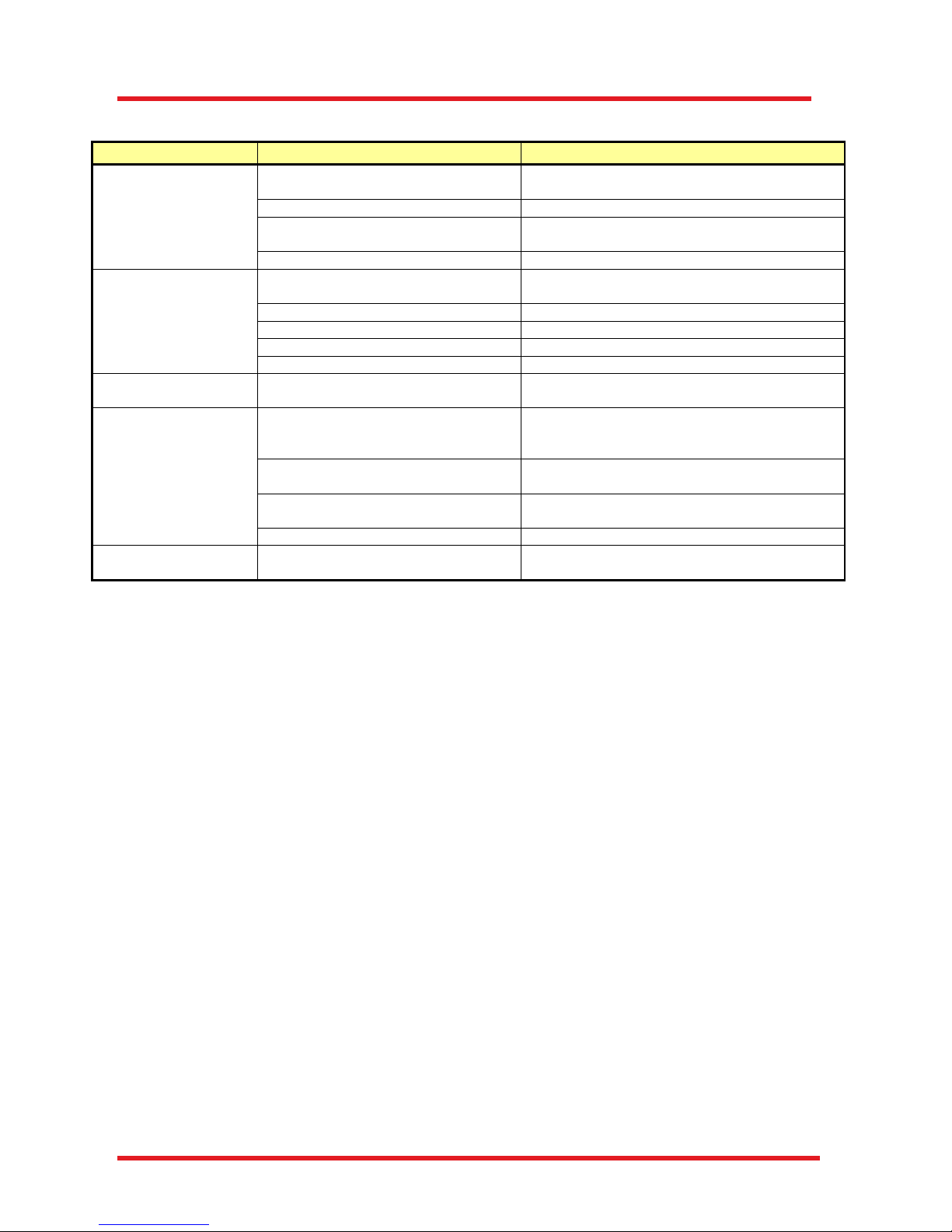

Problem

Possible Cause

Recommended Solution

Poor Reference

Light Intensity

Fiber Not Connected

Remove and Reconnect Fiber, Ensuring that

Alignment Key is Inserted into Key Slot

Aperture is Too Small

Open Aperture

Fiber Tip is Dirty

Clean Fiber Tip (Thorlabs’ MCC-7020 Fiber

Connector Cleaner Recommended)

Other Reason

Contact OCT Service (See Chapter 11)

No Image is Obtained

Optical Path Length of Reference and

Sample Arms is Not Matched

Adjust Reference Arm Length

Beam is Blocked

Check for Obstructions in Optical Path

USB Cable is Loose

Reconnect USB Cable

PC Crashed

Restart PC

Other Reason

Contact OCT Service (See Chapter 11)

Low Scan Resolution

Dispersion in Reference and Sample

Arms is Not Matched

Check if Dispersion compensation is installed

Bad Image Quality

Image Obtained is Being Mirrored

Adjust the Distance Between the Objective and

the Sample. The Image Should Move Towards

the Top of the Computer Window

Optical Path Length of Sample Arm

is Too Short

Move Sample Away From Objective

Reference Intensity is Too High

or Too Low

Close or Open Aperture Iris to Adjust Intensity

Other Reason

Contact OCT Service (See Chapter 11)

Flipped Image

Optical Path Length of Reference Arm

is Incorrect

Adjust Reference Arm Length

Table 3 Troubleshooting

OCTG Series Scanner Chapter 7: Certifications and Compliance

Rev C, April 06, 2016 Page 21

Chapter 7 Certifications and Compliance

OCTG Series Scanner Chapter 8: Specifications

Page 22 MTN004419-D02

Chapter 8 Specifications

OCTG

Optical Specifications

Center Wavelength

900 nm, or 1300 nm

Clear Aperture

Ø6 mm (Max)

Reference Length Fine Adjustment

-2 mm / +10 mm

Scan Distance (Objective Shoulder)

15.0 mm / 28 mm

General Specifications

Video Camera

Color CMOS

Weight of Scanner

1 kg (2.2 lbs)

Storage / Operating Temperature

10 °C to 35 °C

Dimensions of OCTG (L x W x H)

85 mm x 60 mm x 139 mm

Dimensions of OCTG-NR (L x W x H)

85 mm x 60 mm x 71 mm

Airborne Noise Emission

< 70 dBA

Table 4 Specifications OCTG

OCT Scan Lens Kits

Objective Item #

OCT-LK2(-BB)

OCT-LK3(-BB)

OCT-LK4(-BB)

Field of View

6 mm x 6 mm

10 mm x 10 mm

16 mm x 16 mm

Barrel Height (B)

25.5 mm

24.0 mm

37.0 mm

Working Distance

3.4 mm

24.9 mm

41.6 mm

Table 5 Specifications Scan Lens Kits

OCTG Series Scanner Chapter 8: Specifications

Rev C, April 06, 2016 Page 23

8.1. Reflectivity Scanning Mirror

The OCTG series standard scanners are equipped with a semitransparent galvo mirror to enable video

camera imaging.*

Figure 21 Reflectivity of Scanning Mirroor

* In systems delivered prior to February 2017 a coating with different characteristics was used. For further

information about their performance, please contact Thorlabs’ OCT support (see Chapter 11).

90

95

100

800 900 1000 1100 1200 1300 1400 1500

Reflectivity(%)

Wavelength (nm)

OCTG Mirror 45°

S-Pol.

Unpolarized

P-Pol.

OCTG Series Scanner Chapter 9: Warranty

Page 24 MTN004419-D02

Chapter 9 Warranty

9.1. Imaging Systems

Thorlabs offers a one-year warranty on the OCTG standard scanner.

9.2. Non-Warranty Repairs

Products returned for repair that are not covered under warranty will incur a standard repair charge in addition

to all shipping expenses. This repair charge will be quoted to the customer before the work is performed.

9.3. Warranty Exclusions

The stated warranty does not apply to products which are (a) specials, modifications, or customized items

(including custom patch cables) meeting the specifications you provide; (b) ESD sensitive items whose static

protection packaging has been opened; (c) items repaired, modified, or altered by any party other than

Thorlabs; (d) items used in conjunction with equipment not provided by or acknowledged as compatible by

Thorlabs; (e) subjected to unusual physical, thermal, or electrical stress; (f) damaged due to improper

installation, misuse, abuse, or storage; (g) damaged due to accident or negligence in use, storage,

transportation, or handling.

OCTG Series Scanner Chapter 10: Regulatory

Rev C, April 06, 2016 Page 25

Chapter 10 Regulatory

As required by the WEEE (Waste Electrical and Electronic Equipment Directive) of the European Community

and the corresponding national laws, Thorlabs offers all end users in the EC the possibility to return “end of

life” units without incurring disposal charges.

This offer is valid for Thorlabs electrical and electronic equipment:

Sold after August 13, 2005

Marked correspondingly with the crossed out “wheelie bin” logo (see right)

Sold to a company or institute within the EC

Currently owned by a company or institute within the EC

Still complete, not disassembled and not contaminated

As the WEEE directive applies to self-contained operational electrical and electronic products, this end of life

take back service does not refer to other Thorlabs products, such as:

Pure OEM products, that means assemblies to be built into a unit by the user (e. g. OEM laser driver

cards)

Components

Mechanics and optics

Left over parts of units disassembled by the user (PCB’s, housings etc.).

If you wish to return a Thorlabs unit for waste recovery, please contact Thorlabs or your nearest dealer for

further information.

10.1. Waste Treatment is Your Own Responsibility

If you do not return an “end of life” unit to Thorlabs, you must hand it to a company specialized in waste

recovery. Do not dispose of the unit in a litter bin or at a public waste disposal site.

10.2. Ecological Background

It is well known that WEEE pollutes the environment by releasing toxic products during decomposition. The

aim of the European RoHS directive is to reduce the content of toxic substances in electronic products in the

future.

The intent of the WEEE directive is to enforce the recycling of WEEE. A controlled recycling of end of life

products will thereby avoid negative impacts on the environment.

Wheelie Bin Logo

OCTG Series Scanner Chapter 11: Thorlabs OCT Support Contact

Page 26 MTN004419-D02

Chapter 11 Thorlabs OCT Support Contact

If you have a technical question or issue on Thorlabs OCT products, please refer directly to the OCT Support

team located in Luebeck, Germany.

OCT Support

Thorlabs GmbH

Maria-Goeppert-Straße 9

23562 Lübeck

Germany

Tel: +49-(0)8131-5956-0

Fax: +49-(0)8131-5956-99

www.thorlabs.de

Email: oct-support@thorlabs.com

OCTG Series Scanner Chapter 12: Thorlabs Worldwide Contacts

Rev C, April 06, 2016 Page 27

Chapter 12 Thorlabs Worldwide Contacts

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place

Ely CB7 4EX

Great Britain

Te

l: +44

(0) 1353-654440

Fax: +44 (0) 1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau

Germany

Tel: +49-(0) 8131-5956-0

Fax: +49-(0) 8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

Japan

Thorlabs Japan, Inc.

3-6-3 Kitamachi,

Nerima-ku, Tokyo 179-0081

Japan

Tel: +81-3-6915-7701

Fax: +81-3-6915-7716

www.thorlabs.co.jp

Email: sales@thorlabs.jp

China

Thorlabs China

Room A101, No. 100, Lane 2891

South Qilianshan Road

Putuo District

Shanghai

China

Tel: +86 (0) 21-60561122

Fax: +86 (0) 21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

M0009-510-885-D

www.thorlabs.com

Loading...

Loading...