NRT Series

Motorized Translation Stage

User Guide

Original Instructions

HA0136T

NRT Series Motorized Translation Stages

Contents

Chaper 1 Introduction .................................................................................................1

Chaper 2 Safety ...........................................................................................................2

2.1 Safety Information ..............................................................................2

2.2 General Warnings and Cautions .......................................................2

Chaper 3 Installation and Operation .........................................................................3

3.1 Mounting to a Work Surface ..............................................................3

3.1.1 General ................................................................................................... 3

3.2 Environmental Conditions .................................................................3

3.2.1 Mounting a Single Stage to a Work Surface ........................................... 4

3.2.2 Mounting stages in X-Y configurations ................................................... 5

3.2.3 Mounting stages in X-Y-Z configurations ................................................ 6

3.3 Operation .............................................................................................8

3.3.1 System Setup ......................................................................................... 8

3.3.2 Selecting the Stage Type ....................................................................... 8

3.4 Calibration of Motor Drives ..............................................................11

3.5 Maintenance ......................................................................................11

Chaper 4 Specification .............................................................................................12

4.1 Specification .....................................................................................12

4.2 Pin Out ...............................................................................................13

4.3 Parts List ...........................................................................................13

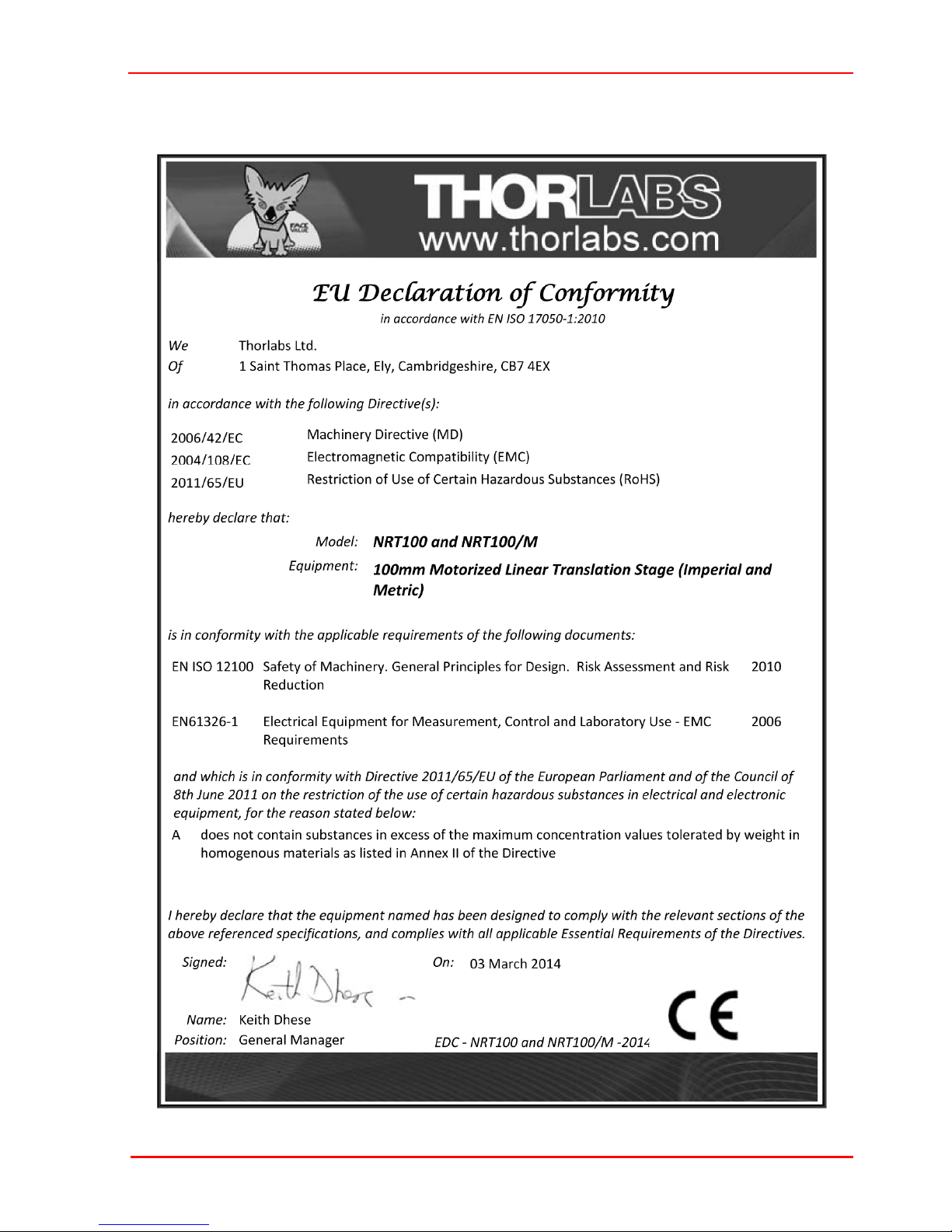

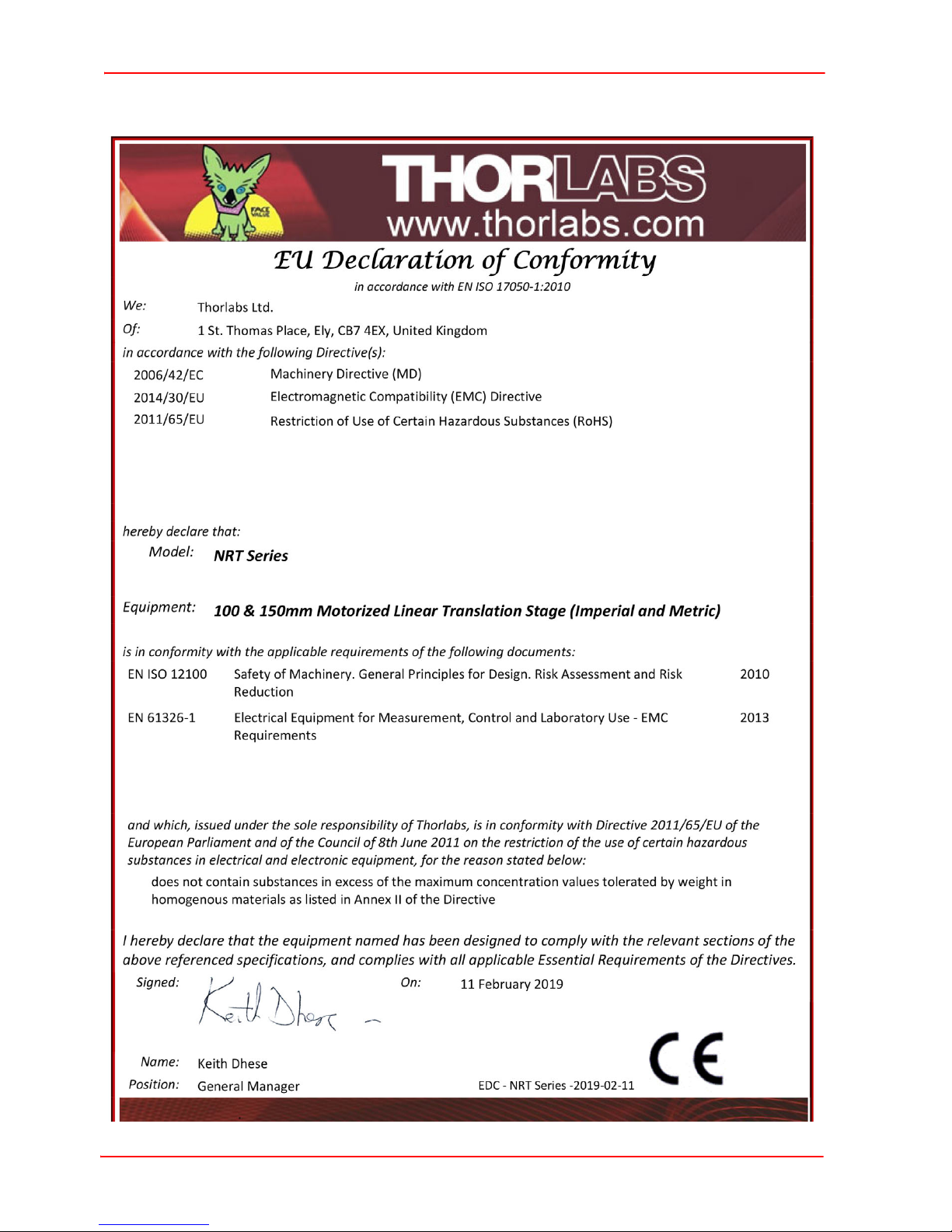

Chaper 5 Regulatory .................................................................................................14

5.1 Declarations Of Conformity .............................................................14

5.1.1 For Customers in Europe ...................................................................... 14

5.1.2 For Customers In The USA .................................................................. 14

Chaper 6 CE Certificate .............................................................................................15

Chaper 7 Thorlabs Worldwide Contacts .................................................................17

Page 0

Chapter 1 Overview

Chapter 1 Overview

1.1 Introduction

The NRT series stages are performance positioning stages which are ideally suited

for measurement and inspection applications. The main platform is supported by 4

recirculating ball carrier bearings mounted to precisely aligned linear guide rails. A

backlash free precision lead screw produces smooth translation, directly driven with

a hybrid 2-phase stepper motor capable of 409,600 micro steps per revolution, and

positioning resolutions of less than 100nm when driven by the BSC series of benchtop

controllers. The highly repeatable, Hall effect (magnetic) home detection limit switch

also provides overdriving protection in both forward and reverse directions.

The high quality stepper motor offers excellent dynamic and static torque

performance and the design provides the detailed features required of any true

nanopositioning product.

Rev 12 Oct 2018

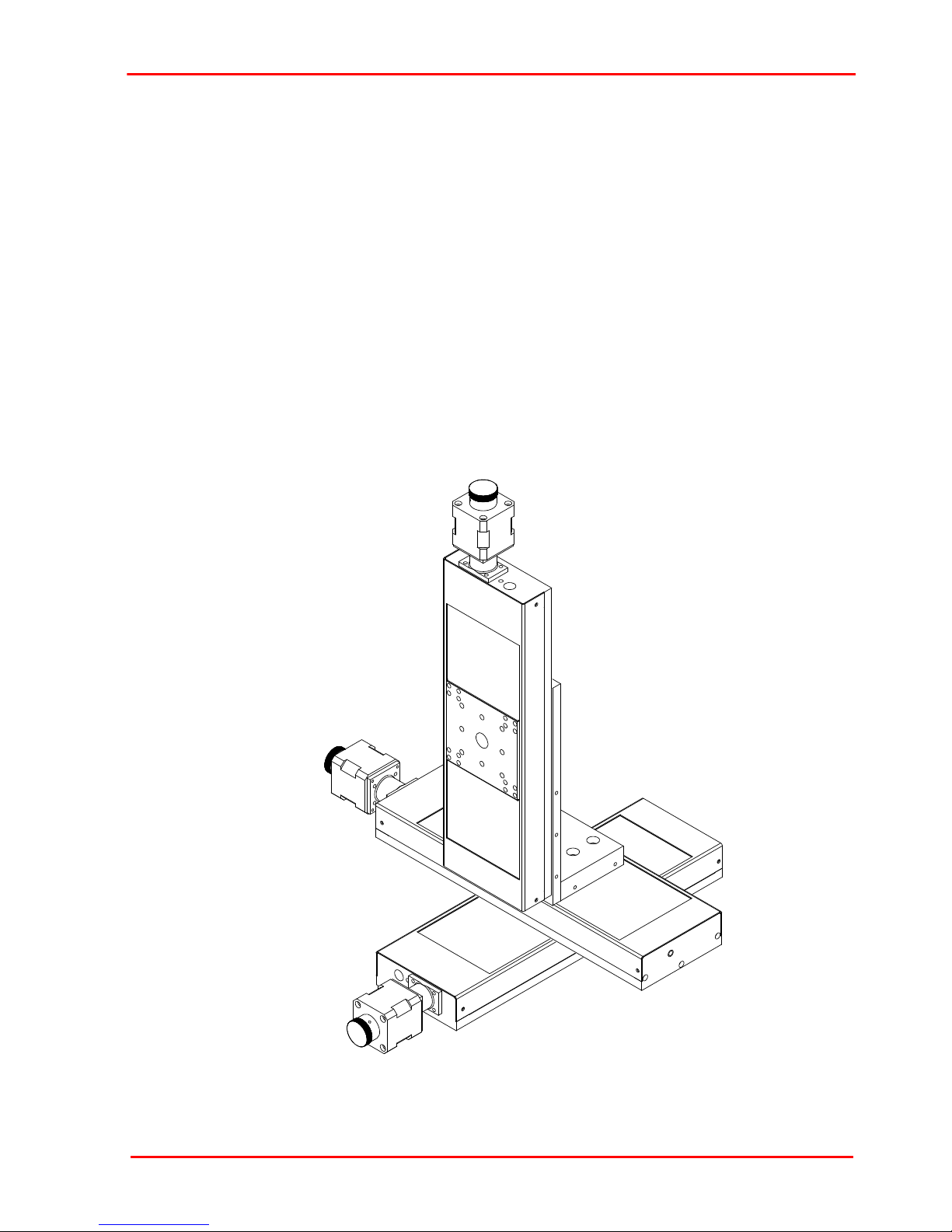

Fig. 1.1 Typical XYZ Configuration

Page 1

NRT Series Motorized Translation Stages

Chapter 2 Safety

2.1 Safety Information

For the continuing safety of the operators of this equipment, and the protection of the

equipment itself, the operator should take note of the Warnings, Cautions and Notes

throughout this handbook and, where visible, on the product itself.

The following safety symbols may be used throughout the handbook and on the

equipment itself.

Warning: Risk of Electrical Shock

Given when there is a risk of injury from electrical shock.

Warning

Given when there is a risk of injury to users.

Caution

Given when there is a risk of damage to the product.

Note

Clarification of an instruction or additional information.

2.2 General Warnings and Cautions

Warning

If this equipment is used in a manner not specified in the handbook, the

protection provided by the equipment may be impaired. In particular, excessive

moisture may impair operation.

Spillage of fluid, such as sample solutions, should be avoided. If spillage does

occur, clean up immediately using absorbant tissue. Do not allow spilled fluid to

enter the internal mechanism.

The equipment is for indoor use only.

When running custom move sequences, or under fault conditions, the stage

may move unexpectedly. Operators should take care when working inside the

moving envelope of the stage.

Page 2

Chapter 3 Installation and Operation

Chapter 3 Installation and Operation

Note

Retain the packing in which the unit was shipped, for use in future transportation.

3.1 Mounting to a Work Surface

3.1.1 General

When mounting the NRT stage close to other equipment, ensure that the travel of the

moving platform is not obstructed. If equipment mounted on the moving platform is

driven against a solid object, damage to the internal mechanism could occur. The

range of travel for each model is as follows:

NRT100 - 100mm, NRT150 - 150mm.

3.2 Environmental Conditions

Warning

Operation outside the following environmental limits may adversely affect

operator safety.

Location Indoor use only

Maximum altitude 2000 m

Temperature range 5

Maximum Humidity Less than 80% RH (non-condensing) at 31°C

To ensure reliable operation the unit should not be exposed to corrosive agents or

excessive moisture, heat or dust.

If the unit has been stored at a low temperature or in an environment of high humidity,

it must be allowed to reach ambient conditions before being powered up.

The unit must not be used in an explosive environment.

o

C to 40oC

Rev 12 Oct 2018

Page 3

NRT Series Motorized Translation Stages

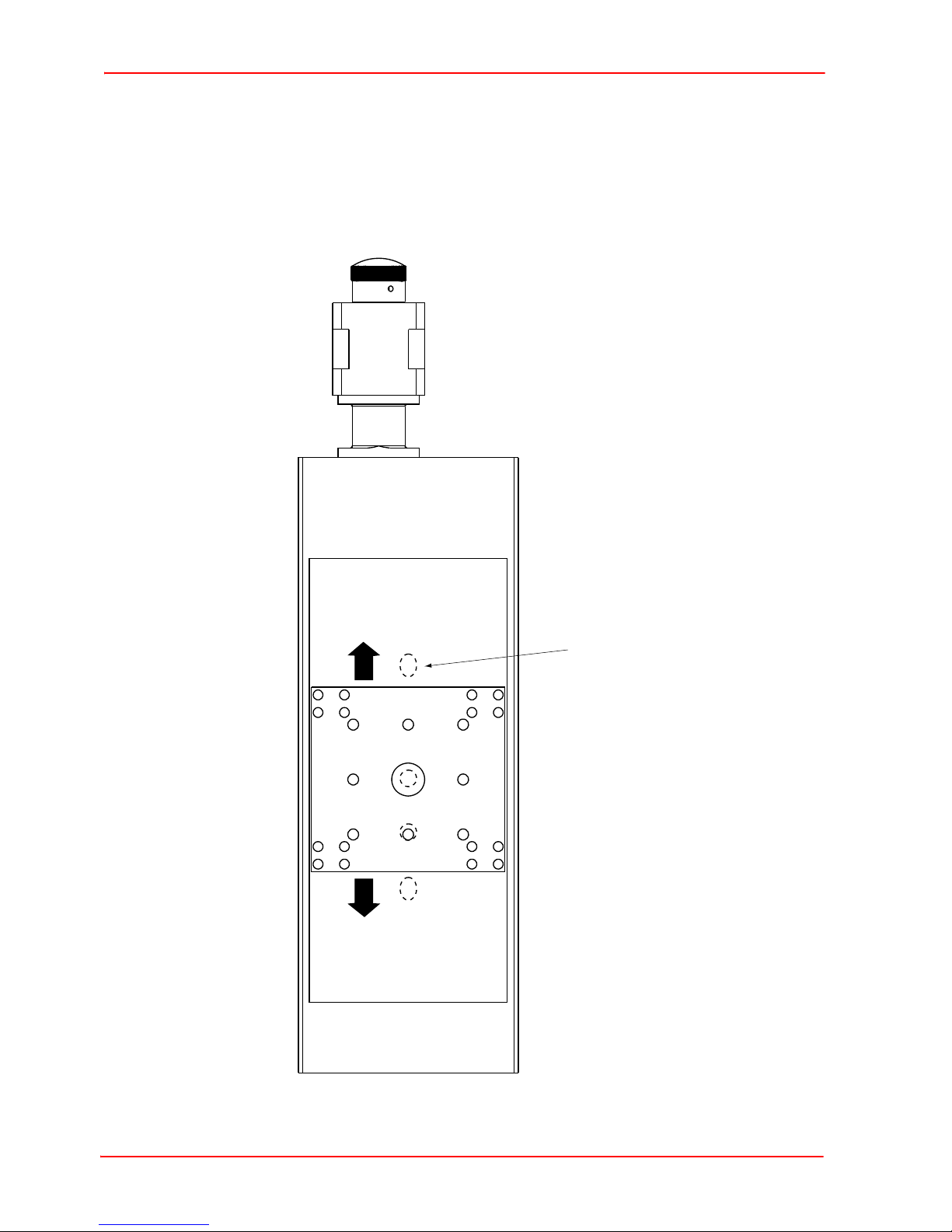

mounting holes thru base

qty 4 NRT100

qty 5 NRT150

3.2.1 Mounting a Single Stage to a Work Surface

The NRT stage is mounted to the working surface by M6 screws through the base. To

access these mounting holes, turn the motor knob to move the carriage until the holes

are visible through the center hole - see Fig. 3.1. The stage can also be mounted in

other orientations - see Section 3.2.2. and 3.2.4

Page 4 14098-D01

Fig. 3.1 Mounting Holes

Chapter 3 Installation and Operation

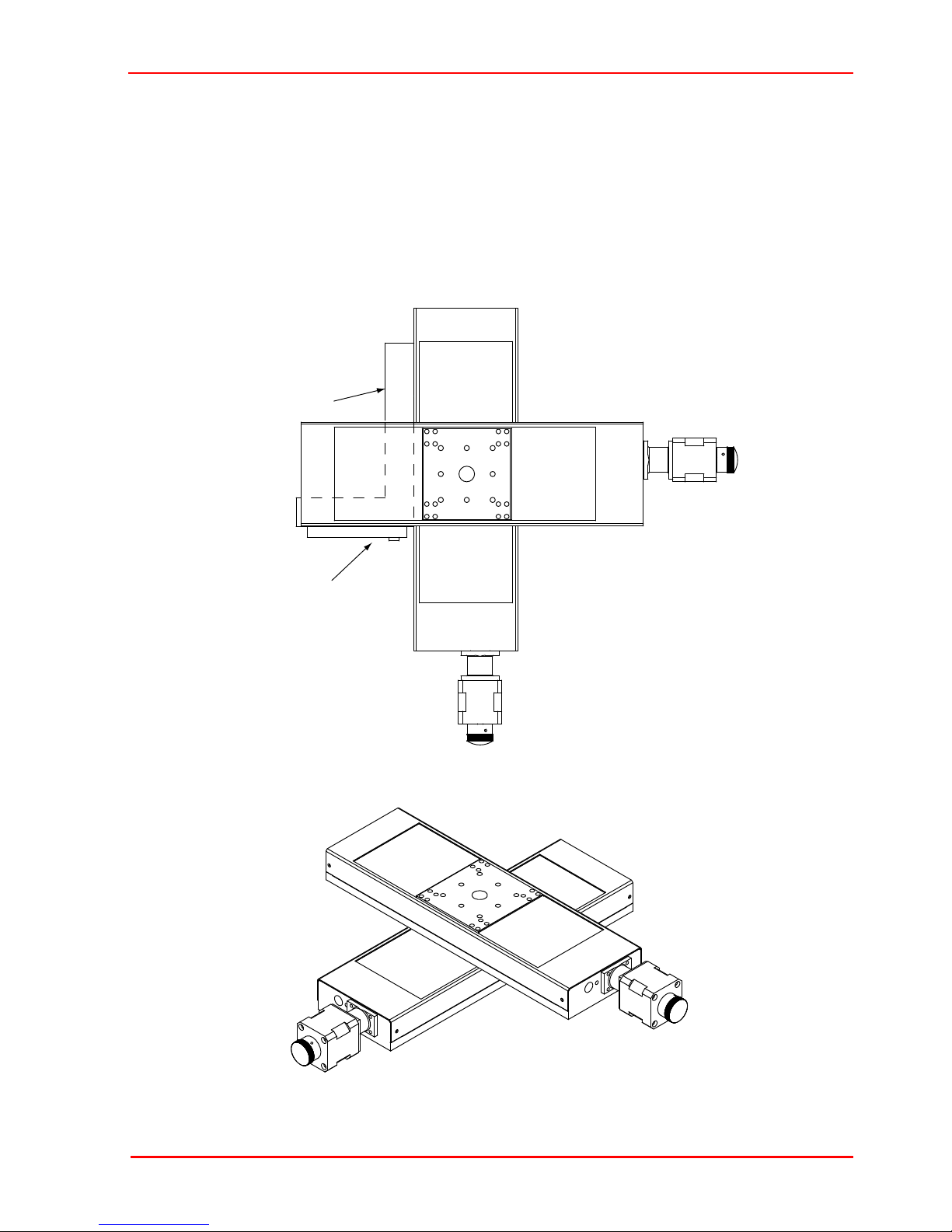

(square)

(flat plate)

3.2.2 Mounting stages in X-Y configurations

Tools required:

5mm hexagon key,

Qty 2, M6 x 12 (1/4-20 UNC x 1/2”) cap head bolts,

Engineers square and a flat plate.

Rev 12 Oct 2018

Fig. 3.2 X-Y configuration

Page 5

NRT Series Motorized Translation Stages

1) Fix the X axis stage to the worksurface, as detailed in Section 3.2.1.

2) Turn the motor knob of the Y axis stage to move the top platform sufficiently to

gain access to the fixing holes in the base plate.

3) Position the stages as shown in Fig. 3.2.

4) Fit and tighten the securing bolts then loosen 1/4 to 1/2 turn.

Caution

Ensure that the screws do not foul the carriage as it moves backwards and

forwards.

5) If all fixing holes cannot be accessed, move the top platform as necessary to gain

access, then repeat items 2) to 5).

6) Position the engineers square and flat plate as shown in Fig. 3.2.

7) Align the stages squarely then tighten the securing bolts.

8) Recheck that the stages are square and readjust as necessary.

3.2.3 Mounting stages in X-Y-Z configurations

1) Fix the X axis stage to the worksurface as detailed in Section 3.2.1.

2) Assemble two stages in an XY configuration as detailed in Section 3.2.2.

3) Fit the Z-bracket assembly (NRT150P1) to the Y axis stage and attach the Z axis

stage as shown in Fig. 3.3.

If accurately square z-axis travel is required, use an engineering square to align the

orthgonality of the z-axis travel by noting the size of the gap between the moving plate

and the square at either end of vertical travel. It there is a noticable difference in the

size of this gap then adjustments should be made through loosening/tightening of the

mounting bracket to the stage:

Page 6 14098-D01

Z bracket assembly

(NRT150P1)

bracket may be turned

through 90° on Y stage

X

Y

Z

Side View

Plan View

Chapter 3 Installation and Operation

Rev 12 Oct 2018

Fig. 3.3 X-Y-Z configuration

Page 7

NRT Series Motorized Translation Stages

3.3 Operation

The NRT stage should be driven by the Thorlabs stepper motor BSC series

controllers - see www.thorlabs.com for further details. The flying lead of the stage is

terminated in a D-type connector - see Chapter 4 for pin out details, and should be

connected to the controller via the extension cable supplied.

Caution

Do not attempt to control this stage using the KST101 or TST101 K-Cube or T-Cube

controllers. There is no software configuration for use with these devices.

The stepper motor controller must be switched OFF before the stages are

plugged in or unplugged. Failure to switch the controller off may result in

damage to either the controller, the stage, or both.

Because it can be software controlled it should be noted that this device could

begin to move unexpectedly for a person within its envelope of operation, who

had not programmed the move. However, max speed and load are such that

risks are minimal.

3.3.1 System Setup

1) Install the electronic hardware and connect the controller to the relevent axes of

the associated stage(s) (see the handbooks supplied with the APT Controllers).

2) For each Stepper Motor Controller in your system, fit the interlock plug (supplied)

to the MOTOR CONTROL connector on the rear panel.

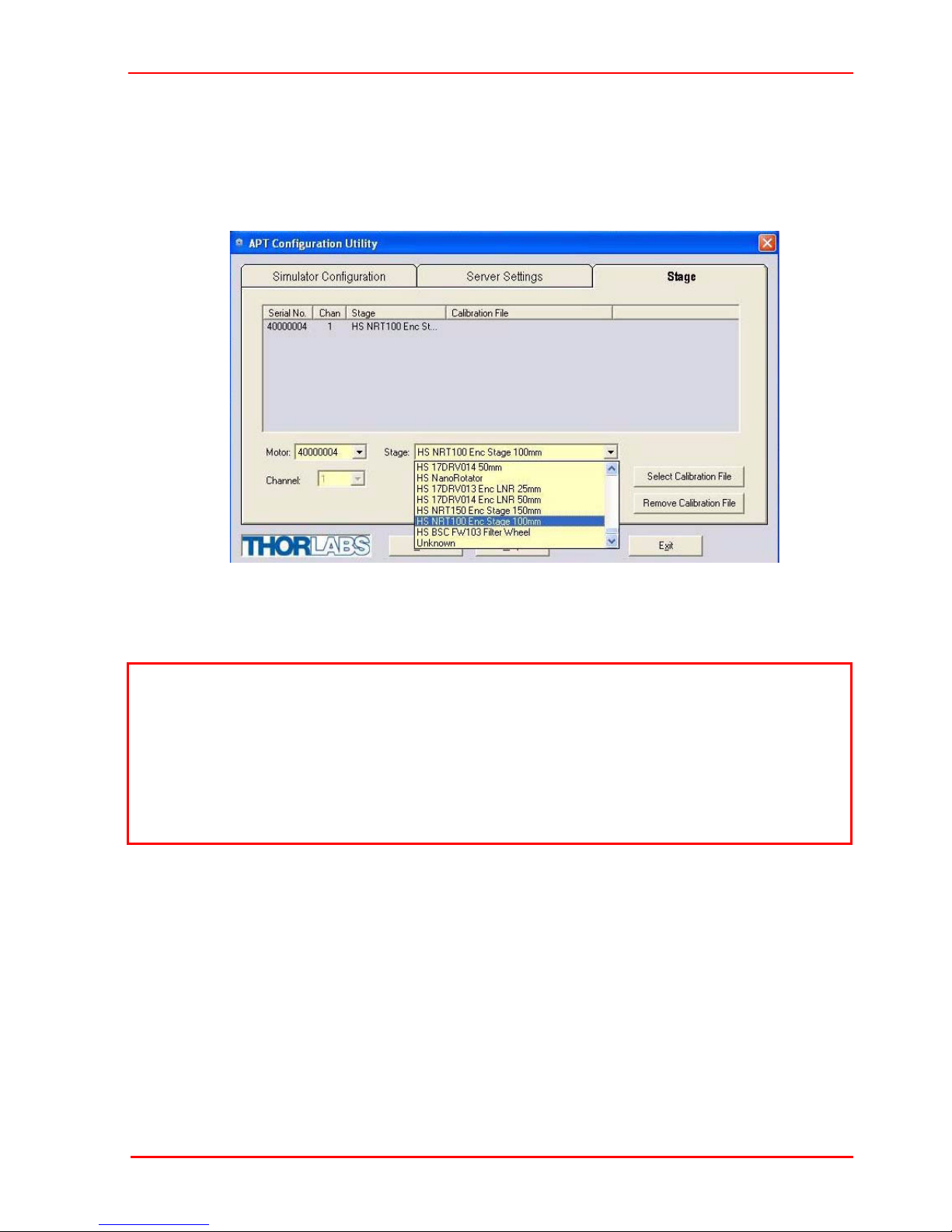

3.3.2 Selecting the Stage Type

To ensure that a particular stage is driven properly by the system, a number of parameters

must first be set. These parameters relate to the physical characteristics of the stage being

driven (e.g. min and max positions, leadscrew pitch, homing direction etc.).

To assist in setting these parameters correctly, it is possible to associate a specific stage

type and axis with the motor controller channel. Once this association has been made, the

server applies automatically, suitable default parameter values on boot up of the software.

Page 8 14098-D01

Chapter 3 Installation and Operation

Using APT Software

3) Shut down all applications using the APT server (e.g. APT User or your own

custom application).

4) Run the APT Config utility - Start/All Programs/Thorlabs/APT Config/APT Config.

5) From the 'APT Configuration Utility' window, click the 'Stage' tab.

Fig. 3.4 APT Configuration Utility - Stage Tab

6) In the ‘Motor’ field, select the serial number of the stepper motor controller to be

configured (this number can be found on the rear panel of the controller unit).

Note

To ensure correct operation, it is important to select the correct stage type for your

controller. If using a MST602 or BSC20x series controller, select the appropriate ‘HS

NRT xxx Enc’ option. If using a legacy BSC0xx or BSC10x controller, choose an

option without the ‘HS’ prefix.

Selecting an incompatible stage type could result in reduced velocity and resolution

or, when using a joystick, the joystick may be inoperable.

7) In the ‘Stage’ field, select the stage (e.g. ‘HS NRT100 Enc’) from the list displayed.

8) Click the 'Add Stage Association' button.

9) A default configuration is set at the factory and stored in the non-volatile memory

of the motor controller. The server reads in the stage and controller information on

start up.

See the handbook for the associated stepper motor controller for more information

on driving the actuator/stage.

Rev 12 Oct 2018

Page 9

NRT Series Motorized Translation Stages

Using Kinesis Software

1) Ensure that the device is connected to the PC and powered up.

2) Run the Kinesis software - Start/All Programs/Thorlabs/Kinesis/Kinesis.

3) On start-up, the 'Actuator/Startup Settings’ window is displayed. This window

allows the correct actuator to be selected.

4) From the drop down menu, select your NRT stage type (e.g. HS NRT100 Enc

Stage 100mm).

5) Click OK.

6) The server reads in the stage and controller information automatically.

See the handbook for the associated stepper motor controller for more information

on driving the actuator/stage.

Page 10 14098-D01

Fig. 3.5 Stage Configuration Window

Chapter 3 Installation and Operation

3.4 Calibration of Motor Drives

Calibration enables the server to correct for any mechanical errors inherent in the

system. Mechanical components, such as the leadscrew and linkages, can be machined

only within a certain tolerance, e.g. the leadscrew may be nominally 1mm but actually

1.0005mm, giving a 0.5 micron error. In practice, these errors accumulate from a number

of sources, however they are repeatable and therefore, can be compensated.

During calibration, the total positional error is measured at a large number of points

and these errors are stored as a look up table (LUT). The LUT is saved as a

calibration file, one file for each axis on a particular stage. These files are then linked

to the appropriate axis as part of the Stage association process performed using the

APT Config utility. Whenever the stage is moved, the LUT is consulted to ascertain

the precise movement required to achieve the demanded position.

The use of a calibration file is optional. Without it, the repeatability and resolution of

the stage are unaffected, but no compensations are made to enhance the accuracy.

Calibration files can be downloaded from the support documents section on the

product web page, one file for each serial number. Details on assigning a calibration

file are contained in the APTConfig On Line Helpfile.

3.5 Maintenance

The unit contains no user servicable parts and must be returned to the manufacturer

for service and/or repair.

Caution

When packing the unit for shipping, use the original packing. If this is not

available, use a strong box and surround the unit with at least 100 mm of shock

absorbent material.

Rev 12 Oct 2018

Page 11

NRT Series Motorized Translation Stages

Chapter 4 Specification

4.1 Specification

Specification NRT100 NRT150

Travel Range 100 mm 150 mm

Load Capacity 20 kg Horizontal

5.0 kg Vertical

Bidirectional Repeatability 1.0 µm

Max Load Capacity 21.8 kg (48 lbs)

Velocity Range* 40.0 µm/s to 30 mm/s

Acceleration 30 mm/s/s

Min Achievable Incremental Movement 0.1 µm

Absolute On-Axis Accuracy 15.29 µm 19.29 µm

Calibrated On-Axis Accuracy 2.0 µm 2.0 µm

Pitch 0.008° (140 µrad)

Yaw 0.05° 873 µrad

Operating Temperature -20µ to +40 µ C

Weight 2.2 kg (4.8 lb) 2.5 kg (5.5 lb)

Construction Aluminum with precision, recirculating linear

bearings

Full Step Angle 1.8°

Step Angle Accuracy 5%

Rated Phase Current 1 A

Phase Resistance 4.6 Ω

Phase Inductance 10.6 mH

Holding Torque 23.1 N•cm

Detent Torque 1.7 N•cm

Rotor Inertia 32 g•cm2

Insulation Class B

Limit Switches Ceramic-Tipped Mechanical

Microsteps per Revolution of Leadscrew 409,600

Motor Type 2-Phase Stepper

Compatible Controllers BSC201, MST602

* The velocity quoted above is only achievable with light loads. When using heavy

loads, the velocity should be reduced accordingly.

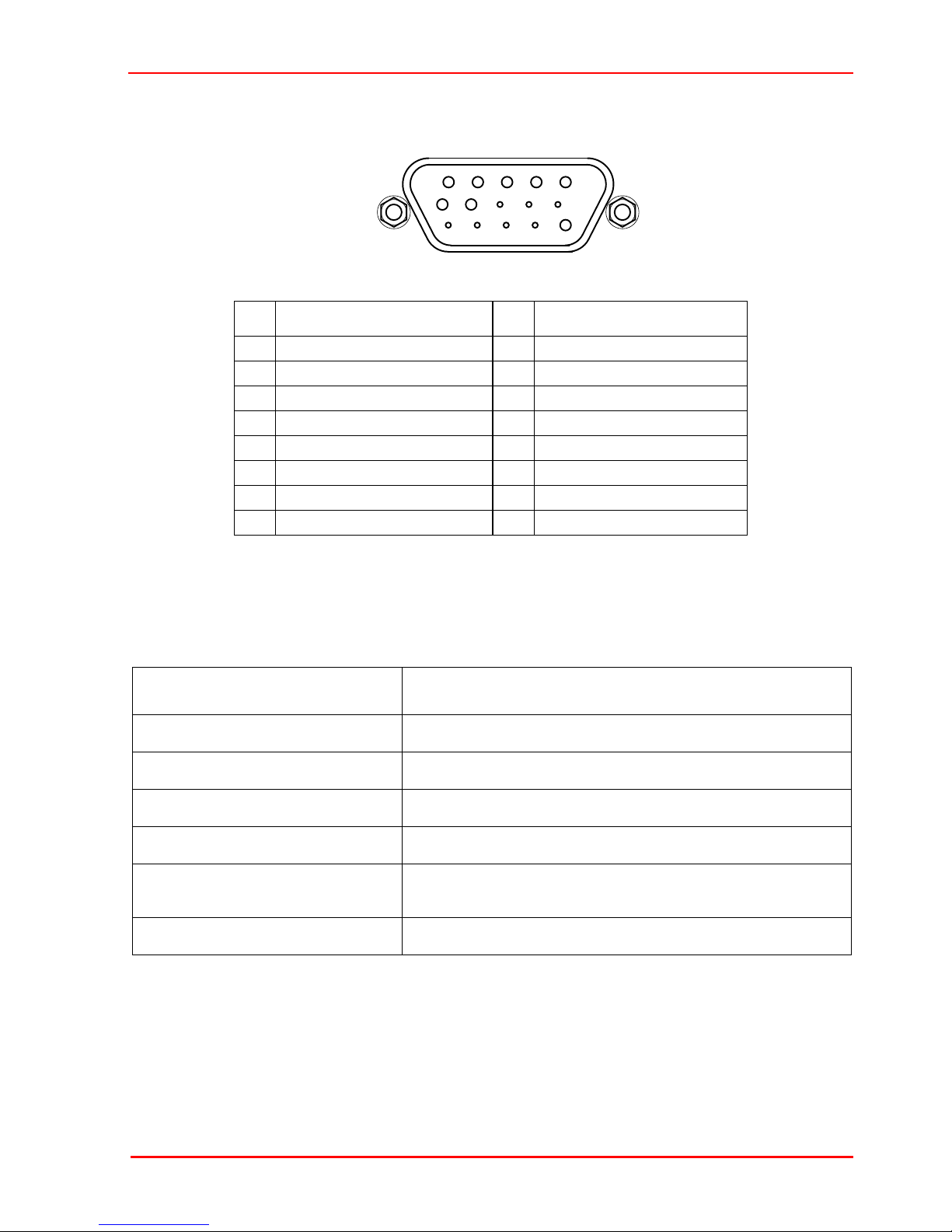

4.2 Pin Out

Page 12

Chapter 4 Specification

5

10

11

15

6

1

The ‘Motor’ connector provides connection to the stepper motor controller. The pin

functions are detailed in Fig. 4.1.

Pin Description Pin Description

1 Limit Switch Ground 9

2 Forward Limit Switch 10

3 Reverse Limit Switch 11

4 Phase B -ve 12

5 Phase B +ve 13 Limit Switch 5V

6 Phase A -ve 14

7 Phase A +ve 15 Ground

8

Fig. 4.1 Motor Connector Pin Descriptions

4.3 Parts List

Part Number Description

PAA612 Connection Cable 1 m (3.3’)

PAA613 Connection Cable 3 m (9.8’)

NRT100 and NRT100/M NanoStep NRT stage with 100mm travel

NRT150 and NRT150/M NanoStep NRT stage with 150mm travel

NRT150P1 ‘Z’ bracket for fixing stages in X-Z, Y-Z and X-Y-Z

configurations

ha0136T Handbook

Rev 12 Oct 2018

Page 13

NRT Series Motorized Translation Stages

Chapter 5 Regulatory

5.1 Declarations Of Conformity

5.1.1 For Customers in Europe

See Section 5.2.

5.1.2 For Customers In The USA

This equipment has been tested and found to comply with the limits for a Class A

digital device, persuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by the company could void the

user’s authority to operate the equipment.

Page 14

5.2 CE Certificate

Chapter 5 Regulatory

Rev 12 Oct 2018

Page 15

NRT Series Motorized Translation Stages

Page 16 14098-D01

Chapter 6 Thorlabs Worldwide Contacts

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau

Germany

Tel: +49-(0)8131-5956-0

Fax: +49-(0)8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

Japan

Thorlabs Japan, Inc.

3-6-3 Kitamachi,

Nerima-ku, Tokyo 179-0081

Japan

Tel: +81-3-6915-7701

Fax: +81-3-6915-7716

www.thorlabs.co.jp

Email: sales@thorlabs.jp

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place, Ely

Cambridgeshire CB7 4EX

Great Britain

Tel: +44 (0)1353-654440

Fax: +44 (0)1353-654444

www.thorlabs.de

email: sales@uk.thorlabs.com

Support: techsupport.uk@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

China

Thorlabs China

Room A101, No. 100

Lane 2891, South Qilianshan Road

Putuo District

Shanghai

China

Tel: +86 (0) 21-60561122

Fax: +86 (0)21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

Chapter 6 Thorlabs Worldwide Contacts

Thorlabs verifies our compliance with the WEEE (Waste Electrical and Electronic

Equipment) directive of the European Community and the corresponding national

laws. Accordingly, all end users in the EC may return "end of life" Annex I category

electrical and electronic equipment sold after August 13, 2005 to Thorlabs, without

incurring disposal charges. Eligible units are marked with the crossed out "wheelie

bin" logo (see right), were sold to and are currently owned by a company or institute

within the EC, and are not dissembled or contaminated. Contact Thorlabs for more

information. Waste treatment is your own responsibility. "End of life" units must be

returned to Thorlabs or handed to a company specializing in waste recovery. Do not

dispose of the unit in a litter bin or at a public waste disposal site.

Rev 12 Oct 2018

Page 17

www.thorlabs.com

Loading...

Loading...