LSS10

LED Lightbox for

Laser Safety Signs

User Guide

Original Instructions

LSS10 LED Light Box

Contents

Chaper 1 Overview ..................................................................................................... 1

1.1 Introduction ........................................................................................ 1

Chaper 2 Safety .......................................................................................................... 2

2.1 Safety Information ................................................. ......................... ... 2

2.2 General Warnings .............................................................................. 2

Chaper 3 Installation .................................................................................................. 4

3.1 Mechanical Installation ...................................................................... 4

3.2 Electrical Connections ...................................................................... 4

Chaper 4 Operation .................................................................................................... 8

4.1 Control and Connection Overview ............ .. ... .................................. 8

4.2 Using the Safety Interlock .......................................... ....................... 9

4.3 Replacing the Internal Fuses .......................................................... 10

4.4 Inserting a Laser Safety Sign ..................................... ... .................. 10

4.5 Disabling the Brightness Control........................................ ... ......... 11

4.6 Cleaning............................................................................................. 11

Chaper 5 Specification ............................................................................................. 12

5.1 General Specifications .................................................................... 12

Chaper 6 Regulatory ................................................................................................ 13

6.1 Declarations Of Conformity ............................................................ 13

6.2 Waste Electrical and Electronic Equipment (WEEE) Directive .... 13

6.3 CE Certificates ................................................................................. 15

Chaper 7 Thorlabs Worldwide Contacts................................................................ 16

Chapter 1 Overview

Chapter 1 Overview

1.1 Introduction

The LSS10 Laser Safety Sign Lightbox provides a clear indication that a laser system

is in use by illuminating the laser safety sign (sold sepa rately) that states the

appropriate warning message and laser classification. The lightbox accepts any one

of the LSS10 se ries Laser Safety Signs available from our website. Signs can be

quickly interchanged making it easy to update signage to meet your cha nging laser

set up requirements.

The box operates at 100 to 240 VAC, (i.e. USA and EU regions) and has two safety

interlock options (internal and external - see Section 4.2.) th at prevent the use of

interlock-equipped laser systems unless the safety light is turned on. The external

interlock socket accepts a 2.5 mm phono jack (supplied).

The lightbox is permanently fixed to a wal l via the moun ting slots in the rear panel.

Two sets of slots are available to allow positioning of the controls for left or right

handed operation. A convenient line cord latch preven ts the AC line cord from

disengaging from the unit.

Illumination is controlled by turning a knob on the right hand side of the unit, allowing

the brightness to be adjusted to suit th e specific location of use. An internal jumper

can be activated which bypasses the external control, thereby making the brightness

tamperproof. Illumination is then controlled by a set of switches on the circuitboard see Section 4.5.

Rev A Nov 2017

Fig. 1.1 LSS10 Laser Safety Sign Lightbox

Page 1

LSS10 LED Light Box

Chapter 2 Safety

2.1 Safety Information

For the continuing safety of the operators of this equipment, and the protection of the

equipment itself, the operator should take note of the Warnings, Cautions and Notes

throughout this handbook and, where visible, on the product itself.

The following safety symbo ls may be u sed throughout the h andbook and on the

equipment itself.

Warning: Risk of Electrical Shock

Given when there is a risk of injury from electrical shock.

Warning

Given when there is a risk of injury to users.

Caution

Given when there is a risk of damage to the product.

Note

Clarification of an instruction or additional information.

2.2 General Warnings

Warning

If this equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired. In particular, excessive

moisture may impair operation.

Spillage of fluid, such as sample solutions, should be avoided.

If spillage does occur, disconnect the power then clean up immediately using

absorbant tissue. Do not allow spilled fluid to enter the internal mechanism.

The equipment is for indoor use only.

The equipment is not designed for use in an explosive atmosphere.

Page 2 ETN037435-D02

Chapter 2 Safety

Warning: Risk of Electrical Shock

The light box is powered by mains voltages. This is hazardous and can cause

serious injury. Appropriate care should be taken when using this device.

Persons using the device must understand the hazards associated with using

high voltages and the steps necessary to avoid risk of e lectrical shock.

Particular care should be observed when adjusting or operating the unit via the

internal PCB controls.

Rev A Nov 2017

Page 3

LSS10 LED Light Box

Chapter 3 Installation

3.1 Mechanical Installation

The lightbox can be permanently fixed to a wall, via the four mounting holes in the rear

panel - see the dra wings available from www.thorlabs.com for details and

dimensions.

Caution

Screws or fittings to attach the unit to the wall are not included. Always choose

M4 (8-32) screws and fittings which are suitable for use in your wall and have

enough holding power. Do not use screws with cou ntersunk heads. If you are

uncertain, contact a specialised installer.

Note

The default configuration and labelling is for right-handed use, however the mounting

holes allow the unit to be mounted for left hand use.

Furthermore, several metalwork knockouts are provided for grommets (supplied) and

cables when hard wiring the unit into an electrical system.

Caution

The unit must be fixed securely to the wall before using the internal wiring option.

Do not use the internal wiring option when the unit is fixed via the keyed slots in

the rear panel.

3.2 Electrical Connections

Warning

The unit uses mains voltages. This is hazardous and can cause serious injury.

The unit must be installed only by suitably trained and qualified personnel who

understand the ha zards associated with using high voltages and the steps

necessary to minimize the risk of electrical shock.

The unit is conn ected to the mains power using the cab le supplied, via the IEC 14

connector on the right hand side - see Fig. 3.1.

Warning

If using a power cord other than that supplied, ensure that the cord is at least

equivalently rated (see Se ction 5.1. fo r power cord ratings) an d does not

exceed 3m in length.

Use only power cords with a factory supplied moulded IEC C13 connector. Do

not use cords fitted with rewirable connectors.

Page 4 ETN037435-D02

Chapter 3 Installation

100 - 240 VAC

50/60 Hz

15 W

A convenient line cord latch prevents the power cord disengaging from the unit. The

cord latch is supplied loose and should be fitted before the lightbox is used.

Fig. 3.1 Power supply connection panel

Although the unit is supplied preset fo r external power connections, power can be

hard wired to the internal PCB as follows:

Cautions for Hard Wiring the Unit

The unit should be hard wired only when it is permanently attached to the wall.

Only use 3-core (0.75 to 1.5 mm2) 218/318 cable to EN 50525-2-11 to hard wire

the unit.

Grommets with a flammability rating of UL94-V-1 or better must be used at the

cable exit points. Suitable grommets are supplied.

In order to preve nt accidental disconnection of cabl es, ensure that the strain

relief clamp provided is used. The clamp is fitted with two M3 x 6mm screws for

use with standard cable diameters. Two M3 x 8 mm screws are also supplied

for use with larger diameter cables.

A switch or circuit breaker must be incl uded in the installation. It must be

conveniently located and easily reached, and must be clearly marked a s the

disconnecting device for the equipment.

1) Ensure that the unit is disconnected from mains power.

2) Using a PZ1 screwdriver or other suitable tool, remove the six M3 PoziDriv screws

securing the front panel.

Rev A Nov 2017

Page 5

LSS10 LED Light Box

Neutral

Earth

Live

FUSES F1 and F2

0.63A, 250 VAC.

CON4

LED PANEL

R15

3) Pull to the left and forward to remove as shown in Fig. 3.2 over the page. Keep the

cover supported until the internal electrical connection is disconnected at the next

step.

Fig. 3.2 Removing the front panel

4) Unclip the connection to the LED circuit CON4 - see Fig. 3.3 then remove the panel.

5) Ensure mains power is disconnected, then move the INT/EXT jumpers at the

bottom of the PCB to the INT position as shown below.

Page 6 ETN037435-D02

Fig. 3.3 Internal mains connection

Chapter 3 Installation

Knock-outs in rear panel 4 Places

Knock-outs in side faces 3 Places

Strain relief clamp

6) Make connections using connector CON2 as shown in

knock-outs, grommets (supplied) and strain relief clamps provided to ensure that

the cable is adequately supported and restrained - see Fig. 3.4.

Fig. 3.3

. Use the cable

Fig. 3.4 Cable knock-outs and strain relief clamp locations

7) If using an internal safety interlock, perform the procedure detailed in Section 4.2.

8) Re-connect the LED circuit at CON4.

9) Refit the front panel.

10) To change from hard-wired power to using the panel connections, isolate the unit

from the mains supply, then reverse the steps previously described.

Rev A Nov 2017

Page 7

LSS10 LED Light Box

+

_

I

O

INTLK

POWER

LSS10

CB74EX UK

Chapter 4 Operation

4.1 Control and Connection Overview

The controls are located on the side panel above the power supply connections as

shown below.

BRIGHTNESS - Used to control the light intensity of the lightbox (when the external

controls (see Section 4.5.) are enabled).

INTLK - For use in laser safety applications - see Section 4.2.

POWER - Used to switch the unit on and off.

Caution

The ON/OFF switch mentioned above removes power from the internal lighting

circuit. It does not remove power from the unit itself.

Page 8 ETN037435-D02

Fig. 4.1 Controls overview

Chapter 4 Operation

laser interlock circuit

lightbox

panel

switch

interlock

relay

4.2 Using the Safety Interlock

The lightbox is fitted with an optional safety interlock output, which allows interlockequipped laser systems to be interlocked to the lightbox such that laser use is

prevented unless the lightbox is illuminated.

External interlock circuits can be connected to the lightbox interlock output externally

or internally. External circuits should not exceed 34V DC/AC, 0 .5A, and should be

electrically isolated from hazardous circuits with reinforced insulation.

External connection is achieved via the jack socket on the right hand control panel

(see Fig. 4.1) which accepts a 2.5mm phono jack (supplied). This should be wired into

the laser interlock circuit as shown in Fig. 4.2.

Fig. 4.2 Jackplug interlock wiring

Caution

When soldering the interlock jack plug, ensure that the contacts are prope rly

isolated from each other.

DO NOT con nect/disconnect the interlock jackplug when the unit is switched

ON and illuminated.

Rev A Nov 2017

Page 9

LSS10 LED Light Box

INTERLOCK

CON6

laser external

interlock circuit

interlock

relay

lightbox

panel

switch

Internal connection is achieved by hard-wiring to the terminal block provided on the

PCB as shown in Fig. 4.3.

4.3 Replacing the Internal Fuses

Fig. 4.3 PCB interlock wiring

The ON/OFF switch on the panel controls power to the interlock relay, and completes

the interlock circuit when the switched ON.

Warning

The unit uses mains voltages. This is hazardous and can cause serious injury.

The fuses must be replaced only by suitably trained and qualified personnel

who understand the hazards associated with using high voltages and the steps

necessary to minimize the risk of electrical shock.

In case of an internal fuse blow, the fuse should be replaced as follows:

1) Remove power from the unit.

2) Remove the front panel - see Fig. 3.2.

3) Locate the broken fuse - see Fig. 3.3

4) Replace the fuse with another of the same type, 0.63A (T) 250 VAC.

5) Refit the front panel.

Page 10 ETN037435-D02

4.4 Inserting a Laser Safety Sign

Safety signs are inserted through a hinged flap as shown below.

Chapter 4 Operation

Fig. 4.4 Inserting a laser safety sign

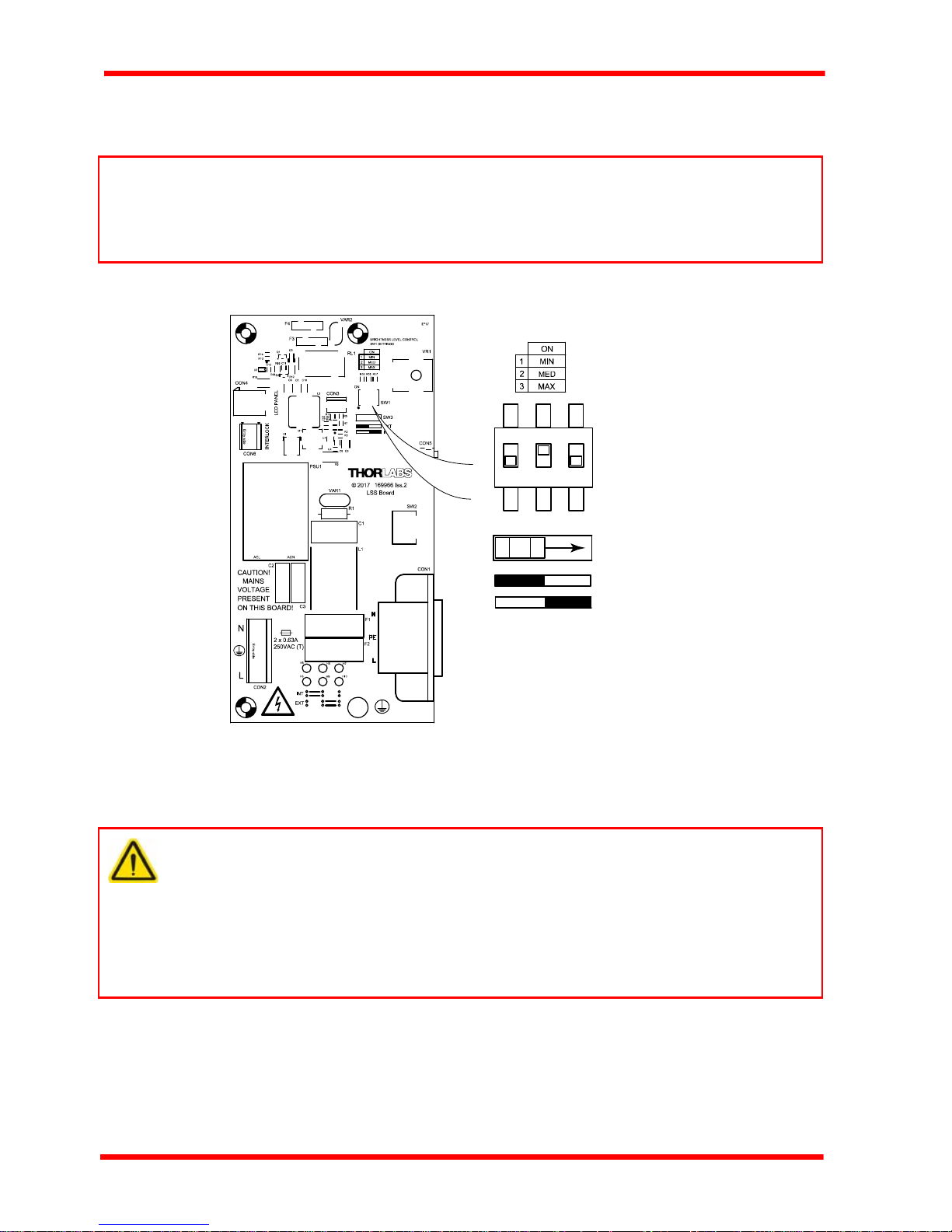

4.5 Disabling the External Brightness Control

Warning

The internal circuit board exposes mains voltages. This is hazardous and can

cause serious injury. Adjustment of the internal controls must be pe rformed

only by suitabl y trained and qualified personnel who understand the hazards

associated with using high voltages and the steps necessary to m inimize the

risk of electrical shock.

To avoid unwanted tampering with the brightness setting, the unit can be configured

such that the external control is bypassed, and brightness is set internally.

1) Isolate the unit from mains power.

2) Remove the front Panel - see Fig. 3.2.

3) Move switch SW3 to the INT position as shown below.

Rev A Nov 2017

Page 11

LSS10 LED Light Box

SW3

EXT

INT

SW1

12 3

4) Adjust the brightness by setting switch SW1 to MIN, MED or MAX. Fig. 4.5 shows

the brightness set to MED.

Note

The ‘MIN’ setting corresponds to the brightness level set to minimum using the

control panel pot. Similarly, the ‘MAX’ setting corresponds to the max brightness

level set using the control panel pot.

5) Refit the front panel.

Fig. 4.5 Switching to internal brightness adjustment

4.6 Cleaning

Warnings

Disconnect the power supply before cleaning the unit.

Never allow water to get inside the case.

Do not saturate the unit.

Do not use any type of abrasive pad, scouring powder or solvent, e.g. alcohol

or benzene.

The unit may be clean ed with a soft cloth, lightly dampened with water or a mild

detergent.

Page 12 ETN037435-D02

Chapter 5 Specification

Chapter 5 Specification

5.1 General Specifications

Parameter Value

Emitted Light Color White (Daylight - 5300K)

Voltage 100 - 240 VAC, 50/60 Hz

Power 8W (Minimum Brightness) to 15 W (Max Brightness)

Internal Fuses Qty 2, 0.63A (T) 250 VAC

Operating Temperature Range 5 to 40 °C

Dimensions (W x D x H) 362.0 x 257 x 50 mm (14.25" x 10.12" x 1.97")

Weight 3.3 Kg

Power Cord Ratings

Cord Type US UK EU

Voltage Rating 125 VAC 250 VAC 250 VAC

Fuse Rating 10 A 10 A 5 A

Temperature Rating 60 °C (140 °F) 70 °C (158 °F) 70 °C (158 °F)

Connector IEC 60320 C13, Moulded

Rev A Nov 2017

Page 13

LSS10 LED Light Box

Chapter 6 Regulatory

6.1 Declarations Of Conformity

6.1.1 For Customers in Europe

See Section 6.2.

6.1.2 For Customers In The USA

This equipment has been tested and found to comply with the li mits for a Class A

digital device, persuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by the compan y could void the

user’s authority to operate the equipment.

Page 14 ETN037435-D02

6.2 CE Certificate

Chapter 6 Regulatory

Rev A Nov 2017

Page 15

LSS10 LED Light Box

Chapter 7 Thorlabs Worldwide Contacts

UK and Ireland

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau / Munich

Germany

Tel: +49-(0) 8131-5956-0

Fax: +49-(0) 8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

Japan

Thorlabs Japan, Inc.

3-6-3, Kitamachi,

Nerima-ku, Tokyo 179-0081

Japan

Tel: +81Fax: +81-3-6915-7716

www.thorlabs.co.jp

Email: sales@thorlabs.jp

3-6915-7701

Thorlabs Ltd.

1 Saint Thomas Place

Ely CB7 4EX

Great Britain

Tel: +44 (0)1353-654440

Fax: +44 (0)1353-654444

www.thorlabs.de

email: sales@uk.thorlabs.com

Support: techsupport.uk@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

China

Thorlabs China

Room A101, No. 100, Lane 2891

uth Qilianshan Road

So

Putuo Distri

Shanghai

China

Tel: +86 (0) 21-60561122

Fax: +86 (0) 21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

ct

Thorlabs verifies our compliance with the WEEE (Waste Electrical and Electronic

Equipment) directive of the European Community and the corresponding national

laws. Accordingly, all end users in the EC may return "end of life" Annex I category

electrical and electronic equipment sold after August 13, 2005 to Thorlabs, without

incurring disposal charges. Eligible units are marked with the crossed out "wheelie

bin" logo (see right), were sold to and are currently owned by a company or institute

within the EC, and are not dissembled or contaminated. Contact Thorlabs for more

information. Waste treatment is your own responsibility. "End of life" units must be

returned to Thorlabs or handed to a company specializing in waste recovery. Do not

dispose of the unit in a litter bin or at a public waste disposal site.

Page 16 ETN037435-D02

www.thorlabs.com

Loading...

Loading...