LDM56(/M) and LDM90(/M)

Temperature-Controlled Mounts for

Ø5.6 and Ø9 mm Laser Diodes

Operating Manual

Temperature-Controlled Laser Diode Mounts

Table of Contents

Chapter 1 Warning Symbol Definitions ........................................... 1

Chapter 2 Safety ................................................................................. 2

Chapter 3 Description ........................................................................ 3

Chapter 4 Setup .................................................................................. 5

4.1. PackageContents..........................................................5

4.2. LaserInstallation...........................................................5

4.2.1. General Configuration ................................................................. 5

4.2.2. Special Note for G Style Configuration Laser Diodes .................. 7

4.3. LaserDiodeControllerConnection.................................8

4.3.1. Using the Thorlabs LDC/ITC Series Laser Controllers ................ 8

4.3.2. Using a Third-Party Laser Controller ........................................... 8

4.4. TECControllerConnection............................................10

4.4.1. Using the Thorlabs TED Series TEC Controllers ...................... 10

4.4.2. Using a Third-Party TEC controller ............................................ 10

4.5. MountingOtherAccessories........................................11

4.5.1. Mounting Thorlabs Fiber Coupled Pigtailed Lasers ................... 11

4.6. MakingtheSafetyInterlockConnections.....................12

Chapter 5 Operation ......................................................................... 13

5.1. RFModulation.............................................................13

5.2. StatusandInterlocks...................................................14

5.3. TemperatureSensor....................................................15

Chapter 6 Maintenance .................................................................... 16

Chapter 7 Troubleshooting ............................................................. 17

Chapter 8 Specifications ................................................................. 18

Chapter 9 Drawing ........................................................................... 19

Chapter 10 Regulatory ....................................................................... 20

Chapter 11 Thorlabs Worldwide Contacts....................................... 21

Temperature-Controlled Laser Diode Mounts Chapter 1: Warning Symbol Definitions

Chapter 1 Warning Symbol Definitions

Below is a list of warning symbols you may encounter in this manual or on your

device.

Symbol Description

Direct Current

Alternating Current

Both Direct and Alternating Current

Earth Ground Terminal

Protective Conductor Terminal

Frame or Chassis Terminal

Equipotentiality

Rev C, February 20, 2018 Page 1

On (Supply)

Off (Supply)

In Position of a Bi-Stable Push Control

Out Position of a Bi-Stable Push Control

Caution: Risk of Electric Shock

Caution: Hot Surface

Caution: Risk of Danger

Warning: Laser Radiation

Caution: Spinning Blades May Cause Harm

Temperature-Controlled Laser Diode Mounts Chapter 2: Safety

Chapter 2 Safety

!

This unit must not be operated in explosive environments

Avoid exposure – laser radiation emitted from apertures.

WARNING

WARNING

!

Page 2 TTN121126-D02

Temperature-Controlled Laser Diode Mounts Chapter 3: Description

Chapter 3 Description

Features

Supports Ø5.6 mm or Ø9 mm Pinout Spacing TO-Can Lasers

Integrated TEC Lockout Circuit to Protect Laser Diode (Can Be

Disabled)

Integrated Bias-T Adapter Allows for RF Modulation of LD Current up to

600 MHz

= T

8 W Heat Dissipation @ T

ambient

TEC Element Prolongs LD Life, Stabilizes Output Power, and Stabilizes

Wavelength

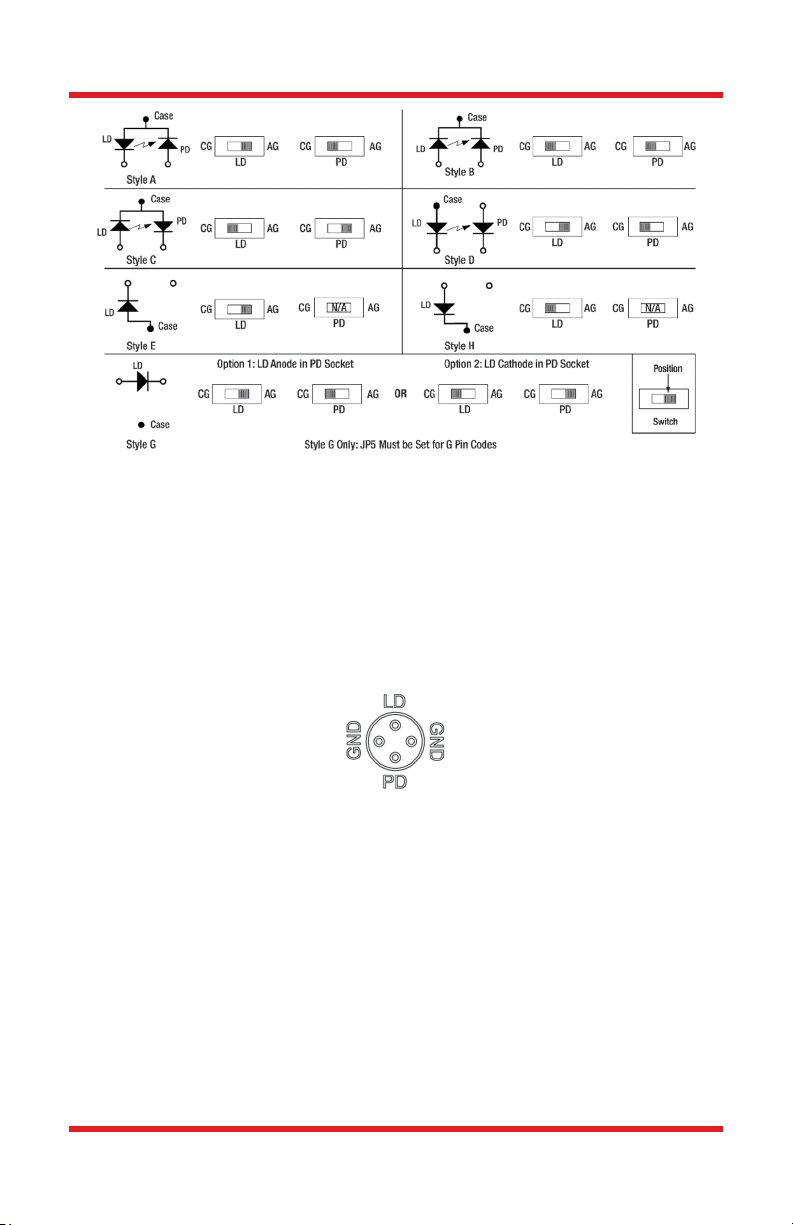

The LDM56(/M) and LDM90(/M) mounts by Thorlabs are ideal for temperaturecontrolled operation of most 3 and 4-pin laser diodes in Ø5.6 mm (TO-56) and

Ø9 mm (TO-9) packages, respectively. The mount can control the laser diode

and monitor photodiode independently making it compatible with a wide variety of

laser diodes including all three-pin style A, B, and C configuration laser diodes,

two-pin style E, G, and H configurations, and all four-pin style D laser diodes.

The LDM56(/M) and LDM90(/M) are also compatible with style G laser diodes by

setting an internal jumper as discussed in section 4.2.2. Please note that style F

laser diodes are incompatible with the LDM56(/M) and LDM90(/M) mounts.

Laser diodes can be quickly and easily changed in the mount. It is as simple as

inserting the laser diode into the socket according to the imprinted pin

assignment and fastening the mounting flange with two screws. The diode socket

is located very close to the front of the cold plate making the connection of short

lead devices easier.

The LDM56(/M) and LDM90(/M) can be easily integrated into any existing optical

setup. The mounting options include multiple 1/4"-20 (M6) mounting holes, and

its front plate is equipped with tapped holes to mount our 30 mm Cage System

and SM1 threading for use with our Lens Tube Assemblies.

The LDM56(/M) and LDM90(/M) includes a Bias-T for RF modulation of the laser

current up to 600 MHz. The mount can be adapted to the polarity of the laser

diode and monitor diode by miniature switches located at the top of the mount.

User protection features include an LED indicating an enabled laser located

along the top of the mount and a remote interlock connector located on the side.

Laser protection features include optional grounding configurations and the TEC

lockout circuit (only useable with our controllers) that prevents enabling the laser

unless the TEC controller is active. The built-in TE cooler enables temperaturecontrolled operation of the laser diode. The mounting flange protects the laser

diode against air drafts, thus temperature stabilities of about 10 mK can be

achieved.

= 25 °C

laser

Rev C, February 20, 2018 Page 3

Temperature-Controlled Laser Diode Mounts Chapter 3: Description

r

LD Switch

Laser On

Indicator

PD Switch

DIP Switches

Pin Code

Select Jumpe

LD Driver

Connector

RF Input

(SMA))

TEC Driver

Connector

Remote

Interlock

Figure 1 Location of Features

Page 4 TTN121126-D02

Temperature-Controlled Laser Diode Mounts Chapter 4: Setup

Chapter 4 Setup

4.1. Package Contents

LDM56(/M) or LDM90(/M) Mount

Diode Retainer(s):

o LDM56(/M): 5.6 mm TO-Can Laser Diode Mounting Flange

o LDM90(/M): 9.0 mm Standard and 9.0 mm High Heat Load

Laser Diode Mounting Flanges

2-56 x 1/8" Screws for Mounting Flange

2-56 x 1/4" Screws for Pigtails Laser Diodes

Hex Key

Operating Manual

4.2. Laser Installation

4.2.1. General Configuration

! !

Make sure the laser diode is installed correctly and the polarity switches on the

driver side are set as per the laser diode pin configuration provided by the

manufacturer. Connecting the LD driver to mount with incorrect installation will

Use of thermal grease is not recommended for use with the TO-can laser diode

mount. Thermal grease will creep and eventually contaminate the laser facet.

To install the laser diode, complete the following steps:

1. Unpack the laser mount. Removing the cover is optional when installing

an A, B, C, D, E, or H pin style laser. If a laser diode with a G style pin

code is being used, follow the steps in section 4.2.2.

2. Determine the laser pin configuration from the laser diode

manufacturer’s data sheets and set the LD (Laser Diode) and PD

(Photodiode) switches located on the top of the unit according to Figure

2.

WARNING

damage the laser diode.

WARNING

Rev C, February 20, 2018 Page 5

Temperature-Controlled Laser Diode Mounts Chapter 4: Setup

Figure 2 Polarity Switch Settings

3. Most laser diodes are three pins with the case tied to one of the laser

pins and also to one of the photodiode pins. The other laser and

photodiode pin will be isolated from the case. The LDM56(/M) and

LDM90(/M) mounts were designed to operate the laser case at ground

potential, therefore this common pin will be inserted into either the 3

o’clock or the 9 o’clock position of the laser connector. Locate the

isolated laser pin and insert it in the 12 o’clock position. The isolated

photodiode should now be in the 6 o’clock position. Refer to the figure

below.

Figure 3 LD and PD Orientation

4. Install the laser mounting flange and the cover. Install both screws

through the mounting flange and loosely into the cold plate, then

carefully tighten each screw a little bit at a time until the flange is just

snug. Do not over tighten either screw – the flange will sit slightly above

the cold plate. If removed during installation reinstall the cover using the

four 2-56 cap head screws provided.

Note: The four sockets comprising the laser diode connector are 0.6" deep, laser

diode leads do not need to be cut unless they are longer than 0.6".

Note: The laser connector is located close enough to the front face of the copper

cold plate to allow easy installation of short leaded lasers. The clearance area

around the LD and PD sockets is sufficient to prevent the pins from contacting

the cold plate.

Page 6 TTN121126-D02

Temperature-Controlled Laser Diode Mounts Chapter 4: Setup

4.2.2. Special Note for G Style Configuration Laser Diodes

Figure 4 LDM56(/M) and LDM90(/M) Internal Circuitry Showing Jumper JP5

In order to drive a style G laser diode, the PD pin in the mount must be

grounded. The red jumper is set across the bottom and left pin for operation with

A, B, C, D, E, and H pin code laser diodes (Figure 5). The jumper is set across

the center and right pin for operation with G pin code laser diodes (Figure 6). The

G pin code setting grounds the photodiode pin which allows the mount to drive a

laser diode only (no photodiode) configuration with the LD pin at the 12 o'clock

position.

5. If the mount will be used with a G style laser diode, unscrew the four

captive 4-40 socket head screws from the front cover using a 5/64" hex

driver.

6. Locate JP5 header and move the red jumper as shown below or in the

note beside the header.

Figure 5 JP5 Position for A, B, C, D, E, & H Pin Code TO-Can Lasers

Figure 6 JP5 Position for G Pin Code TO-Can Lasers

Rev C, February 20, 2018 Page 7

Temperature-Controlled Laser Diode Mounts Chapter 4: Setup

Note: Once the jumper is set for operation of the mount with G style laser diodes

it must be set back to the A, B, C, D, E, and H pin code position for operation

with those diodes.

4.3. Laser Diode Controller Connection

4.3.1. Using the Thorlabs LDC/ITC Series Laser Controllers

The LDM56(/M) and LDM90(/M) is compatible with all Thorlabs LDC LD

controllers and ITC series combination controllers (LD and TEC).

Appropriate cables with DB9 connectors are included with Thorlabs

controllers and ensure that the controllers cannot be connected

incorrectly. Additionally, these controllers have built-in protection

circuitry that protects the laser when not in use.

The nomenclature for the laser diode polarity switch on the LDC/ITC

driver and the LDM56(/M) and LDM90(/M) are consistent with each

other. For example, if the laser polarity on the driver is set to AG (anode

grounded), then the LD polarity switch on the LDM56(/M) and

LDM90(/M) should also be set to AG, and so forth.

The nomenclature for the photodiode polarity switch on the

LDC40xx/80xx and ITC series drivers and the LDM56(/M) and

LDM90(/M) is as follows: The photodiode polarity switch on the

LDM56(/M) and LDM90(/M) must always be set to “CG.” The

photodiode polarity should be set with the internal laser controller switch

only. For more information on how to set polarity settings on the laser

controller, please refer to the appropriate laser controller manual.

4.3.2. Using a Third-Party Laser Controller

When using a third-party controller, a custom cable will have to be made to

properly interface to the laser mount. Please refer to the table on page 9 for laser

connections.

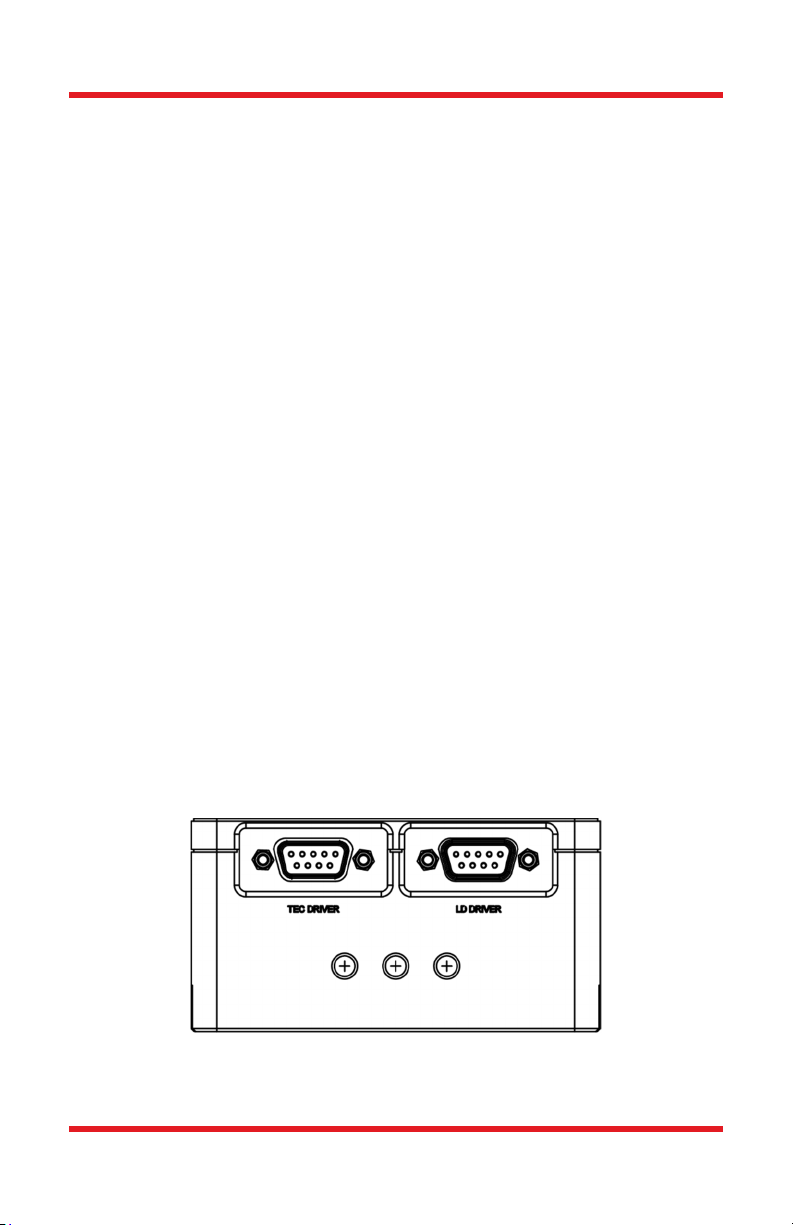

1 5

6 9

Figure 7 Pin Out for LD Driver and TEC Driver Connectors

Page 8 TTN121126-D02

5 1

9 6

Temperature-Controlled Laser Diode Mounts Chapter 4: Setup

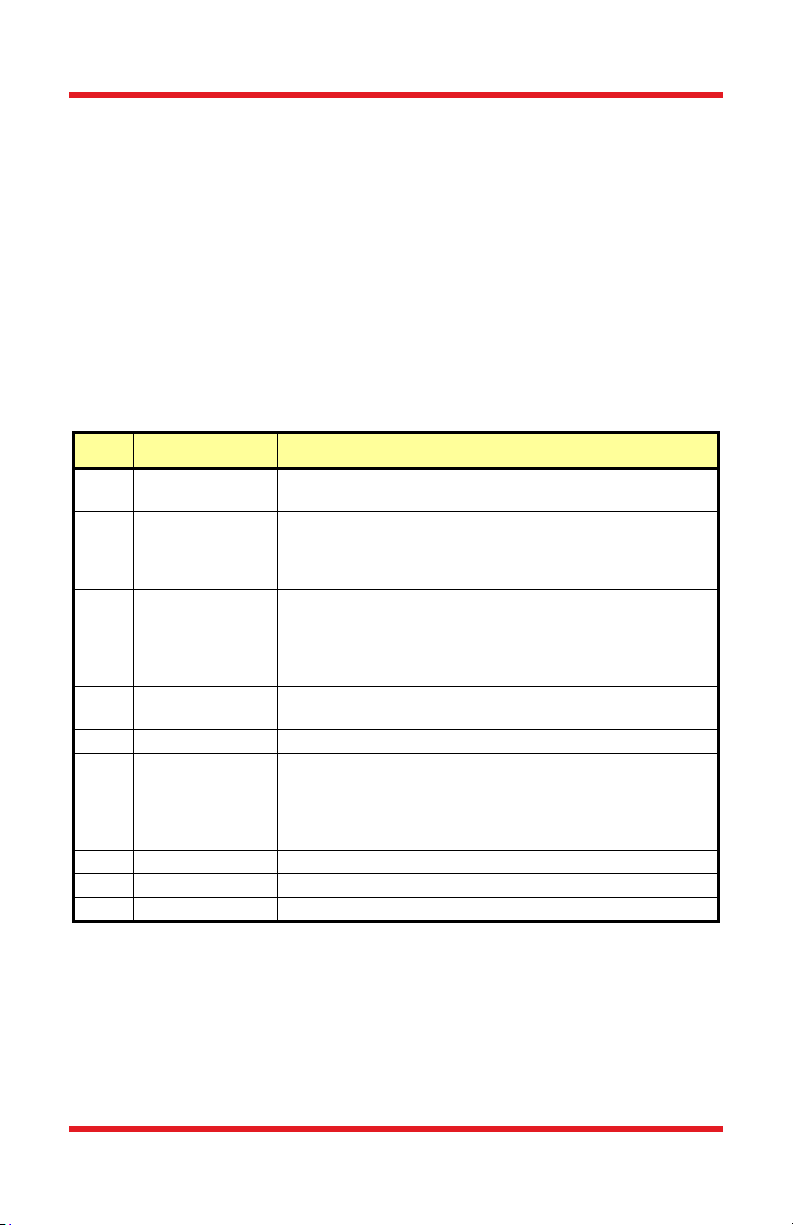

Pin Signal Description

Interlock and

1

(LDC Specific)

Interlock and

5

Status Return

7

8

Laser Ground

3

2

4

Status Pin

Laser Diode

Cathode

Laser Diode

Anode

(Case)

Photodiode

Cathode

Photodiode

Anode

This pin is the input to the LD Status Indicator and Interlock

Circuits. When using Thorlabs LDCs no external circuitry is

required. To use these features with third-party controllers

please refer to the Status and Interlock section of this manual.

This pin is the return side of the Status and Interlock circuitry.

This pin is connected to the 12 o’clock pin on the laser socket

when the LD Polarity Switch is set to AG

1

. Otherwise it is

floating.

This pin is connected to the 12 o’clock pin on the laser socket

when the LD Polarity Switch is set to CG

2

. Otherwise it is

floating.

This pin is connected to the 3 o’clock and 9 o’clock pins on

the laser socket and corresponds to the settings of the LD and

PD polarity switches. i.e. If the LD and PD switches are set to

AG then this pin grounds the Anodes of the laser and photo

diodes.

This pin is connected to the 6 o’clock pin on the laser socket

when the PD Polarity Switch is set to AG. It is attached to

ground and the 3 o’clock and 9 o’clock pins on the laser

socket when the PD Polarity Switch is set to CG.

This pin is connected to the 6 o’clock pin on the laser socket

when the PD Polarity Switch is set to CG. It is attached to

ground and the 3 o’clock and 9 o’clock pins on the laser

socket when the PD Polarity Switch is set to AG.

This pin is connected to LD Interface Pin 7, thru a 499 Ω

resistor, when the LD Polarity Switch is set to AG. It is

attached directly to LD Interface Pin 3 when the LD Polarity

Switch is set to CG.

This pin is connected to LD Interface Pin 8, thru a 499 Ω

resistor, when the LD Polarity Switch is set to CG. It is

attached directly to LD Interface Pin 3 when the LD Polarity

Switch is set to AG.

6

9

Laser Diode

Voltage

(Cathode)

Laser Diode

Voltage

(Anode)

1

AG stands for Anode Ground.

2

CG stands for Cathode Ground.

Rev C, February 20, 2018 Page 9

Temperature-Controlled Laser Diode Mounts Chapter 4: Setup

4.4. TEC Controller Connection

4.4.1. Using the Thorlabs TED Series TEC Controllers

The LDM56(/M) and LDM90(/M) is best used with Thorlabs TED200 or related

TEC controllers. The TED series are shipped with a mating DB9 cable that plugs

directly into the controller and laser mount. Using the cable supplied with the

TED, the controller cannot be connected incorrectly. Simply connect the cable

included with the TED to the Laser Mount and to the controller.

4.4.2. Using a Third-Party TEC controller

When using a third-party controller, a custom cable will have to be made to

properly interface to the laser mount. Please refer to the table below for laser

connections:

Pin Signal Description

4 +TEC

-TEC and TEC

5

1 TEC Lockout (+)

2 +Thermistor

3 -Thermistor The thermistor return pin.

7 AD592 (-)

9 AD592 (+) The positive terminal of the AD592.

6 N.C. Not Used

8 N.C. Not Used

Lockout (-)

This pin is connected to the positive terminal of the TEC

element.

This pin is connected to the negative terminal of the TEC

element, and also is common to the cathode of the photorelay of the TEC Lockout circuit – refer to the Status and

Interlock section of this manual.

This pin is connected to the anode of the photo-relay side

of the TEC Lockout circuit. When using Thorlabs TEDs no

external circuitry is required. To use these features with

third-party controllers please refer to the Status and

Interlock section of this manual.

The 10 k at 25 C NTC thermistor (provided for

temperature feedback).

The negative terminal of the AD592 temperature

transducer. When using Thorlabs TEDs no external

circuitry is required. To use this device with third party

controllers it must be properly biased. Refer to Analog

Devices AD592 Data for application information.

Page 10 TTN121126-D02

Temperature-Controlled Laser Diode Mounts Chapter 4: Setup

4.5. Mounting Other Accessories

The LDM56(/M) and LDM90(/M) includes an SM1 (1.035"-40) threaded hole

centered on the laser for mounting our SM1 series of optics mounts. This is most

often used for mounting aspheric collimating optics.

Each mount also has four 4-40 tapped holes at the corners of the mount for

compatibility with the LDMXY Flexure Adapter, which provides ±1.0 mm of XY

translation for collimation optics.

Also included are eight 4-40 tapped holes for attaching Thorlabs 30 mm or

60 mm cage assembly products. Using the combination of the SM1 threaded

mount and cage assembly products, a wide variety of optical systems can be

easily assembled form off-the-shelf products.

4.5.1. Mounting Thorlabs Fiber Coupled Pigtailed Lasers

Ensuring that the pins are correctly aligned, mount the pigtail housing directly

onto the cold-plate, as shown in Figure 8 below. Note that these mounts are not

optimized for use with pigtailed lasers so TEC performance and compatibility are

not guaranteed. If primarily using pigtailed lasers, we suggest using the LDM9LP

or CLD1011LP.

1. Install the pigtailed laser into the mount's socket, observing the proper

polarity of the laser to the socket (the pigtail’s pin-outs are provided with

the pigtail data sheet).

2. Make sure the pigtail’s laser diode leads are fully inserted into the

socket. The mounting holes on the laser housing should be lined up with

the threaded holes on the cold-plate as shown in the photo below.

3. Secure the housing to the cold-plate using two (2) 2-56 x 1/4" cap head

screws (included).

Figure 8 Installing Fiber Pigtailed Laser

Rev C, February 20, 2018 Page 11

Temperature-Controlled Laser Diode Mounts Chapter 4: Setup

4.6. Making the Safety Interlock Connections

The LDM56(/M) and LDM90(/M) is equipped with a Remote Interlock connector

located on the side panel. In order to enable the laser source, a short circuit must

be applied across the terminals of the remote interlock connector. In practice this

connection is made available to allow the user to connect a remote actuated

switch to the connector (i.e. an open door indicator). The switch (which must be

normally open) has to be closed in order for the unit to be enabled. Once the

switch is in an open state the laser diode must automatically shut down.

All units are shipped configured with a shorting device installed in the interlock

connector. If you are not going to use this feature then you can leave the shorting

device installed and the unit will operate normally as described in the procedures

in this manual. If you wish to make use of the interlock feature you will need to

acquire the appropriate connector mate and wire it your remote interlock switch.

Next, remove the shorting device by pulling it from the input and install the

connector into the interlock input.

The interlock input only accepts a 2.5 mm mono phono jack. This connector is

readily available at most electronics suppliers.

The electrical specifications for the interlock input are as follows:

Specification Value

Type of Mating Connector 2.5 mm Mono Phono Jack

Open Circuit Voltage

Short Circuit Current 10 mA DC Typical

Connector Polarity Tip is positive, barrel is ground.

Interlock Switch Requirements

+5 VDC with Respect to System Ground

(When used in conjunction with Thorlabs

drivers.)

Must be N.O. Dry Contacts (Under no

circumstances should any external

voltages be applied to the Interlock input.)

Figure 9 Remote Interlock Connector

Page 12 TTN121126-D02

Temperature-Controlled Laser Diode Mounts Chapter 5: Operation

Chapter 5 Operation

With the laser mounted and the laser controller and temperature controller

connected, the LDM56(/M) and LDM90(/M) is ready to operate. Please refer to

the operating instructions for the laser and temperature controller for specific

operating instructions.

When operating at low temperatures in high humidity climates the laser mount

may develop internal condensation. If this occurs, turn the laser off, open the

case and allow the mount to dry off completely before re-using.

5.1. RF Modulation

The LDM56(/M) and LDM90(/M) has an RF input for modulating the laser with an

external RF source up to 600 MHz. This is a 50 Ω input that is AC-coupled

directly to the laser through a Bias-Tee network. To calculate the desired RF

power to modulate the laser determine the amount of modulating current needed

from the laser manufacturer’s data sheets and use the following calculations:

50ΩLDModulatingCurrent

It is strongly recommended that you start off conservatively by a factor of 10

below the calculated modulating voltage and slowly bring the RF power up until

the desired depth of modulation is reached. Use the laser controller to establish

the DC operating point of the laser.

!

The RF input is directly coupled to the laser. Any excessive transients or noise

will be coupled into the laser and may cause the laser to be overdriven. In

addition, the laser can be easily overdriven if excessive RF power is applied to

this input. Use the RF modulation input with care to avoid damaging your laser.

Rev C, February 20, 2018 Page 13

WARNING

Max RF Power 200 mW

!

Temperature-Controlled Laser Diode Mounts Chapter 5: Operation

5.2. Status and Interlocks

This unit is equipped with two interlock circuits and an LED that indicates if the

laser diode is enabled. All three circuits are designed to interface with our laser

and TEC controllers with no external circuitry.

The first interlock circuit is controlled by the Interlock connector outlined in

section 4.6. The second interlock is the TEC Interlock DIP SW 1. When the dip

switch is in the down position shown the TEC interlock circuit is closed, enabling

operation.

Figure 10 Switches on Top of LDM56(/M) and LDM90(/M) Mounts

DIP Switch 2 allows the user to internally tie the LD ground to earth ground when

in the down position as shown above. Care should be taken when setting the

LDGND switch. It should be noted this is commonly left open and is only needed

if using a controller that is floating, has no path to earth ground.

If third party controllers are used to drive the laser diode or TEC elements then

only the LD ON indicator can be used. To prevent damage to the Status and

Interlock circuits the following external connections should be followed:

1. Install the shorting device into the INTERLOCK connector that was

shipped with the LDM56(/M) and LDM90(/M).

2. Connect a resistor to LD Interface DB9 Pin 1 appropriately sized to limit

the current into Pin 1 to between 5 – 10 mA.

3. The “driver” side of this resistor should be connected to a DC signal

that, when high, indicates that the laser diode is being driven.

4. If you have any questions regarding these connections please feel free

to contact an engineer at Thorlabs for clarification.

If you wish to make full use all of the status and interlock features with your third

party drivers, please contact your local Tech Support office. An engineer will help

you determine if this is possible and how to implement these features.

Page 14 TTN121126-D02

Temperature-Controlled Laser Diode Mounts Chapter 5: Operation

5.3. Temperature Sensor

The LDM56(/M) and LDM90(/M) includes a 10 kΩ thermistor for temperature

feedback. We recommend setting the sensor type to Thermistor (low) when

operating with a Thorlabs ITC or TED4xxx series controller. The graph below

shows the typical thermistor resistance versus temperature. Full thermistor

specifications can be found in Chapter 8.

Figure 11 Thermistor Resistance vs. Temperature

Rev C, February 20, 2018 Page 15

Temperature-Controlled Laser Diode Mounts Chapter 6: Maintenance

Chapter 6 Maintenance

There are no serviceable parts in the LDM56(/M) and LDM90(/M). The housing

may be cleaned by wiping with a soft damp cloth. If you suspect a problem with

your LDM56(/M) and LDM90(/M), please call Thorlabs and an engineer will be

happy to assist you.

Page 16 TTN121126-D02

Temperature-Controlled Laser Diode Mounts Chapter 7: Troubleshooting

Chapter 7 Troubleshooting

Problem Solution

Remote Interlock is open.

Make sure that either the “shorting device” is installed in

the INTERLOCK connector on the side of the LDM56(/M)

Laser Driver will not

enable.

(If you are using

Thorlabs Laser and TEC

controllers with your

LDM56(/M) and

LDM90(/M) mount.)

Laser wavelength or

power is unstable even

though the TEC

controller shows a stable

temperature.

The LDC series laser

driver indicates an “Open

Circuit” alarm when the

laser is enabled.

The LD does not have an

integrated photodiode,

how does it get installed

and how do the polarity

switches get set?

and LDM90(/M). If you have a remote interlock switch

connected to this INTERLOCK connector it must be in a

closed position.

TEC LOCKOUT circuit is active and the TED series TEC

controller is not enabled.

To determine if you have selected the TEC LOCKOUT

circuit to be active refer to section 5.2. If it is selected

then the TED series TEC controller must be enabled first

before the LDC series laser controller can be enabled.

Make sure your laser diode is fully inserted into the

LDM56(/M) and LDM90(/M) laser socket and its body is

in full contact with the nickel plated cold plate.

Make sure the appropriate mounting flange is installed

over your laser. There are two different flanges; one

specifically for 5.6 mm diodes, one for 9 mm diodes, one

for high heat 9 mm diodes, and a DPSS flange that is

sold separately (LDM56DJ).

The LD and PD polarity switch settings are incorrect.

Refer to Figure 2 and the data sheet for your specific

laser diode to ensure the proper settings. The LD polarity

switch setting on your LDM56(/M) and LDM90(/M) must

also match the LD polarity switch setting on the rear

panel of your LDC series laser diode controller.

The laser diode is installed into the wrong pins on the

laser diode socket. Refer to Figure 3 for the correct

orientation of the laser diode pins and compare this to

the data sheet for your laser diode.

If your laser diode has one of its two active leads

common to the case of the laser, that lead must be

connected to one of the “GND” sockets on the laser

diode connector (refer to Figure 3) while the other pin is

connected to the “LD” socket in the 12 o’clock position.

Depending on the pin orientation of your laser you might

be using either the “GND” socket at 3 o’clock or the

“GND” socket at 9 o’clock. Refer to your laser diode data

for pin orientation. If your Cathode pin is common to the

body of your laser diode, set the LD polarity switch to

“CG”. If your Anode pin is common to the body of your

laser diode, set the LD polarity switch to “AG”. The

setting for the PD polarity switch is irrelevant.

Rev C, February 20, 2018 Page 17

Temperature-Controlled Laser Diode Mounts Chapter 8: Specifications

Chapter 8 Specifications

Specification Value

Laser Specs

Laser Diodes Supported

Max Laser Current 2 A (T

Laser Pin Configurations3

Pin Lead Diameter 0.015" – 0.020" (0.38 – 0.51 mm)

Pin Lead Length, Max 0.6" (15.24 mm)

RF Modulation Frequency 100 kHz to 600 MHz

RF Input Impedance

Max RF Power 200 mW

RF Input Connector SMA

Interlock Connector 2.5 mm Phono Jack

Laser Interface DB9 Female

TEC Specs

Max TEC Current 5 A

Max TEC Voltage 4 V

TEC Heating / Cooling Capacity 8 W (T

Typical Temperature Range

(LD Dependent)

Temperature Sensor

Thermistor

TEC Interface DB9 Male

General

Size

Weight 1.9 lbs (0.87 kg)

Operating Temperature 10 to 40 °C

Storage Temperature 10 to 80 °C

Accessory Mounting SM1 (1.035"-40) Series Internal Thread

Cage Compatibility

Mounting Holes

LDM56(/M): Ø5.6 mm TO Can

LDM90(/M): Ø9 mm TO Can

= 25 °C)

ambient

A, B, C, D, E, G, and H LD Packages,

Switch Selectable

50

= 25 °C)

ambient

0 to 70 C

AD592AN (1 A/K)

10 k ± 3% at 25 C, NTC

Beta = 3977 K ± 0.75%

4.00" x 4.00" x 2.07"

(101.6 mm × 101.6 mm × 52.6 mm)

4-40 Taps (8 Places) for

30 mm and 60 mm Cage Systems

LDM56, LDM90: 1/4"-20 (9 Places)

LDM56/M, LDM90/M: M6x1.0 (9 Places)

3

Note that G style LD configuration requires setting an internal jumper of the LDM56(/M)

and LDM90(/M) mount. Refer to section 4.2.2.

Page 18 TTN121126-D02

Temperature-Controlled Laser Diode Mounts Chapter 9: Drawing

Chapter 9 Drawing

Figure 12 Mechanical Diagram of LDM56(/M) and LDM90(/M) Mounts

(Imperial Mounting Holes: 1/4"-20, Metric Mounting Holes: M6)

Rev C, February 20, 2018 Page 19

Temperature-Controlled Laser Diode Mounts Chapter 10: Regulatory

Chapter 10 Regulatory

As required by the WEEE (Waste Electrical and Electronic Equipment Directive)

of the European Community and the corresponding national laws, Thorlabs offers

all end users in the EC the possibility to return “end of life” units without incurring

disposal charges.

This offer is valid for Thorlabs electrical and electronic equipment:

Sold after August 13, 2005

Marked correspondingly with the crossed out

“wheelie bin” logo (see right)

Sold to a company or institute within the EC

Currently owned by a company or institute

within the EC

Still complete, not disassembled and not

contaminated

As the WEEE directive applies to self-contained

operational electrical and electronic products, this end of

life take back service does not refer to other Thorlabs products, such as:

Pure OEM products, that means assemblies to be built into a unit by the

user (e.g. OEM laser driver cards)

Components

Mechanics and optics

Left over parts of units disassembled by the user (PCB’s, housings etc.).

If you wish to return a Thorlabs unit for waste recovery, please contact Thorlabs

or your nearest dealer for further information.

Waste Treatment is Your Own Responsibility

Wheelie Bin Logo

If you do not return an “end of life” unit to Thorlabs, you must hand it to a

company specialized in waste recovery. Do not dispose of the unit in a litter bin

or at a public waste disposal site.

Ecological Background

It is well known that WEEE pollutes the environment by releasing toxic products

during decomposition. The aim of the European RoHS directive is to reduce the

content of toxic substances in electronic products in the future.

The intent of the WEEE directive is to enforce the recycling of WEEE. A

controlled recycling of end of life products will thereby avoid negative impacts on

the environment.

Page 20 TTN121126-D02

7HPSHUDWXUH&RQWUROOHG/DVHU'LRGH0RXQWV&KDSWHU7KRUODEV:RUOGZLGH&RQWDFWV

Chapter Thorlabs Worldwide Contacts

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau / Munich

Germany

Tel: +49-(0) 8131-5956-0

Fax: +49-(0) 8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

Japan

Thorlabs Japan, Inc.

3-6-3, Kitamachi,

Nerima-ku, Tokyo 179-0081

Japan

Tel: +81-3-6915-7701

Fax: +81-3-6915-7716

www.thorlabs.co.jp

Email: sales@thorlabs.jp

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place

Ely CB7 4EX

Great Britain

Tel: +44 (0) 1353-654440

Fax: +44 (0) 1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

China

Thorlabs China

Room A101, No. 100, Lane 2891,

South Qilianshan Road

Putuo District

Shanghai 200331

China

Tel: +86 (0) 21-60561122

Fax: +86 (0) 21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

Rev &, )HEUXDU\, 2018 Page

www.thorlabs.com

Loading...

Loading...