LCC25

Liquid Crystal Controller

Operating Manual

Liquid Crystal Controller

Table of Contents

Part 1. Important Safety Notice .................................................................. 4

Part 2. Product Overview ............................................................................ 5

Part 3. Setup and Operation ........................................................................ 7

AC Line Voltage .............................................................................................................. 7

Powering ON the LCC25 ................................................................................................ 7

Setting the Voltage and Modulation Frequency .............................................................. 7

Setting the Output ............................................................................................................ 8

Internal Modulation Frequency ....................................................................................... 8

External Modulation Frequency ...................................................................................... 8

Computer Controlled Operation ...................................................................................... 9

3.1. LCC25 Controls and Features .............................................................. 11

Part 4. LCC25 Specifications ..................................................................... 12

4.1. Mechanical Drawing .............................................................................. 13

Part 5. Maintenance ................................................................................... 14

5.1. Fuse Replacement .................................................................................. 14

5.2. Ventilation .............................................................................................. 14

5.3. Troubleshooting ..................................................................................... 15

Part 6. Warranty Information ................................................................... 16

Part 7. Declaration of Conformity ............................................................ 17

Part 8. Regulatory ...................................................................................... 18

Part 9. Thorlabs Worldwide Contacts ...................................................... 19

18828-D02 Rev F, Sept 23, 2011 Page 2 www.thorlabs.com

Liquid Crystal Controller

Table of Figures

Figure 1: A 2 kHz Square Wave Output with no Additional Modulation ..................... 5

Figure 2: A 2 kHz Square Wave Output with 150 Hz Modulation ................................ 6

Figure 3: Front Display ................................................................................................. 6

Figure 4: LCC25 Front Panel ...................................................................................... 11

Figure 5: LCC25 Rear Panel Features ......................................................................... 11

Figure 6: LCC25 Mechanical Drawing ....................................................................... 13

18828-D02 Rev F, Sept 23, 2011 Page 3 www.thorlabs.com

Liquid Crystal Controller

Part 1. Important Safety Notice

Do Not Open Housing!

The LCC25 has no user-serviceable parts. Service should only be

performed by trained service personnel.

All statements regarding safety of operation and technical data in this instruction manual

will only apply when the unit is operated correctly.

SHOCK WARNING

High voltage inside. To avoid electrical shock, before powering

unit, make sure that the protective conductor of the 3-conductor

power cord is correctly connected to the protective earth contact of

the socket outlet. Improper grounding can cause electric shock

resulting in severe injury or even death. Do not operate without

cover installed.

WARNING

This unit must not be operated in explosive environments

Unit is supplied with a 115 V parallel blade line cord for North American use only. For

all other applications use an IEC 320 compatible line cord fitted with a plug appropriate

for your particular AC wall socket.

Make sure that the line voltage rating marked on the rear panel agrees with your local

supply and that the appropriate fuses are installed. Changing of the mains fuse can be

done by the user (see Setting the AC Line Voltage and Installing Fuses). With the

exception of the mains fuses, there are no user serviceable parts in this product.

WARNING

Do Not Operate in Wet/Damp conditions. Do not obstruct the air-

ventilation slots in the housing!

Mobile telephones, cellular phones or other radio transmitters should not to be used

within the range of three meters of this unit since the electromagnetic field intensity may

exceed the maximum allowed disturbance values according to EN50082-1.

18828-D02 Rev F, Sept 23, 2011 Page 4 www.thorlabs.com

Liquid Crystal Controller

Part 2. Product Overview

The LCC25 is a liquid crystal controller compatible with all Thorlabs LC Variable

Retarders. The LCC25 will drive most nematic liquid crystal devices. The liquid crystal

device is connected to the BNC voltage output port. The amplitude of the output voltage,

adjusted by the front panel knob, and external signal, and a computer via a USB interface,

controls the retardance of the LC device.

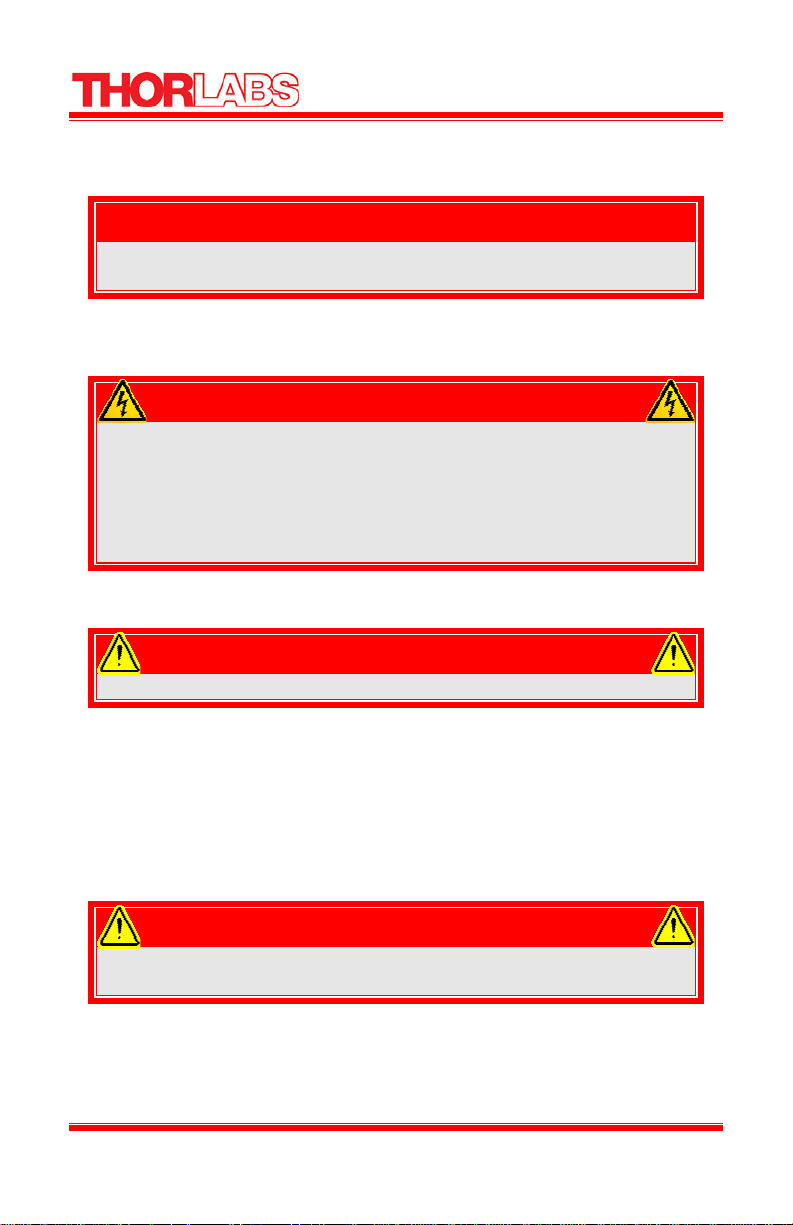

The LCC25 produces a 2 kHz AC square wave with an amplitude that is adjustable from

0 to 25 V

The unit features two selectable set points, Voltage 1 and Voltage 2. Both set points are

controlled by the user, and they produce a square wave that is plus/minus the set point.

For example, if the user sets Voltage 1 to 15.000, the output would be a ±15.000V, 2 kHz

square wave (see figure 1).

RMS

.

Figure 1: A 2 kHz Square Wave Output with no Additional Modulation

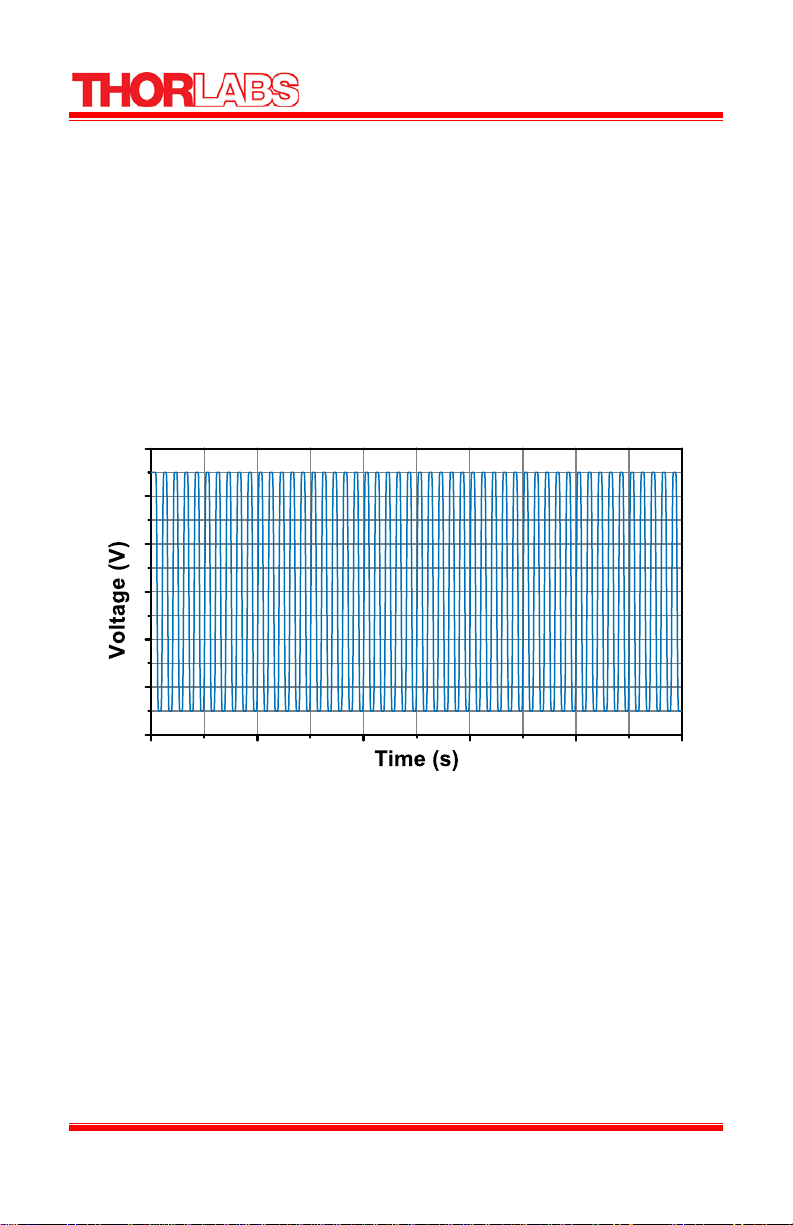

The user can also select a modulated output with a frequency range of 0.5 to 150 Hz. The

First cycle will be equal to Voltage 1 and the second cycle will be equal to Voltage 2 (see

figure 2)

18828-D02 Rev F, Sept 23, 2011 Page 5 www.thorlabs.com

Liquid Crystal Controller

Figure 2: A 2 kHz Square Wave Output with 150 Hz Modulation

The LCC25 will automatically detect and correct any DC offset in real time to within ±10

mV. This feature increases the life of the liquid crystal device.

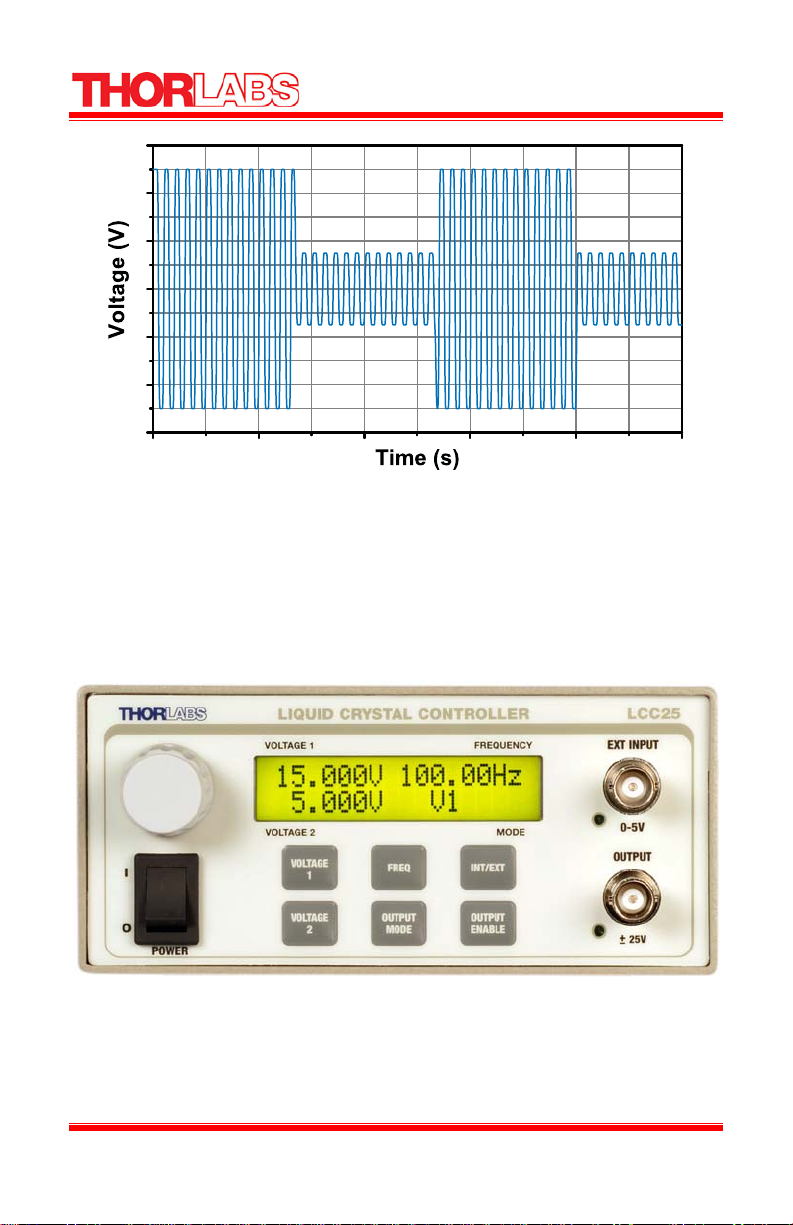

The device can be controlled using tactile buttons on the front panel to select the voltage

and frequency and then using the knob to adjust the levels. The system’s display is a

16 x 2 LCD which displays the voltages and frequency (see figure 3). There are two BNC

connectors. The top BNC is the external input and allows the user to input an external

modulation frequency square wave up to 5 volts. The bottom BNC is the system output.

Figure 3: Front Display

The LCC25 may also be controlled by a command line language through the USB port.

This is offered to enable operation through a terminal interface or for those who may

want to write their own program to control the unit.

18828-D02 Rev F, Sept 23, 2011 Page 6 www.thorlabs.com

Liquid Crystal Controller

Part 3. Setup and Operation

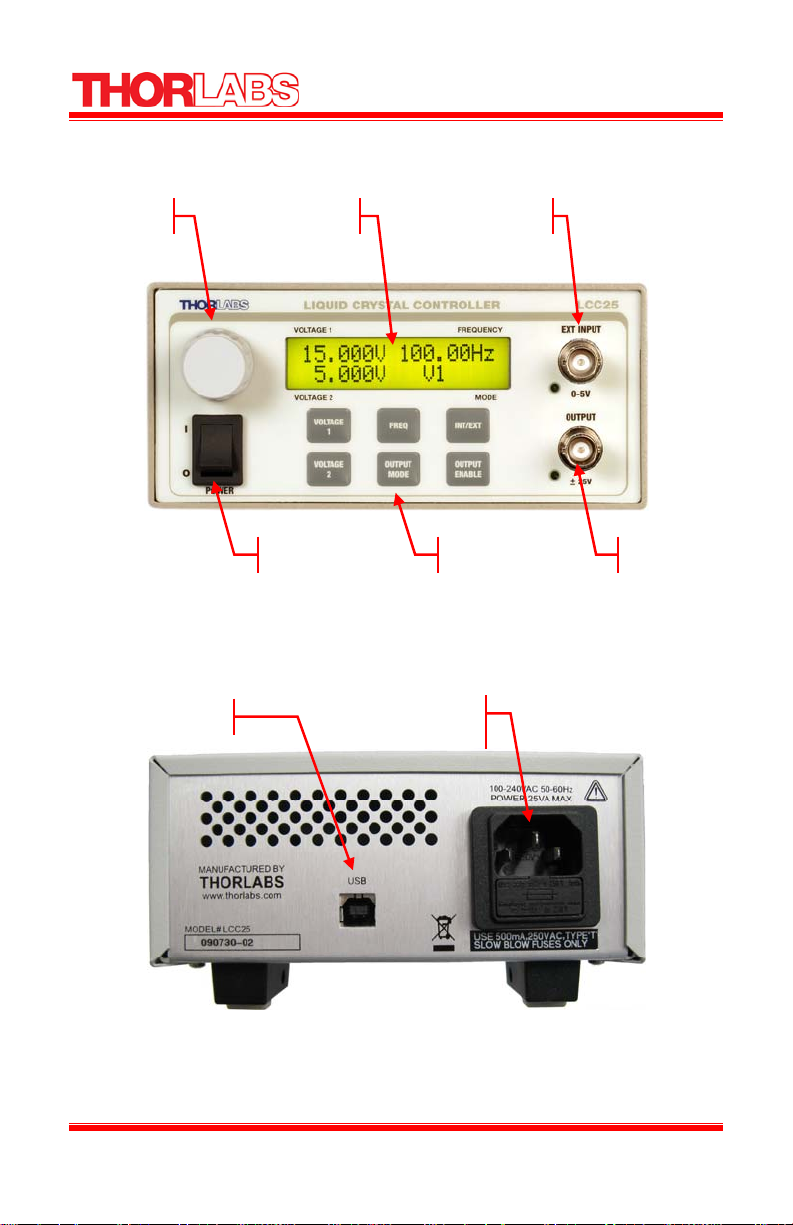

To setup the unit, refer to Figures 4 and 5, and the legend table on the preceding page and

perform the following steps:

NOTE: For optimal performance a warm up time of at least 30 minutes is

recommended.

AC Line Voltage

The LCC25 is designed to operate at 100 to 240 VAC operation. There is no line switch

adjustment to be made. However it may be necessary to replace an open fuse. To do this

you must perform the following procedure on page 14, Fuse Replacement.

Powering ON the LCC25

• Connect the appropriate power cord into the AC receptacle and plug the unit in.

• Set power switch to the ON position. Thorlabs will scroll across the display.

Voltage 1, Voltage 2, and the Frequency then will be displayed.

• BNC Output and External input LED indicators will be OFF. This is the default

state when the unit is power on.

Setting the Voltage and Modulation Frequency

There is a set of 6 buttons beneath the LCD display and a knob for adjustment to the left

of the display.

• To change Voltage 1 press the VOLTAGE 1 key, the LCD top left will flash.

Adjust the knob to the desired Voltage.

• To change Voltage 2 press the VOLTAGE 2 key, the LCD bottom left will

flash. Adjust the knob to the desired Voltage.

• To change Frequency Modulation, press the FREQ key, the LCD top right will

flash. Adjust the knob to the desired Frequency.

After pressing the key, the selected voltage or frequency can be saved by pressing the key

while the cursor is flashing or by letting the cursor time out in about 5 seconds. These

settings will be saved during power down and retrieved on power up.

18828-D02 Rev F, Sept 23, 2011 Page 7 www.thorlabs.com

Liquid Crystal Controller

Setting the Output

Output Mode has three selections. Pressing the OUTPUT MODE key will toggle through

each mode. The selected mode will be indicated in the bottom right of the LCD display.

The sequence is as follows: Voltage 1, Voltage 2, and Modulation. To activate the output,

press the OUTPUT ENABLE button. When active, the LED indicator next to the

OUTPUT BNC connector will be lit.

The supported modes are:

• Voltage 1: The output signal will be a 2 kHz

square wave with an RMS voltage level equal

to the value set by Voltage 1

• Voltage 2: The output signal will be a 2 kHz

square wave with an RMS voltage level equal

to the value set by Voltage 2.

• Modulation: The output signal will be a 2 kHz

square wave at an RMS voltage level

switching between the value currently set for

Voltage 1 and the value set for Voltage 2 at the

currently selected frequency.

Internal Modulation Frequency

The LCC25 has internal modulation frequency adjustable from 0.5 to 150 Hz. To use the

internal modulation, the LED next to the EXT INPUT BNC connect should be off. If it is

lit, press the INT/EXT key disabling the LED indicator. To adjust the modulation

frequency, push the FREQ key and adjust the knob to the desired output.

External Modulation Frequency

The LCC25 can be modulated by an external input. The modulation frequency device is

connected to the EXT INPUT BNC. The input signal can be any waveform with a

frequency from 0.5 to 500 Hz, and any duty cycle, but must be 0 and 5 Volts to trigger

the flip. The output from the LCC25 will be modulated based on the input frequency with

Voltage 1 being the high and Voltage 2 being the low.

To select the external modulation, the LED next to the EXT INPUT BNC connector

should be on. If it is not lit, press the INT/EXT key enabling the LED indicator. When the

external input is enabled, the top right of LCD will display EXT and bottom right will

switch to the modulation square -wave symbol (same as modulation is shown above.

18828-D02 Rev F, Sept 23, 2011 Page 8 www.thorlabs.com

Liquid Crystal Controller

Computer Controlled Operation

The LCC25 may also be controlled by a command line language through the USB port.

This is offered to enable operation through a terminal interface or for those who may

want to write their own program to control the unit. The command language is described

below. Prior to running the command line interface, the included drivers should be

installed, the unit should be powered, and a USB cable should be connected between the

LCC25 and the host.

The terminal emulator should be set as follows:

• Baud Rate: 115.2k b/s (bits per second)

• Data Bits: 8

• Parity: None

• Stop Bits: 1

• Flow Control: None

If the connection is correct and after pressing the Enter key, you will see the following:

Command error CMD_NOT_DEFINED followed by the command prompt, “>”

The basic structure of the interface is a keyword followed by either an equals sign (=) or

a question mark (?). The (=) or (?) will determine if the string is a command or a query.

All strings, commands and queries, must be terminated by a carriage return (CR) or

pressing the ENTER key on the computer.

The command structure is as follows:

Keyword = argument (CR)

Where “keyword” defines the function and “argument” is a numerical value followed by

a carriage return (CR).

The query structure is a follows:

Keyword? (CR)

The “keyword” defines the function and the question mark (?) indicates a query. The

string is terminated with a carriage return (CR).

There are a few exceptions to this which are noted below, also noted are unique shortcut

keys. The following table lists the commands and queries available with this device. The

prompt symbol (>) will appear on power up and after a command is accepted by the

LCC25 indicating it is ready to receive another command line.

If the keyword, format, or argument are incorrect or out of range the unit will return an

error string.

18828-D02 Rev F, Sept 23, 2011 Page 9 www.thorlabs.com

Liquid Crystal Controller

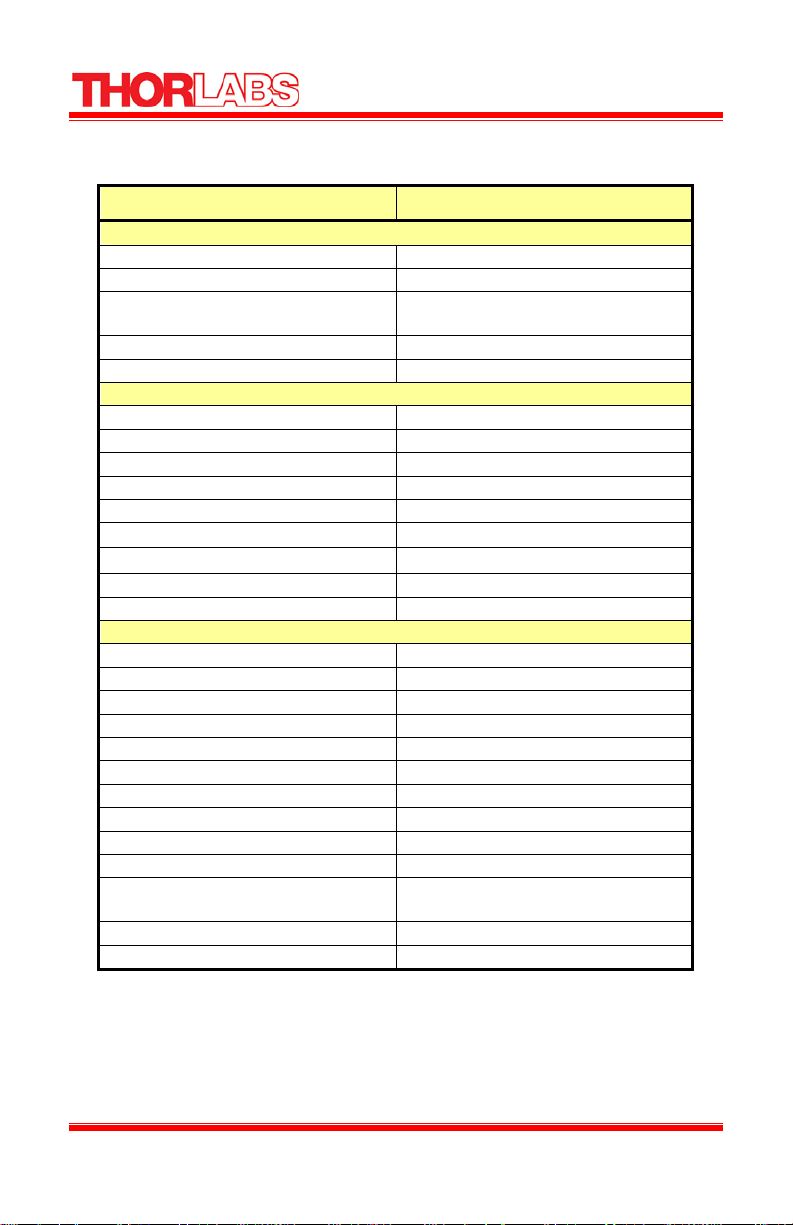

Command Syntax* Description

Get ID *idn? Returns the model number and firmware version

Set Voltage 1 volt1=(n) Where (n) equals a voltage between 0 and 25V

Get Voltage 1 volt1? Returns the current voltage set for Voltage 1

Set Voltage 2 volt2=(n) Where (n) equals a voltage between 0 and 25V

Get Voltage 2 volt2? Returns the current voltage set for Voltage 2

Set Modulation Frequency freq=(n) Where (n) equals a frequency between 5 and 150 Hz

Get Modulation Frequency freq? Returns the current modulation frequency

mode=0 Sets output mode to Modulation

Set Output Mode

Get Output Mode mode? Returns the current output mode

Set Output Enable

Get Output Enable enable? Returns current output enable state

Set External Modulation extern=(n) Where (n) is 0 for internal modulation and 1 for

Get External Modulation extern? Returns current modulation mode – internal or

Set Preset set=(n) Stores the current settings in the preset (n)

Get Preset get=(n) Restores the settings saved in the preset (n)

Save Parameters save Stores parameters in static memory

Restore Default Parameters default Restores the initial factory settings

Set Test Mode Dwell Time (mS) dwell=(n) Sets the dwell time for LC Test Mode

Get Test Mode Dwell Time (mS) dwell? Returns the current dwell time for LC Test Mode

Set Test Mode Increment (V) increment=(n) Sets the voltage step increment for LC Test Mode

Get Test Mode Increment (V) increment? Returns the current voltage step increment for LC

Set Test Min Voltage (V) min=(n) Sets the starting voltage level for LC Test Mode

Get Test Min Voltage (V) min? Returns the current starting voltage level for LC Test

Set Test Max Voltage (V) max=(n) Sets the ending voltage level for LC Test Mode

Get Test Max Voltage (V) max? Returns the current ending voltage level for LC Test

Run Test Mode test Starts the LC Test Mode that will step the output

Remote not shown on Display

Normal use of button on display

Remote shown on Display and

current Set voltage

Locks out use of buttons

Command Query ? Returns a list of these commands

mode=1 Sets output mode to Voltage 1

mode=2 Sets output mode to Voltage 2

enable=0 Output is disabled

enable=1 Output is enabled

external

external

Test Mode

Mode

Mode

voltage from the min voltage to the max voltage by

steps equal to increment. At each voltage level it will

delay for the time specified by dwell.

remote=0 Disables remote from being shown on display.

remote=1 Enables remote shown on display and displays

Normal operation

current Set voltage.

Locks out buttons on from panel.

*) All commands and queries are in lower case letters.

18828-D02 Rev F, Sept 23, 2011 Page 10 www.thorlabs.com

Liquid Crystal Controller

r

3.1. LCC25 Controls and Features

Rotary Knob LCD Display External Input BNC

USB

Main Power Switch Function Keys Output BNC

Figure 4: LCC25 Front Panel

AC Input Connector-IEC

and Fuse Drawe

Figure 5: LCC25 Rear Panel Features

18828-D02 Rev F, Sept 23, 2011 Page 11 www.thorlabs.com

Liquid Crystal Controller

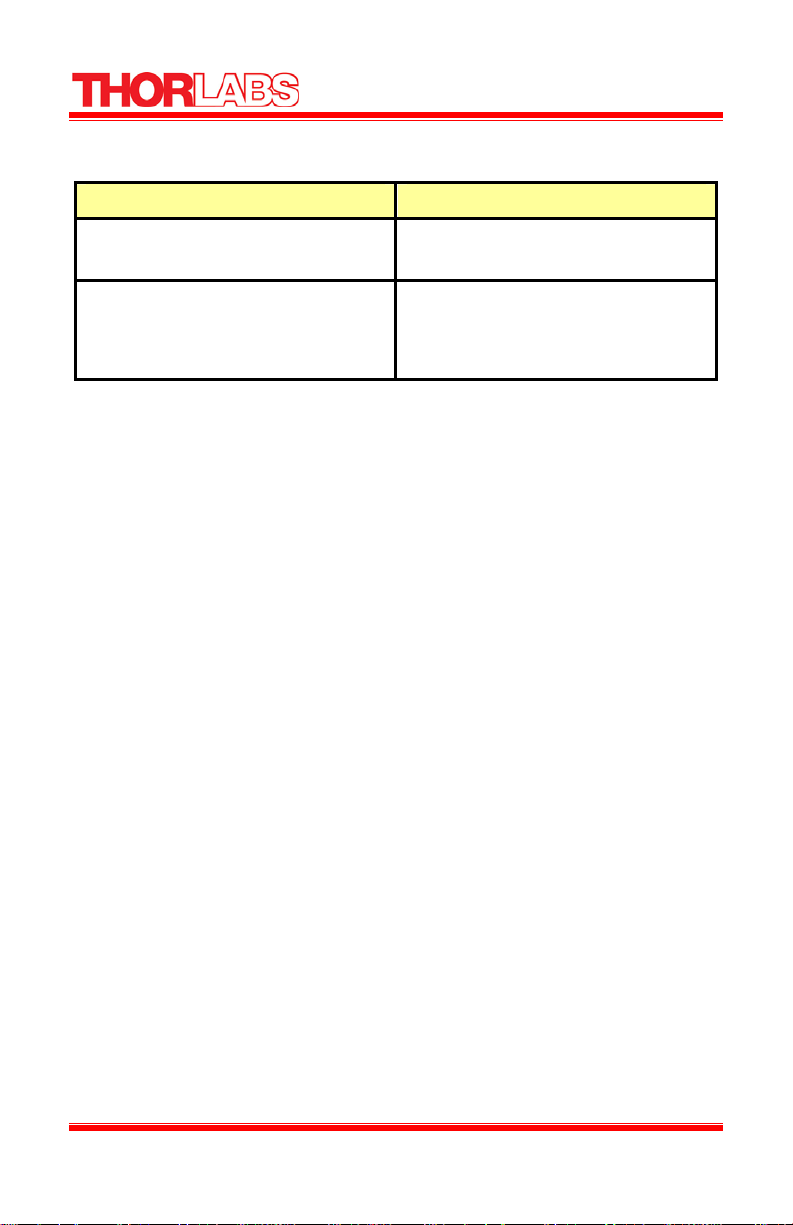

Part 4. LCC25 Specifications

Specification Description

Max Ratings

Max Output Current 15 mA

Max External Input Voltage 5 VDC

Fuse Rating

*See replacement spec. page 14

Operating Temperature Range 10 to 40 °C

Maximum Relative Humidity 85%

Electrical Characteristics

External Input Voltage 0 to 5 VDC Square Wave

Adjustable Output Voltage ± 25 V

Voltage resolution 1.0 mV

Adjustable Internal Modulation Frequency 0.5 to 150 Hz @ 50% Duty Cycle

Switching Frequency 2,000 ± 5 Hz, 50% Duty Cycle

Slew Rate

DC offset ±10 mV

AC Power 85 – 264 VAC, 47 – 63 Hz, 25 VA

Warm Up Time 30 Minutes

Physical Features

External Input Connector BNC

External Input Enable Front Panel: INT/EXT enable Key

External Input Indicator Green LED

Output Connector BNC

Output Enable Front Panel: OUTPUT ENABLE Key

Output Indicator Green LED

Rotary Knob Digital Encoder

Display LCD 16 x 2

Power Switch Rocker Switch

USB interface USB Standard B Plug

Dimensions 5.75” x 3″ x 12.2″

146 mm x 78 mm x 309 mm

Weight 3.6 lbs

Other Tilting Rubber-Padded Feet

500 mA,

5 x 20 mm SLO-BLO

10 V/μs

18828-D02 Rev F, Sept 23, 2011 Page 12 www.thorlabs.com

Liquid Crystal Controller

4.1. Mechanical Drawing

12.160"

(308.88mm)

11.425"

(290.2mm)

5.758"

(146.26mm)

2.586"

(65.69mm)

3.066"

(77.88mm)

Figure 6: LCC25 Mechanical Drawing

18828-D02 Rev F, Sept 23, 2011 Page 13 www.thorlabs.com

Liquid Crystal Controller

Part 5. Maintenance

The LCC25 amplifier needs very little maintenance under normal operating conditions.

The enclosure may be cleaned by wiping with a soft damp cloth.

There are no serviceable parts in the LCC25 and no reason to open the unit. If you

suspect a problem with your LCC25 please call Thorlabs and technical support will be

happy to assist you.

5.1. Fuse Replacement

The AC input is protected by a fuse located in a pull out compartment drawer on the rear

panel AC connector. If replacement is required:

• Remove the AC power cord if it is connected to the unit.

• Locate the Fuse tray directly below the AC power cord connection on the

rear panel of the unit.

• Carefully use a flat blade screwdriver to open the fuse tray.

• Remove the existing fuse and install the appropriate 500mA fuse. The

replacement fuse must be a 5 mm x 20 mm 250 VAC Type T Fuses (IEC

60127-2/III, low breaking capacity, slow blow), see fuse specification

below.

• Push the fuse tray back into place making sure that it snaps and seats

correctly.

• Connect the appropriate power cord into the AC receptacle and plug the

unit in.

* Replace the fuse with the correct rating and type. It is not recommended to use a fuse

other than what is specified. Do not use a fuse with a current rating higher than the unit

is rated for.

Fuse specification:

• Manufacturer: Littlefuse

• Manufacturer part#: 0218.500HXP

• Description: Fuse, 0.500A 250V IEC SLO 5x20mm 218 series

• Thorlabs part#: 4300-GMC-250-500MA

5.2. Ventilation

For proper operation and protection, it is important that the ventilation passages located

on the sides and rear of the unit not be obstructed from free airflow.

18828-D02 Rev F, Sept 23, 2011 Page 14 www.thorlabs.com

Liquid Crystal Controller

5.3. Troubleshooting

Problem Solutions

Unit will not power up. LCD display not

illuminating, unit is not functioning

DC Offset Error

Note: The LCC25 circuitry has been designed to monitor and correct the DC offset in real

time. This will increase the life of the Liquid Crystals. For any unforeseen reason DC

offset is detected above the ±10 mV limit enabling the DC OFFSET ERROR to appear.

To eliminate damage to the LC device disconnect from LCC25 output BNC.

Check the power switch is in the ON position,

the mains connection is correct, and the fuse

has not been damaged.

If Error appears on LCD. Disconnect LC

device from the output of the LCC25. Cycle

power switch to reset parameters. If ERROR

reappears, please contact Thorlabs technical

support for assistance.

18828-D02 Rev F, Sept 23, 2011 Page 15 www.thorlabs.com

Liquid Crystal Controller

Part 6. Warranty Information

General Product Warranty

Thorlabs warrants that all products sold will be free from defects in material and

workmanship, and will conform to the published specifications under normal use and

service when correctly installed and maintained.

Opto-Mechanics

Lifetime Warranty: Thorlabs offers a lifetime warranty on all opto-mechanical components.

Thorlabs will repair or replace any opto-mechanical product which after evaluation has

failed to perform in the above conditions.

Optical Tables and Breadboards

Lifetime Warranty: We provide a lifetime guarantee that all of our passively damped optical

tables and breadboards will meet all originally stated performance specifications under

normal use and proper handling. We additionally guarantee that all our table tops and

breadboards, both active and passive, will be free from defects in workmanship, including

de-lamination of the skins under normal use and handling.

Lasers and Imaging Systems

Thorlabs offers a one year warranty on all lasers and imaging systems, with the exceptions

of laser diodes. Some products are warranted for the number of hours specified in the

operating manual of each laser.

Opto-Electronics, Control Electronics, Optics, and Nano-Positioning Product Lines

Thorlabs offers a two year warranty on the above mentioned product lines, provided normal

use and maintenance of the products and when properly handled and correctly installed.

Thorlabs shall repair or replace any defective or nonconforming product as detailed above.

We ask that buyer contact Thorlabs for a Return Material Authorization number (RMA #)

from our Customer Service/Returns department in order to most efficiently process the

return and/or repair.

Products returned for repair that are not covered under warranty, a Thorlabs standard repair

charge shall be applicable in addition to all shipping expenses. This repair charge will be

quoted to the customer before the work is performed.

Warranty Exclusions

The stated warranty does not apply to Products which are (a) specials, modifications, or

customized items (including custom patch cables) meeting the specifications you provide;

(b) ESD sensitive items whose static protection packaging has been opened; (c) items

repaired, modified or altered by any party other than Thorlabs; (d) items used in conjunction

with equipment not provided by, or acknowledged as compatible by, Thorlabs; (e) subjected

to unusual physical, thermal, or electrical stress; (f) damaged due to improper installation,

misuse, abuse, or storage; (g) damaged due to accident or negligence in use, storage,

transportation or handling.

18828-D02 Rev F, Sept 23, 2011 Page 16 www.thorlabs.com

Liquid Crystal Controller

Part 7. Declaration of Conformity

18828-D02 Rev F, Sept 23, 2011 Page 17 www.thorlabs.com

Liquid Crystal Controller

Part 8. Regulatory

As required by the WEEE (Waste Electrical and Electronic Equipment Directive) of the

European Community and the corresponding national laws, Thorlabs offers all end users

in the EC the possibility to return “end of life” units without incurring disposal charges.

• This offer is valid for Thorlabs electrical and

electronic equipment:

• Sold after August 13, 2005

• Marked correspondingly with the crossed out

“wheelie bin” logo (see right)

• Sold to a company or institute within the EC

• Currently owned by a company or institute within

the EC

• Still complete, not disassembled and not

contaminated

As the WEEE directive applies to self contained operational

electrical and electronic products, this end of life take back service does not refer to other

Thorlabs products, such as:

• Pure OEM products, that means assemblies to be built into a unit by the user

(e.g. OEM laser driver cards)

• Components

• Mechanics and optics

• Left over parts of units disassembled by the user (PCB’s, housings etc.).

If you wish to return a Thorlabs unit for waste recovery, please contact Thorlabs or your

nearest dealer for further information.

Wheelie Bin Logo

8.1. Waste Treatment is Your Own Responsibility

If you do not return an “end of life” unit to Thorlabs, you must hand it to a company

specialized in waste recovery. Do not dispose of the unit in a litter bin or at a public

waste disposal site.

8.2. Ecological Background

It is well known that WEEE pollutes the environment by releasing toxic products during

decomposition. The aim of the European RoHS directive is to reduce the content of toxic

substances in electronic products in the future.

The intent of the WEEE directive is to enforce the recycling of WEEE. A controlled

recycling of end of live products will thereby avoid negative impacts on the environment.

18828-D02 Rev F, Sept 23, 2011 Page 18 www.thorlabs.com

Liquid Crystal Controller

Part 9. Thorlabs Worldwide Contacts

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-579-7227

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau

Germany

Tel: +49-(0)8131-5956-0

Fax: +49-(0)8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

Japan

Thorlabs Japan, Inc.

--, .LWDPDFKL,

1HULPD-ku, Tokyo 17-00

Japan

Tel: +81-3--

Fax: +81-3--

www.thorlabs.FRjp

Email: sales@thorlabs.jp

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place, Ely

Cambridgeshire CB7 4EX

Great Britain

Tel: +44 (0)1353-654440

Fax: +44 (0)1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Mölndalsvägen 3

412 63 Göteborg

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

China

Thorlabs China

Room A101, No. 100

Lane 2891, South Qilianshan Road

Putuo District

Shanghai

China

Tel: +86 (0)21-32513486

Fax: +86 (0)21-32513480

www.thorlabs.hk

Email: chinasales@thorlabs.com

18828-D02 Rev F, Sept 23, 2011 Page 19 www.thorlabs.com

www.thorlabs.com

Loading...

Loading...