KDC101

DC Servo Motor Driver

APT User Guide

Original Instructions

Contents

Chapter 1 Safety ............................................................................................. 4

1.1 Safety Information ..................................................................................4

1.2 General Warnings .................................................................................. 4

Chapter 2 Introduction and Overview ..........................................................5

2.1 Introduction .............................................................................................5

2.2 K-Cube Controller Hub ...........................................................................6

2.3 APT PC Software Overview ...................................................................7

2.3.1 Introduction ........................................................... .............................................. 7

2.3.2 APTUser Utility ...................................................................................................8

2.3.3 APT Config Utility ...............................................................................................9

2.3.4 APT Server (ActiveX Controls) .........................................................................10

2.3.5 Software Upgrades ...........................................................................................11

Chapter 3 Getting Started ............................................................................12

3.1 Install The Software ..............................................................................12

3.2 Mechanical Installation ......................................................................... 13

3.2.1 Environmental Conditions ................................................................................ 13

3.2.2 Mounting Options .............................................................................................13

3.2.3 Using the Baseplate .........................................................................................14

3.3 Electrical Installation .............................................................................14

3.3.1 Rear Panel ....................................................................................................... 14

3.3.2 Front Panel ......................................................................................................15

3.4 Connect The Hardware ........................................................................ 16

Chapter 4 Standalone Operation ................................................................19

4.1 Introduction ...........................................................................................19

4.2 Control Panel ........................................................................................ 20

4.2.1 Overview ..........................................................................................................20

4.2.2 Digital Display - Operating Mode ......................................................................20

4.3 Velocity Wheel Operation .....................................................................21

4.3.1 Homing ................................................................. ............................................ 21

4.3.2 Go to Position ................................................................................................... 21

4.3.3 Jogging ....................... ......................................................................................21

4.3.4 Velocity Moves .................................................................................................22

4.4 Settings Menu ............................................. ... ................................. ... ..22

4.4.1 Overview ..........................................................................................................22

4.4.2 Menu Option - Go to position ...........................................................................23

4.4.3 Menu Option - Start homing .............................................................................24

4.4.4 Menu Option - Velocity .....................................................................................24

4.4.5 Menu Option - Joystick Mode ...........................................................................25

4.4.6 Menu Option - Jog Step Size ...........................................................................26

4.4.7 Menu Option - Teach Position ..........................................................................27

4.4.8 Menu Option - Brightness .................................................................................28

4.4.9 Menu Option - Disp.Timeout .............................................................................28

4.4.10 Menu Option - Disable ...................................................................................... 29

4.4.11 Menu Option - Select Stage .............................................................................29

2 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

Chapter 5 PC Operation - Tutorial ............................................................. 30

5.1 Introduction ........................................................................................... 30

5.2 VUsing the APT User Utility ..................................................................30

5.3 Homing Motors .......... ... ................................................................... ... ..32

5.4 Moving to an Absolute Position ............................................................33

5.5 Changing Motor Parameters ................................................................34

5.6 Jogging .................................................................................................35

5.7 Stopping the Stage .............................................. .................................36

5.8 Graphical Control Of Motor Positions (Point and Move) .......................37

5.9 Setting Move Sequences ......................................................................39

5.10 Creating a Simulated Configuration ......................................................42

5.11 Stage/Axis Tab .................................................................. ...................45

Chapter 6 Software Reference .................................................................... 46

6.1 Introduction ........................................................................................... 46

6.2 GUI Panel .............................................................................................46

6.3 Settings Panel ................................. ... ..................................................48

6.3.1 Moves/Jogs Tab ............................................................................................... 48

6.3.2 Stage/Axis Tab ................................................................................................. 51

6.3.3 Servo Loop Tab ............................................................................................... 54

6.3.4 Panel/Triggering Tab ....................................................................................... 56

6.3.5 Defaults Tab ..................................................................................................... 61

6.3.6 Rotation StagesTab ......................................................................................... 62

Appendices

Appendix A Rear Panel Connector Pinout Detail ...................................... 63

Appendix B Preventive Maintenance .........................................................64

Appendix C Specifications and Associated Products ..............................65

Appendix D Motor Control Method Summary ........................................... 67

Appendix E DC Motor Operation - Background ........................................ 71

Appendix F Regulatory ..................................................... ........................... 76

Appendix G Thorlabs Worldwide Contacts ............................................... 79

3

Chapter 1 Safety

1.1 Safety Information

For the continuing safety of the operators of this equipment, and the protection of the

equipment itself, the operator should take note of the Warnings, Cautions and Notes

throughout this handbook and, where visible, on the product itself.

The following safety symbols may be used throughout the handbook and on the

equipment itself.

Shock Warning

Given when there is a risk of injury from electrical shock.

Warning

Given when there is a risk of injury to users.

Caution

Given when there is a risk of damage to the product.

Note

Clarification of an instruction or additional information.

1.2 General Warnings

Warnings

If this equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired. In particular,

excessive moisture may impair operation.

Spillage of fluid, such as sample solutions, should be avoided. If spillage does

occur, clean up immedia tely using ab sorbant tissu e. Do not allow spilled fluid

to enter the internal mechanism.

Caution

If your PC becomes unresponsive (e.g due to an operating system problem,

entering a sleep state condition, or screen saver operation) for a prolonged

period, this will interrupt communication between the APT Software and the

hardware, and a communications error may be generated. To minimize the

possibility of this happening it is strongly recommended that any such modes

that result in prolonged unresponsiveness be disabled before the APT

software is run. Please consult your system administrator or contact Thorlabs

technical support for more details.

4

Chapter 2 Introduction and Overview

2.1 Introduction

The K-Cube DC Servo Controller (KDC101) is a new very compact single channel

controller/driver for easy manual and automatic control of DC Servo motors. This

driver has been designed to operate with a variety of lower powered DC brushed

motors (up to 15V/2.5W operation) equipped with encoder feedback. The KDC101

has been optimised for 'out of the box' operation with the Thorlabs range of Z8 D C

motor equipped opto-mechanical products, however highly flex ible software settin gs

and closed loop tuning also supports operation with a wide range of third party DC

Servo motors and associated stages/actuators.

Although compact in footprint, this unit offers a fully featured motion control capability

including velocity profile settings, limit switch handling, “on the fly” change s in motor

speed and direction, control over the closed loop PID parameters and, for more

advanced operation, adjustment of settings such as lead screw pitch and g earbox

ratio, allowing support for many different actuator configurations.

For convenience the footprint of this unit has been kept to a minimum, measuring only

60 x 60 x 47mm (2.36" x 2.36" x 1.85") and with the facility to directly mount to the

optical table close to the motorised device - convenient when manually adjusting

motor positions using the top panel controls (velocity control wheel). Table top

operation also allows minimal drive cable lengths for easier cable management..

Fig. 2.1 K-Cube DC Servo Motor Driver

USB connectivity provides easy 'Plug and Play' PC controlled operation - multiple

units can be connected to a single PC via standard USB hub technology or b y using

5

Chapter 2

the new K-Cube Controller Hub (see over) for multi-axis motion control applications.

Coupling this with the very user friendly apt™ software (suppli ed) allows the user to

very quickly get up and running with complex move sequences in a short space of

time – for example all relevant operating parameters are set automatically by the

software for Thorlabs stage/actuator products. Advanced custom motion control

applications and sequences are also possible using the extensive ActiveX®

programming environment also supplied. This programming library is compatible with

many development tools such as LabView, Visual Basic, Visual C++, C++ Builder,

LabWindows/CVI, Matlab and Delphi.

In the remainder of this handbook, operation of the unit is described for both front

panel and PC operation. Tutorial sections (Chapter 4 and Chapte r 5) provide a good

initial understanding on using the unit and reference section (Chapter 6) covers all

operating modes and parameters in detail.

2.2 Power Options

For power, a single way wall plug supply (KPS101) is available for powering a single

K-Cube Driver.

As a further level of convenience when using the new K-Cube Controllers Thorlabs

also offers the 3-channel and 6-channel K-Cube Controller Hubs (KCH301 and

KCH601). These products have been designed specifically with multiple K-Cube

operation in mind in order to simplify issues such as cable management, power

supply routing, multiple USB device communications and different optical table

mounting scenarios.

The K-Cube Controller Hub comprises a slim base-plate type carrier with electrical

connections located on the upper surface to accept the K-Cubes.

Internally the Controller Hub contains a fully compliant USB 2.0 hub circuit to provide

communications for all K-Cubes – a single USB connectio n to the Controller Hub is

all that is required for PC control. The Controller Hub also provides power distribution

for the K-Cubes, requiring only a single power connection.

6 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

2.3 APT PC Software Overview

2.3.1 Introduction

As a member of the APT range of controllers, the K-Cube DC Driver shares many of

the associated software benefits. This includes USB conne ctivity (allowing multiple

units to be used together on a single PC), fully featured Graphical User Inte rface

(GUI) panels, and extensive software function libraries for custom application

development.

The APT software suite supplied with all APT controllers, including the DC Driver KCube, provides a flexible and powerful PC based control system both for users of the

equipment, and software programmers aiming to automate its operation.

For users, the APTUser (see Section 2.3.2.) and APTConfig (see Section 2.3.3.)

utilities allow full control of all settings and operating modes ena bling complete ‘ outof-box’ operation without the need to develop any further custom software. Both

utilities are built on top of a sophisticated, multi-threaded ActiveX ‘engine’ (called the

APT server) which provides all of the necessary APT system software services such

as generation of GUI panels, communications handling for multiple USB units, and

logging of all system activity to assist in hardware trouble shooting. It is this APT

server ‘engine’ that is used by software developers to allow the creation of advanced

automated positioning applications very rapidly and with great ease. The APT server

is described in more detail in Section 2.3.4.

Caution

On start up, wait until the top panel display has stopped flashing before

running the APT software.

Aside

ActiveX®, a Windows®-based, language-independent technology, allows a use r

to quickly develop custom applications that automate the control of APT system

hardware units. Development environments supported by ActiveX® technology

include Visual Basic®, LabView™, Borland C++ Builder, Visual C++, Delphi™,

and many others. ActiveX® technology is also supported by .NET development

environments such as Visual Basic.NET and Visual C#.NET.

ActiveX controls are a specific form of ActiveX technology that provide both a user

interface and a programming interface. An ActiveX control is supplied for each

type of APT hardware unit to provide specific controller functionality to the

software developer. See Section 2.3.4. for further details.

7

Chapter 2

2.3.2 APTUser Utility

The APTUser application allows the user to interact with a nu mb er of APT ha rdware

control units connected to the host PC. This program displays multiple graphical

instrument panels to allow multiple APT units to be controlled simultaneously.

All basic operating parameters can be altered and, similarly, all operations (such a s

motor moves) can be initiated. Settings and parameter changes can be saved and

loaded to allow multiple operating configurations to be created and easily applied.

For many users, the APTUser application provides all of the functionality nece ssary

to operate the APT hardware without the need to develop any further custom

software. For those who do need to further customize and automate usage of the KCube DC Driver (e.g. to implement a positioning algorithm), this application illustrates

how the rich functionality provided by the APT ActiveX server is exposed by a client

application.

Use of the APT User utility is covered in the PC tutorial (Chapter 5) and in the

APTUser online help file, accessed via the F1 key when using the APTUser utility.

Caution

On start up, wait until the top panel POWER led is lit bright green before

running the APT software.

8 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

2.3.3 APT Config Utility

There are many system parameters and configuration settings associated with the

operation of the APT Server. Most can be directly accessed using the various

graphical panels, however there are several system wide settings that can be made

'off-line' before running the APT software. These settings have global effect; such as

switching between simulator and real operating mode, associating mechanical stages

to specific motor actuators and incorporation of calibration data.

The APTConfig utility is provided as a convenient means for making these system

wide settings and adjustments. Full details on using APTConfig are p rovided in the

online help supplied with the utility.

Use of the APT Config utility is covered in the PC tutorial (Chapter 5) and in the

APTConfig online help file, accessed via the F1 key when using the APTConfig utility.

9

Chapter 2

2.3.4 APT Server (ActiveX Controls)

ActiveX Controls are re-usable compiled software components that supply both a

graphical user interface and a programmable interface. Many such Controls are

available for Windows applications development, providing a large range of re-usable

functionality. For example, there are Controls available that can be used to

manipulate image files, connect to the internet or simply provide user interface

components such as buttons and list boxes.

With the APT system, ActiveX Controls are deployed to allow direct control over (and

also reflect the status of) the range of electronic controller units, including the DC

Driver K-Cube. Software applications that use ActiveX Controls are often referred to

as 'client applications'. Based on ActiveX interfacing technology, an ActiveX Control

is a language independent software component. Consequently ActiveX Controls can

be incorporated into a wide range of software development environments for use by

client application developers. Development environments supported include Vi sual

Basic, Labview, Visual C++, C++ Builder, HPVEE, Matlab, VB.NET, C#.NET

VBA, Microsoft Office applications such as Excel and Word.

Consider the ActiveX Control supplied for the KDC101 DC servo driver unit.

and, via

This Control provides a complete user graphical instrument panel to all ow the mo tor

unit to be manually operated, as well as a complete set of software function s (often

called methods) to allow all parameters to be set and motor operations to be

automated by a client application. The instrument panel reflects the current operating

state of the controller unit to which it is associated (e.g. such as motor position).

Updates to the panel take place automatically when a user (client) application is

making software calls into the same Control. For example, if a client application

instructs the associated DC servo motor Control to move a motor, the progress of that

move is reflected automatically by changing position readouts on the graphical

interface, without the need for further programming intervention.

10 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

The APT ActiveX Controls collection provides a rich set of graphical user panels and

programmable interfaces allowing users and client a pplication devel opers to interact

seamlessly with the APT hardware. Each of the APT controllers has an associated

ActiveX Control and these are described fully in system online help or the handbooks

associated with the controllers. Note that the APTUser and APTConfig uti lities take

advantage of and are built on top of the powerful functionality provided by the APT

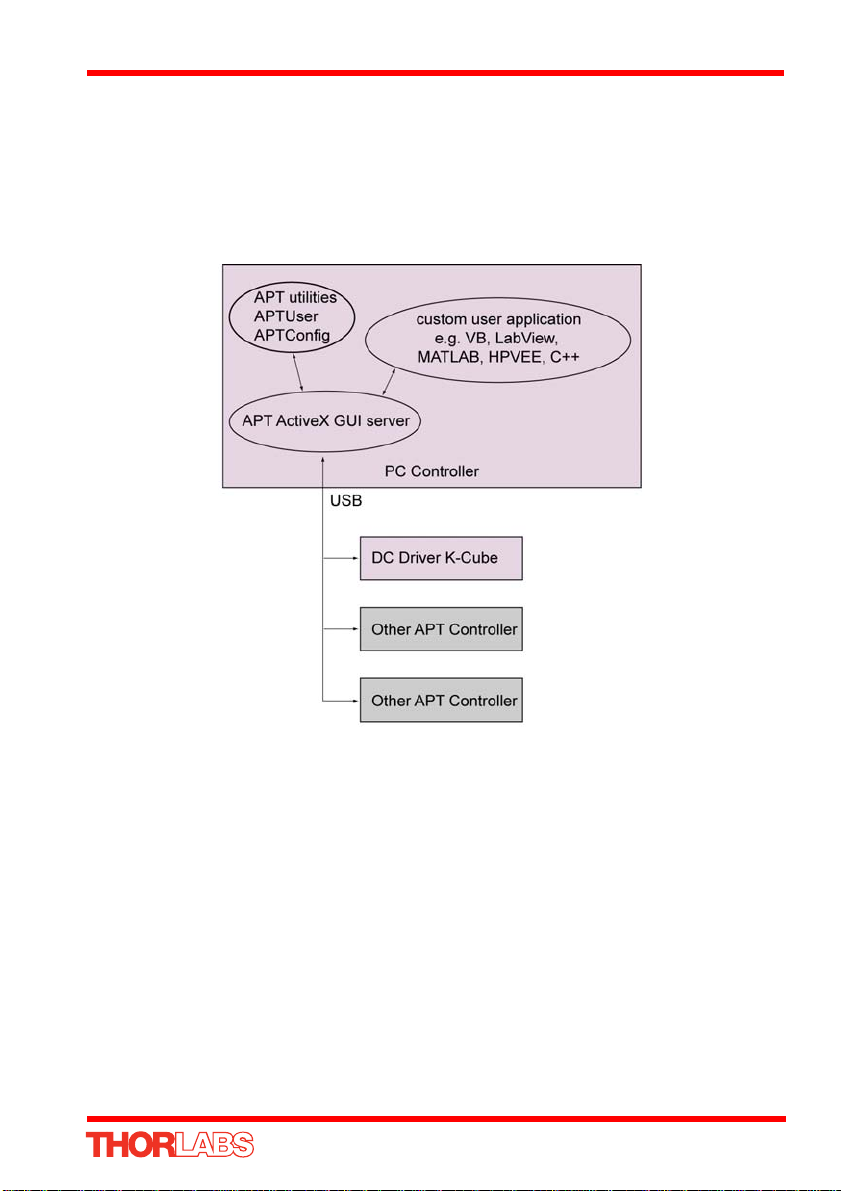

ActiveX Server (as shown in Fig. 2.2).

Fig. 2.2 System Architecture Diagram

Refer to the main APT Software online help file, for a complete programmers guide

and reference material on using the APT ActiveX Controls collection. This is available

either by pressing the F1 key when running the APT server, or via the Start menu,

Start\Programs\Thorlabs\APT\APT Help.

2.3.5 Software Upgrades

Thorlabs operate a policy of continuous product development and may issue software

upgrades as necessary.

11

Chapter 3 Getting Started

3.1 Install The Software

Caution

If your PC becomes unresponsive (e.g due to an operating system problem,

entering a sleep state condition, or screen saver operation) for a prolonged

period, this will interrupt communication between the APT Software and the

hardware, and a communications error may be generated. To minimize the

possibility of this happening it is strongly recommended that any such modes

that result in prolonged unresponsiveness be disabled before the APT

software is run. Please consult your system administrator or contact Thorlabs

technical support for more details.

Caution

Some PCs may have been configured to restrict the users ability to load

software, and on these systems the software may not install/run. If you

are in any doubt about your rights to install/run software, please consult

your system administrator before attempting to install. If you experience

any problems when installing software, contact Thorlabs on +44 (0)1353

654440 and ask for Technical Support.

DO NOT CONNECT THE STAGE TO YOUR PC YET

1) Download the software from www.thorlabs.com.

2) Locate the downloaded setup.exe file and move to a suitable file location.

3) Double-click the setup.exe file and follow the on-screen instructions.

12

K-Cube Brushed DC Servo Motor Driver

3.2 Mechanical Installation

3.2.1 Environmental Conditions

Warning

Operation outside the following environmental limits may adversely affect

operator safety.

Location Indoor use only

Maximum altitude 2000 m

Temperature range 5

Maximum Humidity Less than 80% RH (non-condensing) at 31°C

To ensure reliable operation the unit should not be exposed to corrosive ag ents or

excessive moisture, heat or dust.

If the unit has been stored at a low temperature or in an environment of high humidity,

it must be allowed to reach ambient conditions before being powered up.

3.2.2 Mounting Options

The K-Cube DC Driver is shipped with a baseplate, for use when fitting the unit to a

breadboard, optical table or similar surface.

For multiple cube systems, a 3-channel and 6-channel K-Cube Controller Hub

(KCH301 and KCH601). ) are also available - see Section 2.2. for further details. Full

instructions on the fitting and use of the controller hub are contained in the handbook

available at www.thorlabs.com

o

C to 40oC

Caution

When siting the unit, it should be positioned so as not to impede the

operation of the controls on the top panel.

13

Chapter 3

3.2.3 Using the Baseplate

The baseplate must be bolted to the worksurface before the K-Cube is fitted, as

shown below. The K-cube is then located on two dowels in the baseplate and secured

by two clips.

Fig. 3.1 Using The Baseplate

3.3 Electrical Installation

3.3.1 Rear Panel

Fig. 3.2 Rear Panel Connections

The rear panel of the unit is fitted with a 15 pin D-type connector as shown above,

which is compatible with Thorlabs DC servo motor actuators (refer to Appendix A

for details of pin outs).

Caution

DO NOT connect a motor actuator while the K-Cube is powered up.

Only use motor drive cables supplied by Thorlabs, other cables may have

incompatible wiring.

14 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

_

+

TRIG 1

TRIG 2

USB

POWER

DC 15V 1A

+5V TTL +5V TTL

ON

KDC101

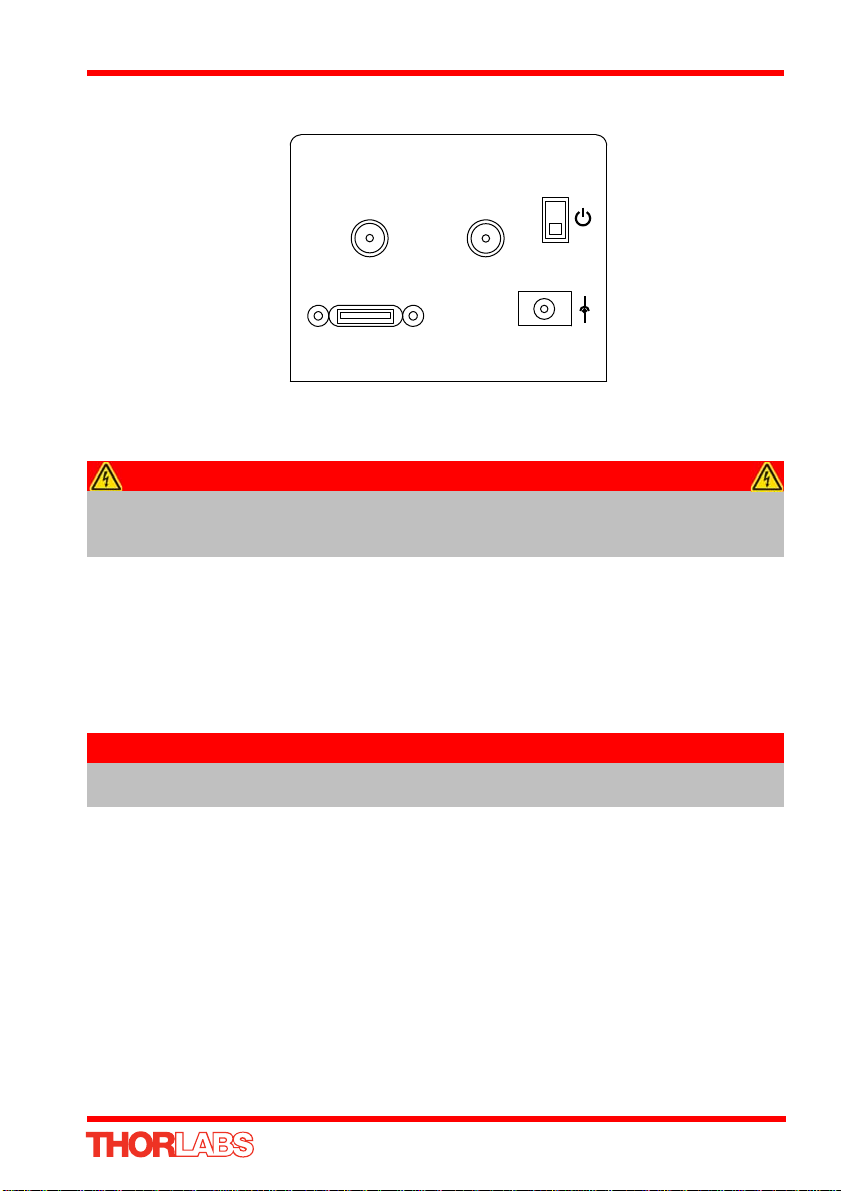

3.3.2 Front Panel

Fig. 3.3 Front Panel Connections

Shock Warning

The unit must be connected only to a DC supply of 15V, 1A regulated.

Connection to a supply of a different rating may cause damage to the unit

and could result in injury to the operator.

POWER - A Standard 3.5 mm front panel jack connector for connecting the unit to a

regulated DC power supply of 15 V, 1A.

Thorlabs offers a compact, multi-way power supply unit (TPS008 ), allowing up to

eight Driver K-Cubes to be powered from a single mains outlet. A single way wall plug

supply (KPS101) for powering a single Driver K-Cube is also available.

USB - USB port for system communications.

Note

The USB cable length should be no more than 3 metres unless a powered

USB hub is being used.

ON - Power ON/Standby switch. When in the ON position, the unit is fully powered

up. When the switch is turned to the Standby position, the unit initiates a controlled

power down sequence, saving all user-adjustable parameters to non-volatile memory

before turning off the power. For the first few seconds, the shutdown can be cancelled

by turning the switch on again, in which case the unit will save the parameters but will

remain powered up. In a powered down (Standby) state, the logic circuits are

powered off and the unit will draw only a small quiescent curre nt. The switch should

always be used to power down the unit.

TRIG 1 and TRIG 2 - SMA connectors for use with external trigger input and output

signals (5V TTL levels). The function is set to trigger IN or OUT via the settings panel

- see Section 6.3.4.

15

Chapter 3

Thorlabs KDC101

SwRev 10002

Stage Connected:

Z812

At 0.0000 mm

Stopped V

3.4 Connect The Hardware

1) Perform the mechanical installation as detailed in Section 3.2.

2) Install the APT Software.

Caution

During items (3) to (6) the instructions should be followed strictly in the

order stated. Problems may occur if the process is not performed in the

correct sequence. DO NOT connect a motor actuator while the K-Cube is

powered up.

3) Connect the Controller unit to your PC.

(Note. The USB cable should be no more than 3 metres in length. Communication

lengths in excess of 3 metres can be achieved by using a powered USB hub).

4) Connect the DC servo motor actuator to the Controller unit - see Section 3.3.1.

Caution

During item (5) ensure the power switch on the front panel of the unit is

switched off before connecting power to the K-Cube. Always power up

the K-Cube unit by its ON switch. DO NOT connect the K-Cube unit to a

'live' external power supply . Doing so (i.e. “hot plugging”) carri es the risk

of PERMANENT damage to the unit. Similarly, to power down the unit,

turn the power switch off before disconnecting the power supply.

5) Connect the Controller unit to the power supply - see Section 3.3.2.

6) Connect the PSU to the main supply.

7) Switch ‘ON’ the unit using the switch on the front panel.

The unit takes about 5 seconds from power application until warm up is finished,

during which time the following screens are displayed.

Fig. 3.4 Start up display

16 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

Thorlabs KDC101

SwRev 020004

Stage persisted:

Z825 <no ID>

At 0.0000 mm

Stopped V

8) WindowsTM should detect the new hardware. Wait while WindowsTM installs the

drivers for the new hardware.

Note

If any problems are encountered during the connection and power up

process, power cycle the unit, which should clear the error.

3.5 Stage identification

Most of the stages compatible with the KDC101 controller are fitted with an

identification device. On power-up the KDC101 reads the stage identifica tion and

loads the correct operating parameters associated with the stage. When the controller

is used with APT software, the type of stage is also reported to the GUI. However,

some legacy stages are not fitted with an identification device. For correct operation

these must be selected manually after power up.

If, on power-up, the controller is able to determine the type of the stage connected, it

will load the operating parameters associated with that stage and the OL ED display

will show "Stage connected: <type of stage>", as shown in Fig. 3.4. In this scenario,

no further action needs to be taken.

If, however, the stage is not fitted with an ID (e.g. Z825V, CR 1-Z7) the user can

manually select the correct stage and persist the setting. To facilitate this, the OLED

display menu contains a menu option called "Select stage". For stages that are not

fitted with an ID resistor, the user needs to use the "Select stage" menu option and

manually identify the stage connected to the controller - see Section 4.4.11. for further

details. This only needs to be done once: on subsequent power-ups the controller will

assume that the stage type has not changed, unless it de tects a stage that is fitted

with an ID resistor. To indicate that the stage type is assumed rather than identified,

the OLED power-up display screen will show "Stage persisted: <stage type> (No ID)"

to warn the user that the type of the stage is only assumed and may not be correct..

Fig. 3.5 Start up display - no stage ID

17

Chapter 3

3.6 Verifying Software Operation

3.6.1 Initial Setup

1) Ensure power is applied to the unit, then switch the unit ON using the switch on

the front panel.

2) Wait until the power up sequence is complete, then run the APTUser utility and

check that the Graphical User Interface (GUI) panel appears and is active.

Fig. 3.6 Gui panel showing jog and ident buttons

3) Click the ‘Ident’ button. The digital display on the top panel of the a ssociated

controller flashes. This is useful in multi-channel systems for identifying which

channel is associated with which GUI.

4) Click the jog buttons on the GUI panel and check that the motor or axis connected

to the DC Driver K-Cube moves. The position display for the associated GUI

should increment and decrement accordingly.

Follow the tutorial steps described in Chapter 4 for further verification of operation.

Note

The 'APT Config' utility can be used to set up simulated hardware configurations

and place the APT Server into simulator mode. In this way it is possible to create

any number and type of simulated (virtual) hardware units in order to emulate a

set of real hardware. This is a particularly useful feature, designed as an aid to

application program development and testing. Any number of 'virtual' control

units are combined to build a model of the real system, which can then be used

to test the application software offline.

If using real hardware, ensure that Simulator Mode is disabled. If using a

simulated setup, enable Simulator Mode and set up a ‘Simulated Configuration’ -

see Section 5.8. or the APTConfig helpfile for detailed instructions.

18 HA0363T Rev D Jan 2017

Chapter 4 Standalone Operation

Brushed Motor Controller

MENU

4.1 Introduction

The DC Driver K-Cube has been designed specifically to operate wi th the extensi ve

range of Thorlabs DC motorised opto-mechanical products. The unit offers a fully

featured motion control capability including velocity profile settings, limit switch

handling, homing sequences and, for more advanced operation, adjustment of

settings such as lead screw pitch and gearbox ratio, allowing support for many

different actuator configurations. These parameters can be set via the APT Server

software - see Chapter 5. Furthermore, many of these parameters are automatically

set to allow “out of the box” operation with no further “tuning” required.

The following brief overview explains how the front panel controls can be used to

perform a typical series of motor moves. It is assumed that the unit has already been

installed and configured for the particular actuator or stage to which it is associated see Chapter 3 for more details.

4.2 Control Panel

4.2.1 Overview

Fig. 4.1 Panel Controls and Indicators

MOVE Controls - These controls allow all motor moves to be initiated.

Velocity Wheel - Used to drive the motor at a varying speed in either forward or

reverse directions for full and easy motor control - see Section 4.3.

Digital Display - The display shows the menu options and settings, accessed via

the menu button - see Section 4.4. When the Ident button on the associated GUI

panel is clicked, the display will flash for a short period.

MENU - used to access the settings menu - see Section 4.4. Also used to stop a

move when the stage is in motion.

19

Chapter 4

Brushed Motor Controller

At 0.0000 mm

Stopped V

4.2.2 Digital Display - Operating Mode

During normal operation, the digital display shows the current position (in millimeters

or degrees) and the current state of the motor (Stopped or Moving). If the stage being

driven has been homed, the display will also show ‘Homed’.

Fig. 4.2 Digital Display - Normal Operation

For rotation stages, the position display will be restricted to the "Eq uivalent Angle"

display mode (see Section 6.3.6. for more details), so the position displayed will

always be a positive number between 0 and 360 degrees. If set to Total Angle in the

settings panel, the LED display will still show the equivalent 0 to 360° value but the

GUI screen will show the total rotation.

4.3 Velocity Wheel Operation

The velocity wheel is a sprung potentiometer, such that when released it returns to its

central position. In this central position the motor is stationary. Different types of move

can be initiated by the wheel, depending on its mode setting. The mode can be set

either via the GUI Settings panel, see Section 6.3.4. or via the top panel display menu,

see Section 4.4. The various operating modes are described in Section 4.3.1. to

Section 4.3.3.

4.3.1 Homing

A ‘Home’ move is performed to establish a datum from which subsequent absolute

position moves can be measured (see Section 5.3. and Section E.2.2. for further

information on the home position).

To initiate a ‘Home’ see Section 4. 4.3.

4.3.2 Go to Position

In ‘Go To Position’ mode, two preset position values can be specified, such that the

motor moves to position 1 when the wheel is moved down, and to position 2 when it

is moved up. These ‘taught’ positions can be set through th e software GUI - see

Section 6.3.4. or via the display menu, see Section 4.4.7.

20 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

This mode of operation is enabled by setting the ‘Wheel Mode’ to ‘Go To Position’

through the software GUI - see Secti on 6.3.4. or via the displa y menu, see Section

4.4.5.

Note for Rotation Stage Users

If the current absolute position is outside the 0 to 360 degree range, then "go

to position" will result in a move to the correct angular position within the

same 0..360 degree full turn "segment". This means that the move will always

stay in the current full turn segment, and from this point of view it is not always

the quickest position move. For example, if you are at 350 degrees and you

enter a "go to" position of 10 degrees, the stage will rotate anticlockwise 340

degrees and not clockwise 20 degrees.

4.3.3 Jogging

The top panel wheel can also be configured to ‘jog’ the motor. This mode of operation

is enabled by setting the ‘Wheel Mode’ parameter to ‘Jogging’ through the software

GUI - see Section 6.3.4. or via the display menu, see Section 4.4.5.

Once set to this mode, the jogging parameters for the wheels are taken from the ‘Jog’

parameters on the ‘Move/Jogs’ settings tab - see Section 6 .3.1. or via the display

menu, see Section 4.4.6.

4.3.4 Velocity Moves

The wheel can also be used to initiate a move at a specified velocity. As the wheel is

moved away from the centre, the motor begins to move. Bidirectional control of the

motor is possible by moving the wheel in both directions. The speed of the motor

increases by discrete amounts as a function of wheel deflection, up to a maximum as

set in through the software GUI - see Section 6.3.4. or via the display menu, see

Section 4.4.4. The move stops when the wheel is returned to its centre position.

21

Chapter 4

At 0.0000 mm

Stopped V

Menu options

Use wheel

Menu options

1 Go to position

Menu options

2 Start homing

Menu options

3 Velocity

Menu options

4 Joystick mode

Menu options

5 Jog step size

Menu options

6 Teach position

Menu options

7 Brightness

Menu options

8 Disp.Timeout

Menu options

9 Disable

Menu options

10 Select stage

MENU

4.4 Settings Menu

4.4.1 Overview

Press the MENU button

Use the wheel to scroll through the menu options

Press the MENU button to enter a particular option

Move the stage to an absolute position - see Section 4.4.2.

Move the stage to the Home position - see Section 4.4.3.

Set the Max Velocity - see Section 4.4.4.

Set the joystick wheel mode - see Section 4.4.5.

Set the Jog Step Size - see Section 4.4.6.

Set the teach positions - see Section 4.4.7.

Set the display brightness - see Section 4.4.8.

Set the display timeout - see Section 4.4.9.

Disable the wheel - see Section 4.4.10.

Select the stage type connected - see Section 4.4.11.

22 HA0363T Rev D Jan 2017

4.4.2 Menu Option - Go to position

At 0.0000 mm

Stopped V

At 2.0000 mm

Stopped V

Menu options

Use wheel

Menu options

1 Go to position

P = 0.00 mm

adjust Pos

MENU

This mode is used to move to an absolute position.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Go to positions

option.

Use the wheel to adjust the position value, (within the

travel range for linear stages, or 0 to 360 ° for rotation

stages) then press the MENU button to store the

selection.

Note for rotation stages. If the current absolute position

is outside the 0 to 360 degree range, then "go to position"

will result in a move to the correct angular position within

the same 0..360 degree full turn "segment". This means

that the move will always stay in the current full turn

segment, and from this point of view it is not always the

quickest position move. For example, if the stage is at

350 degrees and you enter a "go to" position of 10

degrees, the stage will rotate anticlockwise 340 degrees

and not clockwise 20 degrees.

K-Cube Brushed DC Servo Motor Driver

The stage moves to the position entered, and the display

shows the change in position.

To stop the move, press the MENU button.

23

Chapter 4

Menu options

2 Start homing

At 2.0000 mm

Stopped V

Menu options

Use wheel

MENU

At 2.0000 mm

Homing V

At 0.0000 mm

Homed Stopped V

At 0.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

3 Velocity

1.680 mm/s

adjust MaxVel

MENU

At 0.0000 mm

Homed Stopped V

4.4.3 Menu Option - Start homing

This mode is used to home the stage.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Start Homing option.

The display shows a decreasing position count while the

stage is homing.

Once homing is complete, the display shows the position

at 0.0000 mm and ‘Homed’ is displayed.

To stop the move, press the MENU button.

4.4.4 Menu Option - Velocity

This mode is used to move to set the max velocity.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Velocity option.

Use the wheel to adjust the max velocity, e.g. 0.168 mm/ s,

then press the MENU button to store the setting.

Subsequent moves will be performed at the velocity

entered.

24 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

At 0.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

4 Joystick Mode

Velocity control

to select

MENU

Jog to positions

to select

Jogging in steps

to select

At 0.0000 mm

Homed Stopped V

At 0.0000 mm

Homed Stopped V

Homed Stopped P

Homed Stopped J

MENU

4.4.5 Menu Option - Joystick Mode

This mode is used to set the operating mode of the

joystick wheel.

Press the MENU button, then use the wheel to scroll

through the menu options

Press the MENU button to enter the Joystick mode

option. Use the wheel to scroll through the options, then

press MENU when the required option is displayed.

In Velocity control mode, deflecting the wheel starts a

move with the velocity proportional to the deflection. The

maximum velocity (i.e. velocity corresponding to the full

deflection of the joystick wheel) is set in the preceding

3 Velocity option. The move will stop when the wheel is

released.

In Jog to positions mode, deflecting the wheel starts a

move from the current position to one of the two

predefined “teach” positions. The teach positions are

specified in option 6 Teach Position.

In Jog in steps mode, deflecting the wheel initi ates a jog

move, using the parameters specified by the 3 Velocity

and 5 Jog step size options. Keeping the wheel deflected

repeats the move automatically after the current move

has completed.

Use the wheel to display the required option, then press

MENU to store the selection and return to the main

display.

The selected mode is indicated at the right hand side of

the bottom line:

V = Velocity mode

P = Jog to position mode

J = Jog in steps mode

25

Chapter 4

At 0.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

5 Jog step size

S = 0.10 mm

adjust JogStep

MENU

At 0.0000 mm

Homed Stopped V

4.4.6 Menu Option - Jog Step Size

This mode is used to set the jog step size.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Jog step size option.

Use the wheel to adjust the step size, e.g. 0.10 mm, then

press the MENU button to store the selection.

When Jog in steps mode is selected in the Joystick mode

option (see Section 4.4.5.), subsequent moves will be

performed at the step size entered.

26 HA0363T Rev D Jan 2017

4.4.7 Menu Option - Teach Position

At 10.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

6 Teach position

P1 = 10.0000 mm

num store

MENU

At 10.0000 mm

Homed Stopped V

At 5.0000 mm

Homed Stopped V

At 5.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

6 Teach position

P2 = 5.0000 mm

num store

MENU

This mode is used to set the teach positions, used when the Joystick mode optio n is

set to Jog to positions mode - see Section 4.4.5.

To set Teach Position 1...

Move the stage to the position to use as teach position 1.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Teach position

option.

Use the wheel to select P1, then press the MENU button

to store the current position as teach position 1 and ret urn

to the main display.

To set Teach Position 2...

Move the stage to the position to use as teach position 2.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Teach position

option.

K-Cube Brushed DC Servo Motor Driver

Use the wheel to select P2, then press the MENU button

to store the current position as teach position 2 and ret urn

to the main display.

When Jog to position mode is selected in the Joystick

mode option (see Section 4.4.5.), a downwards

deflection of the wheel moves the stage to position 1, and

an upwards deflection moves to position 2.

27

Chapter 4

At 0.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

7 Brightness

Brightness = 67

to adjust

MENU

At 0.0000 mm

Homed Stopped V

At 0.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

8 Disp.Timeout

MENU

At 0.0000 mm

Homed Stopped V

After 2 min

to adjust

4.4.8 Menu Option - Brightness

In certain applications, it may be necessary to adjust the

brightness of the LED display. The brightness is set as a

value from 0 (Off) to 100 (brightest). The display can be

turned off completely by entering a setting of zero,

however, pressing the MENU button on the top panel will

temporarily illuminate the display at its lowest brightness

setting to allow adjustments. When the display returns to

its default position display mode, it will turn off again.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Brightness option.

Use the wheel to adjust the brightness, then press the

MENU button to store the selection and return to the main

display.

4.4.9 Menu Option - Disp.Timeout

'Burn In' of the display can occur if it remains static for a

long time. To prevent this, the display is automatically

dimmed after a specified time interval.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Disp.Timeout option.

The time out interval is specified in minute s in the range

1 to 480.

The adjustment is done in steps of 1 minute if the

timeout is between 1 to 10 minutes, 10 minute steps

between 10 minutes and 1 hour, and 30 minute steps

above, up to a maximum of 480 minutes. After 480

minutes there is an option for Never.

The dim level can only be adjusted via the Settings panel

- see Section 6.3.4.

Press the MENU button to store the se lection and return to

the main display.

28 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

At 0.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

9 Disable

MENU

At 0.0000 mm

Homed Stopped V

At 0.0000 mm

Homed Stopped V

At 0.0000 mm

Homed Stopped V

Menu options

Use wheel

Menu options

10 Select stage

MENU

CR1-Z7

to select

4.4.10 Menu Option - Disable

In certain applications, it may be advantageous to disable

the wheel to remove the possibility of unwanted motion

due to accidental movement of the wheel.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Disable option.

Press the MENU button to store the se lection and return to

the main display.

4.4.11 Menu Option - Select Stage

Most of the stages compatible with the KDC101 controller are fitted with an

identification device. On power-up the KDC101 reads the stage identifica tion and

loads the correct operating parameters associated with the stage. However, some

legacy stages are not fitted with an identification device. For correct operation these

must be selected manually after power up.

Press the MENU button, then use the wheel to scroll

through the menu options.

Press the MENU button to enter the Select stage option.

Use the wheel to scroll to the required option:

CR1-Z7, Z806, Z812, Z825, MTS50-Z8, MTS25-Z8,

PRM1-Z8, CR1-Z6, Z625, Z612 and Z606.

Press MENU to store the selection and return to the main

display.

29

Chapter 5 PC Operation - Tutorial

5.1 Introduction

The following brief tutorial guides the u ser through a typical series of moves and

parameter adjustments performed using the PC based APT software. It assumes that

the unit is electrically connected as shown in Section 3.3.1. and that the APT

Software is already installed - see Section 3.1. For illustration purposes, it also

assumes that a Z812 motor is connected to the ‘Motor’ connector on the rear panel

Caution

If your PC becomes unresponsive (e.g due to an operating system problem,

entering a sleep state condition, or screen saver operation) for a prolonged

period, this will interrupt communication between the APT Software and the

hardware, and a communications error may be generated. To minimize the

possibility of this happening it is strongly recommended that any such modes

that result in prolonged unresponsiveness be disabled before the APT

software is run. Please consult your system administrator or contact Thorlabs

technical support for more details.

5.2 Using the APT User Utility

The APT User.exe application allows the user to interact with any number of APT

hardware control units connected to the PC USB Bus (or simulated via the APTConfig

utility). This program allows multiple graphical instrument panels to be di splayed so

that multiple APT units can be controlled. All basic operating parameters can be set

through this program, and all basic operations (such as motor moves) can be initiated.

Hardware configurations and parameter settings can be saved, which simplifies

system set up whenever APT User is run up.

Fig. 5.1 Typical APT User Screen

1) Wait until the KDC101 has started, then run the APT User program - Start/

Programs/Thorlabs/APT/APT User.

30

K-Cube Brushed DC Servo Motor Driver

2) Notice how the actuator type is displayed in the ‘Settings’ window. Se e Section

5.11. and Section 6.3. for further details on the parameter values shown in the

‘Settings’ display.

Fig. 5.2 DC Driver K-CubeSoftware GUI

The APT User utility will be used throughout the rest of this tutorial to interface with

the DC servo motor controller.

31

Chapter 5

5.3 Homing Motors

Homing the motor moves the actuator to the home limit switch and resets the internal

position counter to zero. The limit switch provides a fixed datum that can be found

after the system has been powered up.

Fig. 5.3 DC Driver K-Cube Software GUI

1) Click the ‘Home’ button. Notice that the led in the button lights to indicate that

homing is in progress and the displayed position counts down to 000.000, i.e the

home position.

Note

After homing, shaft relaxation may cause a small position offset to be

displayed. This relates only to one or two encoder counts and is not

significant in terms of ‘real world’ positioning.

2) When homing is complete, the ‘Homed’ LED is lit as shown above.

See Appendix E Section E.2.2. for background information on the home position.

32 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

5.4 Moving to an Absolute Position

Absolute moves are measured in real world units (e.g. millimetres), relative to the

Home position.

1) Click the position display.

Fig. 5.4 Absolute Position Popup Window

2) Enter 8.0 into the pop up window

3) Click ‘OK’. Notice that the position display counts up to 8.000 to indicate a move

to the absolute position 8.00mm.

33

Chapter 5

5.5 Changing Motor Parameters

Moves are performed using a trapezoidal velocity profile (see Appendix E , Section

E.1.3.). The velocity settings relate to the maximum velocities at which a move is

performed, and the acceleration at which the motor speeds up from zero to maximum

velocity.

1) On the GUI panel, click the ‘Settings’ button (bottom right hand corner of the

display) to show the Settings panel.

Fig. 5.5 Settings Panel - Move/Jogs Tab

2) Select the Move/Jogs tab as shown in Fig. 5.5.

3) In the ‘Moves’ field, enter parameter valu es as follows:

‘Max. Vel’ - ‘0.25’

‘Accn/Dec’ - ‘0.1’

Note

In current versions of software, the ‘Min Vel’ parameter is locked at zero

and cannot be adjusted.

4) Click ‘OK’ to save the settings and close the window.

5) Any further moves initiated will now be performed at a maximum velocity of

0.25mm per second, with an acceleration of 0.1mm/sec/sec.

34 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

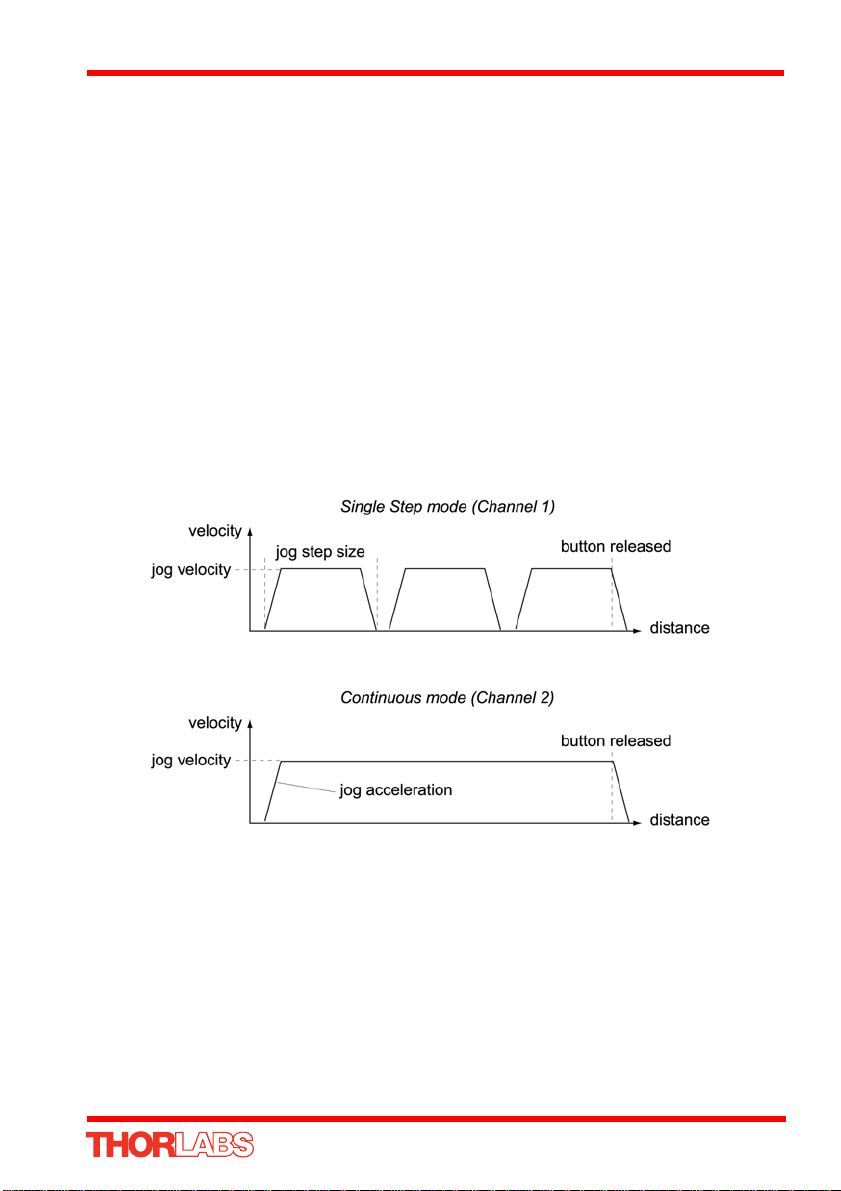

5.6 Jogging

During PC operation, the motor actuators are jogged using the GUI panel arrow keys.

There are two jogging modes available, ‘Single Step’ and ‘Continuous’. In ‘Single

Step’ mode, the motor moves by the step size specified in the Step Distance

parameter. If the velocity wheel is turned and held , single step jogging is re peated

until the wheel is released - see Fig. 6.3. In ‘Continuous’ mode, the motor actuator will

accelerate and move at the jog velocity while the wheel is turned.

1) On the GUI panel, click the ‘Settings’ button to display the Settings panel.

Fig. 5.6 Settings Panel - Move/Jogs Tab

2) Select the Move/Jogs tab as shown in Fig. 5.6.

3) In the ‘Jogs’ field, enter parameter values as follows:

Velocity Profile

‘Max. Vel’ - ‘0.25’

‘Accn/Dec’ - ‘0.1’

Note

In current versions of softwar e, th e ‘Min Vel’ parameter i s locked at zero

and cannot be adjusted.

Operating Modes

‘Jogging’ - ‘Single Step’

‘Stopping’ - ‘Profiled’

‘Step Distance’ - ‘0.1’

4) Click ‘OK’ to save the settings and close the window.

5) Click the Jog Arrows on the GUI panel to jog the motor. Notice that the position

display increments 0.1 every time the button is clicked.

35

Chapter 5

5.7 Stopping the Stage

The drive channel is enabled and disabled by clicking the ‘Enable’ button on the GUI

panel. The green indicator in the button center is lit when the drive channel is enabled.

Disabling the channel removes the drive power.

During operation, the stage can be stopped at any time by clicking the ‘Stop’ button

on the GUI panel. Using this button does not remove power to the drive channel.

.

Fig. 5.7 APTUser GUI screen

36 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

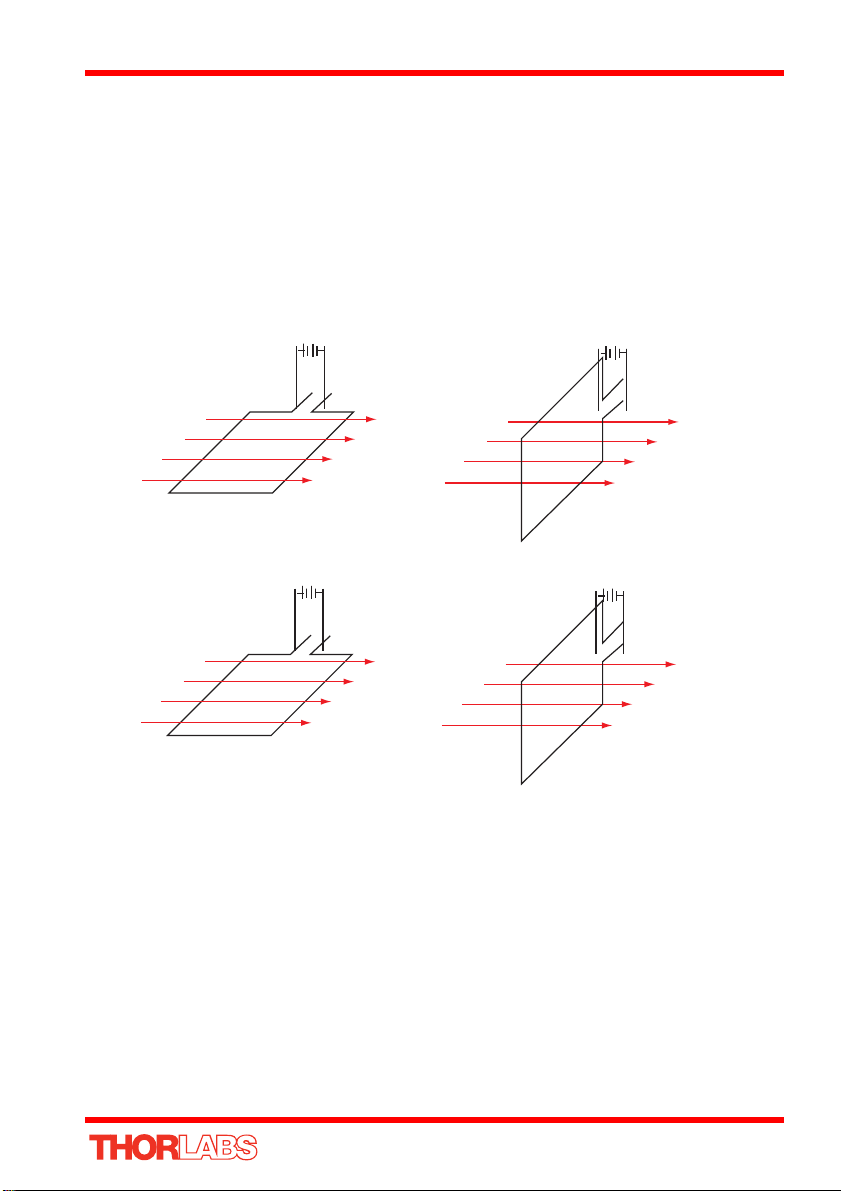

5.8 Graphical Control Of Motor Positions (Point and Move)

The GUI panel display can be changed to a graphical display, showing the position of

the motor channel(s). Moves to absolute positions can then be initiated by positioning

the mouse within the display and clicking.

To change the panel view to graphical view, right click in the screen and select

‘Graphical View’.

Fig. 5.8 DC Driver K-Cube GUI Panel - Graphical View

Consider the display shown above for a DC Driver K-Cube.

The right hand display shows the channel and motor unit pa rameters; i.e. controller

unit type and serial number, associated stage and actuator type, minimum and

maximum positions, current position, units per grid division and cursor po sition. All

units are displayed in real world units, either millimetres or degrees.

Note

For single channel units such as the DC Driver K-Cube, the Channel 2

parameters are greyed out.

The left hand display shows a circle, which represents the current position of the

motor associated with the specified controller (absolute posi tion data is displayed in

the 'Chan Pos' field).

The vertical divisions relate to the travel of the stage/actuator associated with the DC

Driver K-Cube (the stage/actuator is selected in the ‘APT Config’ utility). For example,

the screen shot above shows the parameters for a 50 mm travel MTS50-Z8 stage.

The graph shows 10 divisions in the X axis, which relates to 5 mm of travel per division

(50 mm in total).

The graphical panel has two modes of operation, ‘Jog’ and ‘Move’, which are selected

by clicking the buttons at the bottom right of the screen.

37

Chapter 5

Move Mode

When ‘Move’ is selected, the motors move to an absolute position which corresponds

to the position of the cursor within the screen.

To specify a move:

1) Position the mouse within the window. For reference, the absolute motor position

value associated with the mouse position is displayed in the 'Cursor Position field.

2) Click the left hand mouse button to initiate the move.

Jog Mode

When ‘Jogging’ mode is selected, the motors are jogged each time the left mouse

button is clicked.

The Jog direction corresponds to the position of the cursor relative to the circle

(current motor position), e.g. if the cursor is to the left of the circle the motor will jog

left. The Jog Step size is that selected in the Settings panel - see Section 6.3.

Stop

To stop the move at any time, click the ‘Stop’ button.

Returning to Panel View

To return to panel view, right click in the graphical panel and select ‘Panel View’.

38 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

5.9 Setting Move Sequences

This section explains how to set move sequences, allowing several positions to be

visited without user intervention.

For details on moving to absolute positions initiated by a mouse click – see Section 5.8.

1) From the Motor GUI Panel, select 'Move Sequencer' tab to display the Move

Sequencer window.

Fig. 5.9 Move Sequencer Window

2) Right click, in the move data field to display the pop up menu.

Fig. 5.10 Move Sequencer Pop Up Menu

39

Chapter 5

3) Select 'New' to display the 'Move Editor' panel.

Fig. 5.11 Move Editor Window

Move data is entered/displayed as fol low s:

Dist/Pos: - the distance to move from the current position (if 'Relative' is selected)

or the position to move to (if 'Absolute' is selected).

Dwell Time: - after the move is performed, the system can be set to wait for a

specified time before performing the next move in the sequence. The Dwell time is the

time to wait (in milliseconds).

Return - if checked, the system will move to the position specified in the Dist/Pos field,

wait for the specified Dwell time, and then return to the original position.

4) Min Vel: Acc: and Max Vel: - the velocity profile parameters for the move.

Note

In current versions of software, the ‘Min Vel’ parameter is locked at zero

and cannot be adjusted.

The motor accelerates at the rate set in the Acc field up to the speed set in the Max

Vel field. As the destination approaches, the motor decelerates again to ensure that

there is no overshoot of the position.

40 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

5) Enter the required move data into the Move Editor and click OK. The move data

is displayed in the main window as shown below.

Fig. 5.12 Main Window with Move Data

6) Repeat step 4 as necessary to build a sequence of moves. Move data can be

copied, deleted, cut/pasted and edited by right clicking the data line(s) and

selecting the appropriate option in the pop up menu (shown below).

Fig. 5.13 Pop Up Options

7) To run a single line of data, right click the appropriate data and select 'Run' from

the pop up menu (shown above).

8) To run the entire sequence, click the 'Run' button (shown below). A Home move

can also be performed from this panel by clicking the ‘Home’ button.

Fig. 5.14 Home and Run Buttons

9) To save data to a file, or load data from a previously saved file, click the ‘Save’ or

‘Load’ button and browse to the required location.

41

Chapter 5

5.10 Creating a Simulated Configuration

The 'APT Config' utility can be used to set up simulated hardware configurations and

place the APT Server into simulator mode. In this way it is possible to create any

number and type of simulated (virtual) hardware units in order to emulate a set of real

hardware. This is a particularly useful feature, designed as an aid learning how to use

the APT software and as an aid to developing custom software applications ‘offline’.

Any number of 'virtual' control units can be combined to emulate a colection of

physical hardware units For example, an application program can be written, then

tested and debugged remotely, before running with the hardware.

To create a simulated configuration proceed as follows:

1) Run the APT Config utility - Start/Programs/Thorlabs/APT/APT Config.

2) Click the 'Simulator Configuration' tab.

Fig. 5.15 APT Configuration Utility - Simulator Configuration Tab

3) Enter ‘LAB 1’ in the Configuration Names field.

42 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

4) In the 'Simulator' field, check the ‘Enable Simulator Mode’ box. The name of the

most recently used configuration file is displayed in the 'Current Configura tion'

window.

5) In the ‘Control Unit’ field, se le ct ‘ 1 Ch DC Driver K-Cube (KDC101)’.

43

Chapter 5

6) In the ‘Enter 6 digit serial number’ field, enter a serial number for your KDC101

unit.

Note

Each physical APT hardware unit is factory programmed with a unique 8

digit serial number. In order to simulate a set of ‘real’ hardware the Config

utility allows an 8 digit serial number to be associated with each

simulated unit. It is good practice when creating simulated

configurations for software development purposes to use the same serial

numbers as any real hardware units that will be used. Although serial

numbers are 8 digits (as displayed in the ‘Load Configuration Details’

window), the first two digits are added automatically and identify the type

of control unit.

The prefixed digits relating to the DC Servo Driver K-Cube are:

27xxxxxx - 1 Ch DC Driver K-Cube

7) Click the 'Add' button.

8) Repeat items (1) to (7) as required. (A unit can be removed from the configuration

by selecting it in the 'Loaded Configuration Details' window and clicking the

'Remove' button or by right clicking it and selecting the ' Remove' option from the

pop up window).

9) Click 'Save'.

10)Click 'Set As Current' to use the configuration.

44 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

5.11 Stage/Axis Tab

This tab contains a number of parameters which are related to the physical

characteristics of the particular stage or actuator being driven. They need to be set

accordingly such that a particular stage is driven properly by the system.

Fig. 5.16 Stage/Axis Tab

These parameters were set automatically when the actuator was connected. The APT

server automatically applied suitable defaults for the parameters on this tab during

boot up of APTUser. These parameters should not be altered for pre-defined Thorlabs

stages and actuators selected using APT Config, as it may adversely affect the

performance of the stage.

For third party stage types not available using the APT Config utility, these stage

details must be entered manually.

Individual parameters are described in Section 6.3.

45

Chapter 6 Software Reference

6.1 Introduction

This chapter gives an explanation of the parameters and settings accessed from the

APT software running on a PC. For information on the methods and properties which

can be called via a programming interface, see Appendix D .

6.2 GUI Panel

The following screen shot shows the graphical user interface (GUI) displayed when

accessing the DC Driver K-Cube using the APTUser utility.

Fig. 6.1 DC Driver K-Cube Software GUI

Note

The serial number of the DC Driver K-Cube associated with the GUI panel,

the APT server version number, and the version number (in brackets) of

the embedded software running on the unit, are displayed in the top right

hand corner. This information should always be provided when

requesting customer support.

Jog - used to increment or decrement the motor position. When the button is clicked,

the motor is driven in the selected direction at the jog velocity one step per click. The

step size and jog velocity parameters are set in the 'Settings' panel (see Section 6.3.).

46

K-Cube Brushed DC Servo Motor Driver

Travel - displays the range of travel (in millimeters or degrees) of the motor.

Moving - lit when the motor is in motion.

Enable - applies power to the motor. With the motor enabled, the LED in the button

is lit.

Digital display - shows the position (in millimetres or degrees) of the motor. The

motor must be 'Homed' before the display will show a meaningful value, (i.e. the

displayed position is relative to a physical datum, the limit switch).

Home - sends the motor to its 'Home' position - see Appendix E Section E.2.2. The

LED in the button is lit while the motor is homing.

Homed - lit when the motor has previously been 'Homed' (since power up).

Stop - halts the movement of the motor.

Limit switches - the LEDs are lit when the associated limit switch has been activated

- see Appendix E Section E.2.3. for further details on limit switches.

Settings display - shows the following user specified settings:

Driver - the type of control unit associated with the specified channel.

Stage - the stage type and axis associated with the specified channel.

Calib File - the calibration file associated with the specified channel. See the

APTConfig utility helpfile for more details on assigning and using calibration files.

Min/Max V - the minimum velocity at which a mo ve is initiated, and the maximum

velocity at which the move is performed. Values are displayed in real world units (mm/

s or degrees/s), and can be set via the 'Settings' panel (see Section 6.3.).

Accn - the rate at which the velocity climbs to, and slows from, maximum velocity,

displayed in real world units (mm/s/s or degrees/s/s). The acceleration can be set via

the 'Settings' panel (see Section 6.3.) and is used in conjunction with the Min/Max

velocity settings to determine the velocity profile of a motor move . See Appendix E

Section E.1.3. for more information on velocity profiles.

Jog Step Size - the size of step (in mm or degrees) taken when the jog signal is

initiated. The step size can be set either via the Settings panel or by calling the

SetJogStepSize method.

Settings button - Displays the 'Settings' panel, which allows the operating

parameters to be entered for the motor drive - see Section 6.3.

Ident - when this button is pressed, the di splay on the front panel of the associated

hardware unit will flash for a short period.

Active - lit when the unit is operating normally and no error condition exists.

Error - lit when a fault condition occurs. The Error LED is lit if the difference between

the trajectory generator position (i.e. the demanded motor position) and the actual

position, exceeds 10000 encoder pulses. Typically this can occur transiently if the

maximum velocity specified for the move exceeds the maximum drive velocity of the

motor being controlled.

47

Chapter 6

6.3 Settings Panel

When the 'Settings' button on the GUI panel is clicked, the 'Settings' window is

displayed. This panel allows motor operation parameters such as move/jog velocities,

and stage/axis information to be modified. Note that all of these parameters have

programmable equivalents accessible through the ActiveX methods and propertie s

on this Control (refer to the Programming Guide in the APT helpfile for further details

and to Section 2.3.4. for an overview of the APT ActiveX controls).

6.3.1 Moves/Jogs Tab

Fig. 6.2 DC Driver K-Cube - Move/Jog Settings

Moves - Velocity Profile

Moves can be initiated via the GUI panel, by using the velocity wheel (see Section

4.3.) or by entering a position value after clicking on the posi tion display box (see

Section 5.4.). The following settings determine the velocity profile of such moves, and

are specified in real world units, millimetres or degrees.

Note

The minimum velocity is locked at zero and cannot be adjusted.

MaxVel - the maximum velocity at which to perform a move.

Accn/Dec - the rate at which the velocity climbs from minimum to maximum, and

slows from maximum to minimum.

Note

Under certain velocity parameter and move distance conditions, the

maximum velocity may never be reached (i.e. the move comprises an

acceleration and deceleration phase only).

48 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

Jogs

Jogs are initiated by using the ‘Jog’ keys on the GUI panel (see Section 5.6.), or the

Velocity Wheel on the top panel of the unit.

Velocity Profile (specified in real world units, millimetres or degrees)

MaxVel - the maximum velocity at which to perform a jog

Accn/Dec - the rate at which the velocity climbs from minimum to maximum, and

slows from maximum to minimum.

Operating Modes

Jogging - The way in which the motor moves when a jog command is received (i.e.

front panel button pressed or GUI panel button clicked).

There are two jogging modes available, ‘Single Step’ and ‘Continuous’. In ‘Single

Step’ mode, the motor moves by the step size specified in the Step Distance

parameter. If the jog key is held down, single step jogging is repeated until the button

is released - see Fig. 6.3. In ‘Continuous’ mode, the motor actuator will accelerate and

move at the jog velocity while the button is held down..

Fig. 6.3 Jog Modes

Single Step - the motor moves by the step size specified in the Step Distance

parameter.

Continuous - the motor continues to move until the jog signal is removed (i.e. jog

button is released).

Stopping - the way in which the jog motion stops when the demand is removed.

Immediate - the motor stops quickly, in a non-profiled manner

Profiled - the motor stops in a profiled manner using the jog Velocity Profile

parameters set above.

49

Chapter 6

Step Distance - The distance to move when a jog command is initiated. The step size

is specified in real world units (mm or degrees dependent upon the stage).

Backlash Correction - The system compensates for lead screw backlash during

reverse direction moves, by moving passed the demanded position by a specified

amount, and then reversing. This ensures that positions are always approached in a

forward direction. The Backlash Correction Distance is specified in real world units

(millimeters or degrees). To remove backlash correction, this value should be set to

zero.

Persist Settings to Hardware - Many of the parameters that can be set for the DC

Driver K-Cube can be stored (persisted) within the unit itself, such that whe n the unit

is next powered up these settings are applied automatically. This is particularly

important when the driver is being used manually in the absence of a PC and USB

link. The Velocity Profile and Jogging parameters described previously are good

examples of settings that can be altered and then persisted in the driver for use in

absence of a PC. To save the settings to hardware, check the ‘Persist Settings to

Hardware’ checkbox before clicking the ‘OK button.

Caution

The ‘Persist Settings’ functionality is provided to simplify use of the unit

in the absence of a PC. When the unit is connected to a PC and is

operated via APTUser, the default APTServer settings will be loaded at

boot up, even if the ‘Persist Settings’ option has been checked.

50 HA0363T Rev D Jan 2017

K-Cube Brushed DC Servo Motor Driver

6.3.2 Stage/Axis Tab

Fig. 6.4 DC Driver K-Cube - Stage/Axis Settings

Note

This tab contains a number of parameters which are related to the

physical characteristics of the particular stage being driven. They need to

be set accordingly such that a particular stage is driven properly by the

system.

For Thorlabs stages, the system will recognise the stage and the APT

server will automatically apply suitable defaults for the parameters on

this tab during boot up of the software. These paramete rs should not be

altered for pre-defined Thorlabs stages selecte d usi ng APT Config , as it

may adversely affect the performance of the stage.

For third party stage types not av ailabl e usin g the APT Con fig u tility, t he

stage details must be entered manually. Individual parameters are

described in the following paragraphs.

Caution

Extreme care must be taken when modifying the stage related settings

that follow. Some settings are self consistent with respect to each other,

and illegal combinations of settings can result in incorrect o peration of

the physical motor/stage combination being driven. Consult Thorlabs for

advice on settings for stage/actuator types that are not selectable via the

APTConfig utility.

51

Chapter 6

Stage and Axis Type - For Thorlabs stages, the stage type is displayed automatically

once the axis has been associated using the APTConfig utility. For third party stages,

the display shows ‘Unknown’.

Min Pos - the stage/actuator minimum position (typically zero).

Max Pos - the stage/actuator maximum position.

Pitch - the pitch of the motor lead screw (i.e. the distance travelled (in mm or degrees)

per revolution of the leadscrew).

Units - the ‘real world’ positioning units (mm or degrees).

Homing

When homing, a stage typically moves in the reverse di rection, (i.e. towards the

reverse limit switch). The following settings allow support for stages with both Forward

and Reverse limits.

Note

Typically, the following two parameters are set the same, i.e. both

Forward or both Reverse.

Direction - the direction sense to move when homing, either Forward or Reverse.

Limit Switch - The hardware limit switch associated with the home position, either

Forward HW or Reverse HW.

Zero Offset - the distance offset (in mm or degrees) from the limit switch to the Home

position.