GCM102(/M)

30 mm Cage System Mount

For Small Beam Diameter Galvos

User Guide

Original Instructions

HA 0371T

GCM102(/M) 30 mm Cage System Mount for GVSx02 Series Galvos

Contents

Chaper 1 Overview ..................................................................................................... 1

1.1 Description ......................................................................................... 1

Chaper 2 Safety .......................................................................................................... 2

2.1 Safety Information .................. ............................ ............................ ... 2

Chaper 3 Installation .................................................................................................. 3

3.1 Installing the Galvo Motors ............................................................... 3

3.2 Fitting the Optics and Adapters ....................................................... 8

3.3 Using the Cage Mount with Other Equipment ............................... 11

3.3.1 Mounting to a 1.5” Diameter Post ......................................................... 11

3.3.2 Mounting to 66 mm Rail Components .................................................. 12

Chaper 4 Thorlabs Worldwide Contacts ................................................................ 14

Chapter 1 Overview

Chapter 1 Overview

1.1 Description

The GCM102(/M) cage system adapter is used to mount the GVSX02 dual-axis galvo

systems into a 30 mm cage system. The galvo motors can be fitted and aligned

without dismantling the mount

On the beam input side, the mount features SM1 and SM05 threads for mounting lens

tubes. The output side is th readed SM2, which can be converted to M25 x 0.75 by

fitting the GCMA1 or SM2A33 adapters. The mounting face features an array of M6,

M4 and M3 (1/4-20, 4-40 and 8-32 UNC) threaded holes for use in mounting to our

range of 1.5 OD posts, and XT66 construction rails.

Note: The input and output beams are on different planes. Cage systems should be

adapted accordingly.

Fig. 1.1 GCM102 Cage Mount, post mounted with lens and cage rods fitted

Rev B Jan 2018

Page 1

GCM102(/M) 30 mm Cage System Mount for GVSx02 Series Galvos

Chapter 2 Safety

2.1 Safety Information

For the continuing safety of the operators of this equipment, and the protection of the

equipment itself, the operator should take note of the Warnings, Cautions and Notes

throughout this handbook and, where visible, on the product itself.

The following safety symb ols may be used throughout the handbook and on the

equipment itself.

Warning: Risk of Electrical Shock

Given when there is a risk of injury from electrical shock.

Warning

Given when there is a risk of injury to users.

Caution

Given when there is a risk of damage to the product.

Note

Clarification of an instruction or additional information.

Page 2 ETN032532-D02

Chapter 3 Installation

Removing the blanking plugs

Loosening the motor clamp bolts

Chapter 3 Installation

3.1 Installing the Galvo Motors

1) Using a 2.5 mm hex key, loosen the pinch bolts on the existing mount, and remove

the motor/mirror assemblies. Leave the spacers fitted to the motors and retain the

insulating film for later use. Take care not to touch the mirror surfaces.

2) Once removed, check that the the rmal insulation film is u ndamaged. Damaged

material should be discarded. Replacement film is supplied with the cage mount.

Fig. 3.1 Removing Motor/Mirror Assemblies

3) Using a 3 mm (1/8”) hex key, remove the blanking plugs from the body of the

GCM102(/M) Cage Mount, to gain access to the motor clamp.

Using a 2mm ( 5/64”) hex key, loosen the clamp bolts.

Fig. 3.2 Loosening the motor clamp bolts

Rev B Jan 2018

Page 3

GCM102(/M) 30 mm Cage System Mount for GVSx02 Series Galvos

4) Position the cage mount assembly as shown in Fig. 3.3 and using a 2 mm (5/64”)

hex key, remove the screws securing the small gasket cover. Remove the gasket

cover, then remove the screws securing the large gasket cover.

Fig. 3.3 Removing the Gasket Covers

5) Position the cage mount assembly as shown in Fig. 3.4 and using a 2 mm (5/64”)

hex key, remove the remain ing screws se curing the large gasket cover, then

remove the gasket cover.

Fig. 3.4 Removing the Gasket Covers

6) Position the cage mount as shown in Fig. 3.5, with the fixed side of the gasket to

the left. Slide the large spacer underneath the gasket then pull the gasket over the

Page 4 ETN032532-D02

Chapter 3 Installation

spacer such that it pushes through the hole in the gasket, and the gasket fits tights

around the sides of the spacer..

Fig. 3.5 Inserting the Large Spacer

7) Reposition the cage mount as shown in Fig 3.6, and in sert the small spa cer

underneath the gasket. Pull the gasket over the spacer such that it pushes through

the hole in the gasket, and the gasket fits tights around the sides of the spacer.

Fig. 3.6 Inserting the Small Spacer

Rev B Jan 2018

Page 5

GCM102(/M) 30 mm Cage System Mount for GVSx02 Series Galvos

Detail A

Detail B

8) Roll up the thermal insulation film into a small tube shape and insert into the motor

mounting holes as shown below. Ensure the film is pushed fully into the hole.

Fig. 3.7 Fitting the thermal insulation film

9) Place the cage adapter body on the worksurface as shown below, with the

engraving on the left, and the large open face facing away and to the right.

Fig. 3.8 Inserting the Motors

10) Identify the X-Axis motor assembly. This is the motor with the smallest mirror and

the serial number label has a suffix ‘-X’.

11) Insert the motor into the lower mount on the left hand side - see Fig. 3.8 Detail A.

Caution. Ensure that the wide spacer and the thermal insulation detailed

previously are fitted. The X-axis mirror will be misaligned without the wide

spacer. The clamp pinch bolts will not tighten sufficiently without the

thermal insulation material.

Gently twist the motor bod y as it is pu shed into the clamp, ta king care not to

damage the thermal insulation material.

Page 6 ETN032532-D02

Chapter 3 Installation

12) Ensure that the narrow plastic spacer removed at item (1) is fitted to the remaining

mounting hole, then insert the Y-axis motor into the upper mount on the right hand

side- see Fig. 3.8 Detail B.

Caution. Ensure that the thermal insulation detailed at item (4) is fitted. The

clamp pinch bolts will not tighten sufficiently without this material.

Gently twist the motor bo dy as it i s pushed into the clamp, taking care not to

damage the thermal insulation material.

13) Ensure that the motors are pushed fully into the moun ting holes, then turn the

motors to be aligned as shown in Fig. 3.9. The left hand (X-Axis) motor connector

should point to the right hand side. The right hand (Y-Axis) connector should point

downwards. Check through the large open face that the mirror alignment is as

shown below.

Fig. 3.9 Aligning the motors

14) Using a 2 mm (5/64”) hex key, tighten the pinch bolts on the clamps as shown below.

Fig. 3.10 Tightening the pinch bolts

15) Using a 3 mm (1/8”) hex key, refit the blanking plugs.

16) The system is now ready to be m ounted into a cage system, however further

adjustment of the motor posi tions may be nece ssary to fine tune the mirror

alignment within the application.

Rev B Jan 2018

Page 7

GCM102(/M) 30 mm Cage System Mount for GVSx02 Series Galvos

Distance from

input axis to

reference face

of lens

11.0 mm (0.43”)

GCMA1

screwed down to

bottom face

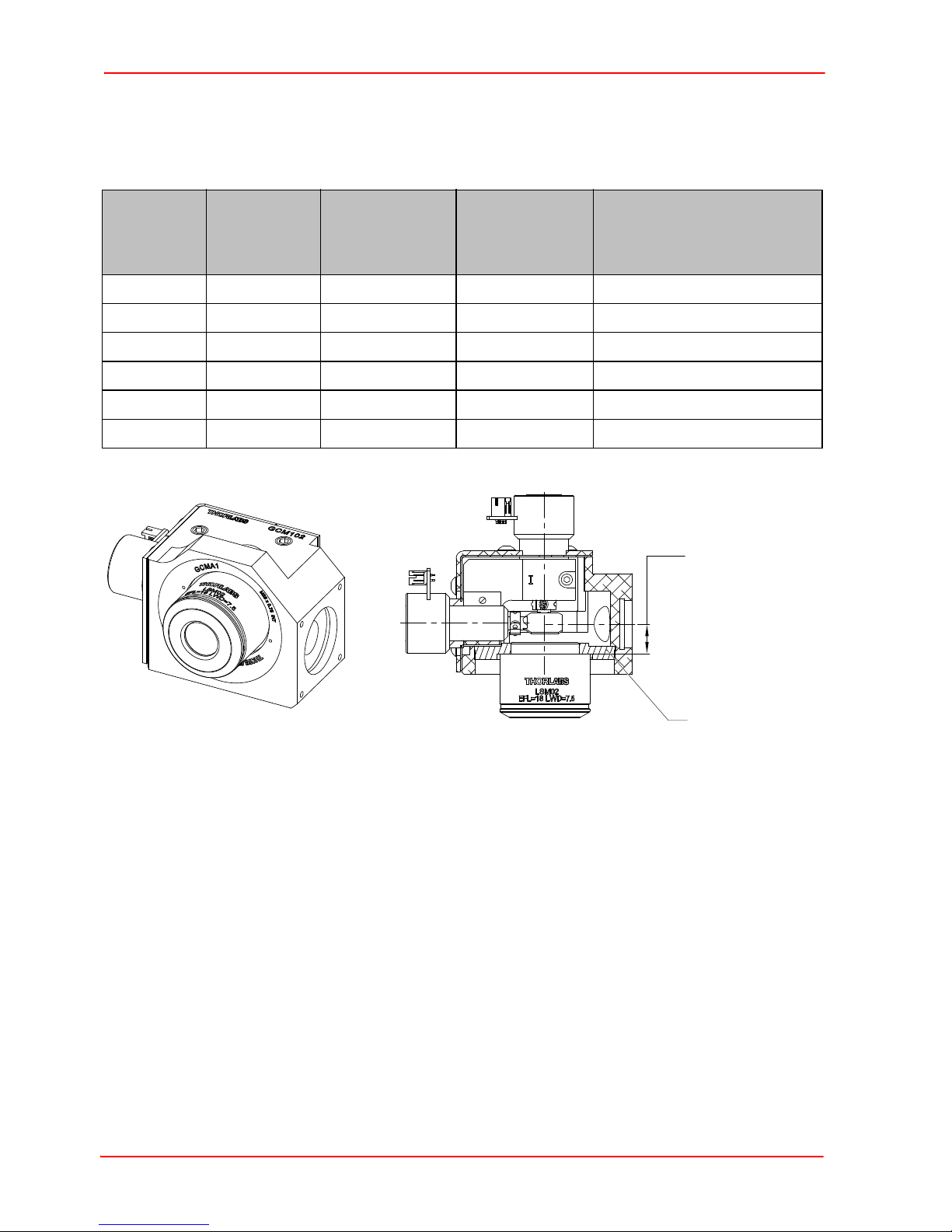

3.2 Fitting the Optics and Adapters

A range optics can be fitted to the GCM102(/M) using various adapters as detailed

below.

Scan

Optic Thread

Distance

(mm)

LSM02 M25 x 0.75 16 3 GCMA1

LSM03 M25 x 0.75 19 6 GCMA1 (reverse fitted)

LSM04 M25 x 0.75 19 6 GCMA1 (reverse fitted)

LSM03-VIS M25 x 0.75 29 16 SM2A33 and SM2L03

LSM05 SM2 75 62 SM2L20

CLS-SL SM2 58 46 SM2L05 and SM2V05

Distance from

start of SM2

thread (mm)

Adapter Required

Page 8 ETN032532-D02

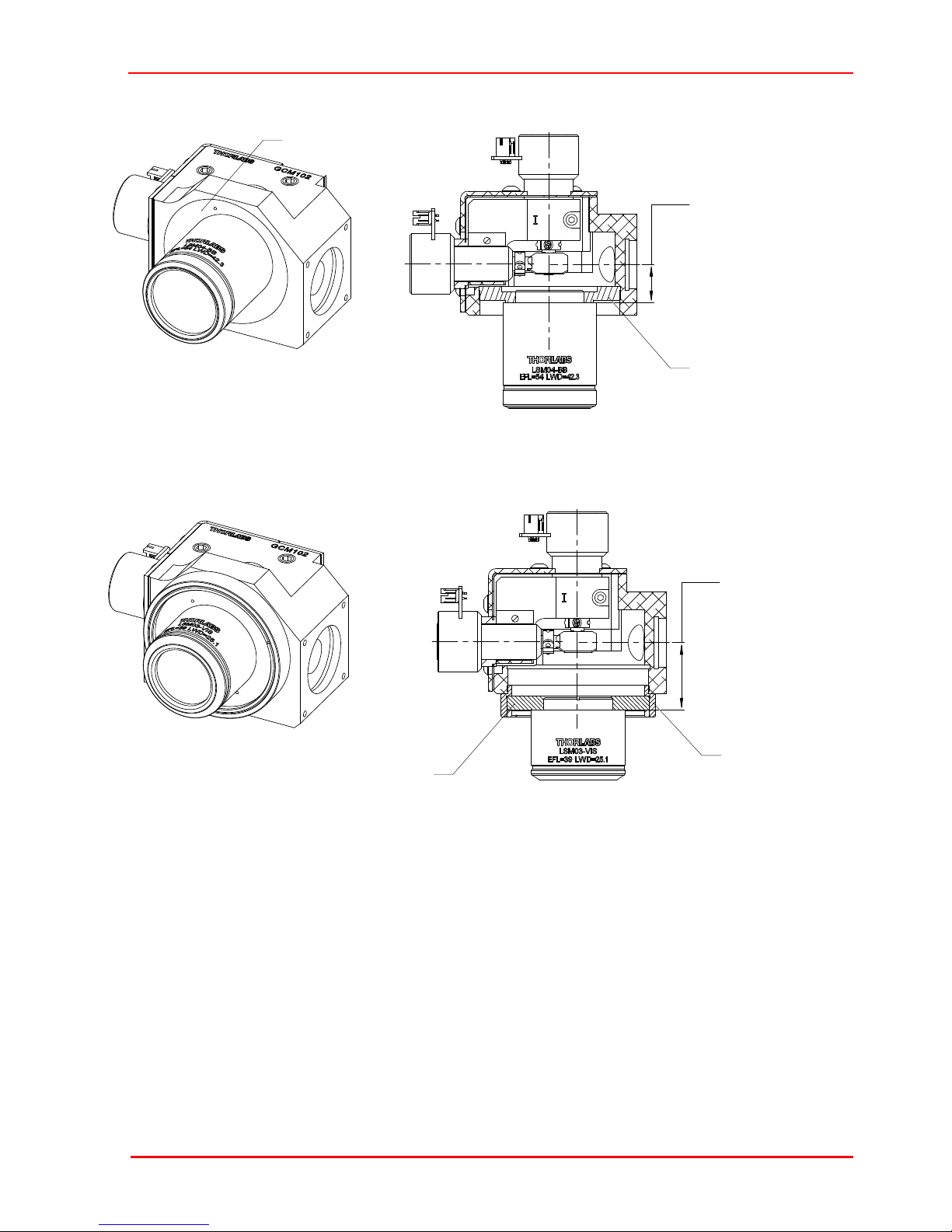

Fig. 3.11 Fitting the LSM02

Fig. 3.12 Fitting the LSM03 and LSM04

Distance from

input axis to

reference face

of lens

14.0 mm (0.55”)

GCMA1 inverted

and screwed down

to bottom face

GCMA1 inverted

Distance from

input axis to

reference face

of lens

24.3 mm (0.96”)

SM2L03

screwed down

to bottom face

SM2A33

Chapter 3 Installation

Rev B Jan 2018

Fig. 3.13 Fitting the LSM03-VIS

Page 9

GCM102(/M) 30 mm Cage System Mount for GVSx02 Series Galvos

Distance from

input axis to

reference face

of lens

70.1 mm (2.76”)

SM2L20

screwed

down to

bottom face

Distance from

input axis to

reference face

of lens

53.1 mm (2.09”)

SM2V05 screwed

down around 5 mm

Lock Nut

SM2L05 screwed

down to SM2V05

Fig. 3.14 Fitting the LSM05

Page 10 ETN032532-D02

Fig. 3.15 Fitting the CLS-SL

Chapter 3 Installation

29.0 mm

[1.14”]

63.8 mm

[2.51”]

C1511

Mounting Clamp

M6 [1/4-20] Cap Screw

6.0 or 10.0 [1/4” or 3/8”] Long

M4 [8-32] Cap Screw

6.0 mm [1/4”] Long

M4 [8-32] Cap Screw

6.0 mm [1/4”] Long

1.5” Dia Post

(e.g. DP8A)

Mounting Option 1

Mounting Option 2

3.3 Using the Cage Mount with Other Equipment

The GCM102(/M) can be used in conjunction with various posts, rails and accessories

available from Thorlabs as follows.

3.3.1 Mounting to a 1.5” Diameter Post

Fig. 3.16 Mounting the GCM102 to a 1.5” Diameter Post

Rev B Jan 2018

Page 11

GCM102(/M) 30 mm Cage System Mount for GVSx02 Series Galvos

36.0 mm

[1.44”]

69.6 mm

[2.74”]

XT66

Construction Rail

M6 [1/4-20] Cap Screw

6.0 or 8.0 mm [1/4” or 5/16”] Long

M3 [4-40] Cap Screws, Qty 2

6.0 or 8.0 mm [1/4” or 5/16”] Long

XT66P2

Rail Carriage

3.3.2 Mounting to 66 mm Rail Components

Fig. 3.17 Mounting the GCM102 to an XT66 Construction Rail

Page 12 ETN032532-D02

Chapter 3 Installation

XT66

Construction Rail

SH6M10LP [SH25LP38]

M6 [1/4-20] Low Profile Channel Screws

XT66RC

Pivot Platform

46.1 mm

[1.82”]

79.2 mm

[3.12”]

6.5 mm

[0.26”]

Fig. 3.18 Mounting the GCM102 to an XT66RC Pivot Platform

Rev B Jan 2018

Page 13

Chapter Thorlabs Worldwide Contacts

USA, Canada, and South America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support: techsupport@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau / Munich

Germany

Tel: +49-(0) 8131-5956-0

Fax: +49-(0) 8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

France

Thorlabs SAS

rue des Côtes

109,

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place

Ely B7 4EX

Great Britain

Tel: +44 (0) 1353-654440

Fax: +44 (0) 1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

Japan

Thorlabs Japan, Inc.

3-6-3, Kitamachi,

Nerima-ku, Tokyo 179-0081

Japan

Tel: +81-3-6915-7701

Fax: +81-3-6915-7716

www.thorlabs.co.jp

Email: sales@thorlabs.jp

Page 14

China

Thorlabs China

Room A101, No. 100, Lane 2891

South Qilianshan Road

Putuo District

Shanghai

China

Tel: +86 (0) 21-60561122

Fax: +86 (0) 21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

www.thorlabs.com

Loading...

Loading...