Manual Fiber

Polarization Controllers

User Guide

Manual Fiber Polarization Controllers

Table of Contents

Chapter 1 Warning Symbol Definitions ..................................... 1

Chapter 2 General Description ................................................... 2

2.1. 3‐PaddleFiberPolarizationControllers....................3

2.2. Miniature2‐PaddleFiberPolarizationControllers....6

2.3. RecommendedNumberofLoops.............................8

Chapter 3 Setup ......................................................................... 10

3.1. LoadingtheFiber...................................................10

3.1.1. 3-Paddle Fiber Polarization Controllers ............................. 10

3.1.2. Miniature 2-Paddle Fiber Polarization Controllers ............. 11

3.2. RemovingtheFiber(AllModels)............................11

Chapter 4 Specifications........................................................... 12

4.1. 3‐PaddlePolarizationControllers...........................12

4.2. Miniature2‐PaddlePolarizationControllers..........14

Chapter 5 Regulatory ................................................................ 16

Chapter 6 Thorlabs Worldwide Contacts ................................ 17

Manual Fiber Polarization Controllers Chapter 1: Warning Symbol Definitions

Chapter 1 Warning Symbol Definitions

Below is a list of warning symbols you may encounter in this manual or on

your device.

Symbol Description

Direct Current

Alternating Current

Both Direct and Alternating Current

Earth Ground Terminal

Protective Conductor Terminal

Frame or Chassis Terminal

Equipotentiality

Rev H, September 11, 2018 Page 1

On (Supply)

Off (Supply)

In Position of a Bi-Stable Push Control

Out Position of a Bi-Stable Push Control

Caution: Risk of Electric Shock

Caution: Hot Surface

Caution: Risk of Danger

Warning: Laser Radiation

Caution: Spinning Blades May Cause Harm

Manual Fiber Polarization Controllers Chapter 2: General Description

Chapter 2 General Description

These manual polarization controllers utilize stress-induced birefringence to

alter the polarization in single mode fiber that is looped around two or three

independent spools to create two or three independent fractional wave plates

(fiber retarders). The amount of birefringence induced in the fiber is a function

of the fiber cladding diameter, the spool diameter (fixed), the number of fiber

loops per spool, and the wavelength of the light. (NOTE: The desired

birefringence is induced by the loop in the fiber, not by the twisting of the fiber

paddles). The fast axis of the fiber, which is in the plane of the spool, is

adjusted with respect to the transmitted polarization vector by manually

rotating the paddles to twist the fiber.

To transform an arbitrary input polarization state into an arbitrary output

polarization state, a combination of three paddles (a quarter-wave plate, a

half-wave plate, and a quarter-wave plate) or two paddles (quarter-wave plate

and a quarter-wave plate) is used. The retardance of each paddle may be

estimated from the following equation:

2

Here, φ is the retardance, a is a constant (0.133 for silica fiber), N is the

number of loops, d is the fiber cladding diameter, λ is the wavelength, and D

is the loop diameter. While this equation is for bare fiber, the solution for Ø900

µm jacketed fiber will be similar enough that the results for this equation can

still be used (i.e., the solution will not vary by a complete loop N for Ø900 µm

jacketed fiber).

The FPC020, FPC030, and FPC560 are empty controllers in which the user

can install a fiber of their choice. The rest of our fiber polarization controllers

have fiber pre-installed to optimize the polarization control at common

wavelengths. These controllers can also be customized using the information

provided in Sections 2.1 through 0.

Page 2 1167-D02

Manual Fiber Polarization Controllers Chapter 2: General Description

2.1. 3-Paddle Fiber Polarization Controllers

A 3-paddle polarization controller combines a quarter-wave plate, half-wave

plate, and quarter-wave plate in series to transform an arbitrary polarization

state into any other polarization state. The first quarter-wave plate would

transform the input polarization state into a linear polarization state. The halfwave plate would rotate the linear polarization state, and the last quarter-wave

plate would transform the linear state into an arbitrary polarization state.

Therefore, adjusting each of the three paddles (fiber retarders) allows

complete control of the output polarization state over a broad range of

wavelengths from 300 to 2100 nm. The 3-paddle polarization controllers are

available with paddles that support either Ø27 mm loops or Ø56 mm loops.

Using FPC030 as an example for the controllers with a Ø27 mm loop

diameter, a plot of calcuated retardation per paddle versus wavelength is

shown in Figure 1 for a fiber with a cladding diameter of 80 μm. For fiber with

a cladding diameter of 125 μm, the retardation per paddle versus wavelength

is shown in Figure 2.

Rev H, September 11, 2018 Page 3

Manual Fiber Polarization Controllers Chapter 2: General Description

Figure 1

Figure 2

Page 4 1167-D02

Manual Fiber Polarization Controllers Chapter 2: General Description

Figure 3 and Figure 4 show the results for Ø80 µm and Ø125 µm clad fiber,

respectively, for the FPC560 controller, which has three paddles with a loop

diameter of 56 mm. The larger loop diameter is ideal for fibers with higher

bend loss.

Figure 3

Figure 4

Rev H, September 11, 2018 Page 5

Manual Fiber Polarization Controllers Chapter 2: General Description

2.2. Miniature 2-Paddle Fiber Polarization Controllers

The 2-paddle polarization controllers use two quarter-wave plates to transform

an arbitrary polarization state into any other polarization state. In this

configuration, however, the control of the polarization will be coupled between

the two paddles. These controllers allow complete control of the output

polarization state over a broad range of wavelengths (300 to 2100 nm).

The retardation per paddle is a function of loop number and the cladding

diameter of the fiber if the loop diameter is fixed. The retardation, in radians,

is plotted for 1, 2, 3, and 4 loops per paddle for a fiber with cladding diameters

of 80 µm and 125 μm (Figure 5 and Figure 6). Due to its small size, the

FPC020 cannot accommodate more than 4 loops per paddle.

Page 6 1167-D02

Manual Fiber Polarization Controllers Chapter 2: General Description

Figure 5

Figure 6

Rev H, September 11, 2018 Page 7

Manual Fiber Polarization Controllers Chapter 2: General Description

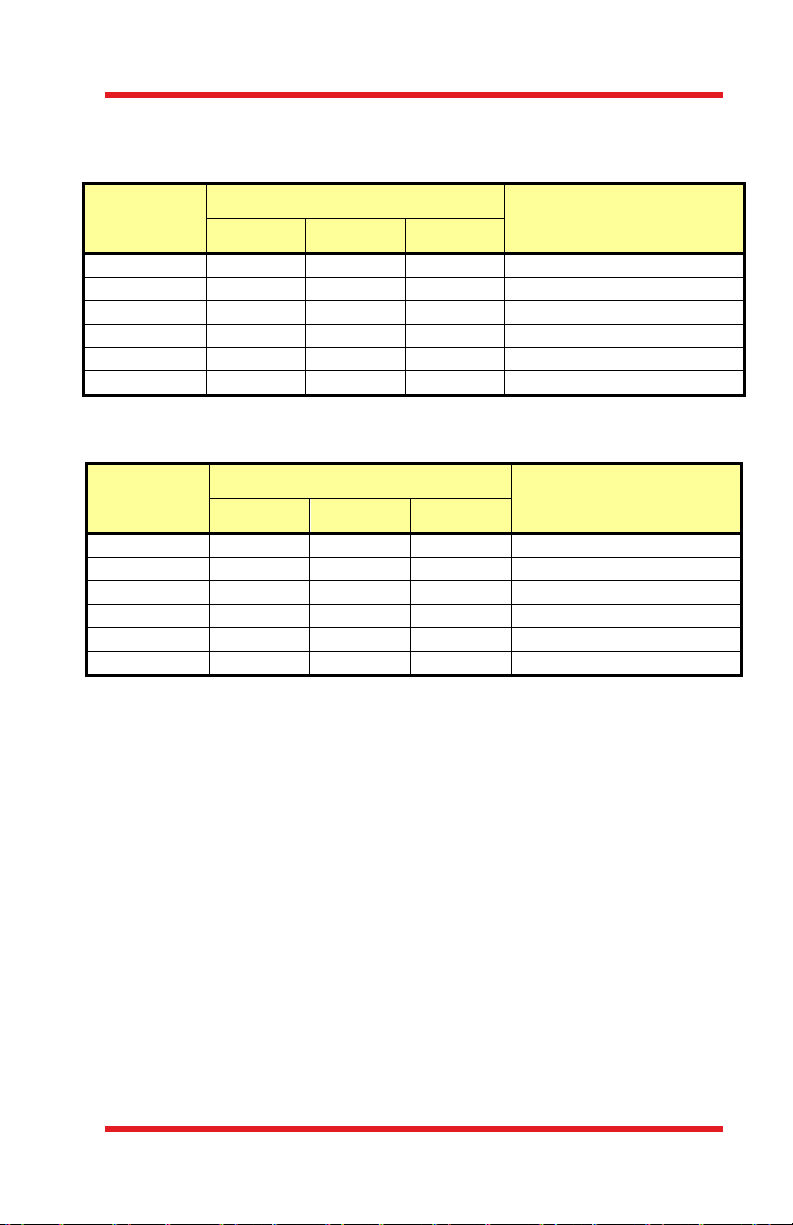

2.3. Recommended Number of Loops

The retardation of multi-order (including zero order) quarter-wave plate is

given by the following equation:

2 1

where m is an integer. Similarly, the retardation of multi-order (including zero

order) half-wave plate is given by:

2 1

See the table below for several solutions to the equations

2

Quarter-Wave

Order m

Zero 0

1st 1

2nd 2

3rd 3

4th 4

5th 5

Plate Retardation

2

3

2

5

2

7

2

9

2

11

2

1.57

4.71

7.85

11.00

14.14

17.28

Half-Wave Plate

Retardation

3.14

3 9.42

5 15.71

7 21.99

9 28.27

11 35.56

The retardation of each paddle should be close to any number above. The

paddle rotation sensitivity should also be taken into consideration when

determining the number of fiber loops. In creasing the number of loops

increases the sensitivity to rotation. One loop is usually too insensitive for most

applications and is rarely used.

Page 8 1167-D02

Manual Fiber Polarization Controllers Chapter 2: General Description

The number of recommended loops and recommended fiber for several

wavelengths is given in the following tables. These combinations come close

to the desired quarter-wave retardation:

# of Loops for ~1/4λ Retardation

Wavelength

480 nm 3 loops N/A 3 loops 460HP, S450, S460

630 nm 3 loops 2 loops 4 loops 630HP or S630

850 nm 3 loops 6 loops 2 loops 780HP, SM800-5.6

980 nm 2 loops 3 loops 2 loops 980HP, HI1060-J9, HI980-J9

1060 nm 2 loops 3 loops 2 loops 980HP, HI1060-J9, HI980-J9

1310 nm 3 loops 2 loops 3 loops SMF28e+ and CCC1310-J9

Recommended Fiber Ø18 mm Ø27 mm Ø56 mm

These combinations come close to the desired half-wave retardation:

# of Loops for ~1/2λ Retardation

Wavelength

480 nm 2 loops 3 loops 2 loops 460HP, S450, S460

630 nm 1 loop 4 loops 3 loops 630HP or S630

850 nm 1 loop 2 loops 4 loops 780HP, SM800-5.6

980 nm 4 loops 2 loops 4 loops 980HP, HI1060-J9, HI980-J9

1060 nm 3 loops 2 loops 5 loops 980HP, HI1060-J9, HI980-J9

1310 nm 2 loops 3 loops 6 loops SMF28e+ and CCC1310-J9

Recommended Fiber Ø18 mm Ø27 mm Ø56 mm

Rev H, September 11, 2018 Page 9

Manual Fiber Polarization Controllers Chapter 3: Setup

Chapter 3 Setup

3.1. Loading the Fiber

3.1.1. 3-Paddle Fiber Polarization Controllers

The FPC030 and FPC560 do not come with fiber and we recommend using

at least 2 m of fiber. The controller can accept bare fiber or a jacket up to

Ø900 µm.

1. Loosen the spool covers on each paddle. Each end of the fiber

polarization controller (FPC) also has a rectangular clamp held in place

by two phillips head screws (Figure 7). Remove one screw and loosen

the other. This should allow a jacketed fiber to be slipped into the clamp.

2. Position the Paddles horizontally so that the groove loops are facing up.

The straight parts of the grooves in the paddles should be aligned with

the grooves in the top of the paddle supports of the base.

3. Lay the fiber in one end of the FPC and continue to lay the fiber along the

grooved path, with the number of desired loops per paddle, until the fiber

is through the other end of the FPC. The fiber should be in contact with

the inside of the groove loops, but not be pulled too snug against the

groove as this will cause optical losses due to induced birefringence as

the paddles are rotated with respect to each other.

4. Make sure that the fiber is sitting in the groove inside each clamp, replace

the second screw, and gently tighten the clamp to hold the fiber in place.

NOTE: The ends of the FPC are designed to ‘clamp’ onto 900 µm

diameter protective tubing. If the fiber placed into the FPC does not have

a protective jacket, pieces of a soft material, such as foam, can be

inserted into the end clamps to prevent the fiber from loosening in the

paddles. The fiber should be held ‘gently’ enough so that the fiber is not

drawn into the FPC, but there should be minimal force applied to the fiber

such that additional birefringence is not induced.

5. Gently tighten the screws that hold the spool covers in place.

Spool Cover

Clamp

Figure 7 Top View of FPC030

Page 10 1167-D02

Manual Fiber Polarization Controllers Chapter 3: Setup

3.1.2. Miniature 2-Paddle Fiber Polarization Controllers

The FPC020 does not come with fiber and we recommend using at least 2 m

of fiber. The controller can accept bare fiber or a jacket up to Ø900 µm.

1. Position both paddles vertically and align the grooves (see Figure 8).

2. Loosen the 4-40 clamp screws (marked a in Figure 8) at each end. If you

are having problems getting the fiber into the spool, you can loosen the

4-40 screw holding the spool cover in place (b), but this should not be

necessary.

3. Lay the fiber in one end of the FPC and route the fiber along the grooved

path. Lay the desired number of loops into each paddle. End by bringing

the fiber out the other end of the FPC. Make sure to wind the fiber snuggly

against the inner wall of each spool but do not make the fiber taught.

4. Making sure the fiber is seated in the groove, tighten the clamp screws

(a) at each end. Be careful not to clamp too tightly or make the fiber too

taught as this will introduce extra loss into the fiber. Tighten the paddle

screws (b) if they were loosened.

(b)

(a)

(b)

(a)

Figure 8 Front View of FPC020

3.2. Removing the Fiber (All Models)

1. Loosen the clamp screws as described in the fiber installation

instructions.

2. Remove the paddle spool covers. For the 2-paddle polarization

controllers, use a 4-40 hex key or ball drive to loosen the screws. On the

3-paddle controllers, knobs on the screws holding the spool covers in

place allow them to be loosened by hand.

3. Remove the fiber and replace the spool covers and clamps when done.

Rev H, September 11, 2018 Page 11

Manual Fiber Polarization Controllers Chapter 4: Specifications

Chapter 4 Specifications

4.1. 3-Paddle Polarization Controllers

Item # FPC030 FPC031 FPC032

Paddle Material

Number of Paddles

Loop Diameter

Paddle Rotation

Foot Print (L x W)

Fiber

Operating Wavelength Range

Design Wavelength

b

Mode Field Diameter

Cladding Diameter

Coating Diameter

Tubing Diameter

Numerical Aperture

Loop Configuration

c

Connectors

Bend Loss

a

8.5" x 1.0" (215.9 mm x 25.4 mm)

None CCC1310-J9

N/A 1260 - 1625 nm

N/A 1310 nm

N/A

N/A 125 ± 0.7 µm

N/A 242 ± 5 µm

N/A Ø900 µm Tight Buffer

N/A 0.14

N/A 2-3-2

N/A FC/PC FC/APC

N/A ≤0.1 dB

a. Retardance varies as a function of wavelength. Refer to Chapter 2 for

more information.

b. Devices with preloaded fiber are optimized for this wavelength.

c. For polarization controllers with fiber preinstalled.

Black Delrin

3

1.06" (27 mm)

±117.5°

8.6 ± 0.4 µm @ 1310 nm

9.7 ± 0.5 µm @ 1550 nm

Page 12 1167-D02

Manual Fiber Polarization Controllers Chapter 4: Specifications

Item # FPC560 FPC561 FPC562

Paddle Material

Number of Paddles

Loop Diameter

Paddle Rotation

Foot Print (L x W )

Fiber

Operating Wavelength Range

Design Wavelength

b

Mode Field Diameter

12.5" x 1.0" (317.5 mm x 25.4 mm)

None SMF-28-J9

a

N/A 1260 - 1625 nm

N/A 1310 nm

N/A

Black Delrin

3

2.2" (56 mm)

±117.5°

9.2 ± 0.4 µm @ 1310 nm

10.4 ± 0.5 µm @ 1550 nm

Cladding Diameter

Coating Diameter

Tubing Diameter

Numerical Aperture

Loop Configuration

Connectors

Bend Loss

c

N/A 125 ± 0.7 µm

N/A 242 ± 5 µm

N/A Ø900 µm Tight Buffer

N/A 0.14

N/A 3-6-3

N/A FC/PC FC/PC

N/A ≤0.1 dB

a. Retardance varies as a function of wavelength. Refer to Chapter 2 for

more information.

b. Devices with preloaded fiber are optimized for this wavelength.

c. For polarization controllers with fiber preinstalled.

Rev H, September 11, 2018 Page 13

Manual Fiber Polarization Controllers Chapter 4: Specifications

4.2. Miniature 2-Paddle Polarization Controllers

Item # FPC020 FPC021 FPC022

Paddle Material Black Delrin

Number of Paddles 2

Loop Diameter

Paddle Rotation ±143°

Foot Print (L x W) 3.06" x 0.5" (77.72 mm x 12.70 mm)

Fiber None SM450 SM600

Operating Wavelength Range

Design Wavelength

Mode Field Diameter N/A 3.3 µm @ 488 nm

Cladding Diameter N/A 125 ± 1.0 µm

Coating Diameter N/A 245 ± 15 µm 245 µm ± 5%

Tubing Diameter N/A Ø900 µm Hytrel Tubing

Numerical Aperture N/A 0.10 - 0.14

Loop Configuration

Connectors N/A FC/APC

Bend Loss N/A <0.1 dB

b

c

a

N/A 450 - 600 nm 600 - 800 nm

N/A 488 nm 633 nm

N/A 3-3

a. Retardance varies as a function of wavelength. Refer to Chapter 2 for

more information.

b. Devices with preloaded fiber are optimized for this wavelength.

c. For polarization controllers with fiber preinstalled.

0.71

" (18 mm)

3.4 µm @ 514 nm

4.3 µm @ 633 nm

4.6 µm @ 680 nm

Page 14 1167-D02

Manual Fiber Polarization Controllers Chapter 4: Specifications

Item # FPC023 FPC024 FPC025

Paddle Material Black Delrin

Number of Paddles 2

Loop Diameter

Paddle Rotation ±143°

Foot Print (L x W) 3.06" x 0.5" (77.72 mm x 12.70 mm)

Fiber 780HP HI1060 CCC1310

Operating Wavelength Rangea 780 - 970 nm 980 - 1650 nm 1260 - 1625 nm

Design Wavelength

Mode Field Diameter

Cladding Diameter 125 ± 1.5 µm 125 ± 0.5 µm 125 ± 0.7 µm

Coating Diameter 245 ± 15 µm 245 ± 10 µm 242 ± 5 µm

Tubing Diameter Ø900 µm

Numerical Aperture 0.13 0.14

Loop Configuration

Connectors FC/APC

Bend Loss <0.1 dB

b

c

780 nm and

850 nm

5.0 ± 0.5 µm

@ 850 nm

Hytrel Tubing

4-4 2-2 3-3

0.71

" (18 mm)

980 nm 1310 nm

5.9 ± 0.3 µm

@ 980 nm

6.2 ± 0.3 µm

@ 1060 nm

Ø900 µm Tight Buffer

8.6 ± 0.4 µm

@ 1310 nm

9.7 ± 0.5 µm

@ 1550 nm

a. Retardance varies as a function of wavelength. Refer to Chapter 2 for

more information.

b. Devices with preloaded fiber are optimized for this wavelength.

c. For polarization controllers with fiber preinstalled.

Rev H, September 11, 2018 Page 15

Manual Fiber Polarization Controllers Chapter 5: Regulatory

Chapter 5 Regulatory

As required by the WEEE (Waste Electrical and Electronic Equipment

Directive) of the European Community and the corresponding national laws,

Thorlabs offers all end users in the EC the possibility to return “end of life”

units without incurring disposal charges.

This offer is valid for Thorlabs electrical and electronic equipment:

Sold after August 13, 2005

Marked correspondingly with the crossed out

“wheelie bin” logo (see right)

Sold to a company or institute within the EC

Currently owned by a company or institute

within the EC

Still complete, not disassembled and not

contaminated

As the WEEE directive applies to self contained

operational electrical and electronic products, this end of

life take back service does not refer to other Thorlabs products, such as:

Pure OEM products, that means assemblies to be built into a unit by

the user (e.g. OEM laser driver cards)

Components

Mechanics and optics

Left over parts of units disassembled by the user (PCB’s, housings

etc.).

If you wish to return a Thorlabs unit for waste recovery, please contact

Thorlabs or your nearest dealer for further information.

Waste Treatment is Your Own Responsibility

Wheelie Bin Logo

If you do not return an “end of life” unit to Thorlabs, you must hand it to a

company specialized in waste recovery. Do not dispose of the unit in a litter

bin or at a public waste disposal site.

Ecological Background

It is well known that WEEE pollutes the environment by releasing toxic

products during decomposition. The aim of the European RoHS directive is to

reduce the content of toxic substances in electronic products in the future.

The intent of the WEEE directive is to enforce the recycling of WEEE. A

controlled recycling of end of life products will thereby avoid negative impacts

on the environment.

Page 16 1167-D02

Manual Fiber Polarization Controllers Chapter 6: Thorlabs Worldwide Contacts

Chapter 6 Thorlabs Worldwide Contacts

USA, Canada, and South

America

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Support:

techsupport@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau

Germany

Tel: +49-(0)8131-5956-0

Fax: +49-(0)8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

France

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Email: sales.fr@thorlabs.com

Japan

Thorlabs Japan, Inc.

3-6-3 Kitamachi,

Nerima-ku, Tokyo 179-0081

Japan

Tel: +81-3-6915-7701

Fax: +81-3-6915-7716

www.thorlabs.co.jp

Email: sales@thorlabs.jp

UK and Ireland

Thorlabs Ltd.

1 Saint Thomas Place, Ely

Cambridgeshire CB7 4EX

Great Britain

Tel: +44 (0)1353-654440

Fax: +44 (0)1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Scandinavia

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

Brazil

Thorlabs Vendas de Fotônicos

Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

Email: brasil@thorlabs.com

China

Thorlabs China

Room A101, No. 100

Lane 2891, South Qilianshan Road

Putuo District

Shanghai

China

Tel: +86 (0) 21-60561122

Fax: +86 (0)21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

Rev H, September 11, 2018 Page 17

www.thorlabs.com

Loading...

Loading...