ELL10(K)

Linear Translation Stage

Operating Manual

Original Instructions

ELL10 Linear Stage Evaluation Kit

Table of Contents

Chapter 1 Introduction .............................................................................................................................................................. 1

Chapter 2 Safety......................................................................................................................................................................... 2

General Warnings and Cautions .................................................................................................................. 2

Chapter 3 Installation ................................................................................................................................................................ 3

Environmental Conditions ............................................................................................................................ 3

Mounting ........................................................................................................................................................ 4

Chapter 4 Operation .................................................................................................................................................................. 6

Getting Started ............................................................................................................................................... 6

4.1.1 Position Error Compensation .............................................................................................................. 6

Controlling the Stage .................................................................................................................................... 7

4.2.1 Hand-held Controller ........................................................................................................................... 7

4.2.2 Software Control ................................................................................................................................. 8

4.2.3 Communications Protocol ................................................................................................................... 9

4.2.4 Connecting Multiple Devices ............................................................................................................... 9

4.2.5 Controlling the stage without the handset ........................................................................................... 9

Frequency Search ........................................................................................................................................ 11

Periodic Cycling of Devices Over Full Range of Travel ........................................................................... 11

Restoring Factory Settings ......................................................................................................................... 11

Simultaneous Movement of Dev ices .......................................................................................................... 11

Chapter 5 Troubleshooting and FAQ ..................................................................................................................................... 12

Chapter 6 Specifications ......................................................................................................................................................... 13

Chapter 7 Regulatory ............................................................................................................................................................... 15

Declarations of Conformity ......................................................................................................................... 15

7.1.1 For Customers in Europe .................................................................................................................. 15

7.1.2 For Customers In The USA ............................................................................................................... 15

Chapter 8 Thorlabs Worldwide Contacts ............................................................................................................................... 16

ELL10 Linear Stage Evaluation Kit Chapter 1: Introduction

Chapter 1 Introduction

The ELL10 Linear Translation Stage is part of the Thorlabs series of resonant piezo motor circuits and bare modules for OEM

applications. The resonant piezo design of these motors offers fast response times and precise positioning, and therefore they

are particularly useful in scanning applications.

The high-speed digital signal processing (DSP) architecture supports a multi-drop serial communication protocol, and a set of

digital IO lines allows the user to control the movement and state manually by switching the lines high (5V) or low (0V).

The stage is designed for closed loop applications requiring linear positioning over a 60 mm (2.36”) travel range, with 0.5 µm of

resolution. The module is powered via an external 5V power supply supplied in the kit.

A hand-held controller is supplied with the ELL10K evaluation kit to allow homing and manual jogging and/or positioning. The

unit can also be driven remotely via PC-based software, downloaded from www.thorlabs.com. A compatible USB driver and

source code are included in the software download package.

Rev. A, Dec, 2017 Page 1

ELL10 Linear Stage Evaluation Kit Chapter 2: Safety

Spillage of fluid, such as sample solutions, should be avoided. If spillage does occur, clean up immediately using

could affect the positioning and homing sensor operation. An

If the device is operated over a prolonged time period, the motor housing may become hot. This does not affect motor

Do not bend the PCB. A bending load in excess of 500 g applied to the board may cause the PCB to deform, which

Chapter 2 Safety

For the continuing safety of the operators of this equipment, and the protection of the equipment itself, the operator should take

note of the Warnings, Cautions and Notes throughout this handbook and, where visible, on the product itself.

Warning: Risk of Electrical Shock

Given when there is a risk of electrical shock.

Warning

Given when there is a risk of injury to the user..

Caution

Given when there is a possibility of damage to the product.

Note

Clarification of an instruction or additional information.

General Warnings and Cautions

Warning

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment

may be impaired. In particular, excessive moisture may impair operation.

The equipment is susceptible to damage from electrostatic discharge. When handling the device, anti-static

precautions must be taken and suitable discharge appliances must be worn.

absorbent tissue. Do not allow spilled fluid to enter the internal mechanism.

Do not expose the stage to magnetic fields as this

external magnetic field close to the sensor should be below +/- 5mT.

operation but may cause discomfort if contacted by exposed skin.

will degrade the performance of the Stage.

Page 2 ETN039959-D02

ELL10 Linear Stage Evaluation Kit Chapter 3: Installation

Chapter 3 Installation

Environmental Conditions

Warning

Operation outside the following environmental limits may adversely affect operator safety.

Location Indoor use only

Maximum altitude 2000 m

Temperature range 15°C to 40°C

Maximum Humidity Less than 80% RH (non-condensing) at 31°C

To ensure reliable operation the unit should not be exposed to corrosive agents or excessive moisture, heat or dust.

Do not expose the stage to magnetic fields as this could affect the positioning and homing sensor operation.

If the unit has been stored at a low temperature or in an environment of high humidity, it must be allowed to reach ambient

conditions before being powered up.

The unit is not designed to be used in explosive environments.

The unit is not designed for continuous operation. Lifetime will depend on several factors, e.g. load, number of homing

operations, number of frequency searches etc. The minimum lifetime is 100 km. See Chapter 5 for more details.

Rev. A, Dec, 2017 Page 3

ELL10 Linear Stage Evaluation Kit Chapter 3: Installation

Although the module can tolerate up to 8kV of air discharge, it must be treated as an ESD sensitive device. When

to magnetic fields as this could affect the positioning and homing sensor operation. An

Mounting

Warning

The safety of any system incorporating this equipment is the responsibility of the person performing the installation.

Cautions

handling the device, anti-static precautions must be taken and suitable discharge appliances must be worn.

Do not expose the stage

external magnetic field close to the sensor should be below +/- 5mT.

When handling the stage, take care not to touch the wires to the motors.

Do not bend the wires over the motor spring as this affects the performance of the unit.

Do not allow the wires to contact other moving parts.

The recommended mounting orientation is horizontal. A base plate is shipped fitted to the stage to allow mounting to a standard

1” or 25 mm pitch optical table or breadboard. If required, a grooved top plate (MMP1(/M)) or tapped top plate (RB13P1(/M))

can be purchased separately to allow components and devices to be mounted to the moving world – see Figure 2.

The stage can be mounted vertically, as long as the resulting motion is in the horizontal plane. The stage should not be

mounted such that motion is vertical.

Figure 1 ELL10(/M) Linear Stage

Page 4 ETN039959-D02

ELL10 Linear Stage Evaluation Kit Chapter 3: Installation

Figure 2 ELL10 with MMP1 top plate fitted, showing stage in backwards/home position

Figure 3 Fixing the ELL10 to the work surface

1. Slide the moving world to one end of travel to gain access to the mounting holes as shown above.

2. Attach the stage to the work surface by passing appropriate standard fixings (not supplied) through the exposed

hole in the PCB and base plate.

3. Slide the moving world to the other end of travel, and repeat item (2).

Rev. A, Dec, 2017 Page 5

ELL10 Linear Stage Evaluation Kit Chapter 4: Operation

Although the module can tolerate up to 8kV of air discharge, it must be treated as an ESD sensitive device. When

If the device is operated over a prolonged time period, the motor housing may become hot. This does not affect motor

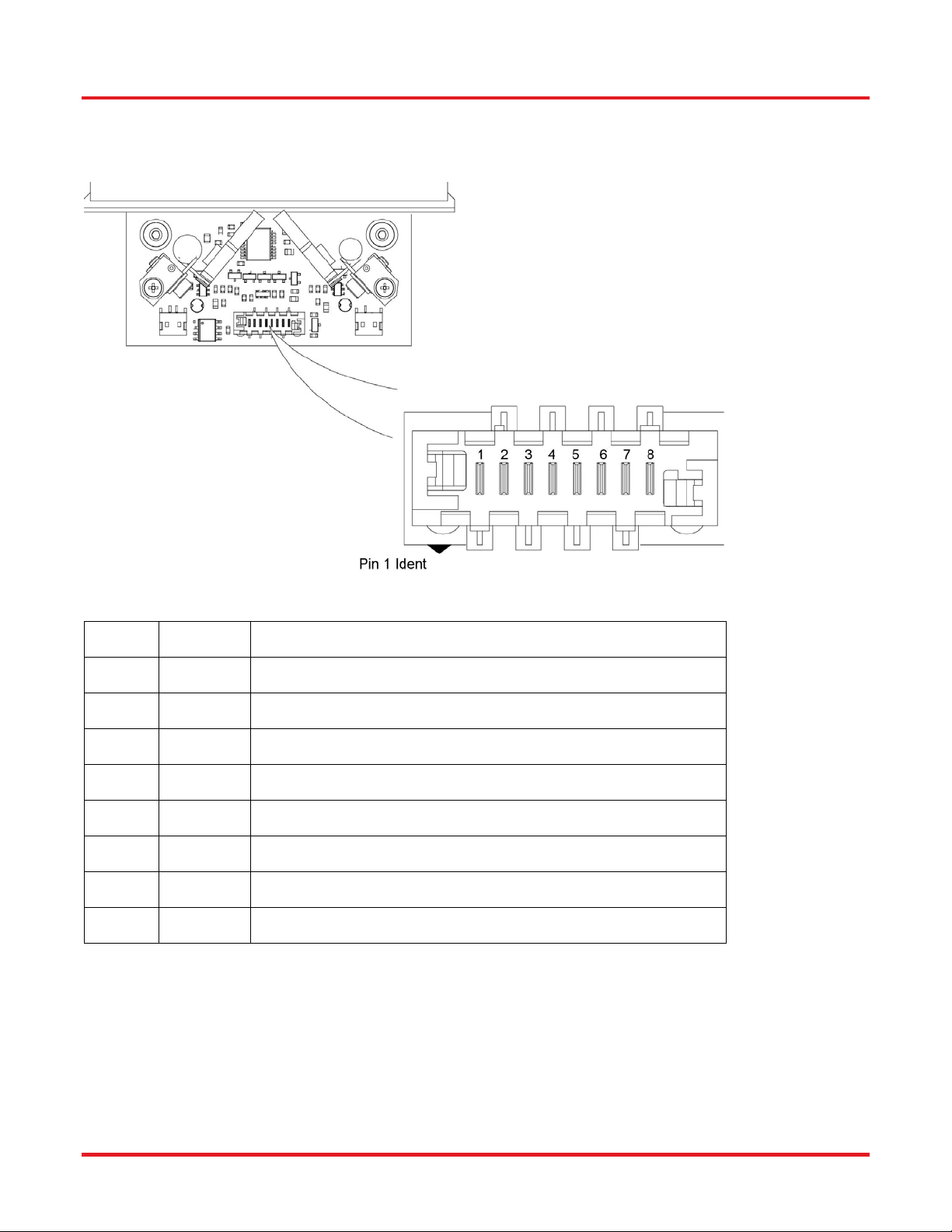

The unit is easily damaged by connections with incorrect polarity. Pin 1 of the connector on the PCB is marked with

Chapter 4 Operation

Getting Started

Caution

handling the device, anti-static precautions must be taken and suitable and discharge appliances must be worn.

Do not expose the Stage to magnetic fields as this could affect the positioning and homing sensor operation.

When power is applied, do not connect or disconnect the ribbon cable connecting the USB/PSU adapter to the Stage

PCB. Always remove power before making connections.

Warning

operation but may cause discomfort if contacted by exposed skin.

1. Perform the mechanical installation as detailed in Section 3.2

2. Connect the handset to the stage if required.

Caution

an arrow (see Figure 4 and Figure 6.) which should be adjacent to the red wire in the connecting cable.

3. Connect the stage to a 5V supply and switch ‘ON’. (A 5V PSU is supplied with the ELL10K).

4. Connect the unit to your PC if required, and wait for the drivers to be installed.

5. Home the stage. Homing is necessary to align the sensor and establish a datum from which all future moves are

measured.

4.1.1 Position Error Compensation

The stage has a positioning error compensation algorithm. When moving from one position to another, the stage detects the

error between the requested and actual positions and will calculate an error compensation value, which is then applied to the

next movement. A default compensation value is loaded on boot up, then the optimum value is calculated within the next 2 to 6

motions. Subsequently, the calculation is continually updated and is applied automatically.

Page 6 ETN039959-D02

ELL10 Linear Stage Evaluation Kit Chapter 4: Operation

Controlling the Stage

The stage can be controlled in three ways; via the handset, by the Elliptec software running on a PC, or by writing a custom

application using the messages described in the communications protocol document. Homing and Jogging functionality can also

be accessed by applying voltages to the digital lines on Connector J1. The modes of control are described in the following

sections.

In all modes, when the unit is mounted in the recommended orientation, Forward moves the stage to the right and backward

moves to the left as shown in Figure 2.

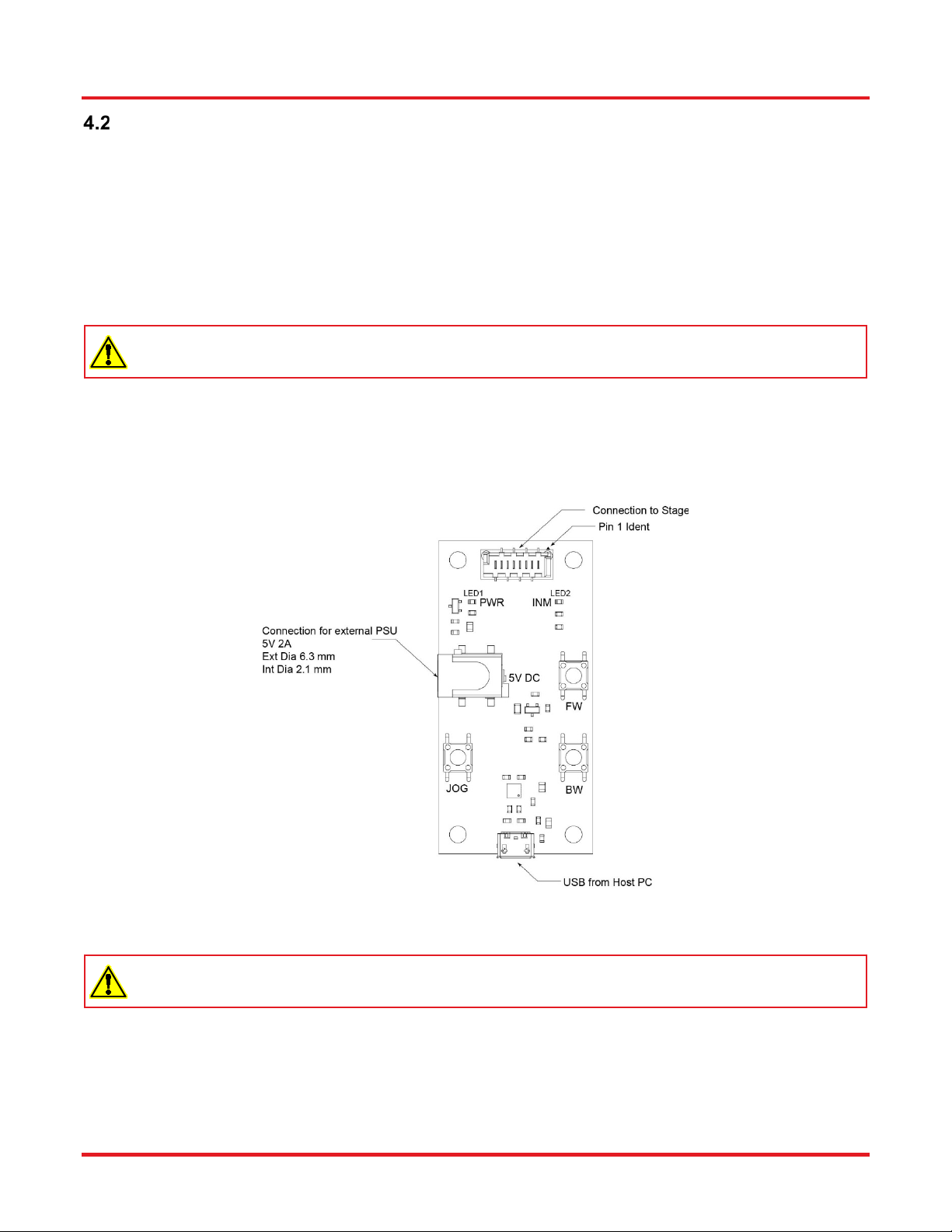

4.2.1 Hand-held Controller

Caution

On power up the stage will move while the unit checks the sensors and then searches for the home position.

The ELL10K Evaluation Kit also contains a hand-held controller, which features two buttons (marked FW and BW) that allow

control of the stage position. The handset also provides for connection to the host PC and to the external 5V power supply.

The external PSU connector allows the stage to be used in the absence of a PC, with control being achieved via the handset

buttons.

LED1 (green) is lit when power is applied to the unit. LED2 (red) is lit when the device being driven is in motion.

Figure 4 Handset details

Caution

The stage must be homed before performing any Jog moves.

1. Connect the hand-held controller to the stage unit.

2. Connect the hand-held controller to the 5V Power Supply and switch on.

3. Home the stage by pressing the BW button.

4. To jog forward, press and hold JOG and then press FW. The default jog step value is 2mm.

The jog step size can be changed in the software GUI, see the helpfile for details.

5. To jog backward, press and hold JOG and then press BW.

Rev. A, Dec, 2017 Page 7

ELL10 Linear Stage Evaluation Kit Chapter 4: Operation

4.2.2 Software C ontrol

When connected to the host PC, the stage can be controlled remotely, via the Elliptec software.

1. Download the Elliptec software from the Downloads section at www.thorlabs.com. Double click the saved .exe file

and follow the on-screen instructions.

2. Connect the hand-held controller to the stage unit.

3. Connect the hand-held controller to the 5V Power Supply and switch on.

4. Connect the hand-held controller to the PC USB port and wait for the drivers to be installed.

5. Run the Elliptec software.

6. In the top left of the GUI panel displayed, select the COM port to which the device is connected, and click

‘Connect’. The software will search the comms bus and enumerate the device.

7. Click the Home Offset ‘Get’ button, then click ‘Home’ to home the stage.

8. The GUI and device are now ready for use. See the helpfile supplied with the software for more information.

Page 8 ETN039959-D02

ELL10 Linear Stage Evaluation Kit Chapter 4: Operation

4.2.3 Communications Protocol

Custom move applications can be written in languages such as C# and C++.

The communication bus allows multi-drop communication with speeds at 9600 baud, 8 bit data length, 1 stop bit, no parity.

Protocol data is sent in ASCII HEX format, while module addresses and commands are mnemonic character (no package length

is sent). Modules are addressable (default address is “0”) and addresses can be changed and/or saved using a set of commands.

Lower case commands are sent by user while upper case commands are replies by the module.

Please refer to the communications protocol manual for more detail about commands and data packet formats.

4.2.4 Connecting Multiple Devices

When a device is first connected to the PC, it is assigned the default address '0'. The software can run multiple devices,

however before more than one device can be recognized, each device must be assigned a unique address. See below for a

brief overview; detailed instructions are contained in the help file supplied with the software.

Connect the first device to the PC USB port, then run the Elliptec software and load the device.

Change the address of the first device.

Connect the next device to the first device.

Change the address of the second device.

Multiple devices can be controlled individually, either via a remote handset connected to each device, via the Elliptec software

or by a third part application written using the messages detailed in the protocol document.

4.2.5 Controlling the stage without the handset

Caution

During normal operation each motor is protected with a time out of 2.5 seconds to prevent overheating. Do not override

this protection or drive the motors continuously.

In the absence of the handset, the stage is controlled via digital lines: forward, backward and mode (J1 pins 7, 6 and 5) by

shorting the corresponding line to ground (pin 1).

When the stage is moving, the open drain IN MOTION digital line (pin 4) is driven low (active low) to confirm movement. The IN

MOTION line goes high (inactive) when the move is completed or the maximum time-out (2 seconds) is reached.

Warning

Do not exceed the voltage and current ratings stated in Figure 6.

Do not reverse polarity.

Rev. A, Dec, 2017 Page 9

ELL10 Linear Stage Evaluation Kit Chapter 4: Operation

PIN

TYPE

FUNCTION

1

PWR

Ground

2

OUT

ODTX - open drain transmit 3.3V TTL RS232

3

IN

RX receive - 3.3V TTL RS232

4

OUT

In Motion, open drain active low max 5mA

5

IN

JOG/Mode, active low max 5V

6

IN

BW Backward , active low max 5V

7

IN

FW Forward, active low max 5V

8

PWR

VCC +5V +/-10% 850mA

Connector J1 Pin Out

Connector model number MOLEX 90814-0808 Farnell order code 1518211

Mating connector model number MOLEX 90327-0308 Farnell order code 673160

Figure 5 Connector J1 pin out details

Page 10 ETN039959-D02

ELL10 Linear Stage Evaluation Kit Chapter 4: Operation

ver the full range of travel, from one end to the other. This will help minimize

the build up of debris on the track and will prevent the motors digging a groove over the most used area of contact.

Frequency Search

Due to load, build tolerances and other mechanical variances, the default resonating frequency of a particular motor may not be

that which delivers best performance. A frequency search can be performed using the Main GUI panel in the ELLO software, or

by using the serial communication line (SEARCHFREQ_MOTORX message), which offers a way to optimize the operating

frequencies for backward and forward movement.

This search can also be performed manually by restoring the factory settings as described in section 4.5.

Periodic Cycling of Devices Over Full Range of Travel

Caution

Periodically, devices should be moved o

Typically, a travel cycle should be performed every 10K operations.

Restoring Factory Settings

Factory settings can be restored during the start up (calibration) test as follows:

1. Remove power from the stage.

2. Press and hold the BW button (do not release until item 6).

3. POWER UP

4. WAIT for red led to switch off

5. Press and hold the FW button to request a reload of factory values (do not release until item 7 is complete).

6. Release BW to reboot

7. Continue to hold the FW button until the stage stops moving and the red LED switches off, then release.

8. Press the BW button to home the stage.

Simultaneous Movement of Devices

If more than one device is connected to the comms bus, movement of the devices can be synchronized. This can be achieved

either by using the handset connected to each stage, or by software. See the protocol document for details on how to use the

‘ga’ message to synchronize moves.

Rev. A, Dec, 2017 Page 11

ELL10 Linear Stage Evaluation Kit Chapter 5: Troubleshooting and FAQ

Chapter 5 Troubl e s hoot ing and FAQ

Stage is moving back and forth after power up

If the digital line “bw” is driven low before powering up the stage, the module will go into calibration mode. Remove power to exit

calibration mode. Keep line tight up to 3.3V or 5V rail during power up or use a serial communication line instead.

Stage not moving

Check power supply lines ratings (polarity, voltage drop or range, available current) or reduce cable length.

Check module is not in boot loader mode (power cycle the module to exit boot loader) consumption must be higher than 36mA

at 5V.

Stage does not complete homing commands

Power cycle the unit.

Perform a frequency search on both motors.

Stage switching time increased / max load decreased

Check power supply voltage provided on J7 connector, increase voltage within specified limits if voltage drop along cable goes

below 5V during system operation.

Clean the moving surfaces. To avoid grease contamination, do not touch the moving parts.

Temperature change may affect the stage performance. Using the software to perform a frequency search will compensate

frequency as needed (required current could reach 1.2A during frequency search, use an additional 5V 1A power supply and a

USB connection).

Integrators should search for optimal frequency on every power up sequence

(commands “s1”, “s2” see ELL protocol document)

How do I restore the factory (default) settings

Factory settings can be restored at any time – see Section 4.5.

What is the product lifetime

ELL10 product lifetime is restricted by the wearing of moving surfaces and the motor contact as motion is started (due to

resonance build up) and performed (due to friction), and is expressed in km travelled. Lifetime will depend on several factors

(e.g. load, number of homing operations, number of frequency searches etc.) and users must take into account all these factors

when considering life time. For example, homing requires more travel than a simple motion, and a frequency search may not

generate any motion at all, but still energizes the motors fully.

The unit is not designed for continuous operation. Users should aim for a duty cycle of less than 40% wherever possible, and

never exceed a duty cycle of 60% for longer than a few seconds.

The minimum lifetime is 100 km.

Handling

The stage and interface board are robust to general handling. To ensure reliable operation, keep the surface of the plastic track

contacted by the motors free of oils, dirt, and dust. It is not necessary to wear gloves while handling the stage, but avoid touching

the track to keep it free of oils from fingerprints. If it is necessary to clean the track, it may be wiped with isopropyl alcohol or

mineral spirits (white spirit). Do not use acetone, as this solvent will damage the plastic track.

Page 12 ETN039959-D02

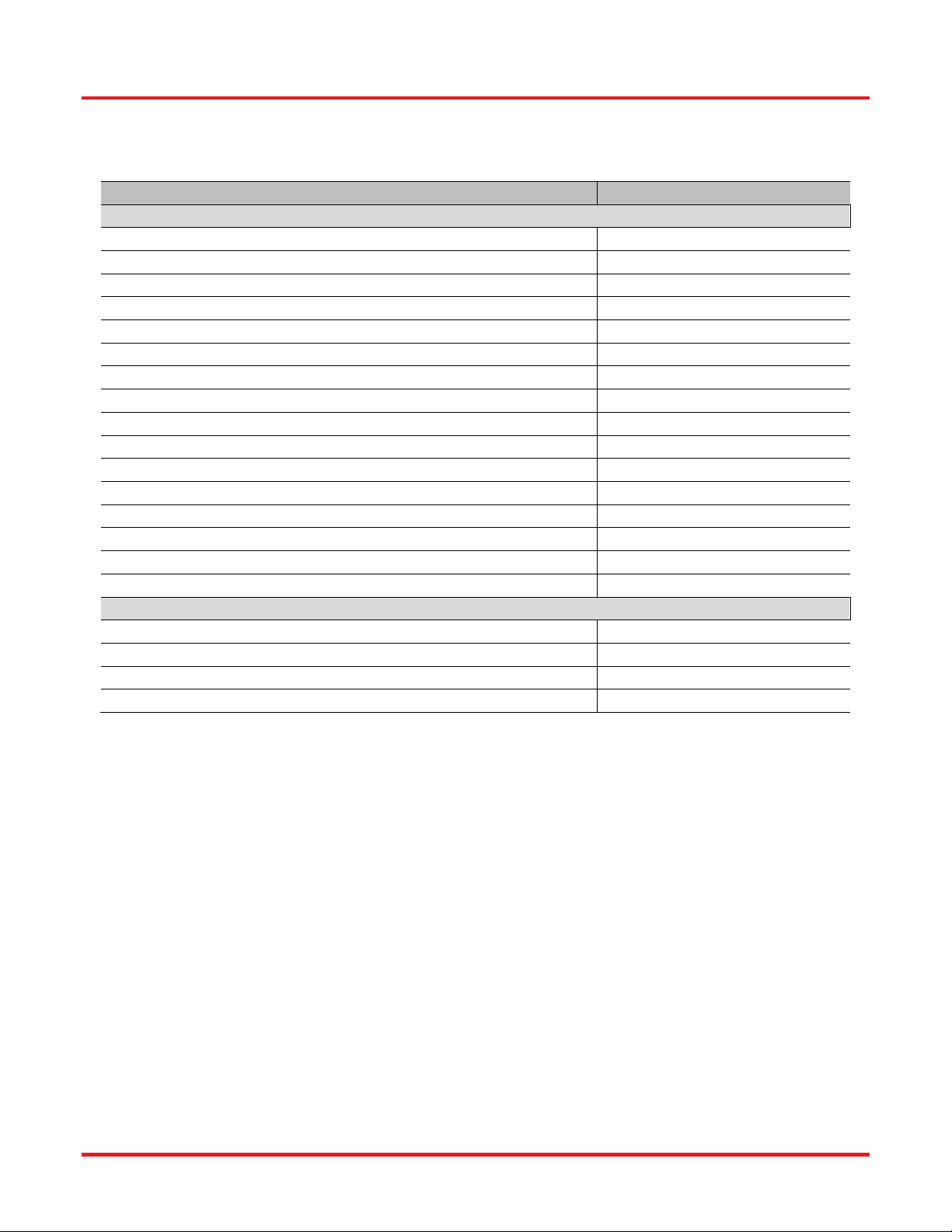

ELL10 Linear Stage Evaluation Kit Chapter 6: Specifications

Parameter

Value

Max Acceleration (No Load)

Horizontal Straightness b

Full Scale Non Linearity Error

Velocity Compensation (No Load) c

Typical Standby Current

Chapter 6 Specifications

Performance

Travel

Homing/Positioning accuracy

Repeatability (with 100g load)

Max Velocity (No Load)

Minimum Motor Holding Force (both motors engaged)

Vertical Straightness b

Pitch (Over Full Travel Range)

Yaw (Over Full Travel Range)

Encoder Resolution

Minimum incremental motion (No Load)

Max Total Load d

Minimum Lifetime e

Electrical

Motor Type

DC Voltage Input

Typical Current Consumption During Movement (No Load)

a

60.0 mm (2.36”)

50 µm

±20 µm

90 mm/s

6.0 m/s/s

1 N

6.3 µm

13.0 µm

2400 µrad

2900 µrad

<120 µm

0.5 µm

8 µm

60 to 100%

200 g

100 km of travel

Elliptec Resonant Piezo

4.5 to 5.5V

0.85 A

0.034 A

Notes

a. Performance specifications are given for the case when the linear stage is mounted as recommended in the Section 2.3.

b. Deviation from the Ideal Path, Referenced to a Theoretical Straight Line

c. The velocity of the stage can be adjusted to a value equal to or greater than 60% of the maximum velocity through use of the

ASCII message calls described in the protocol document.

d. If an application requires collision with the end-stop pins, which are not contacted in normal use, the load should not exceed

100 g.

e. The linear stage is not designed for continuous operation.

Rev. A, Dec, 2017 Page 13

ELL10 Linear Stage Evaluation Kit Chapter 6: Specifications

Connector on Linear Stage Board

Picoflex®

Speed

Operating Temperature Range

Specifications Cont…

Communications

f

Bus

Multi-Drop 3.3 V/5 V TTL RS232

Picoflex®

Connectors on Interface Board

Micro-B USB

5 VDC Power:

[For Plug with Ø5.5 mm OD (Ground)

and Ø2.1 mm ID (+5 V)]

9600 baud

Data Length

Protocol Data Format

Module Address and Command Format

8-Conductor Ribbon Cable Length (Supplied)

8-Conductor Ribbon Cable Length (Maximum)

8 bit (1 Stop Bit, No Parity)

ASCII HEX

Mnemonic Character

250 mm

3 m

General

Dimensions at center travel, with bracket fitted

15 to 40 °C (59 to 104 °F)

102.3 x 67.0 x 18.4 mm

(4.03 x 2.64” x 0.73”)

Dimensions at end of travel, with bracket fitted

114.0 x 67.0 x 18.4 mm

(4.49” x 2.64” x 0.73”)

Dimensions of interface board

66.0 x 32.0 x 12.5 mm

(2.6” x 1.26” x 0.49”)

Weight (Stage plus Bracket)

Weight (Stage Only)

Metric 0.104 kg, Imperial 0.229 lb

Metric 0.069 kg, Imperial 0.152 lb

Note

f. Use two 10 kΩ pull-up resistors in multi-drop mode for RX/TX

Page 14 ETN039959-D02

ELL10 Linear Stage Evaluation Kit Chapter 7: Regulatory

Chapter 7 Regulatory

Declarations of Conformity

7.1.1 For Customers in Europe

7.1.2 For Customers In The USA

This equipment has been tested and found to comply with the limits for a Class A digital device, persuant to part 15 of the FCC

rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a r esidential area is likely to cause harmful interference in which case the user will be r equired to correct the

interference at his own expense.

Changes or modifications not expressly approved by the company could void the user’s authority to operate the equipment.

Rev. A, Dec, 2017 Page 15

ELL10 Linear Stage Evaluation Kit Chapter 8: Thorlabs Worldwide Conta cts

Annex I

USA, Canada, and South America

Support: techsupport@thorlabs.com

Scandinavia

France

Email: sales.fr@thorlabs.com

Brazil

Email: brasil@thorlabs.com

Chapter 8 Thorlabs Worldwide Contacts

UK and Ireland

Thorlabs, Inc.

56 Sparta Avenue

Newton, NJ 07860

USA

Tel: 973-300-3000

Fax: 973-300-3600

www.thorlabs.com

www.thorlabs.us (West Coast)

Email: sales@thorlabs.com

Europe

Thorlabs GmbH

Hans-Böckler-Str. 6

85221 Dachau / Munich

Germany

Tel: +49-(0) 8131-5956-0

Fax: +49-(0) 8131-5956-99

www.thorlabs.de

Email: europe@thorlabs.com

Thorlabs Ltd.

1 Saint Thomas Place

Ely CB7 4EX

Great Britain

Tel: +44 (0) 1353-654440

Fax: +44 (0) 1353-654444

www.thorlabs.com

Email: sales.uk@thorlabs.com

Support: techsupport.uk@thorlabs.com

Thorlabs Sweden AB

Bergfotsgatan 7

431 35 Mölndal

Sweden

Tel: +46-31-733-30-00

Fax: +46-31-703-40-45

www.thorlabs.com

Email: scandinavia@thorlabs.com

Thorlabs SAS

109, rue des Côtes

78600 Maisons-Laffitte

France

Tel: +33 (0) 970 444 844

Fax: +33 (0) 825 744 800

www.thorlabs.com

Japan

Thorlabs Japan, Inc.

3-6-3, Kitamachi,

Nerima-ku, Tokyo 179-0081

Japan

Tel: +81-3-6915-7701

Fax: +81-3-6915-7716

www.thorlabs.co.jp

Email: sales@thorlabs.jp

Thorlabs verifies our compliance with the WEEE (Waste Electrical and Electronic Equipment) directive of

the European Community and the corresponding national laws. Accordingly, all end users in the EC may

return “end of life” Annex I category electrical and electronic equipment sold after August 13, 2005 to

Thorlabs, without incurring disposal charges. Eligible units are marked with the crossed out “wheelie bin”

logo (see right), were sold to and are currently owned by a company or institute within the EC, and are

not dissembled or contaminated. Contact Thorlabs for more information. Waste treatment is your own

responsibility. “End of life” units must be returned to Thorlabs or handed to a company specializing in

waste recovery. Do not dispose of the unit in a litter bin or at a public waste disposal site.

Thorlabs Vendas de Fotônicos Ltda.

Rua Riachuelo, 171

São Carlos, SP 13560-110

Brazil

Tel: +55-16-3413 7062

Fax: +55-16-3413 7064

www.thorlabs.com

China

Thorlabs China

Room A101, No. 100, Lane 2891

South Qilianshan Road

Putuo District

Shanghai

China

Tel: +86 (0) 21-60561122

Fax: +86 (0) 21-32513480

www.thorlabschina.cn

Email: chinasales@thorlabs.com

Page 16 ETN039959-D02

www.thorlabs.com

Loading...

Loading...