Operation Manual

Thorlabs Instrumentation

LED Illumination System for Fluorescence Lifetime Imaging

(FLIM)

DC3100

2009

Version:

Date:

1.3

04.09.2009

© 2009 Thorlabs

Contents

Foreword

1 General Information

1.1 Safety

1.2 Ordering Codes and Accessories

................................................................................................................................... 4

................................................................................................................................... 7

2 Getting Started

2.1 Unpacking

2.2 Preparation

2.3 Operating Elements

................................................................................................................................... 8

................................................................................................................................... 8

................................................................................................................................... 9

Operating Elements on the Front Panel 2.3.1

Operating Elements on the Rear Panel 2.3.2

Operating Elements on the LED Head 2.3.3

......................................................................................................................................................... 9

......................................................................................................................................................... 10

......................................................................................................................................................... 10

3 Operating the DC3100

3.1 Operation and Settings

3.2 Remote Application

3.3 Changing the LED

................................................................................................................................... 11

Navigating the Menus 3.1.1

Operation Modes 3.1.2

3.1.2.1

3.1.2.2

3.1.2.3

Settings and Configuration 3.1.3

3.1.3.1

3.1.3.2

3.1.3.3

3.1.3.4

................................................................................................................................... 17

Installation 3.2.1

3.2.1.1

3.2.1.2

3.2.1.3

3.2.1.4

Operating the DC3100 by the Remote Application 3.2.2

3.2.2.1

3.2.2.2

3.2.2.3

3.2.2.4

3.2.2.5

3.2.2.6

................................................................................................................................... 25

......................................................................................................................................................... 11

......................................................................................................................................................... 12

Constant Current Mode

Internal Modulation Mode

External Control Mode

User Limit

LED Configuration

System Settings

About

The Installation Menu

Installing VISA Runtime Engine

Installing the Remote Application

Driver Installation

Connecting a Device

Constant Current Mode

Internal Modulation Mode

External Control Mode

User Limit Current

Configuring a new LED

.................................................................................................................................................. 12

.................................................................................................................................................. 12

.................................................................................................................................................. 14

......................................................................................................................................................... 15

.................................................................................................................................................. 15

.................................................................................................................................................. 15

.................................................................................................................................................. 16

.................................................................................................................................................. 17

......................................................................................................................................................... 17

.................................................................................................................................................. 17

.................................................................................................................................................. 18

.................................................................................................................................................. 19

.................................................................................................................................................. 20

......................................................................................................................................................... 20

.................................................................................................................................................. 21

.................................................................................................................................................. 21

.................................................................................................................................................. 22

.................................................................................................................................................. 22

.................................................................................................................................................. 23

.................................................................................................................................................. 24

3

4

8

11

4 Computer Interface

4.1 Connecting a Computer

4.2 DC3100 Utility Software

4.3 Command Reference

................................................................................................................................... 26

................................................................................................................................... 26

................................................................................................................................... 27

Command List 4.3.1

4.3.1.1

......................................................................................................................................................... 27

Description

.................................................................................................................................................. 27

26

4.4 Status Reporting

................................................................................................................................... 31

5 Maintenance and Repair

5.1 Maintenance

5.2 Firmware Update

5.3 Troubleshooting

................................................................................................................................... 32

................................................................................................................................... 32

................................................................................................................................... 32

6 Application Note

6.1 Fluorescence Lifetime Imaging (FLIM)

................................................................................................................................... 34

Time Domain FLIM 6.1.1

Frequency Domain FLIM 6.1.2

......................................................................................................................................................... 34

......................................................................................................................................................... 35

7 Appendix

7.1 Warranty

7.2 Certifications and Compliances

7.3 Technical Data

7.4 Letter of Volatility

7.5 Thorlabs 'End of Life' Policy (WEEE)

7.6 List of Acronyms

7.7 List of Figures

7.8 Copyright

7.9 Addresses

................................................................................................................................... 36

................................................................................................................................... 37

................................................................................................................................... 39

Common Data 7.3.1

Technical Data 7.3.2

LED for Frequency Domain FLIM 7.3.3

7.3.3.1

7.3.3.2

7.3.3.3

7.3.3.4

................................................................................................................................... 44

................................................................................................................................... 45

Waste Treatment on your own Responsibility 7.5.1

Ecological Background 7.5.2

................................................................................................................................... 46

................................................................................................................................... 46

................................................................................................................................... 47

................................................................................................................................... 48

......................................................................................................................................................... 39

......................................................................................................................................................... 39

......................................................................................................................................................... 40

LED @ 365nm

LED @ 405nm

LED @ 470nm

LED @ 630nm

.................................................................................................................................................. 40

.................................................................................................................................................. 41

.................................................................................................................................................. 42

.................................................................................................................................................. 42

......................................................................................................................................................... 45

......................................................................................................................................................... 45

32

34

36

Index 49

We aim to develop and produce the best solution for your application

in the field of optical measurement technique. To help us to come up

to your expectations and develop our products permanently we need

your ideas and suggestions. Therefore, please let us know about

possible criticism or ideas. We and our international partners are

looking forward to hearing from you.

Thorlabs GmbH

This part of the instruction manual contains every specific information on how

to handle and use the DC3100 - FLIM LED Driver.

WARNING

This symbol in the manual explains dangers that might result in

personal injury or death. Always read carefully the associated

information before performing the indicated procedure.

ATTENTION

This symbol in the manual explains hazards that could damage the

instrument and connected equipment or may cause data loss.

NOTE

This manual also contains "NOTES" and "HINTS" written in this form.

Please read these advices carefully!

1 General Information

1

1.1

General Information

The LED modulating system (DC3100 series) is designed for frequency domain

Fluorescence Lifetime Imaging (FLIM) and other microscopy applications that

require modulated high-power LED illumination sources.

The compact LED driver in the DC3100 series can supply a high current (up to 1A)

to high-power LEDs. The DC3100 series system includes an optical head,

modulating electronics, and a heat sink designed to dissipate the heat generated by

high-power LEDs. The design of the head allows the user to mount any compatible

star-shaped PCB packaged LED.

Please refer to chapter Fluorescence Lifetime Imaging for application notes.

Safety

ATTENTION

All statements regarding safety of operation and technical data in this

instruction manual will only apply when the unit is operated correctly.

Before applying power to your DC3100 system, make sure that the

protective conductor of the 3 conductor mains power cord is correctly

connected to the protective earth contact of the socket outlet!

Improper grounding can cause electric shock with damages to your health

or even death!

The DC3100 must not be operated in explosion endangered environments!

The LED head, control inputs and outputs must only be connected with duly

shielded connection cables.

Only with written consent from Thorlabs may changes to single components

be carried out or components not supplied by Thorlabs be used.

Do not obstruct the air ventilation slots in housing!

Do not remove covers!

Refer servicing to qualified personal!

This precision device is only dispatchable if duly packed into the complete

original packaging including the plastic form parts. If necessary, ask for a

replacement package.

Mobile telephones, cellular phones or other radio transmitters are not to be

used within the range of three meters of this unit since the electromagnetic

field intensity may then exceed the maximum allowed disturbance values

according to IEC 61326-1.

This product has been tested and found to comply with the limits according

to IEC 61326-1 for using connection cables shorter than 3 meters (9.8 feet).

DC31004

1 General Information

CAUTION

The head of DC3100 can contain an UV light LED! In this case the LED

radiates intense UV light during operation. Precautions must be taken to

prevent looking directly at the UV light with unprotected eyes.

Do not look directly into the UV light or look through the optical system

during operation of the device. This can be harmful to the eyes even for brief

periods due to the high intensity of the UV light.

If there is the possibility to receive a reflection of the UV light, UV light

protective glasses have to be used to prevent that UV light can catch one's

eye directly.

If viewing the UV light is necessary, use UV light protective glasses to avoid

damage by the UV light.

CAUTION

The head of the DC3100 is also a heat sink for the LED and will be heated up

to more than 50°C!

ATTENTION

The following statement applies to the products covered in this manual,

unless otherwise specified herein. The statement for other products will

appear in the accompanying documentation.

DC3100 5

1 General Information

Note: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules and meets

all requirements of the Canadian Interference-Causing Equipment Standard

ICES-003 for digital apparatus. These limits are designed to provide

reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

· Reorient or relocate the receiving antenna.

· Increase the separation between the equipment and receiver.

· Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

· Consult the dealer or an experienced radio/T.V. technician for help.

Thorlabs GmbH is not responsible for any radio television interference

caused by modifications of this equipment or the substitution or attachment

of connecting cables and equipment other than those specified by Thorlabs

GmbH. The correction of interference caused by such unauthorized

modification, substitution or attachment will be the responsibility of the user.

The use of shielded I/O cables is required when connecting this equipment

to any and all optional peripheral or host devices. Failure to do so may

violate FCC and ICES rules.

DC31006

1 General Information

1.2

Ordering Codes and Accessories

Ordering code Short description

DC3100-365 DC3100 - FLIM LED Driver with LED Head @ 365nm

DC3100-405 DC3100 - FLIM LED Driver with LED Head @ 405nm

DC3100-470 DC3100 - FLIM LED Driver with LED Head @ 470nm

DC3100-630 DC3100 - FLIM LED Driver with LED Head @ 630nm

Other wavelengths on request ranging from 365nm up to 940nm.

Please visit our homepage http://www.thorlabs.com for further information.

DC3100 7

1 General Information

2

2.1

2.2

Getting Started

Unpacking

Inspect the packaging for damage.

If the shipping container seems to be damaged, keep it until you have inspected the

contents and you have inspected the DC3100 mechanically and electrically.

Verify that you have received the following items:

1. 1 DC3100 (main unit and LED head)

2. 1 Power cord, connector according to ordering country

3. 1 Power supply 12V / 3.75A

4. 1 USB cable

5. 1 Operation manual

6. 1 Applications and driver CD

Preparation

1.Connect LED head cable with socket labeled "LED" at the back of the main

control unit, see figure 1

2.Connect power supply cable with main control unit, use only the power supply

supplied with your DC3100 unit

3.Plug in power supply

Figure 1 Connecting the LED Head

ATTENTION

Prior to switching on your DC3100 please check if the line voltage

corresponds to the input voltage range of the power supply!

Turn the unit on by pressing the power switch on the rear side of the unit.

DC31008

2 Getting Started

After the device is powered up, the graphics display will show a 'Welcome' screen

for a few seconds.

The DC3100 is immediately ready to use after turning on. The rated accuracy is

reached, however, after a warming-up period of approximately 10 minutes.

2.3

2.3.1

Operating Elements

Operating Elements on the Front Panel

Figure 2 Display and Operating Elements on the Front Panel

DC3100 9

2 Getting Started

2.3.2

Operating Elements on the Rear Panel

Figure 3 Operating Elements on the Rear Panel

2.3.3

Operating Elements on the LED Head

Figure 4 Operating Elements on the LED Head

DC310010

2 Getting Started

3

3.1

3.1.1

Operating the DC3100

The DC3100 can either be controlled via the front panel of the main unit (see chapter

Operation and Settings) or by a remote application (see chapter Remote

Application).

Operation and Settings

The following sub chapters contain the description about the operation of the

DC3100.

Navigating the Menus

The DC3100 is controlled by three buttons and the multi-control knob on the front

panel. The two buttons below the graphics display have an Enter and Escape

functionality. The button with LED indicator is used to switch the LED on or off. The

multi-control is used to select the desired menu or to change the settings.

After switching on the DC3100 a 'Welcome' screen appears for a few seconds.

Figure 5 Welcome Screen

In case no LED head is connected you will be prompted to switch off the main unit,

connect the LED head and switch on the device.

The display will show the screen of one of the 3 LED operation modes (Constant

Current, Internal Modulation or External Control Mode). The 'Main Menu' can be

accessed via the 'ESC' button.

Figure 6 Main Menu

To select an operation mode or a configuration display the multi-control knob is

used. Press the 'Ok' button to enter the selected item.

DC3100 11

3 Operating the DC3100

3.1.2

3.1.2.1

Operation Modes

Only if one of the three operation modes (Constant Current, Internal Modulation or

External Control) is selected the LED can be enabled /switched on.

It is possible to leave the active mode when the LED is switched on and enter the

main menu. However, the LED has to switch off before you can enter another

operation mode. This can be done while the main menu is selected by pressing the

LED button.

Constant Current Mode

The 'Constant Current Mode' provides a constant non-modulated LED current. The

current can be set directly with the multi-control knob. No confirmation is necessary.

The 'Ok' button has no functionality within this mode. The LED is switched on or off

with the LED button. The LED current can be changed when the LED is off as well as

when it is in operation. This allows to increase or reduce the brightness of the LED.

The current limit is displayed at the bottom of the screen.

Return to the main menu with the 'ESC' button.

3.1.2.2

Figure 7 Constant Current Mode

Internal Modulation Mode

This mode can be used to apply a sine wave modulation to the LED with a defined

frequency.

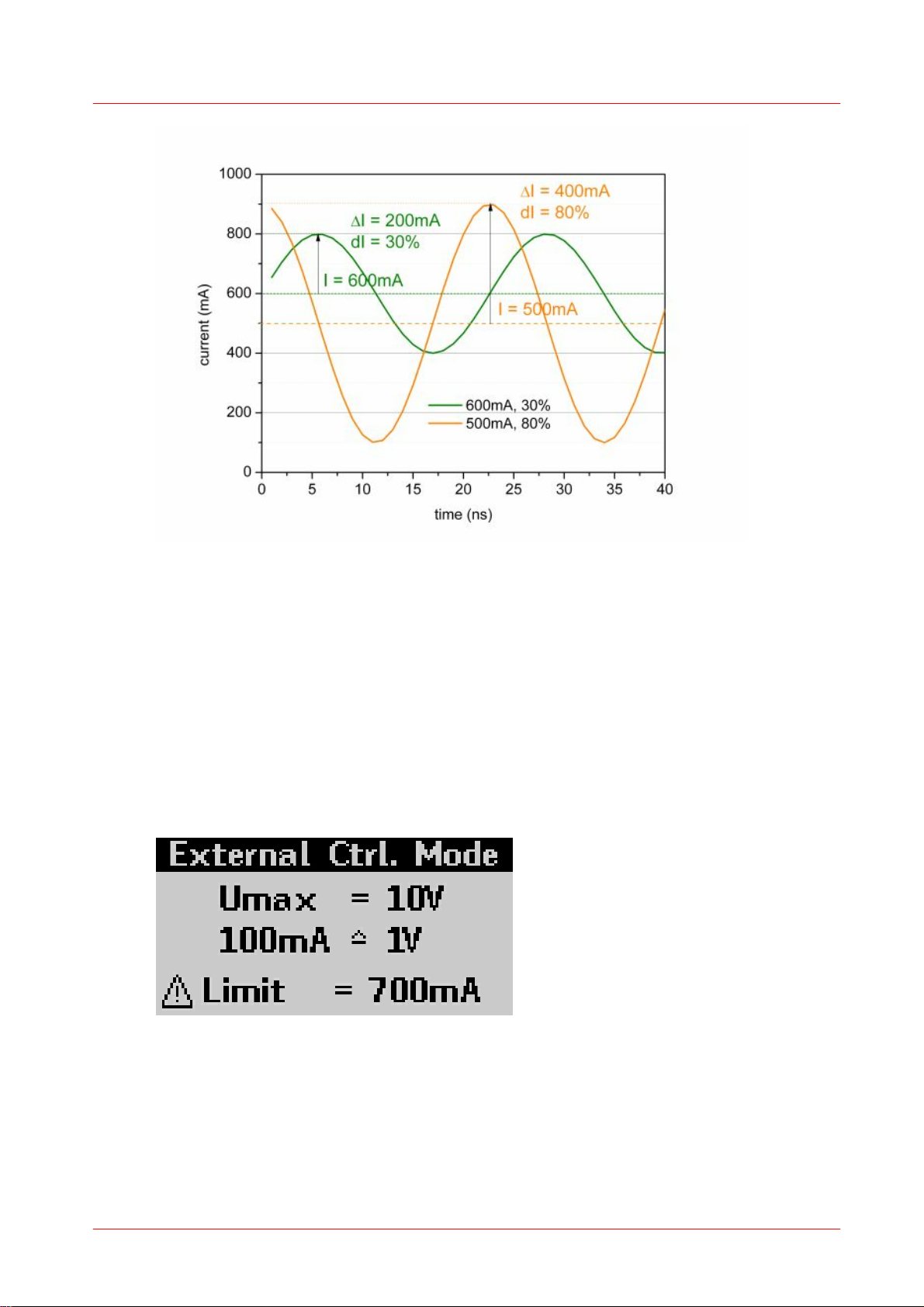

The 'Internal Modulation Mode' features three settings: current, frequency and

modulation depth. The first parameter is the DC component. The frequency can be

set between 10MHz and 100MHz in steps of 0.1MHz. The modulation depth

describes the relation between constant and variable component.

Figure 8 Internal Modulation Mode

DC310012

3 Operating the DC3100

To change the settings select one of the parameters using the multi-control knob and

press the 'Ok' button. The corresponding screen appears and the value for the

current, the frequency or the modulation depth can be adjusted with the multi-control

knob. Changing the value will take effect immediately. However, since the editing

mode is active the value has to be confirmed with the 'Ok' button or can be canceled

with the 'ESC' button.

Figure 9 Internal Modulation - Current Adjustment

Figure 10 Internal Modulation - Frequency Adjustment

Figure 11 Internal Modulation - Modulation Depth Adjustment

See the chapter Technical Data for information about cut-off frequencies for certain

LEDs.

The following diagram illustrates the definition of current and modulation depth:

DC3100 13

3 Operating the DC3100

3.1.2.3

Figure 12 Definition of the Parameter Current and Modulation Depth

External Control Mode

This mode allows to control the DC3100 by an external signal.

The 'External Control Mode' has no parameter settings. The LED can only be

controlled via the BNC connector at the rear panel of the DC3100. The applied

voltage corresponds to the LED current. 1V is equivalent to a LED current of

100mA. A maximum voltage of 10V can be applied, which results in a current of

1000mA.

Please note: The maximum current is limited by the user defined current limit set in

the 'Adjust Limit' menu.

Figure 13 External Control Mode

The Modulation Frequency range is 0 to 100kHz and valid for sine wave modulation.

DC310014

3 Operating the DC3100

The last selected operation mode will be saved. After switching on the DC3100

again this operation mode will be automatically the active mode. All settings are

saved and validated after a shut off. The current settings in the 'Constant Current

Mode' and in the 'Internal Modulation Mode' are two separate parameters and will be

handled individually.

3.1.3

3.1.3.1

Settings and Configuration

There are settings and system configurations, which can be accessed via the main

menu. To enter the main menu from one of the operation modes press the 'ESC'

button.

Figure 14 Main Menu

Select an item with the multi-control knob and press the 'Ok' button to access the

desired setting or configuration panel.

User Limit

3.1.3.2

The current limit can be changed by selecting 'User Limit'. The following screen

appears and the LED current limit can be set using the multi-control knob. The new

value has to be confirmed with the 'Ok' button or canceled with the 'ESC' button. The

LED current limit can be set up to the maximum LED current limit (LED Imax), which

is defined in the EEPROM of the LED head. See next section for more information.

Figure 15 LED Current Limit Setting

LED Configuration

In case a new LED was installed the LEDs maximum current and frequency need to

be configured. These values are saved in the EEPROM of the LED head and can be

changed in the 'LED Configuration' menu.

DC3100 15

3 Operating the DC3100

This menu entry is hidden in normal operation mode. Go to the 'User Limit' screen

described above and hold the "LED" button for about three seconds.

A sub menu appears and the LEDs maximum current (LED Imax) and frequency

(LED fmax) can be set. Press the 'Ok' button to select one of these limits. The multicontrol knob is used to change the value and has to be confirmed with the 'Ok' button

or canceled with the 'ESC' button.

Figure 16 LED Maximum Current

3.1.3.3

Figure 17 LED Maximum Frequency

ATTENTION

A wrong and too high LED maximum current limit can cause damage to the

LED. Prior to changing the LED maximum current limit of the LED head

check if the LED can handle this current!

System Settings

Within the system configuration the LCD backlight brightness can be set. Select

'Configuration' from the main menu via the multi-control knob and press 'Ok'. A sub

menu appears and the 'Brightness' setting can be accessed by pressing the 'Ok'

button. The multi-control knob is used to change the brightness of the LCD backlight

between 0 and 100%. Confirm your setting with 'Ok' or cancel it with 'ESC'.

DC310016

Figure 18 LCD Backlight Brightness Setting

3 Operating the DC3100

3.1.3.4

3.2

About

The item 'About' gives information about the firmware version and serial number of

the DC3100 and the connected LED head.

Figure 19 About Panel

Remote Application

The DC3100 remote software can be used to operate the DC3100 - FLIM LED

Driver via the PC. The device has to be connected to the PC by an USB cable.

3.2.1

3.2.1.1

DC3100 17

Installation

The Installation Menu

Before installing the DC3100 remote application, please make sure that no Thorlabs

DC3100 - FLIM LED Driver is connected. After you inserted the DC3100 installation

CD an autorun menu will appear. If autorun is disabled on your system please

browse the installation CD and run "CD-Drive:\Autorun\Autorun.exe".

3 Operating the DC3100

3.2.1.2

Figure 20 Autorun Menu

NOTE

Please be aware that you need a VISA engine installed on your system to operate

the DC3100 remote application.

Installing VISA Runtime Engine

A VISA runtime 4.3.0 or higher has to be installed on your system to operate the

DC3100 remote application.

You may install the National Instruments©® VISA runtime engine provided on the

installation CD. You may also download the latest NI-VISA runtime engine from the

National Instruments©® web site (www.ni.com/visa).

In case you want to use the VISA engine provided on the installation CD select "NIVISA Engine". An installation wizard will be started. If you are running Windows

VISTA©® you might be prompted to change to the "elevated mode". Please ask

your administrator for help when you do not have administrator privileges.

Follow the instructions of the installation wizard.

DC310018

3.2.1.3

3 Operating the DC3100

Installing the Remote Application

Select "DC3100 - Application software" from the installation menu to start the

installation wizard. If you are running Windows VISTA©® you might be promted to

change to the "elevated mode", as shown in figure 24. Please ask your administrator

for help when you do not have administrator privileges.

Figure 21 Request for Administrator Privileges

After the DC3100 remote application installation wizard finished the initialization you

will be prompted to specify the installation path. Confirm with "Next" when you

selected the installation path of your choice. Follow the instruction of the installation

wizard in order to install the remote software and drivers for the DC3100.

During the installation process a separate installation wizard will start to register the

device drivers on your system. The system will inform you that the software

installation has failed the Windows logo test. This will happen twice.

Ignore the warning and click 'Continue Anyway'.

DC3100 19

3 Operating the DC3100

Figure 22 The Windows Logo Test

3.2.1.4

Driver Installation

The necessary drivers for the DC3100 - FLIM LED Driver is automatically copied to

the system folder during the installation of the DC3100 remote application.

Attention:

The following procedure will only be necessary for Windows XP/2000©®.

On the first connection of a device the 'Found New Hardware Wizard' will start to

install the new device. Depending on the configuration of your system you might be

asked if you want to connect to 'Windows Update to search for Software'.

First the 'USB to DC3100 Bridge' will be installed:

1.

Please select 'No, not this time' and click 'Next' to continue.

2.

Select 'Install the software automatically' and click 'Next' to continue.

3.

A message appears informing that the software has failed the Windows logo test.

Click 'Continue Anyway'.

4.

Finalize the installation by clicking 'Finish'.

After this first installation the 'DC3100 - FLIM LED Driver' will be installed. Repeat

step 1 to 4.

3.2.2

Operating the DC3100 by the Remote Application

The DC3100 remote application can be used to operate a DC3100 - FLIM LED

Driver via the PC.

Every setting made will automatically be used by the device. The parameters are

updated/synchronized once every second.

DC310020

3.2.2.1

3 Operating the DC3100

Connecting a Device

Please connect the DC3100 to your PC with the shipped USB cable. The USB

socket labeled "USB" at the back of the main control.

After starting the application the following window is displayed.

Figure 23 The Start Screen

3.2.2.2

Use the green button or the menu option 'Connect...' to open the device selection

dialog.

Figure 24 The Device Selection Dialog

Select your DC3100 - FLIM LED Driver by double-clicking or pressing the "Accept"

button. The device will be connected and the last active mode will be entered. The

upload of the actual values on the system may take some seconds.

Constant Current Mode

The constant current can be selected by pressing the 'Constant Current Mode' button

(see figure 35) or the corresponding menu entry 'Mode/Constant Current Mode'.

You can either change the value directly by typing into the numeric control, or use the

small arrows. The maximum value depends on the user current limit, which is set in

the configuration menu.

DC3100 21

3 Operating the DC3100

Figure 25 Constant Current Mode

3.2.2.3

Internal Modulation Mode

The internal modulation mode can be selected by pressing the 'Internal Modulation

Mode' button (see figure 36) or the corresponding menu entry 'Mode/Internal

Modulation Mode'.

You can either change the values directly by typing into the numeric controls, or use

the arrow controls.

The maximum user frequency is stored in the LED head and is specific to the

mounted LED.

The maximum current is half of the user current limit, which is set in the configuration

menu.

3.2.2.4

Figure 26 The Internal Modulation Mode

External Control Mode

The 'External Control Mode' can be selected by pressing the 'External Control Mode'

button (see figure 37) or the corresponding menu entry 'Mode/External Control

Mode'.

DC310022

3 Operating the DC3100

This screen is for information purposes only and offers no user inputs.

In this mode the LED can only be controlled via the BNC connector at the rear panel

of the DC3100. The applied voltage corresponds to the LED current. 1V is

equivalent to a LED current of 100mA. A maximum voltage of 10V can be applied,

which will result in a current of 1A.

Figure 27 The External Control Mode

3.2.2.5

User Limit Current

The user can set an individual current limit, which must be below the LEDs maximum

current limit stored in the LED head.

Figure 28 User Limit

DC3100 23

3 Operating the DC3100

Figure 29 User Limit Dialog

3.2.2.6

Configuring a new LED

The DC3100 - FLIM LED Driver offers the possibility to operate a LED of your

choice.

Use the menu 'Configuration/LED Configuration' to set the new LEDs maximum

current and frequency.

Figure 30 LED Configuration Menu

Figure 31 LED Maximum Limit

DC310024

Figure 32 LED Maximum Frequency

3 Operating the DC3100

3.3

Changing the LED

The DC3100 - FLIM LED Driver offers the possibility to operate a LED of your

choice.

Contact Thorlabs for more information!

DC3100 25

3 Operating the DC3100

4

4.1

Computer Interface

The DC3100 has a USB 2.0 interface that allows to send commands from a host

computer to the instrument using the DC3100 - VISA Instrument Driver. The

connection between PC and DC3100 is accomplished by an USB cable with a male

type 'A' connector at the PC side and a type 'B' connector on the instrument side.

See chapter Command List for a complete command reference.

Connecting a Computer

ATTENTION

To successfully complete the installation of the DC3100 USB driver, you

must have Administrator privileges on the PC, on which you are performing

the installation.

Prior to connecting the DC3100 with the PC, please insert the CD that was shipped

with the instrument and install the DC3100 drivers. When the following message

appears after the installation you have to install NI-VISA from the distribution CD or

from the National Instruments web site, too.

4.2

Figure 33 No VISA Engine installed

After successfully installing the software connect the DC3100 to a USB port of your

PC. The PC will find sequentially a DC3100 and a DFU device. Please follow the

instructions of the dialog screens and allow the installation.

DC3100 Utility Software

The DC3100 comes with an utility software, by which the DC3100 can be remotely

operated.

Additionally the DC3100 comes with a driver software, which can be used by C/C++/

LabVIEW and every programming language supporting DLLs.

Please refer to the manuals, which are copied on your system when installing the

device driver.

Note: Please be aware that you need a VISA engine installed on your system to use

the DC3100 - VISA Instrument Driver.

DC310026

4 Computer Interface

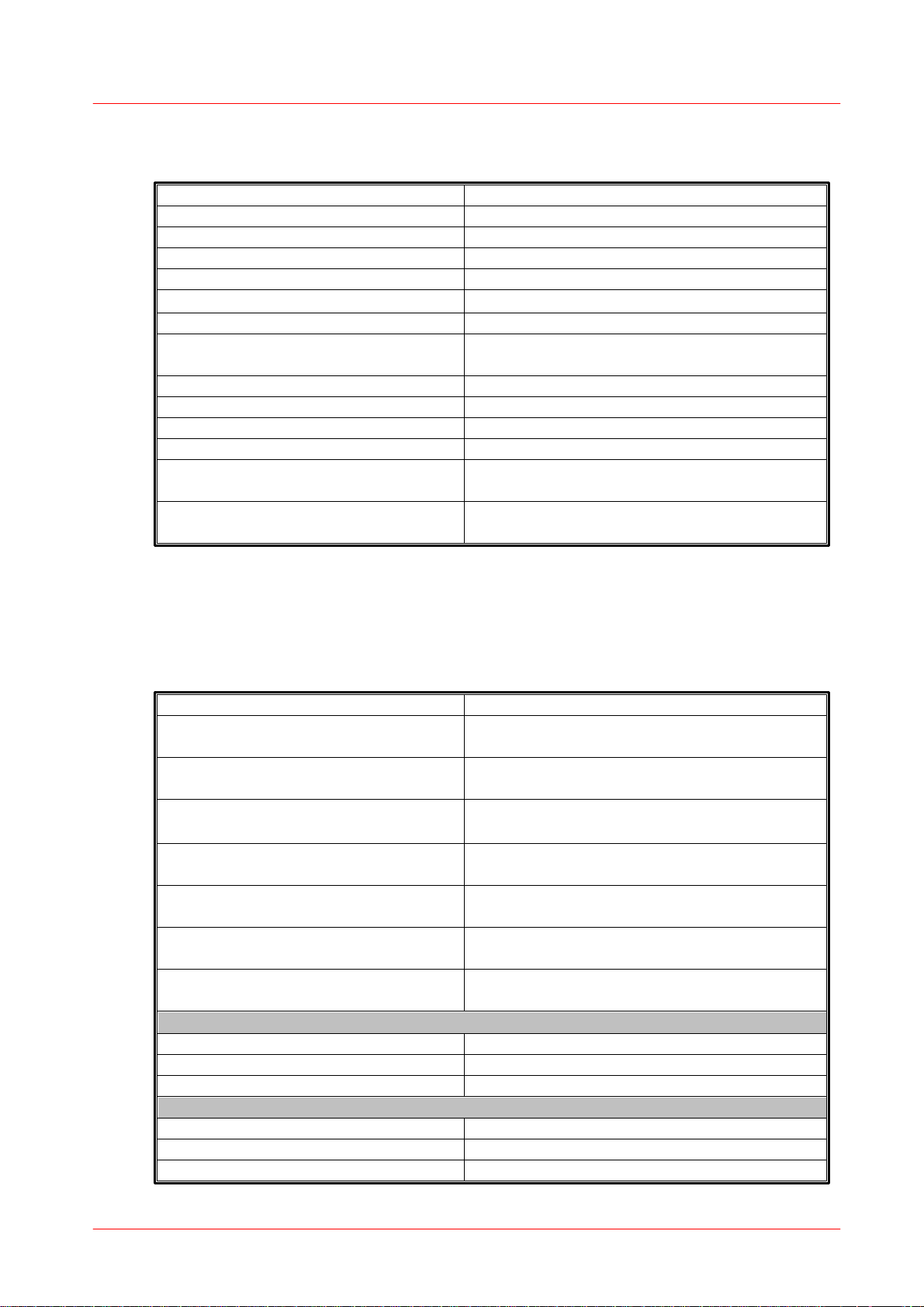

Command

Description

DC3100_setLimitCurrent

Set User Current Limit

DC3100_getLimitCurrent

Get User Current Limit

DC3100_setMaxLimit

Set Maximum Current Limit

DC3100_getMaxLimit

Get Maximum Current Limit

DC3100_setMaxFrequency

Set Maximum Frequency

DC3100_getMaxFrequency

Get Maximum Frequency

DC3100_setOperationMode

Set Operation Mode

DC3100_getOperationMode

Get Operation Mode

DC3100_setLedOnOff

Set LED OnOff

DC3100_getLedOnOff

Get LED OnOff

DC3100_setModuCurrent

Set Internal Modulation Current

DC3100_getModuCurrent

Get Internal Modulation Current

DC3100_setModuFreq

Set Internal Modulation Frequency

DC3100_getModuFreq

Get Internal Modulation Frequency

DC3100_setModuDepth

Set Internal Modulation Depth

DC3100_getModuDepth

Get Internal Modulation Depth

DC3100_setConstCurrent

Set Constant Current

DC3100_getConstCurrent

Get Constant Current

DC3100_setDispBright

Set Display Brightness

DC3100_getDispBright

Get Display Brightness

DC3100_getStatusRegister

Get Status Register

DC3100_errorMessage

Error Message

DC3100_identificationQuery

Identification Query

DC3100_revisionQuery

Revision Query

The DC3100 sample applications will be copied to your VXIPNP directory during the

driver package installation. The default VXIPNP directory is “C:\VXIPNP” or starting

with NI-VISA version 4.2 “C:\Program Files\IVI Foundation”. You can find the sample

applications in:

„C:\VXIPNP\WinNT\Thorlabs DC3100\sample”

or

„C:\Program Files\IVI Foundation\WinNT\Thorlabs DC3100\sample”

4.3

4.3.1

Command Reference

Command List

4.3.1.1

4.3.1.1.1 Set User Limit Current

DC3100 27

Description

Command: DC3100_setLimitCurrent

Parameter: Current limit in Ampere

Response: None

Description: Sets the current limit. This limit may not exceed the LEDs limit

specified in the LED head.

4 Computer Interface

4.3.1.1.2 Get User Limit Current

Command: DC3100_getLimitCurrent

Parameter: None

Response: Current limit in Ampere

Description: Returns the current limit.

4.3.1.1.3 Set Maximum Current Limit

Command: DC3100_setMaxLimit

Parameter: Maximum current limit in ampere

Response: None

Description: Sets the LEDs maximum current limit in ampere. This limit

should only be set in case a new LED was installed.

4.3.1.1.4 Get Maximum Current Limit

Command: DC3100_getMaxLimit

Parameter: None

Response: Maximum current limit in ampere

Description: Returns the current limit.

4.3.1.1.5 Set Maximum Frequency

Command: DC3100_setMaxFrequency

Parameter: Maximum frequency in MHz

Response: None

Description: Sets the maximum frequency in MHz. This limit should only be

set in case a new LED was installed.

4.3.1.1.6 Get Maximum Frequency

Command: DC3100_getMaxFrequency

Parameter: None

Response: Maximum frequency in MHz

Description: Returns the LEDs maximum frequency.

4.3.1.1.7 Set Operation Mode

Command: DC3100_setOperationMode

Parameter: Operation Mode

Response: None

Description: Sets the operation mode.

4.3.1.1.8 Get Operation Mode

Command: DC3100_getOperationMode

Parameter: None

Response: Actual operation mode

Description: Returns the operation mode.

DC310028

4.3.1.1.9 Set LED OnOff

Command: DC3100_setLedOnOff

Parameter: LED output state

Response: None

Description: Sets the LED output.

4.3.1.1.10 Get LED OnOff

Command: DC3100_getLedOnOff

Parameter: None

Response: LED output state

Description: Returns the LED output state.

4.3.1.1.11 Set Internal Modulation Current

Command: DC3100_setModuCurrent

Parameter: Internal modulation current in Ampere

Response: None

Description: Sets the current used for internal modulation.

4.3.1.1.12 Get Internal Modulation Current

4 Computer Interface

Command: DC3100_getModuCurrent

Parameter: None

Response: Internal modulation current in Ampere

Description: Returns the current used for internal modulation in ampere.

4.3.1.1.13 Set Internal Modulation Frequency

Command: DC3100_setModuFreq

Parameter: Frequency in MHz

Response: None

Description: Sets the internal modulation frequency in MHz.

4.3.1.1.14 Get Internal Modulation Frequency

Command: DC3100_getModuFreq

Parameter: None

Response: Frequency in MHz

Description: Returns the internal modulation frequency.

4.3.1.1.15 Set Internal Modulation Depth

Command: DC3100_setModuDepth

Parameter: Modulation depth in percent

Response: None

Description: Sets the internal modulation depth in percent.

4.3.1.1.16 Get Internal Modulation Depth

Command: DC3100_getModuDepth

Parameter: None

Response: Modulation depth in percent

Description: Returns the internal modulation depth in percent.

DC3100 29

4 Computer Interface

4.3.1.1.17 Set Constant Current

Command: DC3100_setConstCurrent

Parameter: Constant current in Ampere

Response: None

Description: Sets the current in ampere used for the constant current mode.

4.3.1.1.18 Get Constant Current

Command: DC3100_getConstCurrent

Parameter: None

Response: Constant current in ampere

Description: Returns the current in Ampere used for the constant current

mode.

4.3.1.1.19 Set Display Brightness

Command: DC3100_setDispBright

Parameter: Display brightness in percent

Response: None

Description: Sets the display brightness.

4.3.1.1.20 Get Display Brightness

Command: DC3100_getDispBright

Parameter: None

Response: Display brightness in percent

Description: Returns the display brightness.

4.3.1.1.21 Get Status Register

Command: DC3100_getStatusRegister

Parameter: None

Response: Status register value

Description: Reads the content of the instruments status register. Refer to

chapter Status Reporting.

4.3.1.1.22 Error Message

Command: DC3100_errorMessage

Parameter: Error code

Response: User readable message string

Description: This function takes the error code returned by the instrument

driver functions, interprets it and returns it as a user readable

string.

4.3.1.1.23 Identification Query

Command: DC3100_identificationQuery

Parameter: None

Response: Manufacturer name

Description: This function returns the device identification information.

Device name

Serial number

Firmware revision

DC310030

4.3.1.1.24 Revision Query

Status

Bit

Name

Description

Bit 0

No LED Changed

The bit 'No LED' has changed.

Bit 1

No LED

The LED head is not connected to the chassis.

Bit 2

VCC Fail Changed

The bit 'VCC Fail' has changed.

Bit 3

VCC Fail

The power supply is out of range.

Bit 4

OTP Change

The bit 'OTP' (Over Temperature) has

changed.

Bit 5

OTP

Over temperature (OTP) in the chassis was

detected. The LED head was switched off.

Bit 6

LED Open Changed

The bit 'LED Open' has changed.

Bit 7

LED OPEN

The LED head is connected but no LED was

installed.

Bit 8

Limit Changed

The bit 'Limit' has changed.

Bit 9

Limit

The adjusted current is greater than the current

limit and was coerced to the limit.

Bit 10

OTP Head Changed

The bit 'OTP Head' (Over Temperature Head)

has changed.

Bit 11

OTP Head

Over temperature in the LED head was

detected. The LED head was switched off.

Bit 12

Interface Refresh

The user has changed settings.

Command: DC3100_revisionQuery

Parameter: None

Response: Instrument driver revision

Description: This function returns the instruments driver revision and the

4 Computer Interface

Firmware revision

devices firmware revision.

4.4

Status Reporting

The DC3100 stores the status in a register. It can be accessed via the

'DC3100_getStatusRegister. The following table lists all status numbers and the

according descriptive messages. Each bit represents an error.

DC3100 31

4 Computer Interface

5

5.1

5.2

Maintenance and Repair

Maintenance

Protect the DC3100 from adverse weather conditions. The DC3100 is not water

resistant.

ATTENTION

To avoid damage to the DC3100, do not expose it to spray, liquids or

solvents!

The unit does not need a regular maintenance by the user.

If necessary the unit and the display can be cleaned with a cloth dampened with

water.

The DC3100 does not contain any modules that could be repaired by the user

himself. If a malfunction occurs, the whole unit has to be sent back to Thorlabs. Do

not remove covers!

Firmware Update

5.3

Firmware upgrades can be done by the user via the USB interface.

You need the batch file DC3100_Firmware_Update.bat and the hex file DC3100.

hex. Both files have to be in the same directory.

Connect the DC3100 with a USB cable to your computer. Check the COM port of

the DC3100. It has to be COM1, COM2, COM3 or COM4. If not please change the

COM port to one of the listed COM ports.

Before you switch on the DC3100 press the LED button and keep it pressed while

you switch on the device. The DC3100 shows 'DC3100 BOOTLOADER' in its

display. Start the batch file. The new firmware will be uploaded to the DC3100.

Please refer to www.thorlabs.com for the latest DC3100 firmware version that can

be downloaded as a *.hex file.

Do not switch off the DC3100 or disconnect the USB cable during the firmware

download.

Troubleshooting

The DC3100 features protection circuits to prevent damage of the unit. The user will

be informed about the occurrence of errors. Example:

DC310032

Figure 34 Error Message

Error

Explanation and Impact

Elimination

Clipped to

Limit Error

The current of the LED was

reduced to the set current limit.

This can happen in the

'External Control Mode', when

a voltage was applied to the

external trigger input at the rear

side representing a current,

which is higher than the limit.

Decrease the input voltage.

Over

Temperature

Error

The temperature within the

DC3100 case reached the

maximum limit and the LED is

switched off.

Make sure that the ventilation

slots are not covered. It is

necessary to ensure an air

ventilation through the DC3100

unit.

Software

Installation

failed

The software cannot be

installed on the computer.

Be sure to have

administrative rights on your

computer, which enables you

to install software at all. Ask

your system administrator to

give you such rights or to do

the installation himself. See

Installation for details.

LED cannot

be switched

on

After pressing the LED button

the LED does not emit light.

Check if the LED current is set

to a value larger than 0mA.

One of the three operation

Modes has to be selected

before you can switch on the

LEDs.

The following table summarizes possible errors:

5 Maintenance and Repair

DC3100 33

5 Maintenance and Repair

6

6.1

6.1.1

Application Note

Fluorescence Lifetime Imaging (FLIM)

FLIM (Fluorescence Lifetime Imaging) is an imaging technology that is primarily

used with confocal microscopy, but the FLIM method has also been applied in other

microscopy methods such as wide field and multiphoton imaging. Especially in the

field of cell and tissue research FLIM is a powerful tool to analyze the distribution of

biological materials.

If a dye molecule is exposed to energy of a specific wavelength, it emits another also

specific wavelength. The color of the emitted light as well as the lifetime of a

fluorescent dye are particular properties of the fluorophore. Due to different

fluorescent dyes the lifetime can vary between a few nanoseconds and several

milliseconds. The lifetime is depended on the ion concentration as well as further

factors like molecular binding, oxygen concentration or hydrophobic properties,

which will provide information about molecules of living cells. The concentration of

the dye, the dimension of the cell or the excitation light intensity will not affect the

lifetime. Therefore, the fluorescence lifetime imaging is a precise measure for ion

concentration.

Time Domain FLIM

The sample will be excited with a light pulse in the ps range. After the pulse the

electrons of the dye will stay in the excited state for a certain time (lifetime). They

return into their ground state and emit a fluorescence photon. The lifetime of the

excited electrons are quite short (ns range). The fluorescence intensity is highest

right after the excitation pulse and decays quickly since there are only a few

electrons with a longer lifetime. The decay can be described with a simple

-t/

exponential function: I(t)=I(t0)*e

Mostly lasers are used to generate pulses with several ps pulse width.

t

.

Figure 35 Time Domain FLIM

DC310034

6 Application Note

6.1.2

Frequency Domain FLIM

The lifetime can also be determined in the frequency domain by using a modulated

light source. The source continuously emits a sine wave signal in the range of 1 to

200MHz and modulates the fluorescence. Due to the lifetime of the electrons in the

excited state there will be a phase shift between the excitation signal and the

fluorescence response. Furthermore, the intensity to the excitation and fluorescence

sine waves will be modulated. The lifetime can be calculated from the modulation

ratio of the intensity. Hence, the FLIM in the frequency domain provides 2 values for

the lifetime.

Figure 36 Frequency Domain FLIM

DC3100 35

6 Application Note

7

7.1

Appendix

Warranty

Thorlabs GmbH warrants material and production of the DC3100 for a period of 24

months starting with the date of shipment. During this warranty period Thorlabs

GmbH will see to defaults by repair or by exchange if these are entitled to warranty.

For warranty repairs or service the unit must be sent back to Thorlabs GmbH

(Germany) or to a place determined by Thorlabs GmbH . The customer will carry

the shipping costs to Thorlabs GmbH, in case of warranty repairs Thorlabs GmbH

will carry the shipping costs back to the customer.

If no warranty repair is applicable the customer also has to carry the costs for back

shipment.

In case of shipment from outside EU duties, taxes etc. which should arise have to be

carried by the customer.

Thorlabs GmbH warrants the hard- and software determined by Thorlabs GmbH for

this unit to operate fault-free provided that they are handled according to our

requirements. However, Thorlabs GmbH does not warrant a faulty free and

uninterrupted operation of the unit, of the soft- or firmware for special applications

nor this instruction manual to be error free. Thorlabs GmbH is not liable for

consequential damages.

Restriction of warranty

The warranty mentioned before does not cover errors and defects being the result of

improper treatment, software or interface not supplied by us, modification, misuse or

operation outside the defined ambient conditions stated by us or unauthorized

maintenance.

Further claims will not be consented to and will not be acknowledged. Thorlabs

GmbH does explicitly not warrant the usability or the economical use for certain

cases of application.

Thorlabs GmbH reserves the right to change this instruction manual or the technical

data of the described unit at any time and without notice.

DC310036

7 Appendix

Certifications and Compliances

Category

Standards or description

EC

Declaration

of

Conformity EMC

Meets intent of Directive 89/336/EEC for Electromagnetic

Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European

Communities:

EN 61326:1997

+A1:1998

+A2:2001

+A3:2003

Electrical equipment for measurement, control and

laboratory use – EMC requirements:

Immunity: complies with immunity test requirements

for equipment intended for use in industrial

locations 1.

Emission: complies with EN 55011 Class B Limits

1,3

,

IEC 610003-2 and IEC 61000-3-3.

IEC 61000-4-2

Electrostatic Discharge Immunity (Performance

criterion C)

IEC 61000-4-3

Radiated RF Electromagnetic Field Immunity

(Performance Criterion A)

5

IEC 61000-4-4

Electrical Fast Transient / Burst Immunity (Perf.

Criterion C)

IEC 61000-4-5

Power Line Surge Immunity (Performance Criterion

A)

IEC 61000-4-6

Conducted RF Immunity (Performance Criterion A)

IEC 61000-411

Voltage Dips, Short Interruptions and Voltage

Variations Immunity (Performance Criterion A / C 6)

FCC EMC

Compliance

Emissions comply with the Class B Limits of FCC Code of Federal

Regulations 47, Part 15, Subpart B

1,3

.

EC

Declaration

of

Conformity Low Voltage

Compliance was demonstrated to the following specification as listed

in the Official Journal of the European Communities:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1:2001

Safety requirements for electrical equipment for

measurement, control and laboratory use.

U.S.

Nationally

Recognized

Testing

Laboratory

Listing

UL 61010-1 2

nd

ed.

Safety requirements for electrical equipment for

measurement, control, and laboratory use.

ISA-82:02.01

Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Canadian

Certification

CAN/CSA C22.2

No. 61010-1-04

Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Additional

Compliance

IEC 610101:2001

Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Equipment

Type

Test and measuring

Safety

Class

Class I equipment (as defined in IEC 60950-1:2001)

1

Compliance demonstrated using high-quality shielded interface cables shorter

than 3 meters.

7.2

Certifications and Compliances

DC3100 37

7 Appendix

3

Emissions, which exceed the levels required by these standards, may occur when

this equipment is connected to a test object.

5

MOD IN port capped at IEC 61000-4-3 test.

6

Performance Criterion C was reached at additional test levels according to EN

61326-1:2006 table 2

DC310038

7 Appendix

Line Voltage (Ext. Power Supply)

100 ... 240VAC (-10%, +10%)

Line Frequency (Ext. Power Supply)

50 ... 60Hz

Power Consumption (max)

20VA

Supply mains over Voltage

Category II (Cat II)

Input Voltage (DC3100 chassis)

12VDC

Operating Temperature

1)

0 ... +40 °C

Storage Temperature

-40 ... +70 °C

Relative Humidity

Max. 80% up to 31 °C

decreasing to 50% at 40 °C

Pollution Degree (indoor use only)

2

Operation Altitude

< 3000 m

Warm-up Time for rated Accuracy

10 min

Weight

< 1 kg

Dimensions (W x H x D) without

operating elements

160 x 80 x 150 mm³

Dimensions (W x H x D) with

operating elements

160 x 80 x 168 mm³

LED Current Range

0 ... 1000mA

Modulation Frequency Range

(Internal Modulation Mode only)

10 ... 100MHz

Modulation

(Internal Modulation Mode only)

Sine Wave

Modulation Depth

1)

(Internal Modulation Mode only)

0 ... 100%

Trigger Output

(Internal Modulation Mode only)

Sine Wave

Modulation Frequency Range

(External Control Mode only)

0 ...100kHz

(Sine Wave)

Modulation

(External Control Mode only)

Arbitrary

Trigger Input

(External Control Mode only)

max. 10V

1V corresponds to 100mA

DC3100-365

Nominal Wavelength

365nm

Maximum Current

700mA

Cut-off Frequency

90MHz

DC3100-405

Nominal Wavelength

405nm

Maximum Current

1000mA

Cut-off Frequency

95MHz

7.3

7.3.1

Technical Data

Common Data

1)

non condensing

7.3.2

Technical Data

All technical data are valid at 23 ± 5°C and 45 ± 15% rel. humidity)

DC3100 39

7 Appendix

DC3100-470

Nominal Wavelength

470nm

Maximum Current

1000mA

Cut-off Frequency

80MHz

DC3100-630

Nominal Wavelength

630nm

Maximum Current

1000mA

Cut-off Frequency

70MHz

1)

depending on LED type and modulation frequency

Microscope Mounting are available for the following microscopes:

· Olympus BX/IX

· Leica DMI

· Nikon F Mount

· Zeiss Axioskop

7.3.3

7.3.3.1

LED for Frequency Domain FLIM

The DC3100 is a LED driver for high brightness (HB) LEDs, which can apply a sine

wave modulation to the LED in the range from 10MHz to 100MHz. A HB LED has an

internal capacity, which limits the maximum frequency. This cut-off frequency is an

intrinsic property of LED. In the following sub chapters the phase difference between

reference output and the emitted light signal are shown.

LED @ 365nm

The DC3100-365 contains the UV LED NCSU033A from Nichia. The LED emits a

wavelength at 365nm and an optical power of up to 310mW.

Warning

This DC3100 head radiates intense UV light during operation. Precautions

must be taken to prevent looking directly at the UV light with unaided eyes.

Do not look directly into the UV light or look through the optical system

during operation of the device. This can be harmful to the eyes even for brief

periods due to the intense UV light.

If there is the possibility to receive a reflection of the UV light, UV light

protective glasses has to be used to prevent that UV light can catch one's

eye directly.

If viewing the UV light is necessary, use UV light protective glasses to avoid

damage by the UV light.

The 10dB cut-off frequency of the DC3100-365 is 90MHz. The maximum current is

limited to 700mA.

DC310040

Figure 37 Phase Difference of DC3100-365

7 Appendix

7.3.3.2

LED @ 405nm

The DC3100-405 contains the UV LED LZ1-00UA05 from LedEngin. The LED

emits a wavelength at 405nm and an optical power of up to 1000mW.

The 10dB cut-off frequency of the DC3100-405 is 95MHz. The maximum current is

1000mA.

Figure 38 Phase Difference of DC3100-405

DC3100 41

7 Appendix

7.3.3.3

LED @ 470nm

The DC3100-470 contains the blue LED LZ1-00B205 from LedEngin. The LED

emits a wavelength at 470nm and an optical power of up to 60lm.

The 10dB cut-off frequency of the DC3100-470 is 80MHz. The maximum current is

1000mA.

7.3.3.4

Figure 39 Phase Difference of DC3100-470

LED @ 630nm

The DC3100-630 contains the red LED LZ1-00R105 from LedEngin. The LED

emits a wavelength at 630nm and an optical power of up to 100lm.

The 10dB cut-off frequency of the DC3100-630 is 70MHz. The maximum current is

1000mA.

DC310042

Figure 40 Phase Difference of DC3100-630

7 Appendix

DC3100 43

7 Appendix

Memory Size

Memory Type

Purpose

Volatility

User Data

Method of

Clearing

8kByte

SRAM

(ATmega1281):

· Program SRAM

yes

no

Power down

128kByte

FLASH

(ATmega1281):

· Program Code

no

no

Cannot be

cleared by

user

4kbyte

EEPROM

(ATmega1281):

· User settings

no

yes

Can be

overwritten

with the

device

1kByte

EEPROM (FTDI

FT232R):

· VID, PID

· IO Configuration

no

no

Cannot be

cleared by

user

256Byte

SRAM (FTDI

FT232R):

· USB receive

buffer

yes

no

Power down

128Byte

SRAM (FTDI

FT232R):

· USB transmit

buffer

yes

no

Power down

7.4

Letter of Volatility

Manufacturer: Thorlabs GmbH

Model Number: DC3100

DC310044

7 Appendix

7.5

Thorlabs 'End of Life' Policy (WEEE)

As required by the WEEE (Waste Electrical and Electronic Equipment Directive) of

the European Community and the corresponding national laws, Thorlabs offers all

end users in the EC the possibility to return "end of life" units without incurring

disposal charges.

This offer is valid for Thorlabs electrical and electronic equipment

· sold after August 13

· marked correspondingly with the crossed out 'wheelie bin' logo (see fig. 1)

· sold to a company or institute within the EC

· currently owned by a company or institute within the EC

· still complete, not disassembled and not contaminated

As the WEEE directive applies to self contained operational electrical and electronic

products, this 'end of life' take back service does not refer to other Thorlabs

products, such as

· pure OEM products, that means assemblies to be built into a unit by the user

(e. g. OEM laser driver cards)

· components

· mechanics and optics

· left over parts of units disassembled by the user (PCB's, housings etc.).

th

2005

7.5.1

7.5.2

If you wish to return a Thorlabs unit for waste recovery, please contact Thorlabs or

your nearest dealer for further information.

Waste Treatment on your own Responsibility

If you do not return an 'end of life' unit to Thorlabs, you must hand it to a company

specialized in waste recovery. Do not dispose of the unit in a litter bin or at a public

waste disposal site.

Ecological Background

It is well known that WEEE pollutes the environment by releasing toxic products

during decomposition. The aim of the European RoHS directive is to reduce the

content of toxic substances in electronic products in the future.

The intent of the WEEE directive is to enforce the recycling of WEEE. A controlled

recycling of end of live products will thereby avoid negative impacts on the

environment.

Figure 41 Crossed out "Wheelie Bin" Symbol

DC3100 45

7 Appendix

7.6

7.7

List of Acronyms

The following acronyms and abbreviations are used in this manual:

AC Alternating Current

AGND Analog Ground

DC Direct Current

DGND Digital Ground

DLL Dynamic Link Library

FCC Federal Communications Commission

FLIM Fluorescence Lifetime Imaging

GUI Graphical User Interface

IEC International Electrotechnical Commission

LCD Liquid Crystal Display

LED Light Emitting Diode

PC Personal Computer

PCB Printed Circuit Board

USB Universal Serial Bus

List of Figures

Figure 1 Connecting the LED Head

Figure 2 Display and Operating Elements on the Front Panel

Figure 3 Operating Elements on the Rear Panel

Figure 4 Operating Elements on the LED Head

Figure 5 Welcome Screen

Figure 6 Main Menu

Figure 7 Constant Current Mode

Figure 8 Internal Modulation Mode

Figure 9 Internal Modulation - Current Adjustment

Figure 10 Internal Modulation - Frequency Adjustment

Figure 11 Internal Modulation - Modulation Depth Adjustment

Figure 12 Definition of the Parameter Current and Modulation Depth

Figure 13 External Control Mode

Figure 14 Main Menu

Figure 15 LED Current Limit Setting

Figure 16 LED Maximum Current

Figure 17 LED Maximum Frequency

Figure 18 LCD Backlight Brightness Setting

Figure 19 About Panel

Figure 20 Autorun Menu

Figure 21 Request for Administrator Privileges

Figure 22 The Windows Logo Test

Figure 23 The Start Screen

Figure 24 The Device Selection Dialog

Figure 25 Constant Current Mode

Figure 26 The Internal Modulation Mode

Figure 27 The External Control Mode

Figure 28 User Limit

Figure 29 User Limit Dialog

Figure 30 LED Configuration Menu

Figure 31 LED Maximum Limit

DC310046

Figure 32 LED Maximum Frequency

Figure 33 No VISA Engine installed

Figure 34 Error Message

Figure 35 Time Domain FLIM

Figure 36 Frequency Domain FLIM

Figure 37 Phase Difference of DC3100-365

Figure 38 Phase Difference of DC3100-405

Figure 39 Phase Difference of DC3100-470

Figure 40 Phase Difference of DC3100-630

Figure 41 Crossed out "Wheelie Bin" Symbol

7 Appendix

7.8

Copyright

Thorlabs GmbH has taken every possible care in preparing this User Manual. We

however assume no liability for the content, completeness or quality of the

information contained therein. The content of this manual is regularly updated and

adapted to reflect the current status of the software. We furthermore do not

guarantee that this product will function without errors, even if the stated

specifications are adhered to.

Under no circumstances can we guarantee that a particular objective can be

achieved with the purchase of this product.

Insofar as permitted under statutory regulations, we assume no liability for direct

damage, indirect damage or damages suffered by third parties resulting from the

purchase of this product. In no event shall any liability exceed the purchase price of

the product.

Please note that the content of this User Manual is neither part of any previous or

existing agreement, promise, representation or legal relationship, nor an alteration

or amendment thereof. All obligations of Thorlabs GmbH result from the respective

contract of sale, which also includes the complete and exclusively applicable

warranty regulations. These contractual warranty regulations are neither extended

nor limited by the information contained in this User Manual. Should you require

further information on this product, or encounter specific problems that are not

discussed in sufficient detail in the User Manual, please contact your local Thorlabs

dealer or system installer.

All rights reserved. This manual may not be reproduced, transmitted or translated to

another language, either as a whole or in parts, without the prior written permission

of Thorlabs GmbH.

Status: 2009

© Thorlabs GmbH. All rights reserved.

DC3100 47

7 Appendix

7.9

Addresses

Our Company is represented by several distributors and sales offices throughout the

world.

Europe

Thorlabs GmbH

Hans-Boeckler-Str. 6

D-85221 Dachau / Munich

Germany

Sales and Support

Phone: +49 (0) 81 31 / 5956-0

Fax: +49 (0) 81 31 / 5956-99

Email: europe@thorlabs.com

Web: www.thorlabs.com

USA

Thorlabs, Inc.

435 Route 206 North

Newton, NJ 07860

USA

Sales and Support

Phone: 1-973-579-7227

Fax: 1-973-300-3600

Email: sales@thorlabs.com

Email: techsupport@thorlabs.com

Web: www.thorlabs.com

Japan

Thorlabs, Inc.

1th Floor, Higashi Ikebukuro Q Building

2-32-2, Higashi Ikebukuro, Toshima-ku

Tokyo 170-0013

Japan

Sales and Support

Phone: +81-3-5979-8889

Fax: +81-3-5979-7285

Email: sales@thorlabs.jp

Web: www.thorlabs.jp

Our company is also represented by several distributors and sales offices

throughout the world.

Please call our hotline, send an Email to ask for your nearest distributor or just visit

our homepage http://www.thorlabs.com

DC310048

Index

Index

- A -

About 17

Accessories 7

Addresses 48

Application Note 34

- C -

Certifications 37

Changing a LED 25

Command List 27

Compliance 37

Computer Interface 26

Configuration 15

Configuring a new LED 24

Connecting a Computer 26

Connecting a Devive 21

Constant Current Mode 12, 21

Copyright 47

Current Limit 15

- D -

Driver Installation 20

- E -

End of Life Policy 45

External Control Mode 14, 22

- F -

Firmware Upgrade 32

Frequenca Domain FLIM 35

Front Panel 9

- G -

General Information 4

- I -

Internal Modulation Mode 12, 22

- L -

LED @ 365nm 40

LED @ 405nm 41

LED @ 470nm 42

LED @ 630nm 42

LED Configuration 15

LED Head 10

LEtter of Volatility 44

- M -

Maintainance 32

Maximum Current 15

Maximum Frequency 15

Menus 11

- N -

Navigation 11

- O -

Operating Elements 9, 10

Operation Modes 12

Ordering Codes 7

- P -

Preparation 8

- R -

Rear Panel 10

Remote Application 19

- S -

Safety 4

Settings 15

Software Installation 17

Status Reporting 31

System Settings 16

- T -

Technical Data 39

Time Domain FLIM 34

Troubleshooting 32

49DC3100

Index

- U -

Unpacking 8

User Limit 15

User Limit Current 23

Utility Software 26

- V -

VISA Installation 18

- W -

Warranty 36

WEEE 45

DC310050

Loading...

Loading...