Scientific-Grade Digital

Camera User Guide

For Models 8051, 4070, 1501, and 340

Scientific Grade Digital Camera

Table of Contents

Chapter 1 Warning Symbol Definitions ............................................................................................. 1

Chapter 2 Safety................................................................................................................................... 2

2.1. Precautions ................................................................................................................... 2

2.2. Product Care ................................................................................................................. 3

2.2.1. Service .................................................................................................................................. 3

2.2.2. Accessories and Customization ............................................................................................ 3

Chapter 3 Description ......................................................................................................................... 4

3.1. Introduction ................................................................................................................... 4

3.2. Receiving and Unpacking ............................................................................................ 4

3.2.1. Important Information Regarding the Power Supply ............................................................. 4

3.3. Supplied Equipment ..................................................................................................... 5

3.3.1. Optional Items ....................................................................................................................... 5

Chapter 4 Setup & Installation ........................................................................................................... 6

4.1. Pre-Installation .............................................................................................................. 6

4.1.1. Gigabit Ethernet (GigE) System ............................................................................................ 6

4.1.2. Camera Link System ............................................................................................................. 6

4.1.3. USB 3.0 System .................................................................................................................... 6

4.2. Installing the Software.................................................................................................. 7

4.2.1. Load the Distribution Disk ..................................................................................................... 7

4.2.2. Driver Selection ..................................................................................................................... 7

4.2.3. Installing 3rd Party Software Applications ............................................................................ 10

4.3. Connecting the Camera .............................................................................................. 11

4.3.1. Configuring your Gigabit Ethernet adaptor for best performance ....................................... 13

4.3.2. Multiple Camera Operation ................................................................................................. 15

4.4. Optical and Mechanical Mounting Considerations .................................................. 16

4.4.1. Using a C-Mount Lens ........................................................................................................ 16

4.4.2. Mounting the Camera .......................................................................................................... 16

4.4.3. Using the Camera with a Cage System .............................................................................. 17

4.4.4. Compatible Adapters for the Camera ................................................................................. 17

4.5. Optical Front End ........................................................................................................ 18

4.5.1. Description of Components ................................................................................................. 19

4.6. Optical Front End Procedures ................................................................................... 20

4.6.1. Removing the C-mount Lock Ring Assembly ..................................................................... 20

4.6.2. Filter Removal and Replacement Procedure ...................................................................... 21

4.6.3. Re-assembly of the C-mount Lock Ring and Flange Focus Adjustment ............................ 22

4.7. Auxiliary Connector .................................................................................................... 23

4.7.1. Pin Descriptions .................................................................................................................. 23

4.7.2. Signal Descriptions ............................................................................................................. 23

4.7.3. Auxiliary I/O Cable Requirements ....................................................................................... 24

Chapter 5 Operation .......................................................................................................................... 25

5.1. Starting the Camera .................................................................................................... 25

5.2. Camera Timing Diagrams ........................................................................................... 26

Chapter 6 8051M Specifications ...................................................................................................... 28

Scientific Grade Digital Camera

6.1. CCD Specifications ..................................................................................................... 28

6.2. Responsivity ............................................................................................................... 28

6.3. Imaging Specifications ............................................................................................... 28

6.4. Example Frame Rates ................................................................................................ 29

Chapter 7 8051C Specifications ....................................................................................................... 30

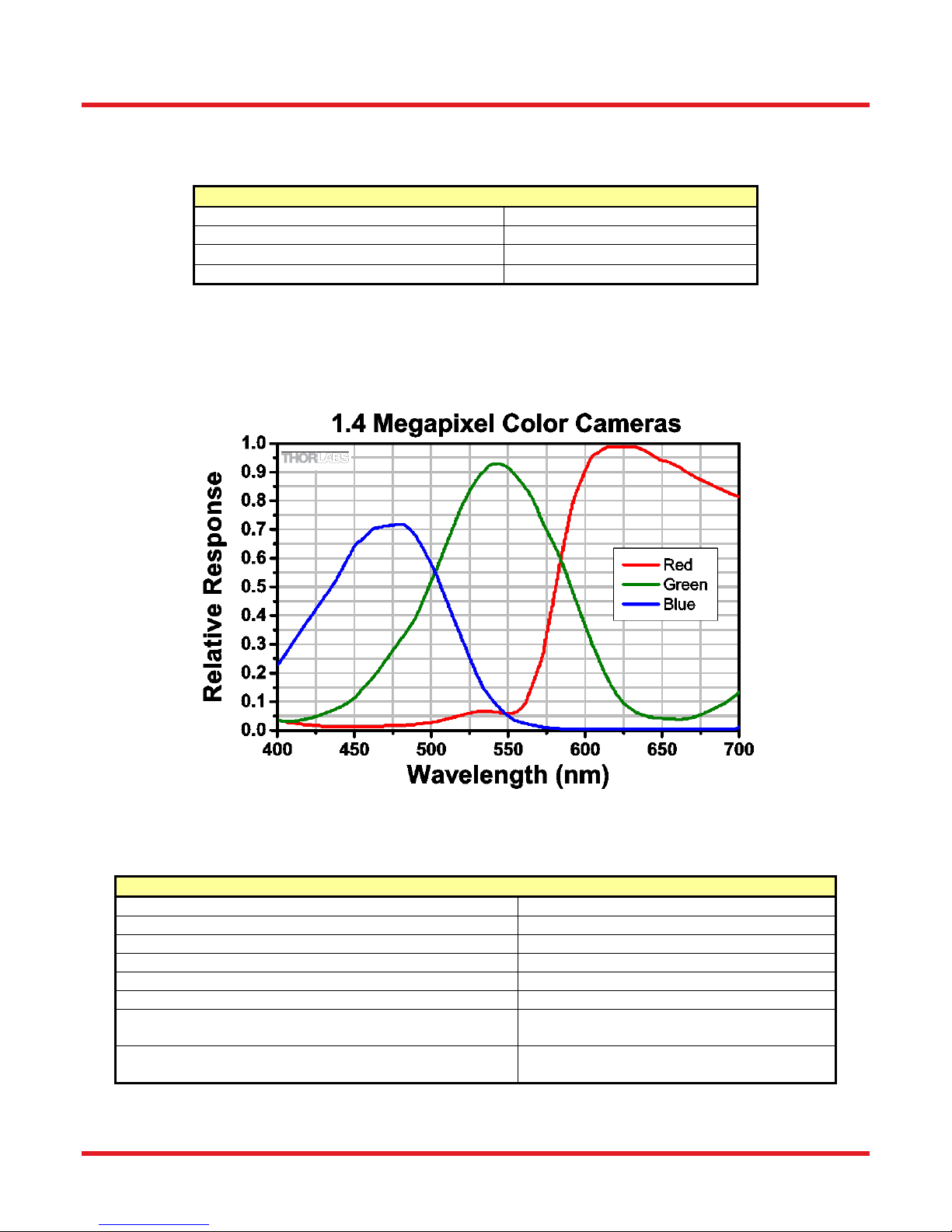

7.1. Color CCD Specifications .......................................................................................... 30

7.2. Responsivity ............................................................................................................... 30

7.3. Imaging Specifications ............................................................................................... 30

7.4. Example Frame Rates ................................................................................................ 31

Chapter 8 4070M Specifications ...................................................................................................... 32

8.1. CCD Specifications ..................................................................................................... 32

8.2. Responsivity ............................................................................................................... 32

8.3. Imaging Specifications ............................................................................................... 32

8.4. Example Frame Rates ................................................................................................ 33

Chapter 9 4070C Specifications ....................................................................................................... 34

9.1. Color CCD Specifications .......................................................................................... 34

9.2. Responsivity ............................................................................................................... 34

9.3. Imaging Specifications ............................................................................................... 34

9.4. Example Frame Rates ................................................................................................ 35

Chapter 10 340M Specifications ........................................................................................................ 36

10.1. CCD Specifications ..................................................................................................... 36

10.2. Responsivity ............................................................................................................... 36

10.3. Imaging Specifications ............................................................................................... 37

10.4. Example Frame Rates ................................................................................................ 37

Chapter 11 1501M Specifications ...................................................................................................... 38

11.1. CCD Specifications ..................................................................................................... 38

11.2. Responsivity ............................................................................................................... 38

11.3. Imaging Specifications ............................................................................................... 39

11.4. Example Frame Rates ................................................................................................ 39

Chapter 12 1501C Specifications ....................................................................................................... 40

12.1. Color CCD Specifications .......................................................................................... 40

12.2. Responsivity ............................................................................................................... 40

12.3. Imaging Specifications ............................................................................................... 40

12.4. Example Frame Rates ................................................................................................ 41

Chapter 13 IR Blocking Filter ............................................................................................................. 42

Scientific Grade Digital Camera

Chapter 14 Mechanical Drawings ...................................................................................................... 43

14.1. 8051/4070/1501-GE-TE ................................................................................................ 43

14.2. 8051/4070/1501/340-GE............................................................................................... 43

14.3. 8051/4070/1501-CL-TE ................................................................................................ 44

14.4. 8051/4070/1501/340-CL ............................................................................................... 44

14.5. 8051/4070/1501-USB-TE ............................................................................................. 45

14.6. 8051/4070/1501/340-USB ............................................................................................ 45

14.7. Switching Power Supply ............................................................................................ 46

Chapter 15 Troubleshooting ............................................................................................................... 47

15.1. Interface ...................................................................................................................... 47

15.1.1. GigE Status Indicators ........................................................................................................ 47

15.2. Optical ......................................................................................................................... 48

15.3. Operational .................................................................................................................. 48

15.4. Software ...................................................................................................................... 49

Chapter 16 Maintenance ..................................................................................................................... 50

16.1. Cleaning Guidelines ................................................................................................... 50

16.1.1. Cleaning the Lens of Optical Assembly .............................................................................. 50

16.1.2. Standard (Non-Cooled) Camera Precautions ..................................................................... 50

16.1.3. TE-Cooled Camera Precautions ......................................................................................... 50

16.1.4. Cleaning the Infrared Filter (Standard and TE-Cooled Cameras) ...................................... 51

Chapter 17 Regulatory ........................................................................................................................ 52

17.1. Waste Treatment is Your Own Responsibility .......................................................... 52

17.2. Ecological Background .............................................................................................. 52

17.3. Certifications and Compliance – CE Declaration of Conformity ............................. 53

17.4. FCC Statement ............................................................................................................ 57

17.5. Auxiliary I/O Cable Requirements ............................................................................. 57

Chapter 18 Warranty ............................................................................................................................ 58

18.1. General Product Warranty ......................................................................................... 58

18.2. Specific Warranties .................................................................................................... 58

18.2.1. Optomechanics ................................................................................................................... 58

18.2.2. Optical Tables and Breadboards ........................................................................................ 58

18.2.3. Lasers and Imaging Systems .............................................................................................. 58

18.2.4. Opto-Electronics, Control Electronics, Optics, and Nano-Positioning Product Lines ......... 58

18.2.5. Non-Warranty Repairs ........................................................................................................ 58

18.2.6. Warranty Exclusions ........................................................................................................... 58

Chapter 19 Thorlabs Worldwide Contacts ........................................................................................ 59

Scientific Grade Digital Camera Chapter 1: Warning Symbol Definitions

Symbol

Description

Direct Current

Alternating Current

Both Direct and Alternating Current

Earth Ground Terminal

Protective Conductor Terminal

Frame or Chassis Terminal

Equipotentiality

On (Supply)

Off (Supply)

In Position of a Bi-Stable Push Control

Out Position of a Bi-Stable Push Control

Caution: Risk of Electric Shock

Caution: Hot Surface

Caution: Risk of Danger

Warning: Laser Radiation

Caution: Spinning Blades May Cause Harm

Chapter 1 Warning Symbol Definitions

Below is a list of warning symbols you may encounter in this manual or on your device.

ITN000081-D02 Rev. R 07/23/2018 Page 1

Scientific Grade Digital Camera Chapter 2: Safety

Chapter 2 Safety

2.1. Precautions

Please read the instruction manual carefully before operating your Digital Camera. All statements regarding safety

and technical specifications will only apply when the unit is operated correctly.

Refer to this User’s Guide whenever the following symbols are encountered on the Digital Camera and Power

Supply.

ATTENTION

This symbol indicates that additional information is available in this user guide.

This equipment is intended for laboratory use only and is not certified for medical applications,

including but not limited to, life support situations.

Transportation and delivery may cause the Digital Camera to be warm or cool upon receipt.

Please wait for the device to reach room temperature before attempting to operate.

Mobile telephones, cellular phones, or other radio transmitters are not to be used within the

range of three meters of this unit since the electromagnetic field intensity may exceed the maximum

allowed disturbance values according to EN50082-1.

CAUTION

Check the supply voltage of the system BEFORE plugging in the power supply. Make sure the

included power cord is the correct type for the service you are connecting to AND connected to a

properly grounded power outlet (100 – 240 VAC; 50 – 60 Hz).

There are NO user accessible fuses in this Digital Camera or the included External Power

Supply.

Do not open the Digital Camera or the External Power Supply. Doing so is dangerous and

could result in damage to the unit or death to the user.

WARRANTY WARNING

Do not open the Digital Camera or the external power supply. There are no user serviceable parts in

this product. Opening the device will void your warranty. Any modification or servicing of this

system by unqualified personnel renders Thorlabs free of any liability. This device can only be

returned when packed into the complete original packaging, including all foam packing inserts. If

necessary, ask for replacement packaging. Please contact Thorlabs’ Technical Support at

techsupport@thorlabs.com and a member of our team will be happy to assist you.

ITN000081-D02 Rev. R 07/23/2018 Page 2

Scientific Grade Digital Camera Chapter 2: Safety

2.2. Product Care

Handle the system with care during transportation and unpacking. Banging or dropping the system can damage

the unit or lower system performance. If the system is mishandled during shipment, the optical components may

become misaligned, which could lead to a decrease in the image quality. If this happens, the system will need to

be realigned by qualified personnel. To ensure proper care and operation of your Scientific-Grade Digital Camera,

please follow the handling instructions below.

Do not store or operate in a damp, closed environment.

Do not use solvents on or near the equipment.

Keep away from dust, dirt, and air-borne pollutants (including cigarette smoke). The system is not

designed for outdoor use. Protect the equipment from rain, snow, and humidity.

Do not expose to mechanical or thermal extremes. Protect the equipment from rapid variation in

temperature.

Handle all connectors with care. Do not use unnecessary force as this may damage the connectors.

Clean using a soft, lint free cloth. Use of isopropyl alcohol is permitted, however do not immerse in any

liquid or solvent.

Clean any accessible optical surfaces with an appropriate optics grade tissue or cloth.

2.2.1. Service

Only trained and approved Thorlabs’ personnel should service the system. Please contact Thorlabs’ Technical

Support at techsupport@thorlabs.com and a member of our team will be happy to assist you.

2.2.2. Accessories and Customization

Although the system is easily adapted for custom interfaces, to achieve the listed specifications, this system

should only be used with accessories provided by Thorlabs. Any modification or servicing by unqualified

personnel renders the warranty null and void, leaving Thorlabs free of liability. Please contact Thorlabs for

questions on customization.

ITN000081-D02 Rev. R 07/23/2018 Page 3

Scientific Grade Digital Camera Chapter 3: Description

Chapter 3 Description

3.1. Introduction

Our scientific-grade camera series consists of four monochrome configurations (M) distinguished by their

interface method (Gigabit Ethernet (-GE), Camera Link (-CL), or USB 3.0 (-USB)) and whether or not a

thermoelectric cooler is used (-TE for 8051, 4070, and 1501 only). Color sensors are available in the 8051C,

4070C, and 1501C models as well.

The model format is nnnnM/C-I/O-TE where:

nnnn is the base sensor number, M/C denotes Monochrome vs. Color, I/O denotes the interface, and TE denotes

TE cooling (blank for non-cooled). Ex. 4070C-GE, 8051M-CL-TE …

The cameras are bundled with the full complement of Thorlabs Scientific Imaging (TSI) software. For end-users,

the ThorCam software application provides full control of the camera through an intuitive user interface, and it

allows the user to acquire, pan, zoom, analyze, and save images and metadata.

For developers, TSI also offers a software developer’s kit, which includes a comprehensive API (Application

Programming Interface) to streamline the integration of any TSI camera into your system. After software

installation, the SDK can be found in the Local Disk\Program Files\Thorlabs Imaging\documentation folder. This is

the same for 32 and 64 bit distributions.

This manual is a functional overview of the camera, and it is meant to be a companion to the Camera Quick Start

Guide (ITN000081-D03), ThorCam User Manual (ITN000493-D02), and the TSI Application Programming

Interface Guide (ITN000195-D02). All support documentation is available at www.thorlabs.com as well as in

the Local Disk\Program Files\Thorlabs folder following the installation of ThorCam.

3.2. Receiving and Unpacking

Your camera was thoroughly tested and carefully packed at the factory. Once the camera shipment is accepted

for delivery, the carrier assumes full responsibility for its safe arrival. Should you receive your shipment with any

damage—concealed or apparent—please contact the carrier at once. The carrier will instruct you on how to

initiate a damage claim. If a visual inspection reveals damage upon receipt, it must be noted on the freight bill or

express receipt and the notation signed by the carrier’s agent. Failure to do so can result in the ca rrier refusing to

honor the claim.

To return your camera to TSI for service, you must first contact your local Thorlabs office or distributor and

request a Return Material Authorization (RMA). Returns will not be accepted without an RMA. See Chapter 11,

titled “Warranty Information” for details.

3.2.1. Important Information Regarding the Power Supply

CAUTION

The switching power supply that is provided by TSI for use with this camera operates automatically

over the following range of voltages (100 – 240 VAC; 50 – 60 Hz). Make sure the included power cord

is the correct type for the service you are connecting to AND connected to a properly grounded

power outlet.

Dangerous voltage exists within the power supply. Do not tamper with or open the supply under any

circumstances. Doing so may expose lethal voltage to personnel and will void the warranty.

ITN000081-D02 Rev. R 07/23/2018 Page 4

Scientific Grade Digital Camera Chapter 3: Description

Supplied Equipment

Available Interface Options

Gigabit Ethernet

Includes Intel® Pro/1000 CT PCIe Desktop Adapter and 14'

CAT 5e Cable

Camera Link Interface

Includes VisionLink F4 Camera Link Board

and two 5 m Camera Link cables

USB 3.0 Interface

and one 3 m USB-SS Cable

Accessories

Regulated switch-mode Power Supply with 72”

cord (Supplied line cord appropriate for user’s

country or region)

Spanner Wrench

Lens cap (and IR filter removal tool)

Included Software

Thorlabs Camera Software and SDK

(Available for download from www.thorlabs.com)

GigE Interface Configuration

Camera Link Configuration

USB Configuration

3.3. Supplied Equipment

The following is a list of equipment that may be supplied with your camera, depending on your order

configuration. Figure 1 below shows the different available configurations.

3.3.1. Optional Items

Figure 1 Available Camera Configurations

Auxiliary I/O Patch cable – The auxiliary connector on the camera allows the user to access optional

camera control and internal status signals (see section 4.7).

Order Thorlabs 8050-CAB1 and TSI-IOBOB or TSI-IOBOB2.

ITN000081-D02 Rev. R 07/23/2018 Page 5

Scientific Grade Digital Camera Chapter 4: Setup & Installation

Chapter 4 Setup & Installation

4.1. Pre-Installation

Before proceeding with installation of hardware or software, please identify whether your camera interface is

Camera Link, Gigabit Ethernet (GigE), or USB 3.0.

4.1.1. Gigabit Ethernet (GigE) System

If you purchased a Gigabit Ethernet camera, an Intel PCIe adapter card is provided for use on desktop computer

systems. Although the system will work with other adapters (including laptop GigE adapters), it is recommended

that this card be used for optimal performance on all desktop installations. See

Recommended Installation Sequence

1. Power down the computer.

2. Taking necessary precautions, install the Intel PCIe GigE adapter.

3. Turn on the computer and accept Windows driver recommendations for the newly installed hardware.

4. Run the software installer – follow the steps outlined in the next section, including driver installation.

5. Connect the camera, then apply power and run ThorCam application software.

4.1.2. Camera Link System

Camera Link cameras include an EDT PCIe interface card. Other Camera Link interface cards are not supported.

Recommended Installation Sequence

1. Run the software installer, follow the steps outlined in the next section.

2. Power down the computer.

3. Taking necessary precautions, install the EDT PCIe Camera Link interface card.

4. Turn on the computer.

5. Accept the driver installation recommendations for the newly installed hardware.

6. Connect the camera, then apply power and run ThorCam application software.

4.1.3. USB 3.0 System

If you purchased a USB 3.0 camera, the USB 3.0 “SS” inputs on your PC are supported. USB 2.0 inputs are not

supported at this time. For higher bandwidth applications a number of third-party PCIe USB3.0 cards have been

tested with our camera. Please refer to the Troubleshooting section under Operation for more information.

Recommended Installation Sequence

1. Run the software installer, follow the steps outlined in the next section.

2. Connect the camera, then apply power.

3. Your PC should discover the new USB device and install the necessary Drivers.

4. Run the ThorCam application software.

ITN000081-D02 Rev. R 07/23/2018 Page 6

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.2. Installing the Software

The Thorlabs camera software runs on Windows 7, 8.1, and 10 operating systems ONLY.

4.2.1. Load the Distribution Disk

A CD or DVD disk can be found with the camera. Load the disk into the CD/DVD drive on the computer you wish

to operate the camera and software.

The installation software will automatically detect whether your system is 32-bit or 64-bit. Loading and detection

could take a minute or two, depending on your drive speed.

4.2.2. Driver Selection

Your camera requires a driver to be installed on your computer. After the welcome screen, acceptance of the

license agreement, and entering your user information, you will be presented with a choice of drivers. Select the

driver that matches the interface on your camera; USB, Gigabit Ethernet, or Camera Link. If you have more than

one camera and with different interfaces, select all that apply. If you’re unsure, select them all.

Select a driver for installation by clicking on the dropdown and selecting either of the two choices; “This feature

will be installed on local hard drive,” or “This feature, and all subfeatures, will be installed on local hard drive.”

There are no subfeatures, so both choices do the same thing.

If you do not wish to install the driver, select “This feature will not be available”

Once a driver is selected, the red X will be replaced with a hard drive icon as shown in the USB selection below.

ITN000081-D02 Rev. R 07/23/2018 Page 7

Scientific Grade Digital Camera Chapter 4: Setup & Installation

Click Next to proceed with the driver installation. Depending on your PC’s configuration and the drivers you

selected, you might encounter the additional Windows security dialogs below. Be sure to click “install” to complete

the operation, otherwise the installer will “roll back” and exit.

Camera Link Driver Installation (if selected). Click “Install”

USB Driver Installation (if selected). Click “Install”

ITN000081-D02 Rev. R 07/23/2018 Page 8

Scientific Grade Digital Camera Chapter 4: Setup & Installation

Gigabit Ethernet Driver Installation (if selected). Click “Install”

Once setup is complete, you may now proceed to the next section that will describe how to connect and power on

your camera. When the camera is connected and powered up, you can navigate to the ThorCam Imaging

Software as shown below

“Start”→”All Programs”→”ThorIabs” →”Scientific Imaging ”→”ThorCam”

Figure 2 Thorlabs Installed Items

ITN000081-D02 Rev. R 07/23/2018 Page 9

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.2.3. Installing 3rd Party Software Applications

After installation of Thorlabs components is complete, you have access to interfaces for select 3rd-party image

analysis packages you may already have installed on your computer, such as MATLAB™.

3rd-party application interfaces in the following directory:

C:\Program Files\Thorlabs\Scientific Imaging\Scientific Camera Support

Important: Do not develop 3rd-party solutions in this directory, as they will be deleted if you update your

ThorCam software.

To use the MATLAB and LabVIEW interfaces, extract from the Zip file and place in the appropriate directory on

your system.

Special note for users of Micro-manager software: support for Thorlabs scientific cameras is included when you

run versions 1.4.14 and later. If you wish to download or update your Micro-Manager software, please visit

https://micro-manager.org/wiki/Micro-Manager_Open_Source_Microscopy_Software

Before using your camera within Micro-Manager, first make sure that your camera is properly installed and

powered-ON. You may run a session of ThorCam to confirm that the camera, software and drivers are properly

installed. Then, shut down your ThorCam session and start a Micro-manager session.

ITN000081-D02 Rev. R 07/23/2018 Page 10

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.3. Connecting the Camera

To connect the camera, follow the steps and refer to the diagram below.

1. With the power supply turned off, connect the power supply to the “POWER” connector on the back of the

camera. The connector on the camera is labeled “POWER”.

2. Connect the auxiliary cable (optional, ordered separately) into the port on the camera labeled as “AUX”.

3. Connect the interface cable, either a Gigabit Ethernet (GigE) or a Camera Link, based on your camera

model.

- If you are utilizing a Cat5e Gigabit Ethernet (GigE) Cable: Connect the Ethernet cable to the

port on the camera labeled “GigE”. Connect the other end into the port of the Intel® Gigabit

CT PCI Express desktop adapter, installed in the computer. For a description of the status

LEDs on the camera’s GigE port, please see section 5.1.

Figure 3 Diagram of Connectors on GigE configuration

ITN000081-D02 Rev. R 07/23/2018 Page 11

Scientific Grade Digital Camera Chapter 4: Setup & Installation

- If you are utilizing a Camera Link Cable: Connect one end of the Camera Link cable into the

port labeled “CL 0”. Connect the other end into the port labeled “0” of the EDT VisionLink F4

Camera Link card, installed in the computer. Connect the second Camera Link cable to the

port labeled “CL 1”, and the other end into the port labeled “1” on the Camera Link card. (Port

0 is the default port, while port 1 is used for multi-tap operation.) See Figure 4.

- If you are utilizing a USB 3.0 Cable: Connect one end of the USB 3.0 cable into the camera

port labeled “USB”. Connect the other end into a USB 3.0 “SS” port on your computer. See

Figure 3. For a description of the status LEDs on the USB rear panel, please see

section 5.1.

Figure 4 Diagram of Connectors on CL configuration (Left) and USB 3.0 (Right)

ITN000081-D02 Rev. R 07/23/2018 Page 12

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.3.1. Configuring your Gigabit Ethernet adaptor for best performance

The Gigabit Ethernet NIC supplied with your camera is essential for the highest data rate performance. Please

use it if at all possible. Ensure that the camera is connected directly to the NIC, not through a switch and shared

with other devices unless necessary, to avoid competition for bandwidth.

Regardless of NIC used, you can configure your NIC for best performance possible by launching the Gigabit

Ethernet Driver installation tool from the Start Menu illustrated in Figure 2. When launched, the following diagram

will appear

Note that USB3 Vision is not installed, even if you have a Thorlabs USB 3.0 camera, as Thorlabs cameras use a

separate USB 3.0 driver. Do not install the USB3 Vision driver.

Click “Advanced…” and select the NIC for your camera from the pulldown in the window shown below. The

Thorlabs NIC is the Intel® Gigabit CT Desktop Adaptor. Depending on your NIC, one or more of the selections

shown will be accessible. Select

eBUS Universal Pro for Ethernet

Jumbo Packet

Maximum value for Receive buffers

Maximum value for Transmit buffer

It should not be necessary to adjust any other parameters.

It is also not necessary to use these settings for your other NICs not associated with the camera (such as the NIC

for your local network).

ITN000081-D02 Rev. R 07/23/2018 Page 13

Scientific Grade Digital Camera Chapter 4: Setup & Installation

ITN000081-D02 Rev. R 07/23/2018 Page 14

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.3.2. Multiple Camera Operation

If multiple camera operation is required, it is recommended that a Gigabit Ethernet switch topology be setup, as

shown below. When multiple cameras are connected and powered on, they will be visible in the Image Detector

dropdown of Hardware Setup panel. Both control and display revert to the camera that is selected from the

dropdown menu.

Figure 5 Gigabit Ethernet Switch Topology Setup for Multiple Cameras

ITN000081-D02 Rev. R 07/23/2018 Page 15

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.4. Optical and Mechanical Mounting Considerations

4.4.1. Using a C-Mount Lens

For the best results, the use of a C-Mount lens that matches the optical format of the 4/3” (22mm) imaging area is

recommended. For more information on Thorlabs C-Mount lenses, please visit www.thorlabs.com

C-mount lenses are specified with a flange focal distance of 17.5 mm. However, there can be considerable

variation in the flange focal distance among commercially available lenses.

To accommodate the variation in commercially available lenses, the camera has an adjustable flange focal range

of ± 1.5 mm. A procedure to set the flange focal distance is described in the next section.

Figure 6 Camera Shown with C-Mount Lens (not supplied) Using the C-Mount Adapter

4.4.2. Mounting the Camera

On most commercial microscopes, the use of a suitable adapter is recommended in order to match the optical

format of the 4/3” (22mm) imaging area. Please note that some commercial 1x adapters may underfill the imaging

area, leading to vignetting of the image.

The adjustable flange focus may also be used to parfocalize a microscope, as described in the next section.

Figure 7 Camera Shown on Microscope Using C-Mount Adapter

ITN000081-D02 Rev. R 07/23/2018 Page 16

Scientific Grade Digital Camera Chapter 4: Setup & Installation

Four 1/4”-20 tapped holes are provided, one on each side of the housing. These may be used with tripods, or

other optical mounting devices. These 1/4”-20 tapped holes are compatible with Thorlabs 1/2” posts. For more

information on Thorlabs Ø1/2" posts, please visit www.thorlabs.com.

Figure 8 Arrows Indicate Two of the Four 1/4”-20 Tapped Holes on Camera

4.4.3. Using the Camera with a Cage System

The cameras have 4-40 tapped holes for compatibility with Thorlabs 60 mm Cage system.

For more information on Thorlabs 60 mm Cage system components, please visit www.thorlabs.com.

Figure 9 Camera Shown as Part of a 60 mm Thorlabs Cage System

4.4.4. Compatible Adapters for the Camera

The cameras standard C-mount (1.000"-32) threading may be adapted with thread-to-thread adapters. For

example, Thorlabs SM1A9 or SM1A9TS adapter with external c-mount threads and internal SM1 1.035"-40

threading may be used with Thorlabs 1" lens tubes.

Figure 10 Thorlabs SM1A9 Adapter with External C-Mount Threads and Internal SM1 Threads

ITN000081-D02 Rev. R 07/23/2018 Page 17

Scientific Grade Digital Camera Chapter 4: Setup & Installation

IR Blocking

Filter

Filter Retaining

Ring

Lens Cap

(and Filter Removal Tool)

C-Mount Adapter

and Lock Nut

4.5. Optical Front End

The images below show the components located on the front end of the camera.

Figure 11 Exploded View of Optical and Mechanical Components

Figure 12 Optical and Mechanical Sub-Assemblies

Figure 13 Reverse View Showing IR Filter and Associated Components

ITN000081-D02 Rev. R 07/23/2018 Page 18

Scientific Grade Digital Camera Chapter 4: Setup & Installation

Figure 14 Reverse View of IR Filter Sub-Assembly. Shows the Lens Cap Used as a Tool for

Installing and Removing the Filters

4.5.1. Description of Components

C-Mount Adapter: Allows the camera to be optically coupled with standard C-mount optics, including

lenses and microscope adapters.

Lock Nut: Used to secure the c-mount adapter to the main camera body, while allowing adjustability of

the back focus distance. A wrench is provided to loosen and tighten the lock nut (See Section 4.6)

Lens Cap: A protective cover that should be installed during shipment and also when the camera is not in

use.

Note Dual use of lens cap as a tool for removing/installing the filter retaining ring) - the lens cap has two

metallic prongs/inserts which allows it to also be reversed and used as a tool for removing or installing the

filter retaining ring. The metal prongs are sized to fit into the two holes in the filter retaining ring, which

can then be screwed into the back of the c-mount adapter ring. A groove in the back of the c-mount

adapter ring accommodates the IR-block as an insert.

IR Blocking Filter: Unless otherwise requested, an IR filter is typically installed and held in place by a

filter retaining ring. Silicon CCD imagers have responsivity that extends beyond the VIS range, into the

NIR spectral range. The IR filter is intended to cut off at higher wavelengths. Users may, at their

discretion, remove the IR filter in NIR imaging applications - or replace it with a custom optical filter with

the same nominal dimensions. Note: maximum filter thickness = 0.050” (1.270 mm). See Chapter 13 for

more information

ITN000081-D02 Rev. R 07/23/2018 Page 19

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.6. Optical Front End Procedures

4.6.1. Removing the C-mount Lock Ring Assembly

Removal of the C-mount lock lens ring is not required for normal operation. It is required if users wish to remove,

replace, or clean the installed filter. Follow the steps below to remove the C-mount ring assembly.

Note: Re-adjustment of the lens back-focus will be required after re-assembly. See the “Back Focus Adjustment”

in Section 4.6.3.

1. Loosen the lens mount lock ring with the supplied wrench.

Figure 15 Loosening the C-mount and IR-Block Filter Assembly from Camera

2. Unscrew the C-mount lock ring assembly from the camera body and remove the lock ring from the Cmount adapter.

Figure 16 Removing the C-mount and IR-Block Filter Assembly from Camera Body

ITN000081-D02 Rev. R 07/23/2018 Page 20

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.6.2. Filter Removal and Replacement Procedure

TSI cameras are typically provided with an IR-blocking filter installed. The CCD has responsivity into the Near

Infrared (for more details refer to specifications sections near the end of this document).

If near-infrared sensitivity is desired, the IR-blocking filter should not be installed.

The optical front end is designed to accommodate standard 1” filters. Users may, at their discretion, operate the

camera without any glass installed or install custom filters in front of the CCD.

Note: If no glass is installed, dust and debris may collect on the CCD faceplate. Please use every precaution to

avoid contact with the CCD faceplate and to keep the camera securely mounted to the optical system or capped

when not in use.

Removal of the Filter from the C-mount Adapter

1. Hold the lens cap with the pins sticking upward in one hand.

2. Lower the C-mount adapter on to the pins with the other hand.

3. Hold the lens cap and rotate the C-mount adapter counter-clockwise and then remove the lens ring.

4. Remove the filter from the filter ring with lens tissue and store in a protective container.

5. Replace the lens ring on to the C-mount adapter and screw on clockwise.

6. Remove the lens cap.

7. To re-install the filter, reverse the above procedure.

8. Screw the C-mount adapter back into the locking ring and screw both back onto the camera.

Figure 17 Removal of the IR-Blocking Filter from the Assembly

ITN000081-D02 Rev. R 07/23/2018 Page 21

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.6.3. Re-assembly of the C-mount Lock Ring and Flange Focus Adjustment

1. Install C-mount ring adapter into the front side of the camera as shown in Figure 18.

Do NOT tighten or lock.

2. Install a C-Mount lens (not provided) onto the camera.

3. Ensure that the lens is screwed all the way into the C-mount adapter but with the tapered lock-nut ring

loosened so that the lens and the adaptor can be adjusted together.

4. Power up the camera and launch ThorCam software.

5. Set gain, black level and exposure to settings that result in a live image.

6. Set Camera Lens Focus to ∞ infinity.

7. Adjust Camera Lens Iris to obtain a viewable image.

8. Point the camera to an object far away which is at infinity.

9. Adjust C-mount lens ring on the camera until image is at best focus.

10. When image is in sharp focus, lens “Back Focus” is properly set.

11. Tighten the Tapered Lock Ring using the Focusing wrench to secure setting

Figure 18 Re-assembly of the C-Mount Assembly onto Camera

Note: To obtain parfocality on a microscope installation, ensure that the camera port of the microscope is

screwed into the lens adapter but with the tapered lock ring loosened. Move the assembly until the camera image

and the images viewed through the oculars are simultaneously in focus. Tighten the Tapered Lock Ring using the

focusing wrench to secure the setting.

ITN000081-D02 Rev. R 07/23/2018 Page 22

Scientific Grade Digital Camera Chapter 4: Setup & Installation

Pin Descriptions

Pin #

Signal

1

Reserved

2

Reserved

3

Reserved

4

STROBE_OUT

5

TRIGGER_IN

6

LVAL_OUT

7

TRIGGER_OUT

8

LVDS_TRIGGER_IN-N

(Differential Pair with Pin 9)

9

LVDS_TRIGGER_IN-P

(Differential Pair with Pin 8)

10

Ground

11

Reserved

12

FVAL_OUT

4.7. Auxiliary Connector

The auxiliary connector on the camera allows the user to access optional camera control and internal status

signals.

4.7.1. Pin Descriptions

Figure 19 Illustration of the Auxiliary Connector on the

Rear of the Camera

4.7.2. Signal Descriptions

Pins 1, 2, 3, 11: Reserved.

Pin 4, STROBE_OUT (Output): STROBE_OUT is a TTL output that is high during the actual sensor

exposure time when in continuous, overlapped exposure mode. STROBE_OUT is typically used to

synchronize an external flash lamp or other device with the camera.

Pin 5 TRIGGER_IN (Input): TRIGGER_IN is a TTL input used to trigger exposures on the transition from

the HIGH state to LOW state.

Pin 6, LVAL_OUT (Output): LVAL_OUT refers to “Line Valid Output.” It is an active-HIGH TTL signal

and is asserted during the valid pixel period on each line. It returns low during the inter-line period

between each line and during the inter-frame period between each frame.

Pin 7, TRIGGER_OUT (Output): TRIGGER_OUT is a 6μs positive pulse that is asserted when using the

various external trigger input options; TRIGGER_IN, LVDS_TRIGGER_IN, or the Camera Link CC1

signal. The CC1 signal, driven from the host, is one of the software-controlled trigger signals for the

camera. The CC1 signal is brought out of the camera as TRIGGER_OUT at the High-to-Low transition to

allow triggering of other devices. The same applies to the other external triggers.

Pins 8, 9 LVDS_TRIGGER_IN_N and LVDS_TRIGGER_IN_P (Input): LVDS_TRIGGER_IN is an LVDS

(low voltage differential signal) input used to trigger exposures on the transition from the HIGH state to

LOW state. Suffixes “N” and “”P identify the negative and positive inputs respectively of the LVDS signal.

Pin 10, GND: This is the electrical ground for the camera signals.

Pin 12, FVAL_OUT (Output): FVAL_OUT refers to “Frame Valid Output” and is a TTL output that is

HIGH during active readout lines. FVAL_OUT remains high throughout the active readout and returns low

between frames.

ITN000081-D02 Rev. R 07/23/2018 Page 23

Scientific Grade Digital Camera Chapter 4: Setup & Installation

4.7.3. Auxiliary I/O Cable Requirements

An auxiliary I/O cable may be fabricated in order to connect to the AUX I/O port of the camera. This cable is

application specific in all cases due to varying lengths and functions that are used. If an Auxiliary I/O cable is to

be used with this camera it must be constructed using shielded cabling in order for the camera to adhere to CE

and FCC compliance. The mating connector for the rear panel connector is HIROSE HR10-10P-12P (73).

A 10 foot long (3m) auxiliary I/O cable and interconnect break-out board are available from Thorlabs allowing

access to some of the I/O control functions (Trigger_In, Trigger_Out, LVAL_Out, FVAL_Out, and Strobe_Out).

Order the “8050-CAB1” and the “TSI-IOBOB”, as well as the required number and style of SMA patch cables for

your specific application. Order the CA28xx SMA-to-BNC series (i.e. CA2848 for 48” cable) or the CA29xx SMAto-SMA series (CA2948 for 48” cable) as needed.

ITN000081-D02 Rev. R 07/23/2018 Page 24

Scientific Grade Digital Camera Chapter 5: Operation

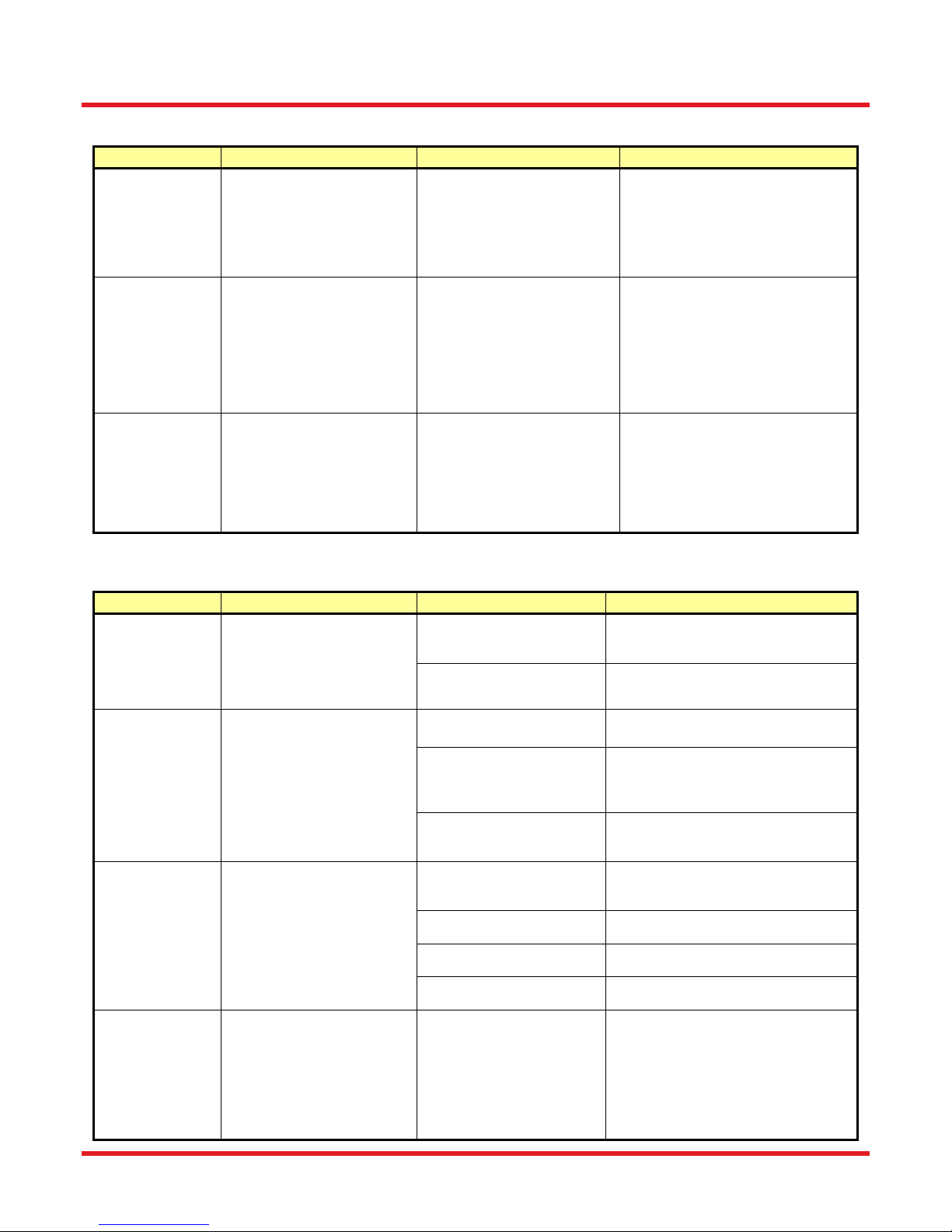

LED

Color

If LED is Flashing

If LED is On

If LED is Off

Green

The Link is Operational, but

the Camera is Currently not

Sending Data

Normal (Indicates

that the Camera is

Sending Data)

There is no Ethernet

Connection

Amber

Normal Operation

Not Applicable

Either there is no Ethernet

Connection, or The

Camera is Plugged into a

10/100 Mbps Network

LED

If LED is Flashing

If LED is On

If LED is Off

Link

Not Applicable

Blue: Connected to

a USB 3.0 Port

Green: Connected

to a USB 2.0 Port

Amber: Camera has

internal USB

problem

There is no USB

Connection or,

Camera is powered off

Status

Green: Camera is sending

frames

Green: Camera is

paused

Camera is powered off

Chapter 5 Operation

The 8051/4070/1501/340-series cameras can be operated using the ThorCam and ThorImageLS (Offered

separately by Thorlabs Imaging Systems). For more details on using ThorCam and ThorImageLS features, please

consult the ThorCam and ThorImageLS User Manuals.

5.1. Starting the Camera

With the camera software installed and the camera connected as instructed, turn on the camera power supply. A

green indicator on the supply indicates it is operating.

In the case of Gigabit Ethernet cameras, both the Yellow and Green indicators should light up on the camera’s

Gigabit Ethernet connector several seconds after power is applied. It is normal for the Yellow indicator to stay on

continuously, and for the Green indicator to flash when the camera is sending data. The table below details the

conditions represented by the status indicators.

In the case of USB 3.0 cameras, the Status LED should light up solid Green several seconds after power is

applied, and start flashing whenever the camera is generating frames. The Link LED will briefly be solid white

when powering up the camera, and is active whenever the camera is connected to, and enumerated by a USB

port. The table below details the conditions represented by the status indicators.

ITN000081-D02 Rev. R 07/23/2018 Page 25

Scientific Grade Digital Camera Chapter 5: Operation

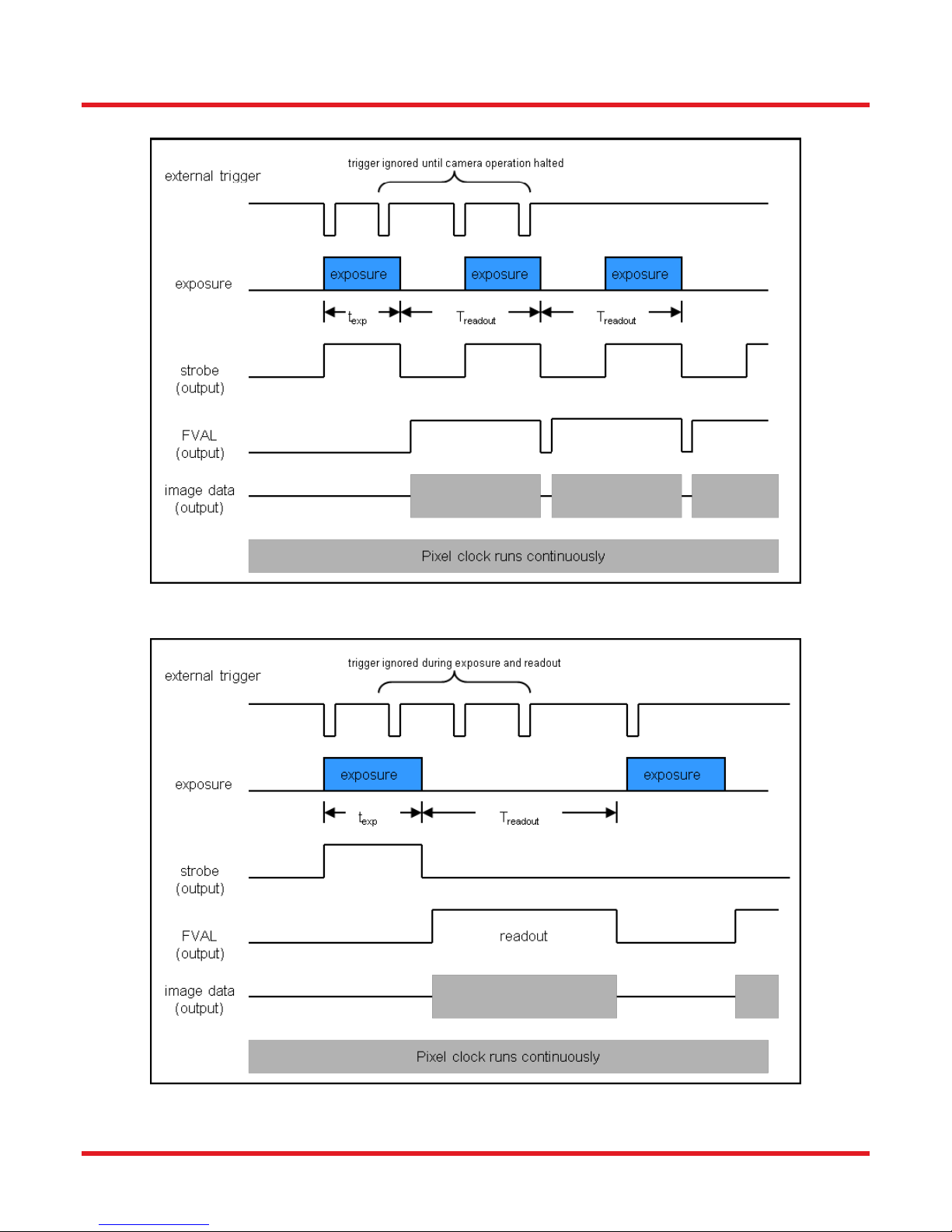

5.2. Camera Timing Diagrams

Figure 20 Timing Diagram – Standard, Frames per Trigger = 0 or > 1

Figure 21 Timing Diagram – Standard, Frames per Trigger = 1

ITN000081-D02 Rev. R 07/23/2018 Page 26

Scientific Grade Digital Camera Chapter 5: Operation

Figure 22 Timing Diagram – Bulb Mode

ITN000081-D02 Rev. R 07/23/2018 Page 27

Scientific Grade Digital Camera Chapter 6: 8051M Specifications

CCD Specifications

CCD Manufacturer and Item Number

On Semi KAI-08051-AXA-JD-BA

Number of Active Pixels

3296 (H) x 2472 (V)

Pixel Size

5.5 m X 5.5 m

Optical Format

4/3” Format (22mm diagonal)

Imaging Specifications

Exposure Time

0 to 1000 seconds in 1 ms increments*

CCD Pixel Clock Speed

20 MHz or 40 MHz

ADC Resolution

-GE 14 bits (1-Tap) / 12 bits (2-Tap)

-CL 14 bits (1-Tap, 2-Tap, 4-Tap)

-USB 14 bits (1-Tap, 2-Tap, 4-Tap)

ADC Gain

0 to 1023 counts

Optical Black Clamp

0 to 1023 counts

Vertical Hardware Binning

1 to 10

Region of Interest

1 x 1 pixel to 3296 x 2472 pixels,

rectangular

Read Noise

< 10 e- @ 20 MHz

Chapter 6 8051M Specifications

6.1. CCD Specifications

6.2. Responsivity

An IR-blocking filter is typically installed. This filter may be removed if NIR responsivity is desired. See Chapter 13

for specifications related to the IR-blocking filter.

6.3. Imaging Specifications

*Exposure time increment varies with operating mode.

ITN000081-D02 Rev. R 07/23/2018 Page 28

Scientific Grade Digital Camera Chapter 6: 8051M Specifications

Example Frame

Rates @

1 ms Exposure Time

One Tap

Two Tap

Four Tap

20 MHz

40 MHz

20

MHz

40

MHz

20

MHz

40

MHz

Full Sensor (3296 x 2472)

2.3 fps

4.5 fps

4.4 fps

8.5 fps

8.8 fps

17.1 fps

Full Sensor, Bin by 2

(1648 x 1236)

4.4 fps

8.5 fps

8.3 fps

15.7 fps

16.6 fps

31.2 fps

Full Sensor, Bin by 10

(329 x 247)

17.0 fps

29.9 fps

29.0 fps

47.1 fps

56.8 fps

92.3 fps

6.4. Example Frame Rates

ITN000081-D02 Rev. R 07/23/2018 Page 29

Scientific Grade Digital Camera Chapter 7: 8051C Specifications

CCD Specifications

CCD Manufacturer and Item Number

On Semi KAI-08051-FXA-JD-BA

Number of Active Pixels

3296 (H) x 2472 (V)

Pixel Size

5.5 m X 5.5 m

Optical Format

4/3” Format (22mm diagonal)

Imaging Specifications

Exposure Time

0 to 1000 seconds in 1 ms increments*

CCD Pixel Clock Speed

20 MHz or 40 MHz

ADC Resolution

-GE 14 bits (1-Tap) / 12 bits (2-Tap)

-CL 14 bits (1-Tap, 2-Tap, 4-Tap)

-USB 14 bits (1-Tap, 2-Tap, 4-Tap)

ADC Gain

0 to 1023 counts

Optical Black Clamp

0 to 1023 counts

Vertical Hardware Binning

1 to 10

Region of Interest

1 x 1 pixel to 3296 x 2472 pixels,

rectangular

Read Noise

< 10 e- at 20 MHz

Chapter 7 8051C Specifications

7.1. Color CCD Specifications

7.2. Responsivity

An IR-blocking filter is typically installed. This filter may be removed if NIR responsivity is desired. See Chapter 13

for specifications related to the IR-blocking filter.

7.3. Imaging Specifications

*Exposure time increment varies with operating mode.

ITN000081-D02 Rev. R 07/23/2018 Page 30

Scientific Grade Digital Camera Chapter 7: 8051C Specifications

Example Frame

Rates @

1 ms Exposure Time

One Tap

Two Tap

Four Tap

20 MHz

40 MHz

20

MHz

40

MHz

20

MHz

40

MHz

Full Sensor (3296 x 2472)

2.3 fps

4.5 fps

4.4 fps

8.5 fps

8.8 fps

17.1 fps

Full Sensor, Bin by 2

(1648 x 1236)

4.4 fps

8.5 fps

8.3 fps

15.7 fps

16.6 fps

31.2 fps

Full Sensor, Bin by 10

(329 x 247)

17.0 fps

29.9 fps

29.0 fps

47.1 fps

56.8 fps

92.3 fps

7.4. Example Frame Rates

ITN000081-D02 Rev. R 07/23/2018 Page 31

Scientific Grade Digital Camera Chapter 8: 4070M Specifications

CCD Specifications

CCD Manufacturer and Item Number

On Semi KAI-04070M

Number of Active Pixels

2048 (H) x 2048 (V)

Pixel Size

7.4 m X 7.4 m

Optical Format

4/3” Format (21.4mm diagonal)

Imaging Specifications

Exposure Time

0 to 1000 seconds in 1 ms increments*

CCD Pixel Clock Speed

20 MHz or 40 MHz

ADC Resolution

-GE 14 bits (1-Tap) / 12 bits (2-Tap)

-CL 14 bits (1-Tap, 2-Tap, 4-Tap)

-USB 14 bits (1-Tap, 2-Tap, 4-Tap)

ADC Gain

0 to 1023 counts

Optical Black Clamp

0 to 1023 counts

Vertical Hardware Binning

1 to 10

Region of Interest

1 x 1 pixel to 2048 x 2048 pixels,

rectangular

Read Noise

< 12 e- at 20 MHz

Chapter 8 4070M Specifications

8.1. CCD Specifications

8.2. Responsivity

An IR-blocking filter is typically installed. This filter may be removed if NIR responsivity is desired. See Chapter 13

for specifications related to the IR-blocking filter.

8.3. Imaging Specifications

*Exposure time increment varies with operating mode.

ITN000081-D02 Rev. R 07/23/2018 Page 32

Scientific Grade Digital Camera Chapter 8: 4070M Specifications

Example Frame Rates

@

1 ms Exposure Time

One Tap

Two Tap

Four Tap

20 MHz

40 MHz

20 MHz

40 MHz

20 MHz

40 MHz

Full Sensor (2048 x 2048)

4.1 fps

7.7 fps

7.4 fps

13 fps

14.8 fps

25.8 fps

Full Sensor, Bin by 2

(1024 x 1024)

7.5 fps

13.1 fps

12.8 fps

20.5 fps

25.3 fps

40.6 fps

Full Sensor, Bin by 10

(204 x 204)

21.6 fps

30.5 fps

30.0 fps

38.1 fps

58.8 fps

75.1 fps

8.4. Example Frame Rates

ITN000081-D02 Rev. R 07/23/2018 Page 33

Scientific Grade Digital Camera Chapter 9: 4070C Specifications

CCD Specifications

CCD Manufacturer and Item Number

On Semi KAI-04070-FBA

Number of Active Pixels

2048 (H) x 2048 (V)

Pixel Size

7.4 m X 7.4 m

Optical Format

4/3” Format (21.4mm diagonal)

Imaging Specifications

Exposure Time

0 to 1000 seconds in 1 ms increments*

CCD Pixel Clock Speed

20 MHz or 40 MHz

ADC Resolution

-GE 14 bits (1-Tap) / 12 bits (2-Tap)

-CL 14 bits (1-Tap, 2-Tap, 4-Tap)

-USB 14 bits (1-Tap, 2-Tap, 4-Tap)

ADC Gain

0 to 1023 counts

Optical Black Clamp

0 to 1023 counts

Vertical Hardware Binning

1 to 10

Region of Interest

1 x 1 pixel to 2048 x 2048 pixels,

rectangular

Read Noise

< 12 e- at 20 MHz

Chapter 9 4070C Specifications

9.1. Color CCD Specifications

9.2. Responsivity

An IR-blocking filter is typically installed. This filter may be removed if NIR responsivity is desired. See Chapter 13

for specifications related to the IR-blocking filter.

9.3. Imaging Specifications

*Exposure time increment varies with operating mode.

ITN000081-D02 Rev. R 07/23/2018 Page 34

Scientific Grade Digital Camera Chapter 9: 4070C Specifications

Example Frame Rates

@

1 ms Exposure Time

One Tap

Two Tap

Four Tap

20 MHz

40 MHz

20 MHz

40 MHz

20 MHz

40 MHz

Full Sensor (2048 x 2048)

4.1 fps

7.7 fps

7.4 fps

13 fps

14.8 fps

25.8 fps

Full Sensor, Bin by 2

(1024 x 1024)

7.5 fps

13.1 fps

12.8 fps

20.5 fps

25.3 fps

40.6 fps

Full Sensor, Bin by 10

(204 x 204)

21.6 fps

30.5 fps

30.0 fps

38.1 fps

58.8 fps

75.1 fps

9.4. Example Frame Rates

ITN000081-D02 Rev. R 07/23/2018 Page 35

Scientific Grade Digital Camera Chapter 10: 340M Specifications

CCD Specifications

CCD Manufacturer and Item Number

On Semi/Truesense KAI-0340

Number of Active Pixels

640 (H) x 480 (V)

Pixel Size

7.4 m X 7.4 m

Optical Format

1/3” Format (5.92 mm diagonal)

Chapter 10 340M Specifications

10.1. CCD Specifications

10.2. Responsivity

An IR-blocking filter is typically installed. This filter may be removed if NIR responsivity is desired. See Chapter 13

for specifications related to the IR-blocking filter.

ITN000081-D02 Rev. R 07/23/2018 Page 36

Scientific Grade Digital Camera Chapter 10: 340M Specifications

Imaging Specifications

Exposure Time

0 to 1000 seconds in 1 ms increments*

CCD Pixel Clock Speed

20 MHz or 40 MHz

ADC Resolution

-GE 14 bits (1-Tap) / 12 bits (2-Tap)

-CL 14 bits (1-Tap, 2-Tap)

-USB 14 bits (1-Tap, 2-Tap)

ADC Gain

0 to 1023 counts

Optical Black Clamp

0 to 1023 counts

Vertical Hardware Binning

1 to 24

Region of Interest

1 x 1 pixel to 640 x 480 pixels, rectangular

Read Noise

< 15 e- at 20 MHz

Example Frame Rates @

1 ms Exposure Time

One Tap

Two Tap

20 MHz

40 MHz

20 MHz

40 MHz

Full Sensor (640 x 480)

57.0 fps

112.3 fps

103.3 fps

200.7 fps

Full Sensor, Bin by 2 (320 x 240)

110.1 fps

213.5 fps

196.8 fps

372.4 fps

Full Sensor, Bin by 10 (64 x 48)

429.0 fps

764.7 fps

712.9 fps

1185.4 fps

10.3. Imaging Specifications

*Exposure time increment varies with operating mode.

10.4. Example Frame Rates

ITN000081-D02 Rev. R 07/23/2018 Page 37

Scientific Grade Digital Camera Chapter 11: 1501M Specifications

CCD Specifications

CCD Manufacturer and Item Number

Sony ICX285AL

Number of Active Pixels

1392 (H) x 1040 (V)

Pixel Size

6.45 m X 6.45 m

Optical Format

2/3” Format (11mm diagonal)

Chapter 11 1501M Specifications

11.1. CCD Specifications

11.2. Responsivity

An IR-blocking filter is typically installed. This filter may be removed and the camera operated in “NIR Boost”

mode if NIR responsivity is desired. NIR Boost mode applies only to monochrome 1501M series cameras. See

Chapter 13 for specifications related to the IR-blocking filter.

ITN000081-D02 Rev. R 07/23/2018 Page 38

Scientific Grade Digital Camera Chapter 11: 1501M Specifications

Imaging Specifications

Exposure Time

0 to 1000 seconds in 1 ms increments*

CCD Pixel Clock Speed

20 MHz or 40 MHz

ADC Resolution

14 bits (All I/O Types)

ADC Gain

0 to 1023 counts

Optical Black Clamp

0 to 1023 counts

Vertical Hardware Binning

1 to 24

Region of Interest

1 x 1 pixel to 1392 x 1040 pixels,

rectangular

Read Noise

< 6e- (-TE Cooled) / < 7e- (Non-cooled)

@ 20 MHz

Example Frame Rates @

1 ms Exposure Time

20 MHz

40 MHz

Full Sensor (1392 x 1040)

12 fps

23 fps

Full Sensor, Bin by 2 (696 x 520)

23 fps

41 fps

Full Sensor, Bin by 10 (139 x 104)

77 fps

112 fps

11.3. Imaging Specifications

*Exposure time increment varies with operating mode.

11.4. Example Frame Rates

ITN000081-D02 Rev. R 07/23/2018 Page 39

Scientific Grade Digital Camera Chapter 12: 1501C Specifications

CCD Specifications

CCD Manufacturer and Item Number

Sony ICX285AQ

Number of Active Pixels

1392 (H) x 1040 (V)

Pixel Size

6.45 m X 6.45 m

Optical Format

2/3” Format (11mm diagonal)

Imaging Specifications

Exposure Time

0 to 1000 seconds in 1 ms increments*

CCD Pixel Clock Speed

20 MHz or 40 MHz

ADC Resolution

14 bits (All I/O Types)

ADC Gain

0 to 1023 counts

Optical Black Clamp

0 to 1023 counts

Vertical Hardware Binning

1 to 24

Region of Interest

1 x 1 pixel to 1392 x 1040 pixels,

rectangular

Read Noise

< 6e- (-TE Cooled) / < 7e- (Non-cooled)

@ 20 MHz

Chapter 12 1501C Specifications

12.1. Color CCD Specifications

12.2. Responsivity

An IR-blocking filter is typically installed. This filter may be removed if NIR responsivity is desired. See Chapter 13

for specifications related to the IR-blocking filter.

12.3. Imaging Specifications

*Exposure time increment varies with operating mode.

ITN000081-D02 Rev. R 07/23/2018 Page 40

Scientific Grade Digital Camera Chapter 12: 1501C Specifications

Example Frame Rates @

1 ms Exposure Time

20 MHz

40 MHz

Full Sensor (1392 x 1040)

12 fps

23 fps

Full Sensor, Bin by 2 (696 x 520)

23 fps

41 fps

Full Sensor, Bin by 10 (139 x 104)

77 fps

112 fps

12.4. Example Frame Rates

ITN000081-D02 Rev. R 07/23/2018 Page 41

Scientific Grade Digital Camera Chapter 13: IR Blocking Filter

Chapter 13 IR Blocking Filter

Figure 23 IR Blocking Filter Dimensions FESH0700

Figure 24 IR Blocking Filter Transmission Curve FESH0700

ITN000081-D02 Rev. R 07/23/2018 Page 42

Scientific Grade Digital Camera Chapter 14: Mechanical Drawings

Chapter 14 Mechanical Drawings

14.1. 8051/4070/1501-GE-TE

14.2. 8051/4070/1501/340-GE

ITN000081-D02 Rev. R 07/23/2018 Page 43

Scientific Grade Digital Camera Chapter 14: Mechanical Drawings

14.3. 8051/4070/1501-CL-TE

14.4. 8051/4070/1501/340-CL

ITN000081-D02 Rev. R 07/23/2018 Page 44

Scientific Grade Digital Camera Chapter 14: Mechanical Drawings

14.5. 8051/4070/1501-USB-TE

14.6. 8051/4070/1501/340-USB

ITN000081-D02 Rev. R 07/23/2018 Page 45

Scientific Grade Digital Camera Chapter 14: Mechanical Drawings

14.7. Switching Power Supply

ITN000081-D02 Rev. R 07/23/2018 Page 46

Scientific Grade Digital Camera Chapter 15: Troubleshooting

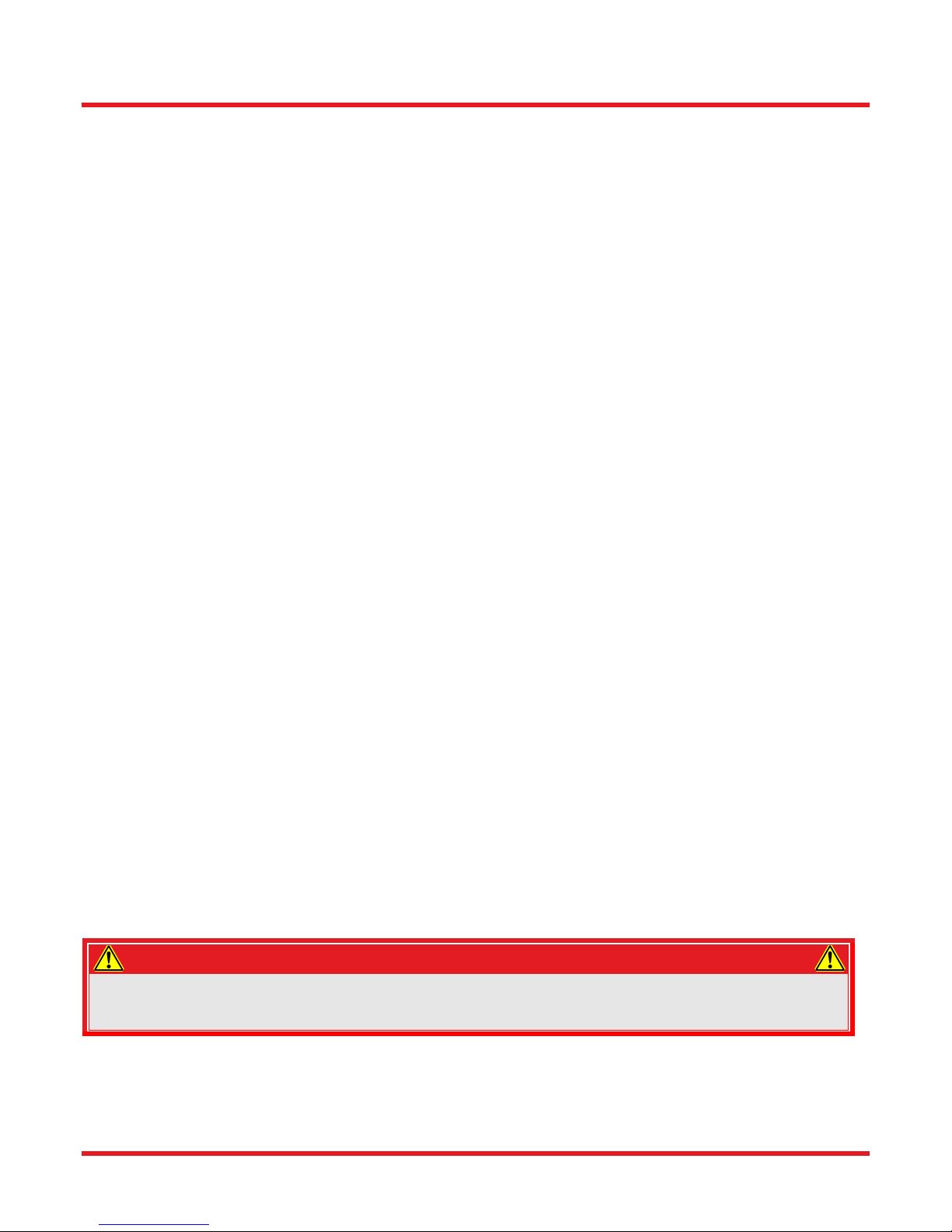

Problem

Symptoms

Possible Cause

Remedy

Green light on

power supply

does not come on

No power to

camera

Camera does not

acquire image

Software cannot

find a connected

camera

1. Power supply not

connected

1. Plug in power supply to outlet

2. Power strip not turned on

2. Turn on power to power strip

3. Bad power supply

3. Contact customer service for

power supply replacement

Software cannot

find a connected

camera

Software does not

display an image

Yellow status light

on Gig E

connector is off

(Gigabit Ethernet

Cameras only)

Software does not

display a

connected camera

1.No power to camera

1. Connect camera power

2. GigE cable not connected

or connected to 10/100 Mbps

network

2. Connect GigE cable to camera

and computer (see table below for

GigE status LED descriptions)

3. Camera Link Cable not

connected

3. Connect Camera Link Cable to

camera and computer

4. Camera Link Cable

connected to wrong port

4. See Section 4.3 for connection

details.

5. Camera has yet to

complete “enumeration”

5. Restart/refresh software after

camera has been powered on and

connected to host-PC for at least 30

seconds

6. USB 3.0 camera not

connected to USB 3.0 Port or

has not enumerated properly

5. See Section 5.1. Disconnect

USB3.0 cable and the reconnect.

First time connections to a PC may

take longer to enumerate and load

drivers.

LED

Color

If LED is On

If LED is

Flashing

If LED is Off

Green

The Link is Operational, but

the Camera is Currently not

Sending Data

Normal (Indicates

that the Camera is

Sending Data)

There is no Ethernet

Connection

Yellow

Normal Operation

Not Applicable

Either there is no Ethernet

Connection, or The

Camera is Plugged into a

10/100 Mbps Network

Green

LED

Yellow

LED

Chapter 15 Troubleshooting

15.1. Interface

15.1.1. GigE Status Indicators

ITN000081-D02 Rev. R 07/23/2018 Page 47

Figure 25 Detail of Gigabit Ethernet Port, showing the two status LEDs.

Scientific Grade Digital Camera Chapter 15: Troubleshooting

Problem

Symptoms

Possible Cause

Remedy

When using a

standard

C-mount lens

(not included),

image is not in

focus

Displayed image is

not in focus

1. Back focus of camera

needs to be set

1. See Section 4.6 on how to set

the camera’s back focus

Displayed image

has spots or

has debris in

image

Debris in displayed

image

1. IR filter has particulates on

it

1. Carefully clean IR filter. See

Section 4.6

“C-mount”

detaches from

camera after

removing from

Microscope

Threaded

“C-mount”

assembly remains

on microscope

1.Lock nut not sufficiently

tight

1. See Section 4.6

Problem

Symptoms

Possible Cause

Remedy

Camera

excessively

warm (too hot to

safely hold with

ungloved hand)

Camera is too hot

to hold with an

ungloved hand

Poor image quality

1. Camera is not properly

ventilated

1. Remove any obstructions or

provide adequate ventilation around

camera

2. Electronics failure

2. Contact customer service

Camera does

not feel warm at

all

Camera is not

warm or feels cold

to the touch

1. Camera not connected

1. Connect camera to power supply

2. TE cooler is not enabled

in software

(8051/4070/1501-xx-TE

models only)

2. Enable TE-cooling in software

(8051/4070/1501-xx-TE models only)

3. Camera was dropped or

otherwise subjected to

unusual mechanical force

3. Contact customer service

Imaging

Software “times

out” without

acquiring image

Imaging software

indicates timeout

No images

acquired – no

frame count

provided

1. Camera is not powered

1. See “Interface” Troubleshooting

above

2. Camera is not connected

to computer

2. See “Interface” Troubleshooting

above

3. Imaging software is not

configured to camera

3.Consult the ThorCam User Guide

4. Camera is not “armed”

and “started” properly

4. Refer to Chapter 5.1

Low Bandwidth

USB 3.0

connection

Excessive dropped

frames

Inconsistent

operation

1. Low bandwidth USB 3.0

port

2. USB 3.0 cable is too

long or poor quality

1. Use a PCIe high bandwidth

USB3.0 Card, such as:

Startech PEXUSB3S25

2. Use the 3m cable supplied with the

camera.

3. Use a 3m (max) cable with 26AWG

signal wires - or a 1m cable.

15.2. Optical

15.3. Operational

ITN000081-D02 Rev. R 07/23/2018 Page 48

Scientific Grade Digital Camera Chapter 15: Troubleshooting

Problem

Symptoms

Possible Cause

Remedy

Camera not

found

Error message, or

camera does not

show up in

Hardware

Connections

1. Power not on

1. Make sure power supply is switched

on

2. Not plugged in

2. Make sure the power and signal

cables are connected

3. Camera Link cable not

plugged into correct channel

in CL card

3. Make sure cable is plugged into

channel closest to the PC motherboard

4. Bad network cable for

GigE camera

4. Try a different set of cables if the

lights don't blink on GigE connector on

camera

5. Bad USB cable or

connection

5. Try a different cable. Refer to

Section 5.1 for information on the

camera’s status indicators.

Insufficient

illumination

Images are all black

1. Exposure time too low

1. Make sure that exposure time is

greater than 0; if the exposure is

already greater than 0, try increasing

the exposure time or gain gradually

2. No light going to the

camera

2. Make sure that the light source is

turned on, and that the aperture of the

lens (or other optics) is not shut.

15.4. Software

ITN000081-D02 Rev. R 07/23/2018 Page 49

Scientific Grade Digital Camera Chapter 16: Maintenance

Chapter 16 Maintenance

There are no user-serviceable parts inside the camera. Removing the rear cover of the camera without

expressed authorization from TSI will void the camera warranty.

TSI scientific grade cameras are manufactured in a clean environment. Before shipping, each camera is tested to

assure that it meets stringent specifications for cleanliness and quality.

16.1. Cleaning Guidelines

Frequent lens changes, especially without careful attention to contaminants, can allow debris to accumulate on

the infra-red blocking filter and lens surfaces. Therefore, TSI provides the following guidelines for cleaning those

components.

To minimize the need to clean the optical surfaces, do not remove the protective lens mount cap shipped with the

camera until you are ready to mount the camera to the optical system.

For an informative tutorial on “Handling and Cleaning Procedures for Optical Components” visit:

http://www.thorlabs.us/newgrouppage9.cfm?objectgroup_id=9025. The following guidelines,

specific to TSI cameras, are meant to be used in conjunction with the procedures described in the

tutorial.

16.1.1. Cleaning the Lens of Optical Assembly

Please follow the lens manufacturer’s recommendations for cleaning. TSI is not responsible for any damage

caused to a lens or optical assembly caused by customer cleaning or misuse.

To ensure optimum image quality with any TSI camera, do not remove the protective lens-mount cap until ready

to mount the camera on the application. If the camera is removed from the application, immediately replace the

cap. Doing so will keep dust and other contaminants from accumulating on the optical surfaces. In addition,

please note the following model-specific guidelines.

16.1.2. Standard (Non-Cooled) Camera Precautions

While the lens mounting ring and locking flange allow the user some lens back-focus adjustment, complete

removal of the ring will expose the CCD faceplate and will likely cause debris to accumulate on its surface.

Extreme care should be taken to avoid completely removing the lens mounting ring and exposing the

CCD faceplate unless absolutely necessary. Fingerprints or other evidence of contact with the CCD

faceplate may void the warranty.

16.1.3. TE-Cooled Camera Precautions

The TSI Thermoelectrically-cooled cameras contain the CCD in a sealed, gas-filled chamber having an antireflective glass window. Do not, under any circumstances, loosen or remove the inner glass window from a

cooled camera. Doing so will void the warranty. If it is suspected that the seal has been broken or if the window

breaks, call your local Thorlabs office or distributor. Do not apply power to the camera. Moisture will have been

introduced into the chamber, and cooling in the presence of moisture will cause condensation and frost on the

CCD, which can damage the entire cooling unit and/or CCD.

ITN000081-D02 Rev. R 07/23/2018 Page 50

Scientific Grade Digital Camera Chapter 16: Maintenance

16.1.4. Cleaning the Infrared Filter (Standard and TE-Cooled Cameras)

The infra-red filter is visible when the lens is removed, mounted inside the lens mounting ring. This filter blocks

invisible, near-infrared light from reaching the CCD sensor. This is desirable in most applications where the

camera is imaging in the visible spectrum.

What must I do before cleaning the infrared filter?

Do not remove the filter from the camera.

First, remove the lens and carefully examine the filter in a clean location under a strong, direct light. Try to

determine if the contaminants are a few dust particles, oily smudge (such as fingerprints) or both.

What if the contamination is only a few dust particles?

Use a CLEAN, DRY (preferably brand-new), camel hair lens cleaning brush (such as those used by

photographers) to gently wipe the particles off of the filter.

What if the contamination includes a smudge?

1. Remove the camera from the optical assembly and bring the camera to a clean, dry location

where it is safe to use flammable solvents (please see “Caution” below)

2. Carefully loosen the lens mount lock ring using the supplied TSI lock ring wrench.

3. Orient the camera so that the lens mount is pointing downward and carefully unscrew the lens

mounting ring and integral filter.

4. Place the camera face down on a clean, dry surface to prevent particles from accumulating on

the CCD faceplate.

5. Once the filter is removed, Use a CLEAN, DRY (preferably brand-new), camel hair lens cleaning

brush (such as those used by photographers) to gently wipe the particles off of the filter.

6. Re-examine the filter after removing the dust. If a smudge is still visible, proceed by dipping a

clean, lint-free cotton swab in ethyl or isopropyl alcohol. The swab should be saturated, but not

dripping.

7. Carefully draw the swab once across the surface, then rotate the swab 180 degrees to expose

the fresh surface and draw it across the filter surface again. Be careful not to pool alcohol on the

glass surface.

8. Re-examine once again and repeat the process once, if necessary.

If contamination continues to be a problem, please call Thorlabs for assistance.

CAUTION

Ethyl and isopropyl alcohols are highly flammable! Do not use near extreme heat, arcing electrical