THOMSON Omnidrive Series, Omnidrive ODM-005i, Omnidrive ODM-010, Omnidrive ODM-010i, Omnidrive ODM-005 Installation Manual

...Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Installation Manual for Models

ODM-005 and ODM-005i

ODM-010 and ODM-010i

ODM-020 and ODM-020i

Thomson Industries, Inc.

Port Washington, NY 11050

2 Channel Drive

OMNIDRIVE and OMNI LINK are trademarks of Thomson Industries, Inc.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Product Notice

Use of OMNIDRIVEs

OMNIDRIVEs are intended for use as transistorized electronic amplifiers powering servo motors in machinery. As

such, they must be part of a controlled system that includes a controlling device. They are not intended to independently control a motor. Instructions in the motor and control system manuals must be observed; this document does

not replace those instructions.

Unless specified otherwise, OMNIDRIVEs are intended for use in a normal industrial environment, installed in a

suitable electrical cabinet without exposure to excessive or corrosive moisture or abnormal ambient temperatures.

The exact operating conditions may be established by referring to the data for the drive. The connection and control

of drives in machinery is a skilled operation, disassembly or repair must not be attempted. In the event that a drive

fails to operate correctly, contact the place of purchase for return instructions.

Safety Notes

There are some possible hazards associated with the use of drives. The following precautions should be observed.

Specific Warnings and Cautions are listed in the Preface to the manual.

Installation and Mai ntenance:

ified service personnel, paying particular attention to possible electrical and mechanical hazards.

Weight:

nents. When handling, take appropriate precautions and lift the equipment using permanent, fixed surfaces, such as

the base; avoid lifting the device using protective cover shields that may be loose. Beware of sharp edges; use protective gloves when handling such assemblies.

Large drives are heavy, the center of gravity may be offset and removable covers shield internal compo-

Flying Leads and Loose Cables:

ging or entanglement, or are disconnected before carrying drives with such leads or cables.

Generation:

power input terminals to the drive. The power connector must be suitably guarded to prevent a possible shock hazard.

Loose Drives:

airflow is provided around the drive to ensure adequate cooling. The mounting surface of the drive is a heatsink and

its surface temperature may increase when the drive is operating. If a motor is connected to the drive, remove the key

which otherwise could fly out and restrain the motor before applying power to the drive.

Damaged Cables:

before energizing the system.

Supply:

protection devices are required. Consult the instructions and adhere to local and national regulations before connecting and energizing the drive. Current limits must be set correctly when operating a ODM-075 using a single phase

power source.

Safety Logic Signals:

removed from the drive. Consult the manual for information on auxiliary power connections that may be employed

when these signals are used for safety purposes.

Safety Requirements:

ity of the machine designer, who should comply with the local safety requirements at the place where the machine is

to be used. In Europe this is likely to be the Machinery Directive, the ElectroMagnetic Compatibility Directive and

the Low Voltage Directive. In the United States this is likely to be the National Electrical Code.

Mechanical Connection

trols and protection. Installation information for the drive is provided in the manual and list the minimum installation

requirements for the drive are provided in the manual. Motors and controlling devices that connect to the drive should

have specifications that complement the capabilities of the drive.

Motors:

line. Use of custom motors requires the entering of a valid thermal time constant, otherwise the motor overload protection will not function properly.

Disposal

may return the drive at your cost for disposal by us.

If a motor is driven mechanically, it may generate hazardous voltages which are conducted from its

When running an unmounted drive, ensure that the cooling fan is adequately guarded and sufficient

Damage to cables or connectors may cause an electrical hazard. Ensure there is no damage

Drives connect to a permanent main power source; not a portable power source. Suitable fusing and circuit

Logic signals from the drive are interruptible signals; they are removed when power is

The safe incorporation of OMNIDRIVE products into a machine system is the responsibil-

:

Motors controlled by the drive should only connect to the drive; they should not connect directly to the AC

: OMNIDRIVEs do not contain hazardous substances. They may be disposed of as mechanical scrap. You

Installation and maintenance or replacement must be carried out by suitably qual-

Ensure that flying leads or loose cables are suitably restrained, to prevent snag-

Drives must be installed inside an electrical cabinet that provides environmental con-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

Installation Manual for Models

ODM-005 and ODM-005i

ODM-010 and ODM-010i

ODM-020 and ODM-020i

Thomson Industries, Inc.

2 Channel Drive

Port Washington, NY 11050

516-883-8000 - main

516-883-9039 - fax

1-800-554-THOMSON - technical support

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

-4

Copyright 1998 Thomson Industries, Inc. Printed in the U.S.A.

The information contained in this manual is subject to change without notice.

THOMSON is the registered in the U.S. Patent and Trademark Office and in the other countries.

OMNI LINK and OMNIDRIVE are registered trademarks of Thomson Industries, Inc.

Mathcad is a registered trademark of MathSoft, Inc.

Microsoft and MS-DOS are registered trademarks, and Windows is a trademark of Microsoft Corporation.

UL and cUL are registered trademarks of Underwriters Laboratories.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

IntroContents

Contents

HAPTER

C

Contents

List of Figures

List of Tables

Preface

Who Should Use this Manual.................................

Intro-5

Intro-11

Intro-15

Intro-17

Intro-17

OMNIDRIVE Product Receiving

and Storage Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thomson Industries Support .................................

Local Product Support.....................................

Technical Product Assistance.................................

Purpose and Contents of this Manual.............................

Additional Instructions and Manuals ..............................

Host Commands and OMNI LINK..............................

TouchPad...........................................

Symbols and Conventions....................................

Typographical and Wording Conventions ..........................

Graphical Symbols and Warning Classifications.......................

1

Safety

Installing and Using the OMNIDRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Classifications........................................

Potential Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Your Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Safety Guidelines.......................................

Intro-17

Intro-17

Intro-18

Intro-18

Intro-18

Intro-20

Intro-20

Intro-20

Intro-21

Intro-21

Intro-22

1-1

1-1

1-1

1-2

1-3

HAPTER

C

2

Selecting Other System Components

OMNIDRIVE Overview........................................

OMNIDRIVE Features ........................................

Drive Power Ratings ........................................

High Performance Microcontroller Technology ..........................

IPM Technology...........................................

Analog and Digital Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Control...........................................

Encoder Output...........................................

Digital I/O..............................................

Analog I/O..............................................

AC Input Power...........................................

Personality Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Protection Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Command Sources......................................

Analog Command Sources.....................................

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

2-1

2-1

2-1

2-1

2-1

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-3

2-3

2-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Intro-6 Contents

HAPTER

C

I/O Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Input............................................

Analog Output...........................................

Digital Inputs............................................

Control Inputs...........................................

Selectable Inputs..........................................

Digital Outputs............................................

Control Outputs ..........................................

Selectable Outputs.........................................

Auxiliary Encoder Interface .....................................

Encoder Inputs...........................................

Encoder Output...........................................

Autotuning..............................................

Agency Approvals ..........................................

Interface Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OMNI LINK Software........................................

Motors.................................................

European Union Requirements....................................

3

OMNI LINK

2-4

2-4

2-4

2-4

2-4

2-4

2-4

2-4

2-5

2-5

2-5

2-5

2-5

2-5

2-5

2-5

2-6

2-6

Installation

Hardware and Software Requirements................................

Installing OMNI LINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Quitting OMNI LINK..................................

The OMNI LINK Start-Up Screen.................................

Version Level ...........................................

The Readme File..........................................

Miscellanious Files..........................................

Firmware Files...........................................

3-1

3-2

3-2

3-3

3-3

3-4

3-4

3-4

HAPTER

C

HAPTER

C

HAPTER

C

4

Unpacking,

Inspecting, and

Storing

Unpacking the Drive.........................................

Inspection Procedure.........................................

Testing the Unit............................................

Hardware Set Up..........................................

Drive Checkout Test........................................

Storing the Unit............................................

5

Installation

Mechanical Installation Requirements................................

Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring...............................................

Electromagnetic Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Line Filters...........................................

6

Interfaces

J1–Controller ............................................

Digital I/O Power .........................................

Digital Inputs............................................

4-1

4-1

4-2

4-3

4-3

4-6

5-1

5-4

5-4

5-4

5-6

6-1

6-3

6-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Contents Intro-7

HAPTER

C

Input Interface Circuit Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Outputs ...........................................

Analog Inputs...........................................

Analog Outputs .........................................

Motor Encoder Output Signals ..................................

IOUT Signal Generation.......................................

Auxiliary Encoder Inputs Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Cable Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J1 Terminal Strip/Breakout Board ................................

J2–Encoder ............................................

J2 Terminal Strip/Breakout Board ................................

J5–Serial Port ...........................................

Serial Communications Overview ................................

RS-232 Connections........................................

Four Wire RS-485 Connections..................................

7

Power Connection s

Motor Power Cabling........................................

Shield Termination of Power Cables ...............................

Motor Overload Protection.....................................

Power Supply Protection......................................

Emergency Stop Wiring.......................................

AC Power Cabling .........................................

DC Bus ...............................................

6-6

6-8

6-13

6-15

6-16

6-17

6-18

6-20

6-24

6-25

6-27

6-27

6-28

6-28

6-30

7-2

7-2

7-3

7-3

7-4

7-5

7-6

HAPTER

C

8

Application and Configuration Examples

Analog Control.............................................

Hardware Set Up ..........................................

Connection Diagram ........................................

Configuration............................................

Tuning ...............................................

Operation ..............................................

Preset Controller............................................

Hardware Set Up ..........................................

Connection Diagram ........................................

Configuration............................................

Tuning ...............................................

Operation ..............................................

Position Follower (Master Encoder)..................................

Hardware Set Up ..........................................

Connection Diagram .......................................

Configuration...........................................

Tuning ..............................................

Operation .............................................

Position Follower (Step/Direction) .................................

Hardware Set Up .........................................

Connection Diagram .......................................

Configuration...........................................

Tuning ..............................................

Operation .............................................

8-1

8-1

8-1

8-1

8-3

8-4

8-5

8-5

8-6

8-6

8-8

8-8

8-9

8-9

8-10

8-10

8-12

8-12

8-13

8-13

8-14

8-14

8-16

8-16

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Intro-8 Contents

Position Follower (Step Up/Step Down)...............................

Hardware Set Up..........................................

Connection Diagram .......................................

Configuration............................................

Tuning ...............................................

Operation..............................................

Incremental Indexing .........................................

Hardware Set Up..........................................

Connection Diagram ........................................

Configuration............................................

Tuning ...............................................

Operation..............................................

Registration Indexing ........................................

Hardware Set Up..........................................

Connection Diagram .......................................

Configuration............................................

Tuning ...............................................

Operation..............................................

Absolute Indexing ..........................................

Hardware Set Up..........................................

Connection Diagram .......................................

Configuration............................................

Tuning ...............................................

Operation..............................................

Modifying User Units.........................................

Changing the Display Units Settings................................

8-17

8-17

8-18

8-18

8-20

8-20

8-21

8-22

8-22

8-22

8-24

8-24

8-26

8-26

8-27

8-27

8-29

8-30

8-31

8-31

8-32

8-32

8-34

8-34

8-35

8-35

HAPTER

C

HAPTER

C

HAPTER

C

9

10

11

Tuning

Tuning Guidelines ..........................................

General Tuning Rules.......................................

High Inertia Loads.........................................

Mechanical Resonance.......................................

Backlash..............................................

Auto Tune Mode...........................................

Auto Tuning............................................

Manual Tune Mode..........................................

Gains ................................................

Filters................................................

Manual Tuning...........................................

Velocity Loop Tuning Examples .................................

Status Display

Status Indicator............................................

Error Messages............................................

Run-Time Error Codes.......................................

Power-Up Error Codes.......................................

Maintenance and Troubleshooting

Maintenance .............................................

Periodic Maintenance .......................................

Firmware Upgrading.........................................

Firmware Upgrade Procedure using OMNI LINK.........................

9-1

9-1

9-1

9-1

9-2

9-3

9-4

9-5

9-5

9-6

9-7

9-9

10-1

10-1

10-1

10-2

11-1

11-1

11-2

11-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

Contents Intro-9

PPENDIX

A

PPENDIX

A

Troubleshooting...........................................

Error Codes............................................

RS-232 Communication Test...................................

Testing Digital Outputs......................................

Testing Digital Inputs.......................................

Testing Analog Output ......................................

Testing Analog Input.......................................

Testing Encoder Inputs......................................

A

TouchPad Instructions

Installation and Operation.......................................

TouchPad Commands.........................................

Supplemental Instructions.......................................

Motor Selection...........................................

Analog Output Scaling .......................................

Displays...............................................

TouchPad Options...........................................

TouchPad Lists.............................................

B

Creating Custom Motor Files

Drive and Motor File Configuration with OMNI LINK........................

Motor Parameter Set.........................................

General Parameters.........................................

Feedback Parameters ........................................

Electrical Parameters........................................

Rating Parameters..........................................

Example of Custom Motor File Creation ..............................

Manufacturer's Data........................................

Parameter Conversions ......................................

Custom Motor File ........................................

Troubleshooting Custom Motor Files ................................

11-3

11-3

11-6

11-7

11-8

11-8

11-9

11-9

A-1

A-3

A-6

A-6

A-6

A-6

A-8

A-9

B-2

B-2

B-4

B-7

B-9

B-9

B-12

B-12

B-13

B-14

B-14

PPENDIX

A

PPENDIX

A

PPENDIX

A

C

D

E

Electromagnetic Compatibility Guidelines for Machine Design

Introduction ..............................................

Filtering ................................................

AC Line Filter Selection ......................................

Grounding...............................................

Shielding and Segregation.......................................

Dynamic Braking Resistor Selection

Introduction ..............................................

Dynamic Braking Equations......................................

Sample Calculations.........................................

Specifications

Power..................................................

Power Dissipation...........................................

Index of Topics

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Help-1

C-1

C-2

C-2

C-4

C-5

D-1

D-1

D-3

E-3

E-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

Intro-10 Contents

Our Warranty

Defective Equipment.......................................

Return Procedure.........................................

Product Support

Help-7

Help-7

Help-7

Help-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

IntroList of Figures

List of Figures

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

C

1

2

3

Safety

Selecting Other System Components

OMNI LINK

Installation

4

Unpacking,

Inspecting, and

Storing

Connection Diagram.......................................

5

Installation

ODM-005 and ODM-005i Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . .

ODM-010, -010i, -020 and -020i Mounting Dimensions . . . . . . . . . . . . . . . . . . . .

MIF Single Phase AC Line Filter Mounting Diagram . . . . . . . . . . . . . . . . . . . . . .

Power Wiring Diagram......................................

6

Interfaces

Digital Input Circuit .......................................

Drive Input Connected to a Switch/Relay Contact........................

Drive Input Connected to an Opto-Isolator............................

Drive Input Connected to an Active High Sourcing Transistor .................

Drive Input Connected to Active Low Output using a Switch/Relay . . . . . . . . . . . . . .

Drive Input Connected to Active Low Output using an Opto-Isolator . . . . . . . . . . . . .

Drive Input Connected to Sourcing Output............................

READY and BRAKE/DRIVE ENABLED Circuits.......................

Digital Output Circuit.......................................

BRAKE/DRIVE ENABLE Application Examples........................

Drive Output Connected to an Opto-Isolator...........................

Drive Output Connected to an LED Indicator..........................

Drive Output Connected to a Resistive Load...........................

Drive Output Connected to a Switch/Relay ...........................

Drive Output Connected to Active Low Input using a Switch/Relay . . . . . . . . . . . . . .

Drive Output Connected to Active Low Input using an Opto-Isolator . . . . . . . . . . . . .

Drive Output Connected to Active High (Sinking) Input ....................

External Current Limit Circuit..................................

Analog COMMAND Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANALOG 1 Output Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Encoder Interface Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J2 Breakout Board Assembly - European Union EMC Compliance...............

Auxiliary Encoder Input.....................................

Auxiliary Encoder Input Circuit.................................

External Encoder Interface via TTL Differential Line Drivers. . . . . . . . . . . . . . . . . .

Complementary Encoder Interface via 7406 Line Drivers with Pull-up Resistors. . . . . . . .

Complementary Encoder Interface via Standard TTL Logic. . . . . . . . . . . . . . . . . . .

Single-Ended Encoder Interface via Open Collector Transistor without Pull-up

(not recommended) ......................................

4-4

5-2

5-3

5-6

5-8

6-3

6-6

6-6

6-6

6-6

6-7

6-7

6-8

6-9

6-9

6-11

6-11

6-11

6-11

6-12

6-12

6-12

6-13

6-13

6-15

6-16

6-17

6-18

6-18

6-20

6-20

6-21

6-21

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

Intro-12 List of Figures

HAPTER

C

Single-Ended Encoder Interface via Standard TTL Signals (not recommended) . . . . . . .

6-21

Single-Ended Encoder Interface via Open Collector Transistor with 5 VDC to 12 VDC Pull-up

(not recommended)......................................

6-22

Single-Ended Encoder Interface via Open Collector Transistor with 24 VDC Pull-up

(not recommended)......................................

External Step/Direction Interface via TTL Differential Line Drivers. . . . . . . . . . . . . .

6-22

6-23

External Step/Direction Interface via Single-Ended TTL Line Drivers

(not recommended)......................................

External CW/CCW (Step Up/Step Down) Interface via TTL Differential Line Drivers . . . .

6-23

6-24

External CW/CCW (Step Up/Step Down) Interface via Single-Ended Line Drivers

(not recommended)......................................

Motor Encoder Interface Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hall Effect Sensor Circuit....................................

OMNIDRIVE Motor Encoder Connections...........................

RS-232/485 Interface Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Connection Diagrams..................................

RS-485/RS-422 Communication Comparison . . . . . . . . . . . . . . . . . . . . . . . . .

Four Wire RS-485 Daisy Chain Connection Diagram .....................

7

Power Connection s

Motor Power EMC Shield Connection.............................

Emergency Stop Contactor Wiring...............................

6-24

6-25

6-25

6-26

6-27

6-29

6-30

6-32

7-2

7-4

HAPTER

C

HAPTER

C

8

9

Application and Configuration Examples

Analog Controller Connection Diagram ............................

Preset Controller Connection Diagram.............................

Position Follower (Master Encoder) Connection Diagram...................

Step/Direction Controller Connection Diagram.........................

Step Up/Step Down Controller Connection Diagram......................

Incremental Indexing Examples.................................

Incremental Indexing Connection Diagram...........................

Registration Indexing Examples.................................

Registration Indexing Connection Diagram...........................

Absolute Indexing Examples..................................

Absolute Indexing Connection Diagram ............................

PC Display Units–Default Dialog...............................

Tuning

Velocity Loop Structure.....................................

Torque Current Conditioning Structure.............................

Signal Nomenclature ......................................

Underdamped Signal ......................................

Overdamped Signal.......................................

Critically Damped Signal (Ideal Tuning)............................

8-2

8-6

8-10

8-14

8-18

8-21

8-22

8-26

8-27

8-31

8-32

8-35

9-2

9-3

9-9

9-9

9-10

9-10

HAPTER

C

HAPTER

C

PPENDIX

A

10

11

A

Status Display

Maintenance and Troubleshooting

TouchPad Instructions

TouchPad Connection and Pinouts................................

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

A-1

Page 14

List of Figures Intro-13

PPENDIX

A

PPENDIX

A

PPENDIX

A

PPENDIX

A

TouchPad Version Number Display...............................

TouchPad Command Tree

B

Creating Custom Motor Files

(sheet 1 of 2)

............................

Thomson Industries Motor Naming Convention ........................

Required Back-EMF and Hall Signal Phasing for Clockwise Rotation.............

Phasing of the Encoder Signals for Clockwise Rotation.....................

Index Offsets...........................................

Hall Offsets ...........................................

Motor Thermal Protection Software Method ..........................

Back-EMF and Hall Signals, Clockwise Rotation........................

C

Electromagnetic Compatibility Guidelines for Machine Design

EMI Source-Victim Model ...................................

AC Line Filter Installation....................................

Single Point Ground Types....................................

D

E

Dynamic Braking Resistor Selection

Specifications

A-2

A-4

B-3

B-3

B-4

B-7

B-8

B-10

B-12

C-1

C-3

C-4

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

Intro-14 List of Figures

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

IntroList of Tables

List of Tables

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

C

1

2

3

Safety

Selecting Other System Components

OMNI LINK

Installation

4

Unpacking,

Inspecting, and

Storing

5

6

Installation

ODM-005 and -005i Mounting Dimensions

ODM-010, -010i, -020 and -020i Mounting Dimensions

AC Line Filters for OMNIDRIVES

.....................................5-5

MIF Single Phase AC Line Filter Engineering Specifications

................................5-2

.........................5-3

......................5-6

Interfaces

J1 Controller Pin-Outs

General and Dedicated Inputs

INPUT1, INPUT2, INPUT3 and FAULT RESET Functions

Operation and Override Mode Combinations

Digital Input Specifications

READY and BRAKE/DRIVE ENABLED Output Specifications

Selectable Output Circuits

OUTPUT1 and OUTPUT2 Functions

Transistor Output Specifications

Analog Inputs (I LIMIT)

External Current Limit Imput Specification

Analog Command Input

Analog Command Input Specifications

Analog Outputs: ANALOG 1

Analog Output Specifications

Motor Encoder Output Signal

Motor Encoder Output Specifications

Motor Encoder Output Signal

Quadrature Interface Specifications

Step/Direction and CW/CCW (Step Up/Step Down) Interface Specifications

J2- Motor Encoder Connector Pin-Outs

J5 – Serial Port Connector Pin-Outs

............................................6-2

........................................6-4

......................6-4

...............................6-5

.........................................6-5

....................6-8

........................................6-10

.................................6-10

.....................................6-10

..........................................6-13

...............................6-13

..........................................6-14

..................................6-14

.......................................6-15

.......................................6-15

.......................................6-16

..................................6-16

.......................................6-18

...................................6-19

.................................6-26

...................................6-28

........... 6-23

HAPTER

C

7

Power Connection s

TB1 – DC Bus and AC Power Terminal Block Connections

Motor Power Terminals

Motor Power Contact and Wire Size Recommendations

TB1 - AC Power Terminals

AC Input Power Sizing Requirements

...........................................7-2

.........................7-3

.........................................7-5

...................................7-5

.......................7-1

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

Intro-16 List of Tables

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

C

PPENDIX

A

8

9

10

11

A

Application and Configuration Examples

Preset Binary Inputs

.............................................8-5

Tuning

Velocity Loop Gains

Position Loop Gains

.............................................9-5

.............................................9-6

Status Display

Run-Time Error Codes

Power-Up Error Codes

...........................................10-1

...........................................10-2

Maintenance and Troubleshooting

Troubleshooting Guide

...........................................11-3

TouchPad Instructions

TouchPad Fault/Error/Warning Displays

Option Selections for the TouchPad

Drive Communications Parameter List for the TouchPad

Baud Rate Parameter List for TouchPad

Encoder Output Parameter List for TouchPad

IO Mode Parameter List for TouchPad

Index Pointer Parameter List for TouchPad

Index Termination Parameter List for TouchPad

Home Type Parameter List for TouchPad

Homing Auto-Start Parameter List for TouchPad

Reverse Enable for Homing

........................................A-10

Digital Input Parameter List for TouchPad

Digital Output Parameter List for TouchPad

Analog Output Parameter List for TouchPad

Drive Status List for TouchPad

......................................A-11

Input Flags Parameter List for TouchPad

Output Flags Parameter List for TouchPad

.................................A-8

....................................A-8

.................................A-9

..............................A-9

..................................A-9

...............................A-9

.............................A-10

................................A-10

............................A-10

................................A-10

...............................A-11

...............................A-11

.................................A-12

................................A-12

........................A-9

PPENDIX

A

PPENDIX

A

PPENDIX

A

PPENDIX

A

B

C

D

E

Creating Custom Motor Files

Electromagnetic Compatibility Guidelines for Machine Design

Dynamic Braking Resistor Selection

Dynamic Braking Resistor Parameters

..................................D-1

Specifications

OMNIDRIVE Power Ratings

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

.......................................E-3

Page 18

IntroPreface

Preface

Read this preface to familiarize yourself with the rest of the manual. This preface covers the following

topics:

• who should use this manual

• the purpose and contents of this manual

• storing the product

• related documentation

• conventions used in this manual

• safety precautions

Who Should Use this Manual

Use this manual if you are responsible for designing, installing, programming, or troubleshooting the

OMNIDRIVE family of products.

If you do not have a basic understanding of the OMNIDRIVE, contact your local Thomson representative

for information available on this product.

OMNIDRIVE Product Receiving

and Storage Responsibility

You, the customer, are responsible for thoroughly inspecting the equipment before accepting the shipment

from the freight company. Check the item(s) you receive against your purchase order. If any items are

obviously damaged, it is your responsibility to refuse delivery until the freight agent has noted the damage

on the freight bill. Should you discover any concealed damage during unpacking, you are responsible for

notifying the freight agent. Leave the shipping container intact and request that the freight agent make a

visual inspection of the equipment.

Leave the drive in its shipping container prior to installation. If you are not going to use the equipment

for a period of time, store it:

• in a clean, dry location

• within an ambient temperature range of -40 to 70° C (-40 to 158° F)

• within a relative humidity range of 5% to 95%, non-condensing

• in an area where it cannot be exposed to a corrosive atmosphere

• in a non-construction area

The “Drive Checkout Test” on page 4-3 is useful to verify that the unit is operating correctly after delivery.

Thomson Industries Support

Thomson Industries offers support services worldwide.

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

Intro-18 Preface

Local Product Support

Contact your local Thomson representative for:

Technical Product Assistance

If you need to contact Thomson Industries for technical assistance, please review the information in the

Appendix , “Maintenance and Troubleshooting” first. Then call your local Thomson distributor. For the

quickest possible response, we recommend that you have the part and model numbers and/or software

revision level of your products available when you call. The Thomson Industries Technical Support

telephone number is listed on the back cover of this manual.

Purpose and Contents of this Manual

This manual is a user guide for the OMNIDRIVE. It gives you an overview of the OMNIDRIVE family

and describes the procedures you use to install, setup, use, and troubleshoot the OMNIDRIVE.

This manual provides instructions on how to setup and connect the OMNIDRIVE to a controlling device

and a motor. A OMNIDRIVE can operate in one of several different functional modes. The hardware

connections necessary to run the drive are detailed in this manual and basic software instructions are

provided for common setup procedures. For detailed explanation of software instructions, refer to the

comprehensive online instructions available in the OMNI LINK software.

The instructions in this manual detail how to install your OMNIDRIVE using OMNI LINK software with

a personal computer. If you are using a TouchPad device, abbreviated command titles are displayed but

the setup steps remain the same. If you are using the serial Host Command Language to control the drive,

comprehensive instructions are accessible through the Host Command Reference icon displayed in the

OMNI LINK window.

This manual is organized into numbered chapters and alphabetical appendices. The topics covered in each

chapter and section are briefly described. Typographical conventions, warning and cautions specific to

the drive, and complementary manuals are also described.

• sales and order support

• product technical training

• warranty support

• support service agreements

Title Description

Safety

Selecting Other System Components

OMNI LINK Installation

Unpacking, Inspecting and Storing

Installation

Interfaces

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Lists general safety requirements that must be followed

when installing or servicing the drive.

Identifies motors and signal types that are compatible

with OMNIDRIVEs.

Provides snapshot instructions for installing, accessing

and exiting OMNI LINK.

Lists what should be included with your OMNIDRIVE

and instructs you on how to perform a basic functional

test before installing or storing the drive.

Instructs you on how to physically install your OMNIDRIVE.

Each signal or set of signals is identified by:

• Power requirements for driving the signal.

• Functions performed by the signal.

• Specifications, including ON and OFF states.

• Schematic depictions of the circuit design for each signal type.

The signals are grouped by the connector on which they

are present.

Page 20

Preface Intro-19

Title Description

• J1 - Controller Connector Diagrams depict the cable connections necessary for

common controller interfaces.

• J2 - Encoder Provides comprehensive information about the encoder

• J5 - Serial Port Diagrams and instructions detail how to communicate

Power Connections

Application and Configuration Examples

• Analog Control • Velocity or torque mode

• Preset Controller • Velocity or torque mode

• Position Follower (Master Encoder) • Velocity mode

• Position Follower (Step/Direction) • Velocity mode

• Position Follower (Step Up/Step Down) • Velocity mode

• Incremental Indexing • Velocity mode

• Registration Indexing • Velocity mode

• Absolute Indexing • Velocity mode

Tuning

Status Display

Maintenance and Troubleshooting

Touchpad Instructions

Creating Custom Motor Files

Electromagnetic Compatibility Guidelines

Dynamic Braking Resistor Selection

Specifications

Warranty

Product

signals, Hall Effect switches and thermostat connections

available through this connector.

with a drive using serial communications.

Provides information on making motor power, DC bus

and AC Power connections.

Describes the hardware and software set up necessary

to install the drive as one of the following types operating

in a specific mode:

Provides instructions on how to tune a drive and motor

combination using the autotuning or manual tuning features in OMNI LINK.

Discusses the Status LED indicator on the front panel.

Operating or Error Messages accessible through the

TouchPad or a PC are explained.

Describes the minimal maintenance necessary with the

OMNIDRIVEs and provides a comprehensive troubleshooting chart of potential problems and their solutions.

Describes how to program an OMNIDRIVE using the

optional TouchPad device. Tables reference the various

motor types that are programmed to work with the

OMNIDRIVE. A copy of the

Tree

card for the current firmware version is bound into

the manual.

Describes how to create a custom motor file for use with

an OMNIDRIVE.

Describes common electrical noise problems and sug-

gests methods to ensure ElectroMagnetic Compatibility.

Provides equations to assist in sizing resistors for

dynamic braking.

Details the design and operational specifications for the

OMNIDRIVEs in a tabular format.

Provides a synopsis of the warranty coverage and how

to obtain warranty assistance.

Describes the product assistance available, and lists

telephone numbers for product assistance and additional on-line information.

TouchPad Command

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

Intro-20 Preface

Additional Instructions and Manuals

Host Commands and OMNI LINK

All OMNIDRIVEs are setup through serial Host Commands. The drives may be configured directly

through the Host Command language or indirectly through the OMNI LINK software. OMNI LINK is a

graphical user interface that provides a visual method of accessing the Host Command language through

the Microsoft Windows Operating System.

All documentation for both the Host Commands and OMNI LINK is on-line. Host Command information

is available through a comprehensive on-line reference manual. OMNI LINK information is available

through Help menus. The on-line documents provide in-depth explanations of the Host Command language as well as the menus, windows and dialog boxes that make OMNI LINK a convenient method for

programming OMNIDRIVE .

• To access the Host Command Reference

Click on the Host Command Reference icon in the OMNI LINK program group.

• To access OMNI LINK Help

Open OMNI LINK by clicking on the OMNI LINK icon in the OMNI LINK group, and

Press the F1 key.

TouchPad

The optional TouchPad may be used to monitor and configure the OMNIDRIVE . The TouchPad command structure is similar to the structure of OMNI LINK, but operates through an abbreviated keypad

interface. The card

and operational instructions in a pocket-sized directory. The

tional instructions for the TouchPad are included in the section titled, “TouchPad Instructions” which

begins on page A-1. The

instructions and the command structure for the OMNIDRIVE. You may find it convenient to refer to the

card when using the TouchPad with a drive.

TouchPad I nstructions

T ouchPad Command T ree Car d

is provided with the TouchPad. It describes the installation

TouchPad Command Tree Card

is a graphical presentation of both the operational

and addi-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

Symbols and Conventions

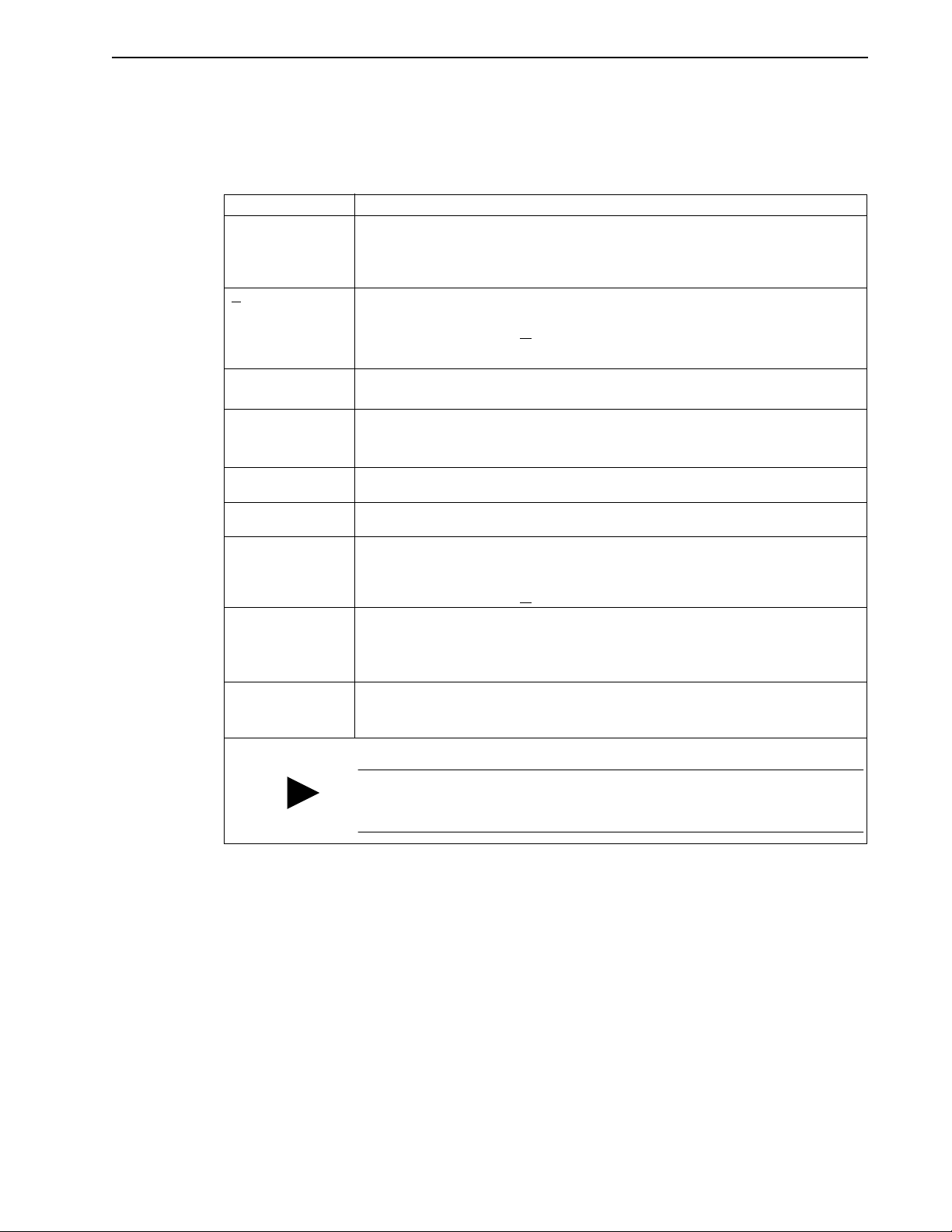

Typographical and Wording Conventions

This manual uses the following typographical and wording conventions:

Example Description

»

D

rive Set Up

OMNI LINK Text shown in this font is information to enter in a window or dialog box. For example,

win Text in lower case bold is information to enter at a keyboard. For example,

a

ALT+F4

ALT, F, N Keys that should be pressed in sequence are shown with a comma (,) between the key

Choose The wording indicates that an icon or a command is to be selected from a window or a com-

Select The wording indicates that options are to be defined or selected from a list. For example,

Type The wording indicates that commands are to be entered into a command box. For example,

Preface Intro-21

Text preceded by right guillemet explains how to access the particular function in the preceding paragraph. For example,

To Start OMNI LINK in Windows

Choose the icon OMNI LINK.

»

Text shown in this font and underlined indicates a Hot Key (keystroke combination) to

quickly access a command. For example,

Choose

indicates typing ALT+D followed by ENTER accesses this command.

rive Set Up

D

Choose the icon OMNI LINK

To start Windows from the DOS prompt, type

.

.

and then

win

press ENTER.

Keys that should be pressed simultaneously are shown with a plus sign (+) between the key

names. This example closes the active window.

names. This example opens the File menu and then opens a new file.

mand box. For example, the instruction for accessing the command icon Drive Set Up

states:

Choose

the instruction for accessing or entering information states:

rive Set Up

D

.

Select Drive Type and Motor Model from the respective list

box.

the instruction for loading OMNI LINK states:

Typ e

a:setup

Tips provide hints or shortcuts that are useful to know. For example,

and then press

ENTER

.

TIP

a. Microsoft® Windows™ reserves certain multiple keystroke combinations to activate Windows commands.

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OMNI LINK always displ ays the Help men u - Quick Start - when i t is first accesse d.

To disable this automatic display, choose the menu item

the Help menu.

Show Quick Start

from

Page 23

Intro-22 Preface

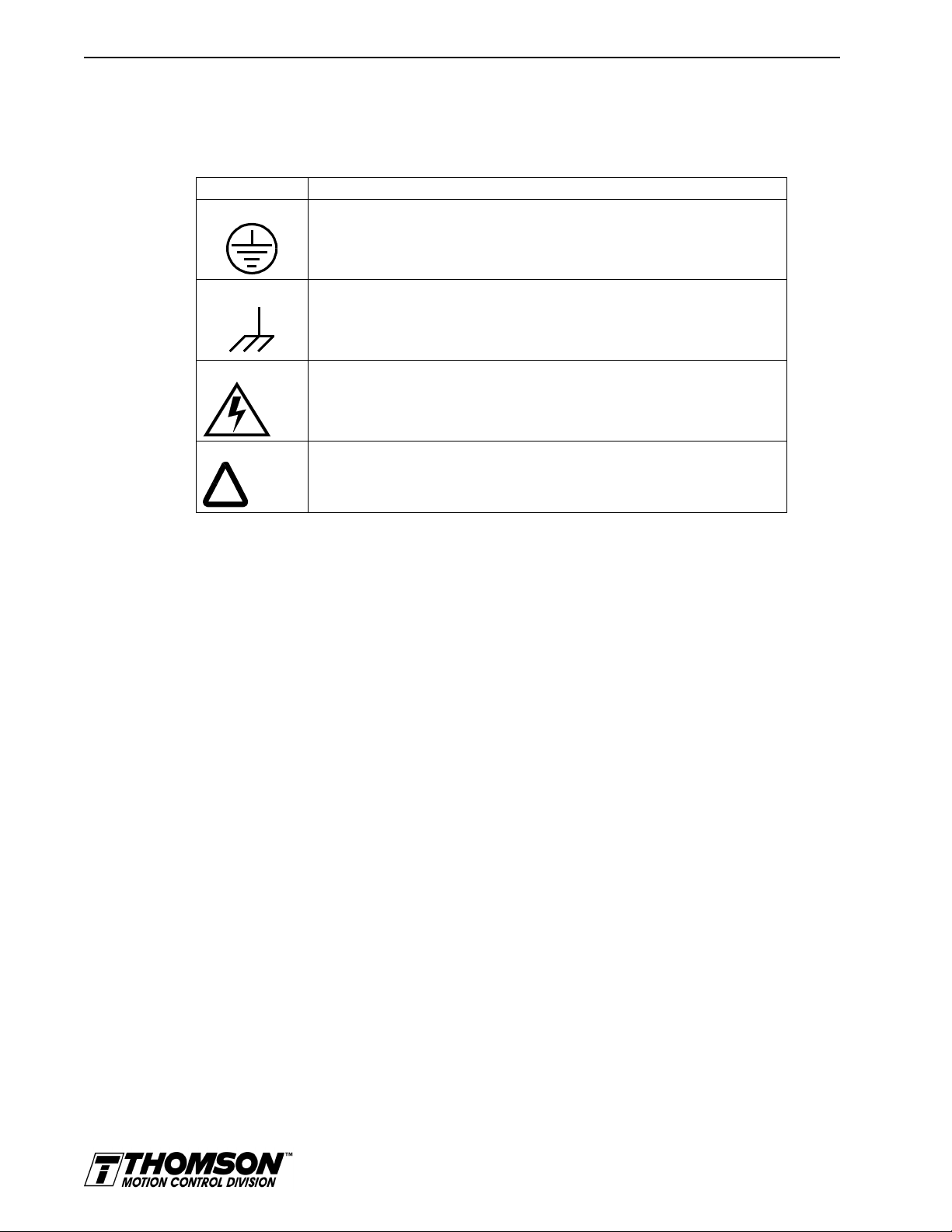

Graphical Symbols and Warning Classifications

This manual uses the following graphical symbols and warning classifications. The use of a symbol and

signal word is based on an estimation of the likelihood of exposure to the hazardous situation and what

could happen as a result of exposure to the hazard.

Example Description

!

Protective conductor terminal (Earth ground)

Chassis terminal (not a protective ground)

Risk of electrical shock.

Symbol plus DANGER, WARNING or CAUTION: These notices provide information

intended to prevent potential personal injury and equipment damage.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

Safety 1-1

HAPTER

C

1:

Safety

Installing and Using the OMNIDRIVE

Read the complete manual before attempting to ins tall or operate the OMNIDRIVE. By reading the manual

you will become familiar with practices and procedures that allow you to operate the OMNIDRIVE safely

and effectively.

Specific Warnings and Cautions appear throughout the manual.

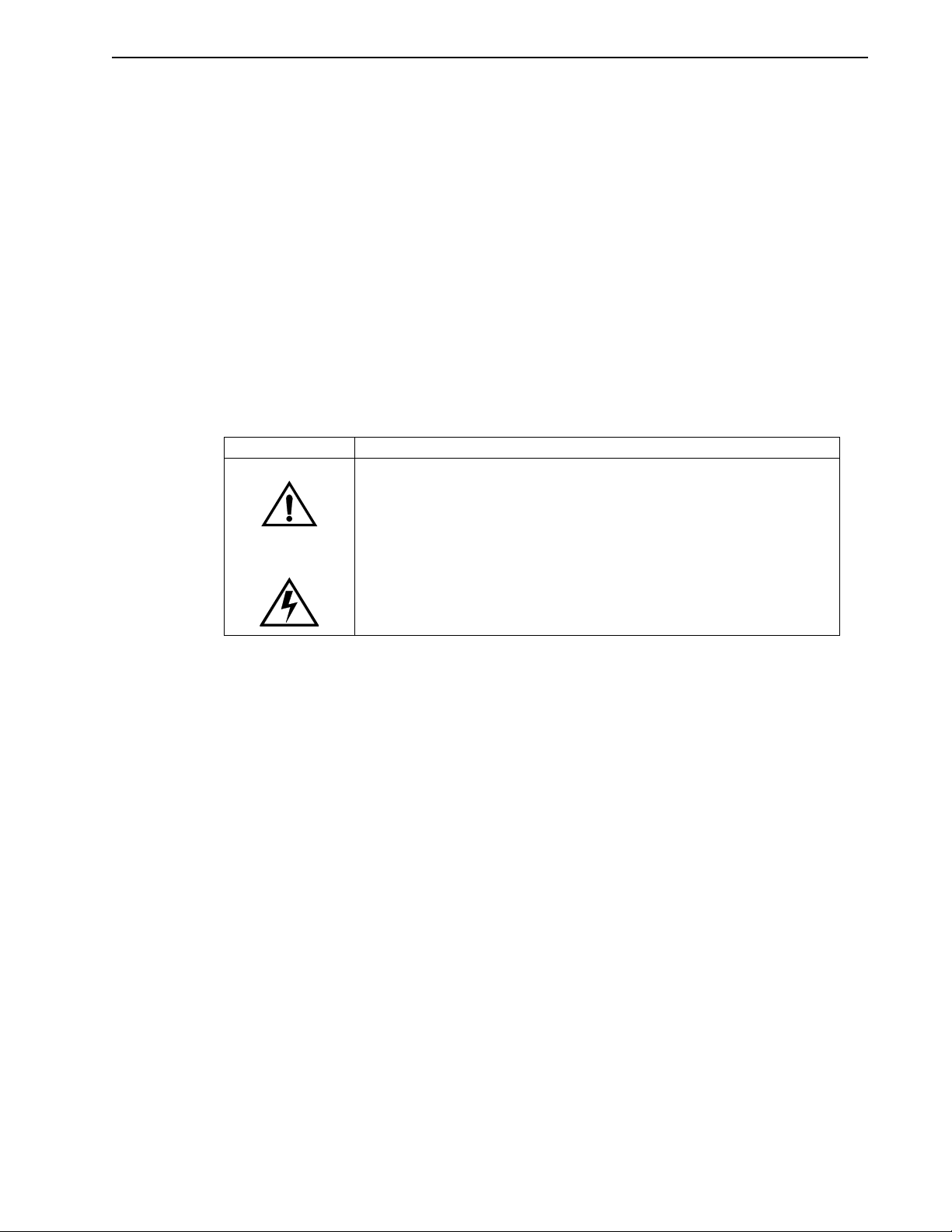

Safety Classifications

Safety notices describe the likelihood of exposure to hazardous situations and what could happen as a

result of exposure to the hazard. Following are symbols and words used to introduce the information that

is intended to prevent potential personal injury and equipment damage.

Symbols Words

or

DANGER

in death or serious injury. This signal word is limited to the most extreme situations.

WARNING

result in death or serious injury.

: Indicates an imminently hazardous situation which, if not avoided, will result

: Indicates a potentially hazardous situation which, if not avoided, could

CAUTION

in minor or moderate injury. It may be used for situations that cause property damage

only. It may also be used to alert against unsafe practices.

: Indicates a potentially hazardous situation which, if not avoided, may result

Potential Ha z a rd s

The equipment described in this manual is intended for use in industrial drive systems. This equipment

can endanger life through rotating machinery and high voltages, therefore it is essential that guards for

both electrical and mechanical parts are

use of this equipment are:

• Electric shock hazards

• Electric fire hazards

• Mechanical hazards

• Stored energy hazards

These hazards must be controlled by suitable machine design, using the safety guidelines which follow.

There are no chemical or ionizing radiation hazards.

not

removed. The main hazards which can be encountered in the

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

1-2 Safety

Voltage Potentials

Voltage potentials for the internal drive circuitry vary from 325 Volts above to 325 Volts below earth

ground for a 240 Volt input. Voltages can exceed 450 VDC or 240 VAC within the OMNIDRIVE. All

circuits, including the connections on the front panel, should be considered “hot” when main or auxiliary

power is connected and for the time specified in the warning on the front of the drive after power is

removed.

Intro

DANGER

DC bus capacitors may retain hazardous voltages for several minutes after

input power has been remov ed, but will normally disch arge in several seconds.

Measure the DC bus voltage to verify it has reached a safe level each time

power is removed before wo rking o n the dri ve; or w ait for th e time indicated in

the warning on the front of the drive. Failure to observe this precaution could

result in severe bodily injury or loss of life.

Your Responsibilities

As the user or person installing this drive, you are responsible for determining the suitability of the product

for the intended application. Thomson Industries is neither responsible nor liable for indirect or consequential damage resulting from the inappropriate use of this product.

A qualified person is someone who is familiar with all safety notes and established safety practices, with

the installation, operation and maintenance of this equipment and the hazards involved. For more detailed

definitions, refer to IEC 364.

It is recommended that anyone who operates or maintains electrical or mechanical equipment should have

a basic knowledge of First Aid. As a minimum, they should know where the First Aid equipment is kept

and the identity of the official First Aiders.

These safety notes do not represent a complete list of the steps necessary to ensure safe operation of the

equipment. If you wish further information, please contact your nearest Thomson Industries

representative.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

General Safety Guidelines

Electrical shock and fire hazards are avoided by using normal installation procedures for electrical power

equipment in an industrial environment. Installation must be undertaken by suitably qualified personnel.

Note that this amplifier must be installed in an industrial cabinet such that access is restricted to suitable

qualified personnel.

Mechanical hazards are associated with potentially uncontrolled movement of the motor shaft. If this

imposes a risk in the machine, then appropriate precautions must be made to electrically disconnect the

motor from the drive when personnel have access to moving parts of the machine. Note also that the

motor must be securely mounted at all times.

Stored energy hazards are both electrical and mechanical.

1. Electrical hazards can be avoided by disconnecting the drive from its power source and measuring

the DC bus voltage to verify it has reached a safe level or by waiting for the time indicated in the warning

on the front of the drive prior to removing the protective covers or touching any connections.

2. Mechanical hazards require a risk analysis on the effects of stored mechanical energy when the

machine is running at speed, as well as the potential for the conversion of electrical energy stored in the

drive being converted to mechanical energy. Electrical energy may be stored in drive for the time indicated

in the warning on the front of the drive.

The following points should be observed for the safety of personnel. These safety notes do not represent

a complete list of the steps necessary to ensure safe operation of the equipment. Contact your nearest

Thomson Industries representative for additional information.

• Only qualified personnel familiar with the equipment are permitted to install, operate andmaintain the device.

• System documentation must be available and observed at all times.

• All non-qualified personnel are kept at a safe distance from the equipment.

• The system must be installed in accordance with local regulations.

• The equipment is intended for permanent connection to a main power input. It is

intended for use with a portable power input.

• Do

• Do

• Always remove power before making or removing

• Before removing the cover of the unit, shut off the main and auxiliary power and measure

• Do

• Be careful of the DC bus and shunt terminals. High voltage is present when power is

• Never connect the DC- terminal to earth ground, the drive requires a floating DC bus.

• Do

• When operating a ODM-075 or ODM-075i with a single phase power input, the current

• Motors without thermal protection devices require a valid thermal time constant. Other-

not

nected.

not

on thedrive.

the DC bus voltage to verify it has reached a safe level or wait for the time indicated in the

warning on the front of the drive.

not

the only points where users should make connections.

applied to the OMNIDRIVE.

not

OMNIDRIVE before maintaining or repairing the unit.

limits must be set correctly.

wise the motor overload protection will not function properly.

Safety 1-3

not

power up the unit without the covers in place and the protective conductor con-

operate the unit without connecting the motor conductor to the appropriate terminal

any

connection on the unit.

make any connections to the internal circuitry. Connections on the front panel are

use the ENABLE input as a safety shutdown. Always remove power to the

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

1-4 Safety

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

Selecting Other System Components 2-1

HAPTER

C

2:

Selecting Other System Components

This chapter reviews the OMNIDRIVE ODM-005, -005i, -010, -010i, -020 and -020i, command sources

and interfaces for the drives, and complementary motors and accessory equipment. Selection of complementary servo components allows you to efficiently connect other devices to your microdrive. Pertinent

information about each is provided to assist you in planning your servo system.

The Thomson Industries OMNIDRIVEs are part of a family of digital drives that use microcontrollers to

manage the current, velocity, and position. All system and application parameters are set in software,

which ensures repeatability of all functions and prevents element drift.

This chapter reviews the OMNIDRIVE and associated motors, command sources and interfaces. Selection

of complementary servo components allows you to efficiently connect other devices to your

OMNIDRIVE. Pertinent information about each is provided to assist you in planning your servo system.

OMNIDRIVE Overview

The OMNIDRIVEs are part of a family of universal digital drives. OMNIDRIVEs use microcontrollers

to digitally manage the current, velocity, and position. All system and application parameters are set in

software, which ensures repeatability of all functions and prevents element drift.

A single unit fully encloses all electronics. An external transformer is

connectors and indicators are accessible and clearly marked on the front panel.

not

required on the power line. All

OMNIDRIVE Features

Drive Power Ratings

Several power levels of OMNIDRIVEs are available. All models have integral power supplies1 and use

a single phase power source. They differ only in physical size, indexing capability and output power:

• ODM-005 and -005i with continuous output power of 500 Watts.

• ODM-010 and -010i with continuous output power of 1000 Watts.

• ODM-020 and -020i with continuous output power of 2000 Watts.

The OMNIDRIVEs, when combined with brushless servo motors, provide continuous torque ranging

from 0.17 Nm to 2.5 Nm (1.5 to 22.5 lb-in) and peak torque ranging from 0.48 Nm to 7.12 Nm (4.3 lbin to 63 lb-in).

High Performance Microcontroller Technology

All digital current, velocity and position loop calculations as well as the motor commutation calculation

are performed by a microcontroller.

IPM Technology

IPM (Intelligent Power Module) technology in the output stage provides a high frequency, digital PWM

(Pulse Width Modulation) sine wave that controls the current loop, including overcurrent, short circuit

and overtemperature protection.

1. ODM-00 5, -005i, -010, -010i and -020 and -020i require an external 12-24VDC power source for I/O.

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

2-2 Selecting Other System Components

Analog and Digital Interfaces

All OMNIDRIVEs allow the user to select one of the following analog or digital command interfaces:

• ±10 Volt analog interface – position, velocity or torque control

• Presets (from one to eight binary inputs) – torque or velocity control

• Quadrature encoder digital interface – electronic gearing position follower

• Step/Direction digital interface – position control

• CW/CCW (step up/step down) interface – position control

• Indexing (available only on ODM-010i, ODM-020i, ODM-030i, ODM-075i and

ODM- 150i).

Encoder Control

A single, motor mounted encoder provides complete commutation information and velocity feedback.

Low velocity regulation is enhanced by the use of a 8000PPR (pulses per revolution) incremental encoder.

Encoder Output

A selectable output allows the encoder resolution to be specified for maximum performance without

adding circuitry. Outputs are differential line drivers capable of dividing the motor encoder signal, PPR,

by a factor of 1, 2, 4 or 8.

Digital I/O

Digital I/O channels allow the user to program the drive to fit the specific application. Power for the I/O

must be supplied by an 12-24 VDC external I/O power supply. Selections include:

• Four selectable (INPUT1, INPUT2, INPUT3 and FAULT RESET), current sinking, optically isolated, active high inputs.

• One dedicated, control (ENABLE), current sinking, optically isolated, active high input.

• Two selectable, current sourcing, optically isolated and short circuit protected, active high

outputs.

• Two dedicated (BRAKE/DRIVEENABLED and DRIVE READY), normally open relay

outputs.

Analog I/O

Two analog inputs are dedicated to current limits and two analog outputs can be customized to fit the

application:

• One dedicated 10 bit, 0 – 10 Volt, analog inputs (EXTERNAL CURRENT LIMIT)

• One selectable, ±10 Volt analog outputs, one 12-bit and one 8-bit (ANALOG).

AC Input Power

OMNIDRIVEs covered by this manual are powered directly from a main 100-240 VAC single phase line.

Personality Module

EEPROM (electrically erasable programmable read-only memory) stores both motor and application

specific settings and parameters for the drive.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

Selecting Other System Components 2-3

Multiple Protection Circuits

Device and circuit protection, and diagnostic information is provided by:

• Bi-color single point LED

• Overtemperature, short circuit and overcurrent protection for the power output

2

T (power-time) protection

• I

• Bus Overvoltage

• Bus Undervoltage

• Overspeed

• Fault diagnostics

• Watchdog timers provide fail-safe operation

Serial Command Sources

OMNIDRIVEs are configured and controlled via a serial communication link. Commands may be issued

from a variety of sources through a serial communications port. Possible command sources include:

• Personal computers

• Host computers

• Programmable Logic Controllers

• Motion controllers

• TouchPad.

The serial communication interface for the OMNIDRIVE supports:

• RS-232 and the four wire RS-485 communications standards

• NRZ (non-return to zero) asynchronous serial format

• Baud rates: 1200, 2400, 4800, 9600 and 19200

• Parity generation and checking: Even, Odd or None.

Connection of communication cables between the drive and user-supplied equipment is described in the

following sections:

One OMNIDRIVE - "Single Position RS-232 Set-up"

Multiple OMNIDRIVEs - "Multiple Position RS-485 Communications".

Analog Command Sources

In the analog mode of operation, the OMNIDRIVE requires a variable ±10 Volt DC external analog signal

capable of driving the servo regulator’s command input at an input impedance of 13.3 kOhms. Choose a

source such as a PLC (programmable logic controller), the DAC (digital-to-analog converter) of a computer, or a motion controller that meets this requirement.

Differential or single-ended line drivers may supply the signals for the auxiliary encoder inputs, step and

direction inputs, and step up/down inputs. The differential signal must be capable of supplying at least 5

mA with 2.0 Volts across the + and - inputs. A differential signal source provides the best noise margin

of all the interface circuit options. Single-ended signals from TTL drivers must be capable of sourcing

or sinking 5 mA.

In the preset mode, the controlling device should be capable of sourcing 10 mA into the digital inputs.

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

2-4 Selecting Other System Components

I/O Interface

Analog Input

One analog input channel is accessible to the user. The analog input limits the peak current available from

the drive.

• I LIMIT (current limit)

The analog signal must be within 0-10 Volt range and single-ended.

If this signal is not provided, the peak current of the drive may be set in software through the Drive

Parameter window.

Analog Output

One analog output channel may be defined by the user through software:

• ANALOG is a ±10 Volt signal. The allowable current draw of the load is ±2 mA

This analog output is designed for monitoring purposes only. This signal should not be used for control

purposes due to the relatively high ripple voltage (1%).

Digital Inputs

Control Inputs

One optically isolated, single ended, active high, dedicated control input provides the controller ENABLE

function. This input operates with switch closure or sourcing type transistor outputs.

The current rating is 10 mA maximum.

Selectable Inputs

Four optically isolated, single ended, active high inputs (INPUT1, INPUT2, INPUT3 and FAULT

RESET) support logic type interfaces. The input circuits operate with switch closure or sourcing type

transistor circuits.

The current rating of each input is 10 mA maximum.

Digital Outputs

Control Outputs

Two normally open relays are dedicated control outputs to the following signals:

The current ratings of each relay is 1 Amp at 30 VDC.

If using a motor with the 90VAC brake option, a user-provided relay may be driven by these outputs up

to the specified levels. Refer to "BRAKE/DRIVE ENABLE Application Exampl" for information about

the necessary hardware connections. Consult the I/O Configuration in the on-line OMNI LINK help for

additional information about the software parameters.

TIP

NOTE: Power for the I/O must be supplied by an external

12 - 24 VDC power source.

• BRAKE/DRIVE ENABLED

• DRIVE READY.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Selectable Outputs

Two optically isolated, single ended, active high, current sourcing, discrete output channels provide logic

outputs under software control.

Each selectable output channel is capable of sourcing 50 mA maximum and is optically isolated and short

circuit protected.

Auxiliary Encoder Interface

The external encoder I/O port permits quadrature type encoder signals for applications, such as electronic

gearing.

Encoder Inputs

Software automatically selects the appropriate input based on the command source:

• Master Encoder

• Step/Direction

• Step Up/Step Down.

Encoder Output

The resolution of the encoder output channel is under software control. The motor encoder signal is

divided by 1, 2, 4 or 8 to provide an output from a differential line driver measured in PPR (pulses per

revolution). The maximum encoder frequency output is 1 MHz (4 MHz quadrature).

Selecting Other System Components 2-5

Autotuning

Digital auto tuning allows easy setup. All adjustments are made in software, which immediately sets the

servo system compensation parameters. This eliminates the time-consuming adjustments required by

potentiometers.

Agency Approvals

Interface Cables

Standard motor power and encoder feedback cables, as well as communications cables, are available to

complete your motion control system and provide reliable, trouble free start-up. Use of factory supplied

cables is required for compliance to the European Electromagnetic Compatibility (EMC) Directive and

to protect your warranty rights.

TIP

• UL listed

• cUL listed

• CE marked

NOTE:

state, please refer to "IOUT Signal Generation" for additional

information.

If a controller requires synchronization to a specific output

OMNI LINK Software

A Windows based software interface provides start-up selections. Tasks are organized for efficient set

up, control and maintenance. Context sensitive, on-line help provides immediate assistance.

Installation Manual for Models ODM-005, ODM-005i, ODM-010, ODM-010i, ODM-020 and ODM-020i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

2-6 Selecting Other System Components

• Set up is simplified by a series of logically arranged set up screens.

• Files can be stored and printed for on-line or off-line modification, and on-site or off-site

back-up.

• Diagnostic and set up tools make system integration easy.

• Critical information is available with complete on-line help.

• User defined velocity, acceleration, position and torque parameters.

• Tuning and diagnosis is aided with an on-screen dual channel digital oscilloscope.

• On-screen meters and software tools provide rapid debugging and measurement.

Motors

The OMNIDRIVE is compatible with many motors, both Thomson motors and motors from other manufacturers. Drive and motor parameters for all compatible motors are programmed into each

OMNIDRIVE at the factory.

OMNI LINK software speeds drive and motor set up by predefined parameters for each drive and motor

combination.

Refer to the Torque/Speed curves in the Thomson Motion Control Catalog and Handbook or contact your

local Thomson distributor for motor sizing and compatibility assistance.

Custom motors or motors not manufactured by Thomson may be interfaced. Contact Product Support for

assistancePhone and fax numbers for product related assistance are listed under “Applications Engineers

and Field Service” on the inside rear cover.. * (see Appendix B).