Page 1

Thomson Electrak® HD

Electric Linear Actuator

Installation Manual

Edition 2016-01

P-264-HD

www.thomsonlinear.com

Page 2

Thomson

Version history

Edition Reason for revision

2016-01 First edition

Warranty

The Thomson Electrak® HD is warranted to be free from defects in materials and workmanship for a

period of twelve (12) months from date of delivery. The application of this product is the responsibility

of the buyer and Thomson makes no representation or warranty as to the suitability of the product for

any particular use or purpose. For a copy of the entire warranty for this product that is contained in our

standard terms and conditions of sale, please go to http://www.thomsonlinear.com/website/com/

eng/support/terms_and_conditions.php.

Disclaimer

Technical changes to improve the performance of the equipment may be made without prior notice!

All rights reserved. No part of this work may be reproduced in any form (by printing, photocopying,

microlm or any other method) or processed, copied or distributed by electronic means without the

written permission of Thomson.

Thomson Electrak® HD Actuator - Installation Manual - 2016-012

Page 3

Contents

Thomson

Contents

1. General ...................................................................................................... 4

1.1 About this manual .................................................................................................. 4

1.2 Target group ........................................................................................................... 4

1.3 Symbols used ........................................................................................................ 4

1.4 Transport and storage ............................................................................................ 4

1.5 Packaging .............................................................................................................. 4

1.6 Disposal ................................................................................................................. 4

1.7 Support .................................................................................................................. 4

2. Safety ......................................................................................................... 5

2.1 Safety notes ........................................................................................................... 5

3. Standards .................................................................................................. 5

3.1 EC Declaration of conformity ................................................................................. 5

4. Installation ................................................................................................ 6

4.1 Product label .......................................................................................................... 6

4.2 Terminology ...........................................................................................................6

4.3 Operation environment ......................................................................................... 6

4.4 Mechanical installation ........................................................................................... 7

4.5 Electrical installation ............................................................................................ 10

4.6 Control options installation and operation ............................................................ 12

5. CANBUS information ............................................................................. 20

5.1 Introduction to CANBUS SAE J1939 ................................................................... 20

5.2 CANBUS SAE J1939 communications protocol .................................................. 20

6. Technical specications ........................................................................ 24

6.1 Technical data ...................................................................................................... 24

6.2 Ordering key ........................................................................................................ 25

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 3

Page 4

Thomson

General

1. General

1.1 About this manual

This manual contains mechanical and electrical installation instructions for the Thomson Electrak® HD

electric linear actuator. It also contains, among other things:

• technical data

• installation data

• type designation key.

It is important to carefully read this manual before installing the actuator and to have the correct

qualications needed to perform the installation.

1.2 Target group

This manual addresses qualied mechanical and electrical personnel.

1.3 Symbols used

This symbol is shown to highlight a general warning, general instruction or as a warning for a

mechanical hazard.

1.4 Transport and storage

The actuator may only be transported and stored in the original packaging supplied by Thomson. The

temperature during transportation and storage must be between -40 to +85° C (-40 to +185° F). Avoid

shocks to the package. If the package is damaged, check the actuator for visible damage and notify the

carrier, and if appropriate also Thomson.

1.5 Packaging

The packaging consists of a cardboard box. The box contains the actuator and this manual. For large

quantity orders bulk packaging may be used in which case the packaging and the content will vary

depending on the order agreement.

1.6 Disposal

Where required by law, used packaging and actuators are taken back by Thomson for professional

disposal if the transportation cost is paid by the sender. Please contact Thomson for shipping information.

1.7 Support

If technical support or information is needed for this product, please contact the nearest Thomson

Service Center. See the back of this manual. You can also visit www.thomsonlinear.com for information

on this product and how to contact us.

Thomson Electrak® HD Actuator - Installation Manual - 2016-014

Page 5

Safety and Standards

Thomson

2. Safety

2.1 Safety notes

• Only properly qualied personnel are permitted to perform mechanical and electrical

installation of this product. Properly qualied personnel are familiar with mechanical or electrical

installation work and have the appropriate qualications for their job.

• Read this manual and any other available documentation before working on the equipment

that the actuator is or shall be a part of.

• Conform strictly to the information contained in this manual and on the actuator product label

on the actuator. Never exceed the performance limits stated herein.

• Never work on the actuator or its installation with the power on.

• Never unplug any cables or connectors during operation or with power on.

• Immediately stop using the actuator if it seems faulty or damaged in any way and notify an

appropriate person so that corrective actions can be taken.

• Never open the actuator as that will compromise the sealing and the function of the

actuator. There are no serviceable components inside.

• Grease may be present on the extension tube. Contact is non-hazardous. Film should not be

removed.

3. Standards

3.1 EC Declaration of incorporation of partly completed machinery

We, Thomson Linear

declare that this product corresponds with the International Standard ISO 13766:2006-05 2nd Edition

(Earth Moving Machinery, Electromagnetic Compatibility). The directive (MD) 2006/42/EC annex 2.1.B,

RoHSII directive 2011/65/EU, and that the standard EN ISO 12100:2010, Safety of machinery, have been

applied.

Thomson Electrak® HD Linear Actuator HDxxBxxx-xxxxxxxxxxx

Product Description

Can be used when the machine or the system, which it shall be, a part of is in accordance with the

demands in the EEC Machinery Directive and/or other relevant regulations.

Håkan Persson Business Unit Manager

Name Title Signature

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 5

Kristianstad 2016-02-16

Date

Page 6

Thomson

Installation

4. Installation

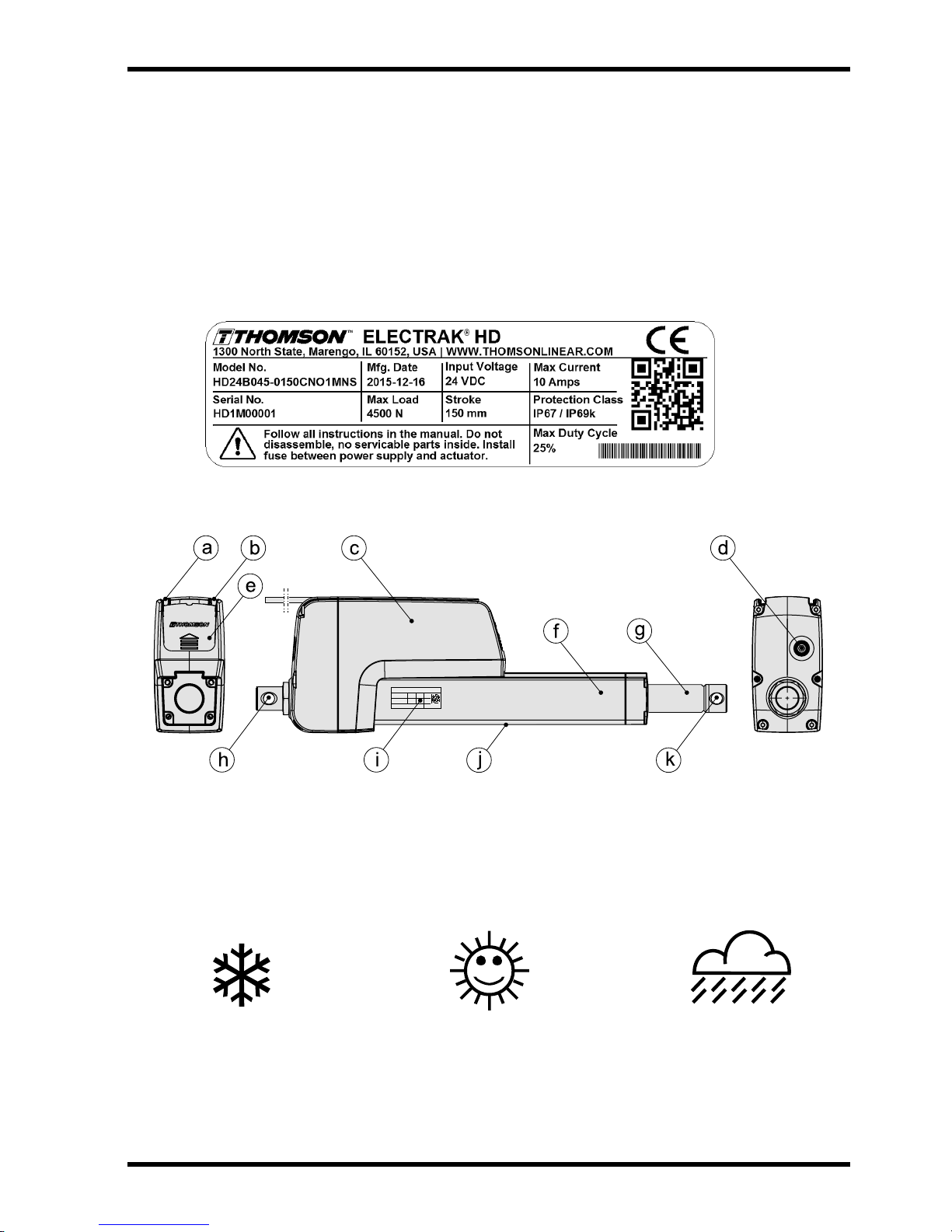

4.1 Product label

The product label can be found on the side of the cover tube. It will tell you which model of actuator

you have, its basic performance data and where it is manufactured. Please study the product label

to determine actuator type before starting any installation or service on the actuator. If you need any

assistance from Thomson, please provide the serial number, manufacturing date and the designation of

the actuator(s) in question. You can also use the QR code on the label to directly access Electrak HD

information on www.thomsonlinear.com.

4.2 Terminology

a. power cable b. signal cable c. housing

d. manual override input e. cable connector cover plate f. cover tube

g. extension tube h. rear adapter i. product label

j. limit switch slots k. front adapter

4.3 Operation environment

Min. -40° C (-40° F) Max. +85° C (+185° F) IP67 / IP69K

1. Operation temperature range is -40 to +85° Celsius (-40 to +185° Fahrenheit).

2. Protection degree against the ingress of water and particles is IP67 / IP69K.

3. Relative humidity range is 10 - 90 % non-condensing.

Thomson Electrak® HD Actuator - Installation Manual - 2016-016

Page 7

Installation

Thomson

4.4 Mechanical installation

4.4.1 General installation safety notes

• Never work on the actuator with the power switched on!

• Do not hold the extension tube while the unit is energized.

• Failure modes of the actuator should be considered to ensure it does not create harm.

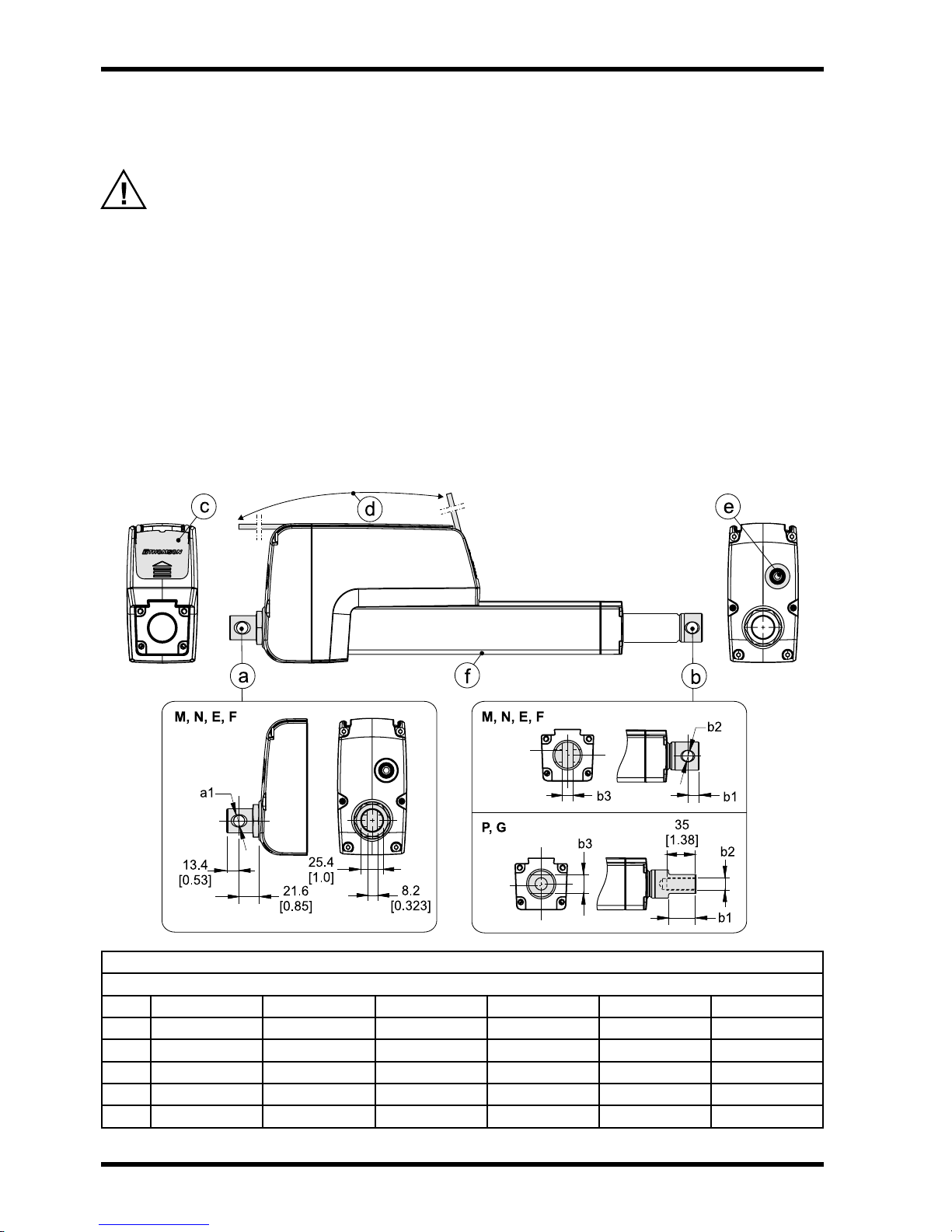

4.4.2 Basic installation considerations

1. Only mount the actuator using the holes in the rear (a) and front (b) adapters. Check the model

number on the actuator product label (section 4.1) and then look at the ordering key (section 6.2)

to nd out your adapter type conguration. See the below drawings and table to nd out the exact

adapter dimensions.

2. Make sure that the actuator mounting position allows access to the cable connector cover plate (c), so

that it can be removed to allow access to the cable connector(s) (section 4.4.4).

3. The cable or cables (d) exit the cable slot at the rear of the actuator housing at delivery but can be

made to leave the housing at any point after the cable connector cover plate.

4. The manual override input (e) must have enough free space around it to allow it to be operated

(section 4.4.5).

5. If external limit switches will be used, the mounting of the actuator must allow access to the limit

switch slots (f) running along the underside of the cover tube (section 4.4.6).

Adapter Dimensions [mm (in)]

M E N F P G

a1 12.2 E9 (0.48) 12.8 (0.506) 12.2 E9 (0.48) 12.8 (0.506) - -

a2 - - 8.2 (0.323) 8.2 (0.323) - -

b1 10.9 (0.429) 10.9 (0.429) 12.9 (0.508) 12.9 (0.508) 30 (1.18) 30 (1.18)

b2 12.2 E9 (0.48) 12.8 (0.506) 12.2 E9 (0.48) 12.8 (0.506) M12 × 1.75 1/2-20 NF-2B

b3 - - 8.2 (0.323) 8.2 (0.323) 19 (0.748) 19 (0.748)

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 7

Adapter type

Page 8

Thomson

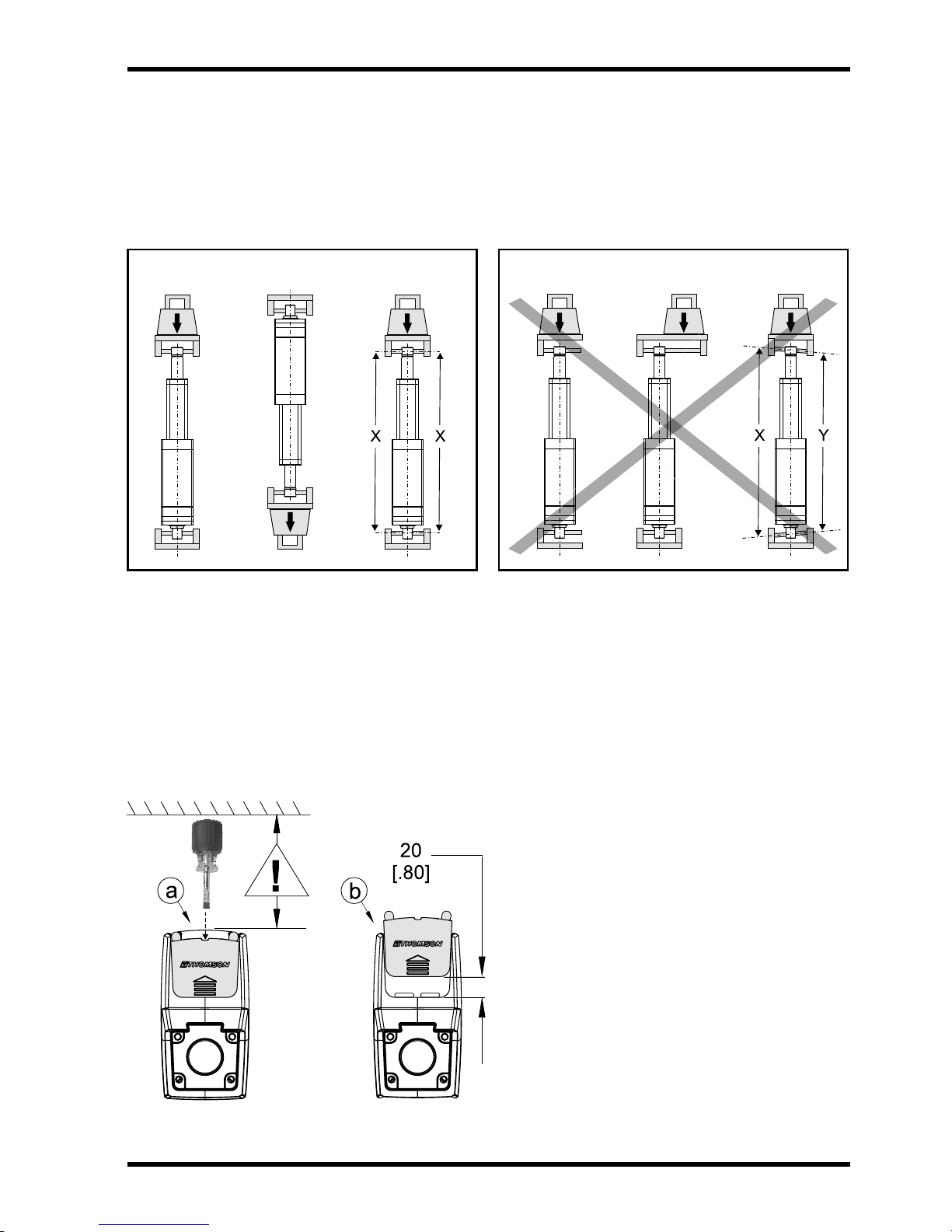

4.4.3 Mounting orientation and forces

1. The actuator can be mounted in any orientation and handle both pushing and pulling loads.

2. Always install actuator so that the force of the load acts in the center of the extension tube and the

rear adapter.

3. Only mount the actuator to the rear and front adapter mounting holes.

4. Only use solid mounting pins and support them at both ends.

5. The mounting pins must be parallel to each other both radially and axially.

YES NO

4.4.4 Cable connector cover plate

1. The cover plate is held in place by a screw (M3 with Torx T10 head) that can be accessed through

the hole in the top of the cover plate (a). Keep in mind to mount the actuator so that there is enough

clearance to access the screw with a tool!

2. Once the cover plate is released it needs to be pushed about 20 mm (0.8 inch) in the direction of

the arrow symbol on the cover plate before it can be removed from the actuator (b). The connectors

are a part of the backside of the cover plate and can be accessed once the cover plate is removed.

3. Make sure to put the cover plate back correctly and torque the screw to 1.2Nm (10.6 in-lb) to ensure

that the actuator cover plate and connectors are properly sealed.

Thomson Electrak® HD Actuator - Installation Manual - 2016-018

Page 9

Thomson

4.4.5 Manual override mounting and operation

1. Make sure when mounting the actuator that there is space enough between the rear adapter and any

object behind it to allow the manual override to be operated!

2. To operate the manual override, remove the cover plug (a) using a at head screw driver. Then

turn on the manual override input hexagon key (b) using a 6 mm hexagon deepwall socket (c).

3. The maximum torque required to move the extension tube at the fully rated actuator load using the

manual override is typically 1.7 Nm (15 in-lb).

4. The distance the extension tube travels per manual override input revolution depends on the

actuator type. See the table below.

Extension Tube Movement / Manual Override Input Revolution [mm (in)]

Actuator type Movement

HDxx-B026 0.224 (0.0088)

HDxx-B045 0.134 (0.0053)

HDxx-B068 0.099 (0.0039)

HDxx-B100 0.059 (0.0023)

Always make sure to switch off the power to the actuator before using the manual override.

Do not apply higher torque than 1.7 Nm (15 in-lb) to the manual override input.

Never run the extension tube in to the end of stroke as that may damage the actuator.

Never use any type of drill or power tool to operate the manual override.

4.4.6 Mounting of optional external limit switches

1. The external limit switches are mounted in the two slots (a) at the bottom of the cover tube.

2. Put the sensor (b) into one of the slots and and lock it at the desired position by turning the clamp

screw 45 degrees (c).

If the sensor is mounted in the immediate vicinity of magnetic components, the

switching characteristics of the sensor may change.

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 9

Page 10

Thomson

Installation

4.5 Electrical installation

4.5.1 General notes

• Make sure the leads/cables leading to the motor can handle the maximum motor current.

• An emergency stop is recommended to reduce the chance of a crushing hazard.

• Never work on the actuator or the wiring with the power switched on!

4.5.2 Fuse size

Protect the actuator and the wiring by using a slow blow fuse between the actuator and the power source.

Recommended Fuse Size

Actuator supply voltage Fuse size

12 VDC 40 A

24 VDC 20 A

4.5.3 Electrical connections

The actuator is always supplied with a power cable (a). Depending on which control option was selected, it

can also have a signal cable (b). The cable(s) have ying leads in one end for customer connections. In the

other end the cable(s) are integrated in to the cable connector cover plate (c) (section 4.4.4). The plug in

connector allows replacing the actuator without disconnecting the ying leads.

4.5.4 Lead cross sections

To avoid malfunction due to voltage drop the cross section of the leads between the actuator power

cable leads and the power source must be of sufcient size. For longer cables than stated in the table,

calculations based on the supply voltage, the current draw, the length of the cables and the ambient

temperature must be done.

2.5

mm2 [AWG 14]

Power cable

X

2

[AWG 20]

0.5 mm

Signal cable

Power Lead Cross Sections

Length of cable (L) Min. allowed cross section (X)

0 - 4 m

4 - 10 m 4 mm

2.5 mm2 [AWG 14]

2

[AWG 12]

Thomson Electrak® HD Actuator - Installation Manual - 2016-0110

Page 11

Installation

Thomson

4.5.5 Inrush current

At the start of the actuator there is an inrush current to the motor that will last between 75 to 150

milliseconds. See below table to determine the inrush current for the control option being used.

Control Option Inrush Current Level

Option Inrush current

EXX, ELX, EXP, EXD, ELP, ELD up to 4 × rated current for the actuator model and load in question

LXX, LLX, LXP, CNO up to 2 × rated current for the actuator model and load in question

If using an AC powered power supply it must be sized to handle the inrush current (batteries

typically have no problem delivering the inrush current). Also contacts, switches and relays must

be sized appropriately to be able to handle the inrush current.

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 11

Page 12

Thomson

4.6 Control options installation and operation

4.6.1 General notes

• Avoid placing signal cables along power cables to reduce the risk of interference.

• Avoid using a vehicle earth as the return conductor. Instead use a two wire system to reduce

the risk of interference.

• In very sensitive applications or where there is a risk of interference we recommend using

shielded signal cables.

• Keep in mind that long cables in combination with small lead cross sections and low voltages

may lead to undervoltage and malfunction due to voltage drop.

• Relays or other coil operated devices should have spark protection to avoid interference.

• Never work on the actuator or the wiring with the power switched on!

4.6.2 How to determine the control option

Electrak HD is equipped with one of the control options in the table below. To determine the option

your actuator has, check the model number on the product label on the actuator (section 4.1) and then

check the ordering key (section 6.2). Use the table below and go to the corresponding section for further

information.

Control Options

Option Functions Section

EXX Electrak Monitoring Package only 4.6.3

ELX Electrak Monitoring Package + End of Stroke Indication Output 4.6.4

EXP Electrak Monitoring Package + Analog Position Output 4.6.5

EXD Electrak Monitoring Package + Digital Position Output 4.6.6

ELP Electrak Monitoring Package + End of Stroke Indication Output + Analog Position Output 4.6.7

ELD Electrak Monitoring Package + End of Stroke Indication Output + Digital Position Output 4.6.8

LXX Electrak Monitoring Package + Low Level Signal Motor Switching 4.6.9

LLX Electrak Monitoring Package + Low Level Signal Motor Switching + End of Stroke Indication Output 4.6.10

LXP Electrak Monitoring Package + Low Level Signal Motor Switching + Analog Position Output 4.6.11

CNO CAN Bus J1939 Control + Open Loop Speed Control 4.6.12

Thomson Electrak® HD Actuator - Installation Manual - 2016-0112

Page 13

Thomson

4.6.3 Control option EXX (Electrak monitoring package only)

Utilizing the internal control system the actuator will:

• Stop the actuator immeditately at each end of mechanical travel and throughout the stroke anytime

current exceeds a factory preset value for the rated load (over load condition). This value is adjusted

during operation automatically to provide consistent force. Resetting the actuator requires motion in

opposite direction to continue normal operation.

• Stop the actuator when the current move is nished in the situation where voltage or temperature

are outside their normal operating ranges. Once within the normal operating range the actuator will

automatically reset and normal operation can be continued.

Always turn power off to the actuator before working on it to eleminate the risk of the actuator

making unplanned moves after it has carried out the automatic reset.

To extend the actuator apply +Vdc to red and -Vdc to black. To retract apply -Vdc to red and +Vdc to

black.

EXX Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

F Fuse

S1 Double pole double throw switch

[Vdc]

9 - 16

18 - 32

red

black

4.6.4 Control option ELX

In addition to all of the features included in the EXX version (section 4.6.3), the ELX also includes the

additional feature of end of stroke indication. These normally open outputs can be used to provide

feedback that the actuator has reached it’s mechanical minimum or maximum stroke.

To extend the actuator apply +Vdc to red and -Vdc to black. To retract apply -Vdc to red and +Vdc to

black.

ELX Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

Output contact type potential free

Limit switch max. voltage [Vdc] 32

Limit switch max. current [mA] 350

Limit switch max. power [W] 5

F Fuse

S1 Double pole double throw switch

[Vdc]

9 - 16

18 - 32

output fully retracted

output fully extended

common

not used

red

black

red

white

brown

blue

black

violet

orange

grey

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 13

Page 14

Thomson

4.6.5 Control option EXP

In addition to all of the features included in the EXX version (section 4.6.3), the EXP adds a

potentiomenter providing a voltage signal for the customer to use to determine position, speed and

direction.

To extend the actuator apply +Vdc to red and -Vdc to black. To retract apply -Vdc to red and +Vdc to

black.

EXP Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

Potentiometer type wirewound

Potentiometer max.

input voltage

Potentiometer max.

power

Potentiometer linearity [%] ± 0.25

Potentiometer output

resolution

50 - 100 mm stroke

150 - 250 mm stroke

300 - 500 mm stroke

550 - 1000 mm stroke

4.6.6 Control option EXD

In addition to all of the features included in the EXX version (section 4.6.3), the EXD also includes an

encoder providing a single pulse train signal to determine position and speed.

[Vdc]

[Vdc] 32

[W] 1

[ohm/mm]

9 - 16

18 - 32

65.62

32.81

19.69

9.84

+ 32 Vdc

potentiometer output

not used

0 Vdc

not used

F Fuse

S1 Double pole double throw switch

red

black

red

white

brown

blue

black

violet

orange

grey

To extend the actuator apply +Vdc to red and -Vdc to black. To retract apply -Vdc to red and +Vdc to

black.

EXD Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

Encoder type gear tooth

Encoder input voltage [Vdc] 4 - 24

Encoder output low

voltage levels (logical

zero)

typical / max.

Encoder resolution

HDxx-B026

HDxx-B045

HDxx-B068

HDxx-B100

[Vdc]

[Vdc]

[mm/pulse]

9 - 16

18 - 32

0.1 / 0.25

0.154

0.092

0.068

0.040

red

black

+ 5 Vdc

encoder output

not used

0 Vdc

not used

red

white

brown

blue

black

violet

orange

grey

F Fuse

S1 Double pole double throw switch

Thomson Electrak® HD Actuator - Installation Manual - 2016-0114

Page 15

Thomson

4.6.7 Control option ELP

In addition to all of the features included in the EXX version (section 4.6.3), the ELP has both end

of stroke indication and a potentiometer providing a voltage signal to determine position, speed and

direction.

To extend the actuator apply +Vdc to red and -Vdc to black. To retract apply -Vdc to red and +Vdc to

black.

ELP Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

Output contact type potential free

Limit switch max. voltage [Vdc] 32

Limit switch max. current [mA] 350

Limit switch max. power [W] 5

Potentiometer type wirewound

Potentiometer max.

input voltage

Potentiometer max.

power

Potentiometer linearity [%] ± 0.25

Potentiometer output

resolution

50 - 100 mm stroke

150 - 250 mm stroke

300 - 500 mm stroke

550 - 1000 mm stroke

[Vdc]

[Vdc] 32

[W] 1

[ohm/mm]

9 - 16

18 - 32

65.62

32.81

19.69

9.84

+ 32 Vdc

potentiometer output

not used

0 Vdc

output fully retracted

output fully extended

common

F Fuse

S1 Double pole double throw switch

red

black

red

white

brown

blue

black

violet

orange

grey

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 15

Page 16

Thomson

4.6.8 Control option ELD

In addition to all of the features included in the EXX version (section 4.6.3), the ELD has both end of

stroke indication and an encoder providing a single pulse train signal to determine position and speed.

To extend the actuator apply +Vdc to red and -Vdc to black. To retract apply -Vdc to red and +Vdc to

black.

ELD Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

Output contact type potential free

Limit switch max. voltage [Vdc] 32

Limit switch max. current [mA] 350

Limit switch max. power [W] 5

Encoder type gear tooth

Encoder input voltage [Vdc] 4 - 24

Encoder output low

voltage levels (logical

zero)

typical / max.

Encoder resolution

HDxx-B026

HDxx-B045

HDxx-B068

HDxx-B100

[Vdc]

[Vdc]

[mm/pulse]

9 - 16

18 - 32

0.1 / 0.25

0.154

0.092

0.068

0.040

+ 5 Vdc

encoder output

not used

0 Vdc

output fully retracted

output fully extended

common

F Fuse

S1 Double pole double throw switch

red

black

red

white

brown

blue

black

violet

orange

grey

Thomson Electrak® HD Actuator - Installation Manual - 2016-0116

Page 17

Thomson

4.6.9 Control option LXX

In addition to all of the features included in the EXX version (section 4.6.3), the LXX option allows the

end user to extend, retract or stop the actuator using low current (<22 mA) input signals instead of

switching the polarity of the input power voltage.

It also includes:

• An automatic soft start capability reducing the inrush current (section 4.5.5).

• A “sleep” mode function is activated when no motion is commanded for 15 seconds. In sleep mode

the current draw is less than 1 mA for a 12 Vdc actuator and less the 2 mA for a 24 Vdc actuator. The

sleep mode will exit and return to normal operation when the next move command is received.

• Dynamic braking throughout the entire stroke length whenever a motion command is removed.

Power the actuator by connecting red to + Vdc and black to - Vdc in the power cable. To extend the

actuator apply +Vdc to violet and to retract apply +Vdc to orange in the signal cable.

LXX Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

Extend / retract input voltage [Vdc] 9 - 32

Extend / retract input current [mA] 6 - 22

[Vdc]

9 - 16

18 - 32

F Fuse

S1 Extend switch

S2 Retract switch

not used

+

–

red

black

red

white

brown

blue

black

violet

orange

grey

4.6.10 Control option LLX

In addition to all of the features included in the LXX version (section 4.6.9), LLX also includes end of

stroke indication. These normally open outputs can be used to provide feedback that the actuator has

–

reached it’s mechanical minimum or maximum stroke.

Power the actuator by connecting red to + Vdc and black to - Vdc in the power cable. To extend the

actuator apply +Vdc to violet and to retract apply +Vdc to orange in the signal cable.

LLX Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

Output contact type potential free

Limit switch max. voltage [Vdc] 32

Limit switch max. current [mA] 350

Limit switch max. power [W] 5

Extend / retract input voltage [Vdc] 9 - 32

Extend / retract input current [mA] 6 - 22

[Vdc]

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 17

9 - 16

18 - 32

F Fuse

S1 Extend switch

S2 Retract switch

common

output fully extended

not used

output fully retracted

+

–

red

black

red

white

brown

blue

black

violet

orange

grey

Page 18

Thomson

4.6.11 Control option LXP

In addition to all of the features included in the LXX version (section 4.6.9), LXP also includes a

potentiometer providing a voltage signal for the customer to use to determine position, speed and

direction.

Power the actuator by connecting red to + Vdc and black to - Vdc in the power cable. To extend the

actuator apply +Vdc to violet and to retract apply +Vdc to orange in the signal cable.

LXP Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

Potentiometer type wirewound

Potentiometer max.

input voltage

Potentiometer max.

power

Potentiometer linearity [%] ± 0.25

Potentiometer output

resolution

50 - 100 mm stroke

150 - 250 mm stroke

300 - 500 mm stroke

550 - 1000 mm stroke

Extend / retract input voltage [Vdc] 9 - 32

Extend / retract input current [mA] 6 - 22

[Vdc]

9 - 16

18 - 32

[Vdc] 32

[W] 1

[ohm/mm]

65.62

32.81

19.69

9.84

F Fuse

S1 Extend switch

S2 Retract switch

32 Vdc

potentiometer output

not used

0 Vdc

+

–

red

black

red

white

brown

blue

black

violet

orange

grey

Thomson Electrak® HD Actuator - Installation Manual - 2016-0118

Page 19

Thomson

4.6.12 Control option CNO

This document assumes the reader is familiar with the SAE J1939 standard. Terminology

from the standard is used, but not described in detail. See section 5 for information on the

CAN Bus operation and communication protocol.

4.6.12.1 General installation data

Voltage is to be directly connected to the actuator. All motion and protection on the CAN Bus option is

handled through the CAN messages including overload protection. Please see section 5 for more details

on the messages.

CNO Control Option Specications

Input voltage

HD12

HD24

Max. actuator current draw [A] see product label

[Vdc]

9 - 16

18 - 32

F Fuse

address select 3

CAN Low

CAN High

address select 1

address select 2

address select common

not used

not used

red

black

red

white

brown

blue

black

violet

orange

grey

4.6.12.2 CAN Bus SAE J1939 installation data

Follow wiring guidelines per ISO-11898 Standard CAN 2.0B, Protocol SAE J1939. Proper termination

resistors (120 Ohm) should be placed in mating wire harness, see below. Please refer to section 5 for

more communication details.

CAN CAN Bus device in actuator or other equipment

R Resistor

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 19

Page 20

Thomson

5. CAN Bus information

5.1 Introduction to CANBUS SAE J1939

This document assumes the reader is familiar with the SAE J1939 standard. Terminology from the

standard is used, but not described in detail. The Electrak® HD actuator is compliant with the standard

J1939, and supports the following PGNs (Parameter Group Number) from the standard.

J1939-21 – Data Link Layer

• Proprietary A 61184 (0x00EF00)

• Proprietary A2 126720 (0x01EF00)

J1939-81 – Network Management

• Address Claimed/Cannot Claim 60928 (0x00EE00)

• Commanded Address 65240 (0x00FED8)

5.2 CANBUS SAE J1939 communications protocol

5.2.1 J1939 NAME

The Electrak HD has the following defaults for the J1939 NAME. Please refer to the SAE J1939/81

standard for more information on these parameters.

J1939 NAME Defaults

Arbitrary Address Capable Yes

Industry Group 0, Global

Vehicle System Instance 0

Vehicle System 0, Non-specic system

Function 255, Not available

ECU Instance 0, First instance

Manufacture Code 547, Thomson Linear LLC

Identity Number 0

5.2.2 Address

The Electrak HD uses a default address value of 19 (0x13). In applications where the default address is

not available, there are three additional methods in choosing a new address.

1. The Electrak HD device is arbitrary address capable, if another device with a higher priority NAME

contends for the selected address, the actuator will continue to request other addresses until it nds

one that it can claim.

2. The Electrak HD device can also use the commanded address PGN to select a specied address.

See J1939/81 for more details about address claiming.

3. In some applications it may be more convenient to select an address through hardware means. In

this case the user can change the default address using the address select wires as dened in

section 4.6.12. Activating individual select pins will create a binary adder to the default address. This

method can allow up to 8 individual actuator addresses on a single bus. The below chart shows some

examples on how this can be implemented.

Address Select

Address select common Address select 3 Address select 2 Address select 1 Binary adder Default address

Gnd 0 0 0 0 19 (0x13)

Gnd 0 0 1 1 20 (0x14)

Gnd 0 1 0 2 21 (0x15)

Gnd 1 1 1 7 26 (0x20)

...

Thomson Electrak® HD Actuator - Installation Manual - 2016-0120

Page 21

Thomson

5.2.3 Sleep operation

The Electrak HD utilizes a sleep mode operation when positioning is no longer required. This feature

allows for a constant battery connection with minimal drain while the engine or vehicle is not running.

After 5 seconds of bus inactivity, the actuator will put itself in a state of sleep. During this state the

quiescent current is <1 mA for 12 Vdc models and <2 mA for 24 Vdc models. When bus activity is

restored the actuator will begin a wake up phase, followed by an address claim request.

5.2.4 J1939 actuator control message (ACM)

All actuator control parameters are adjustable through the proprietary A message (PGN 61184). The

preferred transmission repetition rate is 100ms (can also be sent as required by the application.)

Additional message specic information can be found in the table below, all other Proprietary A

information can be found in the SAE J1939/21 specication.

Actuator Control Message Signal Information

Start position Length Parameter name

1.1 14 bits Position command

2.7 9 bits Current limit

3.8 5 bits Speed command

4.5 1 bit Motion enable

4.6 35 bits Factory use

The least signicant bit of each message is indicated by the start position column

5.2.4.1 Position command

This 14-bit signal is used to set the target position for the next actuator motion. Although resolution

of the signal is represented as 0.1 mm/bit, true positional accuracy will be dependent on the stroke

length of the given model. The actuator uses an internally calculated deadband value to determine

when within a target position range. The 0.0 mm and full extend stroke values represent 0 to 100%

stroke and are only relative to the actual available stroke of the individual unit.

Range: 0.0 mm to 1000.0 mm

Resolution: 0.1 mm/bit, 0 offset

5.2.4.2 Current limit

This 9-bit signal is used to set a current at which the actuator will cease motion. In the event a

force is applied to the actuator that causes the motor current to exceed this settable value for more

than 50 ms, the actuator will stop any current motion and activate a dynamic breaking effect on the

motor. This current limit does not apply during the motor starting phase where in rush current can be

signicantly higher than normal running.

Range: 0.0 A to 25.0 A (12Vdc actuator), 0.0A to 12.5 A (24Vdc actuator)

Resolution: 0.1 A/bit, 0 offset

5.2.4.3 Speed command

This 5-bit signal is used to set the speed of the actuator. The signal adjusts the PWM driver within

the actuator and the voltage applied to the motor. The resultant actuator speed will be a ratio of the

actuators max speed and also dependent on the load applied to the actuator.

Range: 0% to 100% motor duty cycle

Resolution: 5%/bit, 0 offset

5.2.4.4 Motion enable

This 1-bit signal is used to enable motion from the actuator. If this bit is low (0), no motion will be

allowed. This signal can be used to dene the next actuator movement message without starting the

motor. When movement is required this bit can be changed to high (1) and motion will begin using

the other parameter signals encoded in the ACM.

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 21

Page 22

Thomson

5.2.4.5 Factory use

The remaining 35 bits of the ACM are used for factory calibration use only and should be lled with

0x00 or 0xFF when sending this message.

5.2.5 J1939 actuator feedback message (AFM)

All actuator feedback data can be retrieved through the proprietary A2 message (PGN 126720). This

message is transmitted every 100ms. Additional message specic information can be found in Table

2, all other Proprietary A2 information can be found in the SAE J1939/21 specication.

Actuator Feedback Message Signal Information

Start position Length Parameter name

1.1 14 bits Measured position

2.7 9 bits Measured current

3.8 5 bits Running speed

4.5 2 bits Voltage error

4.7 2 bits Temperature error

5.1 1 bit Motion ag

5.2 1 bit Overload ag

5.3 1 bit Backdrive ag

5.4 1 bit Parameter ag

5.5 1 bit Saturation ag

5.6 1 bit Fatal error ag

5.7 18 bits Factory use

The least signicant bit of each message is indicated by the start position column

5.2.5.1 Measured position

This 14-bit signal is used to inform the user of the actual actuator stroke position. Although

resolution of the signal is represented as 0.1 mm/bit, true positional accuracy will be dependent on

the stroke length of the given model. The actuator uses an internally calculated deadband value to

determine when it is within a target position range. The 0.0 mm and ordered full extend stroke values

represent 0 to 100% stroke but the signaled value does not take in to account any mechanical

tolerances or play in the actuator.

Range: 0.0 mm to 1000.0 mm

Resolution: 0.1 mm/bit, 0 offset

5.2.5.2 Measured current

This 9-bit signal is used to inform the user of the actual current being drawn used by the actuator.

Range: 0.0 A to 51.1 A

Resolution: 0.1 A/bit, 0 offset

5.2.5.3 Running speed

This 5-bit signal is used to inform the user of the actual duty cycle being applied to the motor

through the internal actuator controller.

Range: 0% to 100% motor duty cycle

Resolution: 5%/bit, 0 offset

5.2.5.4 Voltage error

This 2-bit signal is used to inform the user that the operational voltage is outside of allowable

running parameters. Any motion already in progress will continue until completed, but additional

movement request will not be allowed until the operational voltage returns within the normal

operating range.

Thomson Electrak® HD Actuator - Installation Manual - 2016-0122

Page 23

Thomson

Voltage Error Message

00 Input voltage within operational range

01 Input voltage below operational range

10 Input voltage above operational range

11 Not used

5.2.5.5 Temperature error

This 2-bit signal is used to inform the user that the operational temperature is outside of allowable

running parameters. Any motion already in progress will continue until completed, but additional

movement request will not be allowed until the operational temperature returns within the normal

operating range.

Temperature Error Message

00 Temperature within operational range

01 Temperature below operational range

10 Temperature above operational range

11 Not used

5.2.5.6 Motion ag

This 1-bit signal is used to inform the user that the actuator is currently in motion.

5.2.5.7 Overload ag

This 1-bit signal is used to inform the user that the last motion the actuator completed caused a

current over load condition. This occurs when the actuator determines the current set in the Current

Limit signal from the ACM is exceeded for a consecutive 50ms. When this ag is set by the actuator

the user must reset the Motion Enable ag in the ACM before attempting additional motion from the

actuator.

5.2.5.8 Backdrive ag

This 1-bit signal is used to inform the user that the actuator has determined positional movement in

the extension tube that was not commanded from the user. This can be caused from excessive static

load or vibration being applied to the actuator.

5.2.5.9 Parameter ag

This 1-bit signal is used to inform the user that one of the parameter signals in the ACM is outside

the allowed parameters the specic model will allow. To prevent damage to the actuator motion is

not allowed while this ag is set.

5.2.5.10 Saturation ag

This 1-bit signal is used to inform the user that the actuator is currently running within 10% of its

maximum capability. Additional speed or current needed from the application may not be able to be

obtained with the chosen actuator model.

5.2.5.11 Fatal error ag

This 1-bit signal is used to inform the user that the actuator needs service. If this ag is set power

can be reset to determine if the ag is resettable, but it is suggested to contact the factory for

additional support. To prevent possible additional damage motion is prohibited while this ag is set.

5.2.5.12 Factory use

The remaining 18 bits of the Actuator Feedback Message are used for factory calibration use only

and under normal operation will be returned with 0x00.

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 23

Page 24

Thomson

6. Technical specications

6.1 Technical data

Technical Specication HD • •

Input voltage [VDC] 12 24

Input voltage tolerance [VDC] 9 - 16 18 - 32

Stroke length [mm] see product label

Static load at fully retracted (Fx), maximum [kN (lbs)] 18 (4050)

Dynamic load (Fx), maximum [N] see product label

Speed, no load / max. rated load

HDxx-B026

HDxx-B045

HDxx-B068

HDxx-B100

Current draw @ rated max. load [A] see product label

[mm/s (inch/s)]

40 / 32 (1.6 / 1.3)

24 / 19 (0.94 / 0.75)

18 / 14 (0.71 / 0.55)

11 / 9 (0.43 / 0.35)

Weight [kg (lbs)]

End play, maximum [mm (in)]

Operating temperature limits, standard units [°C (°F)]

Full load duty cycle @ 25 °C [%] see product label

Restraining torque [Nm (lbf-in)] 0 (internally restrained)

2

Motor cable lead cross section [mm

Signal cable lead cross section [mm

Cable length (depending on option) [mm (in)] 0.3 (11.8), 1.5 (59) or 5 (197)

Protection class - static IP67 / IP69K

Protection class - dynamic IP66

Safety features

static load holding brake

internal end-of-stroke limit switches

overload protection

temperature monitoring

temperature compensation

voltage monitoring

Certications CE, RoHS

Actuator Weight [kg]*

Actuator

model

100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000

(AWG)] 2 (14)

2

(AWG)] 0.5 (20)

Stroke (see product label) [mm]

see table below

1.2 (0.047)

- 40 to + 85 (- 40 to + 185)

yes

yes

yes

yes

yes

yes

HDxx-B026 6.5 6.7 7.0 7.2 7.5 7.7 8.0 8.2 8.5 8.7 9.0 9.2 9.5 9.7 10.0 10.2 11.6 11.9 12.2

HDxx-B045 6.5 6.7 7.0 7.2 7.5 7.7 8.0 8.2 8.5 8.7 9.0 9.2 10.4 10.7 11.0 11.3 11.6 11.9 12.2

HDxx-B068 6.5 6.7 7.0 7.2 7.5 7.7 8.0 8.2 8.5 9.5 9.8 10.1 10.4 10.7 11.0 11.3 11.6 11.9 12.2

HDxx-B100 6.7 7.0 7.2 7.5 7.7 8.0 8.2 9.1 9.4 9.7 10.0 10.3 10.6 10.9 11.2 11.5 11.8 12.1 12.4

* Conversion factor for kilogram to pound: 1 kg = 2.204623 lbs

Thomson Electrak® HD Actuator - Installation Manual - 2016-0124

Page 25

Thomson

6.2 Ordering key

Ordering Key

Position 1 2 3 4 5 6 7 8

Example

1. Actuator type and supply voltage

HD12 = Electrak HD, 12 Vdc

HD24 = Electrak HD, 24 Vdc

2. Screw type, dynamic load capacity

B026- = ball screw, 2.6 kN (585 lbs)

B045- = ball screw, 4.5 kN (1012 lbs)

B068- = ball screw, 6.8 kN (1529 lbs)

B100- = ball screw, 10 kN (2248 lbs)

3. Ordering stroke length

0100 = 100 mm

0150 = 150 mm

0200 = 200 mm

0250 = 250 mm

0300 = 300 mm

0350 = 350 mm

0400 = 400 mm

0450 = 450 mm

0500 = 500 mm

0550 = 550 mm

0600 = 600 mm

0650 = 650 mm

0700 = 700 mm

0750 = 750 mm

0800 = 800 mm

0850 = 850 mm

0900 = 900 mm

0950 = 950 mm

1000 = 1000 mm

HD12 B026- 0300 LXX 2 M M

S

4. Electrak® Modular Control System options

EXX = Electronic Monitoring Package only

ELX = EXX + end-of-stroke indication output

EXP = EXX + analog (potentiometer) position output

EXD = EXX + digital position output

ELP = ELX + analog (potentiometer) position output

ELD = ELX + digital position output

LXX = EXX + low-level signal motor switching

LLX = EXX + LXX + end-of-stroke indication output

LXP = EXX + LXX +analog (potentiometer) position output

CNO = Can bus J1939 + open loop speed control

5. Harness option

1 = 0.3 m long cables with ying leads

2 = 1.5 m long cables with ying leads

3 = 5.0 m long cables with ying leads

6. Rear adapter option

M = cross hole for 12 mm pin

E = cross hole for ½ inch pin

N = forked cross hole for 12 mm pin

F = forked cross hole for ½ inch pin

7. Front adapter option

M = cross hole for 12 mm pin

E = cross hole for ½ inch pin

N = forked cross hole for 12 mm pin

F = forked cross hole for ½ inch pin

P = metric female thread

G = inch female thread

Thomson Electrak® HD Actuator - Installation Manual - 2016-01 25

8. Adapter orientation

S = standard

M = 90 ° turned

Page 26

USA, CANADA and MEXICO

Thomson

203A West Rock Road

Radford, VA 24141, USA

Phone: 1-540-633-3549

Fax: 1-540-633-0294

E-mail: thomson@thomsonlinear.com

Literature: literature.thomsonlinear.com

EUROPE

United Kingdom

Thomson

Office 9, The Barns

Caddsdown Business Park

Bideford, Devon, EX39 3BT

Phone: +44 (0) 1271 334 500

E-mail: sales.uk@thomsonlinear.com

Germany

Thomson

Nürtinger Straße 70

72649 Wolfschlugen

Phone: +49 (0) 7022 504 403

Fax: +49 (0) 7022 504 405

E-mail: sales.germany@thomsonlinear.com

France

Thomson

Phone: +33 (0) 243 50 03 30

Fax: +33 (0) 243 50 03 39

E-mail: sales.france@thomsonlinear.com

Italy

Thomson

Largo Brughetti

20030 Bovisio Masciago

Phone: +39 0362 594260

Fax: +39 0362 594263

E-mail: info@thomsonlinear.it

Spain

Thomson

E-mail: sales.esm@thomsonlinear.com

Sweden

Thomson

Estridsväg 10

29109 Kristianstad

Phone: +46 (0) 44 24 67 00

Fax: +46 (0) 44 24 40 85

E-mail: sales.scandinavia@thomsonlinear.com

ASIA

Asia Paci ic

E-mail: sales.apac@thomsonlinear.com

China

Thomson

Rm 2205, Scitech Tower

22 Jianguomen Wai Street

Beijing 100004

Phone: +86 400 6661 802

Fax: +86 10 6515 0263

E-mail: sales.china@thomsonlinear.com

India

Thomson

c/o CNRG Energy India Pvt., Ltd.

Unit No. FF A 07

Art Guild House, A Wing, 1st Floor, L.B.S. Marg

Kurla - West, Mumbai - 400070 India

Phone. +0091 22 6249 5043

E-mail: sales.india@thomsonlinear.com

Japan

Thomson

Minami-Kaneden 2-12-23, Suita

Osaka 564-0044 Japan

Phone: +81-6-6386-8001

Fax: +81-6-6386-5022

E-mail: csjapan@

South Korea

Thomson

F12 Ilsong Bldg,

507, Teheran-ro, Gangnam-gu,

Seoul, Korea, Zip Code: 06168

Phone: +82 2 6917 5048 & 5049

Fax: +82 2 528 1456 & 1457

E-mail: sales.korea@thomsonlinear.com

SOUTH AMERICA

Brazil

Thomson

Av. Tambore, 1077

Barueri, SP - 06460-000

Phone: +55 11 3616-0191

Fax: +55 11 3611 1982

Email: sales.brasil@thomsonlinear.com

scgap.com

www.thomsonlinear.com

Electrak_HD_Installation_Operation_MNEN-0003-02 | 20170726KB

Specifications are subject to change without notice. It is the responsibility of the product user to determine the suitability of

this product for a specific application. All trademarks property of their respective owners. ©2017 Thomson Industries, Inc.

Loading...

Loading...