Page 1

No copying, translation, modification on other use authorized. All rights reserved worldwide. • Tous droits de reproduction, de traduction, d'adaptation et d'exécution réservés pour tous les pays. • Sämtliche Urheberrechte an diesen Texten und Zeichnungen stehen uns zu. Nachdrucke,

Vervielfältigungen - auch auszugsweise - nur mit unserer vorherigen Zustimmung zulässig. Alle Rechte vorbehalten. • I diritti di riproduzione, di traduzione, e esecuzione sono riservati per tutti i paesi. • Derechos de reproduccion, de traduccion, de adaptacion y de ejecucion reservados para todos los paises.

WARNING : Before servicing this chassis please read the safety recommendations.

ATTENTION : Avant toute intervention sur ce châssis, lire les recommandations de sécurité.

ACHTUNG : Vor jedem Eingriff auf diesem Chassis, die Sicherheitsvorschriften lesen.

ATTENZIONE : Prima di intervenire sullo chassis, leggere le norme di sicurezza.

IMPORTANTE : Antes de cualquier intervención, leer las recomendaciones de seguridad.

- 0903

Plasma

SERVICE MANUAL

DOCUMENTATION TECHNIQUE

TECHNISCHE DOKUMENTATION

DOCUMENTAZIONE TECNICA

DOCUMENTACION TECNICA

TV

50WB03P

Page 2

Indicates critical safety components, and identical components should be used for replacement. Only then can the

operational safety be garanteed.

Le remplacement des éléments de sécurité (repérés avec le symbole ) par des composants non homologués selon la

Norme CEI 65 entraine la non-conformité de l'appareil. Dans ce cas, la responsabilité du fabricant n'est plus engagée.

Wenn Sicherheitsteile (mit dem Symbol gekennzeichnet) nicht durch Original - Ersatzteile ersetzt werden, erlischt die

Haftung des Herstellers.

La sostituzione dei componenti di sicurezza (evidenziati con il segno ) con componenti non omologati secondo la

norma CEI 65 comporta la non conformitá dell'apparecchio. In tal caso è "esclusa la responsabilità " del costruttore.

La sustitución de elementos de seguridad (marcados con el simbolo ) por componentes no homologados segun la

norma CEI 65, provoca la no conformidad del aparato. En ese caso, el fabricante cesa de ser responsable.

MEASUREMENT CONDITIONS - CONDITIONS DE MESURES - MESSBEDINGUNGEN

CONDIZIONI DI MISURA - CONDICIONES DE MEDIDAS

RICEVITORE :

In UHF, livello d'entrata 1 mV, monoscopio barre :

- PAL, norma G. bianco 100%.

Via SCART, livello d'entrata 1 Vpp, monoscopio barre :

Colore, Contrasto, Luminositá media, Suono minimo.

Programma selezionato PR 01.

Tensioni continue rilevate rispetto alla massa con un voltmetro digitale.

RECEIVER :

On UHF,input level : 1 mV, bar test pattern :

- PAL, I standard, 100% white.

Via the scart socket, input level : 1 Vpp, bar test pattern :

Colour, contrast and brightness at mid-position, sound at minimum.

Programme selected : PR 01.

DC voltages measured between the point and earth using a digital

voltmeter.

EMPFÄNGER :

Bei UHF Eingangspegel 1 mV, Farbbalken :

- PAL, Norm G, Weiss 100%.

Über die Scartbuchse : Eingangspegel 1 Vss, Farbbalken :

Farbe, Kontrast, Helligkeit in der Mitte des Bereichs, Ton auf Minimum.

Zugeordnetes Programm PR 01.

Gleichspannungen mit einem digitalen Voltmeter zur Masse gemessen.

RECEPTEUR :

En UHF, niveau d'entrée 1 mV mire de barres

- SECAM, Norm L, Blanc 100%.

Par la prise Péritélévision, niveau d'entrée 1 Vcc, mire de barres .

Couleur, contraste, lumière à mi-course, son minimum.

Programme affecté PR 01.

Tensions continues relevées par rapport à la masse avec un

voltmètre numérique.

RECEPTOR :

En UHF, nivel de entrada 1 mV, mira de barras :

- PAL, norma G, blanco 100%.

Por la toma Peritelevision, nivel de entrada 1 Vpp mira de barra.

Color, Contraste, luz a mitad de carrera, Sonido minimo.

Programa afectado PR 01.

Tensiones continuas marcadas en relacion a la masa con un voltimetro digital.

Do not disconnect modules when they are energized!

Repairs on power supply section are to be carried out only with isolating transformer.

Ne pas retirer les modules lorsqu' ils sont sous tension. N'effectuer les travaux de maintenance sur la partie reliée

au secteur (Switch Mode) qu'au travers d'un transformateur d'isolement.

Module nicht bei eingeschaltetem Gerät entfernen!

Servicearbeiten am Netzteil nur unter Verwendung eines Regeltrenntrafos durchführen.

Non scollegare le piastre quando sono alimentate!

Per le riparazioni sulla sezione alimentatore, utilizzare un trasformatore isolatore.

No desconectar los módulos cuando están activados. Las reparaciones en la sección de alimentación de energía

deben ser ejecutadas solamente con un transformador de separación.

Page 3

First issue 09 / 03 3

Page

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DISASSEMBLING THE MODULES

Removing the SW Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Removing the Digital Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Removing the Y Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removing the X Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BOARD LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DIAGNOSTIC

Led Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

HDCP protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

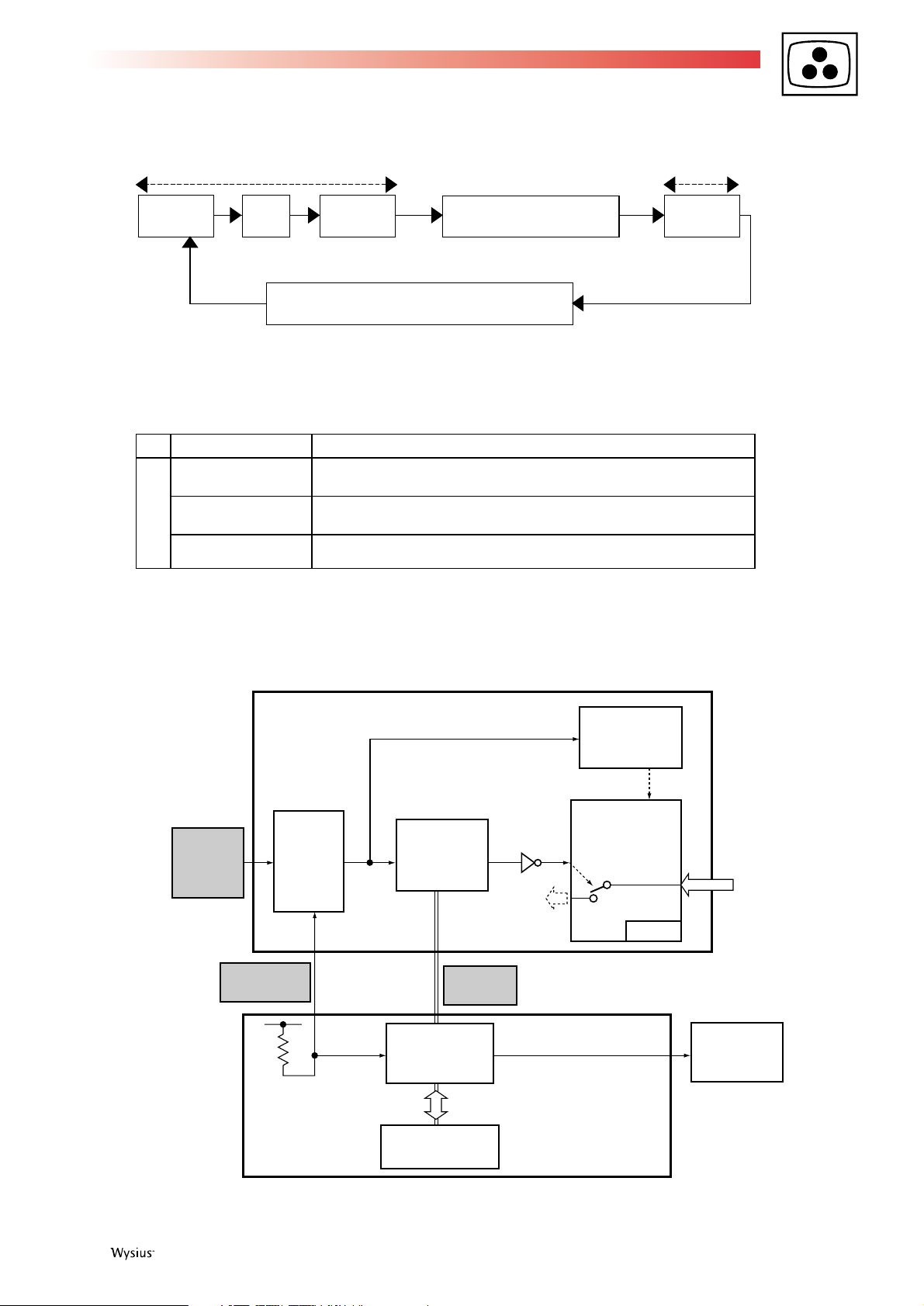

BLOCK DIAGRAM

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

RGB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Digital Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

X Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Y Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sub Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ADR Resonnance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Address connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SIGNAL PATH

Video and Synchronisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Video Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ADJUSTMENTS

Adjusting modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Adjustments required after modules replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CONTENTS

Page 4

4 First issue 09 /03

SAFETY PRECAUTIONS

NOTICE: Comply with all cautions and safety related notes located on or inside the cabinet and on the chassis.

The following precautions should be observed:

1. When service is required, even though the PDP UNIT an isolation transformer should be inserted between the power line and the set

in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment cover shields, isolation resistor capacitor, etc.

3. When service is required, observe the original lead dress. Extra precaution should be taken to assure correct lead dress in the high

voltage circuitry area.

4. Always use the manufacturer's replacement components. Especially critical components as indicated on the circuit diagram should

not be replaced by other manufacturers. Furthermore where a short circuit has occurred, replace those components that indicate

evidence of overheating.

5. Before returning a serviced set to the customer, the service technician must thoroughly test the unit to be certain that it is completely

safe to operate without danger of electrical shock. Also be sure that no protective device built into the set by the manufacture has

become defective, or inadvertently defeated during servicing. Therefore, the following checks should be performed for the continued

protection of the customer and service technician.

6. Perform the following precautions against unwanted radiation and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gasket, Ferrite Core, Ground, Rear Cover, Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the panel face, panel corner, and panel edge (so that the glass does not break).

• Make sure that the panel vent does not break. (Check that the cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the connector will cause it to peel off from the panel.

8. Pay attention to the following.

• When the front case is removed, infrared ray is radiated and may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are removed because this may cause a high risk of disturbance to TVs and

radios in the surrounding.

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the shortcut AC plugs and touch the other lead to each exposed metal part

(input/output terminals, screw heads, metal overlays, control shafts, etc.), particularly any exposed metal part having a return path to

the chassis. Exposed metal parts having a return path to the chassis should have a minimum resistor reading of 0.3MΩ and a

maximum resistor reading of 5MΩ . Any resistor value below or above this range indicates an abnormality that requires corrective

action. Exposed metal parts not having a return path to the chassis will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not use an isolation transformer for this check). Turn the AC power switch

on. Using a "Leakage Current Tester", measure for current from all exposed metal parts of the cabinet (input/output terminals, screw

heads, metal overlays, control shaft, etc.). Do this particularly for any exposed metal part having a return path to the chassis, to a

known earth ground (water pipe, conduit, etc.). Any current measured must not exceed 0.5mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

Leakage

current

tester

Reading should

not be above

0.5mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

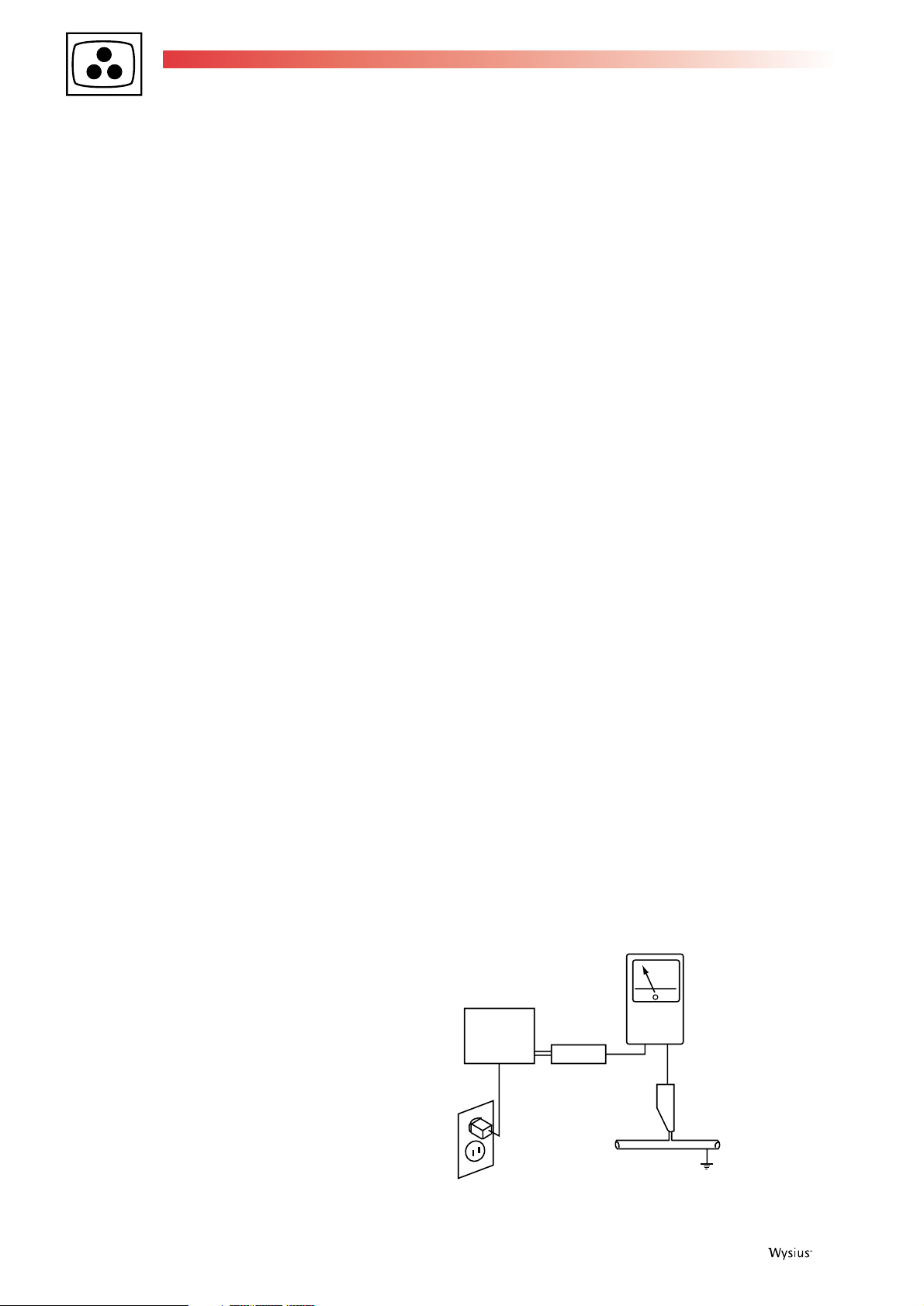

AC Leakage Test

Page 5

First issue 09 / 03 5

Charged Section

The places where the commercial AC power is used without passing through the power supply transformer. If the places are touched,

there is a risk of electric shock. In addition, the measuring equipment can be damaged if it is connected to the GND of the charged

section and the GND of the non-charged section while connecting the set directly to the commercial AC power supply. Therefore, be

sure to connect the set via an insulated transformer and supply the current.

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the SW POWER SUPPLY Module)

5. Standby Transformer and Converter Transformer (In the SW POWER SUPPLY Module)

6. Other primary side of the SW POWER SUPPLY Module

High Voltage Generating Point

The places where voltage is 100V or more except for the charged places described above. If the places are touched, there is a risk of

electric shock.

1. SW POWER SUPPLY Module . . . . . . . . . . . . . . . . . . (225V) 5. SCAN (B) Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . (355V)

2. X DRIVE Assembly . . . . . . . . . . . . . . . . . . . (–300V to 225V) 6. X CONNECTOR (A) Assembly . . . . . . . . . . . (–300V to 225V)

3. Y DRIVE Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . (355V) 7. X CONNECTOR (B) Assembly . . . . . . . . . . .(–300V to 225V)

4. SCAN (A) Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . (355V)

X DRIVE

Assy

X CONNECTOR (B)

Assy

AC Inlet with Filter

Power Cord

Power Switch

(S1)

Y DRIVE

Assy

SCAN (A)

Assy

SCAN (B)

Assy

X CONNECTOR (A)

Assy

SW POWER SUPPLY

Module

Top

Front

Charged Section and High Voltage Generating Point (Rear View)

: Part is the High Voltage Generating Points

other than the Charged Section.

: Part is Charged Section.

Page 6

6 First issue 09 /03

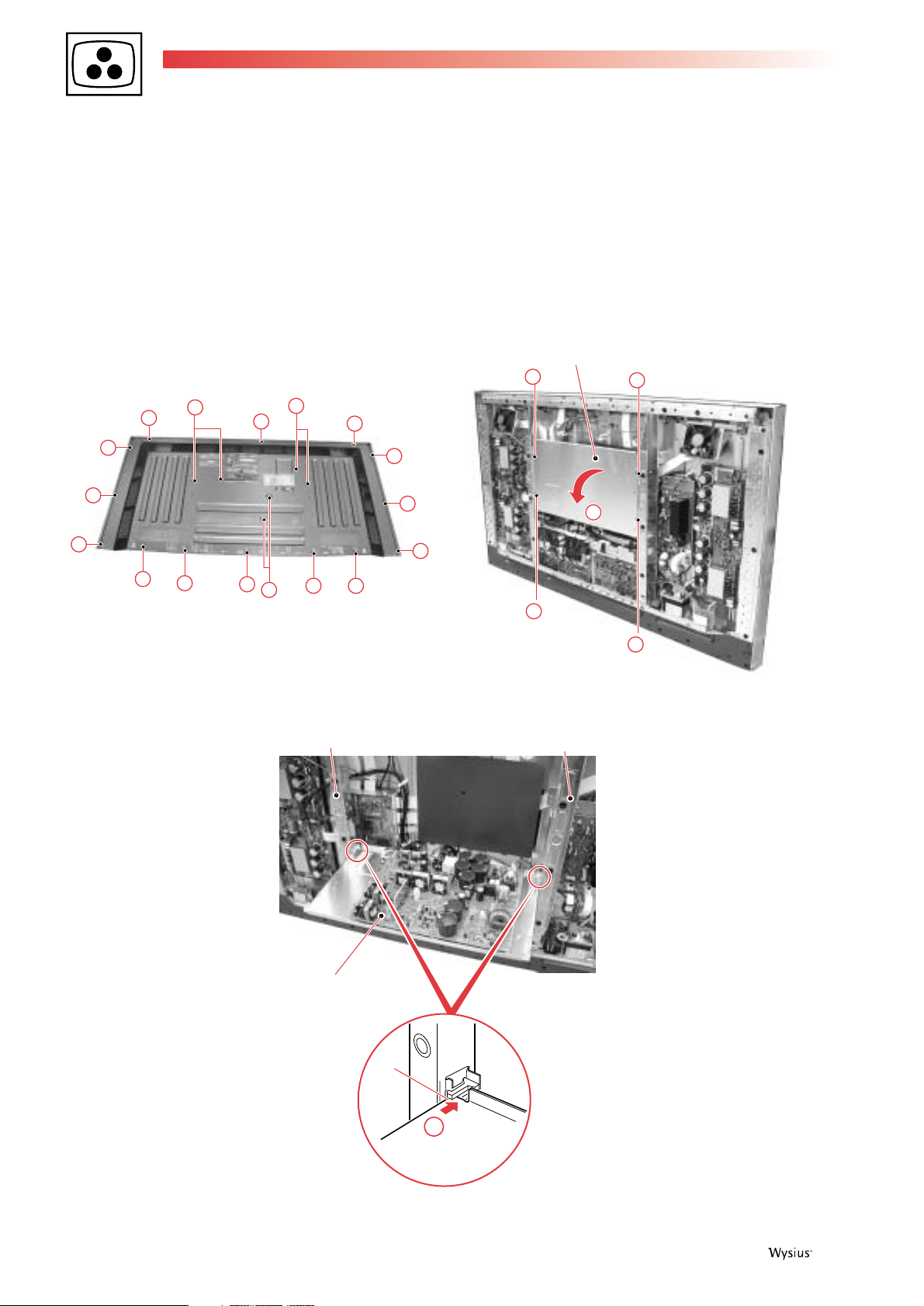

DISASSEMBLING THE MODULES

SW Power Supply Module

1 Remove the Rear Case (50M). (Screws x 20) fig. 1

2 Remove the four screws. fig. 2

3 Remove the SW Power Supply Module. fig. 2

4 Insert the SW Power Supply Module into the slits of Sub Frame L and R. fig. 3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

SW Power Supply

Module

3

2

2

2

2

Sub Frame L

Slit

SW Power Supply

Module

Sub Frame R

4

SW Power Supply

Module

fig. 1

fig. 2

fig. 3

Page 7

First issue 09 / 03 7

DIGITAL VIDEO Assembly

1 Remove the Rear Case (50M). (Screws x 20) fig. 1

2 Remove the SW Power Supply Module. (Connectors, Screws x 4) fig. 2 and fig. 3

3 Remove the 11 screws. fig. 4

4 Remove the one screw. fig. 5

5 Remove the Terminal Panel M. fig. 5

6 Remove the SLOT TMM SERVICE Assembly. fig. 6

7 Remove the four screws. fig. 6

8 Remove the one screw to remove the switch. fig. 6

9 Remove the connectors and binders, and remove the RGB Base with PCB Assembly. fig. 6

10 Remove the DIGITAL VIDEO Assy. (Connectors, circuit board spacers x 6) fig. 7

3

3

3

3

3

3

3

Terminal panel M

4

5

RGB Assy

SLOT TMM SERVICE Assy

RGB base

7

7

8

7

7

6

9

10

DIGITAL VIDEO Assy

fig. 4

fig. 5

fig. 6

fig. 7

Page 8

8 First issue 09 /03

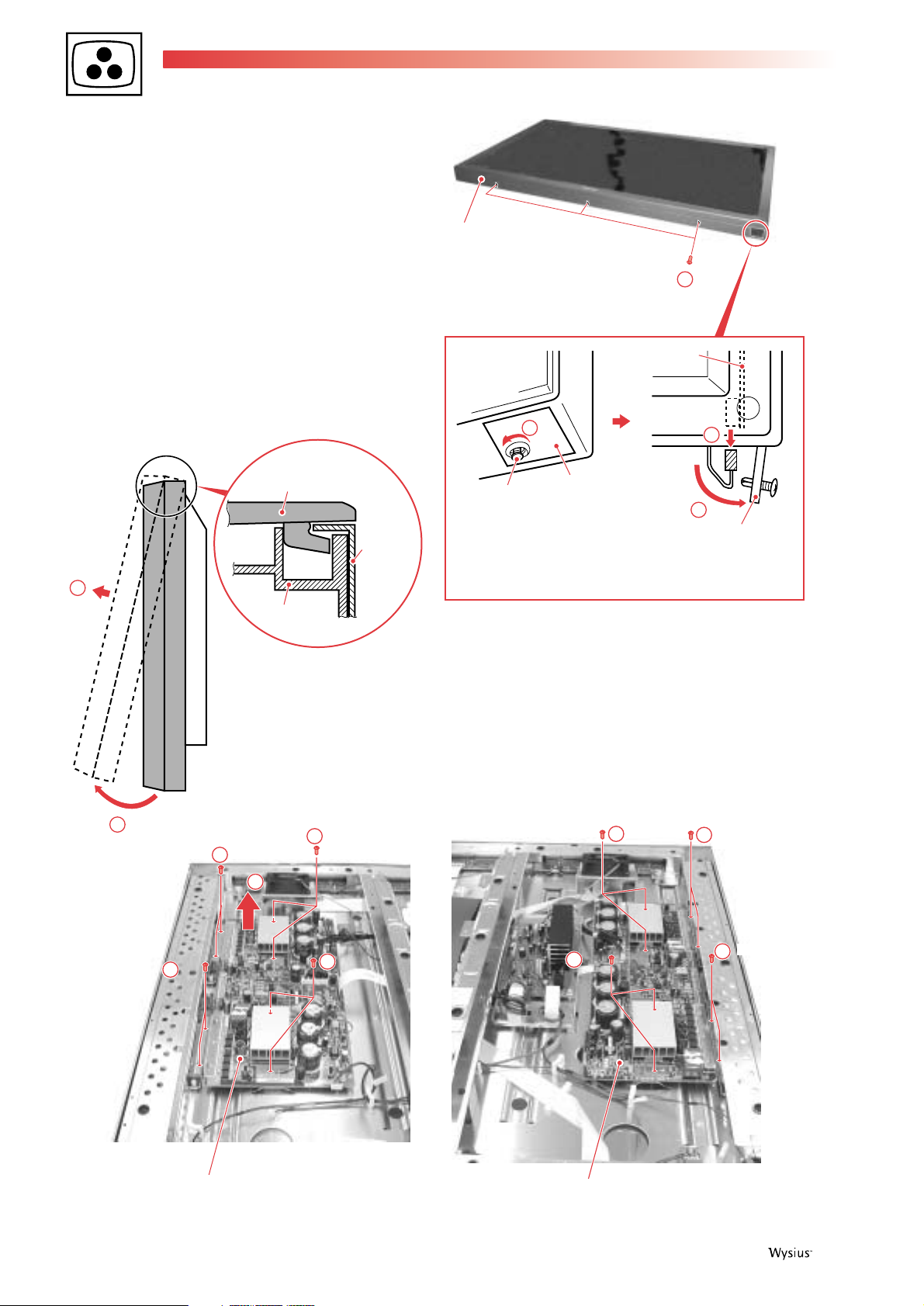

Y DRIVE Assembly

1 Remove the three screws. fig. 8

2 Loosen the Rivet. fig. 8

3 Remove the Lead Cover. fig. 8

4 Pull out the Flexible Cable. fig. 8

5 Detach the lower part of the Front Case 50 so that it can swing open hinged at the top. fig. 9

6 Remove the Front Case 50. fig. 9

7 Remove the Rear Case (50M). (Screws x 20) fig. 1

8 Remove the Y DRIVE Assy. (Connectors, Screws x 8) fig. 10

X DRIVE Assembly

1 Remove the Rear Case (50M). (Screws x 20) fig. 1

2 Remove the X DRIVE Assy. (Connectors, Screws x 8) fig. 11

2

3

Turn the Rivet, taking care not to push

on it, because pushing on it may set

the Rivet to its original position.

Remove the Lead Cover together

with the Rivet when the Rivet is fully

loosened.

Rivet

1

Front Case 50

Lead Cover

Lead Cover

SIDE KEY

Assy

44

5

6

Front Case 50

Aluminum

Materials

The hook of the Front Case 50 is

fixed with the Rear Case (50M) and

the aluminum material, as shown in

the illustration.

Rear Case

(50M)

8

8

8

8

Y DRIVE Assy

8

2

2

X DRIVE Assy

2

2

fig. 8

fig. 9

fig. 10

fig. 11

Page 9

First issue 09 / 03 9

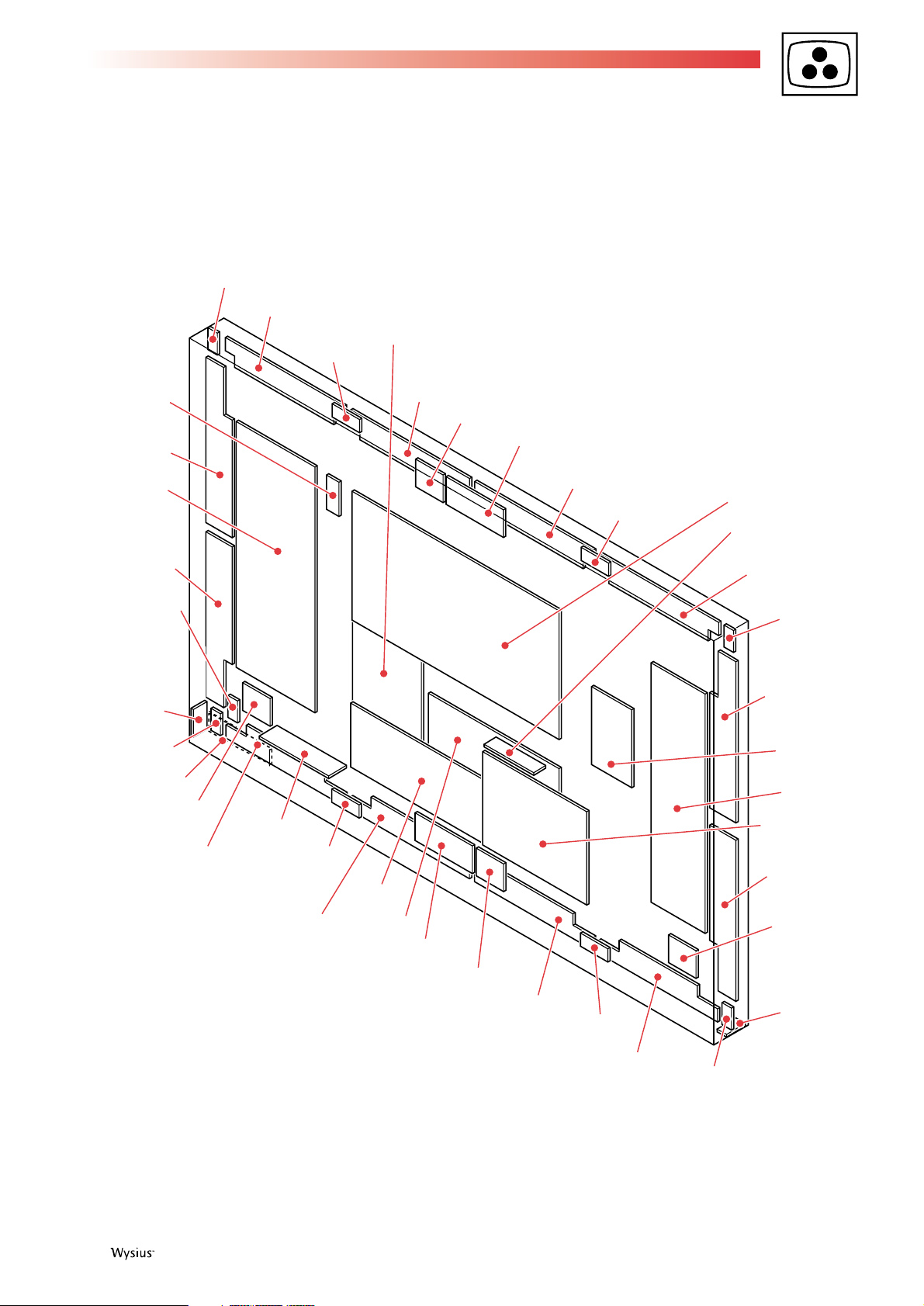

BOARD LOCATION

DIGITAL VIDEO

Assy

BRIDGE B

Assy

ADR CONNECT D

Assy

CLAMP C

Assy

FRONT KEY

TMM Assy

SP OUT R

Assy

SP OUT L

Assy

CONTROL TMM

Assy

KEY

CONNECTOR

Assy

IR RCA Assy

CLAMP D

Assy

CLAMP B

Assy

TMM AUDIO

Assy

X CONNECTOR (A)

X CONNECTOR (B)

Assy

MX LED

Assy

X DRIVE

Assy

SLOT TMM SERVICE

Assy

ADR CONNECT A

Assy

Y DRIVE

Assy

SCAN (A)

Assy

SENSOR

Assy

BRIDGE A

Assy

SCAN (B)

Assy

ADR CONNECT B

Assy

ADR RESONANCE

Assy

SUB ADDRESS A

Assy

SUB ADDRESS B

Assy

ADR RESONANCE

Assy

ADR CONNECT C

Assy

ADR CONNECT D

Assy

CLAMP A

Assy

ADR CONNECT C

Assy

I/O TMM

Assy

RGB Assy

SLOT CONNECTOR

Assy

SW POWER SUPPLY

Module

BRIDGE C

Assy

BRIDGE D

Assy

ADR CONNECT B

Assy

ADR CONNECT A

Assy

Assy

Page 10

10 First issue 09 /03

DIAGNOSTIC

LED

Normal status

Error Status

This is an easy self-diagnostic function by Light Emitting Diode. When PDP does not operate, it shows a reason.

However, it is the simple version. It may not be perfect though regrettable.

Blink of GREEN Light Emitting Diode.

(Ex.: IIC communication NG of MODULE microcomputer. )

Blink of RED Light Emitting Diode

LED STATUS COMMENTS

REDThis indicator is red during standby mode

GREEN This indicator turns to green when the unit is in the FEB mode.

ORANGE This indicator turns to green when the unit is in the STAND-ALONE mode.

Normal Status

Slowly flashes GREEN Power-Management function is operating.

The number of times of blink The reason of a SHUTDOWN

1Communication NG with PANEL microcomputer

2 IIC communication NG of MODULE microcomputer

3Dew condensation NG

4 High temperature NG

5

FAN NG

FAN UNIT PD or Connection fault of the cable to FAN Assembly

6Communication NG with MODULE microcomputer

7Communication NG with WIDE microcomputer

8 IIC communication NG of MAIN microcomputer

9Connection fault of the cable to AUDIO Assembly

It is mainly various poor communications. It is possible to carry out power on again

Green lighting 200ms

The light is not switched on 3s

Blank 100ms Green lighting 200ms

The number of times of blink

The chief reason of a power down

1 Y-DRIVE NG

2

X-DC/DC CONVERTOR NG

Y-DC/DC CONVERTOR NG

3

4 X-DRIVE NG

5POWER SUPPLY NG

6

ADDRESS NG

7ADDRESS RESONANCE NG

8

DC/DC CONVERTOR (DIGITAL) NG

If you switch on a power on again, you once have to shut the main power supply.

Page 11

First issue 09 / 03 11

(Ex.: 1st -> Y-DC/DC CONVERTOR, 2nd -> Y-DRIVE)

Update status

This is in the special state about update of a firmware.

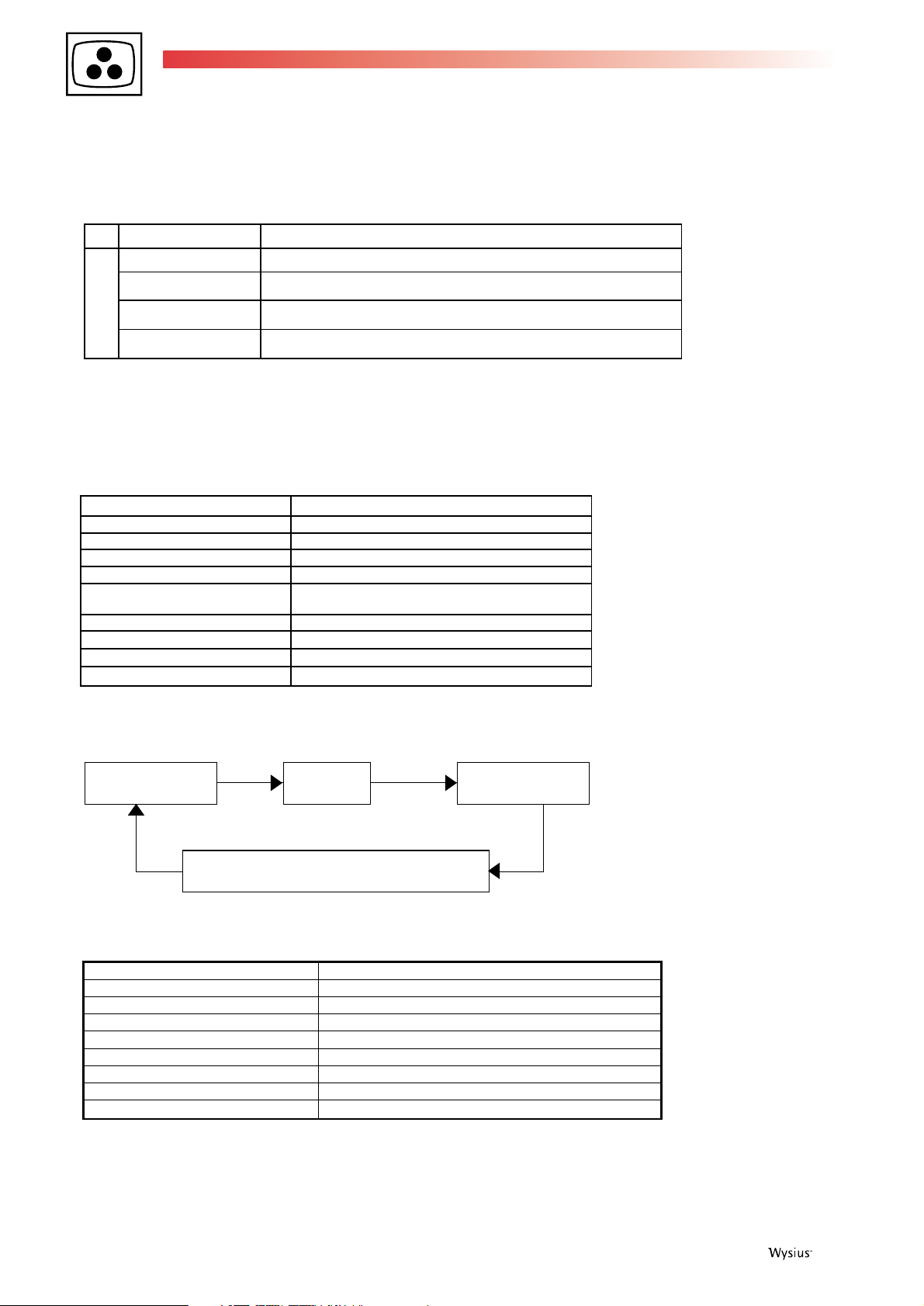

HDCP PROTECTION

Red lighting

200ms

Blank 3s

Blank 1s

Blank

100ms

Red lighting

200ms

Red lighting

200ms

1st 2nd

Slowly flashes

GREEN and RED

Quickly flashes

GREEN and RED

Updating standby or updating end of the Main microcomputer

Or updating end of the Main microcomputer

Main microcomputer is under update.

GREEN When updating data other than the Main microcomputer, it will be in this state

LED STATUS COMMENTS

Normal Status

The detection block of abnormalities

POWER SUPPLY

REGULATOR

SHARP PQ3DZ13

TMDS Rx

Si907B

LOGIC

Circuit

TC74VHC02

MAIN

microcomputer

Detect A.

Rear Case

Open detect

Detect B.

SLOT ST2

Detect C.

PORT I/O SW1

OUTPUT ENABLE

POWER SUPPLY

Module

The history of a LOCK

mechanism of operation

E2PROM (Main)

PORT I/O

EXPANDER

CXA

HDCP key

POWER CONTROL

H : ACTIVE

SW3 S W1

VIDEO

SIGNAL

DVI

TMDS

3.3V

I2C

OUTPUT ENABLE

Page 12

12 First issue 09 /03

Detection in protection mode

The structure of three detections was prepared.

a. Opening of a Rear case is detected by mechanical switch.

b. Simple logic via a connector.

c. It is necessary to control IC by I2C from MAIN microcomputer.

Detection of B and C is for not operating SLOT independently.

Protection mode

When operation of abnormalities is detected, the MAIN microcomputer memorizes a history to E2PROM (MAIN). And it will change to

protection mode.

Light Emitting Diode blinks as follows at the time of protection mode.

Even if you are going to supply AC again, it goes into protection mode again by the history memorized by E2PROM.

Release in protection mode

A procedure is shown below.

1. Pushing INPUT of BODY-KEY is continued 5 seconds or more.

2. Light Emitting Diode changes to lighting of the red that shows a standby state from blink in protection mode.

3. You have to push the following keys in order within 5 seconds from red lighting.

VOL - -> INPUT -> VOL+ -> POWER ON

CAUTION:

PDP will return to protection mode again, when release is impossible within 5 seconds and a mistake is made in pushing body-key.

Red 200 ms

Blank 1100 ms

Blank 100 ms Green 200 ms

Page 13

First issue 09 / 03 13

BLOCK DIAGRAM

GENERAL BLOCK DIAGRAM

DC-DC CONVERTER

MODULE

IC1401 (IC31R)

SUB-FIELD CONV.

for RIGHT with FIELD MEM.

IC1191

FLASH

ROM

IC1207

MODULE

UCOM

V+5V_STB

V+3V_D

V+3V_D

V+3V_IC V+2V_IC

IC1301 (IC31L)

SUB-FIELD CONV.

for LEFT with FIELD MEM.

V+3V_IC V+2V_IC

V+3V_IC

X1801

V+3V_D

+12V

V+5V_STB

+12V

V+5V_D

V+3V_D

V+2V_D

V+3V_D

V+2V_D

V+5V_STB

CLK GEN

TXD0/RXD0

RE SR_UP

TXD/RXD

BA2:9

BB2:9

GA2:9

GB2:9

RA2:9

RB2:9

BIT0:3

ADLCLK UR

ADLCLK_UL

ADL LE UR

ADL_LE_UL

ADL_LE_DL

RELAY

XDRV_SIG

YDRV_SIG

SCAN_SIG

D10D11D15

D7

D18

D6

D2

D14

D4

D3

D13

D17

D8

D12

D1

D9

D16

IIC

LED_SIG

IC1703

XY DRV SEQUENCE

PATTERN GEN.

IC6501

BUFFER IC

CLK/LE

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

IC6601

BUFFER IC

CLK/LE

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

VADR2 VADR2

BGA1

CLAMP

VADR2

CLA1

CLAMP

AA1 AB1

VADR2

SAB1

ADR_CON

SAB3

SAB2

+60V

IC6901

BUFFER IC

CLK/LE

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

IC6801

BUFFER IC

CLK/LE

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVER

IC

Q6706 to Q6711

VADR_GEN

VADR2

K1

VADR2

VADR2

BGC1

CLAMP

VADR2

CLC1

CLAMP

IC6201

ADD

SEL_PULSE

IC6202

ADD

SEL_PULSE

IC6203

ADD

SEL_PULSE

IC6204

ADD

SEL_PULSE

IC6205

ADD

SEL_PULSE

IC6206

ADD

SEL_PULSE

VCC_VH

IC5V

VCC_VH

IC5V

VCC_VH

IC5V

VCC_VH

IC5V

VCC_VH

IC5V

VCC_VH

IC5V

SCAN

IC6001

ADD

SEL_PULSE

IC6002

ADD

SEL_PULSE

IC6003

ADD

SEL_PULSE

IC6004

ADD

SEL_PULSE

IC6005

ADD

SEL_PULSE

IC6006

ADD

SEL_PULSE

VCC_VH

IC5V

VCC_VH

IC5V

VCC_VH

IC5V

VCC_VH

IC5V

VCC_VH

IC5V

VCC_VH

IC5V

PSUS

SCAN

LOGIC

BLOCK

+RESET Block

IC2206

Pulse Module

OFFSET

BLOCK

Photo Coupler

BLOCK

Y-SUS

MASK

BLOCK

IC2214

Pulse Module

Y2

Y-SUS

MASK

BLOCK

Y6

Y1

Y3

Y4

Y5

DC/DC

CONV

BLOCK

+5V

VSUS

+5V VSUS+15V

VCP

VCP

+15V

V_IC5V

SOFT-D

BLOCK

+15V

V_OFSVC_VF+

PSUS

PSUS

Scan Signal

Drive

Signal

VCC_V

H

VCC_VH

V_IC5V

V_IC5V

VCC_VH

V_IC5V

V_OFS

VC_VF-

VC_VF-

VC_VF+

Drive

Signal

+5V VSUS+15V

Co2

Co1

+13.5V

+6.5V

+15V

+12V

VADR

-9V

Cs101

Cs102

Css104

Css

Q125

Switching

Q127

Switching

BA2:9

BB2:9

GA2:9

GB2:9

RA2:9

RB2:9

SD RAM

16M

SD RAM

16M

IC5301(IC30)

IC5102(IC101)

SD RAM

16M

SD RAM

16M

3State Buffer

232C

DRIVER

+3V,+5V,-5V,+9V

+3V,+2V

STB+5V

PC

AUDIO SIGNAL

REG

T1

T2

T4

T3

T5

T6

13.5V,6.5V,-9V

12V,9V, 5V,3V

Plug&Play

E2PROM

9V, 5V,

3V

12V,13.5V,-9V,

6.5V,STB5V

12V,

STB5V

12V,13.5V,

-9V,6.5V

STB5V

N1 DET

C1

R2

R3

R4

AC1

AD1

L OUT

C3

SPR1

KL2

KL1

RE1

SW1

TE1

DIGITAL ASSY

Y DRIVE ASSY

SCAN B ASSY

(LOWER)

SCAN A ASSY

(UPPER)

THERMAL SENSOR ASSY

ADDRESS CONNECT B ASSY

ADDRESS CONNECT A ASSY

ADR RESONANCE ASSY

RGB ASSY

K2

ADDRESS CONNECT D ASSY ADDRESS CONNECT C ASSY

CLAMP C ASSY

CLAMP A

ASSY

BRIDGE C ASSY

BRIDGE A ASSY

CONTROL ASSY

SP OUT R

ASSY

IR TMM

ASSY

KEY CONNECTOR ASSY

FRONT KEY

TMM ASSY

PSUS

I/O ASSY

TRAP SW

IC1101

PANEL UCOM

ADL _LE_DR

ADLCLK_DR

ADLCLK_DL

TEMP

KL_D0:2

KL_U0:2

EXTERNAL

CONTROL

IC6801

BUFFER IC

CLK/LE

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

IC6901

BUFFER IC

CLK/LE

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

VADR2

+60V

SAA1 SAA2

ADR_CON

SAA3

K1

VADR2

VADR2

BGB1

CLAMP

VADR2

CLB1

CLAMP

AC1

AD1

Q6706 to Q6711

VADR_GEN

IC6601

BUFFER IC

CLK/LE

DRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

IC6501

BUFFER IC

CLK/LE

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

DRIVERICDRIVER

IC

VADR2

VADR2

VADR2

BGD1

CLAMP

VADR2

CLD1

CLAMP

+RESET

Pulse

Block

DC/DC

CONV

BLOCK

+5V

Drive

Signal

LOGIC

BLOCK

IC3200

Pulse

Module

X_SUS

MASK

IC3201

Pulse

Module

X_SUS

MASK

+15V

+5V

V_SUS

+15V

+5V

V_SUS

X 1

X 2

X 3

X 4

P_SUS

P_SUS

Drive

Signal

VCP

VCP

v_RN

+15V

v_RN

Co3

Co4

Co5

Co6

VSUS

STB5V

Cs103 Cs104

Cs105

Cs106

LIVE

NEUTRAL

RL101

POWER RELAY

RC101

PRIMARY

SECONDARY

Q128

Q131

M107

Switching

Cl117

Switching

VSUS_CONT

IC5601

WIDE UCOM

IC5505

MAIN UCOM

IC5001(IC102)

IC4803

PLD for SYNC

FLASH

ROM

S3

S1 S2

+11V

+15V,+5VSTB

A1

A_Mute2

R_Audio

L_Audio

+5VSTB

A3

R_OUT

L_OUT

IC8601

POWER AMP

A6

FAN_D

A7

FAN MUTE

IC8701

REGULATOR

+5V_AD/RGB

A5

AUDIO_NG

TEMP3

FAN_NG

+15V

STB+5V

STB+5V

R6

V1

E2PROM

EXPANDER

DVI

REG

+7V,-8V

+3V, +5V, -5V

I2C-BUS

R9

R1

R8

I2C-BUS

AB1

AA1

L OUT

CLAMP

CN901

K3

SPL1

L1

POWER SUPPLY MODULE

SUB ADDRESS A ASSY

ADR RESONANCE ASSY

ADDRESS CONNECT C ASSY

ADDRESS CONNECT D ASSY

TMM AUDIO ASSY

VIDEO SLOT TMM ASSY

SLOT CONNECTOR

ASSY

V MID CLAMP Block

X DRIVE ASSY

X CONNECTOR

A ASSY

X CONNECTOR

B ASSY

SUB ADDRESS B

ASSY

SP OUT L

ASSY

MX LED ASSY

K3

ADDRESS CONNECT B ASSY

ADDRESS CONNECT A ASSY

CLAMP D ASSY

CLAMP B ASSY

BRIDGE D ASSY

BRIDGE B

ASSY

STB+5V

12V,5V

CLAMP

AUDIO

Plug&Play

E2PROM

2-1 SEL

IC8602

REGULATOR

+11V+15V

FAN

LPF IC

V2

PANEL LINK

RECIEVER

GAIN AMP

IC4402

MATRIX

IC4603

A/D PLL AMP

6M LPF

SW POWER SUPPLY

Block

+5V_AD/RGB

K2

Page 14

14 First issue 09 / 03

RGB BLOCK DIAGRAM

13.5V

V+12V V+12V

IC4004

6.5V

-9V

IC4110

(24LCS21A)

Plug&Play

ROM

(TC74VHC541)

TTL

Conv.

INPUT1

Input DET.

IN1DET

WP_SW

Time

Circuit

IC4108

(BA7657F)

RGB

2-1 SW

STB+5V

INPUT1

Component

/RGB

INPUT2

Component

/RGB

Terminator

SW

Audio

Input

Mute

A_MUTE1

EXT_INT

VOL

IC4103

(TC4052BF)

EXT/INT

SEL

IC4104

(TA7630P)

Pre-Amp.

IC4103

(TC4052BF)

FIX/VAL

SEL

Audio

Output

Terminator

SW

INPUT1

Monitor

Out

V-5V V-5V

IC4001

FIX_VAR

A_MUTE2

AUDIO_NG

STB+5V

V+9V V+9V

IC4002

V+5V V+5V

IC4003

V+3.3V V+3.3V AD

IC4005

V+3.3V V+3.3V PLD

IC4006

Audio Amp.

Analog RGB HV / YPbPr

Digital RGB

6M LPF

GeonSYNC(1)

GeonSYNC(2)

2-1

SEL

SYNC SEP

Circuit

EXT_INT

CBLK_MAT

CBLK_LPF

CLP_MAT

CLP_AMP

CLP_AMP

HOLD

IC4402

(CXA2101AQ)

MATRIX ~35M

(3-1 Select)

IC4603

(CXA3516R)

A/D PLL AMP

(2-1 Select)

IC5001

(???????)

IC102

IC5102

(PE5066ACK)

IC101

(LCX125)

CLK SEL

SD RAM

16M

SD RAM

16M

SCP-IN

(31)

HOLD(106)

G/YOUT(2)

B/CbOUT(1)

R_CrOUT(3)

SYNCIN(111/112)

CLPIN(113)

XUNLOCK

(104)

1/2CLK

(101)

DIVOUT

(103)

SDA(56)

SCL(55)

ACL AMP

ACL

I/O ASSY

(LCX541)

2-1

Selector

Buffer

Clamp

SW

DIVOUT(32)

HD_SEP(106)

VD_SEP(107)

CLP_SEP(99)

HPOL(98)

VPOL(97)

HSTATE(96)

VSTATE(93)

CLP_SW1(91)

CLP_SW2(92)

HD_30(72)

HD_PLL(27)

VD_AD(8)

HD_RGB(41)

VD_RGB(42)

HD_PLK2(117)

HD_PLD(119)

VD_PLD(118)

CLP1(5)

CLP_AMP(28)

CLP_MAT(111)

CBLK_MAT(110)

CBLK_LPF(109)

HDLD_PLL(31)

CLP2(6)

HBLKT(7)

VBLKT(8)

VD_PLK2(116)

-HS(100)

+HS(101)

+VS(102)

IPKILL(68)

CS(67)

FILM(70)

HWR(66)

RD(65)

RES(62)

UD[8:15]

UA[0:20]

YI[0:7]

CLP1(278)

CLP2(279)

HBLK1(280)

VBLK1(282)

VD_AD(53)

HD_AD(52)

PBI[0:7]

PR[0:7]

YI[0:7]

PBI[0:7]

PR[0:7]

YP[0:15]

PBP[0:15]

PRP[0:15]

RA_IP[0:7]

GA_IP[0:7]

BA_IP[0:7]

FDET(60)

VACT(61)

WAIT(62)

EMG_IP(67)

CS(66)

HWR(64)

RD(65)

RES(56)

YP[0:15]

PBP[0:15]

PRP[0:15]

HI(57)

VI(58)

FI(64)

HI(168)

VI(167)

FI(166)

HP(55)

VP(56)

HP(170)

VP(169)

CLK(3)

RAO[0:7]RBO[0:7]

GAO[0:7]GBO[0:7]

BAO[0:7]BBO[0:7]

VCLK(132)

DEO(99)

HDO(98)

VDO(97)

CLK(236)

IC4803

(EPM3256ATC144-10)

PLD for SYNC

V+3VD

DC/DC

Converter

IC31

(1/2)

IC31

(2/2)

V+2VD

SD RAM

16M

SD RAM

16M

IC5301

(PD6357B)

IC30

IC5602

(MEM29L800TA-90PFIN)

Flash ROM

100MHz

X'tal

VD Shift

HWR_DLAY

IC5502

(24LC64(I)SN

EEP ROM

THERMO

SENSOR

FAN KEY LED RS-232C REM

Main UCOM

Write Connector

Wide UCOM Write Connector

(PS9248N)

RST IC

IC5504, IC5509

(74HCT00)

SYNC SEL

TC7W126FU

TC7W126FU

Module UCOM

(LM50C1M3)

Thermo

Sensor 2

(M5223)

OP AMP

IC5501

(TC74WHTC541AFT)

3.3V 5V Converter

IC5503

(TC74WHTC541AFT)

5V 3.3V Converter

RST IC

AND

DIGITAL VIDEO

ASSY

RGB ASSY

IC5601

(HD64F2328VF)

Wide UCOM

IC5505

(M3062FGAFP)

Main UCOM

DPMS(7)

H_SYNC(5)

H_SYNC(6)

AUDIO_NC(42)

(E)SDA(82)

(E)SCL(81)

EEPRST(83)

TEMP(94)

FAN_NG(48)

FAN(3)

KEY1_SCAN(20)

LED_G(37)

LED_R(38)

CNVSS(9)

BUS(34)

RXD1(32)

TXD1(31)

RST(12)

CB_MUTE

(50)

REM(18)

REQ_MD(19)

POWER(53)

PNL_MUTE(60)

WE_MD(72)

RXD0(36)

TXD0(35)

TEMP2(95)

BUSY30(55)

RESET(61)

WAIT_FLASH(102)

A13_FLASH(70)

CS_FLASH(69)

RY/BY(102)

WACT_FRCT(32)

HD_W(117)

VD_W(34,73)

DE_W(33,72)

H(119)

VI(31)

FI(118)

CS_30(66)

IC_RST(126)

RDB(91)

HWRS(92)

SGLB_AD(79)

HWR_30

(88)

D_CLK(63)

D_RXD(61)

WU_CE(29)

FEW_CE(60)

MD2(125)

EXT_RXD(62)

EXT_TXD(60)

REQ_WU(71)

D_BUSY(64)

DLK_PLL(105)

PLL_OE(33)

TXD_WU(97)

SCK_WU(101)

RST2(75)

IN5DET(49)

BUSY(54)

REQ_WU(74)

WE_WU(71)

RST_WU(70)

MD2(69)

FWE(68)

WU_CE(47)

OSD_CE

(45)

DIN_SEL

(66)

ACL_SW(58)

SDA(30)

SCL(29)

SIGRST(88)

FR_SEL(51)

PLD_CE(90)

TXD(1)

CLK(2)

H_POL(79)

V_POL(80)

SYNC_ST(85)

RGB_SEL(52)

IN1DET(40)

WP_SW(21)

VOL(4)

EXT_INT(76)

FIX_VAR(84)

A_MUTE1(77)

A_MUTE2(78)

IN3DET(36)

IN4DET(37)

SDIN_SEL(67)

SLOT_ST(93)

SLOT_ST2(22)

UA [0 : 20]

UD [0 : 15]

ULK_PLL(30)

HD_U(140)

VD_U(139)

CLK(125)

FR_SEL(134)

PLD_CE(137)

SCK(128)

TXD(138)

H_POL_U(132)

V_POL_U(131)

SYNC_ST(136)

MCLKI(242)

HIS(300)

CLKI(286)

DEI(296)

HDI(297)

VDI(299)

OSD_RXD(21)

OSD_CLK(22)

OSD_CE(23)

HWRB(301)

RDB(302)

RESETB(303)

CS4B(1)

OSD_V(49)

MCLKO(152)

CLK2A(247)

RA[0:9]RB[0:9]

GA[0:9]GB[0:9]

BA[0:9]BB[0:9]

OSDH(62)

CLKOUT(88)

DEO(92)

HDO(91)

VDO(90)

RAI[0:7]RBI[0:7]

GAI[0:7]GBI[0:7]

BAI[0:7]BBI[0:7]

(LT1399CS)

3CH

Video

Amp.

2-1

SEL

2-1

SEL

(LCX541)

Line Buffer

6M

LPF

SECAM

FLT

Audio

Input A

Audio

Input B

DVI

Y/C

VIDEOINVIDEO

OUT

(TFP201H)

TMDS RECEIVER

Slot

State

6M LPF

3L Y/C

Chroma Decode (4-1 Select)

EEPROM

3D Y/C&CNR

6M LPF

SD RAM

Expan.

DBR

3D_RST

I2C BUS

DVI_PS

VY_SBL

IN4DET IN3DET

Page 15

First issue 09 / 03 15

DIGITAL VIDEO BLOCK DIAGRAM

IC5301

(PD6357)

IC30

Line

Buffer

IC1191

Flash ROM

IC1301 (IC31 L)

(PD6358)

DRAM

IC1401 (IC31 R)

(PD6358)

DRAM

IC1703 (IC23)

(PE5064)

IC1101

(HD64F2328VF)

Panel Microcomputer

CN1201

3.3V 5.0V5.0V 3.3VReset IC

Reset IC

THERMAL

SENSOR

Assy

SW POWER SUPPLY Module

OR

EEP

ROM

DC/DC

Converter

Block

5V

OR

AND

AND

IC1207

(M30624FGAFP)

Module Microcomputer

IC5505

(M30624FGAGP)

Main

Microcomputer

Address Data

Address Data

ADR CONNECT A - D

Assy (Left section)

ADR CONNECT A - D

Assy (Right section)

Y DRIVE Assy

X DRIVE Assy

RESONANCE

Assy

5V

5V

PC_VIDEO

ADR_K_EMG

STOPB

3.3V

3.3V

12V

ADR K PD U

ADR PD

APD MUTE

EXD TXD

RST2

RST PU

EXD RXD

RESET

RESET

RXD

BUSY

REQ_PU

ADR K PD D

DEW DET

RELAY

TEMP1

STB5V

STB5V

STB5V

3.3V

2.5V

3.3V

3.3V

3.3V

VD

HD

VD 31

APLR

STB5V

2.5V

IIC BUS

RGB 2 phase 10 bit

VD

HD

DE

CLK

Address BUS

Data BUS

Control Signal

RXDO

REM

PM_ST

PN_MUTE

MAX_PLS1

DITHER

MOD_SW

POWER

MAX_PLS2

TXDO

REQ_MD TXDO

WE_PN

RXDO

EXT_RXD

EXT_TXD

Reflesh-rate

Det.

AC_OFF

PD_TRIGGER

DCC_PD

Panel W/B ADJ.

Hour/Pulse meter

pn

Address

Resonance

Control

Sustain

Control

RGB ASSY DIGITAL VIDEO ASSY

DIG. ADR. PD

Page 16

16 First issue 09 /03

X DRIVE BLOCK DIAGRAM

23

21

5

7

9

11

13

15

17

19

PN_MUTE

XNR-U

XSUS-B

XSUS-U

XSUS-D

XSUS-G

XSUS-MSK

XCP-MSK

XNR-D1

XNR-D2

CN3001

X2

1

2

3

4

8

11

CN3101

X1

XNR_U

XNR_U

2

4

5

3

6

6

5

2

3

4

9

IC3004

TC74ACT540FT

IC3008

TC74ACT541FT

18

17

14

14

15

18

17

16

16

15

1

5

2

3

4

6

8

9

7

10

IC3008

PE1012A

20

23

22

21

19

17

16

18

15

2

3

4

5

7

8

6

9

IC3001

TC74ACT541FT

IC3102

HCPL-M611

IC3101

TC74ACT541FT

IC3200

STK795-470

Pulse Module

IC3201

STK795-470

Pulse Module

T3701

VRN D-D CONV.

XCP-MSK

XSUS-MSK

VCP

PLD

SUSOUT A

37-40

29,30

K3105

PSUS

K3107

IC3103,IC3104

TND301S

Q3103,

Q3107

Q3104,

Q3109

Q3105,

Q3124

Q3106,

Q3125

SUSOUT B

37-40

29,30

K3106

IC3106,IC3107

TND301S

Q3110,

Q3114

Q3111,

Q3115

Q3112,

Q3126

Q3113,

Q3127

To

X CONNECTOR

ASSY

IC3110

TND301S

IC3113

TND301S

charge pump

circuit

From DIGITAL VIDEO ASSY

Photo

coupler

2-9 11-18

+15V

DGND

XDRIVE_PD

XDC_DC_PD

VSUS

SUSGND

SUSGND

SUSGND

P.D.

DET.

18

17

16

15

13

12

14

11

14

16

18

20

14

16

18

20

VSUS 225V

VRN UVP

VRN OVP

Q3116

Q3120

Q3122

Q3128

XNR-D1

XNR-D2

VRN-300V

X DRIVE

Page 17

First issue 08 / 03 17

Y DRIVE BLOCK DIAGRAM

CLR

CLK

OC1

OC2-1

LE

AB

SI1

SI2

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

VH D-D CONV.

Pulse Module

(STK795-470)

IC2206

YSUS-MSK

OC2-2

PN_MUTE

YPR-U1

YPR-U2

YSUS-B

YSUS-U

YSUS-D

YOFS

YSUS-G

YCP-MSK

YSUS-MSK

YSOFT-D

DEW_DET

Y2

IC2005

TC74ACT541FT

IC2007

TC74ACT540FT

IC2004

YPR-U1

TC74ACT541FT

Pulse Module

(STK795-470)

IC2214

14

16

18

20

14

16

18

20

IC2202

HCPL-M611

IC2006

PE1013

IC2005

TC74ACT541FT

Dew DET.

circuit

Photo Coupler

OC2-2

Y3

Y5

Photo Coupler

SUS muteDET.

circuit

charge pump

circuit

Photo Coupler

VOFS D-D

CONV.

D. GND

+13.5V

SUSGND

D. GND

IC5V, VF

D-D CONV.

IC5V UVP

VOFS UVP

VOFS OVP

VH UVP

VH OVP

VOFS

VF-

IC5V

VF+

VH

YSOFT-D

YOFS

YCP-MSK

VH

VH

IC5V

+13.5V

-9V

IC2208

HCPL-M611

IC2001

TC74ACT541FT

Q2102

IC2504

TC74ACT540FT

IC2506

TC74ACT540FT

IC2503

TC74ACT540FT

IC2516

HCPL-M611

IC2501,IC2502,

IC2505,IC2510,

IC2512,IC2513,

IC2514,IC2525,

HCPL-M611

P.D.

DET.

Vsus

27

25

30

31

40

42

43

45

33

24

19

21

9

10

12

18

13

16

15

22

46

2

+15V

1

3

4

5

6

7

10

11

13

14

CN2501CN2502

To SCAN ASSY

(Lower)

To SCAN ASSY

(Upper)

-9V

YDRIVE_PD

YDC_DC_PD

VOFS_ADJ

VSUS

VSUS

SUSGND

SUSGND

YPR-U2

PSUS

SUSOUT A

VCP

TO

Y CONNECTOR

ASS'Y

SUSOUT B

37-40

37-40

29,30

29,30

IC2201

TC74ACT541FT

K2212

K2203

K2220

PSUS

IC2212

TND301S

Q2219

Q2218

IC2213

TND301S

2-9

11-18

Q2215

Q2216

Q2217

Q2226

IC2217

TND301S

Q2227

Q2220

Q2221

Q2228

Q2232

Q2233

IC2216

TND301S

YPR-U1

YPR-U2

VSUS

SUSGND

Q2210

Q2211

Q2212

Q2204

Q2205

IC2203

TND301S

IC2204

TND301S

IC2210

TND301S

Vsus

15V

5V

Vsus

15V

5V

X DRIVE

Page 18

First issue 08 / 03 18

AUDIO BLOCK DIAGRAM

TMM AUDIO ASS'Y

FAN DRIVE BLOCK

RCA AUDIO BLOCK

+15V

A1

R_AUDIO

GND

A_MUTE2

STBY

GND

L_AUDIO

+5VSTB

+5VSTB

A3

L+

GND

GND

R+

TEMP3

IC8601

POWER AMP

A6

FAN_P

FAN_D

A7

FAN_P

FAN_D

+15V

Vin Vout

Vc Vadj

FAN_Mute

( < 3.4V )

IC8701

REGULATOR

+5V_AD/RGB

A5

AUDIO_NG

TEMP3

FAN_N

FAN

+5V_AD/RGB

+5V_AD/RGB

NOR

(5.5V - 12.35V)

(3.06V - 1.66V)

IC8602

REGULATOR

+15V

Vin

+5V_AD/RGB

11V

R-

L-

+5VSTB

OP-AMP(Buf)

Page 19

19 First issue 08 /03

SUB ADDRESS DIAGRAM

+60V

ADRGND

CN8801

R8801 - R8805 Q8801

V MID SW

ADRK EMG1

Q8803, Q8831 Q8805, Q8806

+12V

DGND

ADR-B ADR EMG 1 Block

ADR-U

12V

ADR-D

ADRK. PD

CN8802

IC8801 IC8801 D8804

(DC+AC) (-AC) 5V

SW

ADR-D

(DC) CLK

ADR-U

ADR-B

+12V

IC8802 IC8802 IC8803

DGND

VADR

ADRGND

CLR

ADROUT

CN8803

IC8804

Current - Voltage

Convert Block

Over Current DET. Block

ADR Output

Resistance Load Block

P.D. Output Block

BUFF Block

Inversion

Block

Additional

Block

Conparator

(EMG : ON)

Flip / Flop

+5V REG

H : EMG1 OFF

L : EMG1 ON

H : V MID CLAMP OFF

L : V MID CLAMP ON

Conparator

(EMG : OFF)

SUB ADDRESS ASSEMBLY

Page 20

First issue 09 / 03 20

ADR RESONNANCE BLOCK DIAGRAM

+60V

+60V

+60V

+60V

CN6702

IC6704 C6703 - C6708

12V

Address Resonance Output Block

ADROUT

ADRGND

ADR B

VADR

C6720 Q6706

DGND

Q6707

+12V

IC6701 Q6701, Q6704 ADR U

ADR-B

C6721 Q6708

ADR-U

Q6709

ADR-D

SW

CN6701

ADR OUT

L6704

IC6702 Q6702, Q6705

VADR

V MID

ADR D

ADRGND

C6722 Q6710

DGND

Q6711

SW

CN6703

DGND

IC6703 Q6703, Q6712 V MID

C6716

C6718

ADRGND

ICP-S1, 0

ADR-B

Pre-Drive

ADR-U

Pre-Drive

ADR-U

Drive

ADR-D

Pre-Drive

ADR-D

Drive

ADR-B

Drive

SAFETY PART :

For continued protection against risk of fire,

replace by original part only

ADR RESONNANCE

ADDRESS CONNECTORS BLOCK DIAGRAM

ADR OUT

ADR PD

Q6502, Q6503

IC6501

CN6501

Buffer

BRIDGE ASSY

OPEN PD

HZ

LBLK

HBLK

LE

CLK

Address Module

(TCP)

Address Module

(TCP)

Address Module

(TCP)

Address Module

(TCP)

Address Module

(TCP)

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

HZ

LBLK

HBLK

LE

CLK

ADDRESS CONNECT.

Page 21

First issue 08 / 03 21

SIGNAL PATH

VIDEO AND SYNCHRONISATION

INPUT Input Signal Signal Route

VIDEO Signal

(480i)

VIDEO Signal

(except 480i)

PC Signal

3/4

VIDEO Signal

(NTSC)

5

VIDEO Signal

(DVI)

INPUT1

INPUT2

INPUT3

INPUT4

INPUT5

Analog Video Signal

Digital Video Signal

1/2

IC4108

BA7657F

IC4403

6M LPF

IC4402

CXA2101AQ

IC4603

CXA3516R

IC5001

PE5067A-K

IC5301

PD6357B

IC4108

BA7657F

IC4402

CXA2101AQ

IC4603

CXA3516R

IC5001

PE5067A-K

IC5301

PD6357B

IC4108

BA7657F

IC4603

CXA3516R

IC5001

PE5067A-K

IC5301

PD6357B

IC7102

UPD64082GF

IC7202

TB1274AF

IC7301

BA7657F

IC4603

CXA3516R

IC5001

PE5067A-K

IC5301

PD6357B

IC7305

SM5301AS

IC7302

M61303FP

IC7301

BA7657F

IC4603

CXA3516R

IC5001

PE5067A-K

IC5301

PD6357B

IC7507

SiI907BCQ52

IC7001

NJM2234

IC7001

NJM2234

IC7507

SiI907BCQ52

IC4108

BA7657F

IC7305

SM5301AS

IC7302

M61303FP

IC7301

BA7657F

IC7102

UPD64082GF

IC7202

TB1274AF

IC4403

6M LPF

IC4402

CXA2101AQ

IC4603

CXA3516R

IC5001

PE5067A-K

IC5301

PD6357B

Total Figure

Page 22

22 First issue 08 /03

VIDEO SLOT

ANALOG OUTPUT

(YCBR/RGB)

IN5DET

AUDIO

OUTPUT

I2C BUS

R-Y

WP SW B-Y

DVI SEL

V/Y SEL

3D RST

Reg cont

INPUT 5

DVI TERMINAL

For

Adjustment

EEPROM

3-1SELECT

2-1

SELECT

Chroma Decode

For EDID

EEPROM

LOGIC

CONV

LPF IC

SM5301AS

CN

SHELD

DET

REG

EXPANDER

CBR ADJ

3cH Gain AMP

M61303

SYNC

CONV

2-1SELECT

BA7657

3D Y/C

(SA:B8/B9)

VOLT CONV

DVI-HDCP

Receiver

SII907

Independent Detection

DE

DAC_P

CL AMP

PROT

LPFSEL (DAC)

Rear Case opening detection

Rear Case opening detection

Page 23

23 First issue 09 /03

ADJUSTMENTS

Adjusting Mode

SERVICE MODE

In this mode, picture-quality adjustments more accurate than those made on the normal user menu and various functions for

alleviating phosphor burn can be performed.

In order to use this mode, you should make PDP the stand-alone. (Or it recommends removing a communication cable with FEB.)

And PDP is made standby (OFF). (Light Emitting Diode must be red lighting.)

The following operations are made into turn in order to go into this menu:

1. It pushes “VOLUME UP” of BODY key first.

2. Next, it pushes “VOLUME DOWN” of Body key.

3. Finally it pushes “POWER ON” of BODY key.

It is necessary to perform these operations quickly. All operations need to carry out within 3 seconds.

If it puts into service mode, a display will come out to the upper left, “SERVICE MODE”(SERVICE MENU).

Operation of a service menu can be performed by the remote control that outputs the Thomson code. And the body key can operate

it also.

To select category (Picture, Screen and etc.), press LEFT or RIGHT key.

Moving a cursor with UP or DOWN key will highlight items (CONTRAST, BRIGHTNESS and etc.). To chose an item, press OK key.

When operating it by the body key, it is the same as menu operation in PC mode at the time of FEB connection.

To escape from a service menu display, press EXIT or MENU key.

Notes:

A service menu does not escape from the mode, even if a signal is lost. (Action differs from the menu for users.) In this case, only

OPTION can be operated.

Again, when a signal is inputted, it is the PICTURE MENU.

Power-Standby mode

Normal Operation mode

: Indicates each mode.

SERVICE MODE

FACTORY MODE

: Indicates a key operation on the remote control unit or the operation panel of the unit.

: Indicates an operation performed with an RS-232C command.

POWER

POWER

Within 3 seconds

MENU

MENU

<FAN>

<FAY> <AJY>

MENU

<AJN>

ADJUSTMENT MODE

Page 24

First issue 09 / 03 24

PICTURE

Picture Item

A sub menu is displayed when the following item is chosen.

In a sub menu, change of an item is possible by UP or DOWN key.

These adjustments are required for each input (INPUT1 to INPUT5) and signals.

Picture Default

Selecting “DEFAULT” by LEFT, RIGHT or OK key press display following menu

If a highlight is moved to "YES", the quality of image is reset in shipping condition. It is memorized by "O.K."

Adjustment range INPUT Item

MIN

MAX

The center value

of shipment *1

CONTRAST 0 255 128

BRIGHT. 0 255 128

H.ENHANCE 0 15 0

PC

V.ENHANCE

0

15

0

CONTRAST 0 255 128

BRIGHT. 0 255 128

COLOR 0 255 128

TINT 0 255 128

H.SHARP 0 15 8

DVI

V.SHARP 0 15

8

*1 It is a value peculiar to a product which has variation by adjustment.

Page 25

25 First issue 09 /03

WHITE BALANCE (WHITE BAL.)

White Balance Item

A sub menu is displayed when the following item is chosen.

*1 It is a value peculiar to a product that has variation by adjustment.

Picture Default

Selecting “DEFAULT” by LEFT, RIGHT or OK key press display following menu

If a highlight is moved to "YES", the quality of image is reset in shipping condition. It is memorized by "O.K."

SCREEN

Screen Item

Adjustment rangeItem

MIN

MAX

The center value

of shipment *1

R HIGH 0 255 255

G HIGH 0 255 255

B HIGH 0 255 255

R LOW 0 255 128

G LOW 0 255 128

B LOW 0 255 128

Page 26

First issue 09 / 03 26

Screen Default

Selecting “DEFAULT” by LEFT, RIGHT or OK key press display following menu

If a highlight is moved to "YES", the quality of image is reset in shipping condition. It is memorized by "O.K."

OPTION

It is moved highlight by UP or DOWN key press. O.K. can change each item after selection by UP and DOWN.

Baud Rate

This item is a baud rate setup of RS-232C. RS-232C is used for factory adjustment. Furthermore, it is used also for upgrade. It is

reference. A baud rate is changed whenever it pushes O.K.

->4800BPS->9600BPS->19200BPS->38400BPS->1200BPS->2400BPS->4800BPS->

Notes: Default is 4800BPS. Don't change this setup.

Full Mask

It is the mode in which a signal is generated inside PDP. It is white, red, green and blue. It changes by O.K. It may be useful to relief

of printing of a screen.

-> OFF -> WHITE -> RED -> GREEN -> BLUE-> OFF ->

Notes: This mode is maintained even if it escapes from service mode. Default is OFF

Adjustment rangeSignal Item

MIN

MAX

Default value

H.POSITION 0 255 128

V.POSITION 0 255 128

CLOCK 0 255 128

PHASE 0 63 32

PC

V.SIZE 0 127 0

DVI V.SIZE 0 127 0

Page 27

27 First issue 09 /03

Side Mask

It is brightness adjustment of a non-drawing part. It is at the time of the screen size “DOT BY DOT” and “4:3”. It can be adjusted

independently, R, G, B.

The default of a side mask differs from others.

When DEFAULT is a highlight, shortly after pushing O.K., it returns to a shipment value. And a value is changed and it returns to a

service menu.

Mask Control

If this mode is turned ON, a non-drawing portion will move. It is at the time of the screen size “DOT BY DOT” and “4:3”. Moreover,

whenever it turns on a power supply, a position moves. It is a kind in printing mitigation mode. It is usually ON.

Orbiter Mode

It is the mode that moves a little display position of a screen with progress of time. It carries out movement of 1 dot at intervals of

about 8 minutes. It is in a horizontal and vertical direction. Since there is fear of a nonsense claim, it is usually OFF.

Inverse Mode

It is the mode that reverses an image. In other words, it is negative & positive reversal. An effect may be in the emergency measure

of printing. Default is OFF.

Fan Control

It is the mode that changes control of FAN.

Adjustment rangeItem

MIN

MAX

Default value

R(ed).LEVEL 0 255 80

G(reen).LEVEL 0 255 80

B(lue).LEVEL 0 255 80

MODE An outline of operation

AUTO

The mode which controls FAN depending on the temperature sensor

inside PDP

MAX

It is not dependent on the sensor inside PDP.

This mode operates FAN at the maximum.

Usually, this mode is not used.

A default is AUTO.

Page 28

First issue 09 / 03 28

Hour Meter

The time when the total operated is counted.

This item counts the drive time of a panel.

The unit of drive time is 1 hour.

It can display for a maximum of 99999 hours.

At the time of factory shipments, it is 0H.

Version

The version of a firmware is displayed.

It is the following for details:

AAA: The version of a MAIN microcomputer

->The microcomputer that mainly controls a user interface

BBB: The version of a WIDE microcomputer

->The microcomputer that mainly controls scale conversion and I/P conversion of an image

CCC: The version of a WIDE flash memory

->The font data for OSD is mainly stored.

DDD: The version of a MODULE microcomputer

->The control microcomputer of a PDP module.

EEE: The version of a PANEL microcomputer

->The microcomputer for control of a panel.

FFF: The version of a PANEL flash memory

->Control sequence data of the PDP panel

Each item is expressed with a number and an easy sign. The part of this model with peculiar MAIN microcomputer and WIDE FLASH

memory.

FACTORY MODE

In this mode, adjustments necessary after changing assemblies can be made.

This mode is operated with RS-232C commands sent from the connected PC. To enter this mode, transmit the "FAY" RS-232C

command in Normal Operation mode.

To return to Normal Operation mode, transmit the "FAN" RS-232C command or press the MENU key on the remote control unit.

RS232C

Specification

Connector D-sub 9 pins

1

6 9

5

Pin No. Signal

1

NC (not connected)

2

TxD (Transmit Data)

3

RxD (Receive Data)

4

NC (not connected)

5

GND (CTS)

6

(Not connected)

7

NC (not connected)

8

V+(RTS)

9

NC (not connected)

Page 29

29 First issue 09 /03

Baud Rate

9600 bps (standard) (Switchable to 1200, 2400, 9600, 19200, 38400 bps)

Data Format

Start: 1-bit

Data: 8-bit

Parity: ODD

Stop: 1-bit

*Therefore, PC and PDP are connected with a straight cable.

Protocol

From computer to plasma display:

(1) When transmitting commands individually

STX (02 hex)+ ID (2 Byte)+ COMMAND (3 Byte)+ ETX (03 hex)

(2) When transmitting commands in batches (up to max. 3 commands).... (NOTE)

STX (02 hex)+ ID (2 Byte)+ COMMAND (3 Byte) +COMMAND (3 Byte) +COMMAND (3 Byte)+ ETX (03 hex)

(3) When transmitting direct numeric commands

STX (02 hex) ID (2 Byte) COMMAND (3 Byte) ARGUMENT (3 Byte) ETX (03 hex)

Note:

COMMAND 3 Bytes (ASCII)

ARGUMENT 3 Bytes (ASCII)

ID 2 bytes: It is ignored in this model. However, 2 bytes of character are required.

What has required waiting time is between commands.

POF -> PON: 6 second

IN1 ~ IN5: 3 second

Etc.

List of RS-232C commands

When a command is received, there is action, such as being displayed. These commands have some which operate by input video

signal limitation.

*Mask color becomes effective at POWEROFF/ON.

- RS-232C adjustment validity:

Shows availability in RS-232C adjustment (service) mode. The AJY command is needed when using these commands.

- Normal validity:

Shows availability in normal operating mode. Valid commands can be used even if they do not follow the sending of the AJY

command.

- Factory adjustment validity:

Shows availability in Factory adjustment mode. As for this mode, it will be used only at the time of exchange of a circuit

board, and a fatal condition. The FAY command is needed when using these commands. Especially factory adjustment mode

should use it carefully. If usage is mistaken, trouble will appear in a product

- Numerical direct validity:

Shows commands that, if transmitted followed by 3-digit numbers, can directly set the adjustment value.

- Up/Down validity:

Shows whether or not a command, if transmitted followed by Upn/DWn (with n a number from 0 to 9), can or cannot increase

the adjusted value by that number alone.

X or Y: Valid blank_: Invalid

NOTE: X = Not put into last memory

Page 30

First issue 09 / 03 30

Command

Name

Full

Name

RS-232C

adjustment

validity

Factory

adjustment

validity

Normal

validity

Numerical

direct

validity

Up/Down

validity

Function

AB0 ABL MODE0 Y

AB1 ABL MODE1 Y

AB2 ABL MODE2 Y

AB3 ABL MODE3 Y

AJNADJUST (SERVICE) NO

ADJUST (SERVICE) YES

X

Terminates RS-232C adjustment (service) mode

Terminates FACTORY mode

Initiates RS-232C adjustment (service) mode

Initiates FACTORY mode

AJY X

AMN AUDIO MUTE NO X X X

Turns audio mute OFF

AMY AUDIO MUTE YES X X X Turns audio mute ON

BBY VIDEO RGB YES Y Y Sets input setting to VIDEO SIGNAL:RGB

BHI BLUE HIGH LIGHT Y Y Y Y Adjusts BLUE HIGH-LIGHT

BLW BLUE LOW LIGHT Y Y Y Y Adjusts BLUE LOW-LIGHT

BRT BRIGHTNESS Y Y Y Y Adjusts brightness

BSL B SIDE MASK LEVEL Y Y Y Y Adjusts BLUE SIDE MASK LEVEL.

CFR Adjusts clock frequency Y Y Y Y Adjusts clock frequency

CL1 CLAMP MODE1 Y Y Sets clamp position to AUTO

CL2 CLAMP MODE2

YY

Sets clamp position to LOCKED

CNT CONTRAST Y Y Y Y Adjusts contrast

COLCOLOUR Y Y Y Y Adjusts colour

CP1 VIDEO COMPONENT1 Y Y

CP2 VIDEO COMPONENT2 Y Y

Sets signal format to COMPONENT2

Sets signal format to COMPONENT1

CPH CLOCK PHASE Y Y Y Y Adjusts clock phase

DSP DISPLAY X X

Displays current input signal information

DW0 DOWN 10 Y Y Y

Reduces adjustment value by 10

DWn DOWN n Y Y Y

Reduces adjustment value by n

Reduces adjustment value to minimum

DWF DOWN FULL Y Y Y

FAN X

FAY X

FCA FAN CONTROL AUTO Y Y

Puts control of fan’s rotation on AUTO

FCM FAN CONTROL MAX Y Y

Puts control of fan’s rotation on MAX

FMB FULL MASK BLUE Y

Turns full mask blue on

FMG FULL MASK GREEN Y

Turns full mask green on

FMN FULL MASK NO Y

Releases full mask

FMR FULL MASK RED Y

Turns full mask red on

FMY FULL MASK YES Y

Turns full mask white on

FRP FRESH POSITION Y Y

Initializes position adjustment data

FST FINAL SET UP (Y)

Various setups are made into a shipment default

FXO FIX OUTPUT Y Y

Fixes sound output (<-> VRO)

GHI G HIGH Y Y Y Y

Adjusts GREEN HIGH-LIGHT

GLW G LOW Y Y Y Y

Adjusts GREEN LOW-LIGHT

GPS GET POSITION DATA X X X

Outputs position data as TxD

GSL G SIDE MASK LEVEL Y Y Y Y

Adjusts GREEN SIDE MASK LEVEL

GS1 FIRMWARE INFORMATION X X

PDP information, versions of firmware

GSO GET STATUS OPTION X X X

Outputs OPTION-related data as TxD

Outputs SET UP-related data as TxD

GSS GET STATUS SET UP X X X

GWB GET WHITE BALANCE X X X

Outputs image quality and white balance

adjustment data as TxD

HCN HIGH CONTRAST NO Y Y

Turns high-contrast setting OFF

Turns high-contrast setting ON

HCY HIGH CONTRAST YES Y Y

HMD HOUR METER DISP. X X

Displays hour meter

HPS HORIZONTAL POSITION Y Y Y Y

Adjusts horizontal position

IN1 INPUT1 Y Y Y

Selects PC

IN2 INPUT2 Y Y Y

Selects DVI

I

H

G

F

D

C

B

A

Page 31

31 First issue 09 /03

MCN

Mask Control No

YY

Releases automatic mask position control setting

MCY

Mask Control Yes

YY

Applies automatic mask position control setting

MTN

Video Mute No

XXX

Turns video mute OFF.

MTY

Video Mute Yes

XXX

Turns video mute ON.

M

M00

Mask Mode Off

Y

M01

Mask Pattern 1(lamp)

Y

M02

(Color Bar)

Y

M03

(Slanting Line)

Y

M04

(W/B Measurement)

Y

M05

(W/B Ajustment)

Y

M06

(W/B Peak Measurement)

Y

M07

(Peak Measurement)

Y

M08

(Reserved)

Y

M09

(Block1)

Y

M10

(Block2)

Y

M11

(Reserved)

Y

M12

(Reserved)

Y

M13

(Reserved)

Y

M14

(Reserved)

(Reserved)

(Reserved)

Y

M51

(Full Mask White)

Y

M52

(Full Mask Cyan274)

Y

M53

(Full Mask Magenta1023)

(Full Mask Magenta98)

(Full Mask Beige)

(Full Mask Beige43)

Y

M54 Y

M55

(Full Mask Cyan1023)

Y

M56

(Full Mask Light Purple)

(Full Mask Light Purple43)

(Full Mask Azure)

(Full Mask Azure1_43)

(Full Mask Yellow)

(Full Mask Blue916)

(Full Mask Azure2_43)

(Full Mask Red)

(Full Mask Green)

(Full Mask Blue)

Y

M57 Y

M58 Y

M59 Y

M60 Y

M61

(Full Mask Black)

Y

The contents of a pattern may change without

a preliminary announcement. It is based on a

production process

M62

(Full Mask Red779)

(Full Mask Red620)

Y

M63

(Full Mask Cyan 218)

Y

M64

(Full Mask Cyan444)

Y

M65 Y

M66

Y

M67 Y

M68 Y

M69 Y

M70 Y

M71 Y

M72 Y

M73 Y

M74 Y

NRH

Digital Nr High

YY

Sets DIGITAL NR to HIGH

NRL

Digital Nr Low

YY

Sets DIGITAL NR to LOW.

NRM

Digital Nr Middle

YY

Sets DIGITAL NR to MIDDLE.

N

NRN

Digital Nr Off

YY

Turns DIGITAL NR OFF

OFY

Offset Mode Yes

X

Initiates OFFSET (FACTORY) mode

OMN

Orbiter Mode No

YY

Turns orbiter mode OFF

Turns orbiter mode YES

OMY

Orbiter Mode Yes

YY

O

Command

Name

Full

Name

RS-232C

adjustment

validity

Normal

validity

Numerical

direct

validity

Up/Down

validity

FunctionFactory

adjustment

validity

Page 32

First issue 09 / 03 32

Command

Name

Full

Name

RS-232C

adjustment

validity

Normal

validity

Numerical

direct

validity

Up/Down

validity

FunctionFactory

adjustment

validity

PBH Panel Blue High Y Y Y

Adjusts BLUE HIGH-LIGHT

Adjusts GREEN HIGH-LIGHT

Adjusts RED HIGH-LIGHT

Adjusts RED LOW-LIGHT

Adjusts GREEN LOW-LIGHT

Adjusts BLUE LOW-LIGHT

PBL Panel Blue Low Y Y Y

PCY Pc RGB Yes Y Y

Sets input setting to 4.3 (SETTING:VGA or XGA)

Sets input setting to wide (SETTING:

WVGA or WXGA)

PGH Panel Green High Y Y Y

PGL Panel Green Low Y Y Y

PLN Bright Enhance Off Y Y

Turn center-brightness enhancement function OFF

Turn center-brightness enhancement function ON

PLY Bright Enhance On Y Y

POF Power Off Y Y Y

Turns power OFF

PON Power On Y

Turns power ON. ONLY stand-by

PRH Panel Red High Y Y Y

PRL Panel Red Low Y Y Y

PS1 Power Save Mode1 Y Y

Sets AUTO POWER OFF to ON.

PS2 Power Save Mode2 Y Y

Turns power management setting ON

PSN Power Save Off Y Y

Turns AUTO POWER OFF/power management

setting OFF

PT0 Panel Color Temp. Y

PT1 Panel Color Temp. Y

PT2 Panel Color Temp Y

PT3 Panel Color Temp Y

PUH Purecinema Hq Y Y

Sets FILM MODE to H.QUALITY (high quality)

PUN Purecinema Off Y Y

Turns FILM MODE OFF

Turns FILM MODE STANDARD

PUS

PWY

Purecinema Standard Y Y

P

Pc Wide Yes Y Y

RFY Reference Yes X

Initiates REFERENCE (FACTORY) mode

RHI R High Y Y Y Y

Adjusts RED HIGH-LIGHT

Adjusts RED LOW-LIGHT

RLW R Low Y Y Y Y

R

RSLR Side Mask Level Y Y Y Y

Adjusts RED SIDE MASK LEVEL

SHP H.sharp Y Y Y Y

Adjusts H.SHARP/H.ENHANCE

SHV V.sharp Y Y Y Y

Adjusts V.SHARP/V.ENHANCE

SM0 Screen Mode 0 Y Y Y

Sets screen size to DOT BY DOT

SM1 Screen Mode 1 Y Y Y

Sets screen size to 4:3

SM2 Screen Mode 2 Y Y Y

Sets screen size to FULL

SM3 Screen Mode 3 Y Y Y

Sets screen size to ZOOM/PARTIAL

SM5 Screen Mode 5 Y Y Y

Sets screen size to WIDE

S

STD Standard W/b Y

Initializes image quality and white balance

adjustment data

TTNT Tint Y Y Y Y

Adjusts TINT

UP0 Up 10 Y Y Y

Increases adjustment value by 10.

UPn Up n Y Y Y

Increases adjustment value by n.

U

UPF Up Full Y Y Y

Maximizes adjustment value.

VOL Volume Y Y Y Y Y

Adjusts audio volume

VPS Vertical Position Y Y Y Y

Adjusts vertical position

Adjusts vertical size

VRO Variable Output Y Y

Sets audio-out to variable output

V

VSI Vertical Size Y Y Y Y

YCM 3d Y/c Motion Y Y

Sets 3D Y/C to MOTION.

Y

YCS 3d Y/c Still Y Y

Sets 3D Y/C to still.

Page 33

33 First issue 09 /03

GET commands

What are GET commands?

- They are commands used for TXD output of adjustment data and the like from the plasma display’s built-in microcomputer

to a personal computer.

- Adjustment data, etc., is output in ASCII code.

NOTE: Command names are given inside brackets < >.

- Data output format

NOTE: STX (02hex) Data Data ···· Data ETX (03hex)

<GPS> (GET POSITION DATA) – SCREEN adjustment data will be output as follows.

<GWB> (GET W/B DATA) – PICTURE and WHITE BALANCE adjustment data will be output as follows.

Order Data Size Remarks

1 H.POSITION 3byte

2 V.POSITION 3byte

3 CLOCK 3byte (NOTE)

4 PHASE 3byte (NOTE)

5 V.SIZE 3byte

(NOTE) If the current input signal is a video signal or digital RGB signal, the

adjustment data will be output as dummy data.

Order Data Size Remarks

1

2

3

4

5

Dummy data 3byte

CONTRAST 3byte

Dummy data 3byte

BRIGHT

3byte

Dummy data 3byte (NOTE)

6

COLOR 3byte

7

Dummy data 3byte (NOTE)

8

TINT 3byte

9

Dummy data 3byte

10

R HIGH 3byte

11

Dummy data 3byte

12

G HIGH 3byte

13

Dummy data 3byte

14

B HIGH

3byte

15

Dummy data 3byte

16

R LOW

3byte

17

Dummy data 3byte

18

G LOW 3byte

19

Dummy data 3byte

20

B LOW

3byte

21

H.ENHANCE (H.SHARP) 3byte

22

V.ENHANCE (V.SHARP) 3byte

(NOTE) If the current input signal is from a personal computer, the

adjustment data will be output as dummy data.

Page 34

First issue 09 / 03 34

<GSS> (GET STATUS SET UP) Set data for SET UP will be output as follows.

Order Data Size RemarksOutput

1

2

3

4

5

1byte

2byte

2byte

2byte

2byte

(NOTE)

6

1byte

7

2byte

8

1byte

9

3byte

10

11

3byte

12

1byte

13

1byte

14

15

3byte

16

1byte

17

1byte

18

3byte

19

1byte

3byte

1byte

COLOR TEMP 1: COLOR TEMP1

2: COLOR TEMP2

3: COLOR TEMP3

4: COLOR TEMP4

5: COLOR TEMP5 (NOTE)

DIGITAL NR 0: OFF, 1: LOW

2: MIDDLE, 3: HIGH (NOTE)

HIGH CONTRAST 0: OFF, 1: ON

FILM MODE Same as RS-232C command

Same as RS-232C command

(NOTE)

(REFER TO PURECINEMA)

COLOUR SYSTEM NTS

CLAMP POSITION 1: AUTO, 2: LOCKED (NOTE)

3D Y/C MODE M: MOTION

S: STILL (NOTE)

SETTING/VIDEO SIGNAL

N/A 0

N/A 0

HDTV MODE H80 1080I

N/ADon’t care

Input functions INx

Screen size 0: DOT-BY-DOT

1: 4:3

2: FULL

3: ZOOM

5: WIDE

N/A 60

N/A 60

N/A 60

N/A 60

N/A 60

(NOTE) For set data unrelated to the current input function, input signal and settings, dummy data will be output.

Page 35

35 First issue 09 /03

<GSO> (GET STATUS OPTION) Set data for OPTION will be output as follows.

<GS1> (GET STATUS 1) Set data for FIRMWARE will be output as follows.

Order Data Size RemarksOutput

1

2

3

4

5

3byte

3byte

5byte

1byte

6

1byte

7

8

3byte

9

3byte

10

11

3byte

12

3byte

13

1byte

14

15

1byte

16

1byte

17

1byte

1byte

1byte

12byte

1byte

Same as RS-232C command

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PWN

1

FULL MASK

R SIDE MASK LEVEL Adjustment value

Adjustment value

Adjustment value

G SIDE MASK LEVEL

B SIDE MASK LEVEL

MASK CONTROL 1byte 0: Fixed, 1: Shifts

ORBITER MODE 1byte 0: OFF, 1: ON

INVERSE MODE 0: OFF, 1: ON

1

N

FAN CONTROL A: AUTO

M: MAX

NO CARE

DUMMY

TEMPERATURE

HOUR METER

0

Order Data Size Output

1

2

3