Page 1

SERVICE MANUAL

DOCUMENTATION TECHNIQUE

TECHNISCHE DOKUMENTATION

DOCUMENTAZIONE TECNICA

DOCUMENTACION TECNICA

No copying, translation, modification on other use authorized. All rights reserved worldwide. • Tous droits de reproduction, de traduction, d'adaptation et d'exécution réservés pour tous les pays. • Sämtliche Urheberrechte an diesen Texten und Zeichnungen stehen uns zu. Nachdrucke,

Vervielfältigungen - auch auszugsweise - nur mit unserer vorherigen Zustimmung zulässig. Alle Rechte vorbehalten. • I diritti di riproduzione, di traduzione, e esecuzione sono riservati per tutti i paesi. • Derechos de reproduccion, de traduccion, de adaptacion y de ejecucion reservados para todos los paises.

WARNING : Before servicing this chassis please read the safety recommendations.

ATTENTION : Avant toute intervention sur ce châssis, lire les recommandations de sécurité.

ACHTUNG : Vor jedem Eingriff auf diesem Chassis, die Sicherheitsvorschriften lesen.

ATTENZIONE : Prima di intervenire sullo chassis, leggere le norme di sicurezza.

IMPORTANTE : Antes de cualquier intervención, leer las recomendaciones de seguridad.

- 1004

42WM03ST

42WM04ST

TV

Plasma

Page 2

Indicates critical safety components, and identical components should be used for replacement. Only then can the

operational safety be garanteed.

Le remplacement des éléments de sécurité (repérés avec le symbole ) par des composants non homologués selon la

Norme CEI 65 entraine la non-conformité de l'appareil. Dans ce cas, la responsabilité du fabricant n'est plus engagée.

Wenn Sicherheitsteile (mit dem Symbol gekennzeichnet) nicht durch Original - Ersatzteile ersetzt werden, erlischt die

Haftung des Herstellers.

La sostituzione dei componenti di sicurezza (evidenziati con il segno ) con componenti non omologati secondo la

norma CEI 65 comporta la non conformitá dell'apparecchio. In tal caso è "esclusa la responsabilità " del costruttore.

La sustitución de elementos de seguridad (marcados con el simbolo ) por componentes no homologados segun la

norma CEI 65, provoca la no conformidad del aparato. En ese caso, el fabricante cesa de ser responsable.

MEASUREMENT CONDITIONS - CONDITIONS DE MESURES - MESSBEDINGUNGEN

CONDIZIONI DI MISURA - CONDICIONES DE MEDIDAS

RICEVITORE :

In UHF, livello d'entrata 1 mV, monoscopio barre :

- PAL, norma G. bianco 100%.

Via SCART, livello d'entrata 1 Vpp, monoscopio barre :

Colore, Contrasto, Luminositá media, Suono minimo.

Programma selezionato PR 01.

Tensioni continue rilevate rispetto alla massa con un voltmetro digitale.

RECEIVER :

On UHF,input level : 1 mV, bar test pattern :

- PAL, I standard, 100% white.

Via the scart socket, input level : 1 Vpp, bar test pattern :

Colour, contrast and brightness at mid-position, sound at minimum.

Programme selected : PR 01.

DC voltages measured between the point and earth using a digital

voltmeter.

EMPFÄNGER :

Bei UHF Eingangspegel 1 mV, Farbbalken :

- PAL, Norm G, Weiss 100%.

Über die Scartbuchse : Eingangspegel 1 Vss, Farbbalken :

Farbe, Kontrast, Helligkeit in der Mitte des Bereichs, Ton auf Minimum.

Zugeordnetes Programm PR 01.

Gleichspannungen mit einem digitalen Voltmeter zur Masse gemessen.

RECEPTEUR :

En UHF, niveau d'entrée 1 mV mire de barres

- SECAM, Norm L, Blanc 100%.

Par la prise Péritélévision, niveau d'entrée 1 Vcc, mire de barres .

Couleur, contraste, lumière à mi-course, son minimum.

Programme affecté PR 01.

Tensions continues relevées par rapport à la masse avec un

voltmètre numérique.

RECEPTOR :

En UHF, nivel de entrada 1 mV, mira de barras :

- PAL, norma G, blanco 100%.

Por la toma Peritelevision, nivel de entrada 1 Vpp mira de barra.

Color, Contraste, luz a mitad de carrera, Sonido minimo.

Programa afectado PR 01.

Tensiones continuas marcadas en relacion a la masa con un voltimetro digital.

Do not disconnect modules when they are energized!

Repairs on power supply section are to be carried out only with isolating transformer.

Ne pas retirer les modules lorsqu' ils sont sous tension. N'effectuer les travaux de maintenance sur la partie reliée

au secteur (Switch Mode) qu'au travers d'un transformateur d'isolement.

Module nicht bei eingeschaltetem Gerät entfernen!

Servicearbeiten am Netzteil nur unter Verwendung eines Regeltrenntrafos durchführen.

Non scollegare le piastre quando sono alimentate!

Per le riparazioni sulla sezione alimentatore, utilizzare un trasformatore isolatore.

No desconectar los módulos cuando están activados. Las reparaciones en la sección de alimentación de energía

deben ser ejecutadas solamente con un transformador de separación.

Page 3

First issue 10 / 04 3

Page

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DISASSEMBLY

Removing the leg tube assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Removing the rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removing the filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TROUBLESHOOTING

No power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

No picture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Vertical line fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Horizontal line fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

No command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ADJUSTMENTS

Power (PLG-421) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power (DGK-420W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Color temperature in DVI mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Color temperature in RGB mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

APPENDIX A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SCHEMATIC DIAGRAMS

Tuner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 - 32

Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 - 51

SPECIAL MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 - 53

EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

CONTENTS

Page 4

4 First issue 10 /04

IMPORTANT SAFETY PRECAUTIONS

1. Before returning an instrument to the customer, always make a safety check of the entire instrument, including the

following items, but not limited to them.

a. Be sure that no built-in protective devices are defective and/or have been defeated during servicing. (1) Protective

shields are provided on this chassis to protect both the technician and the customer. Correctly replace all missing

protective shields, including any removed for servicing convenience. (2) When reinstalling the chassis and/or other

assembly in the cabinet, be sure to put back in place all protective devices, including, but not limited to, non-metallic

control knobs, insulating fishpapers, adjustment and compartment covers/shields, and isolation resistor/capacitor

networks. Do not operate this instrument or permit it to be operated without all protective devices correctly

installed and functioning.

b. Be sure that there are no cabinet openings through which an adult or child might be able to insert their fingers and

contact a hazardous voltage. Such opening include, but are not limited to (1) spacing between the picture tube and

the cabinet mask, (2) excessively wide cabinet ventilation slots, and (3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Leakage Current Hot Check: With the instrument completely reassembled, plug the AC line cord directly into a 230V

AC outlet. (Do not use an isolation transformer during this test.) Use a leakage current tester or a metering system.

With the instrument AC, first switch ON and then OFF. Measure from a known earth ground (metal waterpipe,

conduit, etc.) to all exposed metal parts of the instrument (antennas, handle bracket, metal cabinet, screwheads,

metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the

chassis. Any current measured must not exceed 3.5 mA. Reverse the instrument power cord plug in the outlet and

repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE INSTRUMENT TO THE

CUSTOMER.

2. Read and comply with all caution and safety-related notes on or inside the Monitor cabinet, on the Projection Monitor

chassis or on the picture tube.

+-

Test all exposed

metal surfaces

3. Wire cord

Also test with

plug reversed

(using AC adapter

plug as required)

Device

under

test

Earth ground

Leakage

current

tester

AC Leakage test

(Reading

should not

be above

3.5 mA)

Page 5

First issue 10 / 04 5

3. Design Alteration Warning: Do not alter or add to the mechanical or electrical design of this unit. Design alterations and

additions, including, but not limited to, circuit modifications and the addition of the items such as auxiliary audio and/or

video output connections might alter the safety characteristics of this Projection Monitor and create a hazard to the user.

Any design alterations or additions will void the manufacturer's warranty and will make you, the service, responsible for

personal injury or property damage resulting therefrom.

4. Hot Chassis Warning:

a. Some Monitor chassis are electrically connected directly to one conductor of the AC power cord and may be safely

serviced without an isolation transformer only if the AC power plug is inserted so that the chassis is connected to the

ground side of the AC power source. To confirm that the AC power plug is inserted correctly, with an AC voltmeter

measure between the chassis and a known earth ground. If a voltage reading in excess of 1.0V is obtained, remove

and reinsert the AC power plug in opposite polarity and again measure the voltage potential between the chassis

and a known earth ground.

b. Some Monitor chassis normally have 85V AC (RMS.), between chassis and earth ground regardless of the AC plug

polarity. These chassis can be safely serviced only with an isolation transformer inserted in the power line between

the receiver and the AC power source, for both personnel and test equipment protection.

c. Some Projection Monitor chassis have a secondary ground system in addition to the main chassis ground. This

secondary ground system is not isolated from the AC power line. Insulating material that must not be defeated or

altered electrically separates the two ground systems.

5. Observe original lead dress. Take extra care to assure correct lead dress in the following areas:

a. near sharp edges,

b. near thermally hot parts (be sure that leads and components do not touch thermally hot parts),

c. the AC supply,

d. high voltage,

e. antenna wiring. Always inspect in all areas for pinched, out-of-place, or frayed wiring. Do not change spacing

between components and between components and the printed-circuit board. Check AC powers cord for damage.

6. Components, parts, and/or wiring that appear to have overheated or are otherwise damaged should be replaced with

components, parts, or wiring that meet original specifications. Additionally, determine the cause of overheating and/or

damage and, if necessary, take corrective action to remove any potential safety hazard.

7. PRODUCT SAFETY NOTICE: Many Monitor electrical and mechanical parts have special safety-related characteristics

some of which are often not evident from visual inspection, nor can the protection they give necessarily be obtained by

replacing them with components rated for higher voltage, wattage, etc. Parts that have special safety characteristics are

identified in this service data by shading with a mark on schematics. Use of a substitute replacement part that does not

have the same safety characteristics as the recommended replacement part in this service data parts list might create

shock, fire, and/or other hazards.

Page 6

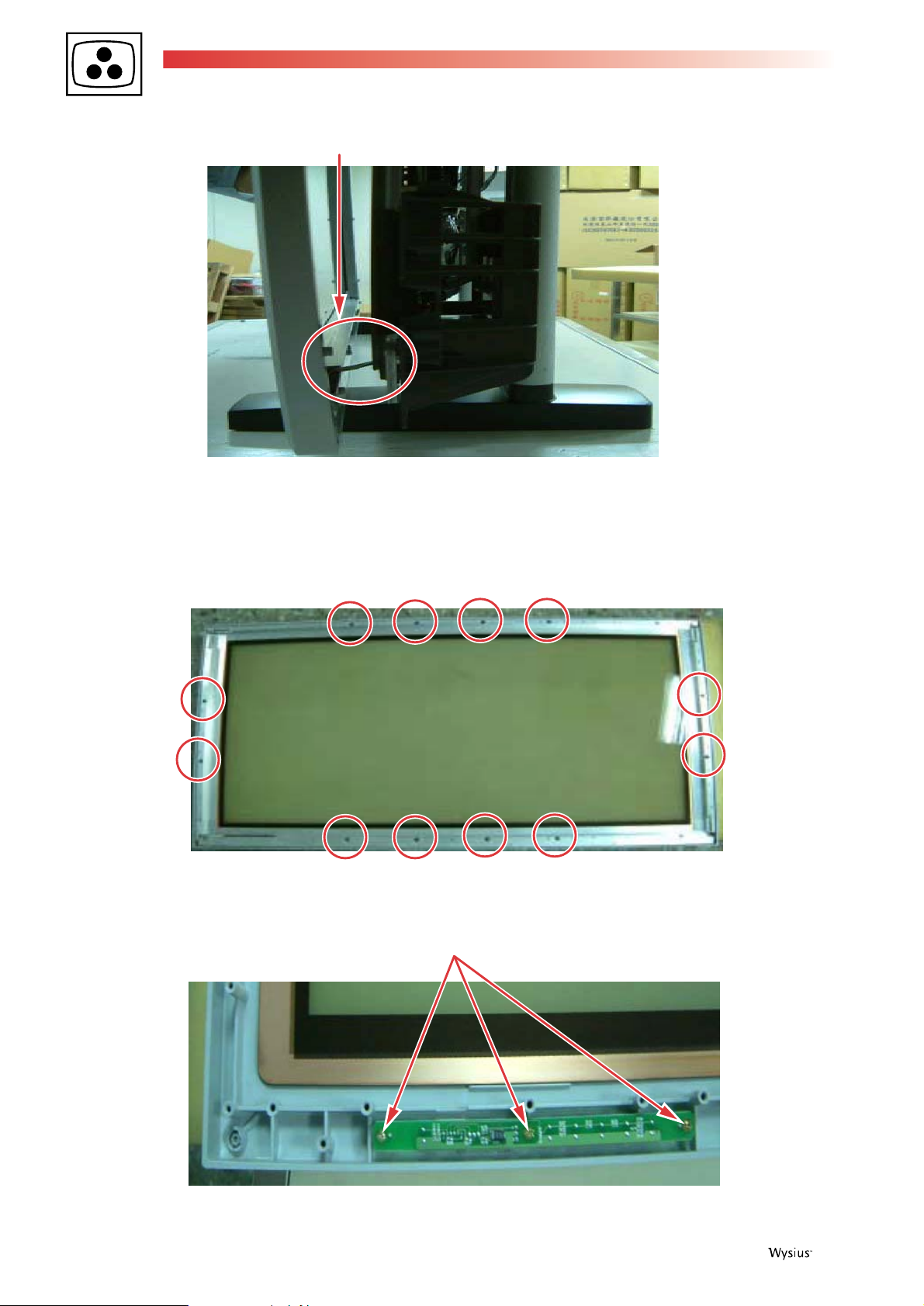

1. Removing the Leg Tube Assembly

Unscrew 4 screws from "Leg Tube Assembly." (Specification of screw driver is 15± 2kg), see fig.1

Push the "Leg Tube Assembly." downward to unlock and pull it away from unit, then unscrew 4 screws from rear cover.

(Specification of screw -driver is 15± 2 kg),

6 First issue 10 /04

Fig. 1

Fig. 2

HOW TO EXCHANGE THE MASK & PANEL PROCEDURE

Page 7

First issue 10 / 04 7

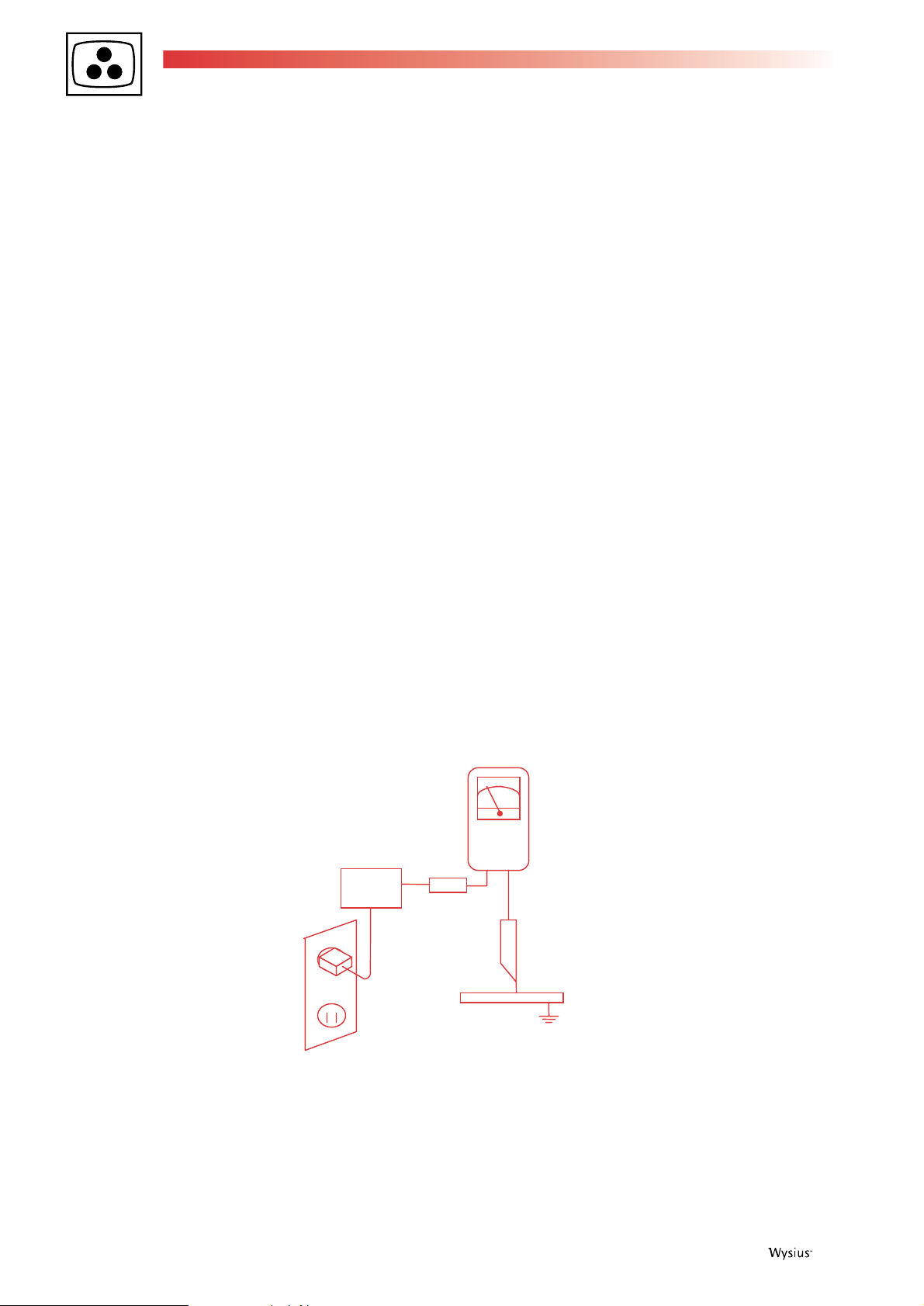

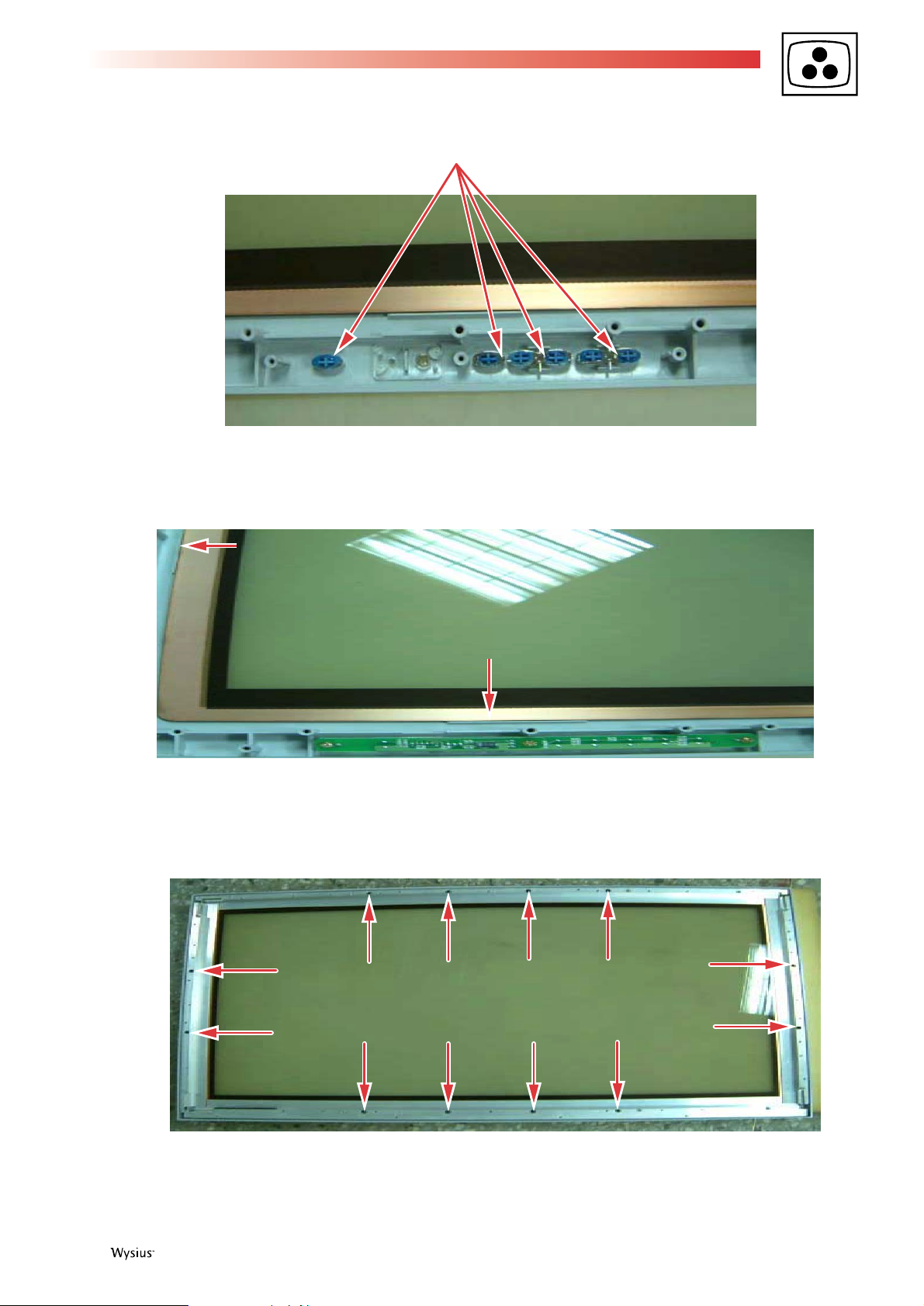

2. Removing the rear cover

Unscrew 12 screws from rear cover, see red arrow (Specification of screw driver is 15± 2 kg)

Unscrew 8 screws from rear cover, and unscrew 2 screws from AC power socket, see red arrow (Specification of screw driver

is 9± 1 kg)

Unscrew 4 screws from rear cover, see red circle (Specification of screw driver is 15± 2 kg)

3. Removing the screws from panel:

Unscrew 20 pieces of screw from panel site (Specification of screw driver is 15± 2 kg)

10 screws

12 screws

4 screws

Fig. 3

20 screws

Fig. 4

Page 8

8 First issue 10 /04

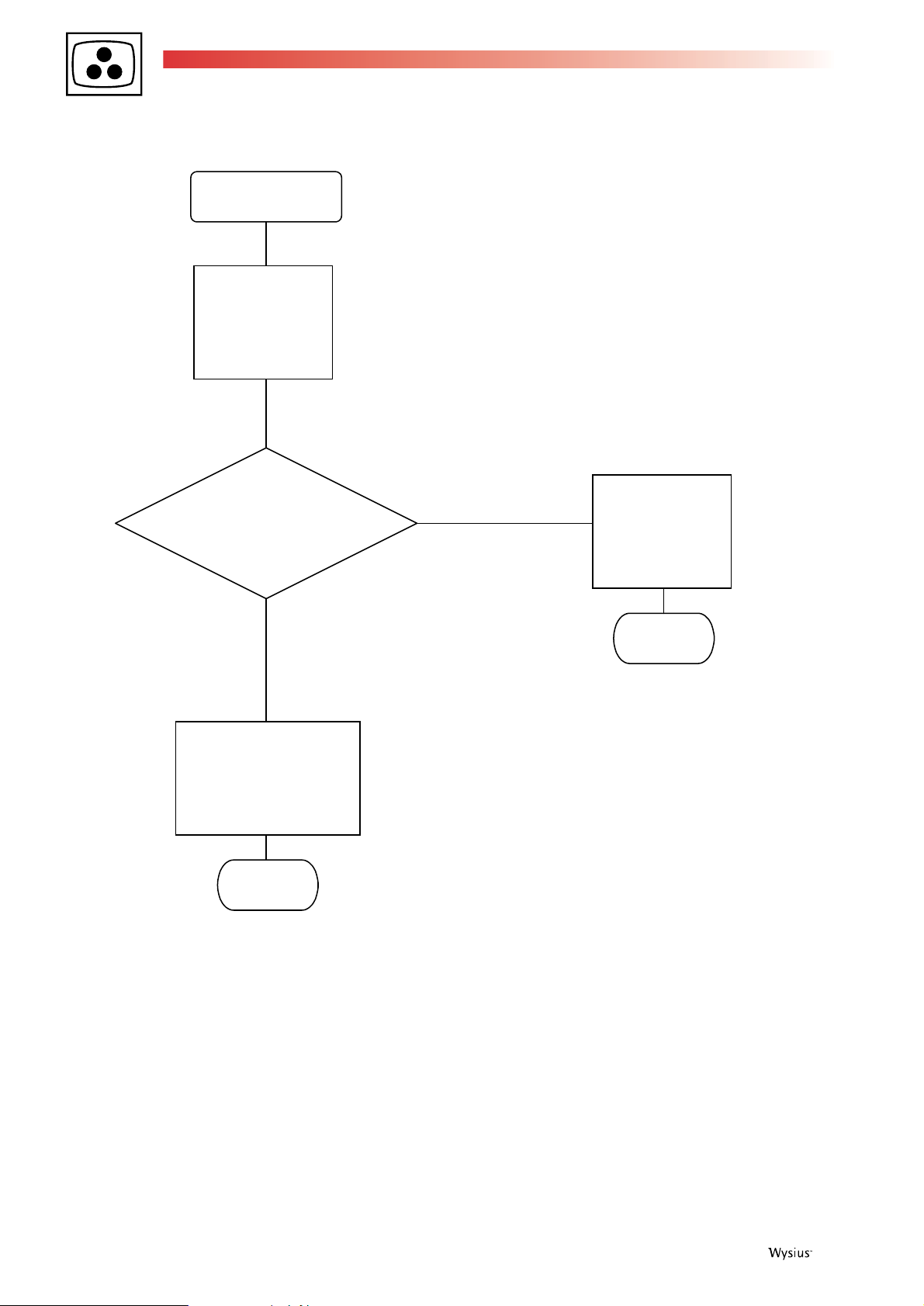

4. Removing the Mask and the J5 cable from PCB

5. Removing the filter

Unscrew 10 screws from mask (Specification of screw driver is 15± 2 kg), then remove four angles that hold the PDP filter. (Be

careful: Please do not bump or scrape when handling the PDP filter.)

Before putting panel back clean PDP filter make sure it's free from dust.

Unscrew 3 screws and remove control board

3 screws

Fig. 6

Fig. 7

J5

Fig. 5

Page 9

First issue 10 / 04 9

Remove the Control buttons from old Mask and reinstall them on the new Mask.

Please to aim at red arrow to guide and there is have a channel when you put down glass back to new mask

Assemble 4 irons back to mask. Be careful: When you lock up 4 irons that screws should be to lock up on "SL&G" point.

6. Proceed in reverse order to re-assemble

Control buttons

Fig. 8

Fig. 9

Top side

Top bottom

Fig. 10

Page 10

10 First issue 10 /04

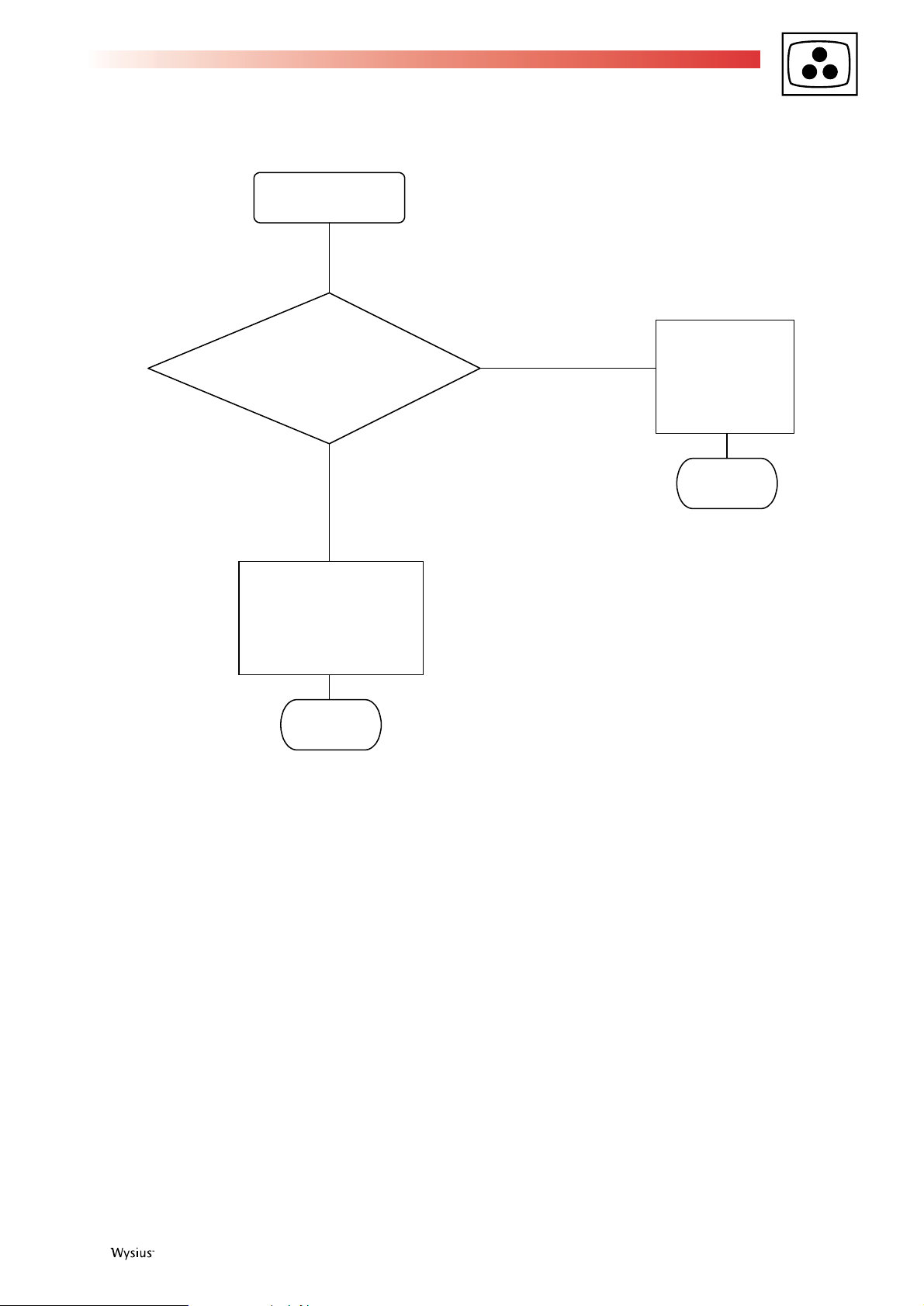

TROUBLESHOOTING

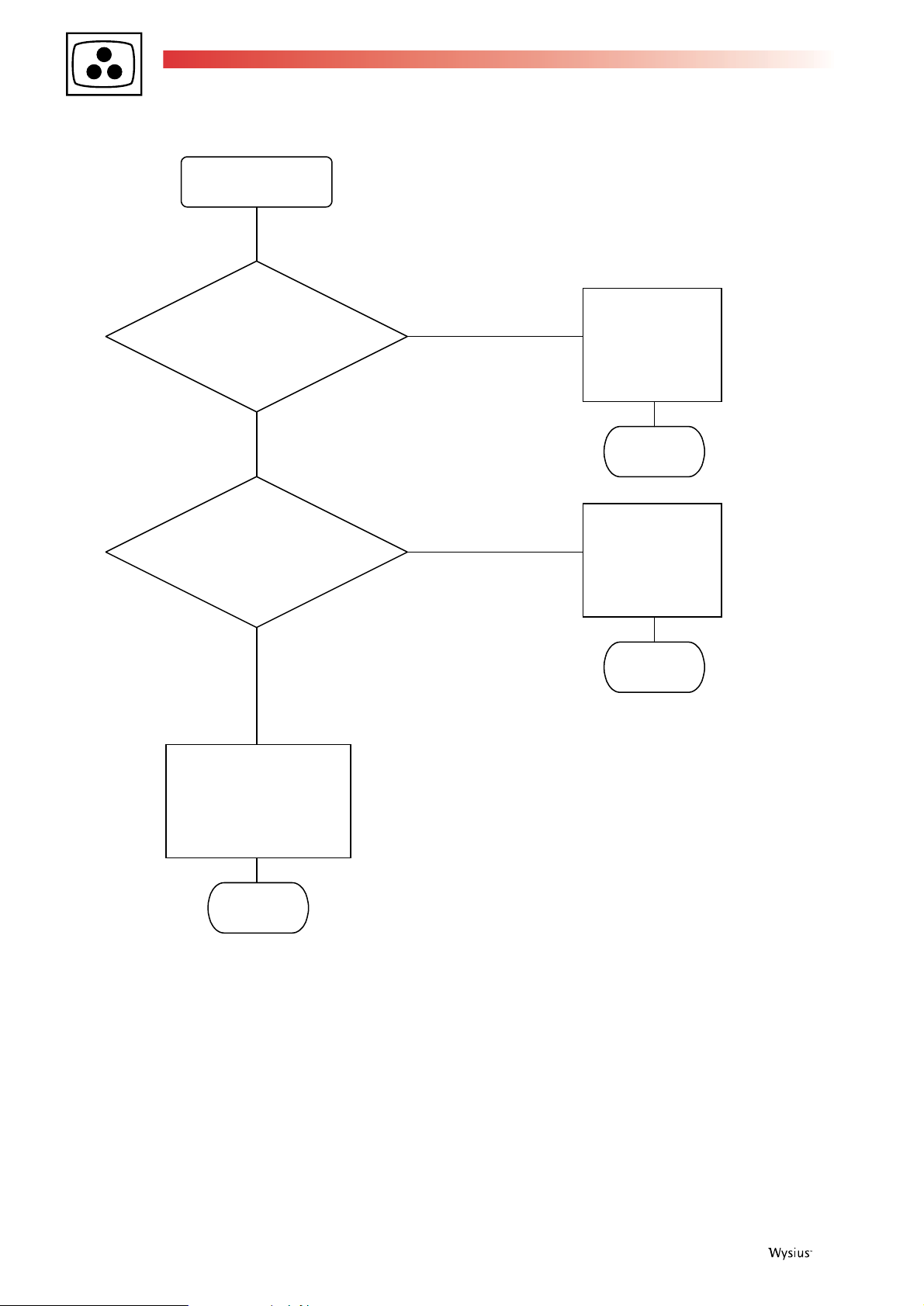

No power

Switch the

power on

Check "Power Switch" module

Not correct

Correct

Replace

"Power Switch"

module

Replace

"Main Power"

module

End

End

Page 11

First issue 10 / 04 11

No picture

Check Image board

Not correct

Correct

Replace

Image board

Replace

PDP module

End

End

Page 12

12 First issue 10 /04

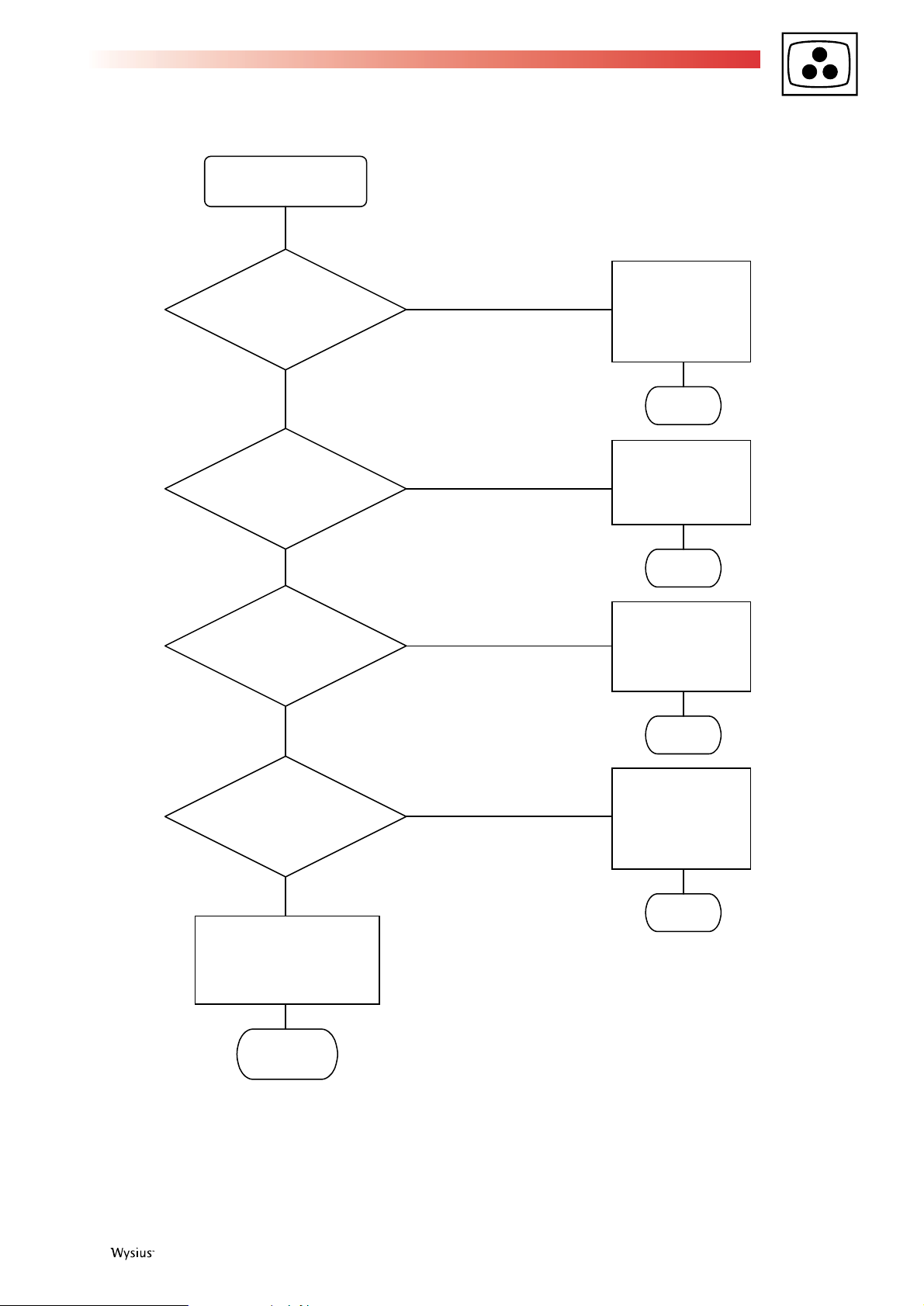

Vertical line fail

Check XR Board

Check Logic Board

Not correct

Correct

Not correct

Correct

Replace

XR

Board

Replace

Logic

Board

Replace

PDP module

End

End

End

Page 13

First issue 10 / 04 13

Horizontal line fail

Check Y-SUS Board

Check Y DRV-Top

Not correct

Correct

Not correct

Correct

Replace

Y-SUS

Board

Replace

Y DRV-Top

Replace

PDP module

End

Check Z-SUS Board

Not correct

Correct

Replace

Z-SUS

Board

End

End

Check Y DRV-Bottom

Not correct

Correct

Replace Y

DRV-Bottom

End

End

Page 14

14 First issue 10 /04

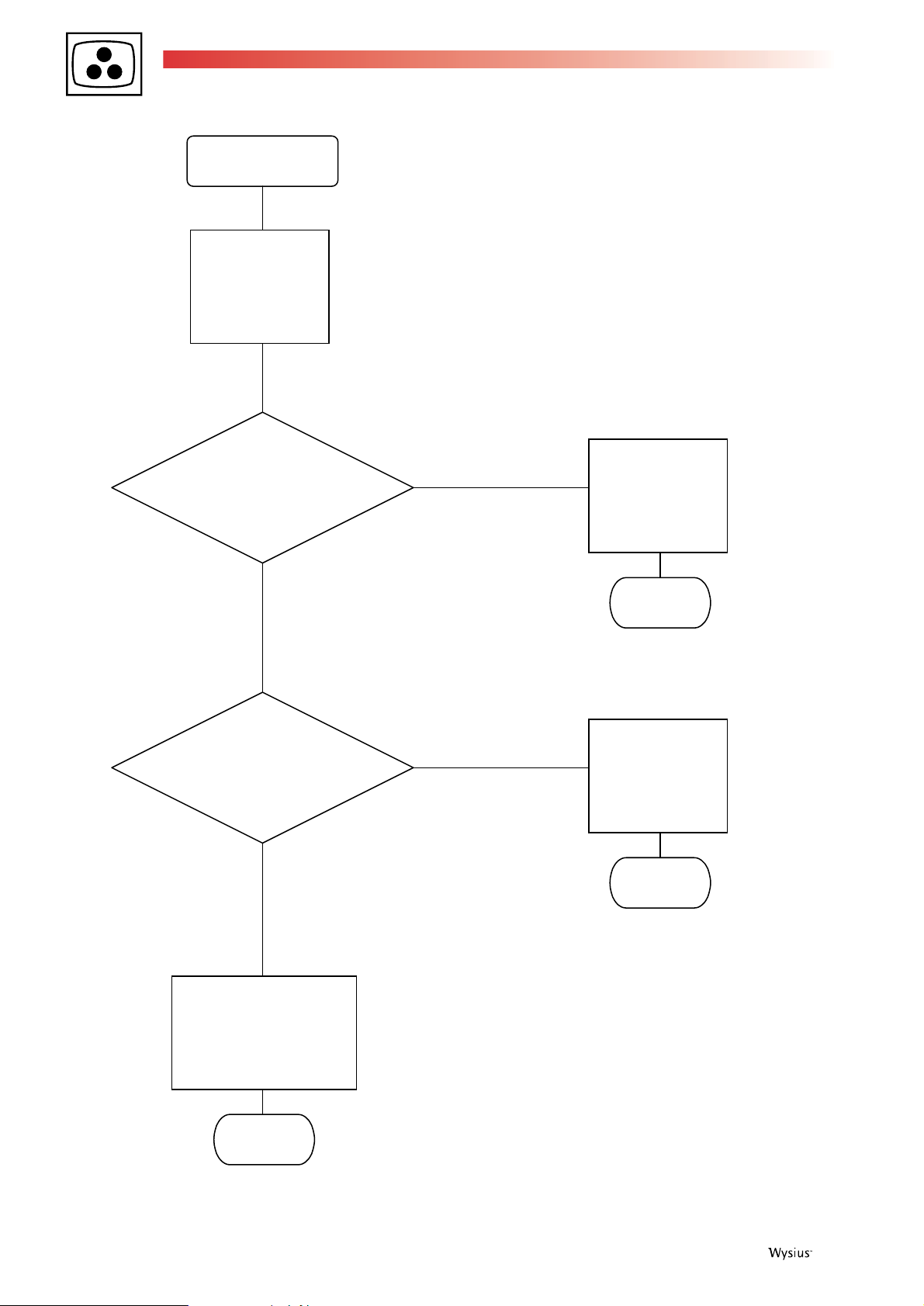

No command

Switch the

power on

Check remote control

Check Front Button

Control Board

Not correct

Correct

Not correct

Correct

Replace the

battery or the

remote control

Replace

Front Button

Control Board

Replace Image

Board

End

End

End

Page 15

First issue 10 / 04 15

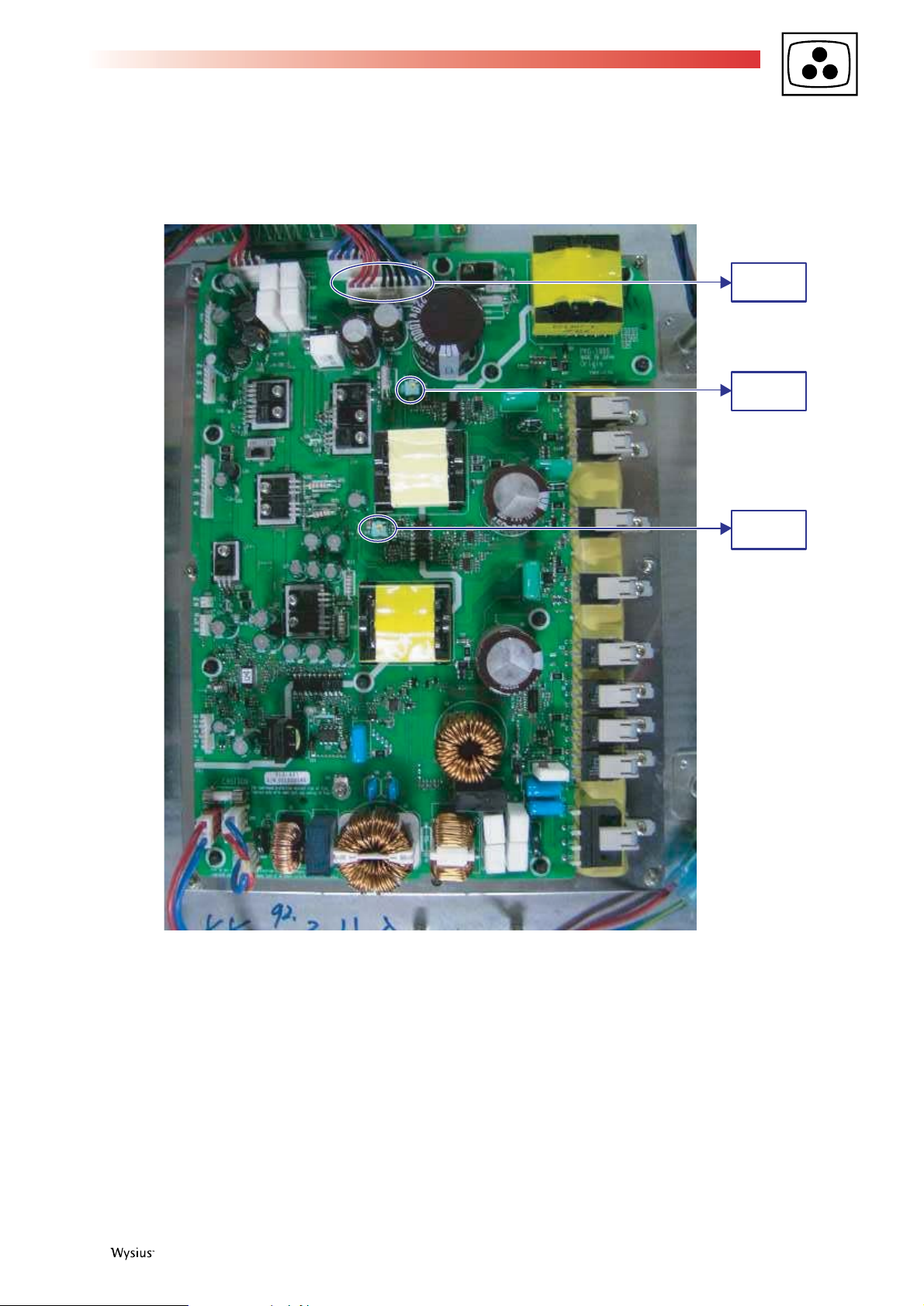

ADJUSTMENTS

PANEL voltage adjustment

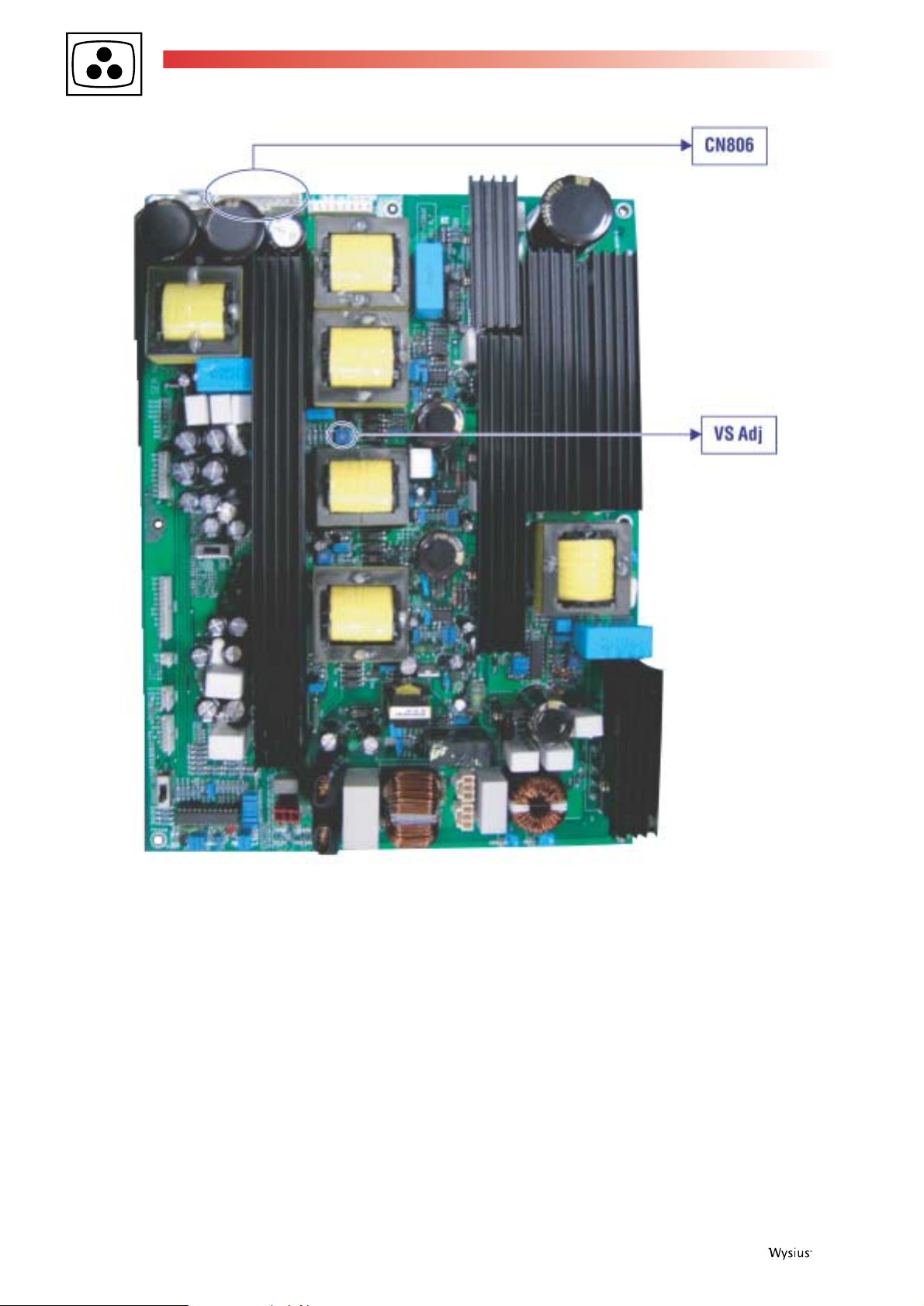

1.1 Origin Power (PLG-421)

1. POWER ON

2. Signal Source: No (black screen).

3. Connect Digital Voltage Meter (-) to Panel GND. Connect Digital Voltage Meter (+) to Plug CN806 Pin#10 and adjust the VA

(Variable Resistor RV204) value to the VA value recorded on the Panel Voltage Label ±0.5VDC (VA ± 0.5VDC= value adjusted).

4. Connect Digital Voltage Meter (-) to Panel GND. Connect Digital Voltage Meter (+) to Plug CN806 Pin#1 and adjust the VS

(Variable Resistor RV203) value to the VS value recorded on the Panel Voltage Label ±0.5VDC (VS ± 0.5VDC= value adjusted).

Remark: The Panel Voltage Label is located at the upper- right corner of the panel.

CN806

RV203

RV204

Page 16

16 First issue 10 /04

1.2 Dae Gil Power (DGK-420W)

1. POWER ON

2. Signal Source: No (black screen).

3. Connect Digital Voltage Meter (-) to Panel GND. Connect Digital Voltage Meter (+) to Plug CN806 Pin#10 and adjust the VA

(Variable Resistor) value to the VA value recorded on the Panel Voltage Label ± 0.5VDC (VA ± 0.5VDC= value adjusted).

4. Connect Digital Voltage Meter (-) to Panel GND. Connect Digital Voltage Meter (+) to Plug CN806 Pin#1 and adjust the VS

(Variable Resistor) value to the VS value recorded on the Panel Voltage Label ± 0.5VDC (VS ± 0.5VDC= value adjusted).

Remark: The Panel Voltage Label is located at the upper-right corner of the panel.

Color Temperature Adjustment

1.1 Color Temperature setting in DVI Mode

1. Turn on PDP set and warm up for over 30 minutes.

Page 17

First issue 10 / 04 17

2. Turn on Color Analyzer CA-100 and reset CA-100.

3. Switch PDP input signal source to DVI mode.

4. Set up Video Pattern Generator (Astro, Model= VG-828H).

Timing set = 640 x 480 @ 60Hz;

Video = Panel Link (the DVI output mode)

Connect PDP DVI input connector with Astro to receive DVI signal.

5. Dark level and bright level center block definition:

A. Dark level center block definition:

[WINDOW]

Mode %

Format 1 Window

Flicker None

Size H/V 28.5/34.0 (%)

Analog R/G/B 25/25/25 (10 IRE white output pattern)

B. Bright level center block definition:

[WINDOW]

Mode %

Format 1 Window

Flicker None

Size H/V 28.5/34.0 (%)

Analog R/G/B 153/153/153 (60 IRE white output pattern)

6. There are 4 different modes (DVI / RGB / AV / YPBPR) color temperature setting; there are 3 different color temperatures

(7180K, 8680K and 10180K) in each mode. Each color temperature needs to adjust dark

level, bright level, and R, G, B.

The OSD menu for color temperature factory setting can be viewed by following the ”Factory Setting Procedure”.

Factory Setting Procedure:

A. Press (Zoom -) key for over 5 seconds and release.

B. Press (Zoom+) key for over 5 seconds and release.

C. Press ”ok” key.

D. Factory setting OSD menu shows up. The values shown up on the OSD menu are the factory default setting values.

The factory default setting values differ from each PDP panel module. The color temperature factory setting OSD menus

are as the following:

*Note: When adjusting the color temperature, please note

what is the input source and what input the PDP is, the input

source and the PDP input mode should be the same.

7. Put the color analyzer CA-100 in the center of the screen.

A. 7180K

DV I -CT : 718 0

K

[x : 3 0 8 y : 2 9 8]

GA IN B IAS

RG B RG B

xx xx xx xx xx xx

xx xx

B. 8680K

DV I -CT : 868 0

o

K

[x : 2 8 8 y : 3 0 1]

GA IN B IAS

RG B RG B

xx xx xx xx xx xx

xx xx

C. 10180K

DV I -CT :10180

o

K

[x : 2 7 0 y : 2 9 2]

GA IN B IAS

RG B RG B

xx xx xx xx xx xx

xx xx

(GAIN Gamma) (BIAS Gamma)

Page 18

18 First issue 10 /04

1.2 Adjusting procedure

1. Receive Astro VG-828H DVI dark level center block signal (14 IRE), follow the ”Factory Setting Procedure” to go into

factory setting mode and you will see the 7180K color temperature setting OSD menu.

2. 7180K dark level center block adjustment procedure:

A. Press (Zoom -) or (Zoom+) key in remote control to select G-BIAS, and adjust Y=0.4 FL±0.1FL

B. Press(Zoom -) or (Zoom+) key in remote control to select R-BIAS, and adjust x=308±15FL

C. Press (Zoom -) or (Zoom+) key in remote control to select B-BIAS, and adjust y=298±15FL

D. Adjust R/G/B-BIAS, make sure the final value x=308±15FL, y=298±15FL, Y=0.4FL±0.1FL

3. 7180K bright level center block adjustment procedure:

(Please set Astro VG-828H DVI bright level center block signal to 60 IRE)

A. Press (Zoom -) or (Zoom+) key in remote control to select G-GAIN, and adjust Y=40±2FL

B. Press (Zoom -) or (Zoom+) key in remote control to select R-GAIN, and adjust x=308±15FL

C. Press (Zoom -) or (Zoom+) key in remote control to select B-GAIN, and adjust y=298±15F

D. Adjust R/G/B-GAIN, make sure the final value x=308±15FL, y=298±15FL, Y=40±2FL.

E. Press (Zoom+) key in remote control to select GAIN Gamma, and then press (Zoom -) or (Zoom+) key to adjust to Y=40

F. Press (Zoom+) key in remote control to select BIAS Gamma, and then press (Zoom -) or (Zoom+) key to adjust to Y=0.4

4. When you want to go ahead for next color temperature setting, double check the Gamma values, make sure GAIN

Gamma and BIAS Gamma values are correct, and then press the ”ok” key in remote control. For each color temperature

setting, please repeat the procedure (1)-(3). Only x and y value will change in different color temperature mode (in 8680K,

x=288, y=301; in 10180K, x=270, y=292) and Y values are all the same in each color temperature mode (dark level Y=0.4,

bright level Y=40).

2.1 Color Temperature setting in RGB Mode

1. Turn on Color Analyzer CA-100 and reset CA-100.

2. Switch PDP input signal source to RGB mode.

3. Set up Video Pattern Generator (Astro, Model= VG-828H).

Timing set = 640 x 480 @ 60Hz;

Video = Analog (the RGB output mode)

Connect PDP RGB input connector with Astro to receive RGB signal.

4. Dark level and bright level center block definition:

A. Dark level center block definition:

[WINDOW]

Mode %

Format 1 Window

Flicker None

Size H/V 28.5/34.0 (%)

Analog R/G/B 25/25/25 (10 IRE white output pattern)

B. Bright level center block definition:

[WINDOW]

Mode %

Format 1 Window

Flicker None

Size H/V 28.5/34.0 (%)

Analog R/G/B 153/153/153 (60 IRE white output pattern)

5. There are 4 different modes (DVI / RGB / AV / YPBPR) need color temperature setting; there are 3 different color

temperatures (7180K, 8680K and 10180K) in each mode. Each color temperature needs to adjust dark level, bright level,

and R, G, B. The OSD menu for color temperature factory setting can be viewed by following the ”Factory Setting Procedure”.

Page 19

First issue 10 / 04 19

Factory Setting Procedure:

A. Press (Zoom -) key for over 5 seconds and release.

B. Press (Zoom+) key for over 5 seconds and release.

C. Press ”ok” key.

D. Factory setting OSD menu shows up.

The values showed up on the OSD menu are the factory default setting values. The factory default setting values differ from

each PDP panel module. The color temperature factory setting OSD menus are as the following:

*Note: GAIN Gamma and BIAS Gamma have no function

under RGB mode.

*Note: When adjusting the color temperature, please note

what is the input source and what input the PDP is, the

input source and the PDP input mode should be the same.

6. Put the color analyzer CA-100 in the center of the screen.

2.2 Adjusting procedure:

1. Receive Astro VG-828H RGB dark level center block signal (14 IRE), follow the ”Factory Setting Procedure” to go into

factory setting mode and you will see the 7180K color temperature setting OSD menu.

2. 7180K dark level center block adjustment procedure:

A. Press (Zoom -) or (Zoom+) key in remote control to select G-BIAS, and adjust Y=0.5 FL±0.1FL

B. Press (Zoom -) or (Zoom+) key in remote control to select R-BIAS, and adjust x=308±15FL

C. Press (Zoom -) or (Zoom+) key in remote control to select B-BIAS, and adjust y=298±15FL

D. Adjust R/G/B-BIAS, make sure the final value x=308±15FL, y=298±15FL, Y=0.5FL±0.1FL

3. 7180K bright level center block adjustment procedure:

(Please set Astro VG-828H RGB bright level center block signal to 60 IRE)

A. Press (Zoom -) or (Zoom+) key in remote control to select G-GAIN, and adjust Y=40±2FL

B. Press (Zoom -) or (Zoom+) key in remote control to select R-GAIN, and adjust x=308±15FL

C. Press (Zoom -) or (Zoom+) key in remote control to select B-GAIN, and adjust y=298±15F

D. Adjust R/G/B-GAIN, make sure the final value x=308±15FL, y=298±15FL, Y=40±2FL.

4. When you want to go ahead for next color temperature setting, double check the Gamma values, make sure GAIN Gamma

and BIAS Gamma values are correct, and then press the ”ok” key in remote control. For each color temperature setting,

please repeat the procedure (1)-(3). Only x and y value will change in different color temperature mode (in 8680K, x=288,

y=301; in 10180K, x=270, y=292) and Y values are all the same in each color temperature mode (dark level Y=0. 5, bright

level Y=40).

3.1 Color Temperature setting in AV Mode

1. Turn on Color Analyzer CA-100 and reset CA-100.

A. 7180K

o

RGB -CT : 7 1 8 0

[x : 3 08 y :298]

GA IN B IAS

RG B RG B

xx xx Xx xx xx xx

K

xx xx

B. 8680K

RGB -CT : 8 6 8 0

[x : 2 88 y :301]

GA IN B IAS

RG B R

Xx xx Xx xx xx xx

xx xx

K

RGB-CT: 1

[x : 2 70 y :

GA IN B

RG B RGB

xx xx xx x xx xx

xx xx

0180

:292]

IAS

GB

o

(GAIN Gamma) (BIAS Gamma)

C. 10180K

o

K

Page 20

20 First issue 10 /04

2. Switch PDP input signal source to AV mode.

3. Set up Video Pattern Generator (Astro, Model= VG-828H).

Timing set = 640 x 480 @ 60Hz;

Video = Analog (the AV output mode)

Connect PDP AV input connector with Astro to receive AV signal.

4. Dark level and bright level center block definition:

A. Dark level center block definition:

[WINDOW]

Mode %

Format 1 Window

Flicker None

Size H/V 28.5/34.0 (%)

Analog R/G/B 25/25/25 (10 IRE white output pattern)

B. Bright level center block definition:

[WINDOW]

Mode %

Format 1 Window

Flicker None

Size H/V 28.5/34.0 (%)

Analog R/G/B 153/153/153 (60 IRE white output pattern)

5. There are 4 different modes (DVI / RGB / AV / YPBPR) need color temperature setting; there are 3 different color

temperatures (7180K, 8680K and 10180K) in each mode. Each color temperature needs to adjust dark level, bright level,

and R, G, B. The OSD menu for color temperature factory setting can be viewed by following the ”Factory Setting Procedure”.

Factory Setting Procedure:

A. Press (Zoom -) key for over 5 seconds and release.

B. Press (Zoom+) key for over 5 seconds and release.

C. Press ”ok” key.

D. Factory setting OSD menu shows up.

The values showed up on the OSD menu are the factory default setting values. The factory default setting values differ from

each PDP panel module.

6. Put the color analyzer CA-100 in the center of the screen.

3.2 Adjusting procedure:

1. Receive Astro VG-828H AV dark level center block signal (14 IRE), follow the ”Factory Setting Procedure” to go into

factory setting mode and you will see the 7180K color temperature setting OSD menu.

2. 7180K dark level center block adjustment procedure:

A. Press (Zoom -) or (Zoom+) key in remote control to select G-BIAS, and adjust Y=1.0 FL±0.1FL

B. Press (Zoom -) or (Zoom+) key in remote control to select R-BIAS, and adjust x=308±15FL

C. Press (Zoom -) or (Zoom+) key in remote control to select B-BIAS, and adjust y=298±15FL

D. Adjust R/G/B-BIAS, make sure the final value x=308±15FL, y=298±15FL, Y=1.0FL±0.1FL

3. 7180K bright level center block adjustment procedure:

(Please set Astro VG-828H RGB bright level center block signal to 60 IRE)

A. Press (Zoom -) or (Zoom+) key in remote control to select G-GAIN, and adjust Y=40±2FL

B. Press (Zoom -) or (Zoom+) key in remote control to select R-GAIN, and adjust x=308±15FL

C. Press (Zoom -) or (Zoom+) key in remote control to select B-GAIN, and adjust y=298±15F

D. Adjust R/G/B-GAIN, make sure the final value x=308±15FL, y=298±15FL, Y=40±2FL.

4. When you want to go ahead for next color temperature setting, double check the Gamma values, make sure GAIN Gamma

Page 21

First issue 10 / 04 21

and BIAS Gamma values are correct, and then press the ”ok” key in remote control. For each color temperature setting,

please repeat the procedure (1)-(3). Only x and y value will change in different color temperature mode (in 8680K, x=288,

y=301; in 10180K, x=270, y=292) and Y values are all the same in each color temperature mode (dark level Y=1.0, bright

level Y=40).

4 .1 Color Temperature setting in YPBPR Mode

1. Turn on Color Analyzer CA-100 and reset CA-100.

2. Switch PDP input signal source to YPBPR mode.

3. Set up Video Pattern Generator (Astro, Model= VG-828H).

Timing set = 640 x 480 @ 60Hz;

Video = Analog (the YPBPR output mode)

Connect PDP YPBPR input connector with Astro to receive YPBPR signal.

4. Dark level and bright level center block definition:

A. Dark level center block definition:

[WINDOW]

Mode %

Format 1 Window

Flicker None

Size H/V 28.5/34.0 (%)

Analog R/G/B 25/25/25 (10 IRE white output pattern)

B. Bright level center block definition:

[WINDOW]

Mode %

Format 1 Window

Flicker None

Size H/V 28.5/34.0 (%)

Analog R/G/B 153/153/153 (60 IRE white output pattern)

5. There are 4 different modes (DVI / RGB / AV / YPBPR) need color temperature setting; there are 3 different color

temperatures (7180K, 8680K and 10180K) in each mode. Each color temperature needs to adjust dark level, bright level,

and R, G, B. The OSD menu for color temperature factory setting can be viewed by following the ”Factory Setting Procedure”.

Factory Setting Procedure:

A. Press (Zoom -) key for over 5 seconds and release.

B. Press (Zoom+) key for over 5 seconds and release.

C. Press ”ok” key.

D. Factory setting OSD menu shows up.

The values showed up on the OSD menu are the factory default setting values. The factory default setting values differ from

each PDP panel module.

6. Put the color analyzer CA-100 in the center of the screen.

4.2 Adjusting procedure:

1. Receive Astro VG-828H YPBPR dark level center block signal (14 IRE), follow the ”Factory Setting Procedure” to go into

factory setting mode and you will see the 7180K color temperature setting OSD menu.

2. 7180K dark level center block adjustment procedure:

A. Press (Zoom -) or (Zoom+) key in remote control to select G-BIAS, and adjust Y=1.1 FL±0.1FL

B. Press (Zoom -) or (Zoom+) key in remote control to select R-BIAS, and adjust x=308±15FL

C. Press (Zoom -) or (Zoom+) key in remote control to select B-BIAS, and adjust y=298±15FL

D. Adjust R/G/B-BIAS, make sure the final value x=308±15FL, y=298±15FL, Y=1.1 FL±0.1FL

Page 22

22 First issue 10 /04

3. 7180K bright level center block adjustment procedure:

(Please set Astro VG-828H RGB bright level center block signal to 60 IRE)

A. Press (Zoom -) or (Zoom+) key in remote control to select G-GAIN, and adjust Y=41±2FL

B. Press (Zoom -) or (Zoom+) key in remote control to select R-GAIN, and adjust x=308±15FL

C. Press (Zoom -) or (Zoom+) key in remote control to select B-GAIN, and adjust y=298±15F

D. Adjust R/G/B-GAIN, make sure the final value x=308±15FL, y=298±15FL, Y=41±2FL.

4. When you want to go ahead for next color temperature setting, double check the Gamma values, make sure GAIN Gamma

and BIAS Gamma values are correct, and then press the ”ok” key in remote control. For each color temperature setting,

please repeat the procedure (1)-(3). Only x and y value will change in different color temperature mode (in 8680K, x=288,

y=301; in 10180K, x=270, y=292) and Y values are all the same in each color temperature mode (dark level Y=1.1, bright

level Y=41).

SPECIFICATIONS

Pin assignments

D-SUB Connector

DVI-Connector

1

15

9

15

824

610

11 15

Pin Pin PinSignal Signal Signal

Pin Pin PinSignal Signal Signal

1

2

3

4

5

RED

GREEN

BLUE

GND

GND

RED GND

GREEN GND

BLUE GND

NC

GND

GND

SDA

H_SYNC

V_SYNC

SCL

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

TMDS Data 2-

TMDS Data 2+

TMDS Data

2/4Shield

TMDS Data 4-

TMDS Data 4+

DDC Clock

DDC Data

NC

TMDS Data 0-

TMDS Data 0+

TMDS Data

0/5 Shield

TMDS Data 5-

TMDS Data 5+

TMDS Clock

Shield

TMDS Clock+

TMDS Clock-

TMDS Data 1-

TMDS Data 1+

TMDS Data

1/3 Shield

TMDS Data 3-

TMDS Data 3+

+5V Power

GND (for +5V)

Hot Plug

Detect

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Page 23

First issue 10 / 04 23

Mode list for RGB / DVI

Note: 1. * : DVI is not supported.

2. Mode 24 to 26 are for use with Apple Macintosh computers.

Y/PB/PR for component

Refresh Horizontal Vertical Vertical Horizontal

Mode No Resolution Rate Frequency Frequency Sync Sync Dot rate

Polarity Polarity

(Hz) (K Hz) (Hz) (TTL) (TTL) (MHz)

1 640(VGA)x480 60 31.5 59.94 - - 25.175

2 640(VGA)x480 72 37.9 72.81 - - 31.500

3 640(VGA)x480 75 37.5 75 - - 31.500

4 640(VGA)x480 85 43.3 85.01 - - 36.000

5 800(SVGA)x600 56 35.1 56.25 + + 36.000

6 800(SVGA)x600 60 37.9 60.317 + + 40.000

7 800(SVGA)x600 72 48.1 72.19 + + 50.000

8 800(SVGA)x600 75 46.9 75 + + 49.500

9 800(SVGA)x600 85 53.7 85.06 + + 56.250

10 1024(XGA)x768 60 48.4 60.01 - - 65.000

11 1024(XGA)x768 70 56.5 70.07 - - 75.000

12 1024(XGA)x768 75 60.0 75.03 + + 78.750

13 1024(XGA)x768 85 68.7 84.99 + + 94.500

14 1280(SXGA)x1024 60 63.98 60.02 + + 108.00

15* 1280(SXGA)x1024 75 79.98 75.03 + + 135.00

16* 1280(SXGA)x1024 85 91.15 85.02 + + 157.50

18 720(DOS)x400 70 31.46 70.08 + - 28.320

19 640(VGA)x480 50 31.5 50 - - 25.175

20* 1280(HDTV)x720P 60 45.15 60 - - 74.250

21* 1920(HDTV)x1080I 60(I) 33.75 60 - - 74.250

22 640(VGA)x350 70 31.50 70 - + 25.175

23 852(WGA)x480 60 31.413 59.835 - - 30.00

24 640x480 67 35.00 66.67 - - 30.240

25 832 x 624 75 49.73 74.55 - - 57.283

26 1152 x 870 75 68.68 75.06 - - 100.000

Mode No Resolution Refresh Rate

1 640x480P 60 Hz

2 1920x1080I 60 Hz

3 1280x720P 60 Hz

4 720x576P 50 Hz

5 1920x1080I 50 Hz

6 1280x720P 50 Hz

Page 24

24 First issue 10 /04

APPENDIX A : Preset Timing Chart

Item Description:

A Total time

B Active display area including borders

C Active display area excluding borders

D Left/Top border

E Right/bottom border

F Blanking time

G Front porch

H Sync -width

I Back porch

Mode No 1 2 3 4 5 6 7 8 9

Resolution

&

Refresh Rate

Pixel clock 25.175 31.5 31.5 36 36 40 50 49.5 56.25 MHz

Horizontal visible 640 640 640 640 800 800 800 800 800 Dots

Horizontal total 800 832 840 832 1024 1056 1040 1056 1048 Dots

Horizontal front porch 16 24 16 56 24 40 56 16 32 Dots

Horizontal sync 96 40 64 56 72 128 120 80 64 Dots

Horizontal back porch 48 128 120 80 128 88 64 160 152 Dots

Horiz blanking time 160 192 200 192 224 256 240 256 248 Dots

Vertical visible 480 480 480 480 600 600 600 600 600 Lines

Vertical total 525 520 500 509 625 628 666 625 631 Lines

Vertical front porch 10 9 1 1 1 1 37 1 1 Lines

Vertical sync 2 3 3 3 2 4 6 3 3 Lines

Vertical back porch 33 28 16 25 22 23 23 21 27 Lines

Vertical blanking time 45 40 20 29 25 28 66 25 31 Lines

Horizontal frequency 31.469 37.861 37.5 43.269 35.156 37.879 48.077 46.875 53.674 kHz

Vertical frequency 59.94 72.809 75 85.008 56.25 60.317 72.188 75 85.061 Hz

Vertical sync polarity - - - - + + + + + TTL

Horiz sync polarity - - - - + + + + + TTL

640

480

60

640

480

72

640

480

75

640

480

85

800

600

56

800

600

60

800

600

72

800

600

75

800

600

85

Hz

Page 25

First issue 10 / 04 25

Mode No 10 11 12 13 14 15 16 18 19

Resolution

&

Refresh Rate

1024

768

60

1024

768

70

1024

768

75

1024

768

85

1280

1024

60

1280

1024

75

1280

1024

85

720

400

70

640

480

50 Hz

Pixel clock 65 75 78.75 94.5 108 135 157.5 28.320 25.175 MHz

Horizontal visible 1024 1024 1024 1024 1280 1280 1280 720 640 Dots

Horizontal total 1344 1328 1312 1376 1688 1688 1728 900 800 Dots

Horizontal front porch 24 24 16 48 48 16 64 18 16 Dots

Horizontal sync 136 136 96 96 112 144 160 108 96 Dots

Horizontal back porch 160 144 176 208 248 248 224 54 48 Dots

Horiz blanking time 320 304 288 352 408 408 448 180 160 Dots

Vertical visible 768 768 768 768 1024 1024 1024 400 480 Lines

Vertical total 806 806 800 808 1066 1066 1072 449 629 Lines

Vertical front porch 3 3 1 1 1 1 1 12 62 Lines

Vertical sync 6 6 3 3 3 3 3 2 2 Lines

Vertical back porch 29 29 28 36 38 38 44 35 85 Lines

Vertical blanking time 38 38 32 40 42 42 48 49 149 Lines

Horizontal frequency 48.364 56.476 60.023 68.677 63.981 79.976 91.146 31.469 31.469 kHz

Vertical frequency 60.004 70.069 75.029 84.997 60.020 75.025 85.024 70.087 50.030 Hz

Vertical sync polarity - - + + + + + + - TTL

Horiz sync polarity - - + + + + + - - TTL

Mode No 20 21 22 23 24 25 26

Resolution

&

Refresh Rate

1280

720P

60

1920

1080I

60I

640

350

70

852

480

60

640

480

67

832

624

75

1152

870

75

Hz

Pixel clock 74.250 74.25 25.175 30 30.24 57.283 100.000 MHz

Horizontal visible 1280 1920 640 852 640 832 1152 Dots

Horizontal total 1650 2200 800 955 864 1152 1456 Dots

Horizontal front porch 110 88 16 19 64 32 32 Dots

Horizontal sync 40 44 96 48 64 64 128 Dots

Horizontal back porch 220 148 48 36 96 224 144 Dots

Horiz blanking time 370 280 160 103 224 320 304 Dots

Vertical visible 720 540 350 480 480 624 870 Lines

Vertical total 750 562.5 449 525 525 667 915 Lines

Vertical front porch 5 3 37 10 3 1 3 Lines

Vertical sync 5 5 2 2 3 3 3 Lines

Vertical back porch 20 15 60 33 39 39 39 Lines

Vertical blanking time 30 23 99 45 45 43 45 Lines

Horizontal frequency 45.000 33.750 31.469 31.414 35.000 49.725 68.681 kHz

Vertical frequency 60 60 70.087 59.835 66.667 74.55 75.062 Hz

Vertical sync polarity - - - - - - - TTL

Horiz sync polarity - - + - - - - TTL

Page 26

First issue 06 / 04 26

WIRING DIAGRAM

PDP Module

AV Module

Board(with

Tuner)

Assy

JP2

Front

Button

Control

Board

Assy

JP1

JA3

Y DRV_TOP

Y DRV_BOTTOM

Y-SUS

Audio

Amplifier

Board Ass'y

(TMDS)

J1

JP4

JP5

J15

(9V)

J25

(5V)

JA2

JA1

Image Board

Ass'y

J14

(5V,SB DET)

J21

(24V,9V)

J28

(RLYON VSON)

J12

(Audio Signal)

J11

(Audio DC,Supply)

(Key)

CN803

CN802/CN809

Main Power

CN801

J5

AC_IN

CN02

CN03

Z-SUS

P21

Logic Board

AC Filter

Power

SW

AC IN

XR BOARD

Page 27

27 First issue 10 / 04

BLOCK DIAGRAM

TUNER

SCART

S-VIDEO

Connecter

Component

Connecter

TU1

Tuner Board Signal Block Diagram

COMPOSITE(AV)

TDA9181

Comb filter

ICT6

TV_CVBS

FB

R

G

B

Philips

UOC

ICT5

Y

C

CVBSO

R

G

B

VDRA

HOUT

for SUB-picture

74HC4053

ICT11

Monostable

Multivibrator

74HC4538

Monostable

Multivibrator

Y1

PB1_CB1

PR1_CR1

74HC211

ICT8

ICT9

R

G

B

H

V

S-VIDEO

TV_CVBS

COMPOSITE(AV)

TA1287P

RGB TO

YUV

ICT7

(48 Pin) (48 Pin)

Y2

CB2

CR2

JPT1

(48 Pin)

JPT1

(48 Pin)

JP4JPT1

S-VIDEO

TV_CVBS

COMPOSITE(AV)

IC3

CON1

CON2

CON3

JP4

(48 Pin)

Y2

CB2

CR2

JP4

(48 Pin)

Y1

PB1_CB1

PR1_CR1

MAIN Board Signal Block Diagram

Y

AV

IC1

MULTIPLEX

SWITCH

MULTIPLEX

SWITCH

IC7

CON1

CON2

CON3

IC3

IC7

C

VIDEO

Y

C

L

TA8551CH

SWITCH

LH

COMP.UOC

SDRAM

U48,49

6630/6730

MAIN Video

YCBCR

YCBCR

(480P720P1080I)

CON1

CON2 Trident

CON3

H

UOCCOMP.

Processor

6630/6730

SUB Video

Porcessor

YPBPR

L

COMP.

I/P

U45

U46

SDRAM

U50,51

MULTIPLEX

HIC2

Color Space

YP BPR(DOUBLE SCAN)

SWITCH

IC2

TA1276

Conveter

U43

RGB I/P

Connector

MULTIPLEX

SWITCH

U34

R,G,B

CPU

U4

RGB O/P

Connector

Converter

AD

U29

SIL161 DVI

U32

SDRAM

U25,26,27

SCALE IC

C711/C713

U23

Clock

Generator

9161A(PLL)

LVDS

TRANSMITTER

P

A

N

E

L

RS232

Connector

DVI IN

Page 28

First issue 10 / 04 28

TUNER BOARD SCHEMATIC DIAGRAM: TUNER & MSP

P9V

TU1

FQ1216MEIH3

ANT IN

VIDEO

5V IF

SOUND_IN _LP[2]

SOUND_IN _RP[2]

T

CT191

0.1uF

25V

Z

S2_LP[2]

S2_RP[2]

+

CT8

+

100uF

16V

CT17

0.01uF

50V

CT51

100uF

16V

PLT3

AF

+

RT47

0

1/16W

CT60

5PF

50V

D

CT67

5PF

50V

D

SB5V_CPU

CT188

0.1uF

25V

Z

D

SC L2P[3,5]

SDA2P[3,5]

CT58

33PF

50V

NCNC5V

1234567

CT18

100PF

50V

RT27

100

1/16W

CT36

1000PF

50V

RT42

1K

1/16W

T

ICT13

LD1117S

3

VIN

CT189

+

47uF

16V

T

RT40

15K

1/16W

RT44

3.3K

1/16W

SDA2P[3,5]

1

SCL

GND

SDAAS-

T

RT28

100

1/16W

RT41

1.5K

1/16W

QT9

2SC2412KBQ

RT46

330

1/16W

VOUT

-

8

RT13

0

1/16W

CT19

100PF

50V

QT8

2SC2412KBQ

2

RT209

124

1/16W

F

RT210

205

1/16W

F

SC L2P[3,5]

SIF

NC

NC

11

109121314

SIF

CT7

0.01uF

50V

LT1

330uH

CT37

0.1uF

16V

CT54

56PF

+

CT190

47uF

16V

50V

10uH

SB2V5

RT45

1K

1/16W

A

CT16

100uF

16V

CT52

0.1uF

16V

T

CT6

10uF

50V

+

CT4

10uF

50V

XT1

18.432MHz

T

RT56

100

1/16W

RT162

560

1/16W

+

FBT3

200 Ω

RT35

3.3K

1/16W

CT57

56PF

50V

CT2

56PF

50V

D_CTLP[5]

RT54

1/16W

RT5

470

1/16W

QT1

2SA1037KQ

TPT1

RT29

3.3K

1/16W

RT31

3.3K

1/16W

RT33

3.3K

1/16W

RT51

1M

1/16W

0

P9V

RT160

TV P[3,5]

RT37

100

1/16W

RT12

1K

1/16W

LT2

10uH

P

CT26

100PF

50V

CT30

T

100PF

50V

CT34

T

100PF

50V

CT47

0.1uF

16V

T

T

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

RT55

AVSUP

AVSUP

ANA_IN1+

ANA_IN-

ANA_IN2+

TESTEN

XTAL_IN

XTAL_OUT

TP

AUD_CL_OUT

NC

NC

D_CTR_I/O_1

D_CTR_I/O_0

ADR_SEL

STBYQ

100

1/16W

22

1/16W

CT157

+

10uF

RT9

6.8K

1/16W

RT14

8.2K

1/16W

CT28

0.47uF16V

CT32

0.47uF

16V

CT42

0.1uF

16V

NC

MONO_IN

50V

VREFTOP

QT15

2SC2412KBQ

RT161

1K

1/16W

CT22

T

100PF

50V

T

CT39

+

10uF

50V

6463626160595857565554535251504948474645444342

NC

NC

AVSS

AVSS

QT2

2SC2412KBQ

RT15

330

1/16W

RT20

390

1/16W

CT20

0.47uF

16V

CT24

0.47uF

16V

SC1_IN_L

SC1_IN_R

ASG

CT180

0.1uF

16V

RT24

10

1/16W

SC2_IN_R

ASG

SC2_IN_L

CT9

3.3uF

50V

+ CT11

100uF

16V

SC3_IN_L

SC3_IN_R

+

ASG

CT25

0.47uF

16V

SC4_IN_R

RT202

68

1/16W

VIDEO IN

1

RT16

220K

1/16W

CT21

0.47uF

16V

CT33

0.47uF

CT43

0.1uF

SC4_IN_L

2

CT12

0.01uF

50V

0.47uF

16V

NC

H.D. OUT

3

CT23

100PF

50V

CT29

16V

16V

AGNDC

ICT1 LA7213

GND

4

CT13

10uF

50V

100PF

+

AHVSS

AHVSS

ICT3

MSP3450G

NC

I2C_CL

I2C_DA

I2S_CL

I2S_WS

I2S_DA_OUT

I2S_DA_IN1

ADR_DA

ADR_WS

ADR_CL

DVSUP

DVSUP

DVSUP

DVSS

DVSS

DVSS

123456789

101112131415161718192021222324

CT77

0.1uF

CT78

100uF

PLT4

10uH

I2S_DA_IN2NCNCNCRESETQNCNC

T

CT76

470PF

50V

16V

+

16V

CT79

0.1uF

16V

FBT4

200 Ω

RT57

1/16W

100

SCART_OUT_CVBS P[2]

V.D. OUT

VCC

5

RT19

2.2K

1/16W

+

T

CT27

T

50V

CT40

3.3uF

50V

41

NC

NC

CAPL_M

AHVSUP

CAPL_A

SC1_OUT_L

SC1_OUT_R

VREF1

SC2_OUT_L

SC2_OUT_R

NC

NC

DACM_SUB

NC

DACM_L

DACM_R

VREF2

DACA_L

DACA_R

RESETQP[5]

T

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

CT31

100PF

50V

A

CT10

0.1uF

16V

RT22

47K

1/16W

CT35

T

100PF

50V

CT41

16V

100uF

+

CT44

0.1uF

16V

T

CT48

470PF

50V

+

CT55

+

10uF

RT49 100 1/16W

RT50 100 1/16W

CT70

1000PF

50V

CT73

1000PF

CT74

1000PF

50V

CT75

1000PF

50V

DT1

RLS4148

RT23

47K

1/16W

RT30

3.3K

1/16W

RT32

3.3K

1/16W

RT34

3.3K

1/16W

CT53

10uF

RT6

22K

1/16W

RT36

3.3K

1/16W

50V

50V

50V

RT7

4.7K

1/16W

QT6

2SC2412KBQ

+

A

RT43 100 1/16W

RT48 100 1/16W

T

RT52

330

1/16W

RT53

330

1/16W

YUV_R P[2]

YUV_L P[2]

DVI_R P[2]

DVI_L P[2]

ICT10

NJM2930L08

1

VOUT

CT38

10uF

50V

CT62

100PF

50V

CT3

0.47uF 16V

CT5

0.47uF 16V

RT17

15K

1/16W

DT2

RLS4148

A

CT63

100PF

T

50V

CT71

0.47uF 16V

CT72

0.47uF

16V

2

GND

T

VIN

CT64

100PF

50V

CT14

1uF

10V

Z

RT207

62K

1/16W

DT7

RLS4148

RT8

4.7K

1/16W

QT3

2SC2412KBQ

3

+

CT49

100uF

16V

A

CT65

T

100PF

50V

CT15

1uF

10V

Z

RT39

5.6

3W

CT192

47uF

16V

RT208

15K

1/16W

V

CT56

2.2uF

CT59

2.2uF

CT61

2.2uF

CT66

2.2uF

V

RT21

10K

1/16W

RT25

100K

1/16W

A

+

+

+

+

+

CT45

+

100uF

16V

50V

50V

50V

50V

RT10

4.7K

1/16W

ZDT1

UDZ3.0B

QT4

2SC2412KBQ

ICT14

ILC6383

8

Vout

7

GND

6

LBO

LBI/SD

5

ICT2

NJM7805FA

1

VIN

A

SOUND_OUT_L P[2]

SOUND_OUT_R P[2]

AUX_OUT_L P[2]

AUX_OUT_R P[2]

DACM_L P[5]

DACM_R P[5]

MTS GND

Lx

Vin

SELVFB

GND

2

RT26

15K

1/16W

LT12

15uH

1

P

2

3

4

RT206

10K

1/16W

V

P9V P[4,5]

3

VOUT

A

RT11

1.8K

1/16W

QT5

2SC2412KBQ

CT46

+

100uF

16V

RT18

100

1/16W

5V_MTS1 P[3,4]

DT8

RLS4148

9V G ND

SD P[5]

SB2V5

Page 29

29 First issue 10 / 04

TUNER BOARD SCHEMATIC DIAGRAM: SOURCE INPUT

SCART_L

SCART_R

DVI_L

DVI_R

JT1A

M1076-1--- A

1

2

JT1B

M1076-1--- A

3

2

JT2D

P1159-1-4-C

6

5

JT2B

P1159-1-4-C

3

2

FBT6

120 Ω

FBT7

120 Ω

FBT8

120 Ω

FBT9

120 Ω

CT80

1000PF

50V

CT85

1000PF

50V

CT89

1000PF

50V

CT91

1000PF

50V

RT204

47K

1/16W

RT205

47K

1/16W

RT71

47K

1/16W

RT76

47K

1/16W

AUX_OUT_L P[1]

AUX_OUT_R

P[1]

DVI_L P[1]

DVI_R P[1]

P[1]

SOUND_IN_RP[1]

SOUND_IN_L

P[3,5]

COMPOSITEP[3,5]

SCART_CTLP[3,5]

SCART_FB

CT81

470PF

T

50V

CT84

470PF

T

50V

CVBS 0~0.4V

RGB 1~3V

CT92

47PF

50V

RT60

47K

1/16W

RT62

47K

1/16W

CT168

0.1uF

16V

C0805

T

RT61

1K

1/16W

RT65

1K

1/16W

RT75

0

1/16W

R0603

T

RT67

4.7K

1/16W

CT88

47PF

50V

RT73

100

1/16W

T

T

FB2

120 Ω

CT166

220PF

50V

CT167

220PF

50V

RT78

N/75

1/16W

FB3

120 Ω

RT66

6.8K

1/16W

RT70

75

1/16W

ZDT5

UDZ6.8B

SOT1

CS1630-1----

2

4

6

8

10

12

14

16

18

20

R I/P

AGND

L I/P

Video

status

NC

NC

RGB

return

RGB

status

SYNC

return

AV/S/SYNC

R O/P

L O/P

B-GND

G-GND

R-GND

shield

SOUND_OUT_R P[1]

FB4

120 Ω

1

3

5

FB5

120 Ω

CT82

1000PF

50V

CT83

1000PF

50V

RT58

220

1/16W

RT59

220

1/16W

T

T

CT169

470PF

50V

CT170

470PF

50V

RT97

47K

1/16W

RT104

47K

1/16W

SOUND_OUT_L P[1]

SCART_RGB_B P[3]

7

B

9

11

G

13

15

R

17

NC

19

NC

21

RT64

75

1/16W

RT69

75

1/16W

RT74

75

1/16W

ZDT2

UDZ6.8B

ZDT3

UDZ6.8B

ZDT4

UDZ6.8B

RT63

100

1/16W

R0603

RT68

100

1/16W

R0603

RT72

100

1/16W

R0603

CT86

47PF

50V

CT87

47PF

50V

CT90

47PF

50V

T

SCART_RGB_G P[3]

T

SCART_RGB_R P[3]

T

SCART_OUT_CVBS P[1]

RT77

ZDT11

UDZ6.8B

75

1/16W

YUV_L

YUV_R

SVIDEO_L

SVIDEO_R

JT2C

P1159-1-4-C

4

5

JT2A

P1159-1-4-C

1

2

JT3D

P1159-1-4-C

6

5

JT3B

P1159-1-4-C

3

2

FBT10

120 Ω

FBT11

120 Ω

FBT12

120 Ω

FBT13

120 Ω

CT93

1000PF

50V

CT95

1000PF

50V

CT97

1000PF

50V

CT98

1000PF

50V

RT79

47K

1/16W

RT82

47K

1/16W

RT85

47K

1/16W

RT86

47K

1/16W

YUV_L P[1]

YUV_R P[1]

S2_L P[1]

S2_R P[1]

PB 1/CB1

PR1/CR1

Y1

ST1B

P1177-1---A

7

8

JT3A

P1159-1-4-C

1

2

JT3C

P1159-1-4-C

4

5

FET7

RFILN1020-1---A

1

FET10

RFILN1020-1---A

1

FET13

RFILN1020-1---A

1

FET6

6

3

1

RFILN1020-1---A

1

FET9

RFILN1020-1---A

1

3

RT80

2

2

N/75

1/16W

3

RT83

N/75

1/16W

ZDT6

UDZ5.1B

ZDT8

UDZ5.1B

S2_C P[3,5]

S2_Y P[3,5]

3

CT94

T

2

2

2

100PF

50V

3

CT96

100PF

T

50V

3

CT99

100PF

T

50V

RT81

N/75

1/16W

RT84

N/75

1/16W

RT87

N/75

1/16W

ZDT7

UDZ6.8B

ZDT9

UDZ6.8B

ZDT10

UDZ6.8B

Y1 P[5]

PB1_CB1 P[5]

PR1_CR1 P[5]

4

2

ST1A

P1177-1---A

5

Page 30

First issue 10 / 04 30

TUNER BOARD SCHEMATIC DIAGRAM: UOC

LT6

10uH

3V3P[5]

LT8

10uH

3V3P[5]

CT102

+

100uF

16V

100 1/16W

100 1/16W

RT91

3.3K

1/16W

RT93

3.3K

1/16W

RT94

15K

1/16W

CT101

0.022uF

50V

SDA

SCL

RT90

3.3K

1/16W

5V_MTS1

RT2

10K

1/16W

TPT3

SYS1

SYS2

INPSEU

RT103 100 1/16W

LINK_OUTP[5]

SCART_CTLP[2,5]

CT105

+

10uF

50V

RT101

RT99

RT96

RT95 100 1/16W

RT98 100 1/16W

RT100 100 1/16W

RT193 0 1/16W

RT137 0 1/16W

RT195 0 1/16W

3V3P[5]

ICT4

AT24C16P27

4 5

VSS SDA

3

A2

A1

A0

TPT8

SCL2P[1,5]

SDA2P[1,5]

TPT9

3V3P[5]

CT100

10uF

50V

SCL

TEST

VCC

5V_MTS1

+

2

1

LT5

10uH

P

RT88

6

RT89

7

8

RT92

3.3K

1/16W

LINK _INP[5]

RT200

1K

CT175

0.1uF

16V

CVBSO

IFIN1

470 1/16W

470 1/16W

N/1K

N/100

T

1/16W

WHSTR

IFIN2

1/16W

1/16W

1/16W

RT201

1K

1/16W

C

GND

CVBS3/Y

QSSO/AMOUTAUDEEM

IREF

VSC

AGCOUT

TPT4

TPT5

SCART_RGB_B P[2]

SCART_RGB_G P[2]

SCART_RGB_R P[2]

SCART_FB P[2,5]

CT138

0.22uF

16V

41

GND

CVBS2

CVBS1

IFVO/SVO

QSSO

SIFAGC

PLLIF

EHTO

DECSDEM

FBISO

HOUT

AUDIO3

AUDIO2

AVL/REF0/SNDIF

SNDPLL

GND2

SIFIN1

SIFIN2

VP1

COMPOSIT E P[2,5]

CT197

T

220PF

50V

40

39

38

37

36

35

34

33

CT195

32

220PF

50V

RT123 100 1/16W

31

30

RT124

29

RT1

28

27

26

25

T

T

CT129

0.1uF

16V

RT121

390

1/16W

CT196

220PF

50V

CT198

220PF

50V

T

CT117

+

4.7uF

50V

CT174

0.22uF

16V

CT130

0.022uF

50V

100 1/16W

3.3K 1/16W

CT136

T

15PF

50V

TV P[1,5]

LT9

10uH

CT131

+

100uF

16V

TPT6

P9V

DT4

RLS4148

Hflyback P[4]

Hdrive P[4]

5V_MTS1 P[1,4]

CT133

1000PF

50V

CT135

0.22uF

16V

CT137

0.1uF

16V

RT125

100K

1/16W

RT126

47K

1/16W

CT140

0.1uF

16V

P

P

P

ICT6

TDA9181T

RT134

N/0

1/16W

T

RT140

N/0

1/16W

T

RT146

N/0

1/16W

T

INPSEL

Y/CVBS2

DGND

VDDD

VCCA

FSCSELFSC

CT182

68PF

50V

CT193

68PF

50V

CT201

68PF

50V

CIN

SC

LT14

15uH

P

LT16

15uH

P

LT18

15uH

P

1

2

3

4

5

6

7

89

CT132

0.1uF

16V

T

+

CT165

0.1uF

16V

T

CT134

0.1uF

16V

CT160

0.1uF

16V

CT172

10uF

50V

CT183

33PF

50V

CT194

33PF

50V

T

CT202

33PF

50V

INPSEU

CT159

0.1uF

16V

+

CT139

10uF

50V

Hflyback

RT139

470

1/16W

RT138

470

1/16W

RT159

470

1/16W

S2_C P[2,5]

S2_Y P[2,5]

LT10

10uH

P

P

LT11

10uH

BOUT P[4]

GOUT P[4]

ROUT P[4]

5V_MTS1

LT13

15uH

CT181

T

33PF

50V

LT15

15uH

CT187

T

33PF

50V

LT17

15uH

CT200

T

33PF

50V

5V_MTS1

RT122

12K

1/16W

16

COUT

15

OUTSEL

14

Y/CVBSOUT

13

AGND

12

Y/CVBS1

SYS1

SYS2

CT141

T

33PF

50V

11

10

QT11

2SC2412KBQ

SYS1

SYS2

RT110 470

RT111

RT112

RT113

G2/BIN

GND3

RT115

CT123 0.022uF 50V

CT126 0.022uF 50V

CT128 0.022uF 50V

RT120 100 1/16W

CT199 220PF 50V

IFVO2

R2/BIN

INSSW2

DECBG

AVL/EWD

VDRB

AUDOUT/AMOUT

VDRA

P

P

CT179

N/100uF

16V

CT112

100uF

16V

CT104

0.022uF

50V

100 1/16W

1/16W

100

1/16W

0

CT171

0.1uF

16V

RT105 100 1/16W

TPT7

CT103

33PF

50V

T

T

CT107

33PF

50V

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

CT108

0.022uF

50V

CT111

0.022uF

50V

XT2

12MHz

6463626160595857565554535251504948474645444342

BO

GO

RESET

VDDP

P1.0/INT1

P1.1/T0

P1.2/INT0

P1.3/T1

P1.6/SCL

P1.7/SDA

P2.0/TPWM

P2.1/PWM0

P2.2/PWM1

P2.3/PWM2

P2.4/PWM3

P2.5/PWM4

SYNC_FILTER

P3.0/ADC0

XTALIN

XTALOUT

P3.1/ADC1

P3.2/ADC2

123456789

Bnd0

VDDC

OSCGND

P3.3/ADC3

VSSC/P

VPE

P0.5

VDDA

P0.6/CVBSTD

RO

BLKIN

BCLIN

B2/UIN

ICT5

TDA9561H

VSSA

SECPLL

VP2

DECDIG

PH2LF

PH1LF

101112131415161718192021222324

+

+

CT109 0.22uF 16V

P9V

DT3

RLS4148

1AP[4]

CT158

0.01uF

50V

5V_MTS1

LT7

10uH

RT109

3.3K

1/16W

QT10

2SC2412KBQ

RT118

N/22K

1/16W

+

RT116

22K

1/16W

CT113

100uF

16V

T

CT121

220PF

50V

CT114

0.22uF

16V

CT122

1000PF

50V

CT115 2200PF 50V

+

CT116 1uF 50V

CT118 4700PF 50V

CT119 0.022uF 50V

CT120

+

2.2uF

50V

RT119

2.2K

1/16W

RT117

100

1/16W

CT110 0.22uF 16V

RT108

1/16W

18K

RT114

2.2K

1/16W

CT124

1000PF

50V

CT125

1000PF

50V

RT163

39K

1/16W

CT127

0.1uF

16V

RT197

N/0 1/16W

TP17

Page 31

31 First issue 10 / 04

TUNER BOARD SCHEMATIC DIAGRAM: SYNCHRONISATION & RGB TO YUV

BOUTP[3]

ROUTP[3]

GOUTP[3]

RT3

620

1/16W

P[3]

P[3]

P[1,3]

CT176

+

2.2uF

50V

Hflyback

Hdrive

5V_MTS1

RT132

3.3K

1/16W

12

13

2

1

5

3

1Y0

1Y1

2Y0

2Y1

3Y0

3Y1

S1

11

16

VCC

ICT11

74HC4053DT

S2

S3

10

9

RT4

8.2K

1/16W

CT177

+

47uF

16V

DT5

RLS4148

VEE

GND

T

CT201

68PF

50V

P9V P[1,5]

LT20

15uH

P

T

CT202

33PF

50V

RT170

470

1/16W

CT142

+

T

CT153

N/180PF

50V

15

2CTC

1RCTC

2

RT154

1M

1/16W

47uF

16V

RT129

2.2K

1/16W

T

RT127

10K

1/16W

CT184

CT185

22PF

22PF

50V

50V

T

T

CT186

T

VCC

1A

15

1RCEXT

1B

2

22PF

50V

RT148

39K

1/16W

+

+

+

CT149

1uF

50V

CT150

1uF

50V

CT151

1uF

50V

14

3

RT131

5.1K

1/16W

CT152

T

220PF

50V

1CEXT

74HC221D

1RD

13

ICT8

4

1Q

1Q

RT136

15K

1/16W

T

14

1Z

15

2Z

4

3Z

6

E_

7

8

CT178

0.1uF

16V

16

1

CT146

12PF

50V

12

2Q

2Q

5

RT152

10K

1/16W

CT144

0.1uF

16V

RT145

10K

1/16W

11

6

CT145

0.1uF

16V

CT147

0.1uF

16V

CT148

0.1uF

16V

2RD

2CEXT

CT154

220PF

50V

1

2

3

4

5

6

7

8

RT149

1K

1/16W

10

2B

1Q

7

T

RT153

27K

1/16W

TA1287P

V IN

Y IN

U IN

CP IN

GND

R IN

G IN

B IN

9

GND 2A

8

ICT7

Matrix

U OUT

Y OUT

V OUT

VCC

YS3

YS2

YS1

16

15

14

13

12

11

10

9

16

VCC

1CTC

1

CT155

270PF

50V

14

2RCTC

1RD

3

RT150

N/100K

1/16W

RT107

N/150K

1/16W

RT141

1/16W

CT143

0.1uF

16V

13

2RD

ICT9

74HC4538D

1A1

4

2.7K

220

220

RT130

RT133

220

RT135

12

5

1/16W

1/16W

1/16W

2A1

1A0

T

CT173

100PF

50V

CB2 P[5]

Y2 P[5]

CR2 P[5]

RT147

N/0

1/16W

QT7

2SC2412KBQ

RT148

N/1K

1/16W

RT142

N/0

1/16W

RT143

N/0

1/16W

GND 2Q

8 9

RT151

N/1K

1/16W

10

11

2Q

2A0

1Q

1Q

6

7

RT167

470

1/16W

RT155

1K

1/16W

RT144

10K

1/16W

LT19

15uH

P

CT203

T

33PF

50V

1AP[3]

Page 32

First issue 10 / 04 32

TUNER BOARD SCHEMATIC DIAGRAM: CONNECTIONS

P9VP[1,4]

(LINK O/P)

(LINK I/P)

CTL1P[3]

CTL2P[3]

SCL2P[1,3]

SDA2P[1,3]

SCART_FBP[2,3]

DACM_RP[1]

DACM_LP[1]

SDP[1]

TUN_DETn

CTL1

CTL2

SCL2

SDA2

SCART_FB

DACM_R

DACM_L

FBT1

120 Ω

FBT2

120 Ω

RT164 0 1/16W

RT165 0 1/16W

RT166 10K 1/16W

RT158

1/16W

0

JPT2A

CP1615-148-B

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

RT156 N/0 1/16W

RT157 0 1/16W

RT168 0 1/16W

SD P[1]

JPT2B

CP1615-148-B

C1

RT102 N/0 1/16W

C2

RT178 N/0 1/16W

C3

RT106 N/0 1/16W

C4

C5

RT192 N/0 1/16W

C6

RT179 N/0 1/16W

C7

C8

C9

C10

C11

D_CTL P[1]

RESETQ P[1]

SCART_CTL P[2,3]

A

C12

C13

C14

C15

C16

SB5V_CPU

TDO

TDI

3V3

TMS

TCK

TP21

TP25

TP22

TP23

TP24

SB5V_CPU

TDO

TDI

3V3 P[3]

TMS

TCK

COMPOSITEP[2,3]

PB1_CB1P[2]

PR1_CR1P[2]

AV_B_DET

JPT1A

CP1615-148-B

COMPOSITE

S2_YP[2,3]

S2_CP[2,3]

Y1P[2]

Y2P[4]

CB2P[4]

CR2P[4]

TVP[1,3]

S2_Y

S2_C

Y1

PB1_CB1

PR1_CR1

Y2

CB2

CR2

AV_B_DET

TV

RT128

0

1/16W

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

TPT25

RT169 N/0 1/16W

A

JPT1B

CP1615-148-B

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

CT161

1000PF

50V

CT162

1000PF

50V

CT163

1000PF

50V

DD D DD

CT164

1000PF

50V

PCn_MPU

PCSCS

PCSI

PCSCLK

SSO

SCL2

SDA2

SCL_MP

SDA_MP

PCn_MPU

PCSCS

PCSI

PCSCLK

SSO

P5V

SCL_MP

SDA_MP

SCL2_33

SDA2_33

Page 33

33 First issue 10 / 04

MAIN BOARD SCHEMATIC DIAGRAM: DIGITAL SYSTEM (CPU & EEPROM)

SB5V

L1

N/0

C1

0.1uF

25V

Z

D1

RLS4148

U5

S80845ANUP

V

I

N

INT_RTCP[2]

INT_DPTV_SP[14]

INT_DPTVP[13]

INT_USB

T

D

D

1

2

3

4 5

R411

10K

1/16W

D

1/8W

R1

10K

1/16W

D

SB5V_CPU

V

12

O

U

TGND

3

C5

0.1uF

25V

C7

T

10PF

50V

U68

AMC7630-5

VIN

VOUT

GND

GND

GND

GND

EN GND

R412

10K

1/16W

R394

N/10

1/16W

N/820

1/16W

N/820

1/16W

P4

P2

P3

P1

P0

U4

HD6413079F

N/47

TP2

D

NMI

R13

47

1/16W

C12

0.1uF

25V

Z

MPU

45

MD1

44

MD0

51

EXTAL

52

XTAL

TP1

46

@

47

STBY

48

RES

57

RESO

49

NMI

54

AS

55

RD

56

WR

69

P80/IRQ0

70

P81/IRQ1

71

P82/IRQ2

72

P83/IRQ3

9

P90/TXD

10

P92/RXD

1/16W

11

P94/SCK/IRQ4

43

P60/WAIT

21

VCC

68

AVCC

53

VCC

12

VSS

58

AVSS

50

VSS

30

VSS

D

67

VREF

SB5V SB5V_IO

EM83010

1

SDT

2

SCK

3

P00

4

P01

5

P02

6

P03

7

P04

8

P05

R399

0

1/16W

L3

0

U8

VDD

P10

P11

P12

P13

P14

P15

P16

P17

VSS

R349

N/1M

1/16W

Y1

16MHz

R6

100K

1/16W

J2

1

2

Z

R50

R51

D

R16

3.3K

1/16W

8

7

6

3

N/CON3

SB5V_CPU

SDA1

SCL1

R396

N/10

1/16W

NMI

TP3

TP4

R17

3.3K

1/16W

SB5V

C428

+

4.7uF

16V

D

R52

N/820

1/16W

AC_DET P[18]

R38

10

1/16W

R40

10

1/16W

D DD

R44

560K

1/16W

SB5V_IO

C2

T

33PF

50V

D D

SB5V_CPU

R8

R9

D

R45

560K

1/16W

R14

N/3.3K

1/16W

C8

0.1uF

25V

Z

SB5V_CPU

R46

560K

1/16W

C3

T

33PF

50V

R7

3.3K 1/16W

INT_RTC

INT_DPTV_S

INT_DPTV

INT_USB

47 1/16W

1/16W

47

R11

R15

3.3K

1/16W

+C9

D

TP5

TP6

TP7

10uF

16V

NEC_PSO

NEC_PSM

P5P5P6

13141516171819

D0D1D2D3D4D5D6

PA2/TIOCA0/TCLKC

PA3/TIOCB0/TCLKD

PA4/TIOCA1/A23

PA5/TIOCB1/A22

PA6/TIOCA2/A21

PA7/TIOCB2/A20

1/8W

18

10

11

12

13

14

15

16

17

9

D

1827364

1/16W

SB5V_CPU

R5

10K

10uF

16V

TXDP[2]

RXDP[2]

SB5V

+

C426

1uF

50V

D

SCART_CTL3

SCART_CTL1

(LINK O/P)

C6

10PF

50V

+C4

CTL2P[18]

P7

20

D7

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

PA0/TCLKA

PA1/TCLKB

PB0/TIOCA3

PB1/TIOCB3

PB2/TIOCA4

PB3/TIOCB4

PB4/TOCXA4

PB5/TOCXB4

PB6

PB7/ADTRG

P70/AN0

P71/AN1

P72/AN2

P73/AN3

P74/AN4

P75/AN5

P76/AN6

P77/AN7

1827364

5

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

5

RP9