Muffle Furnace

OPERATION MANUAL

AND PARTS LIST

Series 1285

Model Voltage Control Display

5300A20/F48025-TS 120V Single Setpoint Model °C

5300A25/F48025-80-TS 120V 8 Setpoint Programmable Model °C

LT1285X5 • 5/12/09

with OTP

with OTP

Table of Contents

Safety Information ..............................................................................................................................................3

Alert Signals..................................................................................................................................................3

Warnings ......................................................................................................................................................3

Introduction..........................................................................................................................................................5

Intended Use ................................................................................................................................................5

General Usage..............................................................................................................................................5

Principles of Operation ................................................................................................................................5

General Specifications ........................................................................................................................................6

Models 5300A20/F48025-TS and 5300A25/F48025-80-TS ........................................................................6

Environmental Conditions ............................................................................................................................7

Unpacking ..........................................................................................................................................................8

Installation ..........................................................................................................................................................9

Site Selection................................................................................................................................................9

Electrical Connections ..................................................................................................................................9

Operation, All Models ........................................................................................................................................10

Power Switch ..............................................................................................................................................10

Cycle Light ..................................................................................................................................................10

Door Safety Switch ....................................................................................................................................10

Single Setpoint Model with OTP ......................................................................................................................11

Single Ramp & Dwell ........................................................................................................................................15

8 Segment Programmable Models with OTP....................................................................................................17

Furnace Loading ..............................................................................................................................................31

Preventative Maintenance ................................................................................................................................32

General Cleaning Instructions ....................................................................................................................32

Troubleshooting ................................................................................................................................................33

Maintenance and Servicing ..............................................................................................................................35

To Replace a Heating Element ..................................................................................................................35

To Replace a Chromel/Alumel Thermocouple ............................................................................................36

To Replace Door Switches (Micro-Switch) ................................................................................................37

To Realign Door Switches (Micro-Switch) ..................................................................................................37

To Replace the Controller ..........................................................................................................................38

Replacement Parts............................................................................................................................................39

Single Setpoint Models with OTP ..............................................................................................................39

8 Segment Programmable Models with OTP ............................................................................................39

Ordering Procedures ..................................................................................................................................39

Wiring Diagrams................................................................................................................................................40

Warranty Repair and Service ............................................................................................................................44

2

Alert Signals

Warning

Warnings alert you to a possibility of personal injury.

Caution

Cautions alert you to a possibility of

damage to the equipment.

Note

Notes alert you to pertinent facts and

conditions.

Safety Information

This manual contains important operating and safety information. You must carefully read and understand the contents of this manual prior to the use of this furnace.

Your Thomas Scientific 5300A20/F48025-TS or

5300A25/F48025-80-TS Muffle Furnace has been

designed with function, reliability and safety in mind. It is

your responsibility to install it in conformance with local

electrical codes. For safe operation, please pay attention to

the alert signals throughout the manual.

Warnings

To avoid electrical shock, this furnace must:

1. Use a properly grounded electrical outlet of correct voltage and current handling capacity.

2. Be disconnected from the power supply prior to

maintenance and servicing.

Hot Surface

Hot surfaces alert you to a possibility of

personal injury if you come in contact

with a surface during use or for a period

of time after use.

3. Have the door switch operating properly.

To avoid personal injury:

1. Do not use in the presence of flammable or combustible materials; fire or explosion may result.

This device contains components which may

ignite such material.

2. Caution: Hot Surface - Avoid Contact. To avoid

burns, do not touch the exterior or interior surfaces of this furnace during use or for a period of

time after use.

3. Always wear safety glasses or a safety shield and

high temperature gloves when loading or unloading the furnace. Long sleeved, fire retardant clothing and a fire retardant apron is also recommended.

4. Refer servicing to qualified personnel.

3

SAFETY INFORMATION

Warning

Refer servicing to qualified personnel.

Warning

This warning is presented for compliance with California

Proposition 65 and other regulatory agencies and only applies

to the insulation in this product. This product contains refractory ceramic, refractory ceramic fiber or fiberglass insulation,

which can produce respirable dust or fibers during disassembly. Dust or fibers can cause irritation and can aggravate preexisting respiratory diseases. Refractory ceramic and refractory

ceramic fibers (after reaching 1000°C) contain crystalline silica,

which can cause lung damage (silicosis). The International

Agency for Research on Cancer (IARC) has classified refractory ceramic fiber and fiberglass as possibly carcinogenic (Group

2B), and crystalline silica as carcinogenic to humans (Group 1).

The insulating materials can be located in the door, the hearth

collar, in the chamber of the product or under the hot plate top.

Tests performed by the manufacturer indicate that there is no

risk of exposure to dust or respirable fibers resulting from operation of this product under normal conditions. However, there

may be a risk of exposure to respirable dust or fibers when

repairing or maintaining the insulating materials, or when otherwise disturbing them in a manner which causes release of dust

or fibers. By using proper handling procedures and protective

equipment you can work safely with these insulating materials

and minimize any exposure. Refer to the appropriate Material

Safety Data Sheets (MSDS) for information regarding proper

handling and recommended protective equipment. For additional MSDS copies, or additional information concerning the

handling of refractory ceramic products, please contact the

Customer Service Department at Thomas Scientific at 1-800345-2100.

4

Caution

Do not exceed operating temperatures

shown in “General Specifications.”

Exceeding these limits will result in

severely reduced element life.

Introduction

Intended Use

The 5300A20/F48025-TS or 5300A25/F48025-80-TS

furnace is a general purpose laboratory and heat treating furnace. For optimum element life, Thomas

Scientific recommends observing these temperature

ranges: from 100°C (212°F) to 1093°C (2000°F) continuous use or from 1093°C (2000°F) to 1200C (2192°F)

for intermittent use. Continuous use is operating the

furnace for more than 3 hours and intermittent use is

operating the furnace for less than 3 hours.

All furnaces consist of: 1) a vented heating chamber;

2) a temperature controller; and 3) a door safety switch

for operator safety.

General Usage

Do not use this product for anything other than its

intended usage.

Principles of Operation

The furnace chamber is heated by open coil electric

resistance elements and is insulated with ceramic fiber

insulation. The controller is located under the furnace

chamber and is well insulated from the heat generated

in the furnace chamber. A door safety switch removes

power to the heating elements whenever the furnace

door is opened. The temperature is controlled by one

of three types of controllers.

5

General Specifications

Models 5300A20/F48025-TS and 5300A25/F48025-80-TS

Dimensions in Inches (cm):

Chamber: 7 (17.8) W x 5 (12.7) H x 10 (25.4) D

Overall: 13.25 (33.7) W x 19 (48.3) H x 19.5 (49.5) D

Weight: 56 lb. (25.4 kg)

Electrical Ratings:

Volts: 120

Amps: 14.5

Watts: 1800

Frequency: 50/60

Phase: 1

Temperature:

Operating Range: 2000°F (1093°C) continuous

2192°F (1200°C) intermittent

6

GENERAL SPECIFICATIONS

Environmental Conditions

Operating: 17°C to 27°C; 20% to 80% relative humidity, non-condensing. Installation Category II

(overvoltage) in accordance with IEC 664. Pollution degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25°C to 65°C; 20% to 80% relative humidity

7

Unpacking

1. Visually check for any physical damage

to the shipping container.

2. Inspect the equipment surfaces that are

adjacent to any damaged area.

3. Open the furnace door and remove the

packing material from inside the furnace

chamber.

4. Vacuum the chamber prior to use to

remove the insulation dust due to shipment. (The 5300A20/F48025-TS and

5300A25/F48025-80-TS furnaces are

supplied with one ceramic shelf.)

5. Retain the original packaging material if

reshipment is foreseen or required.

8

Caution

Be sure ambient temperature does not

exceed 40°C (104°F). The recommended

ambient temperature is 17°C - 27°C.

Ambients above this level may result in

damage to the controller.

Caution

Allow at least six inches of space

between the furnace and any combustible

surface. This permits the heat from the

furnace case to escape so as not to create a possible fire hazard.

Installation

Site Selection

Install furnace on a sturdy surface and allow adequate

space for ventilation.

Electrical Connections

The electrical ratings are located on the specification

plate on the back of the furnace. Consult Thomas

Scientific if your electrical service is different than

those listed on the specification plate. Be sure the front

power switch is in the OFF position before connecting

the furnace to your electrical supply.The

5300A20/F48025-TS or 5300A25/F48025-80-TS furnaces are supplied with a power cord rated at 120V,

15 amps.

Warning

To avoid electrical shock, this furnace

must always use a properly grounded

outlet of correct voltage and current handling capacity.

9

Operation, All Models

Warning

To avoid personal injury do not use in the

presence of flammable or combustible

chemicals; fire or explosion may result.

This device contains components which

may ignite such materials.

Hot Surface

Caution: Avoid Contact. To avoid burns,

this furnace must not be touched on the

exterior or interior surfaces during use or

for a period of time after use.

Warning

Always wear safety glasses or a safety

shield and high temperature gloves when

loading or unloading the furnace. Long

sleeved, fire retardant clothing and a fire

retardant apron is also recommended.

Power Switch

Both the ON/OFF power switch and the digital display

will illuminate when power is switched ON. The furnace will begin to heat to its controller's current setpoint. (See the instructions for your type of controller

for information on checking and setting the setpoint.)

Cycle Light

The amber cycle light will illuminate whenever the

power is being applied to the heating elements. The

cycle light will turn on and off as the furnace reaches

the setpoint.

Door Safety Switch

The door safety switch removes power from the heating elements when the door is opened. Open and

close the door a few times; note that the amber

CYCLE light will switch off when the door is opened.

If this condition is not true, consult the

Troubleshooting section before proceeding. This

check must be done when the furnace is heating and

the cycle light is illuminated.

Warning

To avoid electrical shock, the door safety

switch must be operating properly.

10

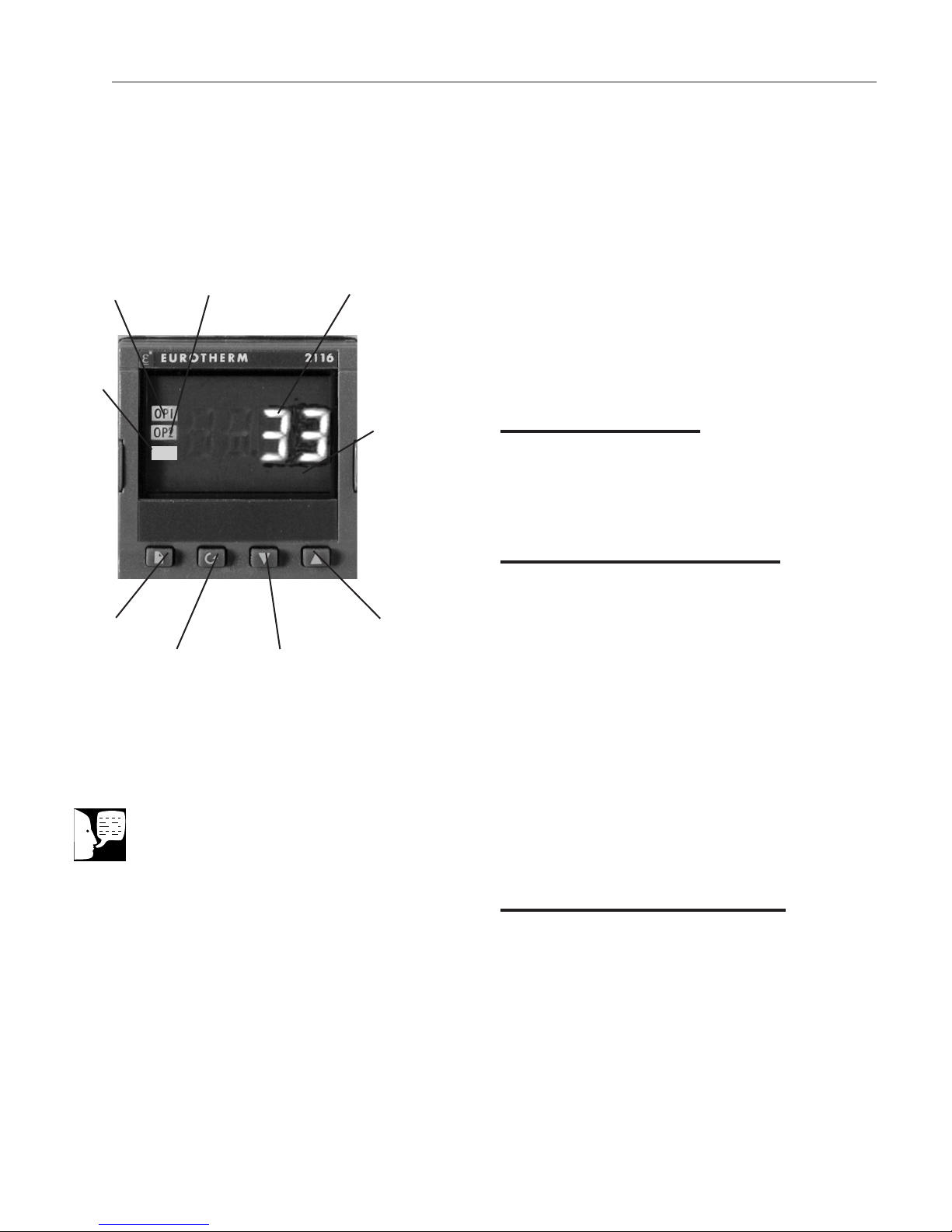

Single Setpoint Model w/OTP

Output 1

Manual

AN

M

PAGE

Button

Single Setpoint Models

SCROLL

Button

Output 2

DOWN ARROW

Button

Temperature

Display

Display

Window

UP ARROW

Button

The single setpoint model w/ OTP furnace controller is a single setpoint controller which provides a

single digital display to indicate the current chamber

temperature or setpoint temperature. This temperature controller features sensor break protection, selftuning capability and over temperature protection

(OTP) with an additional OTP relay device.

Basic Operation

When the controller is turned ON it will perform a

short self-test and then display the measured value

(process value) in the HOME DISPLAY.

Buttons and Indicators

OP1 (Output 1): Illuminates when the logic output is

ON.

OP2 (Output 2): Illuminates when the relay output is

ON (will go out during an alarm situation).

PAGE button: Allows you to select a new list of

parameters.

Note

If at any time you want to return to the

HOME DISPLAY, simultaneously press

the PAGE and SCROLL buttons.

SCROLL button: Allows you to select a parameter

within a list of parameters.

DOWN button: Allows you to decrease a value.

UP button: Allows you to increase a value.

To View or Change the

Setpoint

To view the setpoint, press and release the UP or

DOWN buttons. If you want to change the setpoint,

continue pressing until the desired setpoint value is

displayed and then release the button. A few seconds

after the button is released, the controller will accept

the new value and revert to the HOME DISPLAY.

11

SINGLE SETPOINT MODEL W/OTP

To View the Display Units

From the HOME DISPLAY press the SCROLL button. The

display will show the temperature units in °C/F/K and then

return to the HOME DISPLAY. (Call Customer Service if you

require a different temperature unit.)

To View the % Output Power

From the HOME DISPLAY press the SCROLL button twice.

Press and release the UP or DOWN button to view the %

output power. This value is a read-only value and cannot be

changed.

Controller Parameters

Home display

°C: Temperature units in Celsius. Temperature units can not

be changed without entering the configuration. Contact

Customer Service if a different temperature unit is required.

OP: % output power demand.

IdHi: Deviation high alarm. Factory preset to 50.

AL List (Alarm List)

IdHi: Deviation high alarm. Factory preset to 50.

3FSL: Full scale low alarm. Factory preset to -99°C.

Cannot be adjusted by end users.

Atun List (Autotune List)

tunE: One-shot autotune enable.

Pid List (Proportional, Integral, Derivative)

Pb: Proportional band (in display units). Factory preset to 5.

12

ti: Integral time in seconds. Factory preset to 0.48.

td: Derivative time in seconds. Factory preset to 0.8.

ACCS List Code: Access code (Code needed to enter or

change the other configuration parameters which are not

normally accessible.) Not accessible.

SINGLE SETPOINT MODEL W/OTP

Note

The following alarm messages are factory default settings and may vary if you

have changed the configuration of your

controller:

IDHi: = 50°C

2FSH = 1225°C

Alarms

The controller will flash an alarm message in the home

display if an alarm condition is detected.

2FSH: Measured value full scale high alarm. The full

scale high alarm is for furnace protection. It cannot be

accessed from the user list.

IdHi: Measured value deviation high alarm. The deviation alarm is factory preset at 50°C. If the chamber temperature rises to 50°C above the setpoint temperature,

this error condition will alert end users. The furnace will

continue to control temperature at the alarm setpoint,

which was defined as 50°C above the setpoint. End

users must power off the furnace and contact Customer

Service for troubleshooting assistance. Do not reset this

alarm below 20°C at any time.

S.br: Sensor Break: check that sensor is connected correctly.

L.br: Loop Break: check that the heating circuits are

working properly.

Ld.F: Heater Circuit Fault: indication of either an open or

short solid sate relay, a blown fuse, missing supply or

open circuit heater.

Sensor Break Protection

This controller provides sensor break protection in the

event the thermocouple opens. If an open thermocouple

condition occurs, the digital display will blink “S.br” and

the power to the heating element will be shut OFF (Cycle

light will extinguish).

Over-Temperature Protection

(OTP)

The OTP will be in effect during any alarm condition

when the temperature of the furnace has deviated

beyond the limit. The “Deviation High” alarm is the only

alarm value which can be changed. To change it, press

the SCROLL button until “IdHi” appears on the display.

13

SINGLE SETPOINT MODEL W/OTP

Note

Furnace must be at ambient

temperature before starting a tune.

Press the UP or DOWN button to select the OTP value

you desire. We recommend a value of 20° above your

working temperature to provide protection for your

workload.

In addition to over-temperature protection, units containing a single setpoint controller w/OTP feature a

mechanical OTP relay device which disconnects power

from the elements in an alarm condition (only in furnaces with OTP relay).

Tuning

This controller incorporates a self-tuning feature which

determines the optimum control parameters for the

best temperature accuracy with your load and setpoint.

Use this feature the first time you use your furnace and

each time you change either your setpoint or the type

of load you are heating. Thomas Scientific recommends you use this feature to provide the best temperature accuracy the controller can attain. To use the tuning feature:

1. Adjust the setpoint to your desired value.

14

Note

“Stat” and “Sp.rr” in Sp list must be

set to OFF or “tunE” will not initiate.

Note

Tune has completed when “tunE”

stops flashing on display.

2. Press the PAGE button until display reads,

“Atun.”

3. Press the SCROLL button. Display will read,

“tunE.”

4. Press the UP or DOWN button to select, “on.”

5. Simultaneously press the PAGE and

SCROLL buttons to return to the HOME DISPLAY. The display will alternately flash

between “tunE” and the HOME DISPLAY

while tuning is in progress.

6. The controller will then turn the heating on

and off to induce an oscillation. When the

measured value reaches the required setpoint

the first cycle will end.

7. Tuning will be complete after two oscillation

cycles and then the tuner will turn itself off.

8. Normal control function will resume after the

controller calculates tuning parameters.

Mode 1 (Opt. 1)

Single Ramp & Dwell

Functions

This type of controller has single ramp and dwell programming capabilities. The Ramp and Dwell can be configured

to five different modes.

1. Mode 1 (Opt. 1) is a Ramp (if needed) to the

Setpoint temperature, a Dwell, and then a cool

down.

2. Mode 2 (Opt. 2) is the same as mode 1, except

the controller continues to heat at the Setpoint

after the Dwell has completed. (This mode does

not cool down.)

3. Mode 3 (Opt. 3) is the same as mode 1, except

the Dwell time includes the Ramp (if needed).

Mode 2 (Opt. 2)

Mode 3 (Opt. 3)

Mode 4 (Opt. 4)

4. Mode 4 (Opt. 4) is the same as mode 2, except

the Dwell time includes the Ramp (if needed).

5. Mode 5 (Opt. 5) is a Dwell (delay time) before the

controller Ramps (if needed) to the Setpoint temperature.

Program Overview

• A program mode can be set by changing the

“tm.OP” variable to “Opt. 1, Opt. 2, Opt. 3, Opt. 4,

or Opt. 5.

• A Ramp rate may be set by changing the “SPrr”

variable to a value. The Ramp rate units are in

degrees per minute.

• The Dwell time can be set by changing the

“dwEll” variable to the desired value. Dwell time

units are in minutes.

• The program Status can be set by changing the

“StAt” variable to “run” or “oFF.” This variable will

start or stop the program.

Mode 5 (Opt. 5)

15

SINGLE RAMP & DWELL

Note

The program must be stopped and

the controller must be displaying the

actual temperature before beginning

the Setup.

Program Setup

1. Press the PAGE button until the “SP” is displayed.

2. Press the SCROLL button once, “SPrr” (Ramp

Rate) will be displayed, set the desired Ramp rate

with the UP or DOWN buttons, if the ramp to setpoint feature is needed. If the Ramp rate is not

needed, then set to “OFF” with the UP or DOWN

buttons.

3. Press the SCROLL button once, “tm.OP” (Ramp &

Dwell mode) will be displayed, select the desired

mode with the UP or DOWN buttons. (Opt. 1, Opt.

2, Opt. 3, Opt. 4, Opt. 5)

4. Press the SCROLL button once, “dwEll” will be displayed, set the desired Dwell time with the UP or

DOWN buttons. (Dwell in minutes.)

5. Press the PAGE button until the Actual temperature is displayed.

Running the Program

1. Press the SCROLL button until “StAt” is displayed,

set to “run” with the UP or DOWN buttons.

2. Press the PAGE button to display Actual temperature.

Stopping the Program

Press the SCROLL button until “StAt” is displayed, set to

“oFF” with the UP or DOWN buttons.

Clearing the Flashing End

Press the PAGE and SCROLL buttons at the same time.

16

Verifying a Running Program

Press the SCROLL button until “StAt” is displayed. The display will show “run” if the program is running, or “oFF” if it is

not running. Press the PAGE button to display Actual temperature.

AUTO/MAN

Button

8 Segment Programmable

Model w/OTP

The 8 segment programmable controller consists of

Note

The controller will return to the HOME

DISPLAY if left idle for more than a few

seconds.

Note

Once the desired parameter has been

selected, depressing either the UP or

DOWN button will change the parameter

value. In all cases, the value shown on

the display is the current working value of

that parameter.

Output 1

Display

Window

a microprocessor based three-mode PID

(Proportional, Integral, Derivative), programmable

temperature controller with over-temperature protection and appropriate output switching devices to control the furnace. The digital readout continuously displays chamber (upper display) and setpoint (lower

display) temperatures unless the SCROLL or PAGE

button is depressed. The programmable controller

can be used as a single setpoint controller or as a

programmable controller. The 8 segment digital model

enables eight segments of programming.

Basic Operation

When the controller is turned ON, it will perform a

short self-test and then change to the HOME DISPLAY. The HOME DISPLAY shows the measured

temperature (process value) in the upper display and

the desired value (setpoint) in the lower display.

Upper

Display

Lower

Display

RUN/HOLD

UP ARROW

PAGE

Button

8 Segment Programmable Model with OTP

SCROLL

Button

DOWN ARROW

Button

Button

Button

To Change the Setpoint

If you want to change the setpoint, press the UP or

DOWN button until the desired setpoint value is displayed in the lower display and then release the button.

To View Display Units

From the HOME DISPLAY press the SCROLL button.

The display will briefly show the temperature units in

°C/F/K and then return to the HOME DISPLAY. (If you

require a different temperature unit call Thomas

Scientific Customer Service.)

To View the % Output Power

From the HOME DISPLAY press the SCROLL button

twice. This value is a read-only value and cannot be

changed.

17

8 SEGMENT PROGRAMMABLE MODEL W/OTP

Buttons and Indicators

OP1 (Output 1): illuminates when the heating output of

the temperature controller is on.

AUTO/MAN: (Auto/Manual Mode): when the controller is in the automatic mode the output automatically

adjusts to keep the temperature or process value at the

setpoint. The “AUTO” light will illuminate. The manual

mode has been disabled through factory configuration.

Attempts to operate in manual mode are not recommended.

RUN/HOLD (Run/Hold button):

• Starts a program when pressed once—RUN

light illuminates.

• Holds a program when pressed again—

HOLD light illuminates.

• Cancels hold and continues running when

pressed again—HOLD light is off and RUN

light illuminates.

• Exits a program when the button is held down

for two seconds—RUN and HOLD lights are

off.

• At the end of a program the RUN light will

flash.

• During holdback the HOLD light will flash.

PAGE button: allows you to select a list in the user or

configuration mode.

SCROLL button: allows you to select a parameter

within a list in the user configuration mode.

UP button: allows you to increase the value in the

lower display.

18

DOWN button: allows you to decrease the value in the

lower display.

8 SEGMENT PROGRAMMABLE MODEL W/OTP

Controller Parameters

Home Display

°C: measured temperature in Celsius. Temperature units

can not be changed without entering the configuration.

Contact Customer Service if a different temperature unit

is required.

OP: % output power demand; displayed in lower display

(cannot be changed).

C.id: Controller identification number.

IdHi: Deviation High Alarm. Factory preset to 50.

tunE: One-shot autotune enable.

run LiSt (Program Run List)

PrG (Program): Currently running program (only used on

4x16 programmable models)

StAt (Status): Displays the program status [OFF, run

(running active program), hoLd (program on hold), HbAc

(waiting for process to catch up), End (program completed)] in the lower display. The controller will default to

“OFF.”

FASt (Fast): Fast run through program (no/YES). The

controller will default to “no.”

SEG.d (Segment): Flash active segment type in the

lower display of the home display (no/YES). The controller will default to “no.”

ProG LiSt (Program Edit List)

Hb (Holdback): Press the UP or DOWN ARROW to

select the holdback type [OFF (disables holdback), Lo

(deviation low holdback), Hi (deviation high holdback) or

bAnd (deviation band holdback)] for the entire program.

The controller will default to “OFF.”

Hb.U (Holdback Units): Press the UP or DOWN

ARROW to select the holdback value (in display units).

19

8 SEGMENT PROGRAMMABLE MODEL W/OTP

rmP.U (Ramp Units): Press the UP or DOWN ARROW

to toggle between ramp units (SEc, min or Hour).

Controller will default to “SEc.”

dwL.U (Dwell Units): Press the UP or DOWN ARROW

to toggle between dwell units (SEc, min or Hour).

Controller will default to “SEc.”

Cyc.n (Cycle Number): Press the UP or DOWN

ARROW to set the number of program cycles (1 to 999

or cont). The controller will default to “cont.”

SEG.n (Segment Number): Press the UP or DOWN

ARROW to select the segment number (1-8).

tYPE (Type of Segment): Press the UP or DOWN

ARROW to select the segment type [End (end of program), rmP.r = ramp rate (ramp to a specified setpoint at

a set rate), rmp.t = ramp time (ramp to a specified temperature in a set time), dwEll (to maintain a constant

temperature for a set time), StEP (climb instantaneously

from current to specified temperature). The controller will

default to “End.” Other parameters used with tYPE

include; tGt target setpoint), Rate (rate of temperature

increase) and dur (time to target setpoint or time to

dwell).

20

End.t (End Type): End segment type: dwELL (dwell continuous), rSEt (reset) and S OP (End Segment Output

power level.

AL LiSt (Alarm List)

IdHi: Deviation High Alarm. Factory preset to 50.

Atun LiSt (Autotune List)

tunE: One-shot autotune enable. Resets the PID values

automatically.

drA: Adaptive tune enable. Monitors the process variable

and resets the PID values if the process variable

exceeds the trigger level.

drA.t: Adaptive tune trigger level in display units. Range

= 1 9999.

8 SEGMENT PROGRAMMABLE MODEL W/OTP

Pid LiSt

G.SP (Gain Setpoint): Is the temperature at which

the controller switches from the (SEt1) PID values to

the (SEt 2) PID values.

Pb: Proportional band in display units. (SEt 1)

ti: Integral time in seconds. (SEt 1)

td: Derivative time in seconds. (SEt 1)

Pb2: Proportional band. (SEt 2)

ti2: Integral time in seconds. (SEt 2)

Note

The following alarm messages are factory

default settings and may vary if you have

changed the configuration of your

controller:

IDHi: = 50°C

2FSH = 1225°C

td2: Derivative time in seconds. (SEt 2)

ACCS LiSt (Access List)

Access Code (Code needed to enter or change the

other configuration parameters which are not normally

accessible.) Not accessible.

Alarms

The controller will flash an alarm message in the

home display if an alarm condition is detected.

IdHi: PV deviation high alarm. Factory preset at

50°C.

2FSH: PV full scale high alarm. Factory preset at

1225°C. The full scale high alarm is for furnace protection. The parameter is not accessible from the user

list.

S.br: Sensor break: check that sensor is connected

correctly.

L.br: Loop Break: Check that the heating circuits are

working properly.

21

8 SEGMENT PROGRAMMABLE MODEL W/OTP

Sensor Break Protection

This controller provides sensor break protection in the

event the thermocouple opens. If an open thermocouple

condition occurs, the digital display will Blink “S.br” and

the power to the heating element will be shut OFF (Cycle

light will extinguish).

Over-Temperature Protection

(OTP)

The OTP will be in effect during any alarm condition

when the temperature of the furnace has deviated

beyond the limit. The “Deviation High” alarm is the only

alarm value which can be changed. To change it, press

the SCROLL button until “idHi” appears on the display.

Press the UP or DOWN button to select the OTP value

you desire. We recommend a value of 20° above your

working temperature to provide protection for your workload.

22

To Operate the Controller as a

Single Setpoint Controller

1. Switch the power switch to the “ON” position.

The setpoint temperature presently set in the

controller will appear in the lower display. (The

upper display indicates the actual chamber temperature.)

2. To change the setpoint, press the UP or DOWN

button until the desired setpoint value is displayed; then release the button.

3. From the home list, use the page key (press

and release) to access the run list.

4. From the run list, use the scroll key (press and

release) to view “StAt.” Ensure “StAt” is set to

off. Use up or down arrow to select off if necessary.

5. The furnace will begin to heat if the new setpoint temperature is higher than the present

chamber temperature.

8 SEGMENT PROGRAMMABLE MODEL W/OTP

Programming the Controller

The controller is capable of varying temperature or process

value with time through programming. A program is stored

as a series of segments and can be run once, repeated a

set number of times or run continuously. To create a customized program using the controller parameters listed

under “Controller Parameters” at the beginning of this section, follow the procedures outlined in the proceeding sections of this manual. All programming is accomplished in the

ProG list.

Hb: Holdback

Step 1 in programming the controller is to set the holdback

feature. Holdback consists of a value and a type. If the

measured value lags behind the setpoint by an undesirable

amount during a ramp or dwell, the holdback feature can be

used to freeze the program at its current state (the HOLD

light will flash). The program will resume when the measured value comes within the holdback value.

Holdback can be set to 1 of 4 settings. They are as follows:

1) OFF: holdback is disabled.

2) Lo (Deviation Low Holdback): holds the program back

when process variable deviates below the setpoint by more

than the holdback value.

3) Hi (Deviation High Holdback): holds the program back

when process variable deviates above the setpoint by more

than the holdback value.

4) bAnd (Deviation Band Holdback): combines the features of the high and low deviation holdback in that it holds

the program back when the process variable deviates

above or below the setpoint by more than the holdback

value.

To set the holdback type when programming the controller:

1. Press the PAGE button until you reach the program list (ProG LiSt).

2. Press the SCROLL button until display reads,

“Hb.”

23

8 SEGMENT PROGRAMMABLE MODEL W/OTP

Note

The value set in this parameter is always

for the entire program.

3. Press the UP or DOWN button to toggle between

“bAnd, Hi, Lo and OFF.”

If you choose to activate the holdback feature for your program by selecting Lo, Hi or bAnd, you will also need to set

the holdback value.

Hb U: Holdback Value

Step 2 in programming the controller is to set the Holdback

Value. If you donʼt activate the holdback feature, move on to

“mP.U: Setting Ramp Units”

To set the holdback value:

1. Press the PAGE button until you reach the program list (ProG LiSt).

Note

The holdback value should never be set

less than 10.

Note

The time units you set for the ramp and

dwell apply for the entire program.

2. Press the SCROLL button until display reads,

“Hb.U.”

3. Press the UP or DOWN button to enter a holdback

value.

rmP.U: Setting Ramp Units

Step 3 in programming the controller is defining ramp rate

units. Ramp units are time units which are used in “rmP.r”

segments (ramp to a setpoint at degrees per second, minute

or hour) and “rmP.t” segments (ramp to setpoint in a specific

amount of time). See “Setting the Segment Type” for an

explanation on how to set a ramp segment.

To set the ramp rate units:

1. Press the PAGE button until you reach the program list (ProG LiSt).

2. Press the SCROLL button until display reads,

“rmP.U.”

3. Press the UP or DOWN button to toggle between

seconds, minutes and hours.

24

8 SEGMENT PROGRAMMABLE MODEL W/OTP

dwL.U: Setting Dwell Units

Step 4 in programming your controller is defining dwell

units. Dwell units are time units which are used in

“dwELL” segments (amount of time to remain at a specific temperature ). See “Setting the Segment Type” for an

explanation on how to set a dwell segment.

To set the dwell units:

1. Press the PAGE button until you reach the program list (ProG LiSt).

2. Press the SCROLL button until display reads,

“dwL.U.”

3. Press the UP or DOWN button to toggle

between seconds, minutes and hours.

Note

The program ramp rate is designed to

reduce the heatup rate or cooling rate

that the furnace normally exhibits.

When not using this feature, the furnace will operate at its maximum

heating and cooling capability.

CYC.n: Setting the Number of Cycles

Step 5 in programming the controller is to define the

cycle setting. Set the number of times a group of segments or programs are to be repeated by following the

steps listed below.

To set the cycle setting:

1. Press the PAGE button until you reach the program list (ProG LiSt).

2. Press the SCROLL button until display

reads,”CYC.n.”

3. Press the UP or DOWN button to select the

number of cycles you want to run or, press the

DOWN button to select “cont.” so the program

will run continuously.

Setting the Segment Type

Step 6 in programming the controller is to define the first

segment type. There are five segment types; “rmP.r,”

“rmP.t,” “dwEll,” “StEP” or “End.” Proceed with the following steps according to the type of segment you have

selected.

rmP.r (Ramp)

To ramp linearly at a set rate to a specified temperature:

1. Press the PAGE button until you reach the program list (ProG LiSt).

25

8 SEGMENT PROGRAMMABLE MODEL W/OTP

Note

When the program ramp has ended

or has been reset, the furnace will

continue to maintain setpoint temperature. It will not cool to ambient temperature unless the setpoint is set to

ambient temperature by the program

or by the operator.

2. Press the SCROLL button until display reads,

“tYPE.”

3. Press the UP or DOWN button until display

reads, “rmP.r.”

Steps 4 and 5 are used in the 4 program model only. If you

are using an 8 segment program, skip to step 6.

4. Press the SCROLL button until display reads

“Hb.”

5. Press the UP or DOWN button to toggle between

“bAnd, Hi, Lo and OFF.”

6. Press the SCROLL button until display reads,

“tGt.”

7. Press the UP or DOWN button to set a target setpoint.

8. Press the SCROLL button until display

reads,”rAtE.”

9. Press the UP or DOWN button to select a value

in ramp units (seconds, minutes or hours; set in

the “rmP.U” parameter).

rmP.t

To ramp to a specified temperature at a set time:

1. Press the PAGE button until you reach the program list (ProG LiSt).

2. Press the SCROLL button until display reads,

“tYPE.”

3. Press the UP or DOWN button until display

reads, “rmP.t.”

4. Press the SCROLL button until display reads,

“tGt.”

5. Press the UP or DOWN button to set a target setpoint.

26

6. Press the SCROLL button until display reads,

“dur.”

8 SEGMENT PROGRAMMABLE MODEL W/OTP

7. Press the UP or DOWN button to select a time

in ramp units (seconds, minutes or hours; set

in the “rmP.U” parameter.

dwEll

To maintain a constant temperature for a specified time:

1. Press the PAGE button until you reach the

program list (ProG LiSt).

2. Press the SCROLL button until display reads,

“tYPE.”

3. Press the UP or DOWN button until display

reads, “dwEll.”

4. Press the SCROLL button until display reads,

“dur.”

5. Press the UP or DOWN button to select a time

in dwell units (seconds, minutes or hours; set

in the “dwL.U” parameter).

StEP

To climb instantaneously from the current temperature

to a specified temperature.

1. Press the PAGE button until you reach the

program list (ProG LiSt).

2. Press the SCROLL button until display reads,

tYPE.”

3. Press the UP or DOWN button until the display reads, “StEP.”

4. Press the SCROLL button until display reads,

“tGt.”

5. Press the UP or DOWN button to set a target

setpoint.

End

To end or repeat a program:

1. Press the PAGE button until you reach the

program list (ProG LiSt).

2. Press the SCROLL button until display reads,

“tYPE.”

27

Note

Do to the configuration of these controllers, it is advised NOT to end a

program to the “S OP” type. This will

put the furnace in manual mode. In

manual mode, the output power is

based on percentage. This will ultimately cause heating element failure.

8 SEGMENT PROGRAMMABLE MODEL W/OTP

3. Press the UP or DOWN button until display

reads, “End.”

4. Press the SCROLL button until display reads,

“End.t.”

5. Press the UP or DOWN button to toggle between

“dwEll” (an indefinite dwell), “S OP” (End

Segment Output Power) and “rSET” (reset).

When “dwEll” is selected, the controller will hold

the program at the last setpoint in the program

indefinitely. When “rSET” is selected, the controller will reset the program and control chamber

temperature at the single setpoint temperature.

Make sure the single setpoint temperature is set

to what temperature you want the controller to

regulate, prior to beginning the program.

28

Note

Display will flash “tu.ER” if an error

occurs during tuning. To clear the

error and restart tuning, simultaneously press the PAGE and SCROLL

buttons and follow the steps outlined

in “Autotuning.”

Running a Program

To run a program, press the RUN/HOLD button. (The RUN

light will illuminate.)

Holding a Program

To put a running program on hold, press the RUN/HOLD

button. (The HOLD light will illuminate.)

Cancelling a Program

To cancel a program, hold the RUN/HOLD button down

until the RUN and HOLD lights go off.

Tuning your Furnace

The purpose of tuning your furnace is to match the characteristics of your controller to the characteristics of the

process being controlled. Good control is evidenced by:

stable, straight-line control of the setpoint temperature with

no fluctuations; No overshoot or undershoot of the setpoint

temperature; rapid restoration of the setpoint temperature

when external disturbances cause deviations from the setpoint.

Note

To stop the tuning function, simultaneously press the PAGE and

SCROLL buttons.

8 SEGMENT PROGRAMMABLE MODEL W/OTP

This controller has automatic tuning features which install

optimum tuning parameters to give the best temperature

accuracy. No manual loading of tuning parameters is

needed. We recommend that you tune the furnace to your

specific application to obtain the best results. To provide

the best temperature accuracy possible, use these features when you install your furnace and whenever you

change your application or procedure.

Tuning Error

The display will flash “tu.ER” if an error occurs during tuning. To clear the error and restart tuning, simultaneously

press the PAGE and SCROLL buttons and follow the

steps outlined in “Autotuning.”

Gain Scheduling

G.SP: Gain Scheduling

Gain scheduling is the automatic transfer of control

between two sets of PID values. The 2416 controller does

this at a presettable process value. Gain scheduling is

used for difficult control processes which show large

changes in their response time or sensitivity at high or low

temperatures, or when heating or cooling.

The G.SP gain schedule setpoint is factory set at 700° C.

The G.SP must be adjusted to 200°C from the desired

setpoint temperature when tuning.

Setting the Transfer Point

If gain scheduling has been enabled, “G.SP will appear at

the top of the PID list. This sets the value at which the

transfer will occur. When the process value is below this

level, PID1 will be active and when it is above, Pid2 will

be active. Set a value between the control regions that

show the greatest change to achieve the best point of

transfer.

Tuning

The two sets of PID values can be manually set or automatically tuned. To tune automatically you must tune

above and below the transfer point G.SP. If the process

value is below the transfer point G.SP, the calculated values will automatically be inserted into the (SEt 1) set and

if the process value is above G.SP, the calculated values

will automatically be inserted into the (SEt 2).

29

8 SEGMENT PROGRAMMABLE MODEL W/OTP

Autotuning

The Autotune feature automatically sets up the PID values

in the control parameters to suit new process conditions.

To tune your furnace using autotuning:

1. Load your furnace with a load similar to your normal load and close the door.

2. Set the setpoint temperature.

3. Press the PAGE button until the display reads,

“Atun LiSt.”

4. Press the SCROLL button until “tunE OFF” is displayed.

5. Press the UP or DOWN button to select “on.”

6. Simultaneously press the PAGE and SCROLL

buttons to return to the HOME DISPLAY. The display will flash “tunE” while tuning is in progress.

Adaptive Tuning

Adaptive tuning continuously evaluates tuning parameters.

Adaptive tuning automatically installs new values if better

accuracy is possible. Adaptive tuning should be used when

the characteristics of a process change due to load or setpoint changes or, in a process that can not handle the

oscillation caused by a one-shot tune.

To tune your furnace using adaptive tuning:

1. Load your furnace with a load characteristic of

those you intend to heat in it.

2. Press the PAGE button until display reads, “Atun

LiSt.”

3. Press the SCROLL button until “drA OFF” is displayed.

30

4. Press the UP or DOWN button to select “on.”

5. Press the SCROLL button until “drA.t” is displayed.

6. Press the UP or DOWN button until the desired

trigger value is achieved.

Caution

Do not overload your furnace chamber. If

the load is to be heated uniformly, it

should not occupy more than two-thirds

of the furnace chamber. Maintain at least

a 3/4” gap between the load and elements. Failure to observe this caution

could result in damage to the furnace

components.

Note

This unit is equipped with a venting system on the top of the furnace. This is

for the removal of fumes from the

chamber of the unit.

Furnace Loading

• For best results, use only the center twothirds of the furnace chamber.

• If you are heating a number of small parts,

spread them throughout the center two-thirds

of the furnace chamber.

• Keep objects away from the thermocouple.

• Use insulated tongs and mittens when loading and unloading the furnace.

• Always wear safety glasses.

• Never come into contact with the heating elements. Hitting the elements with tongs or laying the load against them will cause the elements to burn out prematurely.

Thermocouple Sample Port

Heating Elements

Thermocouple

31

Preventive Maintenance

Contamination is a major cause of element failure,

therefore, remove all fume forming material before

heating. (e.g. clean cutting oil from tool steel).

Housekeeping is vital to your electric furnace – KEEP

IT CLEAN. Run your furnace up to 871°C (1600°F)

empty occasionally to burn off the contamination that

may exist on the insulation and elements. Maintain

871°C (1600°F) for at least 4 hours to ensure complete

ashing of foreign materials.

Element life is reduced somewhat by repeated heating

and cooling. If the furnace is to be used again within a

few hours, it is best to keep it at the operating temperature or at a reduced level such as 260°C (500°F). We

highly recommend that you replace the thermocouple

periodically (once every six months) to ensure temperature accuracy.

General Cleaning Instructions

Wipe exterior surfaces with a lightly dampened cloth

containing a mild soap solution.

32

Troubleshooting

The Troubleshooting section is intended to aid in defining and correcting possible service problems. When

using the chart, select the problem category that resembles the malfunction. Then proceed to the possible

causes category and take necessary corrective action.

Problem Possible Causes Corrective Action

Cycle light does not The furnace is not Reconnect furnace to power

illuminate. connected to power supply. supply.

Incorrect power source. Connect to correct power

source.

ON and OFF power switch Replace power switch.

defective.

Defective cycle light. Replace cycle light.

Door switch malfunction. Realign or replace furnace

door safety switch.

Furnace does not heat. No power. Check power source and

fuses or breakers.

Defective electrical hookup. Repair electrical hookup.

Thermocouple has oxidized and Replace thermocouple.

opened the circuit.

Controller malfunction. Replace controller.

Heating elements Replace defective elements.

burned out.

Door switch malfunction. Realign or replace door safety

switch.

Defective OTP relay. Replace relay.

Defective solid state relay. Replace relay.

Door switch does Door switch not functioning. Realign or replace door safety

not cut power to switch.

heating elements.

33

TROUBLESHOOTING

Problem (cont.) Possible Causes (cont.) Corrective Action (cont.)

Controller over-temp. Alarm output device malfunction. Replace controller.

does not cut power

to furnace chamber. OTP relay malfunction. Replace relay.

Element shorted to ground. Replace faulty element.

Slow heatup. Low line voltage. Install line of sufficient size

and voltage (isolate furnace

from other electrical loads).

Heavy load in chamber. Lighten load in chamber to

allow heat to circulate.

Wrong heating element. Install proper element.

Heating element burned Replace element.

out.

Repeated element Overheating furnace. Keep furnace under maximum

burnout. temperature. Closer supervision of

control setting.

Heating harmful materials. Enclose material in container.

Clean up spills in and on

chamber. Ventilate chamber by

leaving top vent slightly open

when heating known harmful

reagents.

Contamination from previous Replace insulation material.

burnout.

Inaccurate temp. Oxidized or contaminated Replace thermocouple.

readout. thermocouple.

Poor thermocouple connection. Tighten connections.

Improper loading procedures. Use proper loading

procedures.

Poor ventilation of control. Clear area around furnace

control.

Thermocouple connections Reconnect thermocouple

reversed. correctly.

34

Maintenance and Servicing

Warning

To avoid electrical shock, this furnace

must always be disconnected from the

power supply prior to maintenance and

service.

Perform only maintenance described in

this manual. Contact an authorized dealer or our factory for parts and assistance.

Refer servicing to qualified personnel.

Note

The ceramic hearth collar may crack.

This is a normal condition and will not

affect the performance of the hearth collar.

To Replace a Heating Element

1. Disconnect the furnace from the power supply.

2. Remove the back terminal cover of the furnace. (Note placement and connection of

wires.)

3. Loosen the nuts on the terminal points of

the four heating element lead wires and

remove the element wires from the terminals.

4. Loosen the thermocouple hold-down clip

and carefully remove the thermocouple from

the rear of the furnace chamber.

5. Remove both the back of the furnace and

the blanket insulation.

6. Grasp the element lead wires and pull out

both elements and the back chamber insulation.

7. Replace the defective element.

8. Reverse the disassembly procedure, making

sure you thread all element lead wires

through the insulating porcelain bushings on

the back of the furnace and cut off any

excess element lead wire after securing the

leads to the terminal points.

9. Reconnect the furnace to the power supply.

10. Test the operation of the furnace.

35

MAINTENANCE AND SERVICING

To Replace a Chromel/Alumel

Thermocouple

1. Disconnect the furnace from the power supply.

2. Remove both back covers. (Note placement

and connection of wires.)

3. Remove the clip holding the thermocouple in

place (1 screw), and remove the two screws

on the thermocouple terminals.

4. Remove the thermocouple. (Note: first pull

the thermocouple straight out of the hole in

the chamber to avoid damage to the insulation.)

5. Guide the looped ends of the new thermocouple through the plastic bushings with the

red (-) lead to the right as you face the back

of the furnace.

6. Insert the thermocouple straight through the

hole in the chamber.

7. Secure the thermocouple with clip and

screw. Connect the looped ends of the thermocouple to the terminals with “+” to “+”

(yellow) and “-” to “-” (red) wires. A polarity

test of the thermocouple and lead wire is

easily made with the use of a magnet. On a

Chromel/Alumel thermocouple and lead

wire, the non-magnetic wire is positive (+)

and the magnetic wire is negative (-).

8. Replace both back covers.

9. Reconnect to the power supply.

10. Test the operation of the furnace.

36

MAINTENANCE AND SERVICING

To Replace Door Switches

(Micro-Switch)

1. Disconnect the furnace from the power supply.

2. Remove the screws on the front dial and the

screws and lock washers on the back cover.

3. Slide the control section forward. (Note: do

not pull excessively on the internal wires.)

4. Disconnect the wires from the door switch.

(Note the connection placement of the wires

to the micro-switch.)

5. Remove the screws and nuts from the

micro-switch.

6. Insert new micro-switches and secure with

the screws and nuts removed in step 5.

7. Reconnect the wires to the new door switch.

8. To realign the door switches, see the following section, “To Realign Door Switches.”

9. Slide the control section back and replace

the screws and lock washers described in

step 2.

10. Reconnect to the power supply.

11. Test the operation of the door switches.

(See next section, step 8.)

To Realign Door Switches

(Micro-Switch):

1. Disconnect the furnace from the power supply.

2. Remove the lower rear cover.

37

MAINTENANCE AND SERVICING

3. With the door closed, loosen the screws on

the micro-switch bracket and gently push the

switch bracket forward until you hear a click.

4. Open and close the door; the switch should

click when the door is opened approximately

3" and 1" to 2” before the door is closed. Slide

the switches backward to increase the distance, forward to decrease the distance.

5. Tighten the two screws to secure the switches. Check the operation of the switch as

described in step 4 after tightening the

screws.

6. Replace the back cover.

7. Reconnect to power supply.

8. To test the operation of the door switch: move

the power switch on, set the control to a setting high enough to keep the control from

cycling, open and close the door; the cycle

light should turn OFF when the door is

opened approximately 3" and turn back ON 1”

to 2” before the door is closed.

To Replace the Controller

The controller plugs into a panel mounting sleeve which

should be left permanently installed in the furnace

housing. To remove the controller, release the side clips

and slide the controller out. Do not attempt to dismantle

this unit further; replace it with a Thomas Scientific

loaner or a new unit.

38

Replacement Parts

Warning

Replace fuses with same type and rating.

Single Setpoint Models with OTP

5300A20/F48025-TS

Part number Description QTY.

0165A30 Controller 1

0165A47 Element 2

0165A51 Line Fuse 2

0165A68 Pilot Light 1

0165A71 S.S. Relay 1

0165A73 Mechanical Relay 1

0165A80 Door Switch 2

0165A78 Power Switch 1

0165A89 Terminal Block 1

0165A83 Thermocouple 1

8 Segment Programmable Models with OTP

5300A25/F48025-80-TS

Part number Description QTY.

0165A25 Controller 1

0165A51 Line Fuse 2

0165A68 Pilot Light 1

0165A71 S.S. Relay 1

0165A73 Mechanical Relay 1

0165A80 Door Switch 2

0165A78 Power Switch 1

0165A89 Terminal Block 1

0165A83 Thermocouple 1

Ordering Procedures

Please refer to the Specification Plate for the complete model number, serial number, and series number

when requesting service, replacement parts or in any correspondence concerning this unit.

39

Wiring Diagrams

SINGLE SETPOINT CONTROL W/OTP

40

WIRING DIAGRAMS

8 SEGMENT PROGRAMMABLE CONTROL

41

42

43

Warranty Repair and Service

In addition to manufacturer warranties, Thomas Scientific (the Company) warrants all instruments and equipment (other than supplies, small items, reagents and chemicals) delivered to and retained by their original purchasers to be free from defect in material and workmanship for one year from the date of the Companyʼs

invoice to the purchaser (Thomas Scientific makes no warranty with respect to consumable parts or supplies).

For a period of one year from the date of such invoice, the Company will correct, either by repair or replacement at the Companyʼs sole election, any defect in material or workmanship (not including defects due to misuse, abuse, abnormal conditions or operation, accident, alteration, improper installation, acts of God, or service or modification of the product without prior authorization of the Company) without charge for labor, parts or

shipment of the product to and from the service facility designated by the Company. Manufacturer warranties

that extend beyond this 1-year period are the sole responsibility of the manufacturer.

The determination of whether any product has been subject to misuse or abuse will be made solely by the

Company. The Company shall not be liable for any delay in performance under this warranty caused by any

contingency beyond the Companyʼs control, including war, government restrictions, strikes, acts of God, or

reduced supply of materials. The Company shall not be liable for any special, incidental, or consequential

damages, or any damage to plant, personnel, equipment or products, directly or indirectly resulting from the

use or misuse of any product. Representations and warranties made by any person, including dealers and

representatives of the Company which are inconsistent, in conflict with or in excess of the terms of this warranty shall not be binding upon the Company unless placed in writing and approved by an officer of the

Company.

This warranty and all claims hereunder shall be governed by the laws of the State of New Jersey, United

States of America.

The foregoing warranty is in lieu of all other warranties, guarantees, or representations, whether oral, written

or implied, including any warranty of merchantability or fitness for use or purpose.

The Companyʼs liability under this warranty or otherwise with respect to products of their use (including liability

for negligence or otherwise in tort) is limited exclusively to the remedies provided herein and no other right or

remedy shall be available to any person.

Thomas Scientific

P.O. Box 99

Swedesboro, NJ 08085

T: 800-345-2100

www.thomassci.com

Loading...

Loading...