Page 1

Gas-Fired T ubular,

Radiant, Low-Intensity

Infrared Heater

®

INST ALLA TION FORM RZ-NA-I-TR

Obsoletes Form 456 (Version B)

APPLIES TO: INFRA-REZ® Heater Models TR/TR-H

Table of Contents

Paragraph No. Page Paragraph No. Page

GENERAL................................................................................................. 1

HEATER INSTALLATION............................................................... 1-21

1A. Installation Codes ............................................................................... 2

1B. Warranty .............................................................................................. 2

2. Description/General .............................................................................. 2

3. Specifications ........................................................................................ 3

4. Clearances to Combustibles ................................................................. 3

5. Location and Mounting Height .......................................................3- 4

6. Uncrating/Packaging ............................................................................ 4

7. High Altitude Operation ....................................................................... 5

8. Suspension Dimensions and Preparation ........................................... 5

9. Prepare and Install Burner/Control Box and

Combustion Chamber Tube ......................................................... 6-8

10. Install the Heat Exchanger Tube(s), Tail Pipe

Tube, and Turbulator Strip ....................................................... 8-11

11. Install Reflectors (including Standard Reflectors, Optional

Side Shield, and Optional Reflector Gap and End Covers) ..... 1 2

REFERENCES: Operation/Maintenance/Service Manual, Form RZ-NA-O-TR

Suspension Dimensions and Configuration Drawings Booklet, Form RZ-NA 607

Replacement Parts Manual, Form RZ-NAP-VR/TRP/TR

12. Venting ........................................................................................ 13-17

13. Combustion Air ................................................................................ 17

14. Gas Piping and Pressures .......................................................... 17-19

15. Electrical Supply and Connections .......................................... 19-20

16. Check Installation and Start-Up ..................................................... 2 1

OPTIONAL EQUIPMENT - Field Installed ................................ 22-23

17. Optional Heat Exchanger Tubes ("U", "L", 5-ft) ......................... 22

18. Hanger Kit, Option CK11 ............................................................... 22

19. Turnbuckle Kit, Options CK12-18 ................................................ 22

20. Combustion Air Inlet Kit, Option DE2 ......................................... 2 3

21. Dual Vent Kit, Option CC5 ............................................................. 23

22. Optional Side Shield, Options CD13-20 ....................................... 23

23. Optional Reflector Gap and End and Gap Covers ...................... 2 3

24. Multiple Heater Control, Options CL31 and 32 .......................... 23

25. Optional Unit-Mounted Thermostat Bracket Kit,

Option CM3 ................................................................................... 23

Index......................................................................................................... 24

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open

containers in the vicinity of this appliance is

hazardous.

WARNING: Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury or death.

Read the installation, operation, and

maintenance instructions thoroughly before

installing or servicing this equipment.

WARNING: Gas-fired appliances are not

designed for use in hazardous atmospheres containing

flammable vapors or combustible dust, in

atmospheres containing chlorinated or halogenated

hydrocarbons, or in applications with airborne

silicone substances. See Hazard Levels, Page 2.

GENERAL

Installation should be done by a qualified agency in accordance with the instructions in this manual and in compliance with all codes and requirements of

authorities having jurisdiction. The instructions in this manual apply to the

heater models shown below .

Model Characteristics

TR Indoor, Gas-Fired,

Low-Intensity

Infrared Tubular

System, 0-2000 ft

(0-610M) elevation

TR-H Indoor, Gas-Fired,

Low-Intensity Infrared

Tubular System,

for 2001-8000 ft

(611-2438M) elevation

Form RZ-NA-I-TR, Mfg No. 121027 Rev 5,

Page 1

Page 2

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or death and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury or death and/or property dam-

age.

3. CAUTION: Failure to comply could result in minor personal injury and/or property damage.

1A. Installation Codes

These units must be installed in accordance with local building codes.

In the absence of local codes, in the United States, the unit must be

installed in accordance with the National Fuel Gas Code ANSI Z223.1a

(latest edition). A Canadian installation must be in accordance with the

CAN/CGA B149.1 and B149.2 Installation Code for Gas Burning

Appliances and Equipment. These codes are available from CSA Information Services, 1-800-463-6727. Local authorities having jurisdiction should be consulted before installation is made to verify local

codes and installation procedure requirements.

All electrical wiring must be in accordance with the National Electric

Code ANSI/NFPA NO. 70 (latest edition) or, in Canada, the Canadian

Electrical Code, part I-C.S.A. Standard C22.1.

The installing contractor must be familiar with all of the various requirements and is responsible for installing this heater in compliance

with the applicable codes.

Special Installations --

Aircraft Hangars: In the United States, the heaters must be installed

in accordance with ANSI NFPA 409 (latest edition), Chapter 5. NFP A

Publications are available from the National Fire Protection Association, Batterymarch Park, Quincy , MA 02269. In Canada, installation

in an aircraft hangar must comply with CAN/CGA-B149.2, Section

4.21. Both ANSI NFPA 409 and the CAN/CGA-B149.2 specify that

the heater shall not be located in an area of an aircraft hangar where it

may be subjected to physical damage by aircraft, cranes, moveable

scaffolding, or other objects.

NFP A 409 specifies a c learance of 10 feet to the bottom of the heater

from the highest surface of the wings or engine enclosures of the

highest aircraft which may be housed in the hangar. CAN/CGA B149.2

specifies that an infrared heater installed in an aircraft hangar be at least

10 ft (3m) above either the highest fuel storage compartment or the

highest engine enclosure of the highest aircraft which may occupy the

hangar. NFPA 409 and CAN/CGA B149.2 specify a minimum clearance of eight feet from the floor to the heater in other sections, such as

offices, or shops, that communicate with the aircraft hangar .

Public Garages: In the United States, heaters installed in public garages must be in accordance with National Fire Protection Association

(NFP A) 88B (latest edition), Section 3-2.3. Overhead heaters must be

located not less than eight feet above the floor and installed in accordance with the conditions of their approval. NFPA 88B requires the

following warning:

W ARNING: Minimum clearance marked on the

heater must be maintained from vehicles parked

under the heater .

In Canada, in a garage, the minimum clearance from the bottom of an

infrared heater to the upper surface of the highest vehicle which may be

housed therein shall be 50 percent greater than the certified clearance,

and in no case less than eight feet (2.4m).

W ARNING: These tubular radiant heaters DO

NOT qualify f or explosion-proof installations.

WARNING: The installing contractor must be

certain that the area where the heater is being

installed does not contain corrosive or toxic fumes

or that elements in the atmosphere do not produce

corrosive or toxic fumes in the presence of an open

flame.

The chlorine atmosphere in enclosed swimming

pool areas may cause burner and tube corrosion if

the area is not ventilated. ASHRAE design guides

suggest a minimum of 5-6 air changes per hour.

The manufacturer recommends outside

combustion air . T o pro vide outside combustion air ,

Option DE2, Combustion Air Inlet Kit, must be

used.

1B. Warranty

Refer to limited warranty information on the warranty sheet in the "Owner's

Envelope".

2. Description/General

These radiant tubular heaters are low-intensity infrared heaters using a

power burner that fires into a 4" diameter steel tube, either 20, 30, 40, 50,

60, or 70 feet in length. The power burner is equipped with a blower for

supplying combustion air and a spark-to-pilot-to-main burner ignition system. The highly emissive tubes are in 10-foot sections, and each section

has a polished reflector. The tube section attached to the burner is the

combustion chamber and all other sections are heat exchanger tubes with

the exhaust end heat exchanger tube being identified as the tail pipe. Optional "L"-shaped, "U"-shaped, and 5-foot heat exchanger tubes are available to change the heater configuration to adapt to various applications.

Standard model heaters are designed to operate at full input rates of 50,000,

75,000, 100,000, 125,000, 150,000, 175,000, or 200,000 BTUH at altitudes from 0 to 2000 ft elevation. High altitude model heaters are designed

to operate at full input rates of 50,000, 75,000, 100,000, 125,000, 150,000,

175,000, or 200,000 BTUH at altitudes from 2001 to 6000 ft elevation and

from 6001 to 8000 ft at full input rates from 50,000 to 175,000 BTUH.

Venting may be either vertical or horizontal. A vent cap must be used.

Install a vent cap supplied as Option CC1 or a fully-comparable, fieldsupplied vent terminal cap such as a T ype L Breidert Air-x-hauster®. (Type

L Air-x-hauster® is a trademark of The G. C. Breidert Company.) Dual

venting of two units is permissible when using an Optional Dual Vent Kit

(Option CC5). These heaters are also approved for operation without

outdoor venting.

Combustion air can either come from the heated space or be piped from

outside. Outside combustion air should be supplied (1) if the building

atmosphere has negative pressure; (2) if the building atmosphere is dirty or

dusty; (3) if the building atmosphere contains substances that will cause

toxic gas when combined with flame or flue products; or (4) if the heater is

being installed in a tightly closed room that does not provide required air

for combustion. Installation of an Optional Combustion Air Inlet Kit is

required to provide outside combustion air .

Form RZ-NA-I-TR, Page 2

3. Specifications

Page 3

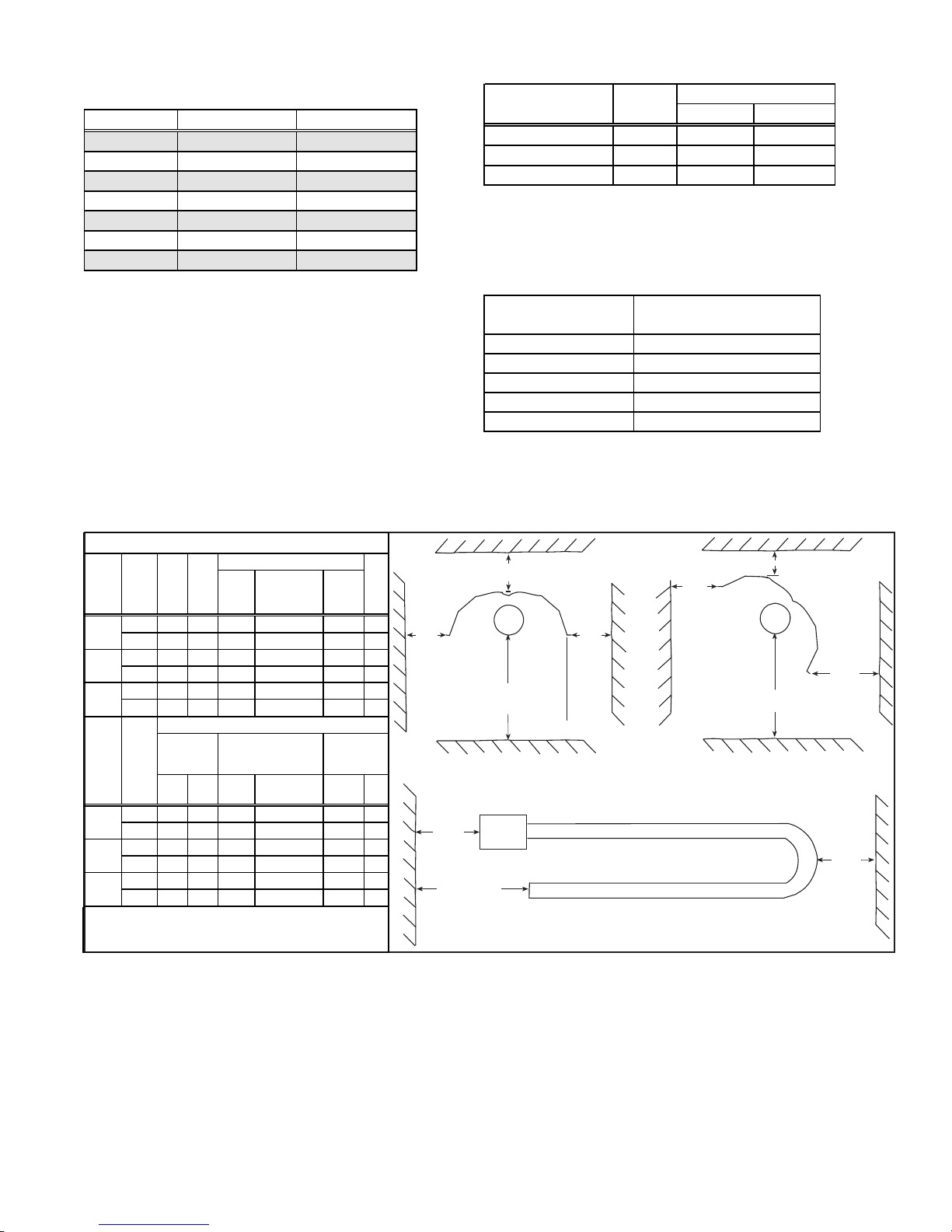

BTUH/Length/Configurations

Depending on the length and size of the heater, the heat exchanger

sections may be installed in various configurations. Optional "L"-

BTUH I nput M inimum Length Maxim um Length

50,000 20 feet 30 feet

75,000 20 feet 40 feet

100,000 30 feet 50 feet

125,000 40 feet 50 feet

150,000 50 feet 60 feet

175,000 50 feet 70 feet

propane gas. Sizes 175-200 are available for use with natural gas only . The

BTUH Gas Supply Pressure

Input Type Minimum Maximum

50,000 - 150,000 Natural 4.5" w.c. 14" w.c.

175,000 - 200,000 Natural 6" w.c. 14" w.c.

50,000 - 150,000 Propane 11" w.c. 14" w.c.

supply pressure listed is the gas pressure required at the gas valve inlet.

Measure gas pressure with a manometer.

Electrical Characteristics

200,000 50 feet 70 feet

shaped, 5-foot, and "U"-shaped heat exchanger tubes are available

to adapt the heaters to these configurations (Option UC2 for "L";

Option UB3 for "U"; Option UA1 for 5-foot heat exchanger tube).

Refer to the Suspension Dimensions and Configuration Drawings

Booklet (in the Owner's Envelope) to determine the permissible

configurations for each size and length of heater and guidelines for

using the 5-ft heat exchanger tube.

Gas Type and Supply Gas Pressure

Voltage/Phase

Frequency

Maximum Amps

Flame Safety

Pilot Burner Ignition

Main Burner Ignition

Standard 115/1; Optional

208/1, 230/1, 460/1

60 Hertz

3.0

Electronic

Spark

Pilot

Sizes 50-150 heaters are available for use with either natural or

4. Clearances to Combustibles

Required clearances depend on the size of the heater (BTUH input), the position of the reflector, and the addition of an optional side shield on the rear

side of the heater. Refer to illustrations in Figure 1 to def ine clearances.

Clearances to Combustibles

BTUH

Input

(000)

inches

50/75/

100

125/

inches 78

150

175/

inches 84

200

BTUH

Input

(000)

inches

50/75/

100

125/

inches 42 42 66 32 42 12

150

175/

inches 54 54 78 36 54 12

200

* If the heater is not vented to the outside of the building, the

top clearance to combustibles is 18" (457mm).

** Refer to Paragraph 10 for side shield installation.

Below

66 12 24 36 24 6

1676 305 610 914 610 152

mm

1981

mm

mm

2134 305 762 1219 610 152

0-30

Front

30 30 48 18 36 12

762 762 1219 457 914 305

mm

1067 1067 1676 813 1067 305

mm

mm

1372 1372 1981 914 1372 305

Horizontal Clearances

Burner

Top*

End

12

30 48

305

762 1219

12

30 48

With Reflector Positioned

o

Front Rear Front

Rear

Heat

Exch anger

Bend (U o r L )

o

31-45

Exhaust

End

24 6

610 152

24 6

0-30o wit h

Si de Sh i e l d

**

Vent

Rear

Front

of

Reflector

Top of Reflector

Below the Reflector

or Below the Tube

HORIZONTAL REFLECTOR

Burner

End

Exhaust End

Rear

of

Reflector

Optional

Side

Shield

HORIZONTAL CLEARANCES

Figure 1 - Clearance Orientation

Front

of

Reflector

Top of Reflector

Rear

of

Reflector

Below the Tube

REFLECTOR ANGLED (1° TO 45°)

Heat

Exchanger

Bend

Clearance to combustibles is defined as the minimum distance from

the heater to a surface or object that is necessary to ensure that a

surface temperature of 90°F above the surrounding ambient temperature is not exceeded.

The clearances listed in the tables are installation requirements. In

addition, ANSI Z-223-1, Section 6.18, requires that signs be posted

specifying the maximum permissible stacking heights to assure that

the required clearances from the heater to combustibles are maintained in areas where items are stored under the heater.

Refer to Paragraph 1, Special Installations, for specific clearance

requirements for heaters installed in aircraft hangars and public garages.

5. Location and Mounting Height

When selecting the installation location, major factors to consider are (1)

Personal and Property Safety, (2) Personal Comfort, and (3) Heating Efficiency

(1) Safety

The location must meet the Installation Codes listed in Paragraph 1 and any

local codes. These heaters are approved for indoor commercial/industrial

installations only. Do not install these tubular radiant heaters in areas that

contain corrosive or toxic fumes or where elements in the atmosphere could

produce corrosive or toxic fumes in the presence of an open flame. These

heaters do not qualify for explosion-proof installations.

Form RZ-NA-I-TR, Mfg No. 121027 Rev 5,

Page 3

Page 4

5. Location and Mounting

Height (cont'd)

Clearance to combustibles must be observed (See Paragraph 4), including clearances to stock that might be periodically stacked underneath

the heater.

The supporting structure must have a load-carrying capacity of at least

200 lbs.

Do not locate the heater above or too close to electric lines, gas pipes,

emergency sprinkler systems, or any such structures that could be

adversely affected by radiant or convection heat.

Do not locate the heater where it could be damaged by high lifts, cranes,

or any other such equipment.

Since chain suspension is required to allow for expansion and contraction of the tubes, proper positioning near large door openings is important. If the heater is being installed near a large door (ex: garage, loading

dock, aircraft hangar, etc.), position the heater so that it will not "swing"

in the wind. Lateral movement of the tubular system should be limited.

(2) Comfort

Because of the unique heat transfer features of an infrared heater, the

comfort quality of the heat is greatly affected by the location of the

heater. Rays of heat are emitted from the surface of the tubes and

directed by the reflectors. When radiant heat rays reach a surface, those

rays are absorbed, raising the temperature of that "object". Since infrared heat does not heat the air, a comfort advantage is that stratification

does not occur. When the rays are not obstructed from reaching the

floor, the floor and lower level areas maintain a more comfortable

temperature than with convection (warm air) heating equipment.

For optimum comfort when infrared heaters are being used to "heat"

personnel (spot heating), it is recommended that (1) the rays of heat be

directed toward the person(s) from an angle rather than from directly

overhead, and (2) the heater(s) be arranged so that rays are directed

against at least two sides (or front and back) of the person(s). If the

heater must be hung directly overhead, a higher mounting height will

increase the comfort level because the greater distance will decrease the

intensity level of the rays. Another significant factor when locating

the heater in relation to people is that the heat emitted from the

burner/combustion chamber end of the tubular infrared heater is

more intense than the heat emitted from the exhaust end. For this

reason, a U-tube configuration is often best suited for overhead

spot heat applications.

Tubular radiant heaters are engineered to provide comfort-level personal spot and space heating, but each application should be designed

individually to determine the best, quality-comfort locations.

(3) Efficiency

Because of the unique features of radiant heat transfer, selecting the

most efficient location for infrared equipment depends on the "floor"

coverage of the emitted heat rays. Floor coverage distance can be figured as approximately two times the mounting height of the unit. However , comfort level heating depends on the infrared intensity , and intensity levels decrease with higher mounting heights and greater floor

coverage. For more accurate measurement, consult the manufacturer's

flux density tables.

For space heating infrared applications, the location of the units must be

evaluated as part of the heater size selection. Determine the total BTU's

required, the floor coverage required, and the mounting height. From

this information design a heater size and location plan that will provide

the most complete floor coverage without excessive overlapping. In

most cases, perimeter heaters should be located parallel to the wall. The

distance from the wall is determined by whether the reflectors will be

angled or horizontal.

For spot heating applications, the tubular system should be located to

direct the rays toward the area requiring heat. Depending on the installation, this can be done from directly overhead or reflector angled from

the side. U-tube configurations are often best suited to overhead spot

Form RZ-NA-I-TR, Page 4

heating applications. Refer to the recommended minimum mounting heights

below . Use the mounting height, the size of the heater, the heater conf iguration, and the application conditions to determine the most efficient location of the heater.

Recommended Minimum Mounting Height

R e flec tor Size (000 B TUH Input)

Position 50 75 100 125 150 175 200

11 12 13 15 16 17 18

Horizontal

30° Angle

45° Angle

feet

3.4 3.7 4.0 4.6 4.9 5.2 5.5

M

9 101113141516

feet

M 2.7 3.0 3.4 4.0 4.3 4.6 4.9

8 9 10 11 13 14 15

feet

2.4 2.7 3.0 3.4 4.0 4.3 4.6

M

6. Uncrating/Packaging

Check for shipping damage. If any damage is found,document the damage with the shipping agency and immediately contact your Reznor

Dsitributor.

Because of their modular design, these heaters are packaged in sections

and require field assembly . The burner/control box is in one carton, and

the tubes are packaged in one, two or three cartons depending on the

length of the system.

Burner/Control Box Carton - For the convenience of both the stocking

and the non-stocking distributor, the burner/control boxes have two different packaging methods. Read carefully to determine whether or not

the burner/control box requires field conversion before being installed.

(1) Burner/Control Box Packages

Package Contents

TR50 Factory-assembled Size 50,000 BTUH heater

TR75/100 Factory-assembled Size 75,000 BTUH heater

Conversion kit to change to a Size 100,000 BTUH heater

TR125/150 Factory-assembled Size 125,000 BTUH heater

Conversion kit to change to a Size 150,000 BTUH heater

TR175/200 Factory-assembled Size 175,000 BTUH heater

Conversion kit to change to a Size 200,000 BTUH heater

(2) Burner/Control Box Factory Built to a Specific Size - If the burner/

control box carton does not have a label about field conversion, the carton

contains a burner/control box factory-built to a specific size. Check the

rating plate to verify size and type of gas.

Tube Cartons - Tubes are also packaged so that a minimum number of

cartons will cover all lengths of heater systems. This package identification system applies to all heaters, whether shipped from distributor stock

or shipped to order from the factory . Before beginning installation, verify

that the packages at the job site match the length of heater being installed.

Packaging Scheme for Tubes

Pkg P/N Contents

120294 Combustion Chamber Tube; T ail Pipe with T urbulator

120295 Combustion Chamber Tube; Heat Exchanger T ube;

Tail Pipe with Turb ulator

120296 Heat Exchanger Tube; Heat Exchanger T ube with

Turbula tor

Tube Packages (left) Required by Length of System

Length Qty Pkg Qty Pkg

20 ft system requires 1 P/N 120294

30 ft system requires 1 P/N 120295

40 ft system requires 1 P/N 120294 1 P/N 120296

50 ft system requires 1 P/N 120295 1 P/N 120296

60 ft system requires 1 P/N 120294 2 P/N 120296

70 ft system requires 1 P/N 120295 2 P/N 120296

Reflectors, reflector brackets, and hardware packages are included in

Page 5

each carton. (NOTE: Chain for hanging is not included. Use either an Optional Hanger Kit and/or Turnbuckle Kit or field-supplied hardware. See

suspension requirements in Paragraph 7.)

Accessory Cartons -- All field-installed options are shipped in separate cartons.

7. High Altitude Operation

All factory-built Model TR-H units are designed to operate at full input rates at elevations from 2001 to 6000 ft (611-1830M). In addition, Model TRH in Sizes 50 to 175 will operate at full rate at elevations from 2001 to 8000 ft (611-2440M).

High altitude kits are available to convert Size 50, 75, 100, 175, and 200 sea level burner/control boxes for use at high altitudes. Kits are available for

all sizes to convert from one high altitude le vel to another .

If the heater being installed requires high altitude conversion, contact your distributor to obtain the appropriate kit and complete the conversion as part

of the burner/control box preparation in Paragraph 9.

High Altitude Conversion Kits

Gas feet meters

Natural

Propane

*Kits for Size s 125 and 150 may only be used to change a Model TR -H from one high altitude elevation to another.

DO NOT attempt to field convert a sea level Model TR125 or TR150 to high altitude.

**Canadian high altitude installations must choose kits designed for 2001-4000 ft (610-12 19M) elevation.

2001-4000 610-1219 U.S. or Canada** 126440 120880 120882 132664 132667 132670 132673

Gas

4001-6000 1220-1828 U.S. Only 126442 120884 120886 132682 132685 132688 132691

Only

6001-8000 1829-2438 U.S. Only 126444 120888 120890 132700 132703 132706 N/A

2001-4000 610-1219 U.S. or Canada** 126441 120881 120883 132676 13 2679 N/A N/A

Gas

4001-6000 1220-1828 U.S. Only 126443 120885 120887 132694 132697 N/A N/A

Only

6001-8000 1829-2438 U.S. Only 126445 120889 120891 132712 132715 N/A N/A

(full rate operation)

8. Suspension Dimensions and Preparation

Refer to the Suspension Point Dimensions and Installation Configuration Drawings Booklet. This booklet provides suspension

point dimensions, illustrations of permissible configurations for

each size and length of heater, and requirements that must be met to

include an optional 5-ft heat exchanger tube in the system.

From the dimensions on the selected configuration drawing, determine the building suspension points.

WARNING: Install heaters only in the

configurations illustrated or noted in the

configuration booklet (Form RZ 607 in the

Owner's Envelope). Don't install a heater in

a configuration that is not permissible for that

BTUH input capacity or length. See

Paragraph 3 and Hazard Levels on page 2.

Suspension Point Requirements:

1) Supporting structure must have a minimum load-carrying capacity of 200 lbs. (Do not suspend the heater from gas piping

or electrical conduit.)

2) Clearances to combustibles must be observed. See Paragraph

4.

3) Heater must be suspended by hanging chains. Chain, "S" hooks,

and/or turnbuckle length at each suspension point must be a

minimum of 12 inches. All chains suspending tubes must be

plumb. See Figure 2 for dimensions for burner/control box

suspension points.

4) Refer to Paragraph 5 for recommended minimum mounting

heights. The installer is responsible for properly and adequately

fastening the chains to the building and supporting the weight of

the heater. Depending on the type of building construction at the

installation site, either attach the chain support directly to the building or attach and extend a support to the location needed.

SUPERSTRUT® brackets or a comparable metal strut material is

well suited as a support structure that requires numerous suspension points.

Chain must accept a 1/4" "S" hook and have a minimum of 200

lbs working load rating. Use either optional hanging chain kit

(Option CK11) or field-supplied chain.

TR/TR-H TR-H only

50 75 100 125* 150* 175 200

Since the heater must be level, turnbuckles are recommended at the "S"

hook connections on the heater. Turnb uckles must be of steel or malleable

iron. Use either optional turnbuckle kits (Options CK12-20) or field-supplied equivalent.

A minimum length of 12" of chain, "S" hooks and/or turnbuckle is required

at each suspension point.

Chains suspending tubes must be plumb when the heater is installed.

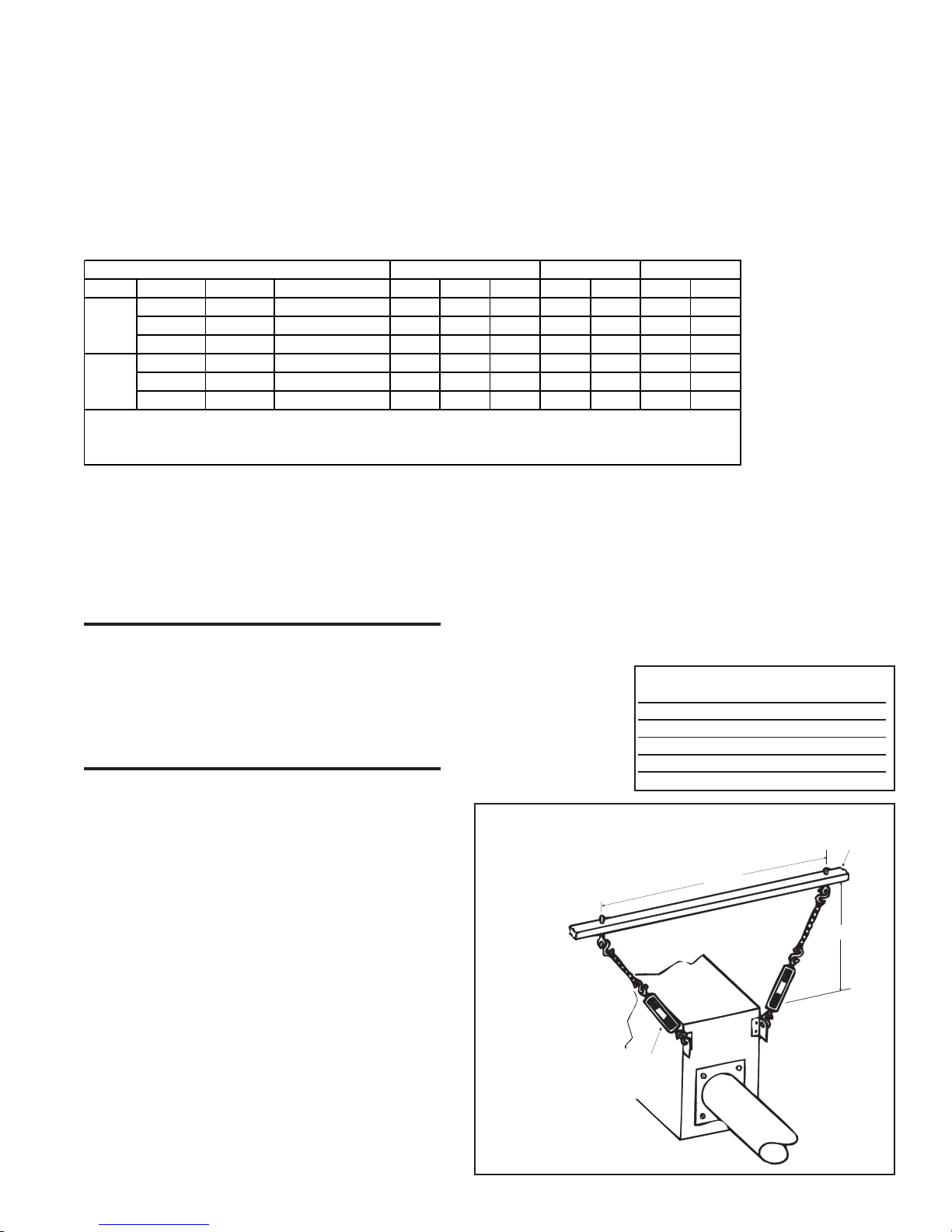

Suspension points required for the burner/control box are illustrated in

Figure 2.

This tubular radiant heater

must be suspended with

chain because the tubes will

expand when heated. The

overall length of a straight

system will expand approximately as shown in

the table.

TR/TR-H

Straight System Expansion Length

70 ft 2-3/4" (70mm)

60 ft 2-3/8" (60mm)

50 ft 2-1/8" (54mm)

40 ft 1-7/8" (48mm)

30 ft 1-1/2" (38mm)

20 ft 1-1/8" (29mm)

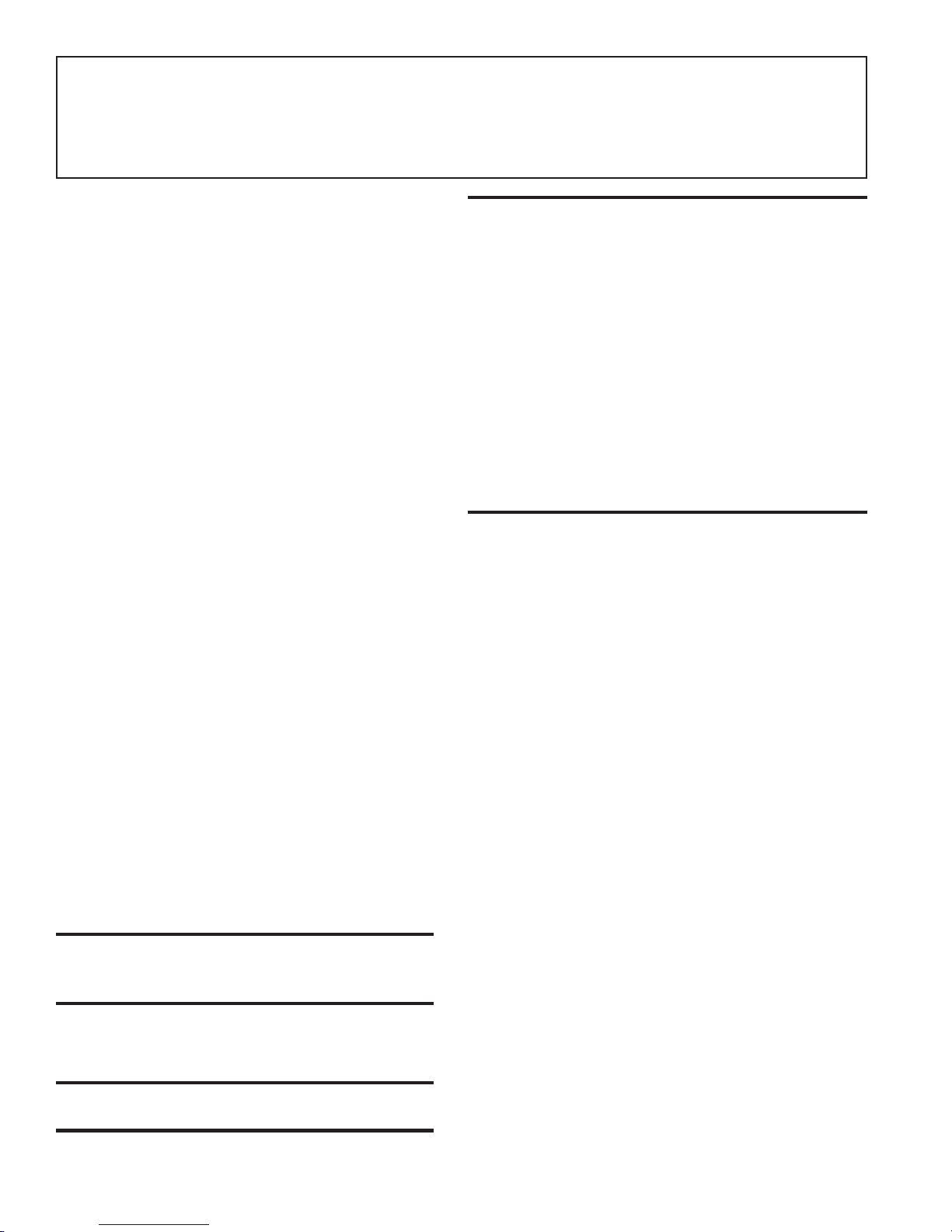

Figure 2 - Suspension

Dimensions and Hanging

Arrangement of the

installer or part of the building structure

Burner/Control Box

A + A/4

Optional turnbuckle

Use for convenience

if space permits.

Form RZ-NA-I-TR, Mfg No. 121027 Rev 5,

Structural support added by the

A

At least 12

(305mm) of

chain MUST

BE used for

proper expansion

movement.

Page 5

Page 6

9. Prepare and Install Burner/Control Box and Combustion Chamber

Model Size is stamped

in the upper left hand corner

Combustion Air

Restrictor Plate

10-32 Nuts

Rubber tubing (attaches to

combustion airflow sensor)

Combustion Airflow Sensor

Tube

There are very important steps that must be followed to prepare, suspend, and assemble these tubular radiant heaters. Preparing the heater,

suspension, and field assembly are the responsibility of the installer.

Follow all instructions carefully .

STEP 1) Prepare Burner/Control Box

All burner/control boxes require some field preparation. The type of

preparation depends on how the unit was ordered and where it will be

installed. Determine which of these six situations matches your application and follow the appropriate instructions. The first three are for units

ordered by specific size; the last three are for burner/control box packages that cover two sizes. (Refer to Paragraph 6 for further explanation

on packaging.)

• The unit was ordered as a specific size to be installed at a specific

elevation (sea level or high altitude) and is being installed at

that elevation. Proceed to STEP 2 of these Preparation instructions.

• The unit was ordered as a specific size to be installed at sea level

to 2000 ft and is being installed above 2000 ft (NOTE: Does not

apply to Sizes 125 and 150). Install the high altitude kit selected in

Paragraph 7. Follow the instructions provided with the kit. When the

kit is installed, proceed to STEP 2 of these Preparation Instructions.

• The unit was ordered as a specific size to be installed at an

elevation above 2000 ft and is being installed at a different elevation above 2000 ft. Install the high altitude kit selected in Paragraph

7. Follow the instructions provided with the kit. When the kit is

installed, proceed to STEP 2 of these Preparation Instructions.

• The burner/control box was ordered as a TR75/100, TR125/

150, or TR175/200 and will be installed at sea level to 2000 ft as

a Size 75, 125, or 175. Proceed to STEP 2 of these Preparation

instructions. (The Size Conversion Kit shipped with the burner/control box will not be used.)

• The burner/control box was ordered as a TR75/100 or TR175/

200 and will be installed above 2000 ft elevation as a Size 75, 100,

175, or 200. Install the high altitude kit selected in Paragraph 7.

Follow the instructions provided with the kit. When the kit is installed, proceed to STEP 2 of these Preparation Instructions. (The

Size Conversion Kit shipped with the burner/control box will not be

used.)

• The burner/control box was ordered as a TR75/100, TR125/

150, or TR 175/200 and will be installed at sea level to 2000 ft

elevation as a Size 100, 150, or 200. Follow the instructions below

to install the size conversion kit shipped with the burner/control box.

Instructions to Change the Combustion Air Restrictor Plate and

Burner Orifice to Field Convert a Burner/Control Box from Size

75,000 to 100,000; or from Size 125,000 to 150,000; or from Size

175,000 to 200,000.

Parts Required: Conversion package in the burner/control box includ-

ing a burner orifice, a combustion air restrictor plate, and conversion

labels.

1. Conversion Size Labels (one on the restrictor plate, one or two

loose) -- Fill-in all labels stating that the burner/control box has been

converted to either a Size 100,000, 150,000 or 200,000.

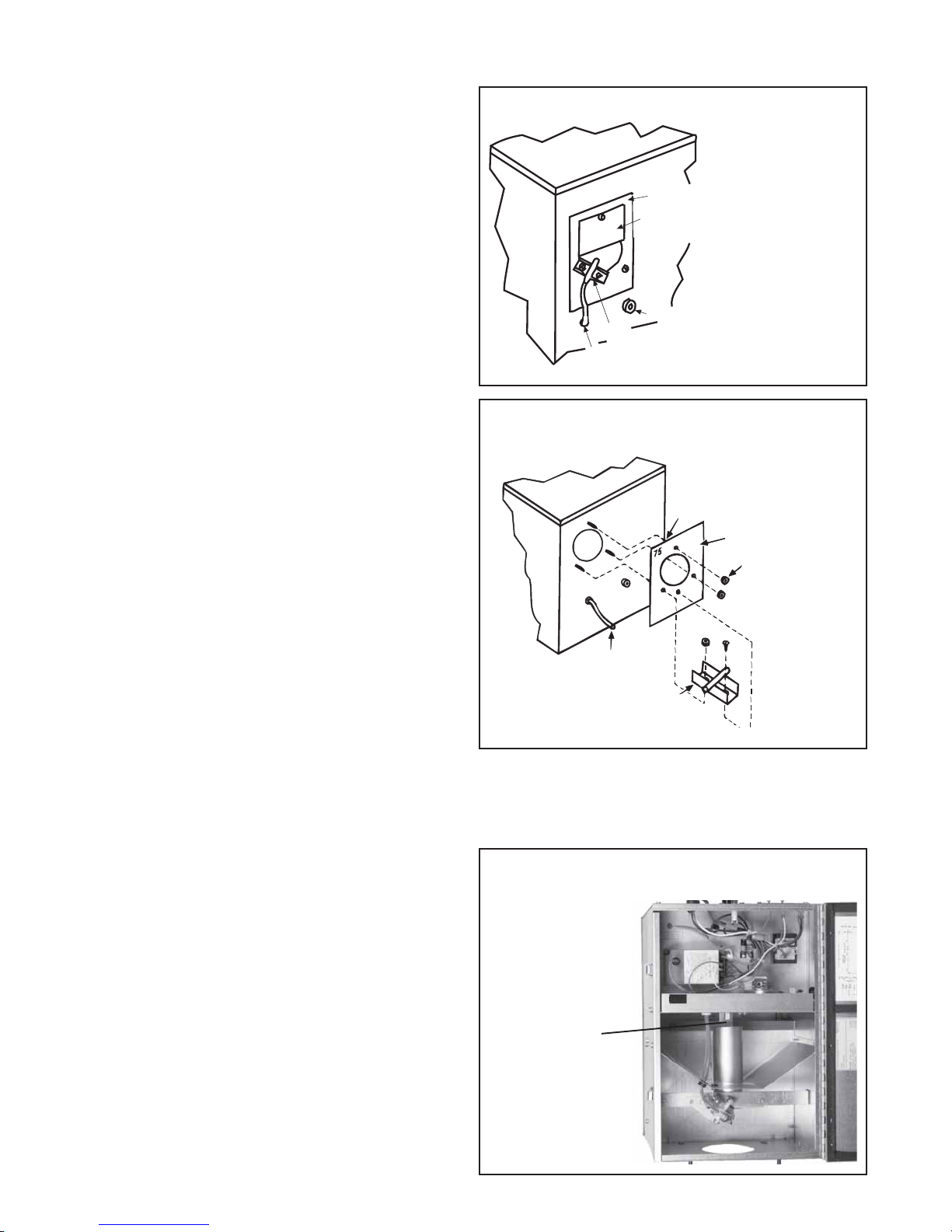

2. Change Air Restrictor Plate -- Refer to Figure 3A and identify the

combustion air inlet on the side of the burner box. Locate the paper

warning label on the factory-installed combustion air restrictor plate.

Attached to the restrictor plate is a combustion air sensor tube and

bracket. See Figure 3B.

Remove the hardware (screws and/or nuts) holding the combustion

air sensor bracket and the restrictor plate. Remove and discard the

factory-installed combustion air restrictor plate. Using the same hardware, attach the combustion air restrictor plate shipped in the parts

bag. Re-attach the combustion air flow sensor bracket.

Form RZ-NA-I-TR, Page 6

Figure 3A - Combustion Air Inlet Side of

Burner/Control Box

Combustion Air Restrictor Plate

IMPORTANT

Tubing to Pressure Switch

Warning label which

must be removed

Static Pressure Port

Combustion Airflow Sensor

Figure 3B - Remove factory-installed air restrictor plate

and replace with the restrictor plate in the parts bag

3. Change Burner Orifice - Open the hinged access panel on the

bottom of the burner/control box. Locate the burner orifice. See Figure 4. Using a 9/16" open-end wrench, remove and discard the factory-installed burner orifice. Install the burner orifice shipped in the

parts bag. Close the bottom panel.

Figure 4 - Burner/Control Box Showing Location of

the Burner Orifice

Burner Orifice

-- Remove with

9/16" open end

wrench

Page 7

4. Adhere label(s) to the burner/control box directly below the rating

plate.

Field size conversion is complete. Continue to STEP 2) Install Com-

bustion Air Inlet Cover.

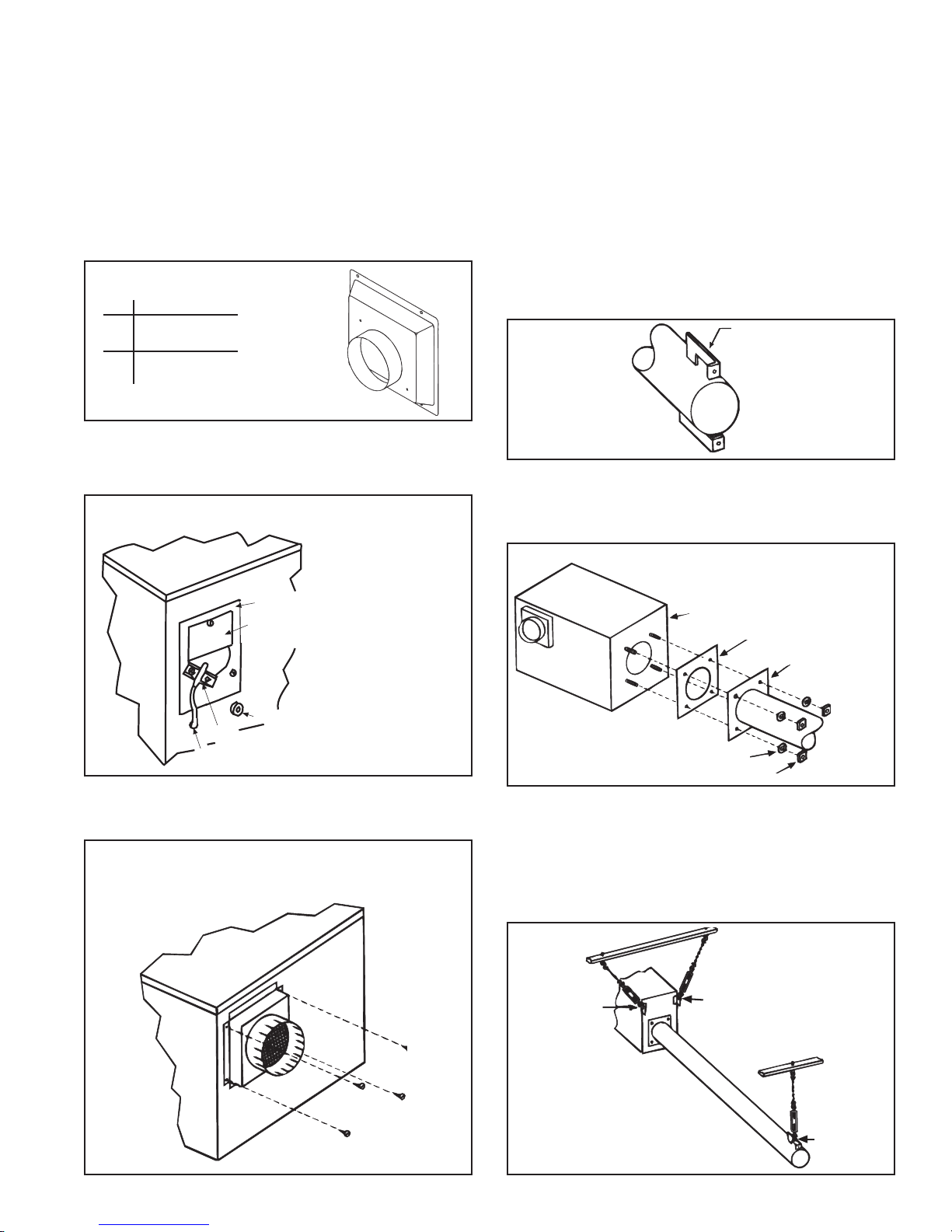

STEP 2 -- Install Combustion Air Inlet Cov er -- Applies to all burner/

control boxes.

From the hardware bag in the burner/control box, remove the instruction

sheet and the parts listed in Figure 5.

Figure 5 - Combustion Air Inlet Cov er

Qty Description

1 Combustion Air

Inlet Cover

4 Screws, #10 x

1/2" long

Instructions:

1. Refer to Figure 6 and identify the combustion air inlet side of the

burner box. If paper warning label is attached, remove.

Figure 6 - Combustion Air Inlet Side of the Burner/

Control Box

STEP 3 -- Assemble and Suspend the Burner/Control Box and

Combustion Chamber Tube

Use these parts (from the hardware bag) to assemble the box and tube.

Qty Description P/N

4 Lockwashers 1333

4 Nuts 1035

1 Gasket 116029

Instructions:

1. Identify the Combustion Chamber Tube -- The tube with the

square flange welded to one end.

2. Attach Combustion Chamber Tube to Burner/Control Box --

Slide the gasket over the bolts on the burner end of the burner/control

box (See Figure 8B). Position the tube so that the hangers (on the end

of the tube) are toward the top and bottom. See Figure 8A.

Slide the flange over the bolts. See Figure 8B.

Figure 8A - End

of Combustion

Chamber T ube

Position hanger

brackets at the top

and bottom

Showing

Position of

Hanger

Brackets

Use the washers and nuts to attach the combustion chamber flange

securely to the burner/control box. (The bolts are pre-welded to the

inside of the box.)

3. Suspend the Combustion Chamber Tube/Burner Box Assem-

Combustion Air Restrictor Plate

Warning label which

RTANT

PO

IM

Tubing to Pressure Switch

2. Position the combustion air inlet cover over the air inlet opening.

Using the four screws in the parts bag, attach the cover to the burner/

control box. See Figure 7.

must be removed

Static Pressure Port

Combustion Airflow Sensor

Figure 7 - Attach Combustion Air Inlet Cover (Fieldattachment of the combustion air inlet cover is

required with either an indoor or outdoor combustion

air supply. )

Figure 8B - Attach the Combustion

Chamber T ube to the Bur ner/Control

Box. Alter nately tighten nuts.

Burner/Control Box

Fiberglass

Gasket

Combustion

Chamber

Lock washers

5/16-16 Nuts (tighten alternately)

bly

Parts needed from the hardware bag: 3 "S" Hooks

Attach the two "S" hooks to the hanger brackets on the burner/control

box. Attach the third to the top hanger bracket on the end of the

combustion chamber tube. Suspend the assembly from the three hanging chains. Refer to Figure 9.

The illustration in Figure 9 includes turnbuckles. Tur nbuckles are

Attach

Attach "S" Hook

"S"

Hook

Figure 9 Suspended Burner/

Control Box with

attached

Combustion

Chamber T ube

Attach

"S"

Hook

Form RZ-NA-I-TR, Mfg No. 121027 Rev 5,

Page 7

Page 8

9. Install Burner/Control Box and Combustion Chamber Tube (cont'd)

3. Suspend the Combustion Chamber Tube/Burner Box Assembly (cont'd)

recommended for use in leveling the heater. If turnbuckles are included in heater suspension, use only optional turnbuckles or field-supplied

turnbuckles of steel or malleable iron.

4. Draw Bolts -- There are two 4-1/2" long bolts left in the hardware bag. These bolts are provided as an aid in connecting tubes. Keep the bolts and

follow the tube connection instructions in Paragraph 10.

10. Install the Heat Exchanger Tube(s), Tail Pipe Tube, and Turbulator

Strip

There are very important steps that must be followed to suspend and assemble these tubular radiant heaters. Preparing the heater, suspension, and filed

assembly are the responsibility of the installer. Follo w all instructions carefully. Throughout the instructions, continued reference to the installation

configuration drawing is required.

1) Identify the Heat Exchanger and Tail Pipe Tubes and the Parts Packaged with them (Refer to the illustrations in Figures 10A-10E and

the configuration drawing in the configuration booklet):

Expanded

End

10' Straight Tube

5' Straight Tube

T w o Hanger

Brackets

"U"

"L" T ube

Tube

"U" and "L" tube packages include

field-assembled reflectors

Figure 10B - Tail Pipe Tube (10')

Expanded

End

A parts bag is supplied with each

heater tube and tail pipe. The bag

contains hardware needed to

connect two tubes, an "S" hook,

and an instruction sheet.

Figure 10C Connection

Hardware Parts Bag,

P/N 116017

Figure 10E Reflector,

Reflector

Retainer , and

Retainer

Reflector

Bracket and

Hardware (Ubolt and nuts)

Bolts

Square

Nuts

Figure 10A - Heat Exchanger

T ubes (Straight, "U", and "L")

Swedged End with One

Hanger Bracket

Figure 10D - One Section of the

Field-Installed T urbulator Strip

Clamping

Rings

Lock

W ashers

Reflector

Bracket

One 10' reflector and two reflector retainers and two brackets with hardware per 10' straight tube.

Optional 5' heat exchanger tube includes a 5' reflector and two sets of retainers and brackets with hardware.

Follow installation instructions in Paragraph 11.

2) Suspend and Connect the Heat Exchanger Tubes and Tail Pipe

-- Follow the Configuration Drawing Layout

Connect each tube as it is suspended. If your configuration requires a

turbulator strip before a "U" or "L" tube, insert the turbulator strip before

the "U" or "L" tube is connected. Follow the instructions in Step No. 3)

on pages 9-11, and install two sections of turbulator strip. (This will only

Form RZ-NA-I-TR, Page 8

occur when installing a 40' to 70' system in a configuration where a "U"

or "L" tube connects directly to the tail pipe.)

Suspending Straight (5-ft or 10-ft) Heat Exchanger Tubes and

"U" T ubes - Attach an "S" hook to the hanger bracket and suspend the

tube from the next hanging chain. Slide the expanded end over the previous tube and make the connection.

Page 9

Installing "L" Heat Exchanger T ubes - "L" tubes do not require a suspension point. When the configuration requires an "L" tube, slide the expanded

end over the previous tube and make the connection.

Suspending the T ail Pipe - Attach an "S" hook to the hanger bracket and suspend the tube from the last hanging chain. Slide the expanded end over

the previous tube and make the connection.

Connecting the Tubes - Using the hardware in the bag packaged with each tube, follow the steps in Figure 11 to connect the tubes.

1) Connection Hardware

Square

Nuts

Bolts

2) Step 1

Combustion

products flow

direction

Figure 11 - Steps for Connecting Tubes

Lock

Washers

Suspended T ube

Section

T ube Section to be

added (suspend at

opposite end)

Clamping

Rings

3) Step 2

4) Connected Tubes

Tighten

bolts

securely.

IMPORT ANT: If tubes do not slide together easily, f ollow

Installation Tip below .

Be certain inner tube mates to

bottom of expansion in outer tube.

Installation Tip: If tubes are difficult to slide tubes together , use the two 4-1/2" long bolts from the b urner/contr ol box

parts bag to draw the tubes together . F ollow illustrated Step 2 (Figure 11, page 9), using the 4-1/2" bolts. Alternate

tightening the upper and lower bolts. When the tubes are in position, remove one of the long bolts, replace with a

connecting bolt, and secure. Repeat, replacing the other bolt. Re-use the 4-1/2" bolts as needed.

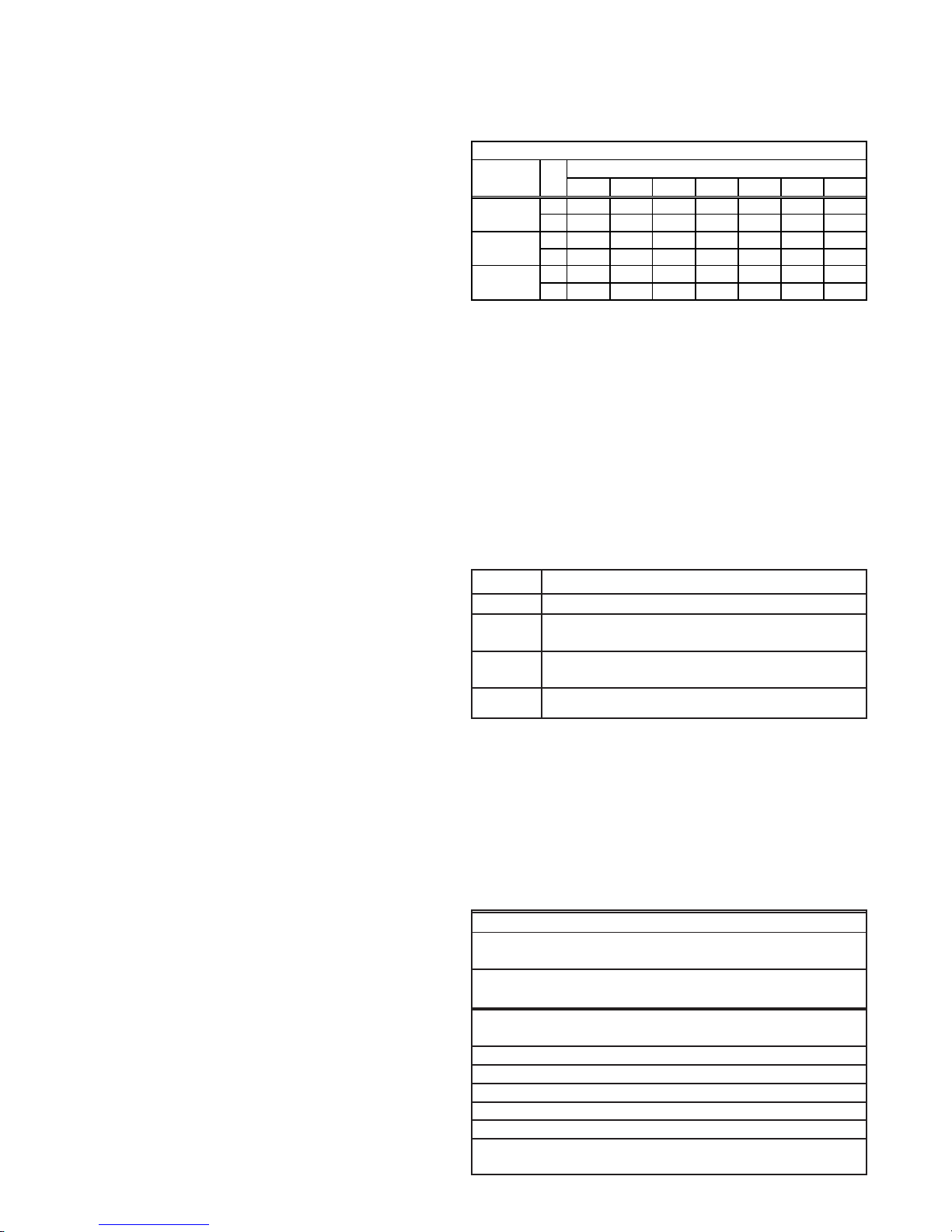

3) Install the Turbulator Strip -- Locate turbulator strip sections.

System L ength 20 30 40 50 60 70

Tube Package(s) E F E G F G E G G F G G

Full Size Turbulator

Section, 37-1/8" long

Sma ll Turbulator

Section, 26" long

333232322322

101000100000

Figure 12A - Turbulator Strip Section

Figure 12B - Interlock Sections as Turbulator Strip is

Instructions: Install a turbulator strip in a tube only after

that tube has been suspended and connected to the previous

tube. Refer to Figures 12A and 12B. Install the turbulator

strip by sliding a section into the tube, connecting the next

section, and sliding the connected sections on into the tube(s).

Follow the selected configuration drawing in the configuration booklet and the instructions in the chart on page 11.

Installed

Turbulators interlocked ready

for insertion into heat exchanger

Slide Together

Turbulators

tubes.

Form RZ-NA-I-TR, Mfg No. 121027 Rev 5,

Page 9

Page 10

10. Installing the System (cont'd)

g

Length

of

Strai

Tubes

20 ft

25 ft

30 ft

BTUH

Size

ht

(000)

50

75

50

75

50

75 0 - 8000 ft*

Ele vation

0 - 8000 ft*

0 - 8000 ft*

Configuration

(Must be illustrated in t he

Suspension Dimension and

Configuration Booklet.)

St ra igh t

"U" or "L"

All

All

Turbulator Sections

In Tube

Packages

Qty Size** Qty Size**

3 37-1/8"

1 26"

3 37-1/8"

1 26"

3 37-1/8"

3 37-1/8"

Configuration

3 37-1/8"

1 26"

3 37-1/8"

3 37-1/8"

3 37-1/8"

100

35 ft

40 ft

45 ft

50 ft

75

0 - 8000 ft*

100

75

0 - 8000 ft*

100

125

100

0 - 8000 ft*

125

100

125

0 - 8000 ft*

150

175

0 - 2000 ft

200

175 2001-8000 ft*

All

Str aight heat exchanger tube adjacent

to the tail pipe

"U" or "L" tube adjacent to the tail

pipe

(See Figure 12D)

Str aight heat exchanger tube adjacent

to the tail pipe

"U" or "L" tube adjacent to t he tail

pipe

(See Figure 12D)

Str aight heat exchanger tube adjacent

to the tail pipe

"U" or "L" tube adjacent to t he tail

pipe

(See Figure 12D)

All 5 37-1/8"

(See Figure 12C)

(Se e Figure 12C)

(See Figure 12C)

3 37-1/8"

5 37-1/8"

1 26"

5 37-1/8"

1 26" 3 long sections after tail

5 37-1/8"

1 26"

5 37-1/8"

1 26" 3 long sections after tail

5 37-1/8"

5 37-1/8"

3 37-1/8"

5 37-1/8"

5 37-1/8"

5 37-1/8"

5 37-1/8"

5 37-1/8"

5 37-1/8"

3 37-1/8"

200 2001-6000 ft*

55 ft

150 0 - 8000 ft*

175

0 - 2000 ft

200

175 2001-8000 ft*

Str aight heat exchanger tube adjacent

to the tail pipe

"U" or "L" tube adjacent to t he tail

pipe

(See Figure 12D)

All 5 37-1/8"

(See Figure 12C)

5 37-1/8"

5 37-1/8"

5 37-1/8"

5 37-1/8"

3 37-1/8"

200 2001-6000 ft*

60

150 0 - 8000 ft*

ft

175

200

175 2001-8000 ft*

0 - 2000 ft

Str aight heat exchanger tube adjacent

to the tail pipe

"U" or "L" tube adjacent to the tail

pipe

(See Figure 12D)

All 7 37-1/8"

(See Figure 12C)

7 37-1/8"

7 37-1/8"

5 37-1/8"

5 37-1/8"

3 37-1/8"

200 2001-6000 ft*

65 o r

70 ft

175

0 - 2000 ft

200

175 2001-8000 ft*

Str aight heat exchanger tube adjacent

to the tail pipe

"U" or "L" tube adjacent to the tail

pipe

(See Figure 12D)

All 7 37-1/8"

(Se e Figure 12C)

7 37-1/8"

7 37-1/8"

5 37-1/8"

5 37-1/8"

3 37-1/8"

200 2001-6000 ft*

* To install a heater above 2000 ft elevation, that heater must either be factory-built for the required elevation or field-conver ted to that

elevation. Check the rating plate or field conversion label for allowable altitude.

** Metric equivalent: 37-1/8" is 943mm; 26" is 660mm

Form RZ-NA-I-TR, Page 10

(Some sections may not be used; follow instr uctions.)

Used

in the

Quantity, Type and

WHEN to Instal l

All 4 sections after tail

pipe is connected

3 long sections after tail

pipe is connected

All 3 sections after tail

pipe is connected

All 3 sections after tail

pipe is connected

All 3 sections after tail

pipe is connected

5 long sections after tail

pipe is connected

2 long sections before

"U" or "L" is con nected

pipe is connected

5 long sections after tail

pipe is connected

2 long sections before

"U" or "L" is con nected

pipe is connected

All 5 sections after tail

pipe is connected

2 sect ions before "U" Int o end of st raight

or "L" is connected before "U" or "L"

3 sections after t ail pipe

is connected

3 sections after t ail pipe

is connected

All 5 sections after tail

pipe is connected

2 sections before "U"

or "L" is connected

3 sections after t ail pipe

is connected

3 sections after t ail pipe

is connected

5 sections after tail pipe

is connected

2 sect ions before "U" Int o end of st raight

or "L" is connected before "U" or "L"

3 sections after t ail pipe

is connected

3 sections after t ail pipe

is connected

5 sections after tail pipe

is connected

2 sect ions before "U" Int o end of st raight

or "L" is connected before "U" or "L"

3 sections after t ail pipe

is connected

3 sections after t ail pipe

is connected

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into end of straight

tube before "U" or "L"

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into end of straight

tube before "U" or "L"

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into end of straight

tube before "U" or "L"

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

Into exhaust end of tail

pipe

WHERE to Inst all

Page 11

Figure 12C - Examples of Configurations with the Tail Pipe Adjacent to a Straight Heat Exchanger Tube

Tail Pipe

Tube

Tail Pipe

Straight

Tube

Straight

Straight

Tube

Figure 12D - Examples of Configurations that require more than three turbulator

strips and have the tail pipe adjacent to an "L" or "U" heat exchanger tube

Tail Pipe

LTube

Straight

Tube

Straight

Tube

Tail Pipe

U

Tube

Tail Pipe

T o install turb ulator:

1) Attach the tail pipe to the straight

pipe.

2) Insert a turbulator section into the

tail pipe.

3) Interlock turbulator sections as

they are inserted (See Figure

12B).

4) Continue until all required sections are in place.

T o install turb ulator:

1) Before attaching the "U" or "L" tube,

insert two interlocked turbulator sections (See Figure 12B) into the last

straight tube.

2) Attach the "U" or "L" heat exchanger

tube to the straight tube.

3) Attach the tail pipe to the "U" or "L"

tube.

4) Insert three interlocked turbulator

sections into the tail pipe.

Su mmary of Number of Sections Required to "Build" Turbulator Strip

(NOTE : There may be sections in the packages that ar e not used.)

Elevation of

Installation (ft)

0 - 8000 50-75-100 30 ft 3

0 - 2000 175-200 50 ft 5

2001-8000 175-200* 3

0 - 8000 150 55, 60 ft 5

0 - 2000 175-200 55, 60, 5

2001-8000 175-200* 65, 70 ft 3

*Size 200 - Maximum elevation is 6000 feet.

BTUH Sizes

(000)

50-75 20 ft "U" or "L" 3

75-100 35 ft Straight, 3

75-100-125 40 ft "U", 5

100-125 45 ft and 5

100-125-150 "L" 5

4) Level the System and Close "S" Hooks

Tubes must be lev el. Use a spirit level and adjust the turnb uckles or chain links. Close all "S" hooks being careful not to change the chain length. When

the system is level, re-check to be sure that all bolts connecting the tubes are tightened securely .

Straight systems should be straight; systems with "L" tubes should be at right angles; and "U" shaped systems should be parallel.

Length

(Straight)

20 ft Straight 4 (3 long, 1 short)

25 ft 3

Configuration

No. of Sections used in

Turbulator Strip

Form RZ-NA-I-TR, Mfg No. 121027 Rev 5,

Page 11

Page 12

11. Install Reflectors (including Standard Reflectors, Optional Side

Shield and Optional Reflector Gap and End Covers)

WARNING: Do not operate heater without reflectors. See Hazard Intensity Levels, page 2.

Packaged with each straight tube is a reflector, two reflector brackets with hardware, and two reflector retainers (Refer to Figure 10E on page 7). Follow

the instructions to install a reflector on all straight tubes.

NOTE: If the installation includes an optional side shield, the side shield package (Options CD13-20) includes two additional reflector brackets and

retainers for each 10-ft tube. All four br ackets must be attached to each 10-ft tube before installing the reflector.

Reflector Installation Instructions

1. From the table, determine the

number of brackets (and retainers) required per tube and

select the appropriate illustration (Figure 13A or 13B).

2. Install Reflector Brackets

Tube

Length

Side

Shield

Number of

Brackets

Refer to

Figure

10-ft Without 2 13A

10-ft With 4 13B

5-ft Without 2 13A

5-ft With 2 13B

(See Figure 13A or 13B)

a) Slide the U-bolt over the tube at the determined location.

b) Position the reflector bracket as illustrated (end flanges extend-

ing upward) and slide the bracket over the bolt ends. Adjust the

bracket to the desired reflector angle (0-45

o

). Use the nuts to

attach the reflector bracket to the U-bolt.

c) Repeat the procedure to install all required brackets.

Figure 13A - Locations for Reflector Brackets for

Systems without an Optional Side Shield

10-ft Heat Exchanger Tube

U-Bolt

Optional 5-ft Heat Exchanger Tube

12

(305mm)

Reflector Bracket

6 feet (1.8M)

36 (914mm)

12

(305mm)

approximate

3. Install the Reflector, Optional Side Shield, and Reflector

Retainers (Refer to Figure 15)

a) All Installations -- Nestle the reflector inside the flanged edges

of the reflector brackets.

b) Installations with Optional

Side Shield -- The side shield is

modular with two sections per

10-ft tube. When side shields are

included in the installation, drill a

Figure 14 - With

optional side shield,

insert a screw in each

tube joint to prevent

tubes from turning

9/64" hole in each tube joint and

insert the screw provided (See

Figure 14). Hang the side shield

sections over the ends of the reflector brackets (Maximum angle

with side shield is 30°). IMPOR-

TANT: Install side shield on

one side of the system only.

U-bolt

1/2" (13mm)

Reflector

Drill

9/64"

hole

Reflector

Retainer

Optional

Side

Shield

Reflector

Bracket

Figure 15 - Install Reflector ,

Side Shield (Optional), and

Reflector Retainers

Form RZ-NA-I-TR, Page 12

Figure 13B - Locations for Reflector Brackets for Systems

with an Optional Side Shield

10-ft Heat Exchanger Tube

2 ft

(610mm)

13

(330mm)

Optional

5-ft Heat

Exchanger

Tube

32-3/4

(832mm)

c) All Installations -- Position a wire retainer over the reflector and hook the

ends through the holes in the reflector brackets. Install a retainer at each

reflector bracket.

d) All Installations -- Repeat the instructions to install reflectors on each

straight section of tube in the system. Do not operate the heater without all

reflectors installed.

4. Install Optional Reflector Gap Covers -- The optional gap covers are

designed to provide the infrared tubular

system with a continuous reflector while

still allowing for system expansion. If

optional reflector gap covers are included

in the installation, follow the illustrated

instructions included in the option package. Reflectors on systems with gap covers cannot be rotated.

5. Install Optional Reflector End Cover -

- The optional end covers are designed to

"close" the vertical space on both the combustion chamber end and the tail pipe end

of the reflector length. The end covers may

only be installed on units that have optional reflector gap covers. Follow the illustrated instructions included in the option package.

6. Rotating Reflectors -- Reflectors on straight systems without reflector gap

covers or a side shield may be angled up to 45° by rotating the U-bolt and

reflector bracket.

Reflectors with gap covers cannot be rotated.

Reflectors on straight systems with a side shield may be angled up to 30°.

The side shield must hang vertically .

13

(330mm)

24-1/2

(622mm)

(832mm)

32-3/4

32-3/4

(832mm)

Figure 16A Optional

Reflector Gap

Cover

Figure

16B Optional

Reflector

End

Covers

Page 13

If the system includes a "U" or "L" heat exchanger tube, the reflectors on

either adjacent side of the "U" or "L" reflector cannot be rotated and must

remain horizontal. All reflectors in a section or leg of the tubular system

should be at the same angle.

12. Venting

V enting must be in accordance with the National Fuel Gas Code Z223.1 (NFP A

54) or CAN/CGA B149.1 and B149.2, Installation Code for Gas Burning

Appliances and Equipment, and all local codes.

ANSI standard applicable to this heater does not require venting categorization; if such a requirement existed, this heater would be in Category III. (Category III appliances have a positive-pressure vent requiring a gastight sealed

vent system.) These tubular infrared heaters have been designed to operate

safely and efficiently with vent pipe lengths sho wn in the Vent Length T able.

Vent systems may either be vertical or horizontal. The type of vent required

depends on the size of heater and the vent run configuration.

Type of Vent Required by Vent Category

Model Sizes 50-125 150-200

- with a Horizontal Vent Run Category III Category III

- with a Vent Run that is at least one-half Category I

vertical (using equivalent lengths from the or Category III

Vent Length Table below) Category III

- with a Dual Vent Adapter (Option CC5) Category III Category III

V ent terminal end may be either single-wall pipe or double-wall pipe . A vent

terminal cap is required. Install a vent cap supplied as Option CC1 or a fullycomparable, field-supplied vent terminal cap such as a T ype L Breidert Air-xhauster®. (T ype L Air-x-hauster® is a trademark of The G. C. Breidert Company.) Dual v enting of two units is permissible when using an Optional Dual

Vent Kit (Option CC5).

Comply with the specific requirements and instructions in the following paragraphs.

Specific V ent Requirements

1. Vent Pipe Length - The vent lengths sho wn in the V ent T able are based on

(1) the maximum permissible resistance to flow at which each model size will

operate and (2) the potential for continuous condensing. Condensing in the

vent pipe should not occur after equilibrium has been reached when the surrounding ambient temperature is 60°F unless otherwise noted (See Requirement No. 6, Condensation).

Do not exceed maximum vent length. Minimum vent length is 5 feet.

Use equivalents listed when calculating for elbows and optional dual vent

adapter (Option CC5).

Ven t Length T able for Tubula r Infra red H ea ters

Vent Length Equivalent Length for

Straight

Tube

Length

(ft)

Input Size (000)

50 20, 25, 30 4 20 5 6.1 1.5 3 0.9 1-1/2 0.5 3 0.9

20, 25 4 45 5 13.7 1.5 6 1.8 3 0.9 6 1.8

75 30, 35 4 35 5 10.7 1.5 5 1.5 2-1/2 0.8 5 1.5

40 4 20 5 6.1 1.5 3 0.9 1-1/2 0.5 3 0.9

30, 35 4 45 5 13.7 1.5 6 1.8 3 0.9 6 1.8

100 40, 45 4 35 5 10.7 1.5 5 1.5 2-1/2 0.8 5 1.5

50 4 20 5 6.1 1.5 3 0.9 1-1/2 0.5 3 0.9

125 40, 45, 50 4 60 5 18.3 1.5 12 3.7 6 1.8 12 3.7

150 50, 55, 60 4 60 5 18.3 1.5 12 3.7 6 1.8 12 3.7

50, 55, 60,

175

65, 70

50, 55, 60,

200

65, 70

Must be deducted from the total vent length of

*

Vent Diameter

feet M

(inches)

Max Min Max Min ft M ft M ft M

4 60 5 18.3 1.5 12 3.7 6 1.8 12 3.7

4 60 5 18.3 1.5 12 3.7 6 1.8 12 3.7

Elbow

each

90°

heater.

45°

Elbow

Dual

Vent

Adapter

Box

*

2. Vent Pipe Type - Use only 4-inch diameter vent pipe.

If the type of vent required is Category III (refer to table

above), use either a vent pipe approved for a Category III heater or

appropriately sealed 26-gauge galvanized steel or equivalent singlewall pipe.

If the type of vent required is Category I (refer to table above),

unsealed 26-gauge galvanized steel or equivalent single-wall pipe

or double-wall (T ype B) vent pipe may be used.

3. Vent Pipe Joints - Vent system joints depend on the vent category and the type of pipe being used.

If installed as a Category III appliance and using single-wall

vent pipe, join pipes with at least two non-corrosive screws per

vent pipe joint and seal all joints to prevent leakage of flue gases

into the building. For sealing joints, the use of Alumin um or

TEFLON® (trademark of DuPont Corporation) tape suitable for

550°F is recommended (required in California). Vent tape of this

type is available from the heater manufacturer as P/N 98266.

If installed as a Category III appliance and using vent pipe

specifically approved for Category III vent systems, follow

the pipe manufacturer's instructions for proper sealing.

If installed as a Category I appliance (allowed only for Sizes

50-125 when at least half of the total equivalent length of the

vent system is vertical), use at least two non-corrosive screws per

vent pipe joint on single-wall pipe or follow the pipe manufacturer's

instructions for joining double-wall pipe.

Attach Vent Pipe to Heater - The last heat exchanger section

4.

(tail pipe) is designed to permit direct attachment of a vent pipe,

either straight or elbow .

Attach metal vent pipe using three non-corrosive screws spaced

equal distance apart. See Figures 17A and 17B.

Non-corrosive sheetmetal

screws spaced approximately

120° apart

Suspended

Tail Pipe

Figure 17A Attach Metal

V ent Pipe to

Tail Pipe

Single wall

elbow or

Single wall straight pipe section

T ape joint with high temperatur e

aluminum tape or seal with high

temperature silicone rubber sealant.

Figure 17B - Seal

T ail Pipe and Vent

Pipe Joint

5. Vent System Support - Vent pipe support is especially impor-

tant with the tubular infrared system because of the added stress

which may be caused by expansion and contraction of the overall

system. Support lateral runs a minimum of every six feet using

non-combustible material, such as steel strap or chain. Do not rely

on the heater for support of either horizontal or vertical vent pipe.

Form RZ-NA-I-TR, Mfg No. 121027 Rev 5,

Page 13

Page 14

g

e

.

11. Venting (cont'd)

6. Condensation - If single-wall vent pipe is exposed to cold air or run

through unheated areas, it must be insulated. Where extreme conditions

are anticipated, install a means of condensate disposal.

7.

Vent Terminal and Vent Cap - The vent system must be terminated

with the type of vent cap approved for use with this heater. The vent

terminal and vent cap must be the same diameter as the vent run. Use

either an optional (Option CC1) vent cap or equiv alent such as a T ype L

Breidert Air-x-hauster®. (Type L Air -x-hauster® is a trademark of The G.

C. Breidert Company.) A different style vent cap could cause nuisance

problems and/or unsafe conditions.

See the illustrations in Figures 18 and 19 for requirements of both vertical and horizontal vent termination. Using either single or double wall

vent terminals is illustrated. Many local codes require the use of doublewall (T ype B) vent for the portion of vent pipe (terminal) on the outside

of the building.

If double-wall pipe is used in the vent terminal, follow the instructions

below to attach the vent cap and to connect the double-wall pipe to the

single-wall vent system.

INSTRUCTIONS FOR DOUBLE WALL PIPE INSTALLATION: Material Required: Double wall (Type B) Vent Pipe (Note:

Use only one piece of double wall vent pipe.); a thimble designed for

double wall pipe (if construction is combustible); six 3/4" long

sheetmetal screws; the vent cap; and a tube of silicone sealant.

Instructions to attach VENT CAP to DOUBLE WALL (Type B)

VENT TERMINAL

Look for the "flow" arrow on the vent pipe. Attach the vent ca p to the

"exhaust" end of the double wall pipe.

1) Slide the vent cap inside the pipe.

2) Drill a hole through the pipe and the vent cap. (Hole should be

slightly smaller than the sheet metal screw being used.) Using a 3/4"

long sheet metal screw , attach the cap to the pipe.

3) Repeat Step 2) drilling and inserting two additional screws evenly

spaced (120° apart) around the pipe.

Instructions to connect the SINGLE WALL VENT system to a

DOUBLE WALL (Type B) VENT TERMINAL:

1) Slide the single wall pipe inside the inner wall of the double-wall

terminal pipe.

2) Drill a hole through both walls of the double wall pipe and the single

wall pipe. (Hole should be slightly smaller than the sheet metal screws

being used .) Using a 3/4" long sheet metal screw , attach the two pieces

of pipe. Do not overtighten.

3) Repeat Step 2) drilling and inserting two additional screws evenly

spaced (120° apart) around the pipe.

4) T o seal the annular opening (the gap between the single and double

wall pipe), run a large bead of silicone sealant in the opening. The bead

of sealant must be large enough to seal the opening, but it is not

necessary to fill the full volume of the annular area.

Figure 18A - Vertical Vent Terminal Arrangements (drawings are not proportional; read all information)

SINGLE WALL - Single wall vent run and single wall

terminal end

6 ft

(1829mm)

minimum

Roof Flashing

Roof pitched

Parapet or adjoining building

from 0 to 45°

Vertical flue extension must

be 6 (152mm) higher than

anticipated snow depth but no

less than 24 (610mm) above

the roof. Vertical pipe extension

must be insulated.

An approved clearance

thimble for single-wall

vent pipe is required when

the flue piepe extends

h combustible maerial.

throu

DOUBLE WALL - Single wall vent run and double

wall terminal end

6 ft

(1829mm)

minimum

Roof Flashing

6 (152mm)

Parapet or adjoining building

minimum

Follow the instructions above to join double wall and

single wall pipe and to attach a vent cap to double wall pipe.

Vertical flue extension

to be 6 (152mm) higher than

anticipated snow depth but no

less than 24 (610mm) above

the roof. Vertical pipe extension

must be insulated.

Roof pitched

from 0 to 45°

Clearance to be as specified on

Type B (double wall) vent pipe

Figure 18B - Vertical Vent Terminal/Air Intake Arrangements (dra wings are not proportional; read all information)

SINGLE WALL - Single wall vent run; single wall

terminal end; and single wall fresh air intake

6 ft

(1829mm)

minimum

Vertical flue extension

to be 6 (152mm)

higher than anticipated snow depth

but no less than 24

(610mm) above the roof.

Parapet or adjoining building

Vertical pipe extension

must be insulated.

Roof pitched

from 0 to 45°

An approved clearance

thimble for single wall

vent pipe is required

when the flue pipe extends

through combustible

mat

rial

Form RZ-NA-I-TR, Page 14

3 ft (914mm)

minimum

Roof Flashing

If the fresh air intake is

within 10 feet (3M) of the

flue extension, the flue

extension must be at least

12 (305mm) higher than

the fresh air intake.

Fresh air intake must

be 6 (152mm)

higher than anticipated snow depth.

DOUBLE WALL - Single wall vent run; double wall

terminal end; and single wall fresh air intake

6 ft

(1829mm)

minimum

Vertical flue extension

to be 6 (152mm)

higher than anticipated

snow depth but no less

Parapet or adjoining building

than 24 (610mm) above

the roof. Vertical pipe

extension must be

insulated.

Roof pitched

from 0 to 45°

6 (152mm)

minimum

Follow the instructions above to join double wall and single

wall pipe and to attach a vent cap to double wall pipe.

3 ft (914mm)

minimum

Roof Flashing

Clearance to be

as specified on

Type B

(double wall)

vent pipe

If the fresh air intake is

within 10 feet (3M) of the

flue extension, the flue

extension must be at least

12 (305mm) higher than

the fresh air intake.

Fresh air intake must

be 6 (152mm)

higher than anticipated snow depth.

Page 15

Horizontal Vent Terminal Clearances (See Figure 19)

(

Air Inlet Terminal Clearance -- The bottom of the air inlet

terminal shall be located not less than one foot (30 cm) above

grade and at least 6 inches (15 cm) above anticipated snow depth.

The distance of termination of the horizontal vent from adjacent

public walkways, adjacent buildings, openable windows, and

building openings must be in accordance with local codes , or in

the absence of local codes, must conform with the National Fuel

Gas Code. More stringent local codes supersede all provisions in

these instructions and in the National Fuel Gas Code. Minimum

clearances for the horizontal vent terminal are shown in the table

on the right.

NOTE: Maintain the required 18" clearance from the wall to

the vent terminal cap for stability under wind conditions

and to protect the building. Products of combustion can cause

discoloration of some building finishes and deterioration of masonry materials. Applying a clear silicone sealant that is normally

used to protect concrete driveways can protect masonry materials.

If discoloration is an esthetic problem, relocate the vent or install

Structure

Forced air inlet within 10 ft (3.1m) 3 ft (0.9m) above*

Combustion air inlet of another

appliance

Door, window or gravity air inlet 4 ft (1.2m) horizontally

(any building opening) 4 ft (1.2m) below

Electric meter, gas meter ** and

reli ef equipment

Gas regulator ** 3 ft (0.9m)

Adjoining building or parapet 6 ft (1.8m)

Grade (ground level) 7 ft (2.1m) above

*This heater is approved for installation as illustrated in Figure 19B.

**Do not terminate the vent directly above a gas meter or service regu lator.

Minimum Clearances for Vent

Termination Location (all

directions unless specified)

6 ft (1.8m)

3 ft (0.9m) above

4 ft (1.2m) horizontally

a vertical vent.

Figure 19A - Horizontal Vent Terminal Arrangements (drawings are not proportional; r ead all information)

SINGLE WALL - Single wall vent run and single wall

terminal end

Approved

clearance

thimble is

required

when flue

pipe extends

through

combustible

material.

18

(457mm)

minimum

Roof or building overhang

3 ft (914mm)

minimum

6 ft (1829mm)

minimum

DOUBLE WALL - Single wall vent run and double

wall terminal end

18

(457mm)

minimum

Roof or building overhang

Follow the

instructions

on page 14

to join double

wall and single

wall pipe and

to attach a vent

Parapet or adjoining building

cap to double

wall pipe.

6 (152mm)

minimum

3 ft (914mm)

minimum

6 ft (1829mm)

minimum

Parapet or adjoining building

Wall

Pitch flue pipe

down toward outlet

1/4 per foot for

condensate drainage.

Note position of

vent cap openings.

Clearance to be

as specified on

Type B (double

wall) vent pipe

Wall

Pitch flue pipe

down toward outlet

1/4 per foot for

condensate drainage.

Note position of

vent cap openings.

Figure 19B - Horizontal Vent Terminal/Air Intake Arrangements (drawings ar e not proportional; read all information)

SINGLE WALL - Single wall vent run; single wall

terminal end; and single wall fresh air intake

Approved

clearance

thimble is

required

when flue

pipe extends

through

combustible

material.

18 (457mm)

minimum

Pitch flue pipe

down toward outlet

1/4 per foot for

condensate drainage.

Wall

18

(457mm)

minimum

229mm) maximum

9

Roof or building overhang

3 ft (914mm)

minimum

Note position of

vent cap openings.

Fresh air intake cap

6 ft (1829mm)

minimum

DOUBLE WALL - Single wall vent run; double wall

terminal end; and single wall fresh air intake

Follow the

instructions

on page 14

to join double

wall and single

Parapet or adjoining building

wall pipe and

to attach a vent

cap to double

wall pipe.

18 (457mm)

minimum

6 (152mm)

Clearance to be

as specified on

Type B (double

wall) vent pipe

minimum

Wall

Roof or building overhang

18

(457mm)

minimum

Pitch flue pipe

down toward outlet

1/4 per foot for

condensate drainage.

Fresh air intake cap

9 (229mm)

maximum

3 ft (914mm)

minimum

6 ft (1829mm)

Note position of

vent cap openings.

minimum

Parapet or adjoining building

Form RZ-NA-I-TR, Mfg No. 121027 Rev 5,

Page 15

Page 16

11. Venting (cont'd)

Vent T erminal Arrangements (cont'd)

WARNING: Dual venting of two heaters is permitted only when using the Dual Vent Kit, Option

CC5. (Refer to Figures 20A and 20B.) No other manifolding of vent runs is permitted due to possible

back pressure and recirculation of combustion products into the building. See Hazard Levels, page

2.

Duel V enting -- By using the Dual

Vent Option Kit, Option CC5, two

heaters may use the same vent terminal. No other dual venting arrangement is approved.

Follow the installation instructions

and requirements included in the Option Kit. See Vent Te rminal Arrangements in Figures 20A and 20B.

Figure 20B - Horizontal Dual Vent

T erminal Arrangement

Single wall outer dual vent pipe

Single wall inner dual vent pipe

clearance to combustibles

Dual Vent

Adapter Box

Figure 20A - Vertical

Dual V ent T erminal

Arrangement

6 ft (1829mm)

minimum

Roof Flashing

Parapet or adjoining bulding

6 (152mm)

clearance to combustibles

Vent pipe

from heater

6 (152mm)

Vertical extension must be 6 (152mm)

higher than anticipated snow depth

but not less than 24 (610mm) above

the roof

Approved thimble required when the flue pipe

extends through combustible materials.

Dual Vent

Adapter Box

Roof or building overhang

3 ft (914mm)

18 (457 mm)

minimum

Single wall outer dual vent pipe

Single wall inner dual vent pipe

6 ft (1829mm)

maximum

Vent pipe

from heater