Page 1

Hydraulic Crimping Tool

Catalog Number: TBM14MC

IMPORTANT: Read and understand all of the instructions and safety

information in this manual before operating or servicing this tool.

Table of Contents

1.0 General Information ..................................................................................2

1.1 General Characteristics ...............................................................................2

1.2 Overall View ................................................................................................. 2

2.0 Instruction for use ....................................................................... 3

2.1 Preparation ..................................................................................................3

2.2 Die Advancement.........................................................................................3

2.3 Compression ................................................................................................ 3

2.4 Release of Dies ............................................................................................3

2.5 Die Replacement .........................................................................................3

3.0 Maintenance ................................................................................4

3.1 Cleaning .......................................................................................................4

3.2 Storage ........................................................................................................4

3.4 Purging Air Bubbles .....................................................................................4

3.5 Adding Oil .................................................................................................... 4

3.6 Tool Position ................................................................................................4

4.0 Parts List for Type 2 ........................................................................5

5.0 Parts List for older models ............................................................... 7

TA02982 E page 1 of 8

Page 2

1.0 GENERAL INFORMATION

WARNING

1. BEFORE USING THE TOOL, CAREFULLY READ

INSTRUCTIONS IN THIS MANUAL.

2. WHEN OPERATING THE TOOL, NEVER PLACE HANDS

OR OTHER BODY PARTS BETWEEN THE CRIMPING

DIES.

3. DO NOT OPERATE WHEN DIES ARE NOT IN PLACE.

4. RISK OF ELECTRICAL SHOCK. DO NOT USE ON

ENERGIZED LINES.

1 2 33 4

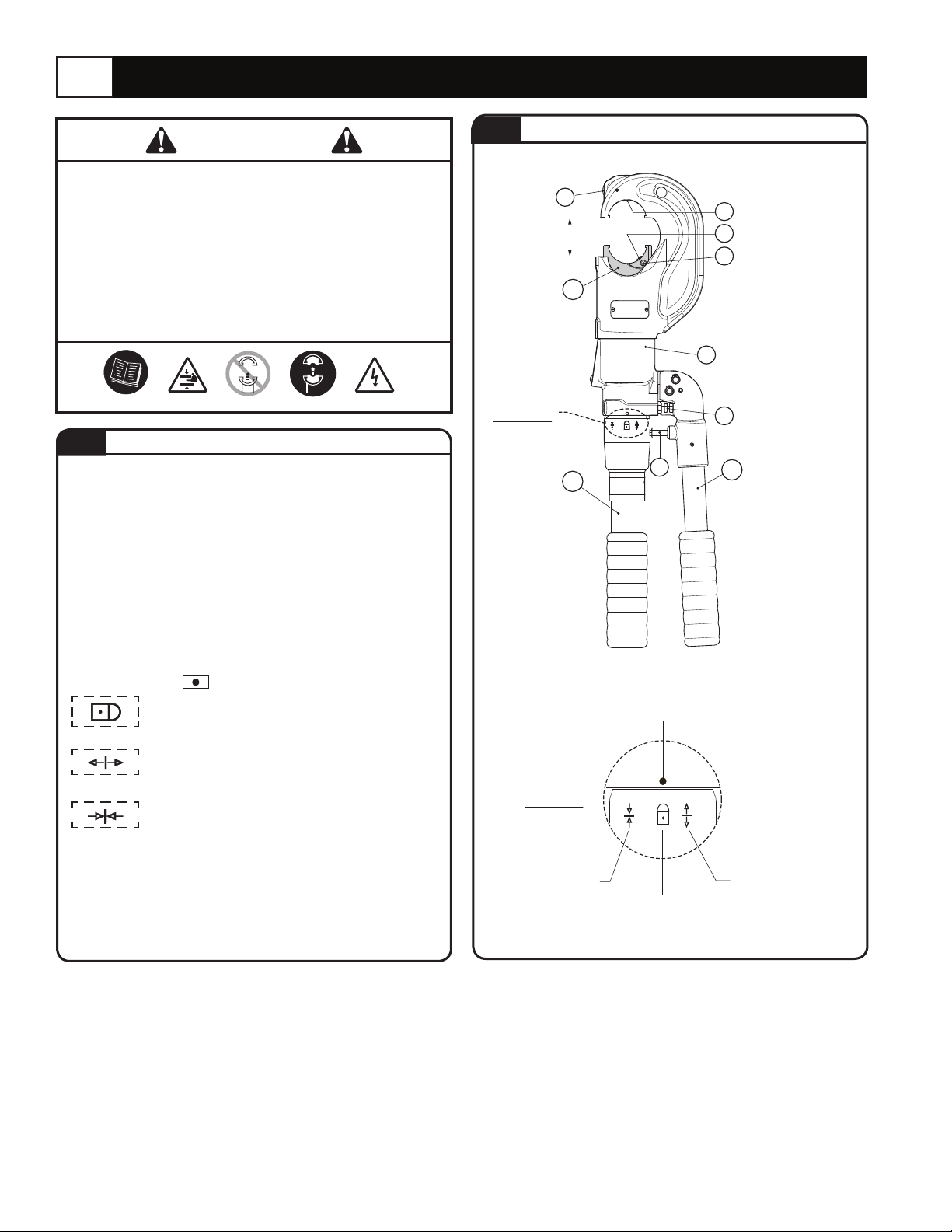

1.1

Head: “C” shaped with large jaw opening, see Figure 1.

Application range: suitable for installing electric compression

connectors (lugs and splices) on conductors

Crimping Force: ................................................................ 14 tons

Rated operating pressure: ........................... 700 bar (10,000 psi)

Dimensions: length ............................................................21.3”

width (with handles closed) ..........................5.67”

height (with handles open) ..........................13.54”

Weight: .............................................................................. 15.6 lbs

Recommended Oil: .......................... AGIP ITE 360 or equivalent

Operating positions: The three operating positions are identied

on the main handle (13) (see Figure 1)

Advancing speed: The tool has two forward speeds of the ram

and automatically switches from a fast advancing speed of dies

to a slower crimping speed.

Safety:

GENERAL CHARACTERISTICS

up to ....900 MCM

Rest position: (Handles locked): Lock handles

together by means of the handle latch (49) when

tool is in use.

Release position: Close the moveable handle (203)

against the xed handle (200), in order to discharge

the oil pressure and retract the dies.

Operating position: On releasing the moveable

handle (203), the xed handle (200) rotates

automatically to this position. Operate the

moveable handle (203) to build up pressure and

close the dies.

The tool is provided with a maximum pressure relief valve.

1.2

Die/Head

Release Pin

Complete Ram

Detail A

Handle Grip

Detail A

Operating Position

FIGURE 1

OVERALL VIEW

30

“ 56.1

mm 24

)*(

202

200

49

Latch

Reference Symbol

Rest Position

Die/Head Retaining Pin

32

Die/Head Release Pin

36

Die/Ram Retaining Pin

37

Tool Body

13

65

Complete

Movable

203

Handle

Release Position

TA02982 E page 2 of 8

Page 3

2.0 INSTRUCTION FOR USE

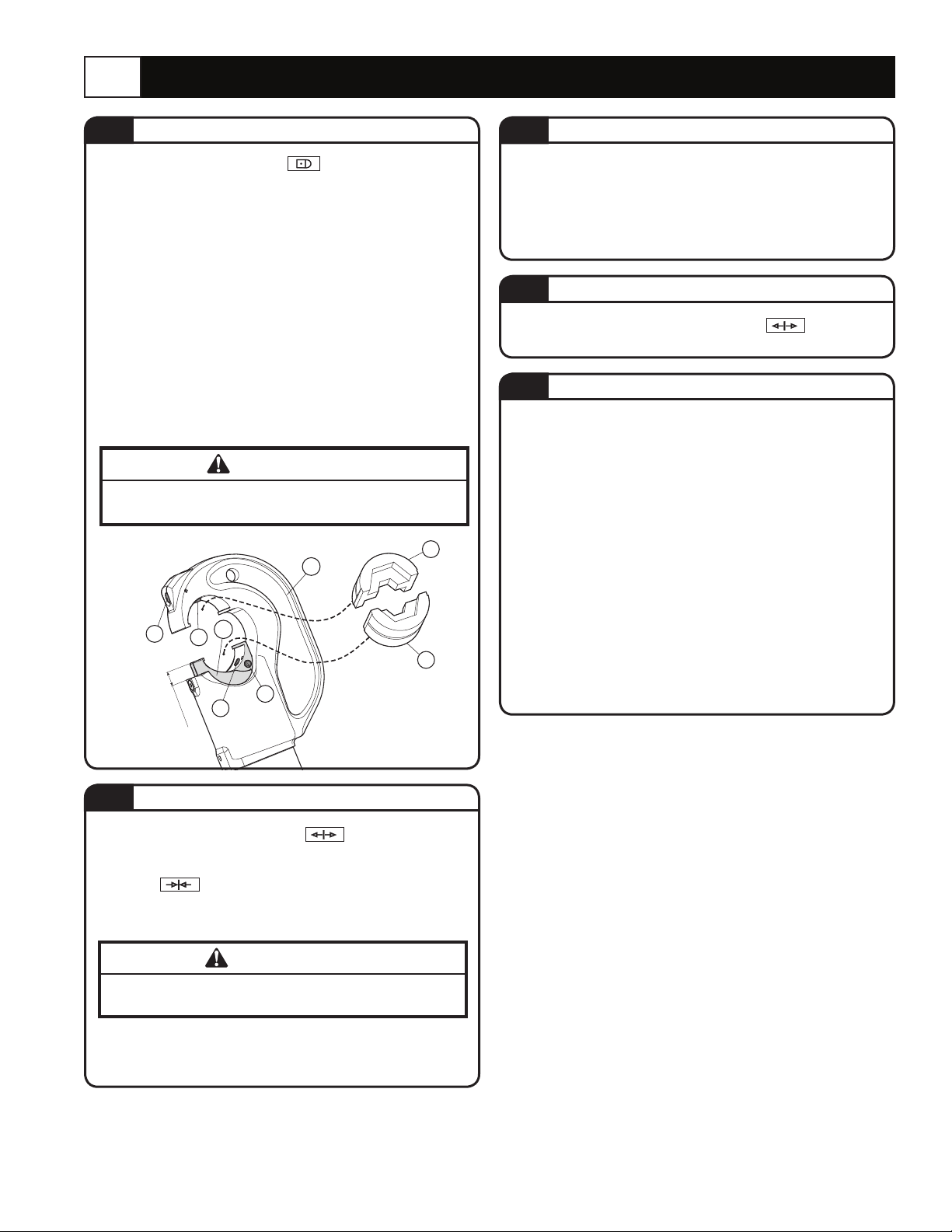

2.1

With the tool in the rest position prepare the tool as

follows: (see Figure 2)

− Select the appropriate die set for the connector.

− Insert the die (91) in the upper seat of the tool head until it is

locked by die/head pin (32). To ease the die insertion, keep

die/head release pin (30) depressed.

− Operate the tool (per 2.2) to advance the ram (202) 8-10 mm

(0.3 - 0.4 in.) and insert the die (90) into the seat on the ram

until it is locked by die/ram retaining pin (37). To ease this

operation, keep die/ram release pin (36) depressed.

− Insert the conductor in the connector.

− Position the connector between the dies and ensure the

correct location of the crimp.

− For ease of operation, the tool head can rotate through 180°.

PREPARATION

WARNING

DO NOT ATTEMPT TO TURN THE HEAD IF THE

HYDRAULIC CIRCUIT IS PRESSURISED.

91

201

32

~ 8 ÷ 10 mm

)

202

90

36

37

30

(0.3 - 0.4 in.

FIGURE 2

2.3

− Continue operating the movable handle (203). The tool will

automatically change over to the high pressure stage. The ram

will advance until the dies meet.

− Continue pumping until the maximum pressure valve is

activated and a “click” is heard.

2.4

− Rotate the xed handle to release position

handles. The ram will then retract, and the dies will open.

2.5

To replace dies proceed as follows: (Refer to Figure 2)

Upper die (91)

− Take the die off its guide by pushing the die/head release

pin (30).

− Insert replacement die until secured by the die/head retaining

pin (32).

Lower die (90)

− Take the die off its guide by pushing the die/head release

pin (36).

− Insert replacement die until secured by the die/ram retaining

pin (37). To facilitate this operation an advancement of the ram

by 8-10 mm (0.3 - 0.4 in.) is suggested.

COMPRESSION

RELEASE OF DIES

Close

DIE REPLACEMENT

2.2

− Set the tool in the release position by rotating the xed

handle (200). The moveable handle (203) will be released and

the main handle will rotate automatically to the operating

position .

− Operate moveable handle (203) for lower die advancement.

This rst stage rapidly closes the dies to the connector.

DIE ADVANCEMENT

WARNING

Never place the tool under pressure without inserting the

dies, this could cause damage to the head and the ram.

Make sure the dies are exactly positioned on desired crimp point,

otherwise re-open dies following instructions as per 2.4 and

reposition the connector.

TA02982 E page 3 of 8

Page 4

3.0 MAINTENANCE

Compliance with the following points should help to maintain the optimum performance of the tool.

3.1 3.5

Dust, sand and dirt are a danger for any hydraulic device.

Every day, after use, the tool must be cleaned with a clean

cloth, taking care to remove any residual particles, especially

close to pivots and moveable parts.

3.2

When not in use, the tool should be put in the rest position

and placed in the plastic case for storage and transportation.

The plastic case can also accommodate 14 die sets

(See Figure 3).

To put the tool in the rest position:

−

Retract the ram completely

as describe in 2.4.

− Keeping the handles

completely closed, release

the xed handle which will

rotate automatically to the

rest position . The

moveable handle will then

be locked by means of the

handle latch (49).

CLEANING

STORAGE

Every six months, check the oil level in the reservoir.

If necessary, bring the oil level up to the top lip of the

reservoir, see section 3.4 , a, b, c, e, g, h and i.

− Always use clean recommended oil, see section 1.1, pg. 2.

−

−

IMPORTANT: Ensure that disposal of used oil is in

accordance with current legislation.

3.6

200

FIGURE 3

ADDING OIL

Do not use old or recycled oil.

Do not use hydraulic brake uid.

TOOL POSITION

A

54

53

1

3.4

Air in the hydraulic circuit may affect the performance

of the tool (e.g. no lower die advancement; slow

advancement of lower die; lower die pulsating).

See Figures 4 and 5.

To purge air bubbles from hydraulic circuit:

a. Hold tool upright with the head in a vice and handles

open (Figure 4).

b. Using a 2,5mm allen key, remove screws (17 and

56), slide off the xed handle (200) to expose the oil

reservoir (3). Recover spring (54) and spring cover (53).

c. Remove reservoir cap (1).

d. Operate the moveable handle (203) three or four times

to advance the ram (202).

e. Depress pressure release pin (65) until ram is fully

retracted.

f. Repeat points d and e at least ve times, to ensure all

air bubbles in the hydraulic circuit are purged into the

reservoir.

g.

If the oil level is low, top off as directed in paragraph 3.5.

h. Replace the cap (1).

i. With the tool in the horizontal position, relocate spring

(54) and spring cover (53) in seat A (see detail in Fig. 4).

Reassemble the xed handle (200), insert screws (17

and 56) complete with washers (55) in their respective

positions and tighten them.

If the tool continues to malfunction, return the tool for

service/repair as detailed on page 8.

PURGING AIR BUBBLES

55

17

56

55

65

FIGURE 4 For Maintenance Operations

3

203

TA02982 E page 4 of 8

Page 5

4.0 PARTS LIST For Type 2

See Figure 5 for complete tool assembly.

Code N° Item Description Qty

6800040 1

6720100 3

6360260 8

6040685 8

6900621 9

6360160 10

6740060 11

6520765 12

6160044 13

6740140 14

6520180 15

6340566 16

6900059 17

6100037 18

6900211 27

6100035 28

6340540 34

6362035 38

6362010 39

6641140 40

6360240 41

6362020 42

6620382 43

6700100 46

6560420 48

6600101 53

6520862 54

6640205 55

6900080 56

6340720 57

6520861 58

6635011 59

6895050 60

6740120 61

6600100 62

6520260 63

6740080 64

6620120 65

6360120 66

The items marked with (K) are those that Thomas & Betts

recommends replacing if the tool is disassembled.

These items are supplied on request in the

“TBM14MC Spare Parts Package”

RESERVOIR CAP

OIL RESERVOIR

O-RING

GUIDING RING

SUCTION SCREW

O-RING

BALL

SPRING

TOOL BODY

BALL

SPRING

DOWEL

SCREW M4x8

KEY

SCREW M5x10

KEY

GRUB SCREW

SEAL

SEAL

BACK-UP RING

O-RING

SEAL

PUMPING RAM

CIRCLIP

PIN

SPRING COVER

SPRING

WASHER

SCREW M4x8

GRUB SCREW

SPRING

PIN

COMPLETE VALVE

BALL

BALL SUPPORT

SPRING

BALL

PIN

O-RING

1

1

1

2

1

2

2

2

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

4

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

Code N° Item Description Qty

6040060 67 BACK-UP RING 1

6080080 68 BUSH 1

K

K

K

K

K

K

K

K

K

K

K

K

K

K

K

K

K

6232589 77 TA04568 LABEL 1

6170143 88 PLASTIC CAP 2

6480407

6380265

6370238

6620245

6760160

6620440

6522006

6340540

6800088

6620250

6620312

6700250

6170140

6362058

6040128

6520619

6520611

6300079

6522006

6760040

6620445

6620320

6480196

6760320

6200032

6760280

6480269

6380240

6900280

6180200

The warranty is void if parts used are not original Thomas & Betts parts.

When ordering spare parts always specify the following:

− Code Number of Item

− Name of Item

− Type of Tool

− Tool Serial Number

200

200

201

201

201

201

201

201

201

201

202

202

202

202

202

202

202

202

202

202

202

202

203

203

203

203

203

203

203

203

COMPLETE MAIN

HANDLE

2 HANDLE GRIP 1

COMPLETE

INSULATED HEAD

30 PIN 1

31 PIN 1

32 PIN 1

33 SPRING 1

34 GRUB SCREW 1

75 PLASTIC CAP 1

76 PLASTIC CAP 1

COMPLETE RAM 1

19 CIRCLIP 1

20 COVER 1

21 SEAL 1

22 BACK-UP RING 1

23 SPRING 1

24 SPRING 1

25 RAM GUIDE 1

33 SPRING 1

35 PIN 2

36 PIN 1

37 PIN 1

COMPLETE

MOVEABLE HANDLE

44 SPLIT PIN 1

49 LATCH 1

50 SPLIT PIN 1

51 MOVEABLE HANDLE 1

MOVEABLE HANDLE

52

GRIP

69 SCREW M5x18 1

70 NUT 1

TA02982 E page 5 of 8

K

1

1

K

K

1

1

Page 6

1

46

44

50

48

203

51

49

70

46

52

16

69

68

15

16

14

43

65

15

42

14

41

66

67

13

40

39

12

53

54

17

8

55

59

55

11

61

56

57

58

62

18

63

12

60

10

9

10

11

7

34

64

17

3

200

2

77

38

19

20

24

25

23

35

33

37

35

36

FIGURE 5 Complete Tool Assembly for Type 2

Serial number

21

22

201

x

x

x

x

x

x

202

88

34

32

75

33

76

28

30

31

27

88

TA02982 E page 6 of 8

Page 7

5.0 PARTS LIST for Older Models

CODE N° ITEM DESCRIPTION QTY.

6800040

6380265

6720100

6480043

6780114

6360260

6040685

6900621

6360160

6740060

6520765

6160044

6740060

6520765

6740140

6520180

6340566

6900059

6700250

6170140

6100037

6520619

6520611

6300081

6620317

6900022

6100038

6760160

6620245

6340540

6522006

6620440

6370219

6362035

6040320

6360420

6362010

6641140

6360240

6362020

6620382

6760320

6780265

6700100

6080060

01

●

02

03

●

04

●

05

★

06

07

08

★

09

★

10

★

11

12

★

13

★

14

★

15

★

16

17

18

▲

19

▲

20

21

▲

22

▲

23

▲

24

▲

25

26

27

■

28

■

29

■

30

■

31

■

32

■

33

★

34

★ ▲ 35

★ ▲ 36

★

37

★

38

★

39

★

40

41

✚

42

✚

43

★

44

✚

45

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

4

Reservoir Cap

Fixed Handle Grip

Oil Reservoir

Fixed Handle

Fixed Handle Support

O-Ring

Guiding Ring

Suction Screw

O-Ring

3/16” Ball

Suction Spring

Body

3/16” Ball

Suction Spring

9/32” Ball

Spring

Ball Positioning Dowel

M 4x8 Screw

Ø 36 Circlip

Spring Cover

Key

Ram Return Outer Spring

Ram Return Inner Spring

Ram Spring Guide

Ram

M3x8 Screw

Key

D.3x28 Spring Pin

Die/Head Release Pin

M 10x8 Grub Screw

Spring

Die/Head Retainer Pin

“C” Head

Seal

Back-Up Ring

O-Ring

Seal

Back-Up Ring

O-Ring

Seal

Pumping Ram

D.5x30 Spring Pin

Moveable Handle Support

Circlip

Movable Handle Bushing

CODE N° ITEM DESCRIPTION QTY.

6560420

6760280

6200032

6480269

6380240

6760014

6232006

6340720

6520861

6635011

6740140

6520180

6340566

6180200

6900280

6080080

6620445

6760040

6522006

6620320

6040060

6360120

6620120

6340540

6740080

6520260

6600100

6740120

6360160

6895050

6900080

6640205

6760040

6520862

6600101

6640205

6900059

6480407

6620318

6370237

6480196

6000058

46

✚

47

✚

48

✚

49

✚

50

●

51

52

55

56

57

★

58

★

59

60

✚

61

✚

62

63

▲

64

▲

65

▲

66

▲

67

★

68

★

69

70

71

★

72

73

74

★

75

★

76

77

78

79

▲

80

★

81

★

82

83

84

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Moveable Handle Pivot

D.4x30 Spring Pin

Movable Handle Latch

Moveable Handle

Movable Handle Grip

3x4 Spring Pin

Label (TG. 0356)

Pressure Release Dowel

Pressure Release Spring

Pressure Release Pin

9/32” Ball

Non Return Spring

Ball Positioning Dowel

M5 Nut

M 5x18 Screw

Pressure Release Ram Bushing

Die/Ram Release Pin

D. 3x8 Spring Pin

Spring

Die/Ram Retainer Pin

Back-Up Ring

O-Ring

Pressure Release Pin

M 10x8 Grub Screw

5/16” Ball

Spring

Ball Positioning Dowel

7/32” Ball

O-Ring

Max Pressure Valve

M 4x8 Screw

Washer

D. 3x8 Spring Pin

Spring

Spring Cover

Washer

M 4x8 Screw

Complete Main Handle

Complete Ram

Complete “C” Head

Complete Moveable Handle

Spare Parts Package

●

▲

■

✚

★

The items marked with ( ) are those Thomas & Betts

recommends replacing if the tool is disassembled.

These items are supplied on request in the

“TBM14MC Spare Parts Package”

The warranty is void if parts used are not original

Thomas & Betts parts.

When ordering spare parts always specify the following:

− Code Number of Item

− Name of Item

− Type of Tool

− Head Serial Number

TA02982 E page 7 of 8

Page 8

68

69

70

71

72

73

74

75

76

77

78

79

80

B-B

84

83

82

81

29

28

27

E-E

26

25

67

66

65

64

63

62

61

60

59

58

57

56

55

24

23

22

21

20

19

18

17

16

15

14

13

12

E

B

E

B

F

11

10

H

H

09

08

07

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

06

05

52

04

03

02

01

H-H

51

FIGURE 6 Complete Tool Assembly for Older Models

In case of a breakdown contact the Thomas & Betts Tool Service Center at 1-800-284-TOOL (8665).

WARRANTY: Thomas & Betts sells this product with the understanding that the user will perform all necessary tests to

determine the suitability of this product for its intended use. Thomas & Betts manufactures its goods and tools in a manner

to be free of defects. Should any defect occur in its goods within two (2) years (or tools within time stated on warranty card) of

date of purchase, Thomas & Betts, upon prompt notication, will at its option, exchange or repair the goods or tools or refund

the purchase price. Proof of purchase required.

Limitations and Exclusions: THIS WARRANTY IS IN LIEU OF ALL OTHER REPRESENTATIONS AND EXPRESSED AND

IMPLIED WARRANTIES (INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE),

AND UNDER NO CIRCUMSTANCES SHALL THOMAS & BETTS BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR LOSSES OF ANY KIND.

Thomas & Betts Corporation

Memphis, Tennessee

Website: www.TNB.com

© 2010 Thomas & Betts Corporation. All Rights Reserved.

TA02982 E page 8 of 8

Loading...

Loading...