STAR TECK® Teck Cable Fittings

STAR TECK® Jacketed Metal-Clad Cable Fittings

Overlapping range of sizes. STAR TECK® jacketed metal-clad cable fittings are designed to accommodate a broad

range of cables, thereby minimizing the possibility of mismatched cables and fittings in the field.

Application

• Provide means for passing armored,

metal-clad, jacketed cables through

a bulkhead or enclosure in hazardous

Cord & Cable Fittings

®

Conduit & Fittings — T&B

areas (these fittings are suitable for

hazardous areas when used with T&B

sealing compound)

• Form a mechanical grip and water-

and/or oil-resistant termination

• Provide grounding continuity

ofcablearmor

Cable Type

• JMC, MC-HL, Teck

Features

Easy Installation

• Exclusive power-grip. Provides a grip

that’s high up on the cable — not

on the first convolution — sostrip

length and cutting of cableare not

as critical

Dependable Service

• Stainless steel retaining ring.

Withstands corrosive environments.

Non-magnetic

Dependable Grounding

• Power-Grip grounding ring is non-

magnetic stainless steel. Provides

360° long-term dependable

grounding. It makes immediate

contact with the cable

Watertight

• Tapered bushing. Cone shaped

toprovide a secure, tight fit while

eliminating cupping or water in

vertical installations

Installing the STAR TECK® Fitting

Easy to Install in Tight Spaces

• Low-profile gland nut fits tight

spaces. Has grooves for screwdriver

installation, and flats for a wrench.

Durable and reusable with funnel

entry for easy cable insertion

Materials

Aluminum is standard material

Add suffix “S” for steel

with zinc plating

Add suffix “PVC” for corrosion- resistant

PVC coating

Add suffix “SS” for stainless steel Grade 316

1

material (

⁄2"–2" sizes)

Environment Classification

Meets NEC® Class I Division 2/Zone 2

and Class II Division 2/Zone 22 requirements

when installed as per Articles 501.10/505.15

and 502.10/506.15

NEMA4

Suitable for use in wet locations andconcrete

tight (steel) applications per UL 514B

UL File No. E82038/E38947

CSA File No. LR638/LR23086

Range

Available in hub sizes from1⁄2" to 4",

and will handle outerjacket diameters

from .525"to4.340"

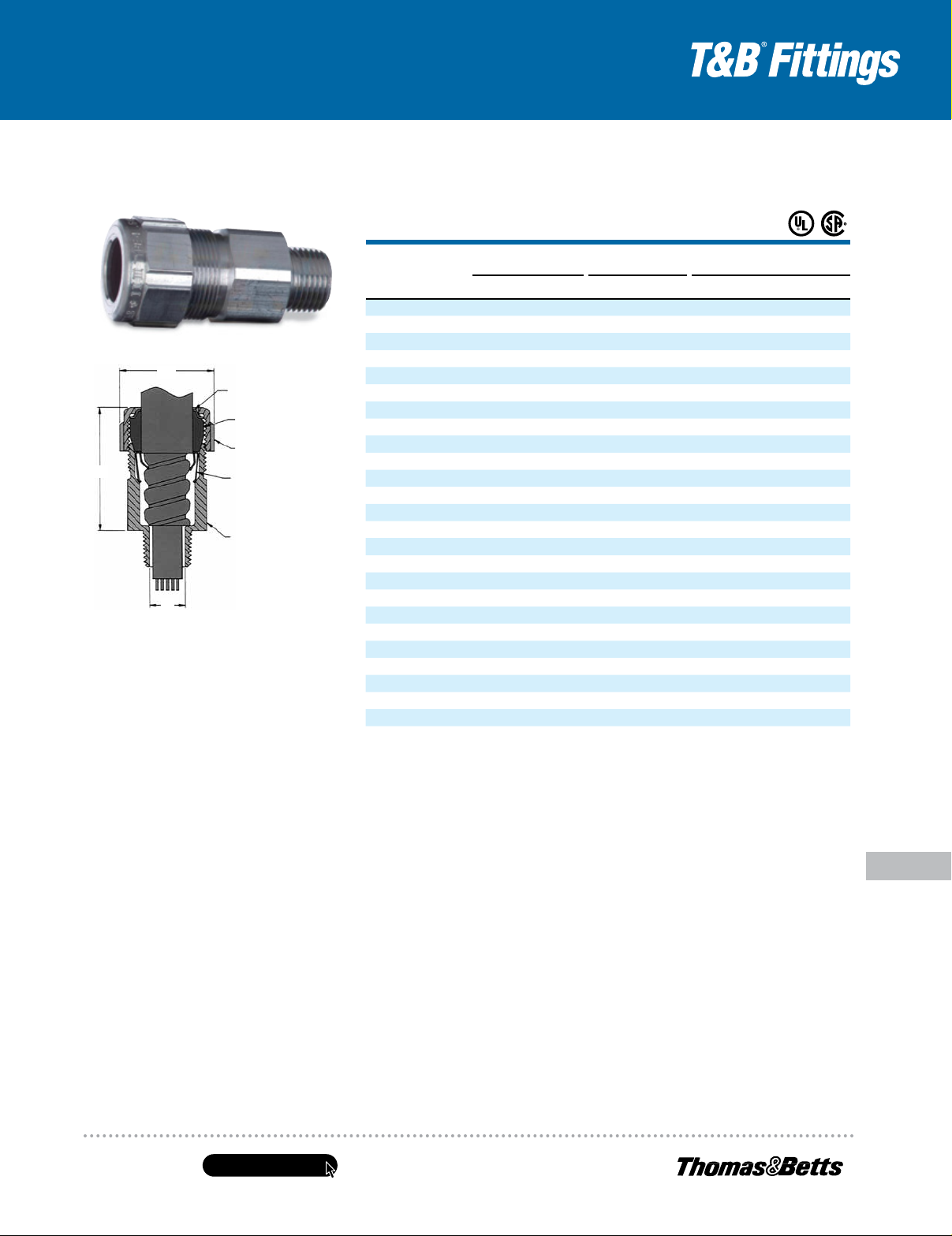

Easy Installation.

Exclusive power-

grip. Provides a

grip that’s high

up on the cable

— not on the first

convolution —

sostrip length and

cutting of cable

are not critical.

Dependable

Service.

Stainless steel

retaining ring.

Withstands

corrosive

environments.

Non-magnetic.

Watertight

Tapered bushing.

Cone shaped

to provide a

secure, tight fit

while eliminating

cupping or

water in vertical

installations.

Dependable

Grounding.

Power-Grip

grounding ring

isnon-magnetic

stainless steel.

Provides 360°

long-term

dependable

grounding.

Itmakes

immediate

contactwith

thecable.

Easy to Install

in tight spaces.

Low-profile gland

nut fits tight spaces.

Has grooves

for screwdriver

installation

and flats for a

wrench. Durable

and reusable

with funnel entry

foreasy cable

insertion.

E-124

1. Prepare cable

United States

Tel: 901.252.8000

800.816.7809

Fax: 901.252.1354

Technical Services

Tel: 888.862.3289

3. Tighten gland nut2. Insert cable

www.tnb.com

STAR TECK® Teck Cable Fittings

STAR TECK® Jacketed Metal-Clad Cable Fittings for Ordinary Locations

CAT.

NO.

ST050-4621⁄2 .525 .650 .415 .570 .395 2.020 1.224

ST050-464

ST050-465

C

B

A

Retaining ring

(stainless steel)

Bushing (neoprene)

Gland nut (aluminum)

Grounding ring

(stainless steel)

Body (aluminum)

• Overlapping sizes minimize

possibility of mismatched

cables and fittings in the field

• Available in hub sizes from 1⁄2" to 4",

handling outer jacket diameters from

.525" to 4.34"

• Suitable for hazardous locations

(Class 1 Div. 2; Class II Div. 2;

Class III)

• Where explosion-proof or

dust-proof boxes are required

by code, use STAR TECK XP®

fittings (STX050-462 Series)

ST050-466

ST075-467

ST075-468

ST100-469 1 1.187 1.375 1.077 1.295 1.039 2.601 2.230

ST125-470 1

ST125-550 1

ST125-471 1

ST150-472 1

ST150-473 1

ST200-551 2 1.900 2.187 1.790 2.107 1.715 3.640 3.620

ST200-474 2 2.100 2.375 1.990 2.280 1.995 3.640 3.620

ST200-475 2 2.300 2.565 2.190 2.485 2.057 3.640 4.020

ST200-476 2 2.500 2.750 2.390 2.656 2.057 3.640 4.020

ST250-477 2

ST250-478 2

ST300-479 3 2.790 3.060 2.640 2.970 2.630 4.700 5.050

ST300-480 3 3.000 3.270 2.870 3.190 2.860 4.790 5.480

ST300-481 3 3.210 3.480 3.042 3.390 3.032 4.790 5.480

ST350-482 3

ST350-483 3

ST400-484 4 3.810 4.030 3.600 3.930 3.590 4.840 6.435

ST400-485 4 3.965 4.185 3.755 4.065 3.745 4.840 6.435

ST400-486 4 4.120 4.340 3.910 4.220 3.900 4.840 6.435

* Approximate dimension before installation.

Suggested specifications for metal-clad cable fitting.

1. All metal-clad cable fittings for jacketed interlocked armor cable or continuous corrugated cable shall be

approved by a nationally recognized testing laboratory, inspection agency or product evaluation organization.

2. Where corrugated-jacketed metal-clad cable exposed to intermittent or continuous moisture is terminated

into a threaded opening, the fitting shall be watertight type furnished with:

a. An elastomeric beveled bushing.

b. A funnel entry, splined gland nut.

c. A non-magnetic stainless steel grounding device with dual grounding action.

d. A taper threaded hub.

e. A hexagonal body and gland nut as manufactured by Thomas & Betts (aluminum series ST050-464).

3. Where cable is terminated into a threadless opening, a suitable moisture-resistant elastomeric gasket as manufactured

byThomas & Betts, series 5262, shall be provided between the outside of enclosure and fitting shoulder.

4. With single-conductor cable and/or in corrosive environments, aluminum fittings such as Thomas & Betts series

ST050-464 shall be installed.

Class I Div 2; Class II Div. 2; Class III. Where explosion-proof or dust-ignition-proof boxes are required by Teck, fitting must

beused in conjunction with an approved sealing fitting.

CABLE RANGE OVER

HUB

SIZE

NPT

1

⁄2 .600 .760 .490 .680 .485 2.020 1.363

1

⁄2 .725 .885 .615 .805 .612 2.133 1.633

1

⁄2 .825 .985 .715 .905 .612 2.133 1.633

3

⁄4 .880 1.065 .770 .985 .819 2.450 2.080

3

⁄4 1.025 1.205 .915 1.125 .819 2.450 2.080

1

⁄4 1.357 1.625 1.240 1.545 1.182 3.282 2.824

1

⁄4 1.500 1.625 1.390 1.545 1.370 3.282 2.824

1

⁄4 1.600 1.875 1.490 1.795 1.370 3.282 2.824

1

⁄2 1.700 1.965 1.590 1.885 1.557 3.620 3.260

1

⁄2 1.900 2.187 1.790 2.107 1.600 3.620 3.260

1

⁄2 2.380 2.640 2.240 2.560 2.230 4.700 4.750

1

⁄2 2.580 2.840 2.440 2.750 2.430 4.700 4.750

1

⁄2 3.420 3.690 3.270 3.590 3.260 4.790 5.980

1

⁄2 3.610 3.870 3.440 3.770 3.430 4.790 5.980

JACKET (IN.)

MIN. MAX. MIN. MAX. A B* C

CABLE RANGE OVER

ARMOR (IN.) DIMENSIONS (IN.)

Conduit & Fittings — T&B

®

Cord & Cable Fittings

www.tnb.com

United States

Tel: 901.252.8000

800.816.7809

Fax: 901.252.1354

Technical Services

Tel: 888.862.3289

E-125

Loading...

Loading...