Page 1

USER INSTRUCTIONS

Limitorque MX DeviceNet Field Unit

FCD LMENIM2328-00 – 11/05

Installation

Operation

Maintenance

Experience In Motion

Page 2

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Limitorque MX DeviceNet Field Unit Installation and

Operation Manual

©2005 Copyright Flowserve. All rights reserved. Printed in the United States of America

Disclaimer

This document is meant for use with the Limitorque MX Installation and Operation Manual for MX-05

through MX-40. Information in this document is also applicable to MX-85 and MX-140. No part of

this book shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic,

mechanical, photocopying, recording, or otherwise without the written permission of Limitorque. While

every precaution has been taken in the preparation of this book, the publisher assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained herein.

This document is the proprietary information of Flowserve, furnished for customer use ONLY. No other

uses are authorized without written permission from Limitorque.

Limitorque reserves the right to make changes, without notice, to this document and the products it

describes. Limitorque shall not be liable for technical or editorial errors or omissions made herein;

nor for incidental or consequential damages resulting from the furnishing, performance or use of this

document.

The choice of system components is the responsibility of the buyer, and how they are used cannot be

the liability of Limitorque. However, Flowserve Limitorque’s sales team and application engineers are

always available to assist you in making your decision.

This manual contains information that is correct to the best of Flowserve’s knowledge. It is intended

to be a guide and should not be considered as a sole source of technical instruction, replacing good

technical judgment, since all possible situations cannot be anticipated. If there is any doubt as to exact

installation, configuration, and/or use, call Flowserve Limitorque at (434) 528-4400. The latest revisions

to this document are available online at http://www.limitorque.com

2

Page 3

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Contents

Declaration of DeviceNet Conformance – ODVA Certification 5

Abbreviations

1 Introduction

1.1 Purpose

1.2 How to Use this Manual

1.3 User Safety

1.4 User Knowledge

1.5 DeviceNet System Capabilities and Features

1.5.1 General Specifications

2 System Components 1

2.1 Introduction 1

2.2 Hardware 1

2.2.1 Limitorque MX 1

2.2.2 DeviceNet Field Unit 1

2.2.3 Hardware interface 1

2.2.4 Network Cable 1

3 Installation and Configuration 1

3.1 Site and Network Cable Preparation 1

3.1.1 Site Preparation 1

3.1.2 Network Cable Preparation 1

3.2 Installation Verification 1

3.2.1 Network Cabling Installation Verification 1

3.2.2 DNFU Installation Verification 1

4 Object Model Diagram 1

4.1 Assembly Objects 1

4.2 Output Assembly Instances 1

4.2.1 DI_Position_and_Bus_Mode_Chan 2

4.2.2 DI_Position_Chan 2

4.2.3 DI_Actuator_Faults_1_Chan 2

4.2.4 DI_Actuator_Faults_2_Chan 2

4.2.5 DI_Actuator_Alarms_Chan 2

4.2.6 DI_Disc_User_Input_Chan 2

4.2.7 DI_Read_Disc_Output_Chan 2

4.2.8 DO_Position_Chan 2

4.2.9 DO_ESD_Chan (Read Only) 2

4.2.10 DO_Relay_Chan 2

4.2.11 DO_Actuator_Faults_3_Chan 2

4.2.12 Ctrl_Status_Chan 2

4.2.13 DI_Alarms_2_Chan 2

4.2.14 DI_Actuator_Faults_3_Chan 2

4.3 Channel Interface 2

4.4 Transducer Block Object 2

4.4.1 MAC ID 3

4.4.2 Baud Rate 3

4.5 Network Management 3

4.5.1 Offline Connection Set 3

4.5.2 Device Heartbeat Message 3

6

7

7

7

7

8

8

8

0

0

0

0

1

2

2

3

3

3

3

6

6

7

7

8

8

2

2

2

3

3

4

4

4

4

5

5

5

5

5

6

8

0

1

1

1

1

3

flowserve.com

Page 4

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

4.5.1 Device Shutdown Message 32

4.6 Configuration Confirmation 3

4.6.1 Checking Connections 3

4.6.2 View Settings 3

5 View DeviceNet Status 3

5.1 Checking the Normal Display 3

5.2 EDS File 3

6 Associated Documents 3

7 Troubleshooting 3

7.1 Workmanship 3

8 How to Order Parts 3

9 Regulatory Information 3

10 Wiring Diagram 3

2

2

2

3

4

5

5

5

6

7

7

8

4

Page 5

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Declaration of Conformity

to the DeviceNet™ Specification

DeviceNet and the DeviceNet CONFORMANCE TESTED logo mark and word marks are trademarks of ODVA.

Copyright © ODVA Inc. 2004 PUB00014R4 www.odva.org Page 1 of 1

ODVA hereby issues this Declaration of Conformity to the DeviceNet™ Specification for the product(s) described below. The Vendor

listed below (the "Vendor") has holds a valid the Terms of Usage Agreement for the DeviceNet Technology from ODVA, which is

incorporated herein by reference, thereby agreeing that it is the Vendor’s ultimate responsibility to assure that its DeviceNet

Compliant Products conform to the DeviceNet Specifications and that the DeviceNet Specifications are provided by ODVA to the

vendor on an AS IS basis without warranty. NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE BEING PROVIDED BY ODVA.

In recognition of the below DeviceNet Compliant Product(s) having been DeviceNet Conformance Tested at ODVA-authorized Test

Service Provider and having received a passing result from ODVA at the Composite Test Revision Level specified below, this

Declaration of Conformity authorizes the Vendor to use the DeviceNet Certification Marks in conjunction with the specific DeviceNet

Compliant Product(s) described below, for so long as the Vendor's Terms of Usage Agreement for the DeviceNet Technology remains

valid.

DeviceNet CONFORMANCE TESTED ™

Certification Logo Mark Certification Word Mark

This Declaration of Conformity is issued on 27 February 2006

on behalf of ODVA by:

Katherine Voss

Executive Director

Vendor Information

Vendor Name Flowserve Corporation

Vendor Address 5114 Woodall Road

Lynchburg, VA 24506

USA

Test Information

Test Date 16-17 February 2006

Composite Test Revision 18

ODVA File Number 10331

Product Information

Identity Object Instance 1

Device(s) Under Test Value

Vendor ID (Identity Object Attribute 1) 966

Network Category Node

Device Type (Identity Object Attribute 2) 0

Device Profile Name Generic Device

Product Revision (Identity Object Attribute 4) 1.002

Products Covered Under This Declaration of Conformity

No. Product Code (Identity Object Attribute 3) Product Name (Identity Object Attribute 7) SOC File Name

1 19800 Flowserve MX DLI.stc

Declaration of DeviceNet Conformance –

ODVA Certification

5

flowserve.com

Page 6

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Abbreviations

CIP Common Industrial Protocol

CAN Controller Area Network

COS Change of State

ODVA Open DeviceNet Vendor Association

UCMM Unconnected Message Manager

NV-RO Non-Volatile Read Only. Data is stored in non-volatile memory and can only be read. Data is

stored during Power-Off. For DeviceNet Limitorque Interface this storage area is FLASH

NV-RW Non-Volatile Read Write. Data is stored in non-volatile memory and can be read and write.

Data is stored during Power-Off. For DeviceNet Limitorque Interface this storage area is EEPROM

V-RO Volatile Read Only. Data is stored in volatile memory and can only be read (e.g. Status). Data is

lost during Power-Off. For DeviceNet Limitorque Interface this storage area is RAM

V-RW Volatile Read Write. Data is stored in volatile memory and can be read and write data is lost

during Power-Off, for DeviceNet Limitorque Interface this storage area is RAM.

DNFU DeviceNet Field Unit (PCB w/in actuator control compartment)

SPI Synchronous Peripheral Interface

PCB Printed Circuit Board

6

Page 7

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

1 Introduction

1.1 Purpose

This manual explains how to install and operate the Limitorque MX™/DeviceNet field unit (DNFU) and is

to be used as an addendum to Bulletin LMENIM2306, Limitorque MX Installation and Operation Manual.

Up to 63 actuators, each containing a DeviceNet field unit, may be connected by a single 5 strand,

twisted-pair cable to form a DeviceNet network, two wires for connection to the data highway and two

wires for connection to the DC power lines of the network highway, plus a screen connection. A suitable

power supply and termination resistors on the highway are required in order for the FU to function

correctly. This network permits the actuators to be operated by various control room devices such as a

distributed control system (DCS), a programmable logic controller (PLC), or a personal computer (PC).

The DeviceNet system communicates status and alarm data from each MX actuator.

1.2 How to Use this Manual

Each section provides the MX user with information on installing and operating the MX DNFU.

Section 1, Introduction: Details user safety and knowledge requirements, system capabilities, and

features.

Section 2, System Components: Focuses on the description of the DeviceNet system hardware and

software components.

Section 3, Installation and Configuration: Provides details for installing and configuring a DNFU.

Section 4, Object Model Diagram: Provides a list of inputs and outputs supported through the Assembly

Object system information.

Section 5, View DeviceNet Status

Section 6, Associated Documents

Section 7, Troubleshooting

Section 8, How to Order Parts

Section 9, Regulatory Information

Section 10, Wiring Diagram

1.3 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury

and damage to the equipment. The user must read and be familiar with these instructions before

attempting installation, operation, or maintenance. Failure to observe these precautions could result

in serious bodily injury, damage to the equipment, warranty void, or operational difficulty. User must

follow local and state safety regulations.

Safety notices are presented in this manual in three forms:

WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow

c

warning notices could result in personal injury or death.

c

7

flowserve.com

Page 8

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in

a

personal injury and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the actuator’s installation and

operation.

1.4 User Knowledge

It is recommended that the user read this manual in its entirety before the DeviceNet equipped actuator

is installed and operated.

The user needs to have a fundamental knowledge of electronics and microprocessor concepts. An

understanding of valve actuators and digital control systems is also of benefit to the DNFU user.

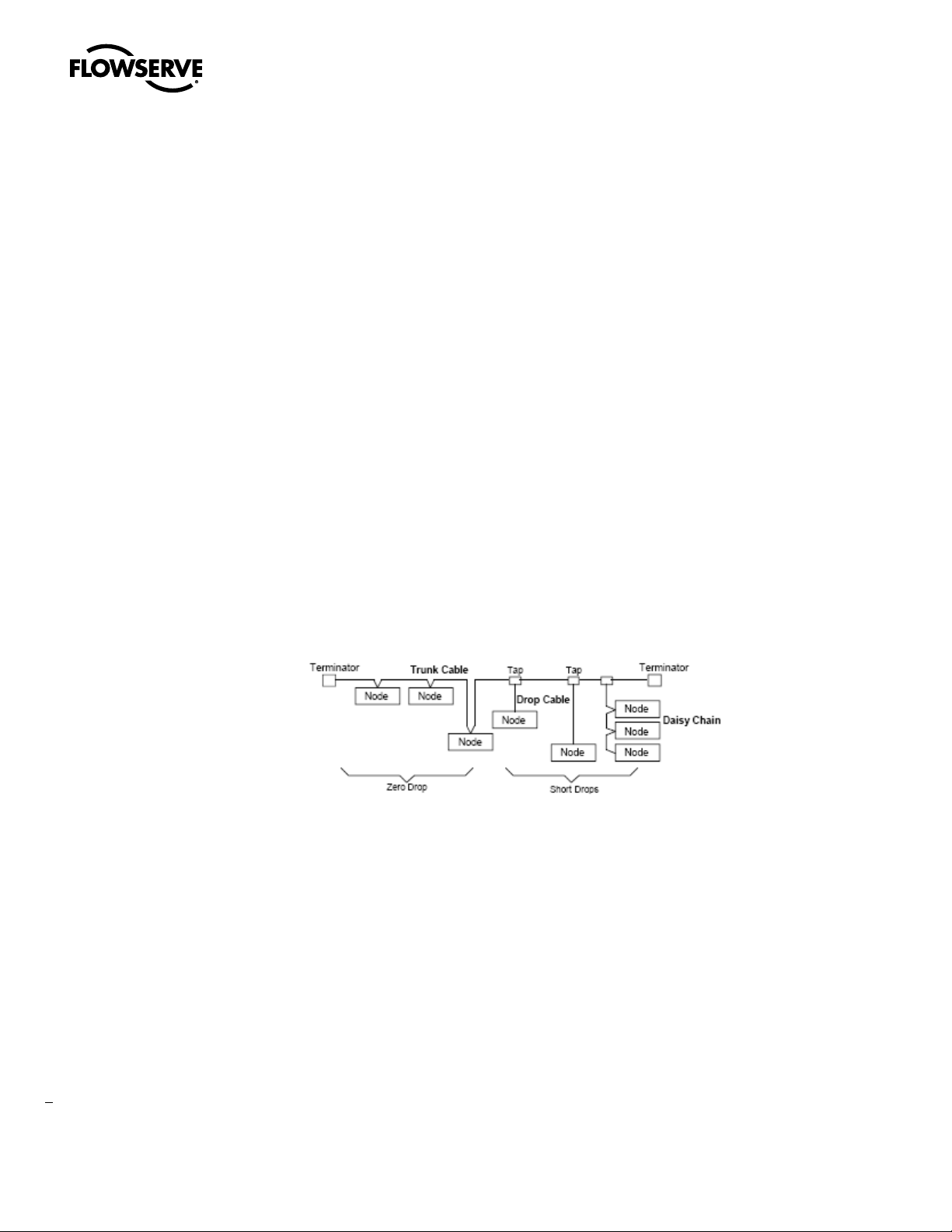

1.5 DeviceNet System Capabilities and Features

DeviceNet is a low cost communications protocol which permits up to 64 nodes (devices) to be

installed over a single network and is based upon CAN (Controller Area Network), a broadcast protocol

developed for the automotive industry. DeviceNet™ protocol is defined as an open network standard and

Limitorque’s device is certified for use by the ODVA, Open Device Standard Association. DeviceNet is

usually PLC input controlled and the Limitorque MX electronic actuator is well suited for this communication system. A typical network is seen in Figure 1.1.

Figure 1.1 – Typical Network

1.5.1 General Specifications

1.5.1.1 Network Specifications

DeviceNet is a digital, trunk/drop network that connects and serves as a communication network

between industrial controllers and I/O devices.

DeviceNet follows the Open Systems Interconnection (OSI) model, an ISO standard for network

communications that is hierarchical in nature. Networks that follow this model define all necessary functions from the physical implementation up to the protocol and methodology to communicate control

and information data within and across networks.

8

Page 9

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 1.1 – Network specifications

Network Size Up to 63 Nodes

Network Length Selectable end-to-end network distance varies with speed

Bus Topology Linear (trunkline/dropline); power and signal on the same network cable

Bus Addressing Multi-Master and Master/Slave special case; polled of change-of-state

System Features Selectable end-to-end network distance varies with speed

Termination resistor (121 ohms) must be used at each end of the network

1.5.1.2 MX Field Unit Specifications

CIP Generic Device Profile (Device Type = 00hex) extended to DNFU requirements

•

Group 2 Server

•

UCMM capable device

•

Predefined Master/Slave Connection Set supporting

•

Explicit Connection

•

Polled I/O Connection

•

Bit-Strobed I/O Connection

•

Change of State / Cyclic I/O Connection

•

Full support of fragmentation protocol

•

Device Heartbeat Message

•

Device Shutdown Message

•

Offline Connection Set

•

Galvanical Isolation: The isolation voltage for the DNFU is up to 1,500 VRMS for 1 minute (1,800

•

VRMS for 1 second

Power Supply: The DNFU Interface will be powered from the DeviceNet bus. A switching regulator is

•

used to generate the internal supply voltage: VCC nominal 5.0 V ± 5 %

Surge Suppression: The DNFU Interface is equipped with surge suppression for the DeviceNet

•

network data and power lines. Surge suppression is compliant with IEC 61000-6-2:2001.

125 Kbps 500 m (1,640 ft)

250 Kbps 250 m (820 ft)

500 Kbps 100 m (328 ft)

(exception-based)

Environmental conditions

The DNFU environmental parameters are within the same environmental constraints as the actuator.

9

flowserve.com

Page 10

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

2

1

2

3

7

8

4

5

11

12

10

6

9

2 System Components

2.1 Introduction

This section gives an overview of the components used in the DeviceNet system. The field unit is

installed in each MX actuator. The network cable connects the field unit to the network via the actuator

terminal block. The network cable is connected to a host controller, typically a PLC.

2.2 Hardware

NOTE: Recommended storage procedures are detailed in Bulletin LMAIM1314 Limitorque MX

Maintenance and Spare Parts Manual. Failure to comply with recommended procedures will void the

warranty. For longer-term storage, contact Limitorque for procedures and recommendations.

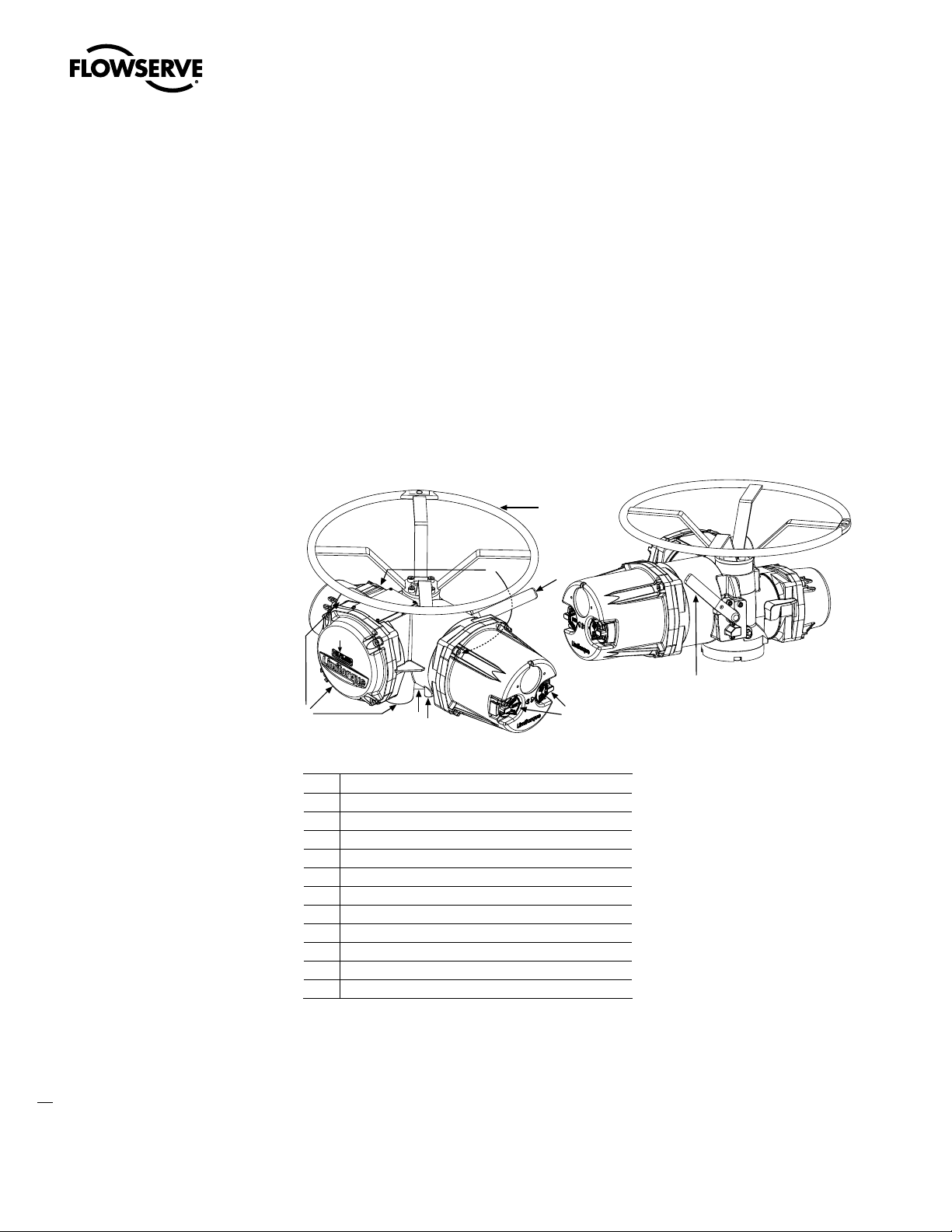

Figure 2.1 – MX-05 Actuator

10

Table 2.1 – MX-05 Actuator

1 Handwheel

2 Declutch Lever

3 Oil Fills (dotted arrow depicts fill on declutch side)

4 Controls Compartment (field unit location)

5 LCD Display

6 Control Knobs

7 Ground Lug

8 Thrust/Torque Base

9 Conduit Entries

10 Terminal Compartment

11 Motor

12 Nameplate

2.2.1 Limitorque MX

The MX is a multi-turn valve actuator designed for operation of ON-OFF and modulating valve applications. This actuator controls the opening and closing of valves. See Figure 2.1.

Page 11

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

The MX features include:

Non-intrusive setup

•

Separately sealed terminal chamber

•

Patented absolute encoder for valve position sensing (no battery required)

•

32-character LCD for indication and calibration with configuration permitted in six languages.

•

Sophisticated electronic control, monitoring, and diagnostic capabilities with patented LimiGard™

•

technology

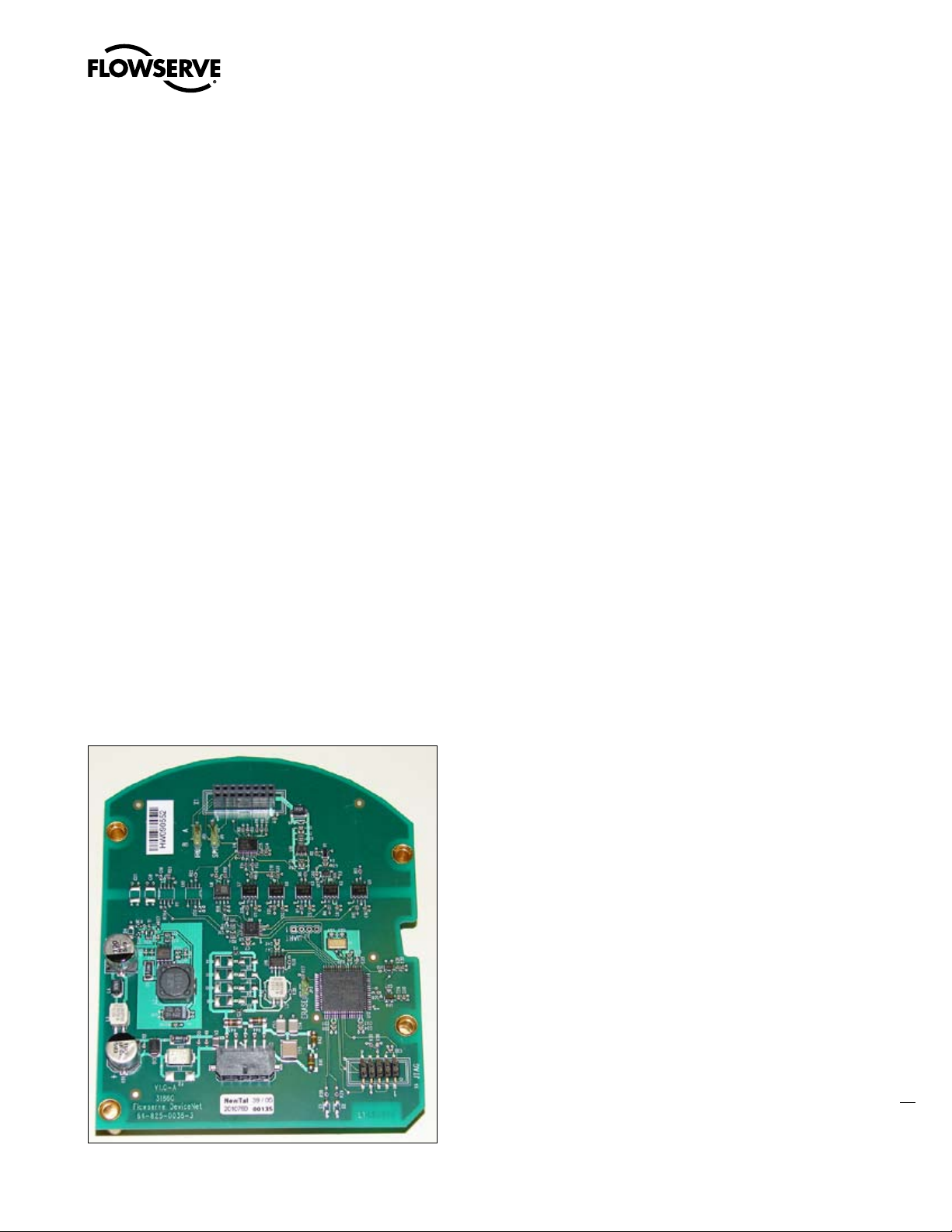

2.2.2 DeviceNet Field Unit

The DeviceNet field unit is installed in the MX controls compartment. This unit permits the actuator to

be controlled by a host controller, typically a PLC, via the DeviceNet network. The DNFU includes two

high-level, surge-protected, and isolated network communication channels, configurable digital I/O, and

configuration via LCD screen. The following commands and information may be transmitted over the

DeviceNet network:

“OPEN,” “STOP,” and “CLOSE” commands

•

“ESD” and “MOVE–TO” position commands

•

Actuator status and alarm messages

•

Six digital inputs and two analog inputs for user

•

A surge-protected and isolated communication channels

•

MX control panel configuration

•

Torque output (for reference only) and position feedback

•

Four digital outputs (standard)

•

Figure 2.2 – DeviceNet Field Unit

11

flowserve.com

Page 12

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

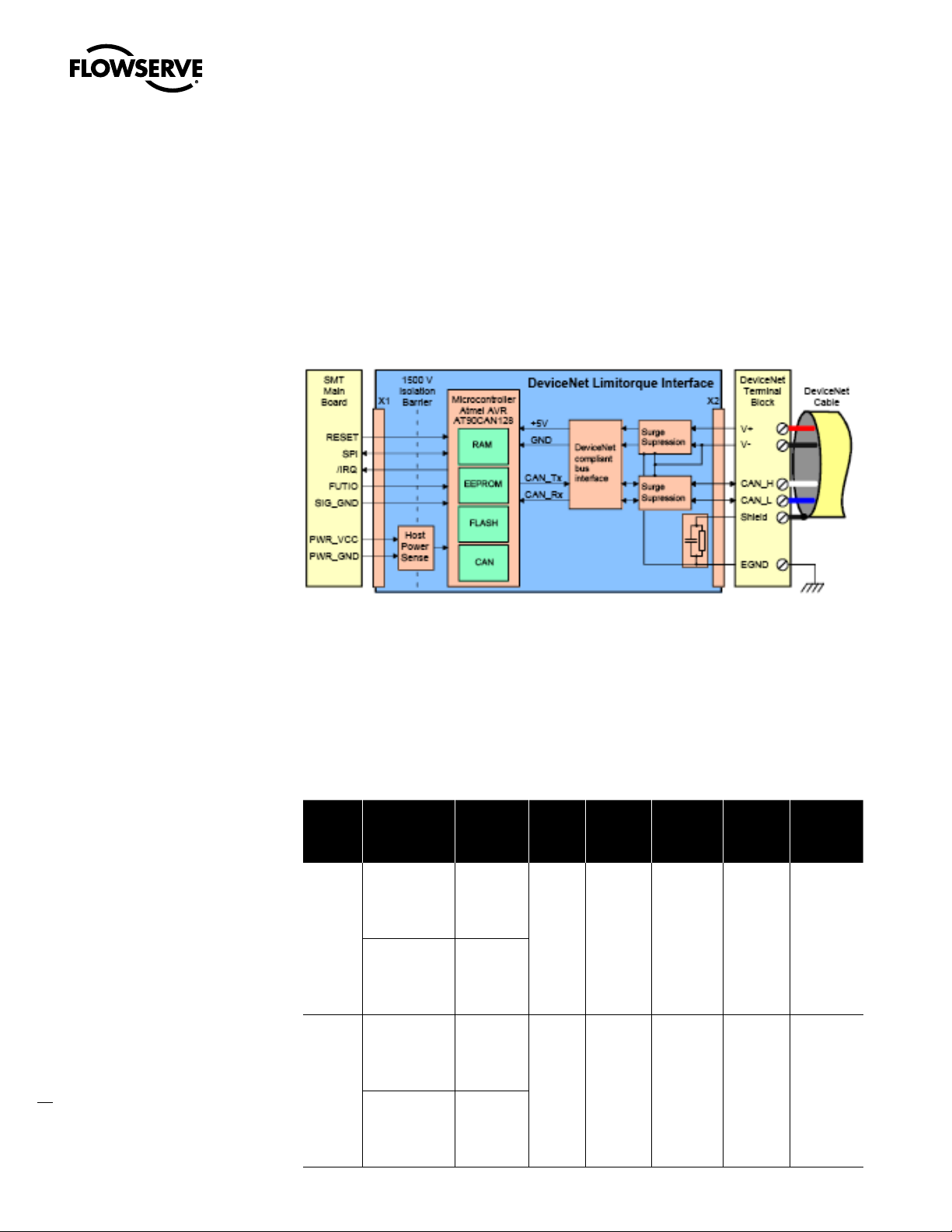

2.2.3 Hardware interface

The DeviceNet Limitorque Interface is comprised of a minimum of one PCB with two interfaces - One

for the DeviceNet Terminal Block connector and one for the SMT Main Board.

Figure 2.3 gives an overview about the hardware. The microcontroller on the DeviceNet Limitorque

Interface handles the DeviceNet protocol, stores the DeviceNet parameters in an EEPROM, and communicates with the SMT Main Board via SPI.

Figure 2.3 – DeviceNet Limitorque Interface

12

2.2.4 Network Cable

DeviceNet is a CAN - based protocol that uses 5 wires including a shield. Two of the conductors are

used for 24V DC power & up to 8 amps (4 amps for NEC Class 2) may be passed along the hi-way from

a suitable power source. Two conductors are used for the CAN bus signals, CAN_H and CAN_L, which

are usually smaller in diameter. Limitorque recommends Belden cable for connecting to a DeviceNet

network. The specifications for thick and thin cable (per site requirements) are as follows:

Table 2.2 – Belden Cable Specifications

Belden

Part No.

3082A

3084A

AWG

(Stranding)

dia. Inches

Nom. DCR

2 – 15 AWG

(19 x 28)

3.6 ohm/1000 ft

11.8 ohm/km

2 – 18 AWG

(19 x 30)

6.9 ohm/1000 ft

22.7 ohm/km

2 – 22 AWG

(19 x 34)

17.5 ohm/1000 ft

57.4 ohm/km

2 – 18 AWG

(19 x 36)

28.0 ohm/1000 ft

91.9 ohm/km

Insulation

material

(color code)

Power pair

(Black/Red)

Data pair

(Blue/White)

Power pair

(Black/Red)

Data pair

(Blue/White)

Nominal

O.D.

12.2 mm

7.2 mm 120 12.0 pF/ft

Nom

Impedance

(ohms)

120 12.0 pF/ft

Capacitance

Nominal

Test

Frequency

(MHz)

0.125

0.5

1

0.125

0.5

1

Maximum

Attenuation

dB/100ft

0.13

0.25

1.36

0.29

0.50

1.70

Page 13

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 2.3 – Total cable length between repeaters or nodes:

Network Size 125 KBPS 250 KBPS 500 KBPS

Thick Trunk Length 500 m (1,640 ft) 250 m (1,640 ft) 100 m (1,640 ft)

Thin Trunk Length 100 m (328 ft) 100 m (328 ft) 100 m (328 ft)

Flat Trunk Length 380 m (1,250 ft) 200 m (656 ft) 75 m (246 ft)

Maximum Drop Length 6 m (20 ft) 6 m (20 ft) 6 m (20 ft)

Cumulative Drop Length 156 m (512 ft) 78 m (256 ft) 39 m (128 ft)

Note: Each actuator includes 0.60 meters of internal drop length.

3 Installation and Configuration

3.1 Site and Network Cable Preparation

3.1.1 Site Preparation

Prepare the site and associated equipment for operation of the DeviceNet controlled MX actuators as

follows:

1. Prepare a detailed site plan consisting of the following:

Actuator locations, tag numbers, DeviceNet addresses

•

Junction boxes, terminal strip locations, and tag numbers

•

2. Provide free access to the MX control panel and terminal block for setup, configuration, and

troubleshooting.

3. Prepare cable and label all wires. See Section 3.1.2, Network Cable Preparation.

4. Install power and control wires in separate conduits. Shielding is not sufficient to prevent induction

of stray voltages onto signal leads from the power lines.

5. Install and verify earth grounds.

NOTE: Limitorque defines an effective local earth ground as a low impedance (less than 5 ohms) path

to:

A ground electrode placed in close vicinity of the actuator that is free of ground loop currents. OR

•

A safety ground that is free of ground loop currents running from the actuator back to the system

•

ground electrode. If the signal wiring is run on aerial cable where it may be exposed to highenergy electrostatic discharge (such as lightning), a low impedance path to ground that is capable

of high current must be provided a short distance from the actuator as described above. OR

A power distribution grid identifying the impact of power isolation to a particular actuator or

•

group of actuators should be provided.

3.1.2 Network Cable Preparation

3.1.2.1 Network Cable Connection to the Field Unit

The DeviceNet field unit is connected to the network via the MX terminal block. The network cable is

connected to the terminal block as shown in Figure 3.1.

13

flowserve.com

Page 14

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

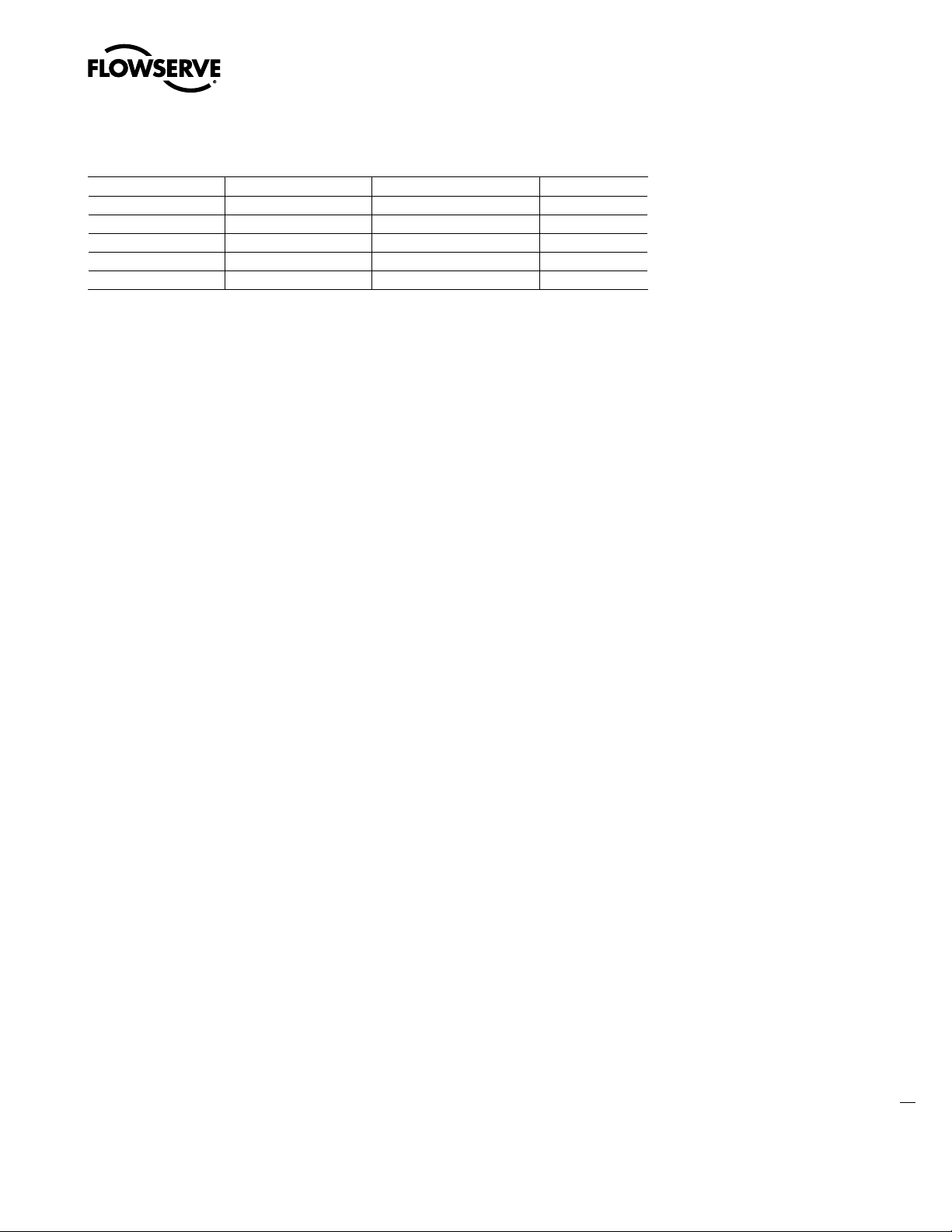

Figure 3.1 – Network cable connection to terminal block

NOTE: Recommended DeviceNet cable is Belden 3084A or equal. 121 ohm, ¼ W +/-1% termination

resistors must be connected at each segment end. Customer is required to connect wire between

terminal 30 and chassis ground for surge protection. Preferred network wiring is to connect shield to

terminal 48 for only one unit on each segment. Connect remaining individual network cable shields

together to ensure proper shielding of entire network. Consult wiring diagram for exact terminal

connection points as they may change.

Prepare the network cable for connection to the MX terminal block as follows.

CAUTION: Strip stranded conductors carefully; do not damage the strands. This will weaken the

a

conductor. Do not nick conductors or conductor insulation when stripping away the insulation.

Nicking stresses the conductor and can cause the conductor to break. This type of damage may

not be apparent and failure can occur later without warning.

NOTE: Excess cable should be cut, not coiled or looped, to prevent noise induction into the network and

to reduce signal loss through unnecessarily long cable runs.

Cable Preparation

1. Remove two to three inches (5 to 8 cm) of the outer plastic jacket.

2. Separate the cable parts. Unbraid the shield and peel back the foil shield to the same point where

the outer jacket was removed. Cut away the braided shield and the foil shield. Strip the insulation

from the conductors approximately 0.4 inch (1 cm).

3. Apply heat shrink tubing to insulate the drain wire and to provide stress relief to the cable.

CAUTION: Do not melt the insulation. NOTE: Ungrounded drain wires should be cut even with

a

the cable sheath. The brand foil and drain wire should have heat shrink tubing applied.

4. Install ring tongue connectors. Flowserve recommends the use of Thomas & Betts #RZ22-6 for

optimum results.

14

5. Connect the network cables to the MX terminal block as shown in Wiring Diagram #18-499-0038-3.

Table 3.1

48 Shield

15 (Blue) DATA (-)

16 (White) DATA (+)

29 (Black) Network 0 V

41 (Red) Network 24V

30 Earth ground for surge protection circuit

Page 15

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

NOTE: Ground each segment of the cabling at only one point to prevent ground loops, which can affect system

performance. Verify the actuator is properly grounded.

6. Install jumper cable from terminal block pin 30 to earth ground or ground lug.

3.2 Installation Verification

3.2.1 Network Cabling Installation Verification

After installation is complete and prior to operation, inspect the network cable and its connection to

each field unit for the following:

NOTE: Units should be disconnected from power. Network should be disconnected from host.

1. There should be:

No nicks in the insulation—this can cause a short between conductors or to the grounded shield.

•

No cut strands in a stranded conductor—this can cause a poor connection and eventually an

•

open circuit.

2. Verify that there is data wiring on each actuator per wiring diagram.

3. Cable armor should not be shorted to the cable shield/drain wire. Cable armor may not be at ground

potential and could be subject to lightning surges.

The shield/drain wire should only be grounded at one end of each cable segment (the section between

adjacent actuators between the host system and an actuator) to avoid ground loop problems.

The ground/earth connection should be at true ground potential and effective at all times. See Section

3.1.1, Site Preparation.

3.2.2 DNFU Installation Verification

NOTE: Connect to either 24 V DC power or mains and activate power.

Verify the field unit is installed as follows:

1. Enter the “SETUP” mode as detailed in Bulletin LMAIM1306/2306, MX Installation and Operation

Manual.

2. In the “SETUP” mode, use the black control knob to select “YES” to the main menu selection “VIEW

DIAGNOSTICS?”

3. Select “YES” to the display “VIEW HARDWARE STATUS?”

4. Select “YES” to scroll through the menu selections. The LCD will read “DeviceNet (OK) – NEXT?” if

installed.

NOTE: If the “DeviceNet (OK) – NEXT?” does not appear, contact Flowserve for assistance.

19. To return to the normal display, use the red knob to select either “LOCAL” or “REMOTE.”

15

flowserve.com

Page 16

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

4 Object Model Diagram

Figure 4.1 – Object Model of DeviceNet Limitorque Interface

16

4.1 Assembly Objects

The Assembly Object binds attributes of multiple objects, which allows data to or from each object to

be sent or received over a single connection. Assembly Objects can be used to bind input data or output

data. The terms input and output are defined from the networks point of view. An input will produce data

on the network and an output will consume data from the network

The terms input and output are defined from the networks point of view.

An input is a signal produced at the actuator and sent to the PLC via the network. •

Page 17

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

An output is a signal produced at the PLC and sent to the actuator via the

•

network.

The user may select one output and one input instance.

The default assembly objects are as follows: Polled input - 105, Polled output - 100, Bitstrobe - 107,

COS - 109.

Table 4.1

Instance ID Type Data Component Name Size

100 Output Output 1 (All Control Channels) 9

101 Output Output 2 (Analog Control and ESD only) 5

102 Output Output 3 (Discrete Control and ESD only) 4

103 Output Output 4 (Analog Control only) 3

104 Output Output 5 (Discrete Control only) 3

105 Input Input 1 (All Status Information) 16

106 Input Input 2 (Position and Faults only) 6

107 Input Input 3 (Position and Faults only) 8

108 Input Input 4 (Position, User and Faults only) 11

109 Input Input 5 (Faults and Alarms only) 6

4.2 Output Assembly Instances

Table 4.2 – Output Assembly Instance 100

Assembly

Object

Instance ID

100 Output 1 100 Channel

Data

Component

Name

Table 4.3 – Output Assembly Instance 101

Assembly

Object

Instance ID

101 Output 2 100 Channel

Data

Component

Name

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

Instance

ID

1 20 Ctrl_Status_Chan BYTE

1 1 AO_Ctrl_Valve_ Flow_Chan INT

1 9 DO_Position_Chan BYTE

1 21 DO_ESD_Poll_Cnxn BOOL

1 11 DO_Relay_Chan BYTE

1 18 DO_Move_Test_Chan BOOL

1 19 AO_Analog_Output_Chan UNIT

Instance

ID

1 20 Ctrl_Status_Chan BYTE

1 1 AO_Ctrl_Valve_ Flow_Chan INT

1 21 DO_ESD_Poll_Cnxn BOOL

1 10 DO_Move_Test_Chan BOOL

Attribute

Data

Type

Attribute

Data

Type

17

flowserve.com

Page 18

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.4 – Output Assembly Instance 102

Assembly

Object

Instance ID

102 Output 3 100 Channel

Data

Component

Name

Table 4.5 – Output Assembly Instance 103

Assembly

Object

Instance ID

103 Output 4 100 Channel

Data

Component

Name

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

Class

ID Name ID Name

Interface

100 Channel

Interface

Instance

ID

1 20 Ctrl_Status_Chan BYTE

1 9 DO_Position_Chan BYTE

1 21 DO_ESD_Poll_Cnxn BOOL

1 18 DO_Move_ Test_Chan BOOL

Instance

ID

1 20 Ctrl_Status_Chan BYTE

1 1 AO_Ctrl_Valve_ Flow_Chan INT

Attribute

Data

Type

Attribute

Data

Type

Table 4.6

Assembly

Object

Instance ID

104 Output 5 100 Channel

Data

Component

Name

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

Instance

ID

1 20 Ctrl_Status_Chan BYTE

1 9 DO_Position_Chan BYTE

1 21 DO_ESD_Poll_Cnxn BOOL

Attribute

Data

Type

18

Page 19

Table 4.7 – Input Assembly Instance 105

Assembly

Object

Instance ID

105 Input 1 100 Channel

Data

Component

Name

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Instance

ID

1 17 DI_Actuator_

1 4 DI_Actuator_

1 6 DI_Actuator_ Alarms_Chan BYTE

1 2 DI_Pos_And_

1 5 DI_Actuator_

1 12 AI_Position_Chan INT

1 7 DI_Disc_User_ Input_Chan BYTE

1 8 DI_Read_Disc_

1 13 AI_Analog_ Input_2_Chan INT

1 14 AI_Analog_ Input_2_Chan INT

1 16 DI_Alarms_2_

1 15 AI_Torque_Chan INT

Attribute

Data

Type

BYTE

Faults_3_Chan

BYTE

Faults_1_Chan

BYTE

Bus_Mode_Chan

BYTE

Faults_2_Chan

BYTE

Output_Chan

BYTE

Chan

Table 4.8

Assembly

Object

Instance ID

106 Input 2 100 Channel

Data

Component

Name

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

Instance

ID

1 17 DI_Actuator_

1 4 DI_Actuator_

1 6 DI_Actuator_ Alarms_Chan BYTE

1 2 DI_Pos_And_

1 12 AI_Position_Chan INT

Attribute

Data

Type

BYTE

Faults_3_Chan

BYTE

Faults_1_Chan

BYTE

Bus_Mode_Chan

19

flowserve.com

Page 20

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.9 – Input Assembly Instance 107

Assembly

Object

Instance ID

107 Input 3 100 Channel

Data

Component

Name

Table 4.10 Input Assembly Instance 108

Assembly

Object

Instance ID

108 Input 4 100 Channel

Data

Component

Name

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

Instance

ID

1 17 DI_Actuator_

1 4 DI_Actuator_

1 6 DI_Actuator_ Alarms_Chan BYTE

1 2 DI_Pos_And_

1 12 AI_Position_Chan INT

1 15 AI_Torque_Chan INT

Instance

ID

1 17 DI_Actuator_

1 4 DI_Actuator_

1 6 DI_Actuator_ Alarms_Chan BYTE

1 2 DI_Pos_And_

1 12 AI_Position_Chan INT

1 7 DI_Disc_User_ Input_Chan BYTE

1 13 AI_Analog_ Input_2_Chan INT

1 15 AI_Torque_Chan INT

Attribute

Data

Type

BYTE

Faults_3_Chan

BYTE

Faults_1_Chan

BYTE

Bus_Mode_Chan

Attribute

Data

Type

BYTE

Faults_3_Chan

BYTE

Faults_1_Chan

BYTE

Bus_Mode_Chan

20

Table 4.11 Input Assembly Instance 109

Assembly

Object

Instance ID

109 Input 5 100 Channel

Data

Component

Name

Class

ID Name ID Name

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

100 Channel

Interface

Instance

ID

1 17 DI_Actuator_

1 4 DI_Actuator_

1 6 DI_Actuator_ Alarms_Chan BYTE

1 2 DI_Pos_And_

1 5 DI_Actuator_

1 16 DI_Alarms_2_

Attribute

Data

Type

BYTE

Faults_3_Chan

BYTE

Faults_1_Chan

BYTE

Bus_Mode_Chan

BYTE

Faults_2_Chan

BYTE

Chan

Page 21

4.2.1 DI_Position_and_Bus_Mode_Chan

Table 4.12

Value Definition

0x21 Remote + Opened

0x22 Remote + Closed

0x24 Remote + Opening

0x28 Remote + Closing

0x30 Remote + Stop

0x41 Local + Opened

0x42 Local + Closed

0x44 Local + Opening

0x48 Local + Closing

0x50 Local + Stop

0x81 Stop + Opened

0x82 Stop + Closed

0x84 Stop + Opening

0x88 Stop + Closing

0x90 Stop + Stop

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

4.2.2 DI_Position_Chan

Table 4.13

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved Reserved Stop Closing Opening Closed Opened

Table 4.14 – Possible values of DI_Position_Chan

Value Definition

0x01 Opened

0x02 Closed

0x04 Opening

0x08 Closing

0x10 Stop

4.2.3 DI_Actuator_Faults_1_Chan

Table 4.15

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved Motor Over

Temp

Phase Error Over Torque Manual

Moved

Valve

Jammed

Monitor

Relay

flowserve.com

21

Page 22

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.16 – Possible values of DI_Actuator_Faults_1_Chan

Value Definition

0x01 Monitor Relay

0x02 Valve Jammed

0x04 Manual Moved

0x08 Over Torque

0x10 Phase Error

0x20 Motor Over Temperature

0x03 Monitor Relay + Valve Jammed

0x05 Monitor Relay + Manual Moved

0x09 Monitor Relay + Over Torque

0x11 Monitor Relay + Phase Error

0x21 Monitor Relay + Motor Over

0x07 Monitor Relay + Valve Jammed +

0x13 Monitor Relay + Valve Jammed +

0x23 Monitor Relay + Valve Jammed

Temperature

Manual Moved

Phase Error

Motor Over Temperature

22

4.2.4 DI_Actuator_Faults_2_Chan

Table 4.17

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved Close

Torque

Switch Fault

Open Torque

Switch Fault

Manual

Moved

Valve

Jammed

Phase Error Thermal

Overload

Table 4.18 – Possible values of DI_Actuator_Faults_2_Chan

Value Definition

0x01 Thermal Overload

0x02 Phase Error

0x04 Valve Jammed

0x08 Manual Moved

0x10 Open Torque Switch Fault

0x20 Close Torque Switch Fault

0x03 Thermal Overload + Phase Error

0x05 Thermal Overload + Valve Jammed

0x09 Thermal Overload + Manual Moved

0x18 Manual Moved + Open Torque Switch Fault

0x28 Manual Moved + Close Torque Switch Fault

4.2.5 DI_Actuator_Alarms_Chan

Table 4.19

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved Move Test

Active*

* Available with Revision 1 to DeviceNet board.

Not in

Remote

Close Inhibit

Active

Open Inhibit

Active

Remote ESD

Active

Local ESD

Active

Page 23

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.20 – Possible values of DI_Actuator_Alarms_Chan

Value Definition

0x01 Local ESD Active

0x02 Remote ESD Active

0x04 Open Inhibit Active

0x08 Close Inhibit Active

0x05 Local ESD Active + Open Inhibit Active

0x09 Local ESD Active + Close Inhibit Active

0x06 Remote ESD Active + Open Inhibit Active

0x0A Remote ESD Active + Open Inhibit Active

0x0C Open Inhibit Active + Close Inhibit Active

4.2.6 DI_Disc_User_Input_Chan

Table 4.21

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Discrete

Input #8

Discrete

Input #7

Discrete

Input #6

Discrete

Input #5

Discrete

Input #4

Discrete

Input #3

Discrete

Input #2

Discrete

Input #1

4.2.7 DI_Read_Disc_Output_Chan

Table 4.22

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Relay

Discrete

Output #7

Relay

Discrete

Output6 #

Relay

Discrete

Output #5

Relay

Discrete

Output #4

Relay

Discrete

Output #3

Relay

Discrete

Output #2

Relay

Discrete

Output #1

4.2.8 DO_Position_Chan

Table 4.23

Value Definition

0x00 Stop

0x01 Open

0x02 Close

0x03

– 0xFF

Reserved

4.2.9 DO_ESD_Chan (Read Only)

Table 4.24

Value Definition

0x00 Disable Network ESD

0x01 Enable Network ESD

DO_ESD_Chan can’t be written directly via the DeviceNet network, it is Read-Only. The attribute

Enable_Broadcast_ESD_Ctrl defines if a device is part of the broadcast ESD control scheme from BitStrobe Connection or not. The resulting DO_ESD_Chan is defined in the following table.

The MX allows the standard I/O connection to assert ESD, or the broadcast bit strobe connection to

assert ESD.

23

flowserve.com

Page 24

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.25

DO_ESD_ Poll_Cnxn

Attribute 21

X 0 X 0 0

0 1 X 0 0

1 1 X 0 1

X 0 0 1 0

X 0 1 1 1

1 1 1 1 1

0 1 0 1 0

0 1 1 1 1

1 1 0 1 1

Ctrl_Status_Chan

Attribute 20

Bit 2

DO_ESD_

Bit_Strobe_Cnxn

Attribute 22

Enable_Broadcast_

ESD_Ctrl

Attribute 23

DO_ESD_ Chan

4.2.10 DO_Relay_Chan

Table 4.26 Available with Revision 1 to DeviceNet board

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved User Output

AR-3

User Output

AR-2

User Output

AR-1

User Output

AS-4

User Output

AS-3

User Output

AS-2

User Output

AS-1

4.2.11 DI_Actuator_Faults_3_Chan

Available with Revision 1 to DeviceNet board.

Table 4.27

Bit 7 – Bit 4 Bit 6 Bit 5 Bit 4 Bit 3

Reserved Reserved Interboard Power

failure

Interboard

Communications

Failure

Reserved

4.2.12 Ctrl_Status_Chan

Outputs are not used by the device unless the corresponding bit from the table below is enabled.

Table 4.28

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved Reserved Reserved DO_ Relay_

Chan

DO_

ESD_Poll_

Cnxn

DO_

Position_

Chan

AO_ Ctrl_

Valve_

Flow_ Chan

4.2.13 DI_Alarms_2_Chan

Table 4.29

Bit 7 – Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Battery not installed

(only until first

time installed)

Flat battery indication Low battery

indication

Indication of

24VDC UPS

power available

24

Page 25

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

4.2.14 DI_Actuator_Faults_3_Chan

Table 4.30

Bit 7 – Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Low Battery

Indication

Interboard

Power Fault

Interboard

Communication Fault

Limiguard Fault

4.3 Channel Interface Object

Table 4.31

Data

Attribute ID Access Rule Name

1 RW AO_Crtl_Valve_ Flow_Chan INT Desired valve

2 RO DI_Position_And_

3 RO DI_Position_ Chan BYTE Valve Status Section 4.2.2

4 RO DI_actuator_ Faults_1_Chan BYTE Mechanical and

5 RO DI_actuator_ Faults_2_Chan BYTE Mechanical and

6 RO DI_Actuator_ Alarms_Chan BYTE Emergency shut-

7 RO DI_Disc_ User_Input_Chan BYTE Discrete input from

8 RO DI_Read_Disc_ Output_Chan BYTE Monitor state of

9 RW DO_Position_ Chan BYTE Command

10 RO DO_ESD_ Chan BOOL Command

11 RW DO_Relay_ Chan BYTE Command Energize

12 RO AI_Position_ Chan INT Current valve

13 RO AI_Analog_ Input_1_Chan INT Value of generic

14 RO AI_Analog_ Input_2_Chan INT Value of generic

15 Get

(V-RO)

Bus_Mode_Chan

AI_Torque_Chan INT Current torque

Description of

Type

Attribute

position

BYTE Valve Status and

Control Mode

electrical faults 1

electrical faults 2

down and inhibit

information

user

relay Discrete

outputs

Stop/Open/Close

Emergency

ShutDown

relays

position

Analog input 1

Analog input 2

output

Semantics of Value

Range 0 - 1000

Section 4.2.1

Section 4.2.3

Section 4.2.4

Section 4.2.5

Section 4.2.6

Section 4.2.7

Section 4.2.8

Section 4.2.9

Section 4.2.10

Range 0 - 1000

Range 0 – 100%

Range 0 – 100%

Range 0-120%

16 Get

(V-RO)

17 RO DI_actuator_ Faults_3_Chan BYTE Mechanical and

18 Get/Set

(V-RW)

19 Get/Set

(V-RW)

20 RW CTRL_Status_ Chan BYTE Set the status

Continued on next page

DI_Alarms_2_Chan BYTE Battery & power

supply information

electrical faults 3

DO_Move_Test_Chan BOOL Move test request 0-no request

AO_Analog_Output_Chan UINT Control of generic

analog output

associated with

the various control

values

Section 4.2.13

Section 4.2.14

1-request move test

Range 0-1000%

Section 4.2.12

25

flowserve.com

Page 26

26

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.31 – Continued

Data

Attribute ID Access Rule Name

21 Get/Set

(V-RW)

22 Get/Set

(V-RW)

23 Get/Set

(NV-RW)

DO_ESD_

Poll_Cnxn

DO_ESD_

Bit_Strobe_Cnxn

Enable_

Broadcast_

ESD_Ctrl

Description of

Type

Attribute

BOOL Command emer-

gency shutdown

from

Poll Connection

BOOL Command emer-

gency shutdown

from

Bit-Strobe

Connection

BOOL Enable device to

be a part of the

broadcast

ESD control scheme

from Bit-Strobe

Connection

Semantics of Value

Section 4.2.9

Section 4.2.9

Section 4.2.9

0 = Disable (Default)

1 = Enable

4.4 Transducer Block Object

Table 4.32

Attribute ID Access Rule Name Data Type Description Semantics of Value

1 RW Setp_Cutoff_Dec UINT When the servo

setpoint goes below

the defined percent

of span, the position

goes to the limit

position CLOSE

2 RW Setp_Cutoff_Inc UINT When the servo

setpoint goes above

the defined percent

of span, the position

goes to the limit

position OPEN

3 RO Scaled_values_0 WORD APT/ATT scaling

information

4 RO Scaled_values_1 WORD APT (Modbus

Register 3)

5 RO Scaled_values_2 WORD ATT (Modbus

Register 4)

6 RO TP_Status_0 UINT Reserved Engineering Use

7 RO TP_Status_1 UINT Start_Position Engineering Use

8 RO TP_Status_2 UINT Stop_Position Engineering Use

9 RO TP_Status_3 UINT Num_Samples Engineering Use

10 RO TP_Status_4 UINT Max_Torque_Mid Engineering Use

11 RO TP_Status_5 UINT Max_Torque

Postion

12 RO TP_Status_6 UINT Avg_Torque Engineering Use

13 RO TP_Status_7 UINT Stop_Torque Engineering Use

14 RO TP_Status_8 UINT Max_Torque_BOT Engineering Use

15 RO TP_Status_9 UINT Maz_Torque_EOR Engineering Use

16 RO TQ_Status_0 UINT Reserved Engineering Use

17 RO TQ_Status_1 UINT MB_TQ_Close_

Avg_Last

18 RO TQ_Status_2 UINT MB_TQ_Open_Avg_

Last

19 RO TQ_Status_3 UINT MB_TQ_Open_

Peak_Last

Continued on next page

Range 0 – 1000

Default = 0

Range 0 – 1000

Default = 0

See Table 4.33

Engineering Use

Engineering Use

Engineering Use

Engineering Use

Engineering Use

Engineering Use

Page 27

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.32 – Continued

Attribute ID Access Rule Name Data Type Description Semantics of Value

20 RO TQ_Status_4 UINT MB_TQ_Open_

Breakout_Last

21 RO TQ_Status_5 UINT MB_TQ_Close_

Breakout_Last

22 RO TQ_Status_6 UINT MB_TQ_Open_

Ending_Last

23 RO TQ_Status_7 UINT MB_TQ_Close_

Ending_Last

24 RO TQ_Status_8 UINT MB_TQ_Close_

Peak_Last

25 RO TQ_Status_9 UINT MB_TQ_Open_

Peak_Last

Engineering Use

Engineering Use

Engineering Use

Engineering Use

Engineering Use

Engineering Use

26 RO TQ_Status_10 UINT MB_TQ_Open_

27 RO TQ_Status_11 UINT MB_TQ_Close_

28 RO TQ_Status_12 UINT MB_TQ_Open_

29 RO TQ_Status_13 UINT MB_TQ_Close_

30 RO TQ_Status_14 UINT MB_TQ_Close_

31 RW Travel_Limit_Low UINT Lower limit of the

32 RW Travel_Limit_Up UINT Upper limit of the

33 RW Valve_Maint_ Date SHORT-

STRING

34 RW Valve_Serial_Num SHORT-

STRING

35 RO Valve_status_0 WORD Requested relay

36 RO Valve_status_1 WORD Status Register

37 RO Valve_status_2 WORD Fault Register

38 RO Valve_status_3 WORD Digital Output

39 RO Valve_status_4 WORD Digital Input #1

40 RW Valve_status_5 WORD Digital Input #2

Continued on next page

Breakout_Ref

Breakout_Ref

Ending_Ref

Ending_Ref

Peak_Ref

valve position in

percent of travel

span

valve position in

percent of travel

span

Date of last valve

maintenance

Serial number of

the valve belonging

to the positioner of

electronic device

channel value

– Modbus Register

9

– Modbus Register

10

Register – Modbus

Register 11

Register – Modbus

Register 12

Register – Modbus

Register 13

Engineering Use

Engineering Use

Engineering Use

Engineering Use

Engineering Use

Range 0 – 1000

Default = 0

Range 0 – 1000

Default = 0

String length is limited

to 16 char. Default = 0

(empty)

String length is limited

to 16 char. Default = 0

(empty)

Default = 0

Default = 0

Default = 0

Default = 0

Default = 0

Default = 0

27

flowserve.com

Page 28

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.32 – Continued

Attribute ID Access Rule Name Data Type Description Semantics of Value

41 RW Valve_Type USINT Type of valve 0 = linear moving

42 RO Actuator_Type USINT Type of actuator 0 = electropneumatic

43 RO Diagnostic_ Values_0 UINT Reserved Engineering Use

44 RO Diagnostic_ Values_1 UINT Main Voltage Engineering Use

45 RO Diagnostic_ Values_2 UINT Actuator Position Engineering Use

46 Diagnostic_ Values_3 UINT Analog input #1 Engineering Use

47 Diagnostic_ Values_4 UINT Analog Input #2 Engineering Use

48 RW Tag_Name SHORT-

49 Get/Set

(NV-RW)

50 Get/Set

(NV-RW)

51 Get/Set

(NV-RW)

52 Get/Set

(NV-RW)

53 Get/Set

(NV-RW)

54 Get/Set

(NV-RW)

55 RW Actuator_Control_

Comm_Loss_

Action

Comm_Loss_

Position

Comm_Loss_

Timeout

Deadband UINT Deadband

Proportional_

Band

TQ_Switch_

Adjust

Mode

STRING

USINT Actuator action

UINT Position to take

UINT Time to wait

UINT Proportional band

USINT Percentage of full

USINT Configure actuator

Tag name for

generic use

upon detection of

communication loss

upon a communica-

tion loss

after detection of

communication loss

until actuator action

is taken

percentage to use

when positioning

percentage to use

when positioning

torque to limit

operation to

for open/close

or positioning

operation

valve, sliding valve

(Default) 1 = rotary

moving valve, partturn 2 = rotary moving

valve, multi-turn

1 = electric (default)

2 = electrohydraulic 3

= others

String length is limited

to 32 char. Default = 0

(empty)

0 = No Action

(Default)

1 = Open

2 = Close

3 = Stop

4 = Preset Position

Range = 0 – 1000

Default = 0

Range = 0 – 4095

Default = 255

Range = 0 – 1000

Default = 2

Range = 0 – 1000

Default = 8

Range = 0 – 100 %

Default = 0 (Disabled)

1 = Analog

(Positioning Mode)

2 = Digital (Open/

Close Mode)

Default = 2

28

NOTE: Attributes 49-55 are reserved for Revision 1 to DeviceNet.

Table 4.33 – Transducer Attribute – Scaled values attribute 3

Bit 7 - 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Unused DDC Offset

0 = 0 mA 1

= 4 mA

ATT Polarity

0 = high

value 4 mA

1 = high

value 20 mA

Analog

Torque

Transmitter

(ATT) 0

= ATT

Disabled 1 =

ATT Enabled

APT Polarity

0 = high

value 4 mA

1 = high

value 20 mA

Analog

Position

Transmitter

(APT) 0

= APT

Disabled 1 =

APT Enabled

Page 29

Table 4.34

Bit 15 - 11 Bit 10 - 9 Bit 3

Unused Scaling 0 =

0 – 100 1 =

0 – 255 2 =

0 -4095 3 =

Reserved

Unused

4.4.1 Identity Object Instance Attributes

Table 4.35 – Identity Object Instance Attributes

Attribute

ID

1 Get

2 Get

Access Rule Name Data Type

Vendor ID UINT Identification of

(NV-RO)

Device Type UINT Indication of general

(NV-RO)

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Description of

Attribute

each vendor by

number

type of product

Semantics of Value

966 (3C6hex)

(Note 1)

00hex

(Generic Device)

3 Get

(NV-RO)

4 Get

(NV-RO)

5 Get

(V-RO)

6 Get

(NV-RW)

7 Get

(NV-RW)

8 Get

(V-RO)

10 Get/Set

(NV-RW)

100 Get

(V-RO)

Product Code UINT Identification of a

Revision STRUCT ofRevison of the item

Major Revision USINT Major Revision of

Minor Revision USINT Minor Revision of

Status WORD Summary status of

Serial Number UDINT Serial number of

Product Name SHORT_

STRING

State USINT Present state

Heartbeat Interval USINT The nominal interval

EEPROM Failure BOOL Result of EEPROM

particular product

of an individual

vendor

the Identity Object

represents

DeviceNet

Limitorque Interface

DeviceNet

Limitorque Interface

device

device

Human readable

identification

of the device as

represented by

the state transition

diagram

between heartbeat

messages in

seconds

checksum

verification

19800 (4D58hex)

(Note 2)

1.1

(Note 3)

(Note 4)

(Note 5)

”Flowserve MX”

(Note 6)

The default value

is 0. Zero disables

transmission of the

heartbeat message.

0 = EEPROM contents

is o.k.

1 = EEPROM contents

may be defective due

to checksum error

The further optional attributes

Configuration Consistency Value (Attribute ID 9)

•

Active Language (Attribute ID 11)

•

Supported Language List (Attribute ID 12)

•

29

flowserve.com

Page 30

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

International Product Name (Attribute ID 13)

•

Semaphore (Attribute ID 14)

•

are not supported by DeviceNet Limitorque Interface.

Some of the instance attributes do not have any external interfaces, these values are managed directly in

the DeviceNet Slave Software.

NOTE 1:

The Vendor ID is managed by the ODVA. Flowserve has already obtained a valid Vendor ID.

The Vendor ID will be assigned during compile time as a constant of the DeviceNet Slave Software and

stored in Flash-Memory of the DeviceNet Limitorque Interface. Thus it cannot be altered during runtime.

NOTE 2:

The Product Code of the DeviceNet Limitorque Interface has already been assigned by

Flowserve. It typically maps to a catalog or model number. The Product Code will be assigned during

compile time as a constant of the DeviceNet Slave Software and stored in Flash-Memory of the

DeviceNet Limitorque Interface. Thus it cannot be altered during runtime.

NOTE 3:

The Revision of the DeviceNet Limitorque Interface. Has already been assigned by Flowserve.

It typically links to the revision control system of a company. The format of the revision is Major.Minor,

starting with 1.1, because 0 is not allowed in CIP. The default value for this attribute is therefore 0x0101.

The revision must match the entry of the EDS-File delivered with the DeviceNet Limitorque Interface.

The Revision will be assigned during compile time as a constant of the DeviceNet Slave Software and

stored in Flash-Memory of the DeviceNet Limitorque Interface. Thus it cannot be altered during runtime.

30

NOTE 4:

The Status represents the current status of the device. Important here are the bits 8 to 11

which make faults visible to the user.

NOTE 5:

The Serial Number is used in conjunction with the Vendor ID to form a unique identifier for

each device. Flowserve is responsible for guaranteeing the uniqueness of the serial number across all of

its devices. The SMT Main Board will initialize the DeviceNet Limitorque Interface with data every time a

loss of communication condition between the DeviceNet Limitorque Interface and the SMT Main Board

had occurred. A part of this initialization data will be a unique board ID coming from the SMT Main

Board. Upon reception of this unique board ID from the SMT Main Board, the DeviceNet Limitorque

Interface will construct a Serial Number value. The transducer/spi software will then get the currently

stored serial number value from the DeviceNet stack, compare it to the one just constructed based on

the data from the main board, and if different, set the new value in the Identity Object / EEPROM. Also,

if the values were different, the transducer / spi software will then request that the DeviceNet board

reset to it’s “factory default” non-volatile condition (exception: the serial number in EEPROM is not

overwritten again).

NOTE 6:

The Product Name should represent a short description of the product/product family

represented by the product in attribute 3. It is limited to 32 characters. The product name should default

to “Limitorque”. However, at “spi initialization time”, the product name attribute can be updated by some

kind of API function call by the transducer / spi driver.

4.4.2 Behavior

Table 4.36 – Behavior

Event Source Description

Power Applied DeviceNet Limitorque Interface Connect DeviceNet bus power

Passed Tests DeviceNet Limitorque Interface No errors detected during internal selftest

Page 31

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

FailedTests DeviceNet Limitorque Interface One or more of the following errors have been

Activated SMT Main Board Is_Active-Flag is TRUE

Deactivated SMT Main Board Is_Active-Flag is FALSE OR

Minor Fault SMT Main Board Conditions that can cause this event are e.g.

Major Recoverable Fault SMT Main Board Conditions that can cause this event are e.g.

Major Unrecoverable Fault DeviceNet Limitorque Interface Internal Diagnostic Fault detected e.g.

detected during self-test of the DeviceNet

Limitorque Interface e.g.

- FLASH Checksum Error

- RAM Memory Test Error

EEPROM Checksum Error

valve jam, overtemp, overtorque and phase loss.

This event is triggered if Attribute DI_Actuator_

Faults_1_Chan in Channel Object Class is ≠

0x00

communication fault, power fault or Limiguard

fault of the SMT Main Board.

This event is triggered if Attribute DI_Actuator_

Faults_3_Chan in Channel Object Class is ≠

0x00

- Receive Queue Overrun

- Transmit Queue Overrun

- CAN Controller Overrun

4.4.3 DeviceNet Object Instance Attributes

Table 4.37 – DeviceNet Object Instance Attributes

Attribute

ID

1 Get/Set

2 Get/Set

3 Get/Set

4 Get/Set

5 Get

6 Get

7 Get

8 Get

9 Get

100 Get/Set

Access Rule Name

(NV-RW)

(NV-RW)

(V-RW)

(V-RW)

(V-RO)

(V-RO)

(V-RO)

(NV-RW)

(NV-RW)

(NV/RW)

MAC ID USINT Node Address Range 0 – 63

Baud Rate USINT Baud Rate Range 0 – 2

BOI BOOL Bus-Off Interrupt

Bus-Off Counter USINT Number of times

Allocation Information STRUCT

Allocation Choice Byte BYTE See [2] Chapter 3-5

Master’s MAC ID USINT MAC ID of Master

MAC ID Switch Changed BOOL The Node Address

Baud Rate Switch Changed BOOL The Baud Rate

MAC ID Switch Value USINT Actual Value of

Baud Rate Switch Value USINT Actual Value of

Autobaud BOOL Enable/Disable

Data

Type

of

Description of

Attribute

CAN went to the

bus-off state

(from allocate)

Switch(es) have

changed since last

power-up/reset

Switch(es) have

changed since last

power-up/reset

Node Address

Switch(es)

Baud Rate

Switch(es)

Autobaud Detection

Semantics of Value

see also

Chapter 5.2.1

0 = No Change

1 = Change since

last power-up

or reset

0 = No Change

1 = Change since

last power-up

or reset

Range 0 – 99

Range 0 – 9

0 = Disable

1 = Enable (default)

31

flowserve.com

Page 32

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

NOTE 1: At boot time of the DeviceNet Limitorque Interface the values stored in non-volatile memory

are used. The SMT Main Board could at any time send new values via SPI.

The other instance attributes do not have any external interfaces, these values are managed in the

protocol stack of the DeviceNet Slave Software.

The further optional attribute Quick Connect (Attribute ID 10) is not supported by DeviceNet Limitorque

Interface.

32

4.4.4 Discrete Input Point Object – Class ID 8 (08

hex

)

The Discrete Input Point Object is used to provide an interface to a subset of the discrete inputs of the

MX.The Discrete Input Point Object is implemented with 15 instances described in Table 3.1-25, so that

each of the selected discrete inputs of the MX is connected to one instance.

The purpose of this object is to have a SINGLE-BIT access to the discrete inputs from user and to

monitor the state of relay discrete outputs of the MX via the DeviceNet network for test and diagnostic

purposes.

The Discrete Input Point Object is just another representation of the selected discrete input data in the

Channel Interface Object Instance Attribute 7 (DI_Disc_User_Input_Chan) and Attribute 8 (DI_Read_

Disc_Output_Chan) see Chapter 3.2.1.2.

Table 4.38 – Discrete Input Point Object

Instance ID Channel Interface Object Source

1 Instance Attribute 7, Bit 0 DI_Disc_User_Input_Chan

2 Instance Attribute 7, Bit 1 DI_Disc_User_Input_Chan

3 Instance Attribute 7, Bit 2 DI_Disc_User_Input_Chan

4 Instance Attribute 7, Bit 3 DI_Disc_User_Input_Chan

5 Instance Attribute 7, Bit 4 DI_Disc_User_Input_Chan

6 Instance Attribute 7, Bit 5 DI_Disc_User_Input_Chan

7 Instance Attribute 7, Bit 6 DI_Disc_User_Input_Chan

8 Instance Attribute 7, Bit 7 DI_Disc_User_Input_Chan

9 Instance Attribute 8, Bit 0 DI_Read_Disc_Output_Chan

10 Instance Attribute 8, Bit 1 DI_Read_Disc_Output_Chan

11 Instance Attribute 8, Bit 2 DI_Read_Disc_Output_Chan

12 Instance Attribute 8, Bit 3 DI_Read_Disc_Output_Chan

13 Instance Attribute 8, Bit 4 DI_Read_Disc_Output_Chan

14 Instance Attribute 8, Bit 5 DI_Read_Disc_Output_Chan

15 Instance Attribute 8, Bit 6 DI_Read_Disc_Output_Chan

Discrete Input #1

Discrete Input #2

Discrete Input #3

Discrete Input #4

Discrete Input #5

Discrete Input #6

Discrete Input #7

Discrete Input #8

Relay Discrete Output #1

Relay Discrete Output #2

Relay Discrete Output #3

Relay Discrete Output #4

Relay Discrete Output #5

Relay Discrete Output #6

Relay Discrete Output #7

Page 33

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

4.4.5 Discrete Output Point Object – Class ID 9 (09

The Discrete Output Point Object is used to provide an interface to a subset of the discrete outputs of

the MX. The implementation of this object follows the guidelines of [1] Chapter 5-10.

The Discrete Output Point Object is implemented with 7 instances described in Table 3.1-29, so that

each of the selected discrete outputs of the MX is connected to one instance.

The purpose of this object is to have a SINGLE-BIT access to the relays of the MX via the DeviceNet

network for test and diagnostic purposes.

The Discrete Output Point Object is just another representation of the selected discrete output data in

the Channel Interface Object Instance Attribute 11 (DO_Relay_Chan) see Chapter 3.2.1.2.

Table 4.39 – Discrete Output Point Object

Instance ID Channel Interface Object Source

1 Instance Attribute 11, Bit 0 DO_Relay_Chan User Output AS-1

2 Instance Attribute 11, Bit 1 DO_Relay_Chan User Output AS-2

3 Instance Attribute 11, Bit 2 DO_Relay_Chan User Output AS-3

4 Instance Attribute 11, Bit 3 DO_Relay_Chan User Output AS-4

5 Instance Attribute 11, Bit 4 DO_Relay_Chan User Output AR-1

6 Instance Attribute 11, Bit 5 DO_Relay_Chan User Output AR-2

7 Instance Attribute 11, Bit 6 DO_Relay_Chan User Output AR-3

4.4.6 Analog Input Point Object – Class ID 10 (0A

The Analog Input Point Object is used to provide an interface to a subset of the analog inputs of the MX.

The implementation of this object follows the guidelines of [1] Chapter 5-11.

hex

hex

)

)

The Analog Input Point Object is implemented with 2 instances described in Table 3.1-33, so that each

of the selected analog inputs of the MX is connected to one instance.

The purpose of this object is to have a SINGLE access to the generic analog inputs of the MX via the

DeviceNet network for test and diagnostic purposes.

The Analog Input Point Object is just another representation of the selected analog input data in

the Channel Interface Object Instance Attribute 13 (AI_Analog_Input_1_Chan ) and Attribute 14

(AI_Analog_Input_1_Chan) see Chapter 3.2.1.2.

Table 4.40 – Analog Input Point Object

Instance ID Channel Interface Object Source

1 Instance Attribute 13 AI_ANALOG_INPUT_1_CHAN

2 Instance Attribute 14 AI_ANALOG_INPUT_2_CHAN

4.4.7 Analog Output Point Object – Class ID 11 (0B

The Analog Output Point Object is used to provide an interface to a subset of the analog outputs of the

MX. The implementation of this object follows the guidelines of [1] Chapter 5-12.

The Analog Output Point Object is implemented with 1 instance described in Table 3.1-37, so that each

of the selected analog outputs of the MX is connected to one instance.

The purpose of this object is to have a SINGLE access to the generic analog outputs of the MX via the

DeviceNet network for test and diagnostic purposes.

hex

)

33

The Analog Output Point Object is just another representation of the selected analog output data in the

Channel Interface Object Instance Attribute 19 (AO_Analog_Output_Chan) see Chapter 3.2.1.2.

flowserve.com

Page 34

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

Table 4.41 – Analog Output Point Object

Instance ID Channel Interface Object Source

1 Instance Attribute 19 AO_Analog_Output_CHAN

4.4.8 MAC ID

The MX-DeviceNet unit may have the MAC ID set by one of two different methods. The first is the MX

LCD display. The other is via the DeviceNet bus.

4.4.9 Baud Rate

The MX-DeviceNet unit may have the Baud Rate set by one of two different methods. The first is the MX

LCS display. The other is via the DeviceNet bus.

4.5 Network Management

4.5.1 Offline Connection Set

NOTE: The DeviceNet Limitorque Interface supports Offline Connection Set. The Offline Connection Set

is used to bring back a node to the DeviceNet bus which is in the Communication Fault State. This state

will be entered in the case of a duplicate MAC ID error is detected.

4.5.2 Device Heartbeat Message

The DeviceNet Limitorque Interface supports Device Heartbeat message. This message broadcasts the

current state of the DeviceNet Limitorque Interface. Table 4.42 shows the format of the data field of the

Device Heartbeat Message.

Table 4.42 – Format of the Device Heartbeat Message

Byte Set 7 6 5 4 3 2 1 0

0 DeviceNet Protocol Specific

1

2 Identity Object Instance ID = 1

3

4 Device Stats = 3

5 Reserved

(0)

6 (0) because the Configuration Consistency Value (Attribute 8 of the Identity Object Instance) is not

7

EV Event Flag, zero (0)

SF System Fault, a fault in the device caused by DeviceNet bus interaction (e.g. connection timeout).

This flag is set, when a system fault is present. This DeviceNet Limitorque Interface flag is set when a

connection times out.

UF User Fault, a fault in the device caused by user interaction. This flag is set when a user fault is

present. The conditions under which is set are vendor specific. This DeviceNet Limitorque Interface flag

is not used and is zero (0).

supported by the DeviceNet Limitorque

EV

(0)

SF UF

(0)

DF

34

DF Device Fault, an internal fault in the device not caused by user or bus interaction (e.g. hardware

fault). This flag is set when a device fault is present. This DeviceNet Limitorque Interface flag is set

under the following conditions:

(DI_Actuator_Faults_1_Chan ≠ 0) OR (DI_Actuator_Faults_3_Chan ≠ 0)•

Page 35

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

The Device Heartbeat Message is triggered by the Identity Object Instance Attribute Heartbeat Interval

(Attribute ID 10). For this, the Heartbeat Interval has to be set to the time interval of the Device

Heartbeat Message in seconds.

4.5.1 Device Shutdown Message

The DeviceNet Limitorque Interface supports the Device Shutdown Message. The DeviceNet Limitorque

Interface produces this message when it transitions to the offline state. Table 4.43 shows the format of

the data field of the Device Shutdown in Message.

Table 4.43 – Format of the Device Shutdown Message

Byte

Offset

0 DeviceNet Protocol Specific

1

2 Class ID

3

4 Instance ID

5

6 Shutdown Code

7

7 6 5 4 3 2 1 0

Range 200hex – 2FFhex

For the DeviceNet Limitorque Interface, the Class ID and the Instance ID of this message depends on the

originator of the Device Shutdown Message, e.g. after Reset-Service performed on the Identity Object,

Class ID 1 and Instance 1, a Device Shutdown Message is sent.

For application purposes 2 Bytes of the Device Shutdown Message are reserved for the Shutdown

Code. Then vendor specific range of this code is 200 – 2FF. Table 4.44 lists all Shutdown Codes of the

DeviceNet Limitorque Interface.

Table 4.44 – Device Shutdown Codes

Class ID Instance ID

1 1 4 Remote Reset: Reset service of the identity Object

3 1 4 Remote reset: Setting of the MAC ID via Attribute 1 of the DeviceNet

0 0 5 Internal diagnostic fault: An internal diagnostic fault has caused the

0 0 4 DeviceNet Limitorque Interface will be reset because SMT Main Board

102 1 0x201 DeviceNet Limitorque Interface will be reset because SMT Main Board

102 1 0x202 DeviceNet Limitorque Interface will be reset because SMT Main Board

Shutdown

Code

Causes of Shutdown

Object

service to shut down. Reason for this can be an overrun of the CAN

transmit queue, CAN receive queue or CAN Controller receive buffer

signal RESET is active.

has changed MAC ID via LCD

has changed Baud rate via LCD

4.6 Configuration Confirmation

DNFU operation cannot be verified until the complete DeviceNet system is operational. However, routine

checks can be performed to verify many functions.

4.6.1 Checking Connections

Verify that all connections, including data wires, shield ground, are in accordance with MX wiring

diagrams and DNFU diagrams in Section 3.1.2, Network Cable Preparation.

35

flowserve.com

Page 36

Limitorque MX DeviceNet Field Unit FCD LMENIM2328-00 – 11/05

YES

NO

CHANGE

DEVICENET?

(ON)

YES

NO

STATUS

(OFF)-OK?

(CLOSE)

(OPEN)

(STOP)

(POSITION)

YES

NO

ESD ACTION

(IGNORE)-OK?

(CLOSE)

(OPEN)

(STOP)

(POSITION)

YES

NO

COMM LOSS ACTION

(NONE)-OK?

(0-4095)

YES

NO

COMM LOSS DELAY

(60 SEC)-OK?

(0-100%)

**

YES

NO

MOVE TO

XXX% OPEN

(0-100%)

YES

NO

MOVE TO

XXX% OPEN

(125K)

(250K)

(500K)

(NET CTRL)

YES

NO

BAUD RATE

AUTO-OK?

(0-63)

YES

NO

DNET ADDRESS

NET CTRL-OK?

(0-255)

(0-4095)

YES

NO

ANALOG SCALE

(0-100)-OK

YES

NO

CHANGE PROP

DEAD BAND?

(1-100%)

YES

NO

PROP BAND

(8%)-OK?

(1-?%)

YES

NO

DEADBAND

(2%)

* If POSITION is chosen, as action,

this menu will appear.

YES

NO

CHANGE

DEVICENET?

(ON)

YES

NO

STATUS

(OFF)-OK?

(CLOSE)

(OPEN)

(STOP)

(POSITION)

YES

NO

ESD ACTION

(IGNORE)-OK?

(CLOSE)

(OPEN)

(STOP)

(POSITION)

YES

NO

COMM LOSS ACTION

(NONE)-OK?

(0-4095)

YES

NO

COMM LOSS DELAY

(60 SEC)-OK?

(0-100%)

**

YES

NO

MOVE TO

XXX% OPEN

(0-100%)

YES

NO

MOVE TO

XXX% OPEN

(125K)

(250K)

(500K)

(NET CTRL)

YES

NO

BAUD RATE

AUTO-OK?

(0-63)

YES

NO

DNET ADDRESS

NET CTRL-OK?

(0-255)

(0-4095)

YES

NO

ANALOG SCALE

(0-100)-OK

YES

NO

CHANGE PROP

DEAD BAND?

(1-100%)

YES

NO

PROP BAND

(8%)-OK?

(1-?%)

YES

NO

DEADBAND

(2%)

* If POSITION is chosen, as action,

this menu will appear.

4.6.2 View Settings

Refer to Bulletin LMAIM1306/2306, MX Installation and Operation Manual to access the “VIEW

SETTINGS” menu. Verify the settings as follows:

5 View DeviceNet Status

Figure 5.1 – DeviceNet Screens

36

VIEW DNET STATUS?

This selection permits the User to view pertinent information which summarizes the status of the

DeviceNet option board.

VIEW MODULE STATUS?

Answer "YES" to determine status of individual DN board within the actuator.

•

Configuration choices are:

•

"OFF" = board installed but turned off

•

“OPERATIONAL” – The device is operating in a normal condition.

•

"STANDBY" = The device needs commissioning due to configuration missing, incomplete or incorrect.

•

"RECOVERABLE FAULT" = Conditions that can cause this event are e.g. communication fault, power

•

fault or Limigard fault of the SMT Main Board. Device may need resetting.

"UNRECOVERABLE FAULT" = Internal Diagnostic Fault detected e.g.

•

•

•

•

Device may need replacing.

•

"SELF TESTING" = The device is in self-test mode.

•

VIEW NETWORK STATUS?

Answer “YES” to determine status of DN network.

"NOT ON LINE" = Device is not on-line.

•

Receive Queue Overrun

Transmit Queue Overrun

CAN Controller Overrun

Page 37