Page 1

Table of Contents

Page

Warnings ......................................... 1

Installation/Operation ............... 2-29

Check/Test/Startup.................. 30-31

Accessories..................................... 32

Maintenance/Service ............... 32-40

Index (by page)

Burners ....................................... 13, 33

Burner Orifice ................................... 35

California Warning Label .................... 2

Clearances ........................................... 6

Installation Codes ............................... 2

Combustion Air .................................... 6

Confined Space ....................................6

Destratification ................................. 18

Dimensions ..........................................4

Electrical Connections ..................... 13

Fan ............................................. 20, 36

Fan Control (Destratification) ....18, 38

Fan Motor .................................... 21, 36

Gas Piping and Pressures................... 10

Gas V alve......................................21, 37

General ................................................ 2

Hazard Intensity Levels...................... 2

Heat Exchanger Maintenance ...........33

High Altitude.................................. 3, 12

High Limit Control ...................... 17, 38

Ignition System ........................... 18, 35

LED Flash Codes ............................... 38

Limit Control .............................. 17, 38

Location (Heater) ................................ 7

Louvers ................................... 3, 10, 32

Maintenance Schedule ................ 32-33

Nozzle (Option) ............................ 3, 32

Pressure Switch

(Combustion Air)............... 5, 17, 37

Replacement Parts.... See Form P-LDAP

Sound Data...........................................8

Startup................................................ 30

Suspending Heater .............................. 8

Technical Data .....................................4

Thermostat (Option) .......................... 14

Throw Data .......................................... 7

Transformer ......................................38

Troubleshooting ......................... 38-40

Uncrating and Preparation ................. 3

Valve Outlet Pressure .........................12

Vent System Maintenance ................ 38

Venter Motor (Heat Section) ............ 35

Venter Motor (Main) ........................ 36

Venting ...............................................26

Wall Mounting ..................................... 9

Warranty..............................................2

Weights ................................................8

Wiring Diagrams .......................... 22-25

Indirect Fired,

Indoor , Downflow,

Packaged Heaters

Installation/Operation FORM RZ-NA I-LDAP

APPLIES TO: Model LDAP

P

R

O

Y

C

C

N

E

G

A

C

C

U

S

T

O

M

E

CQS

R

Q

U

P

R

O

D

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

The use and storage of gasoline or other flammable vapors and

liquids in open containers in the vicinity of this appliance is

hazardous.

W ARNING: Impr oper installation, adjustment, alteration, service,

or maintenance can cause property damage, injury , or death. Read

the installation, operation, and maintenance instructions

thoroughly before installing or servicing this equipment.

WARNING: Gas-fired appliances are not designed for use in

hazardous atmospheres containing flammable vapors or

combustible dust, in atmospheres containing chlorinated or

halogenated hydrocarbons, or in applications with airborne silicone

substances. See Hazard Levels, page 2.

WARNING: Should overheating occur, or the gas supply fail to

shut off, shut off the manual gas valve to the appliance before

shutting off the electrical supply.

WARNING: Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to inspect

the appliance and replace any gas control that has been under water .

E

S

R

E

G

S

V

E

N

N

O

T

P

U

-

T

R

A

T

S

M

A

L

I

T

Y

U

C

T

Y

E

T

T

S

Y

S

N

A

R

R

A

W

Reznor

®

Model

LDAP 1200

FOR YOUR SAFETY

FOR YOUR SAFETY

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 1

Page 2

Hazard Levels of

Warnings in this

Manual

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in sever e personal injury or death

and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury or

death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal injury and/or

property damage.

1. General

2. Installation

Codes

Special Installations

(Aircraft Hangars/

Repair Garages/

Parking Garages)

All Model LDAP high bay packaged heaters are design certified by ITS for use in

industrial and commercial installations. All models and sizes are available for use

with either natural or propane gas. The type of gas, the input rate, and the electrical

supply requirement are shown on the heater rating plate. Check the rating plate to

determine if the heater is appropriate for the intended installation.

®

The instructions in this manual apply only to Reznor

Installation should be done by a qualified agency in accordance with these instruc-

tions. The qualified service agency installing this heater is responsible for the installation.

These heaters must be installed in accordance with local building codes. In the absence of local codes, in the United States, the heater must be installed in accordance

with the National Fuel Gas Code, ANSI Z223.1. A Canadian installation must be in

accordance with the CSA B149 Installation Codes. These codes are available from

CSA Information Services, 1-800-463-6727. Local authorities having jurisdiction

should be consulted before installation is made to verify local codes and installation

procedure requirements.

Installations in aircraft hangars should be in accordance with ANSI/NFPA No. 409

(latest edition), Standard for Aircraft Hangars; in public garages in accordance with

ANSI/NFPA No. 88A (latest edition), S tandard for Parking S tructures; and for repair

garages in accordance with ANSI/NFP A No. 88B (latest edition), S tandard for Repair

Garages. In Canada, installations in aircraft hangars should be in accordance with the

requirements of the enforcing authorities, and in public garages in accordance with

CSA B149 codes.

Model LDAP heaters.

California Warning

Label

Massachusetts

Requirement

3. Warranty

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 2

If the heater is being installed in the state of California, the installer MUST attach a

warning label on the outside of the access door . The California W arning label is shipped

in the owner’s envelope along with this manual, the warranty form, and any other

paperwork that applies.

If installation is in California, select a location on the heater access panel. Be sure the

surface is clean and dry and adhere the label.

If the heater is being installed in the Commonwealth of Massachusetts, this heater

must be installed by a licensed plumber or licensed gas fitter.

Refer to the limited warranty information on the Warranty Card in the "Owner's Envelope".

Warranty is void if ...

a. Wiring is not in accordance with the diagram furnished with the heater.

b. The heater is installed without proper clearance to combustible materials.

c. The heater is connected to a duct system or if the air delivery system is

modified by other than manufacturer-designed accessories.

Page 3

4. Uncrating and

Preparation

This heater was test operated and inspected at the factory prior to crating and was in

operating condition. If the heater has incurred any damage in shipment, document

the damage with the transporting agency and contact an authorized Reznor Distributor. If you are an authorized Distributor , follow the FOB freight policy procedures as

published by Thomas & Betts for Reznor products.

Check the rating plate for the gas specifications and electrical characteristics of the

heater to be sure that they are compatible with the gas and electric supplies at the

installation site.

MPORTANT: The crate bottom should be removed after the heater is lifted.

I

Shipping brackets are attached with cabinet screws. When removing shipping

brackets, re-insert ALL screws into the cabinet.

Read this booklet and become familiar with the installation requirements of your

particular heater. If you do not have knowledge of local requirements, check with the

local gas company or any other local agencies who might have requirements concerning this installation. If the installation is above 2000 ft (610M) elevation, follow

the instructions in Paragraph 5 and Paragraph 12.

Before beginning, make preparations for necessary supplies, tools, and manpower.

Locate the hardware kit supplied with the heater. The plastic bag contains spring

nuts, hex nuts, “U”-shape fittings, lock washers, louvers, and compression springs.

Be sure that all shipped-separate options that were ordered are at the installation site.

Shipped-separate items could include a vent cap, louvers, nozzles, hanger kit, a manual

shutoff valve, a thermostat, multiple heater controls, high temperature tape, and/or a

high altitude kit.

5. High Altitude

Operation

Pressure Switch

Instructions for Changing

Heat section Pressure

NOTE: Do not change the

main pressure switch located

on top of a Size 800 and Size

1200 heater. It is the same for

all elevations.

If the heater is being installed at an elevation above 2000 ft (610M), the input rate

will have to be derated. This is done by adjusting the outlet pressure of the gas valve

and can only be done after the heater is in operation. Follow the instructions in Paragraph 12.

If the heater is being installed at an elevation above 6000 ft (1830M), the heat section

pressure switch(es) will need to be changed. If ordered with the heater as Option

DJ20, the pressure switch is shipped separately.

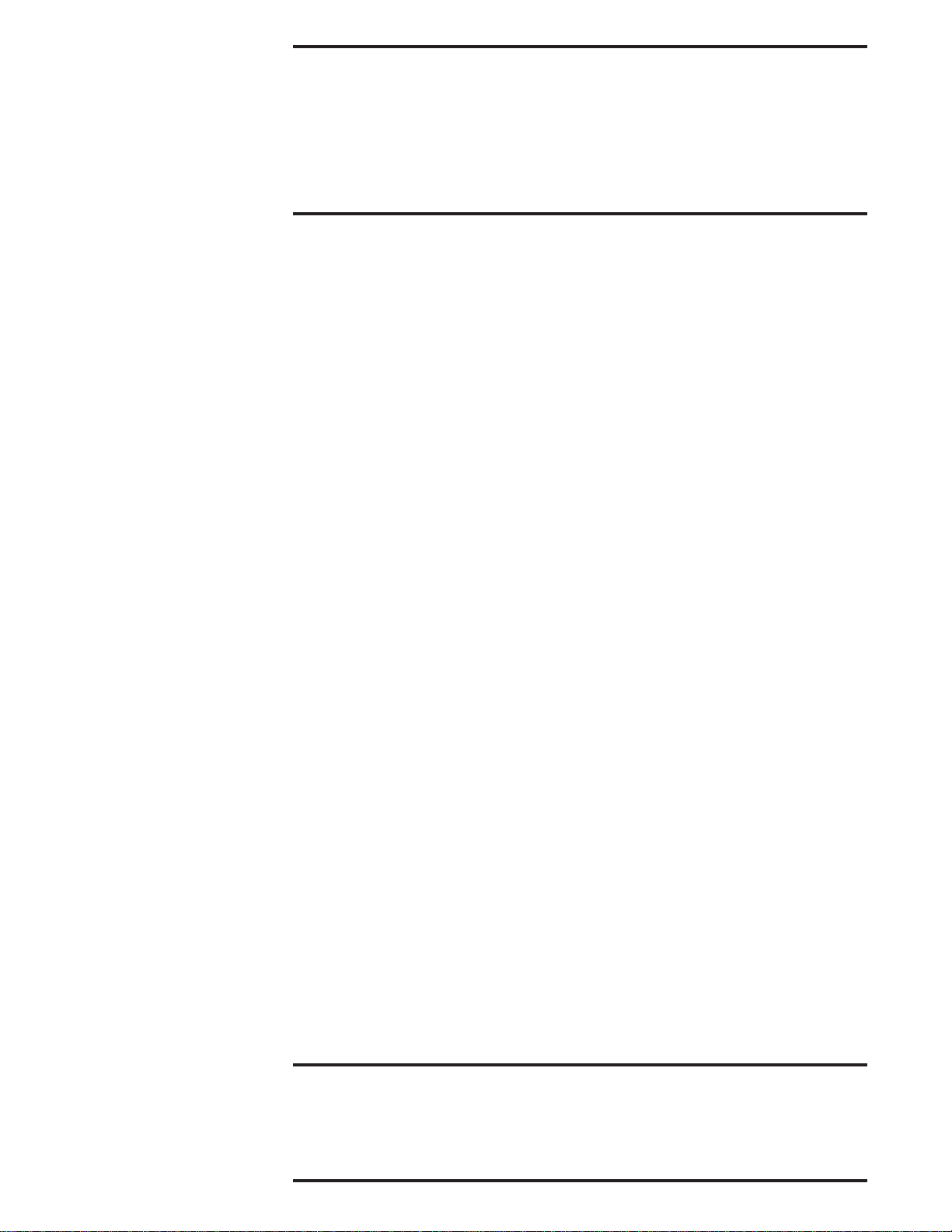

High Altit u de Unit Pressure Sw it ch (es)

Start-up Cold Equilibrium Hot Setpoint OFF Setpoint ON

QtySize

400 1 1.75 to 1.45 1.00 to 0.80 0.60 0.78 Lt. Blue 197029

800 2 1.85 to 1.55 1.05 to 0.85 0.60 0.78 Lt. Blue 197029

1200 3 2.35 to 1.85 1.50 to 0.95 0.60 0.78 Lt. Blue 197029

Label

Color

Switch

Part No.Differential Pressure (in. w.c.)

Switch(es)

1. In the control compartment of the first heat section, locate the pressure switch.

2. Mark and disconnect the two wires attached to the pressure switch.

3. Mark and disconnect the sensing tubes from the pressure switch.

4. Locate the two screws holding the switch mounting bracket. Remove the screws

(save screws) and the pressure switch.

5. Using the same screws, install the high altitude pressure switch. Attach the

sensing tubes and wires.

6. If installing a Model LDAP 400, the pressure switch change for high altitude is

complete. If installing a Model LDAP 800, repeat Steps 1-5 to change the

pressure switch on the second heat section. If installing a Model LDAP 1200,

repeat Steps 1-5 to change the pressure switches on the second and third heat

sections.

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 3

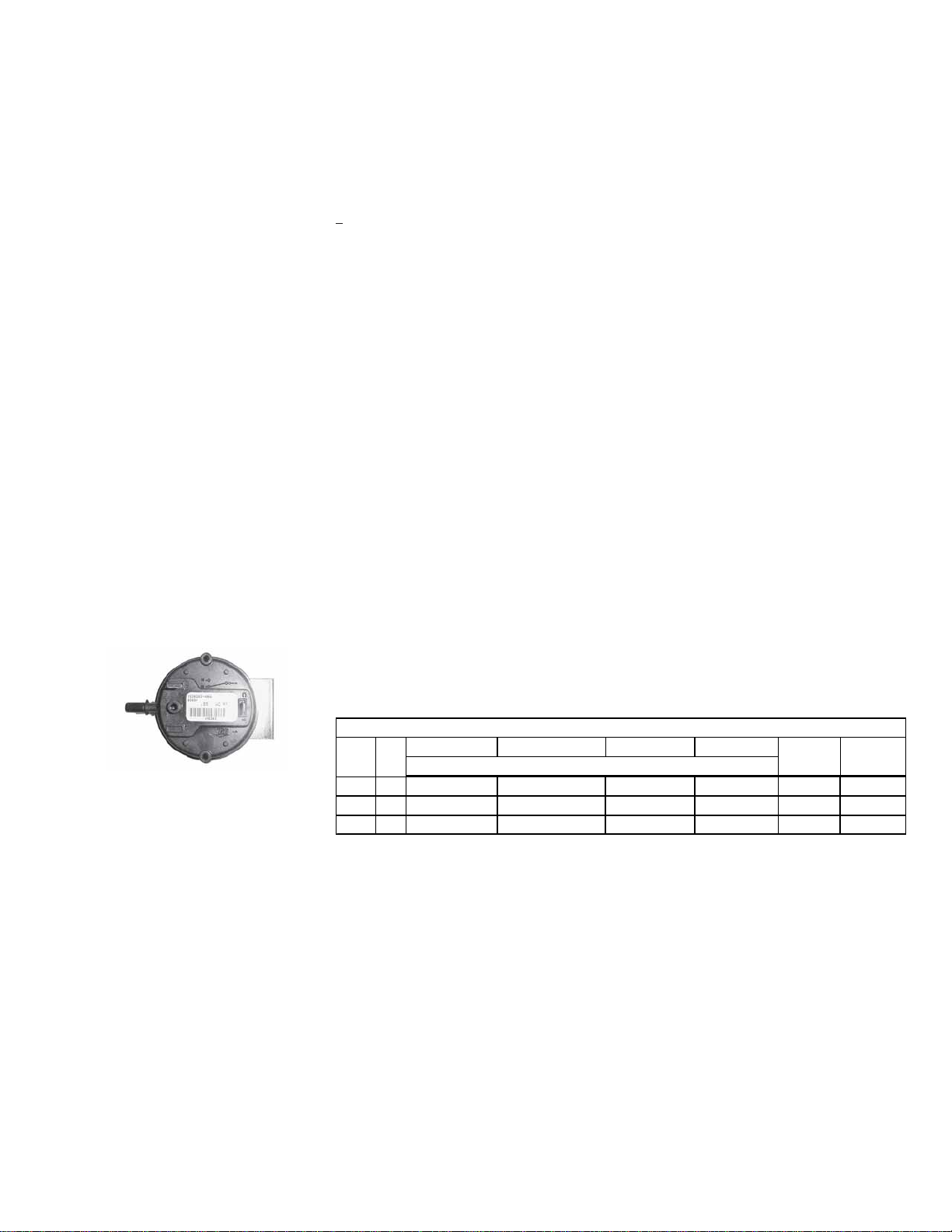

Page 4

6. T echnical Dat a

38

(965mm)

13-1/8

(333mm)

2-5/8

(67mm)

5

(127mm)

9-7/8

(251mm)

43-1/2

(1,105mm)

RIGHT SIDE VIEW

LINE VOLTAGE

CONNECTION

DISCONNECTION

SWITCH

1 NPT

GAS CONNECTION

m

m

m

m

Model

LDAP

400

Model LDAP 800

Model LDAP 1200

One

Downflow

Heater

One Heater

with Two

Downflow

Heat

Sections

One Heater with

Three Downflow

Heat Sections

Mo del LDAP Size

Input Heating Capa c ity

btuh 400,000 800,000 1,200,000

kw/h 117.1 234.2 351.4

Thermal Efficiency (%)

O ut put Heating Capacity

btuh 332,000 664,000 996,000

kw/h 97.2 194.4 291.6

Gas Co nnection (I nches)

Vent Connection Diameter (Inches)

Contr ol Amps ( 24 volt)

Fu ll Load Amps (208 volt)

Fu ll Load Amps (230 volt)

N orm al Power Consumpti o n @ 2 08V (w a t ts)

N orm al Power Consumpti o n @ 2 30V (w a t ts)

Discharge Air Temperature Rise (°F)

Air Volum e (Heat @ High Speed)

D ischarge Ai r Opening Are a

Outlet Velocity (Heat @ High

Speed)

Air Volume (Destratification @

Medium Speed)

Outlet Velocity (Destrati ficati on

@ Me dium Speed)

Air Volume (Destratification @

Low Speed)

Outlet Velocity (Destrati ficati on

@ L ow S peed)

cfm 5589 11178 16768

3

/minute

2

ft

2

fpm 1521 1521 1521

m/minute 464 464 464

cfm 4650 9300 13950

3

/minute

fpm 1266 1266 1266

m/minute 386 386 386

cfm 3250 6500 9750

3

/minute

fpm 885 885 885

m/minute 270 270 270

Fan Motor HP (Qty)

Fan Motor RPM

Fan Diameter (I nches)

400 800 1200

83 83 83

11-1/41-1/4

68 8

1.0 2.0 3.0

5.6 13.6 19.4

5.5 12.8 18.5

1150 2448 3730

1230 2597 3959

55 55 55

158 317 475

3.67 7.35 11.02

0.34 0.68 1.02

132 263 395

92 184 276

1 (1) 1 (2) 1 (3)

1050 1050 1050

24 24 24

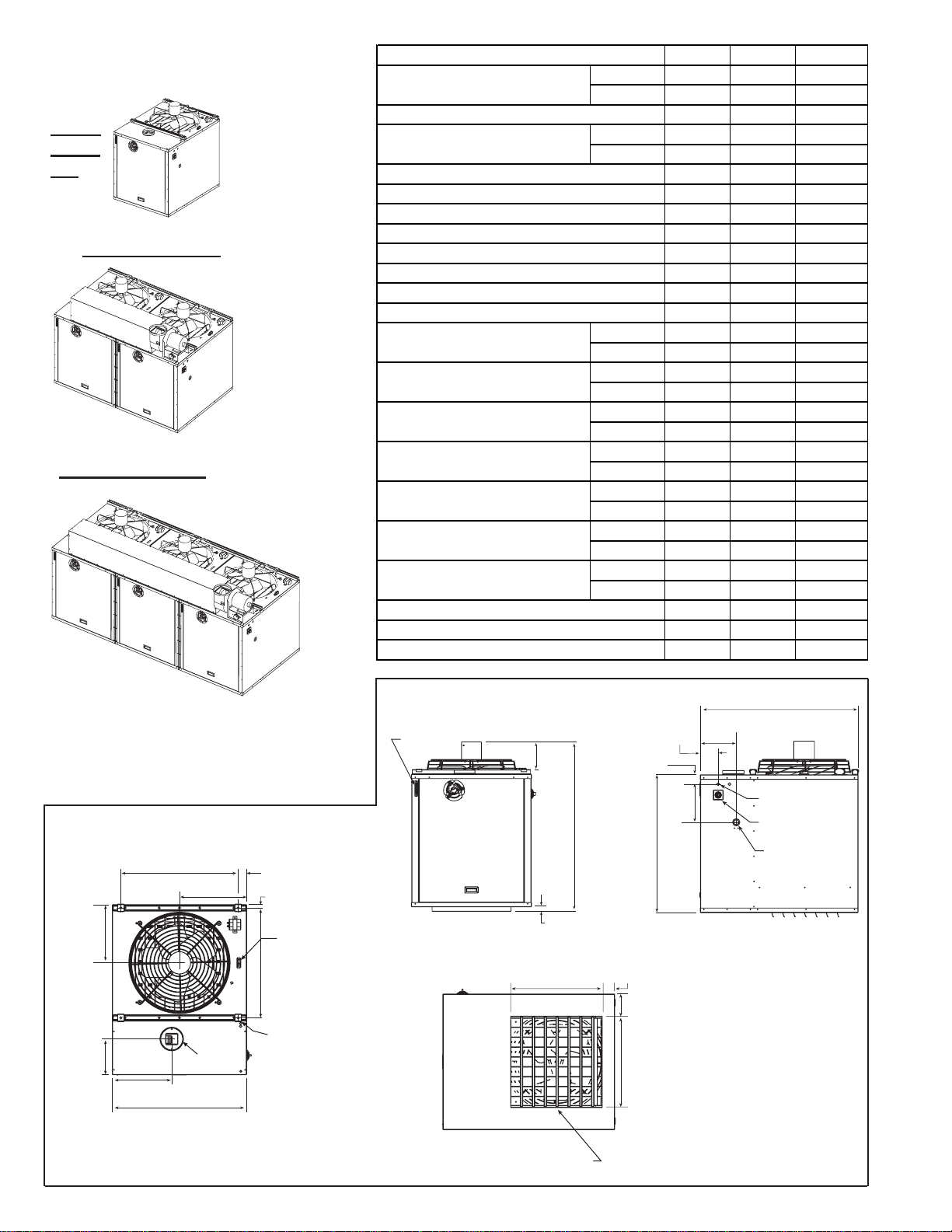

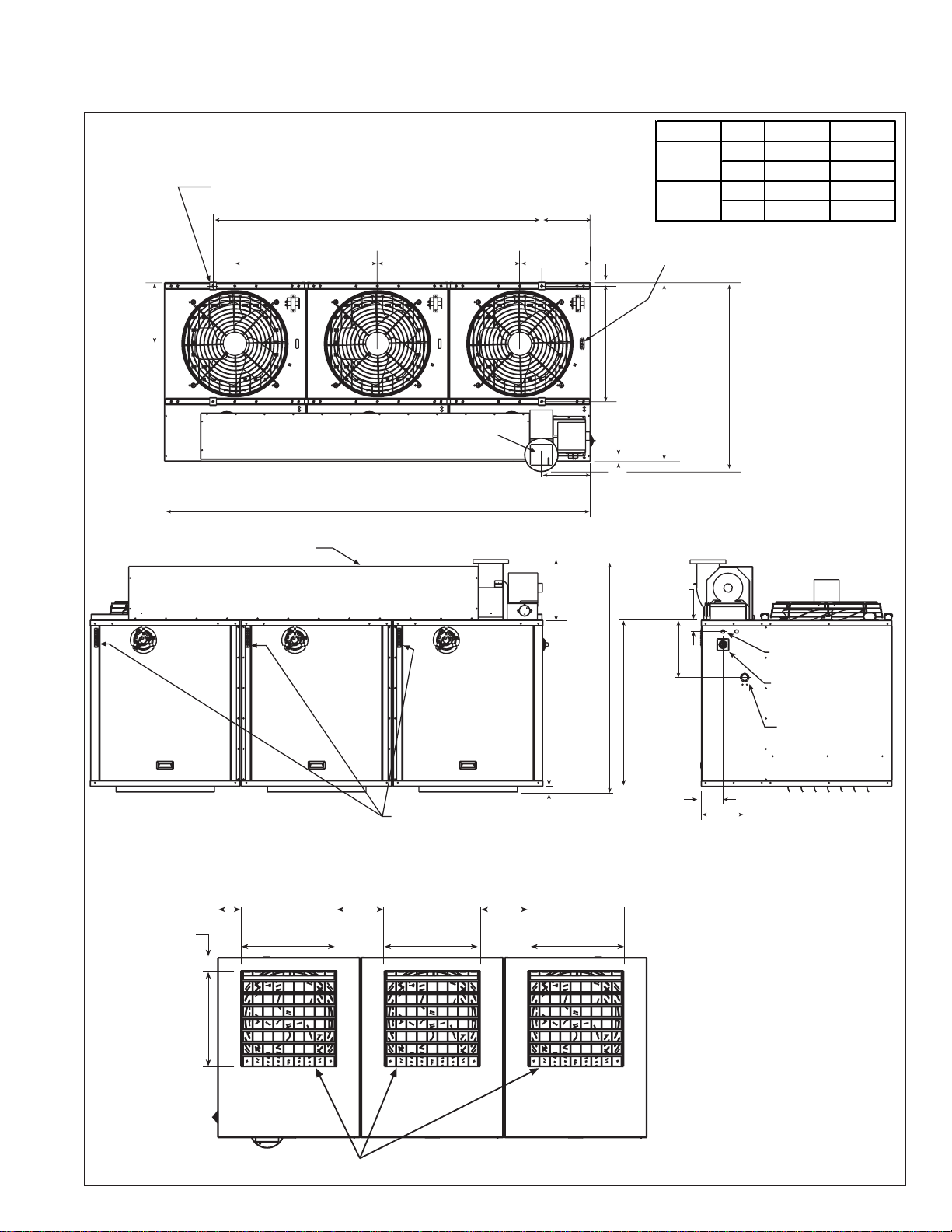

7. Dimensions

FIGURE 1A - Model LDAP 400

30

(762mm)

17-1/8

(435mm)

14-7/8

(378mm)

9-1/8

(232mm)

15-1/4

(387mm)

34-3/8

(873mm)

TOP VIEW

ø 6 FLUE

OUTLET

2-1/8

(54mm)

7/8

(22mm)

AIR DESTRATIFICATION

FAN CONTROL

28-1/8

(714mm)

HANGER LOCATION

1/2 - 13 FEMALE THREAD

THERMOSTAT

CONNECTION

FRONT VIEW

BOTTOM VIEW

DISCHARGE OPENING

9-1/4

(235mm)

1-1/4

(32mm)

23

(584mm)

48-1/2

(1,232mm)

3-1/4

(83mm)

5-5/8

(143mm)

23

(584mm)

NOTE: If an optional

nozzle is added to the

discharge opening,

see dimensions on

page 32.

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 4

Page 5

FIGURE 1B - Model LDAP800 and Model LDAP1200

RIGHT SIDE VIEW

LINE VOLTAGE

CONNECTION

DISCONNECT

SWITCH

1 NPT

GAS CONNECTION

38

(965mm)

13-1/8

(333mm)

2-5/8

(67mm)

5

(127mm)

9-7/8

(251mm)

A Model LDAP1200 with three heat sections is illustrated. A Model LDAP800 has two heat sections. A Model LDAP800

is the same layout as illustrated less the middle heat section.

Size A B

HANGER LOCATION

1/2 - 13 FEMALE THREAD

800

11-7/8

A

(302mm)

1200

inches

mm

inches

mm

46 69

1168 1753

80 103-3/4

2032 2635

14-7/8

(378mm)

COMBUSTION BOX ASSEMBLY

34-3/4

(883mm)

TOP VIEW

B

34-3/4

(883mm)

ø8 FLUE OUTLET

17-1/8

(435mm)

12

(305mm)

13-3/4

(349mm)

(1,346mm)

7/8

(22mm)

1-5/8

(41mm)

53

28-1/8

(714mm)

AIR DESTRATIFICATION

FAN CONTROL

43-1/2

(1,105mm)

46

(1,168mm)

1-1/4 NPT

5-5/8

(143mm)

3-1/4

(83mm)

23

(584mm)

FRONT VIEW

THERMOSTAT

CONNECTIONS

11-3/4

(298mm)

23

(584mm)

(584mm)

DISCHARGE OPENING

11-3/4

(298mm)

23

BOTTOM VIEW

1-1/4

(32mm)

23

(584mm)

NOTE: If optional

nozzles are added to the

discharge openings, see

dimensions on page 32.

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 5

Page 6

8. Clearances

(

)

Heaters must be installed so that the clearances in the table are provided for combustion air space, inspection and service, and for proper spacing from combustible construction. Clearance to combustibles is defined as the minimum distance from the

heater to a surface or object that is necessary to ensure that a surface temperature of

90°F above the surrounding ambient temperature is not exceeded.

Clearances inches/mm

9. Combustion

Air

Size

400

800

1200

Top

inches mm inches mm inches mm inches mm in ches mm inches mm inches mm

12 305 6 152.4 18 457 2 50.8 18 4 57 2 50.8 60 1524

12 305 6 152.4 18 457 2 50.8 18 4 57 2 50.8 60 1524

12 305 6 152.4 18 457 2 50.8 18 4 57 2 50.8 60 1524

This heater must be supplied with the air that enters into the combustion process and

is then vented to the outdoors. Sufficient air must enter the equipment location to

replace that exhausted through the heater vent system. In the past, the infiltration of

outside air assumed in heat loss calculations (one air change per hour) was assumed

to be sufficient. However, current construction methods using more insulation, vapor

barriers, tighter fitting and gasketed doors and windows, weather-stripping, and/or

mechanical exhaust fans may now require the introduction of outside air through wall

openings or ducts.

The requirements for combustion and ventilation air depend upon whether the heater

is located in a confined or unconfined space. An "unconfined space" is defined as a

space whose volume is not less than 50 cubic feet per 1000 BTUH of the installed

appliance. Under ALL conditions, enough air must be provided to ensure there will

not be a negative pressure condition within the equipment room or space.

Flue

Connector

Front

Access Panel

Rear

Disconnect

Side

Side

Bottom

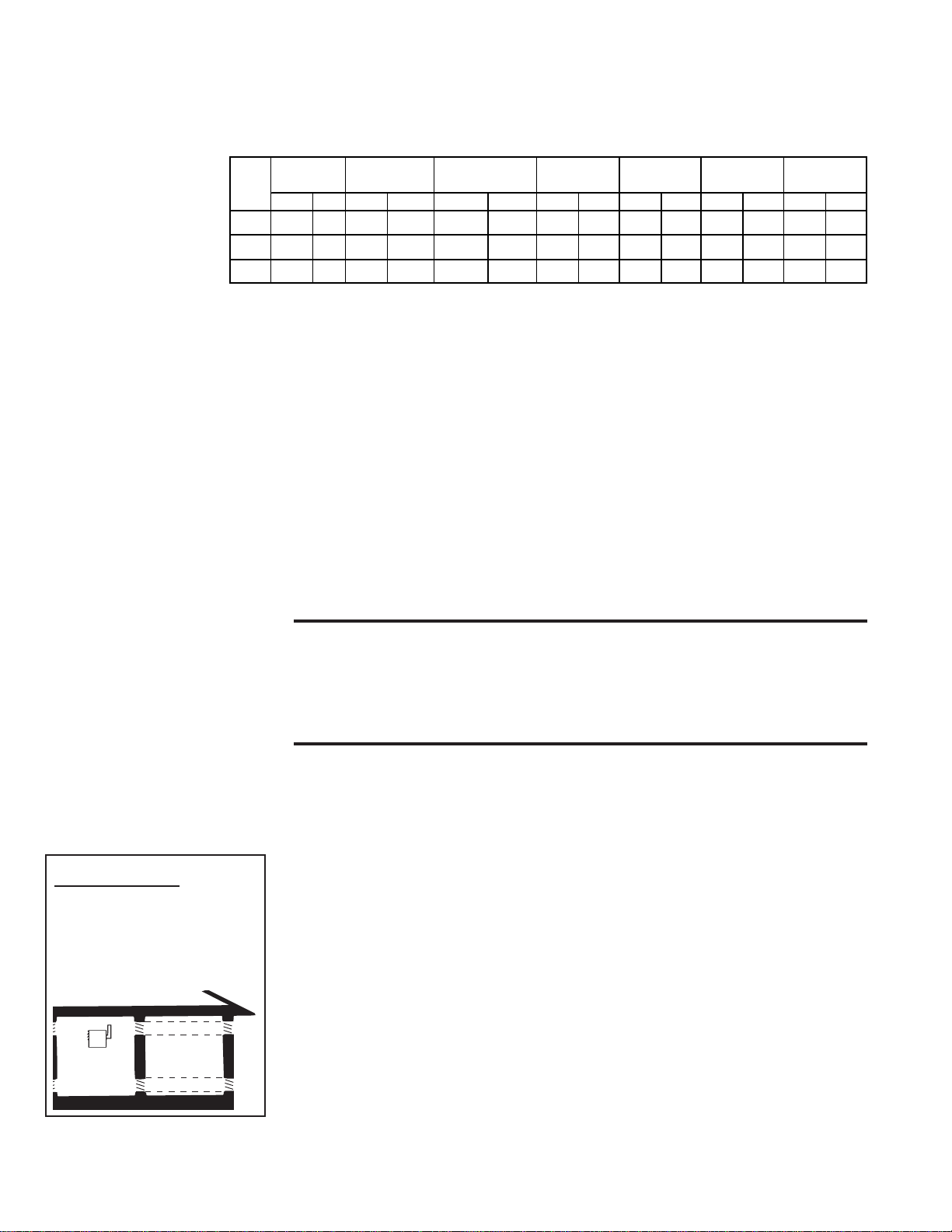

FIGURE 2 - Definition of

Confined Space and

Required Openings for

Combustion Air

Confined Space:

A space whose volume is

less than 50 cubic feet

per 1000 BTUH of the

installed appliance input

rating

(3)

Confined

Space

(3)

(1)

(1)

(2)

(2)

W ARNING: A Model LDAP power-vented heater is designed to take

combustion air from the space in which the heater is installed and is

not designed for connection to outside combustion air intake ducts.

Connecting outside air ducts voids the warranty and could cause

hazardous operation. See Hazard Levels, page 2.

Combustion Air Requirements for a Heater

Located in a Confined Space

Do not install a heater in a confined space without providing wall openings leading to

and from the space. Provide openings near the floor and ceiling for ventilation and air

for combustion as shown in FIGURE 2, depending on the combustion air source as

noted in Items 1, 2, and 3 below.

Add total BTUH of all appliances in the confined space and divide by figures below

for square inch free area size of each (top and bottom) opening.

1. Air from inside the building - openings 1 square inch free area per 1000 BTUH.

Never less than 100 square inches free area for each opening. See (1) in FIGURE 2.

2. Air from outside through duct - openings 1 square inch free area per 2000 BTUH.

See (2) in FIGURE 2.

3. Air direct from outside - openings 1 square inch free area per 4000 BTUH. See

(3) in FIGURE 2.

NOTE: For further details on supplying combustion air to a confined space, see the

National Fuel Gas Code ANSI Z223.1a (latest edition).

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 6

Page 7

10. Heater

Location

Use the clearances in Paragraph 8; the combustion air requirements in Paragraph 9;

the mounting height requirements, throw information, sound data, and location recommendations below; the weights in Paragraph 11; and the venting requirements in

Paragraph 24 to determine where to suspend the heater.

CAUTION: Do not locate the heater where it may be exposed to

water spray, rain, or dripping water.

Mounting Height

Locate the heater so that it is a minimum of 15 feet (4.6M) above the floor and in

compliance with the clearances in Paragraph 8.

WARNING: If touched, the vent pipe and internal heater surfaces

that are accessible from outside the heater will cause burns. Suspend

the heater a minimum of 15 feet (4.6M) above the floor.

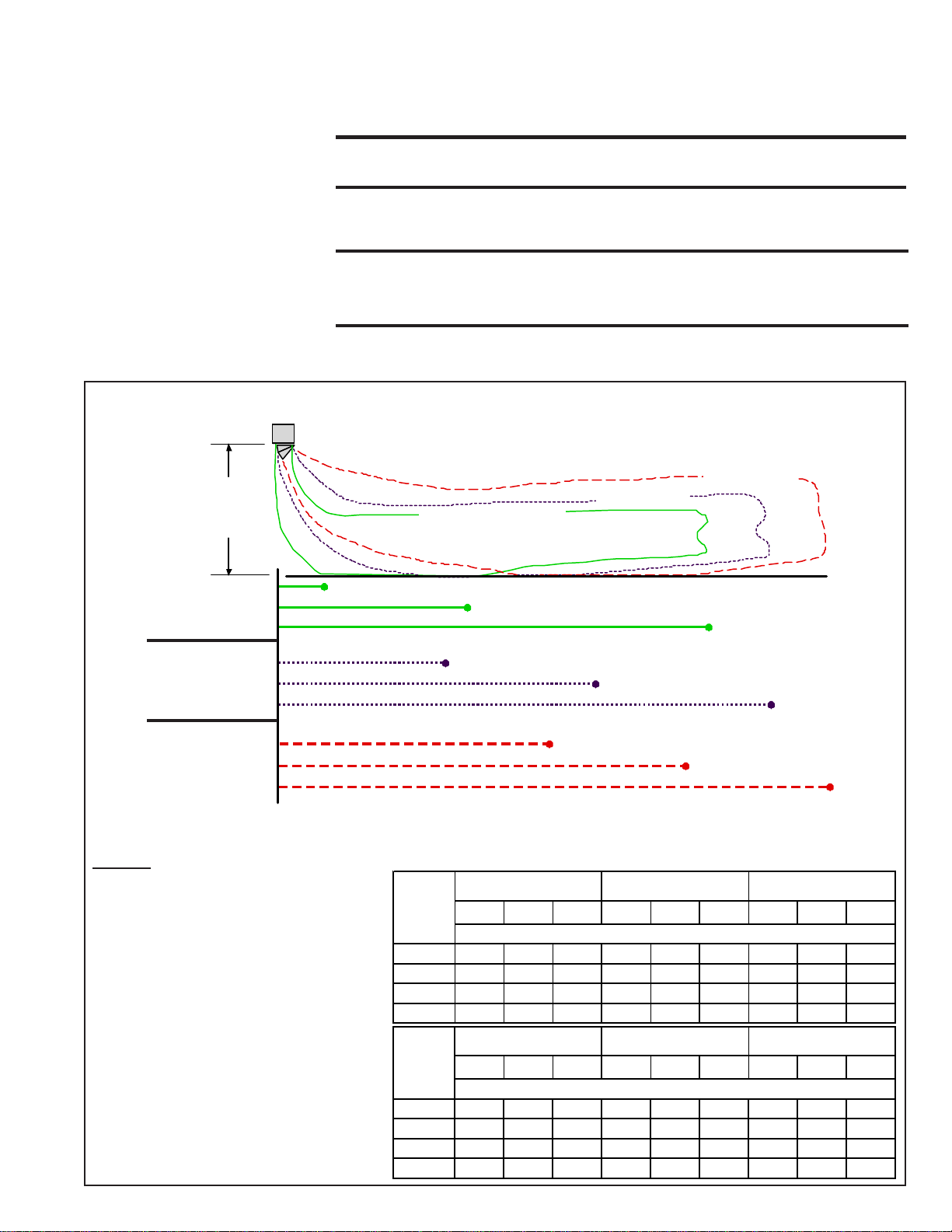

Heater Throw All Models

FIGURE 3 - Model LDAP Air Throw (Heat Mode @ High Speed) - Applies to All Sizes

60° Nozzle

Mounting

Height

Standard

Louvers

Standard Louvers

0

X

Y

Z

30° Nozzle

X

30° Nozzle

Y

Z

X

60° Nozzle

Y

Z

= “Rear” of Heater Discharge

0

NOTES:

• X = Distance from “0” to beginning

of floor coverage.

• Y = Distance from “0” to end of

floor coverage.

• Length of floor coverage = Y - X.

• Z = Distance from “0” to the point

where the air velocity drops below

50 feet (15.2M) per minute.

• Throws listed are with standard

louvers facing one direction and

fully open. Throw pattern changes

with louver angle, 2-way louver

direction, and or optional 4-way

louvers.

Throw (feet and meters)

Sta ndard Lou vers 30° Degree No zzle 60° Degree Nozzle

XYZXYZXYZ

Mounting

Height

(feet)

20

30

40

50

Mounting

6.1

9.1

12.2

15.2

Height

5 55 134 40 90 146 70 125 158

8 53 121 44 86 133 76 119 145

12 49 109 47 81 120 N/A N/A N/A

17 45 96 N/AN/AN/AN/AN/AN/A

Sta ndard Lou vers 30° Degree No zzle 60° Degree Nozzle

XYZXYZXYZ

(Meters)

1.5 16.8 40.8 12.2 27.4 44.5 21.3 38.1 48.2

2.4 16.2 36.9 13.4 26.2 40.5 23.2 36.3 44.2

3.7 14.9 33.2 14.3 24.7 36.6 N/A N/A N/A

5.2 13.7 29.3 N/A N/A N/A N/A N/A N/A

Th row ( f eet )

Th row ( meters)

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 7

Page 8

10. Heater

Location

(cont’d)

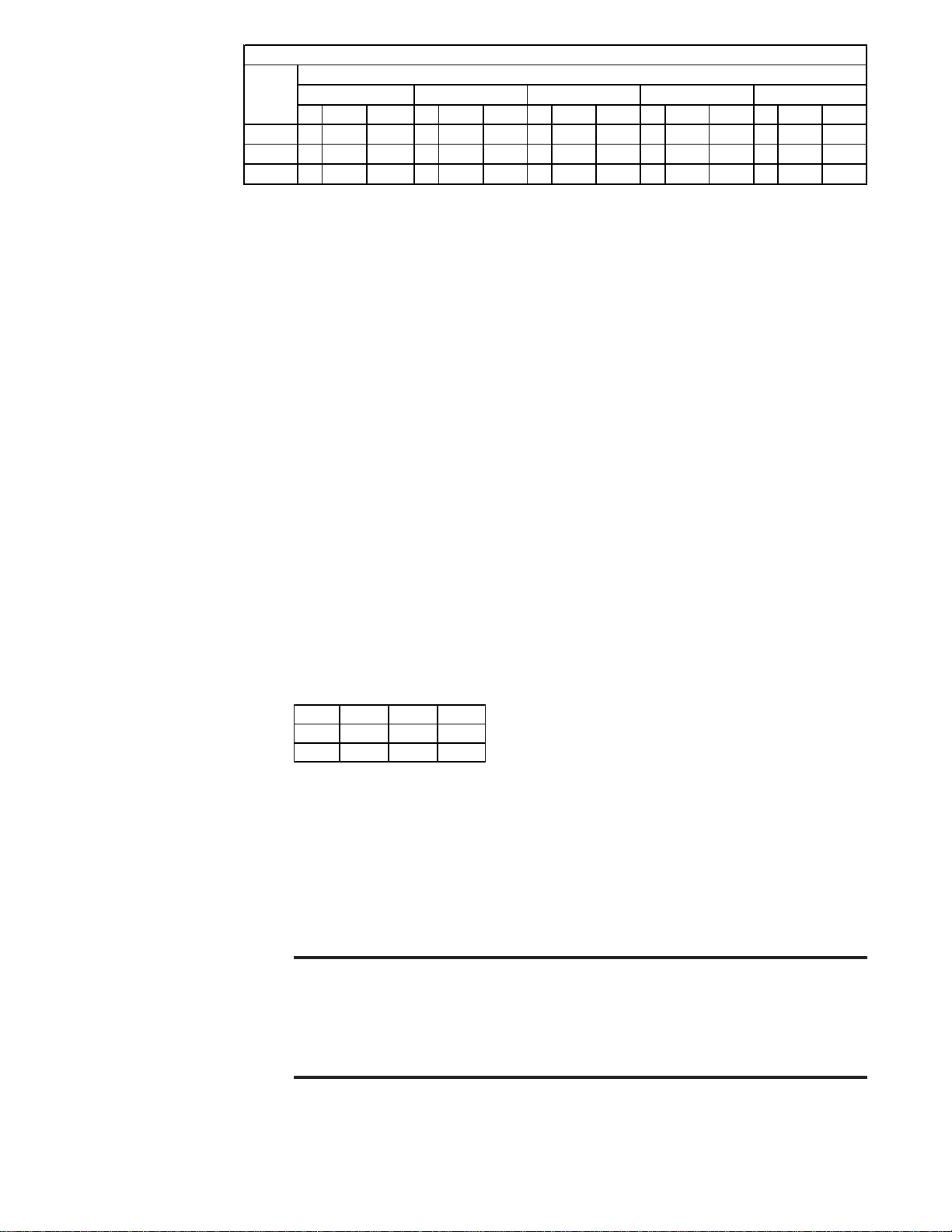

Sound Data

Model

LDAP

Size

400

800

1200

µbar = microbar Pa = Pascal

20 ft (6.1M) 25 ft (7.6M) 30 ft (9.1M) 35 ft (10.7M) 40 ft (12.2M)

db Pa µbar db Pa µbar db Pa µbar db Pa µbar db Pa µbar

69 0.058 0.580 65 0.037 0.371 62 0.026 0.258 60 0.019 0.189 57 0.015 0.145

72 0.080 0.800 68 0.051 0.512 65 0.036 0.356 62 0.026 0.261 60 0.020 0.200

74 0.100 1.000 70 0.064 0.640 67 0.044 0.444 64 0.033 0.327 62 0.025 0.250

Sound Chart - Model LDAP

DISTANCE

Location

Recommendations

NOTE: Venting

requirements may affect

location. Consult

requirements in Paragraph 24

before making final

determination.

Hazards of Chlorine

For best results, the heater should be placed with certain rules in mind. In general, a

heater should be located from 15-40 feet (4.6-12.2 M) above the floor. If two or more

heaters are installed in the same room, a general scheme of air circulation should be

maintained for best results.

Suspended heaters are most effective when located as close to the working zone as

possible, and this fact should be kept in mind when determining the mounting heights

to be used. However, care should be exercised to avoid directing the discharged air

directly on the room occupants.

Partitions, columns, counters, or other obstructions should be taken into consideration when locating the heater so that a minimum quantity of airflow will be deflected

by such obstacles.

The presence of chlorine vapors in the combustion air of gas-fired heating equipment

presents a potential corrosion hazard. Chlorine found usually in the form of freon or

degreaser vapors, when exposed to flame will precipitate from the compound, and go

into solution with any condensation that is present in the heat exchanger or associated

parts. The result is hydrochloric acid which readily attacks all metals including 300

grade stainless steel. Care should be taken to separate those vapors from the combustion process. This may be done by wise location of the heater with regard to exhausters or prevailing wind directions. Chlorine is heavier than air. Keep these facts in

mind when determining installation location of the heater in relation to building exhaust systems.

11. Hanging or

Mounting

the Heater

Weight (lbs/kg)

Size 400 800 1200

lbs 375 805 1195

kg 170 365 542

and

Suspending the Heater

Installing

Louvers

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 8

Locate the hardware kit shipped with the heater. The kit contains spring nuts, hex

nuts, “U”-shape fittings, and lock washers for suspending the heater. It also includes

louvers and the compression springs needed to install them.

When the heater is lifted for suspension, support the bottom of the heater with the

crate bottom. If the bottom is not supported, damage could occur. Before hanging or

mounting, verify that any screws used for holding shipping brackets were re-installed

in the cabinet.

WARNINGS: Check the supporting structure to be used to verify

that it has sufficient load carrying capacity to support the weight of

the heater . Suspend the heater only fr om the threaded nut retainers

or with a manufacturer provided kit. Do NOT suspend from the

heater cabinet.

See FIGURE 1A or 1B for the appropriate hanging locations, and install the ½”-13

spring nuts in the strut that is attached to the top of the unit. Comply with the requirements in FIGURE 4A when using threaded rod. If ordered with swivel connectors

for 1” pipe, Option CK10, attach the swivels to the spring nuts according to illustration in FIGURE 4B and suspend with 1” pipe.

Before installing the heater, check the supporting

structure to be used to verify that it has sufficient loadcarrying capacity to support the weight.

Page 9

WARNING: All heaters must be level for proper operation. Do not

place or add additional weight to the suspended heater. Hazard

Levels, page 2.

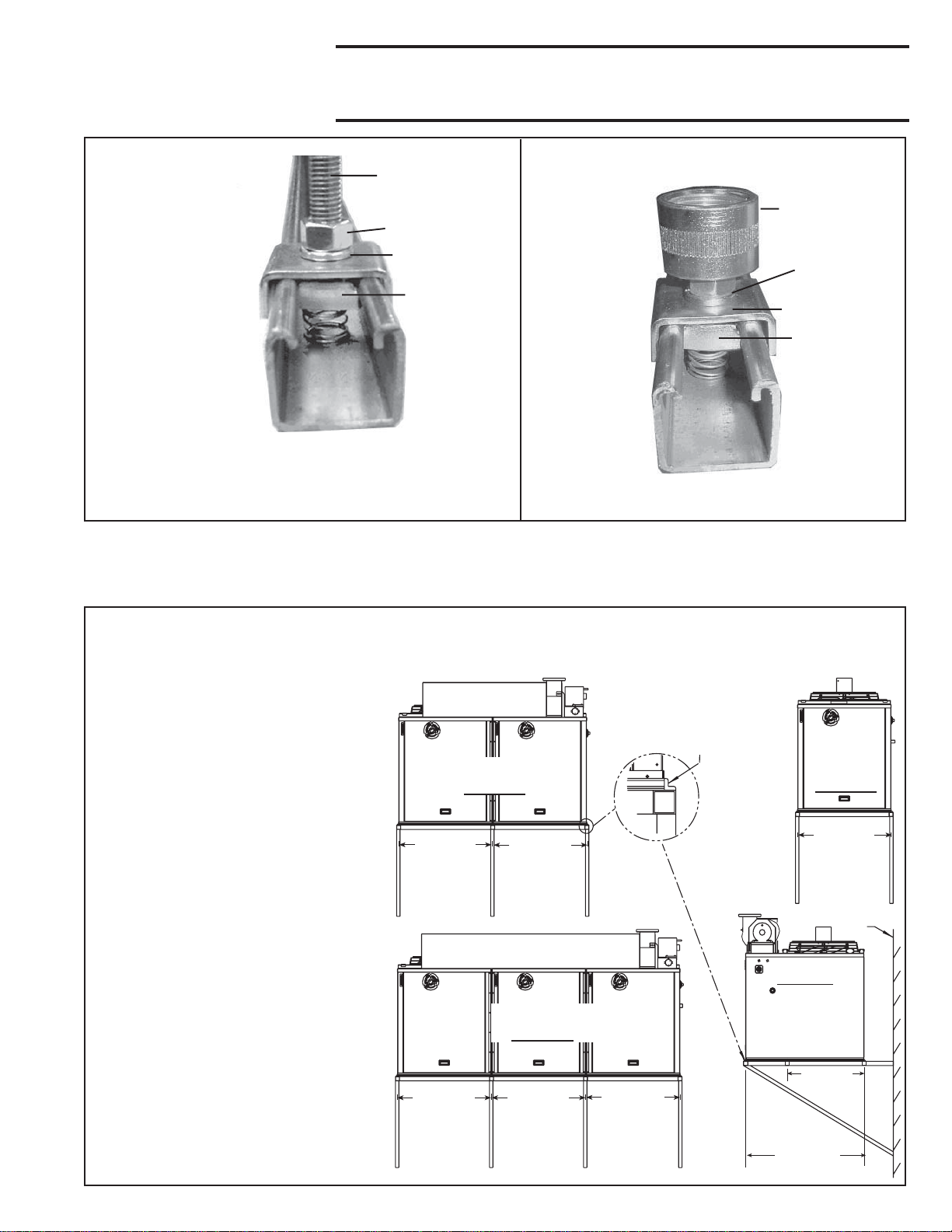

FIGURE 4A Suspending the

Heater with Rods

from the Threaded

Nut Retainers

1/2”-13

Threaded Rod

Hex Nut

Lockwasher

“U”-shape

Fitting

Spring

Nut

Strut

attached to

top of heater.

Be sure the threaded hanger rods are locked to the heater as

illustrated. Recommended maximum hanger rod length is 6

feet (1.8M).

W all Mounting

The heater may be attached to a wall. Place supports as shown in FIGURE 5 and

comply with all guidelines listed.

FIGURE 4B- Swivel Connectors to

Suspend the Heater from 1” Pipe, Option

CK10

Pipe Coupling

Assembly

Hex Nut

“U”-shape

Fitting

Lockwasher

Spring

Nut

Strut

attached to

top of heater.

Be sure the threaded swivel connectors are locked

to the heater as illustrated.

Guidelines for Wall Mounting

Model LDAP Heaters

Mounting is the responsibility of the

installer. Verify that the supporting

structure has sufficient load-carrying

capacity to support the weight. (See

weights, page 8.)

Prior to installation, be sure that the

method of support is in agreement with

all local building codes. Check for

service platform requirements.

Maintain a minimum of 2” (51mm)

clearance from the discharge air

openings to structural supports. Additional clearance will be required if an

optional nozzle is to be field installed.

Determining the need for installing

vibration or noise isolation is the

responsibility of the installer.

To prevent potential movement, field-

supplied angles must be placed around

the perimeter of the heater to anchor it

to the structural supports.

Structural supports must be placed as

shown to prevent damage to the heater.

All structural supports must be non-

combustible materials.

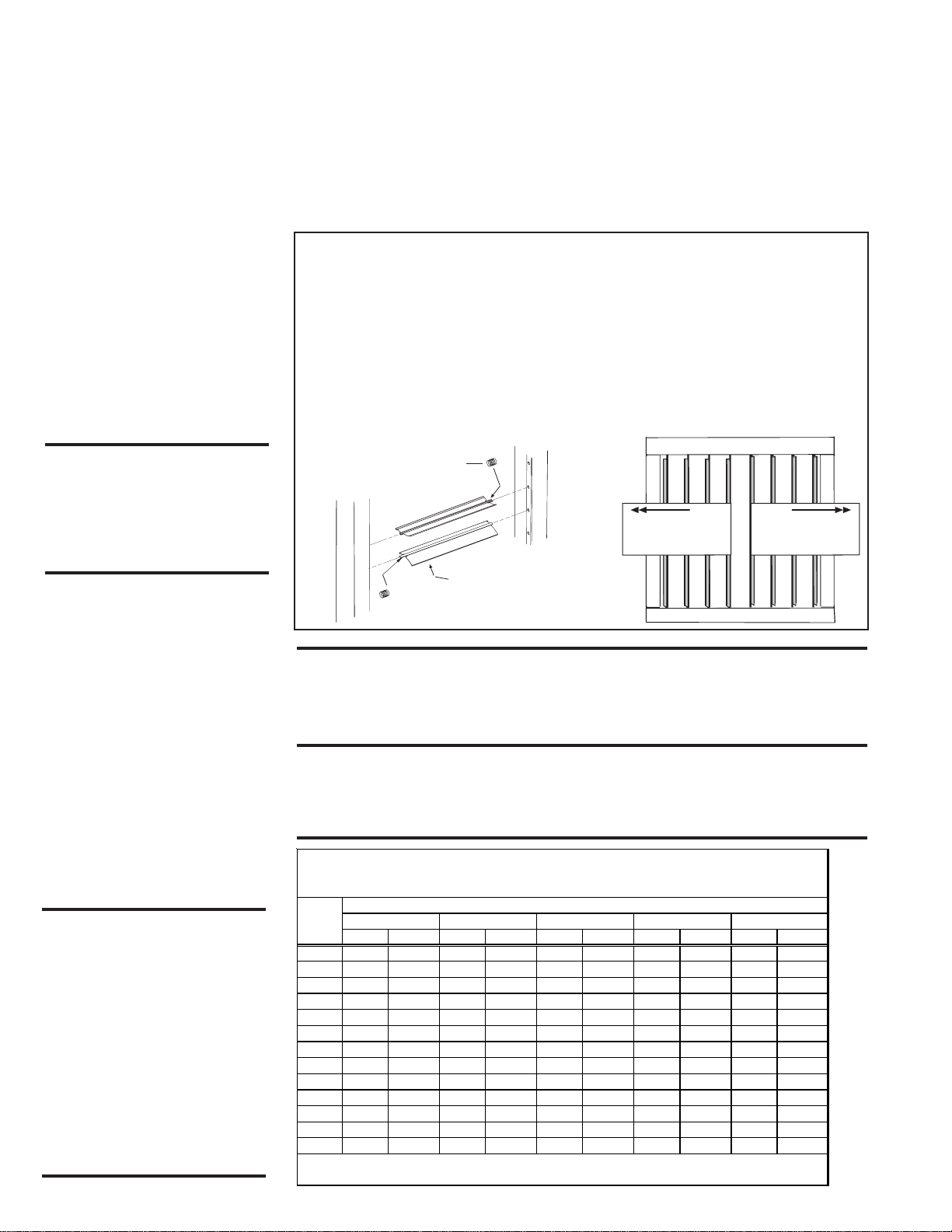

FIGURE 5 - Wall Mounting

(All structural supports and angles are field supplied.)

All dimensions are measured from centerlines of field-supplied structural supports.

Field-Supplied

Mounting Angles

(MUST be on all

Model LDAP 800

(2 heat sections)

Front View

34-33/64

(877mm)

34-33/64

(877mm)

34-33/64

(877mm)

Model LDAP 1200

(3 heat sections)

Front View

34-43/64

(881mm)

four sides of the

heater.)

Side View

Dimensions are

centerline of the

mounting angles

and apply to all sizes.

34-33/64

(877mm)

(1080mm)

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 9

Model

LDAP 400

(1 heat

section)

Front View

34-11/32

(872mm)

Wall

28-1/4

(718mm)

42-1/2

Page 10

Airflow direction;

springs are on

the upper end.

Airflow direction;

springs are on

the lower end.

l

11. Installing

Heater and

Louvers

(cont’d)

Installing Louvers

NOTE: Do not install louvers

if installing a nozzle. Follow

the instructions shipped with

the nozzle.

FIGURE 6 - Use

Compression Springs to

Install Louvers in the

Discharge Opening(s)

CAUTION: To avoid getting

burned, adjust louvers while

heater is not operating. If

adjusting louvers while

heater is operating, wear

gloves.

After the unit is suspended/mounted, install the air directional louvers or optional

nozzle. If an optional nozzle is being installed, follow the instructions included with

the nozzle. If a nozzle is not being used, install the louvers in the discharge opening(s).

Louvers and springs are in the hardware kit shipped with the heater.

Before actually installing the louvers, note the louver curve and determine how the

louvers should be positioned to provide the optimal throw pattern. Opening is square

so louvers may be installed either horizontal or vertical. Louvers may be installed

with the curve all the same direction (either way) or the right half one way and left

the other as illustrated in FIGURE 6.

Louver Installation Instructions:

1) With the wider section of the louver facing out of the heater, place one of the compres-

sion springs over the tab on the notched end of a louver. The end of the louver with the

spring will fit in any direction in the square opening. How the louver turns depends on

which end of the louver is inserted first.

2) Depending on the throw pattern selected, push the louver tab with the spring into a

hole in the discharge opening and insert the louver tab on the other end into the

corresponding hole on the opposite side.

3) Continue until all louvers are installed.

Adjust the louvers to provide the

desired throw pattern.

Compression Spring

Wider side of the louver

blade must always be

facing out of the heater.

Airflow direction depends on

how the louvers are installed.

12. Gas Piping

and

Pressures

Sizing Gas Supply

Line

W ARNING: All components of a gas supply

system must be leak

tested prior to placing

equipment in service.

NEVER TEST FOR

LEAKS WITH AN OPEN

FLAME. Failure to

comply could result in

personal injury, pr operty

damage or death.

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 10

WARNING: This appliance is equipped for a maximum gas supply

pressure of 1/2 psi, 3.5 kPa, or 14 inches water column. Supply

pressure greater than 1/2 psi requires installation of an additional

lockup-type service regulator external to the heater.

W ARNING: PRESSURE TESTING SUPPLY PIPING

Test Pressures Above 1/2 PSI: Disconnect the heater and manual valve from the

gas supply line which is to be tested. Cap or plug the supply line.

T est Pressur es Below 1/2 PSI: Before testing, close the manual valve on the heater .

Capacity of Piping

Specific Gravity for Natural Gas -- 0.6 (Natural Gas -- 1000 BTU/Cubic Ft)

Specific Gravity for Propane Gas -- 1.6 (Propane Gas -- 2550 BTU/Cubic Ft)

Length Diame te r of Pipe

of 1" 1-1/4" 1-1/2" 2" 2-1/2"

Pipe Natura

20' 350 214 730 445 1100 671 2100 1281 3300 2013

30' 285 174 590 360 890 543 1650 1007 2700 1647

40' 245 149 500 305 760 464 1450 885 2300 1403

50' 215 131 440 268 670 409 1270 775 2000 1220

60' 195 119 400 244 610 372 1105 674 1850 1129

70' 180 110 370 226 560 342 1050 641 1700 1037

80' 170 104 350 214 530 323 990 604

90' 160 98 320 195 490 299 930 567 1500 915

100' 150 92 305 186 460 281 870 531 1400 854

125' 130 79 275 168 410 250 780 476 1250 763

150' 120 73 250 153 380 232 710 433 1130 689

175' 110 67 225 137 350 214 650 397 1050 641

200' 100 61 210 128 320 195 610 372 980 598

Note: When sizing supply lines, consider possibilities of future expansion and increased requirements.

Propane Natural Propane Na t uralPropane NaturalPropane Natural Propane

Refer to National Fuel Gas Code for additional information on line sizing.

- Cubic Feet per Hour based on 0.3" w.c. Pressure Drop

1600

976

Page 11

Gas Connection Size

Ga s Connection - inches/mm

400

800

1200

Size

inches

mm

inches

mm

inches

mm

Natural

Gas

25.4 25.4

1-1/4 1-1/4

31.8 31.8

1-1/4 1-1/4

31.8 31.8

Propane

Gas

11

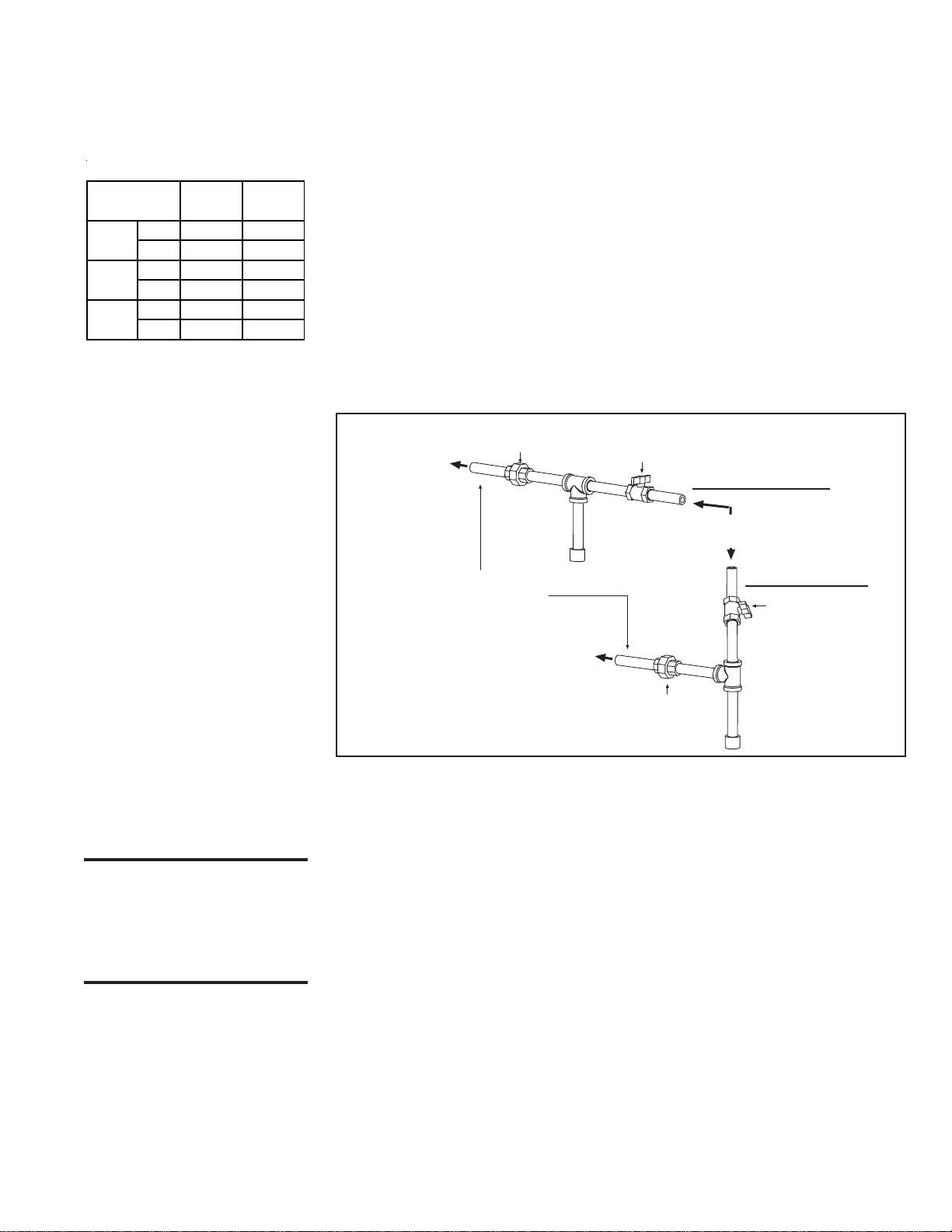

FIGURE 7 - Gas

connection is at the pipe

nipple that extends outside

the cabinet.

IMPORTANT: Two pipe

wrenches are required when

installing gas piping. The gas

pipe that is supplied with the

heater MUST be held with a

pipe wrench to prevent damage

to the heater.

NOTE: Gas Conversion Kits

are available for changing

from propane gas to natural

gas or natural gas to propane

gas. A factory-authorized

conversion kit MUST be

used.

Valve Outlet or

Orifice Pressure

Setting

W ARNING: V alve outlet

gas pressure must never

exceed 3.5" w .c. for

natural gas and 10" w .c.

for propane gas.

All piping must be in accordance with requirements outlined in the National Fuel

Gas Code ANSI/Z223.1a (latest edition) or CSA-B149.1 and B149.2 (See Paragraph

2). Gas supply piping installation should conform with good practice and with local

codes. Support gas piping with pipe hangers, metal strapping, or other suitable material; do not rely on the heater to support the gas pipe.

The heater is orificed for operation with natural gas having a heating value of 1000

(± 50) BTUH per cubic ft or propane gas with a heating value of 2500 (± 100) BTUH

per cubic ft. If the gas at the installation does not meet these specifications, consult

the factory for proper orificing.

Pipe joint compounds (pipe dope) shall be resistant to the action of liquefied petroleum gas or any other chemical constituents of the gas being supplied.

Install a ground joint union and manual shutoff valve upstream of the heater control

system, as shown in FIGURE 7. Installation of a trap with a minimum 3" (76mm)

drip leg is required.

To connect the gas, the heater is equipped with a nipple that extends outside the

cabinet.

Leak-test all connections by brushing on a leak-detecting solution.

Ground

To Gas Valve

(inside the

cabinet)

Pipe nipple extending

outside the cabinet.

Joint Union

To Gas Valve

(inside the

cabinet)

Manual shutoff

Drip

Leg

Ground

Horizontal Supply

From Gas Supply

(horizontal or vertical)

Vertical Supply

Drip

Joint

Union

Leg

Manual

shutoff

Measuring valve outlet gas pressure cannot be done until the heater is in operation. It

is included in the steps of the "Check-Test-Start" procedure in Paragraph 25. The

following warnings and instructions apply. Model LDAP 400 has one gas valve;

Model LDAP 800 has two gas valves; and Model LDAP 1200 has three gas valves.

For Natural Gas: When the heater leaves the factory, the combination gas valve(s)

is set so that the valve outlet gas pressure for a single stage valve or high fire of a two

stage valve is regulated to 3.5" w .c. Low fire on a two-stage valve (Size 400 only) is

set to 1.8” w .c. Inlet supply pressure to the heater for natural gas must be a minimum

of 5" w.c. or as noted on the rating plate and a maximum of 14" w.c.

For Propane Gas: When the heater leaves the factory , the combination gas valve(s)

is set so that the valve outlet gas pressure for a single stage valve or high fire of a two

stage valve is regulated to 10" w.c. Low fire on a two-stage valve (Size 400 only) is

set to 5.0” w.c. Inlet supply pressure to the heater for propane gas must be a minimum of 11" w.c. and a maximum of 14" w.c.

Before attempting to measure or adjust valve outlet gas pressure, the inlet

supply pressure must be within the specified range both when the heater is in operation and on standby. Incorrect inlet pressure could cause excessive valve outlet gas

pressure immediately or at some future time. If natural gas supply pressure is too

high, install a regulator in the supply line before it reaches the heater. If natural gas

supply pressure is too low , contact your gas supplier .

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 11

Page 12

12. Gas

g

g

Pressures

(cont’d)

Check V alve Outlet

Pressure (can only

be done after heater

is operating)

NOTE: If operating at high

altitude, outlet pressure

requires adjustment. Follow

instructions below.

NOTES: If installation is

above 6000 ft (1830M), a

high altitude pressure switch

is required on each heat

section (all sizes). See

Paragraph 5.

The main combustion air

pressure switch (Sizes 800

and 1200 only) does not need

to be changed for high

Instructions

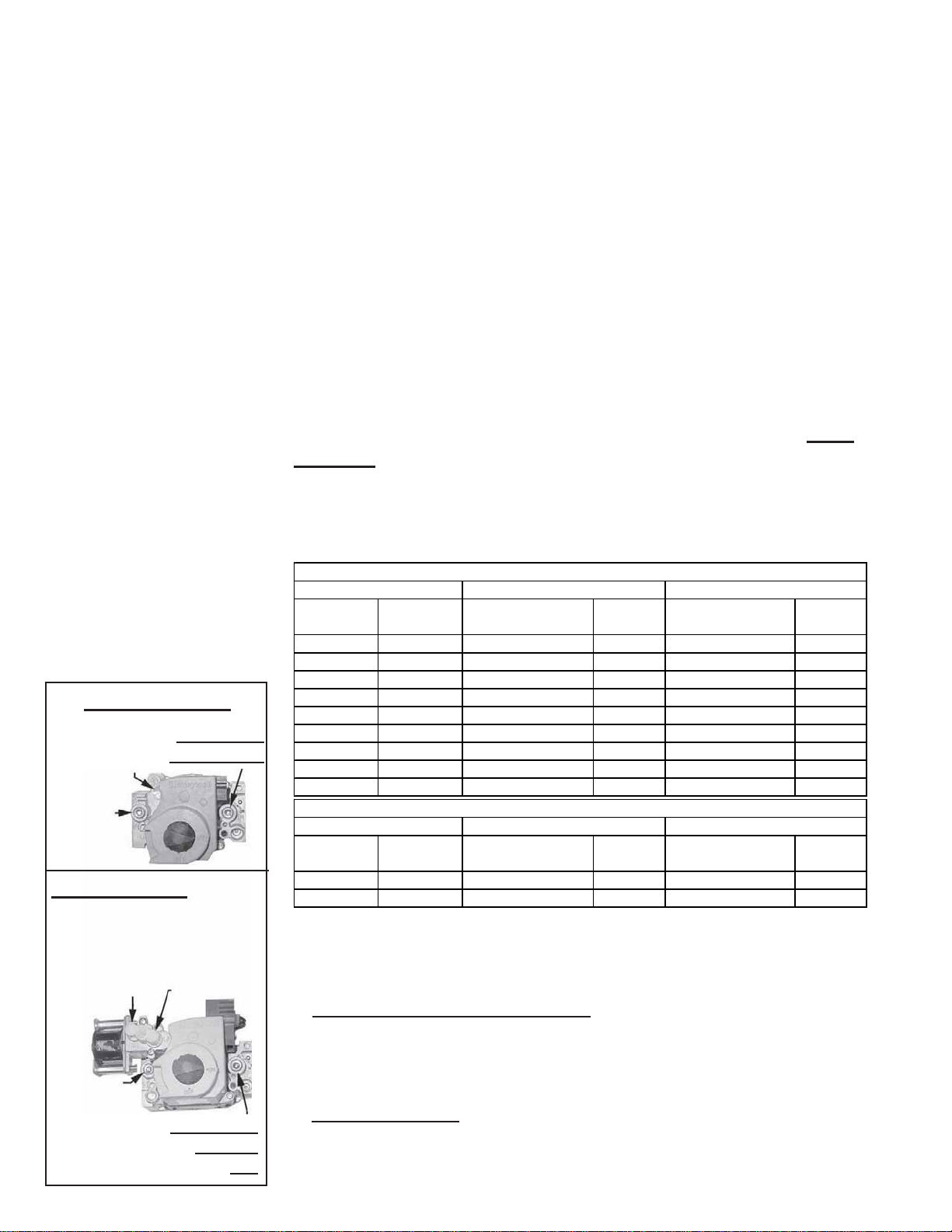

1) Locate the 1/8” output pressure tap on the first valve (See FIGURE 8). With

the manual valve turned off to prevent flow to the gas valve, connect a manom-

eter to the 1/8" pipe outlet pressure tap in the valve. NOTE: A manometer (fluid-

filled gauge) is recommended rather than a spring type gauge due to the difficulty

of maintaining calibration of a spring type gauge.

2) Open the manual valve and operate the heater. Measure the outlet pressure of

the gas valve. To measure low-stage pressure on a Size 400 unit equipped with a

two-stage valve, disconnect the wire from the “HI” terminal on the valve. (Be

sure to reconnect wire after testing.)

Normally when operating at sea level, adjustments should not be necessary to the

factory setting(s). (For high altitude settings, see below .) If adjustment is neces-

sary, remove the cap from the adjustment screw(s). Set pressure to correct

settings by turning the regulator screw IN (clockwise) to increase pressure. Turn

regulator screw OUT (counterclockwise) to decrease pressure.

3) If installing a Model LDAP 800, repeat to verify outlet pressure on second valve.

If installing a Model LDAP 1200, repeat to verify outlet pressure check on

second and third valve.

Derate by Valve Outlet Pressure Adjustment for High

Altitude Operation

Instructions for High Altitude Derate

1. Determine the required valve outlet pressure for the elevation where the heater

will be operating. If unsure of the elevation, contact the local gas supplier.

Valve Outlet Pressure Settings by Elevation

altitude installation.

FIGURE 8 - Top View of

Valves showing Outlet

Pressure Tap and

Adjustment Locations

Single-Stage Valve

Output

Adjustment

Screw

Inlet

Pressure

Tap

1/8” Output

Pressure Tap

Two -Stage Valve (optional

Feet Meters

0-2000 0-610 3.5 2.0 10.0 5.6

2001-3000 611-915 3.1 1.7 8.8 5.0

3001-4000 916-1220 3.0 1.7 8.5 4.8

4001-5000 1221-1525 2.8 1.6 8.1 4.6

5001-6000 1526-1830 2.7 1.5 7.7 4.4

6001-7000 1831-2135 2.6 1.5 7.4 4.2

7001-8000 2136-2440 2.5 1.4 7.1 4.0

8001-9000 2441-2745 2.4 1.3 6.7 3.8

9001-10000 2746-3045 2.4 1.3 6.7 3.6

Feet Meters

0-2000 0-610 3.5 2.0 10.0 5.6

2001-4500 611-1373 2.8 1.6 8.1 4.6

on Model LDAP 400 only)

Adjust High

Pressure

Output

Inlet

Pressure

Tap

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 12

Adjust Low

Pressure

Output

1/8” Output

Pressure

Tap

2. Locate the 1/8” output pressure tap on the first valve (See FIGURE 8). Turn

the knob on the top of the valve to “OFF”. Connect a manometer to the 1/8"

pipe outlet pressure tap in the valve. Use a water column manometer that is

readable to the nearest tenth of an inch.

Single-Stage and Two-Stage High Fire - Turn the knob on the top of the

3.

valve to “ON”. Remove the cap from the pressure adjusting screw and adjust

the gas train pressure to the pressure selected from the table above. Adjust

pressure by turning the regulator screw IN (clockwise) to increase pressure or

OUT (counterclockwise) to decrease pressure.

Two-Stage Low Fire - Disconnect the wire from the “HI” terminal on the gas

valve and check the low fire pressure. Turn the regulator screw to adjust the low

fire outlet pressure to the “Low Fire” pressure selected from the table. Reconnect the wire to the gas valve.

M anifold Pressure Settings by Altitude for the UNI T ED STATES

Al titude Natural Gas (inches w.c .) Propane Gas (i nc he s w.c .)

Single-Stage and

Two-Sta

Ma nifold Pressure Settings b y Altitude for CANADA

Al titude Natural Gas (inches w.c .) Propane Gas (i nc he s w.c .)

Single-Stage and

Two-Sta

e High Fire

e High Fire

Two-Stage

Low Fire

Two-Stage

Low Fire

Single-Stage and

Two-Stage High Fire

Single-Stage and

Two-Stage High Fire

Two-Stage

Low Fire

Two-Stage

Low Fire

Page 13

4. Turn up the thermostat. Cycle the burners once or twice to properly seat the

adjustment spring in the valve.

Re-check the pressure(s). When the outlet pressure is right for the installation,

remove the manometer and replace the cap.

Check for leak at the pressure tap fitting.

5. If installing a Model LDAP 800, repeat the adjustment at the second single-stage

gas valve. If installing a Model LDAP 1200, repeat the adjustment at the second

and third single-stage gas valves.

6. With the heater operating determine that the inlet pressure to the heater for

natural gas is between 5 and 13.5 inches w.c. and for propane between 10 and

13.5 inches w.c. Take this reading at the inlet pressure tap of the first gas valve.

If the inlet pressure is not within the specified range, the inlet pressure must be

corrected and Steps 3 - 5 repeated.

7. Find the High Altitude Adjustment label in the plastic bag that contained these

instructions. Using a permanent marker, fill-in the appropriate information from

the “BTUH Input & Capacity by Altitude” Table, below. Select a location for the

label on the outside of the heater main access panel so that it will be conspicuous

to anyone operating or servicing the heater. Be sure the surface is clean and dry

and adhere the label.

High Altitude

Capacity Changes

BTUH Inputs & Capacities by Altitude in the UNI T ED STATES for Model LDAP

Altitude

Feet Meters

0 - 2000 0 - 610 400000 332000 300000 800000 664000 400000 1200000 996000 400000

2001 - 3000 611 - 915 37600 0 312080 282000 752000 624160 376000 1128000 936240 376000

3001 - 4000 916 - 1220 368000 305440 276000 736000 610880 368000 1104000 916320 368000

4001 - 5000 1221 - 1525 360000 298800 270000 720000 597600 360000 1080000 896400 360000

5001 - 6000 1526 - 1830 352000 292160 264000 704000 584320 352000 1056000 876480 352000

6001 - 7000 1831 - 2135 344000 285520 258000 688000 571040 344000 1032000 856560 344000

7001 - 8000 2136 - 2440 336000 278880 252000 672000 557760 336000 1008000 836640 336000

8001 - 9000 2441 - 2745 328000 272240 246000 656000 544480 328000 984000 816720 328000

9001 - 10000 2746 - 3045 320000 265600 240000 640000 531200 320000 960000 796800 320000

Altitude

Feet Meters

0 - 2000 0 - 610 400000 332000 300000 800000 664000 400000 1200000 996000 400000

2001 - 4500 611 - 1373 360000 298800 270000 720000 597600 360000 1080000 896400 360000

Normal

Input

Normal

Input

13. Burners

The input and/or the capacity of the heater changes with the derate. The tables below

list inputs and capacities at altitudes from sea level to 10,000 ft (3045M) for the U.S.

and to 4500 ft (1373M) for Canada.

Thermal Output

Capacity

BTUH Inputs & Capacities by Altitude in the CANADA for Mod el LDAP

Thermal Output

Capacity

Size 400 Size 800 Size 1200

Each heat section in this heater has a one-piece TCORE

Minimum

Input

Minimum

Input

Normal

Input

Normal

Input

Thermal Output

Cap a city

Size 800 Size 1200Size 400

Thermal Output

Cap a city

Minimum

Input

Minimum

Input

Normal

Input

Normal

Input

Thermal Output

Cap a city

Thermal Output

Cap a city

2

®

burner assembly (U.S.

Minimum

Input

Minimum

Input

Patent No. 6,889,686) designed to provide controlled flame stability without lifting or

flashback with either natural or propane gas.

The burner can be removed as a unit for inspection or service; see Maintenance

Section for removal instructions.

14. Electrical

Supply and

Connections

Supply Wiring

All electrical wiring and connections, including electrical grounding MUST be made

in accordance with the National Electric Code ANSI/NFPA No. 70 (latest edition) or ,

in Canada, with CSA Standard C22.1. In addition, the installer should be aware of

any local ordinances or gas company requirements that might apply.

Check the rating plate on the heater for the supply voltage and current requirements.

A dedicated line voltage supply with disconnect switch should be run directly from

the main electrical panel to the heater. All external wiring must be within approved

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 13

Page 14

14. Electrical

Supply and

Connections

(cont’d)

conduit and have a minimum temperature rise rating of 60°C. Conduit must be run so

as not to interfere with the heater access panel.

CAUTION: Route wires so that they do not contact the flue wrapper

or venter housing. When running electrical conduit, be car eful that

it is clear of all access panels.

Supply Wiring

(cont’d)

Disconnect Switch

FIGURE 9 - Built-in

Disconnect Switch

24V Control Wiring

Connections

The heater is equipped with a built-in, non-fusible, lockable disconnect switch (FIGURE 8). If a fusible disconnect is required, it must be field supplied. The built-in

disconnect switch requires copper wiring with ampacity based on 60°C maximum

temperature rating at the line side terminals.

WARNING: To prevent injury or death due to electrocution or

contact with moving parts, lock disconnect switch open. See Hazard

Levels, page 2.

WARNING: If you turn off the power supply , turn off the gas. See

Hazard Levels, page 2.

Model LDAP supply wiring enters above and connects directly to the disconnect

switch (See FIGURE 1A or 1B in Paragraph 7 and FIGURE 9). A circuit board (See

FIGURE 13 in Paragraph 20) is located in the control compartment of each heat

section. The circuit boards are polarity sensitive. It is advisable to check the electrical

supply to be certain that the black wire is the “hot” wire and that the white wire is the

neutral wire. The supply connection made to “L1” on the disconnect switch must be

the “hot” wire.

Each heat section in the heater has a terminal strip for 24-volt thermostat connections. The terminal strip is located on the outside of the cabinet at the front of each

heat section (See FIGURE 1A or 1B in Paragraph 7). W ires from the terminal strip(s)

are factory wired to the circuit board(s).

15. Thermostat

and

Connections

Use either an optional thermostat available with the heater or a field-supplied 24-volt

thermostat. Install according to the thermostat manufacturer's instructions, paying

particular attention to the requirements regarding the location of the thermostat.

Make sure that the heat anticipator setting on the thermostat is 0.6 amps (or in accordance with the amperage value noted on the wiring diagram of your heater).

Make thermostat connections at the terminal strip on the front of the heater. The strip

has seven terminals, R, G, C, Y1, Y2, W1, and W2. Refer to the wiring diagram on

the heater.

IMPORTANT: All heaters MUST be operated by a 24-volt thermostat. Never

use a line voltage disconnect switch as a means of operating the heater. Operating by

means other than a 24-volt thermostat may result in the high limit control tripping

and may cause damage to the heater from excessive heat.

Connections for Reznor optional thermostats are shown in FIGURE 10 for LDAP

400; in FIGURE 11 for LDAP 800; and in FIGURE 12 for LDAP 1200.

• Option CL1 - Single-Stage Thermostat, 40-80°F

• Option CL2 - Single-Stage Thermostat with Fan Switch, 40-80°F

• Option CL3 - Single-Stage Thermostat, 40-90°F

• Option CL7 - Two-Stage Thermostat (for use with optional two-stage gas valve

on Size 400 or for staging heat sections on Sizes 800 and 1200)

• Option CL18 - Two-Stage Thermostat with Fan Switch (for use with optional

two-stage gas valve on Size 400 or for staging heat sections on Sizes 800 and

1200)

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 14

Page 15

FIGURE 10 - Thermostat

Connections for Model

LDAP 400 with Option CL1,

CL2, CL3, CL7, or CL18

LDAP 400 THERMOSTAT WIRING

FIELD WIRING

NOTES:

1) Set the anticipator at 0.6 amps.

2) Set thermostat first stage anticipator at

0.6 amps and second stage anticipator at

0.2 amps.

3) Jumper thermostat terminals RH to RC.

4) Jumper thermostat terminals RH to RC

and G to W1.

5) Set thermostat first stage anticipator at

maximum amps and second stage

anticipator at 0.6 amps.

LDAP 400 - Thermostat Option CL1,

CL2, CL3, CL7 or CL18

WD# 189504 REV. #2

SINGLE STAGE HEATING TWO STAGE HEATING

CL2

W-S23-6 SUBBASE

(OPT CL2) W.R. 1C30-341

(SEE NOTE #1)

CL1

CL3

(SEE NOTE #1)

(OPT CL3) T874F THERMOSTAT OR

(OPT CL1) W.R. 1C30-341 THERMOSTAT

TERMINAL STRIP

G

W

R

W

R

G

W1

R

W2

C

Y1

Y2

SINGLE STAGE HEATING

WITH RECIRCULATION

CL18

W1

G

W2

RH

(OPT CL18) T874F THERMOSTAT

SEE NOTES #4 & #5)

RC

(

Q674C SUBBASE (SEE NOTES #4 & #5)

CL7

W1

W2

Q674G SUBBASE

(SEE NOTE #5)

(OPT CL7) T874F THERMOSTAT

R

TERMINAL STRIP

G

W1

R

W2

C

Y1

Y2

CL18

G

W1

Q674C SUBBASE

RH

(OPT CL18) T874F THERMOSTAT

RC

(SEE NOTE #2 AND #3)

W2

CL7

W1

R

Q674G SUBBASE

(SEE NOTE #2)

(OPT CL7) T874F THERMOSTAT

W2

TERMINAL STRIP

G

W1

R

W2

C

Y1

Y2

FIGURE 11 - Thermostat

Connections for Model

CL2

LDAP 800 with Option

CL1, CL2, CL3, CL7, or

CL18

W-S23-6 SUBBASE

(OPT CL2) W.R. 1C30-341

(SEE NOTE #1)

CL1

CL3

(OPT CL3) T874F THERMOSTAT OR

(OPT CL1) W.R. 1C30-341 THERMOSTAT

(SEE NOTE #1)

LDAP 800 THERMOSTAT WIRING

FIELD WIRING

NOTES:

1) Set the anticipator at 0.6 amps.

2) Set thermostat first stage anticipator

at 0.6 amps and second stage anticipator

at 0.2 amps.

3) Jumper thermostat terminals RH to RC.

4) Jumper thermostat terminals RH to RC

and G to W1.

5) Set thermostat first stage anticipator at

maximum amps and second stage

anticipator at 0.6 amps.

LDAP 800 - Thermostat Option CL1,

CL2, CL3, CL7 or CL18

WD# 189505 REV. #2

TERMINAL STRIP

SINGLE STAGE HEATING

G

W

G

PR

W1

R

R

R

W2

C

W

Y1

R

Y2

TERMINAL STRIP

UNIT #1

PR

G

W1

R

R

W2

C

Y1

Y2

UNIT #2

SINGLE STAGE HEATING

WITH RECIRCULATION

CL18

W1

G

G

W1

W2

Q674C SUBBASE

RH

(OPT CL18) T874F THERMOSTAT

RC

(SEE NOTES #4 & #5)

CL7

W1

R

W2

C

W2

Q674G SUBBASE

(OPT CL7) T874F THERMOSTAT

R

(SEE NOTE #5)

TERMINAL STRIP

Y1

Y2

UNIT #1

G

W1

R

W2

C

Y1

Y2

TERMINAL STRIP

UNIT #2

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 15

CL18

PR

R

(OPT CL18) T874F THERMOSTAT

TWO STAGE HEATING

G

W1

Q674C SUBBASE

RH

RC

W2

(SEE NOTE #2 AND #3)

CL7

W1

G

PR

W1

R

R

W2

C

Y1

R

Q674G SUBBASE

(OPT CL7) T874F THERMOSTAT

W2

(SEE NOTE #2)

PR

Y2

TERMINAL STRIP

UNIT #1

G

PR

W1

R

R

R

W2

C

Y1

Y2

TERMINAL STRIP

UNIT #2

Page 16

15. Thermostat and Connections (cont’d)

SINGLE STAGE HEATING

WITH RECIRCULATION

CL18

W1

G

W2

Q674C SUBBASE

RH

(OPT CL18) T874F THERMOSTAT

RC

(SEE NOTES #6 & #7)

G

W1

R

W2

CL7

W1

W2

Q674G SUBBASE

(OPT CL7) T874F THERMOSTAT

R

(SEE NOTE #7)

TERMINAL STRIP

UNIT #1

C

Y1

Y2

G

FIGURE 12 - Thermostat

Connections for Model

LDAP 1200 with Option

CL1, CL2, CL3, CL7, or

CL18

SINGLE STAGE HEATING

CL2

G

W

W-S23-6 SUBBASE

(OPT CL2) W.R. 1C30-341

R

(SEE NOTE #1)

CL1

CL3

W

R

(OPT CL3) T874F THERMOSTAT OR

(OPT CL1) W.R. 1C30-341 THERMOSTAT

(SEE NOTE #1)

TERMINAL STRIP

UNIT #1

G

W1

R

W2

Y1

Y2

G

PR

R

C

PR

TWO STAGE HEATING

CL18

G

PR

W1

RH

Q674C SUBBASE

R

RC

(OPT CL18) T874F THERMOSTAT

W2

G

W1

R

W2

PR

NOTE 2

NOTE 3

R

(SEE NOTE #4 AND #5)

CL7

W1

C

Y1

R

G

Y2

PR

Q674G SUBBASE

(OPT CL7) T874F THERMOSTAT

W2

(SEE NOTE #4)

TERMINAL STRIP

UNIT #1

PR

LDAP 1200 THERMOSTAT WIRING

FIELD WIRING

FACTORY WIRING

CRIMP TERMINAL

NOTES:

1) Set the anticipator at 0.6 amps.

2) For 400,000 BTUH low fire, do

not install this jumper.

3) For 800,000 BTUH low fire, do

not install this jumper.

4) Set thermostat first stage anticipator

at 0.6 amps and and second stage

anticipator at 0.2 amps.

5) Jumper thermostat terminals RH

to RC.

6) Jumper thermostat terminals RH

to RC and G to W1.

7) Set thermostat first stage anticipator at

maximum amps and second stage

anticipator at 0.6 amps.

LDAP 1200 - Thermostat Option CL1,

CL2, CL3, CL7 or CL18

WD# 189506 REV. #2

W1

W2

TERMINAL STRIP

UNIT #2

W1

W2

Y1

R

Y1

Y2

W2

TERMINAL STRIP

UNIT #2

W1

R

Y1

Y2

W1

W2

Y1

R

C

PR

G

R

R

C

W1

R

R

R

W2

C

C

Y1

Y2

TERMINAL STRIP

PR

G

UNIT #2

PR

G

W1

R

R

R

R

W2

C

C

Y1

TERMINAL STRIP

Multiple Heater

Control - Option

CL31 and Option

CL32

If the heater was ordered with a multiple heater control option, one thermostat can be used

to control multiple heaters. The option will control a maximum of six Size 400 heaters, a

maximum of three Size 800 heaters, or a maximum of two Size 1200 heaters.

The option includes a 40 VA transformer that replaces the standard transformer in the

”master” heater and a relay assembly that attaches to the “slave” heater. Option CL31

provides for control of two heaters. If control of additional heaters is desired, Option CL32

which is the relay assembly only must be added to each of the “slave” heaters.

The option packages are shipped separately and include complete instructions for installation and wiring.

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 16

UNIT #3

Y2

TERMINAL STRIP

Y2

UNIT #3

TERMINAL STRIP

Y2

UNIT #3

Page 17

16. Combustion

Air Proving

[Pressure

Switch(es)]

The combustion air proving switch is a pressure sensitive switch that monitors air

pressure to ensure that proper combustion airflow is available. The switch is a single

pole/normally open device which closes when a differential pressure is sensed between the venter housing and the flue collection box. Each section in the heater has a

pressure switch. (For switch location, see FIGURE 22, page 33.) In addition, heaters

with more than one heat section (Size 800 and Size 1200) have a main pressure switch

which senses the negative pressure in the main venter housing.

NOTE: For high altitude,

follow instructions in

Paragraph 5 to change heat

On startup when the heater is cold, the sensing pressure is at the highest level, and as

the heater and flue system warm up, the sensing pressure becomes less. After the

system has reached equilibrium (about 20 minutes), the sensing pressure levels off.

section pressure switch(es).

The main combustion air

pressure switch (Sizes 800

and 1200 only) does not need

to be changed for a high

altitude installation.

Pressure Switch Settings

Sea Level Pressure Switc h Settings (Ap plies to elevatio ns up to 6000ft /1830M)

Main P ressure Switch

St a rt-up Cold

Model

LDAP

400 1 1.80 to 1.50 1.05 to 0.85 0.65 0.83 Yellow 197028

800 -1.30 to -1.00 -0.85 to -0.65 -0.15 -0.33 Gray 205445 2 1.90 to 1.60 1.10 to 0.90 0.65 0.83 Yellow 197028

1200 -1.40 to -0.90 -0.97 to -0.59 -0.15 -0.33 Gray 205445 3 2.40 to 1.90 1.55 to 1.00 0.65 0.83 Yellow 197028

St a rt-up Cold

Model

LDAP

400 1 1.75 to 1.45 1.00 to 0.80 0.60 0.78 Lt. Blue 197029

800 -1.25 to -0.95 -0.80 to -0.60 -0.15 -0.33 Gray 205445 2 1.85 to 1.55 1.05 to 0.85 0.60 0.78 Lt. Blue 197029

1200 -1.35 to -0.85 -0.92 to -0.54 -0.15 -0.33 Gray 205445 3 2.35 to 1.85 1.50 to 0.95 0.60 0.78 Lt. Blue 197029

Equilibrium

Hot

Negative Pressure (in. w.c.) Differential Pressure (in. w.c.)

Main P ressure Switch

Equilibrium

Hot

Negati ve Pressure ( in. w .c.)

If a restriction or excessive flue length or turns cause the sensing pressure to be outside the switch setpoint, the pressure switch will function to shutoff the burner . If the

main combustion air pressure switch opens, it will interrupt the electric supply to all

gas valves. If a heat section pressure switch opens, it will interrupt the electric supply

to the gas valve in that heat section. The burner(s) will remain off until the system has

cooled and/or the flue system resistance is reduced.

The Table below lists the approximate water column differential pressure settings of

the heat section pressure switch(es) and the negative pressure readings of the main

pressure switch.

Heat Section Pressure Sw it ch (es)

Setpoint

High Altitu de Pr essur e Switc h Set tings, Units Abo ve 6000ft/ 1830M

Setpoint

OFF

OFF

Setpoint

ON

Setpoint

ON

Label

Color

Label

Color

Switch

Part No.

Switch

Part No.

Qty

Qty

Start-up

Cold

Start-up

Cold

Equilibrium

Hot

Heat Section Pressure Sw it ch (es)

Equilibrium

Hot

Differential Pressure (in. w.c.)

Setpoint

OFF

Setpoint

OFF

Setpoint

ON

Setpoint

ON

Label

Color

Label

Color

Switch

Part No.

Switch

Part No.

DANGER: Safe operation of this heater requir es proper venting flow . NEVER bypass combustion

air proving switch(es) or attempt to operate the heater without the venter running and the pr oper

flow in the vent system. Hazardous conditions could result. See Hazard Intensity Levels, page 2.

17. Limit Control

Each heat section is equipped with a temperature activated auto reset limit control.

The control is factory set and is non-adjustable. If the setpoint is reached, the limit

control will interrupt the electric supply to the gas valve in that heat section. This

safety device provides protection in the case of motor failure or lack of airflow due to

a restriction at the inlet or outlet. (For location, see FIGURE 22, page 33.)

CAUTION: The auto reset limit control will shut down the heater

until the cause is corrected. Do not bypass the limit control;

hazardous conditions could result. See Hazard Intensity Levels, page

2.

18. High Limit

Control

Each heat section is equipped with a temperature activated, manually reset high limit

control. The high limit control is located at the top of each heat section. It is factory

set and is non-adjustable. If the setpoint is reached, the high limit control acts to

interrupt the electric supply to the gas valve in that heat section. If the high limit

control activates, identify and correct the cause before resetting the switch. Refer to

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 17

Page 18

18. High Limit

Control

(cont’d)

the Maintenance Section for information on probable causes . (For location, see FIGURE 22, page 33.)

DANGER: If a manual reset high limit control activates, identify

and correct the cause before r esetting the switch. Never bypass the

high limit control; hazardous conditions could result. See Hazard

Intensity Levels, page 2.

19. Adjustable

Air Destratification Fan

Control

20. Ignition

System

An adjustable fan control is located on top of the first heat section. It is adjacent to the

circulating air fan and motor and controls the fan motors in all heat sections. The

purpose of the fan control is to energize the fan motor(s) when the ambient air temperature around the heater reaches the setting on the control. The fan motor(s) will be

de-energized when the fan control is satisfied. The fan(s) re-circulates the heated air

near the ceiling down to the floor level (destratification) and improves heat recovery .

A call for heat by the thermostat overrides the air destratification fan control.

Set the adjustable fan control for the desired temperature setting for energizing the

circulating air fan(s). The fan control setting should be set 5 to 10°F higher than the

wall-mounted thermostat setting. The heater is factory wired to energize the fan(s) at

medium speed when energized by the adjustable fan control. For lower mounting

heights it may be desirable to operate the fan(s) at low speed. Switching the blue

(medium speed) and red (low speed) fan motor wires on each heat section will change

the fan motor(s) speed. Refer to the wiring diagram for the wire locations.

T o manually override the fan control, the heater may be tuned off at the circuit breaker

in the main electrical panel, or a field-installed electrical box with a SPST switch can

be located near the wall thermostat with the switch wired in series with the fan control.

The air destratification can also be a benefit in the summer time. Using the fan(s) in

the summer time can improve working conditions by alleviating stagnant air conditions and creating a cooling effect for the occupants.

Each heat section in this heater is equipped with a direct spark integrated control

module (circuit board). The module monitors the safety devices and controls the

operation of the fan and venter motors and the gas valve between heat cycles.

FIGURE 13 – DSI

Integrated Control

Module (circuit

board) in Each

Heat Section

Supply

Voltage

Connections

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 18

Spark

Transformer

x

Plug

Control

Fuse

Thermostat

Connections

Dip

Switch

Fan/Blower

Off

Delay

Status

Lights

LED

Lights

Page 19

Normal Heat

Cycle Operating

Sequence

NOTE: All LED Flash

Codes are on page 38.

Swit ch Settng Chart for Fan

OFF Delay (See SW1 on W.D.)

TIME SW1 SW2

90 sec OFF ON

120 sec OFF OFF

160 sec ON OFF

45 sec ON ON

1) Call for Heat - The thermostat calls for heat by energizing the “W” terminal. The

control checks to see that the limit and high limit switches are closed and the heat section

pressure switch is open and the main combustion air pressure switch (Sizes 800 and

1200) is open. If the limit or high limit switch is open, the control responds as defined in

the “Abnormal Heat Cycle, Limit Switch Operation”. If the heat section pressure switch

or main combustion air pressure switch are closed, the control will do four flashes on the

green LED and wait indefinitely for the heat section pressure switch or main combustion

air pressure switch to open. If the heat section pressure switch and main combustion air

pressure switch are open, the control proceeds to prepurge.

2) Prepurge - The control energizes the heat section venter motor and main venter motor

(Sizes 800 and 1200) and waits for the heat section pressure switch and main combustion

air pressure switch to close. If the heat section pressure switch or main combustion air

pressure switch does not close within 30 seconds of the heat section venter motor and

main venter motor energizing, the control will do two flashes on the green LED. The

control will leave the heat section venter motor and main venter motor energized indefinitely as long as the call for heat remains and the heat section pressure switch or main

combustion air pressure switch is open.

When the heat section pressure switch and main combustion air pressure switch are proven

closed, the control begins the prepurge time. If flame is present any time while in prepurge,

the prepurge time is restarted. If flame is present long enough to cause lockout, the control responds as defined in “Fault Modes, Undesired Flame”.

The control runs the heat section venter motor and main venter motor for a 20 second

prepurge time, then proceeds to the ignition trial period.

3) Ignition T rial Period - The control energizes the spark and main gas valve. The venter

remains energized. If flame is sensed during the first 16 seconds, the spark is de-energized and the control proceeds to heat fan on delay. If flame has not been sensed during

the first 16 seconds, the control de-energizes the spark output and keeps the gas valve

energized for an additional one second flame proving period. If flame is not present after

the flame proving period, the control de-energizes the gas valve and proceeds with ignition re-tries as specified in “Abnormal Heat Cycle, Ignition Re-try”. If flame is present,

the control proceeds to the fan on delay.

4) Fan On Delay - The control waits for 30 seconds from the time the gas valve opened

and then energizes the fan motor. The gas valve, heat section venter motor, and main

venter motor remain energized. The control proceeds to steady heat mode.

5) Steady Heat - Control inputs are continuously monitored to ensure limit, high limit,

heat section pressure switch, and main combustion air pressure switch are closed, flame

is established, and the thermostat call for heat remains. When the thermostat call for heat

is removed, the control de-energizes the gas valve and begins post-purge and fan off

delay timing.

6) Post Purge - The heat section venter motor and main venter motor outputs remain on

for a 45 second post-purge period after the thermostat is satisfied.

7) Fan Off Delay - The fan motor is de-energized after a fan off delay as selected by the

dip switches. Timing begins when the thermostat is satisfied. Delay times are as in the

table on the left. The factory default when shipped is 120 seconds.

Abnormal Heat

Cycle Functions

Interrupted Thermostat Call for Heat - If the thermostat demand for heat is removed

before the flame is recognized, the control will run the heat section venter motor and

main venter motor for the post purge period and de-energize all outputs.

If the thermostat demand for heat is removed after successful ignition, the control will

de-energize the gas valve, run the heat section venter motor and main venter motor through

post purge, and run the fan motor on heat speed for the selected delay off time.

Ignition Retry - If flame is not established on the first trial for ignition period, the control

de-energizes the gas valve and the heat section venter motor and main venter motor

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 19

Page 20

20. Ignition

System

(cont’d)

Abnormal Heat

Cycle Functions

(cont’d)

remain energized for an inter-purge period of 10 seconds. The spark and gas valve are

then re-energized, and the control initiates another trial for ignition.

If flame is not established on the second trial for ignition, the control de-energizes the gas

valve, energizes the fan motor on heat speed, and the heat section venter motor and main

venter motor remain energized. The fan motor is shut of f after the longest selectable fan

delay time (160 seconds). When the fan motor de-energizes, the spark and gas valve are

re-energized and the control initiates another trial for ignition. (This fan delay is a selfhealing feature for an open auxiliary limit switch).

If flame is not established on the third trial for ignition period, the control de-energizes

the gas valve, and the heat section venter motor and main venter motor remain energized

for an inter-purge period of 10 seconds. The control then re-energizes the gas valve and

spark and initiates another trial for ignition.

If flame is not established on the fourth trial for ignition (initial try plus 3 re-tries), the

control de-energizes the gas valve and goes into lockout. The control goes to one flash on

the green LED to indicate ignition failure lockout.

Limit and High Limit Switch Operation - The high limit and limit switch are ignored

unless a call for heat is present (W energized). If the high limit or limit switch are open

and a call for heat is present, the control de-energizes the gas valve and turns the fan

motor on heat speed and runs the heat section venter motor and the main venter motor.

When the switch re-closes or the call for heat is lost, the control runs the heat section

venter motor and main venter motor through post purge and runs the fan motor through

the selected fan off delay. The control will return to normal operation after fan off delay

is completed.

Heat Section Pressure Switch (all sizes) and Main Combustion Air Pressure Switch

(Sizes 800 and 1200) - If the heat section pressure switch or main combustion air pres-

sure switch opens before the trial for ignition period, the heat section venter motor and

main venter motor will run through the heat section pressure switch and main combustion air pressure switch recognition delay (2 seconds), the gas valve will be de-energized,

and the heat section venter motor and main venter motor will run through the postpurge

time. The control will re-start the heat cycle at the heat section pressure switch and main

combustion air pressure switch proving state if the call for heat still exists.

Heat section pressure switch or main combustion air pressure switch opening for less

than 2 seconds during the trial for ignition period shall not interrupt the heat cycle. (Gas

valve will de-energize while the heat section pressure switch and main combustion air

pressure switch is open.)

If the heat section pressure switch or main combustion air pressure switch opens after a

successful ignition, the control will de-energize the gas valve. If flame is lost before the

end of the 2 second pressure switch recognition delay , the control will respond to the loss

of flame. If the heat section pressure switch and main combustion air pressure switch

remains open for 2 seconds and the flame remains, the control de-energizes the gas valve,

the heat section venter motor and main venter motor runs through postpurge, and the fan

motor runs on heat speed through the selected fan off delay. When the fan off delay is

over, the fan motor is de-energized, and a heat cycle is begun if the call for heat still

exists.

Continuous Fan

Operation

Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 20

When the thermostat calls for continuous fan (G) without a call for heat, the fan motor is

energized after a .25 second delay. NOTE: This brief on delay is to allow the “G” terminal to energize slightly before “Y” and an external changeover relay to switch from “G”

to “W” without causing momentary glitches in the fan motor output. The fan remains

energized as long as the call for fan remains without a call for heat.