Page 1

Operating Instructions

FOR HMC5750-LI

HYDRAULIC COMPRESSION TOOL

Table of Contents

Page

1.0 GENERAL INFORMATION......................................................... 2

1.1 Safety Rules........................................................................... 2

1.2 Features................................................................................. 2

1.3 Specifications......................................................................... 2

2.0 Parts & Accessories .................................................................. 3

2.1 Hydraulic Compression Tool................................................... 3

2.2 Battery. .................................................................................. 3

2.3 Charger. ................................................................................. 3

2.4 Carrying Case ........................................................................ 3

3.0 Operating Instructions .............................................................. 4

3.1 Charging the Battery. ............................................................. 4

3.2 Attaching & Detaching the Battery. ......................................... 4

3.3 Compression Cycles .............................................................. 4

TA04748 A Page 1 of 8

Page

3.4 Switch Operations.................................................................. 4

3.5 Compression Operation ......................................................... 5

3.6 Maintenance & Operation....................................................... 5

3.7 Trouble Shooting .................................................................... 5

4.0 Important Operation Precautions ............................................ 6

4.1 Precautions for the Compression Tool .................................... 6

4.2 Precautions for the Battery. .................................................... 6

4.3 Precautions for the Charger.................................................... 6

5.0 Parts Breakdown....................................................................... 7

5.1 Parts Diagram ........................................................................ 7

5.2 Parts List................................................................................ 8

Page 2

IMPORTANT: Read and understand all of the

instructions and safety information in this manual

before operating or servicing this tool.

1.0

1.1

1. BE FAMILIAR WITH YOUR TOOL.

Read the instruction manual. Become aware of its proper

usage as well as the potential hazards.

2. KEEP WORK AREA CLEAN AND WELL LIGHTED.

Poor lighting and cluttered areas invite accidents.

3. USE SAFETY GLASSES.

4. MAINTAIN TOOL WITH CARE.

Keep tool in good condition at all times. Keep it clean for

best and safest performance.

5. DON'T OVER-REACH.

Keep proper footing and balance at all times.

6. NEVER ATTEMPT TO MAKE A COMPRESSION ON A

"HOT" LINE.

Never assume the power is OFF! Determine beforehand if

any electrical hazards could exist when making a

connection to a line or wire.

7. KEEP FINGERS AND OTHER BODY PARTS AWAY

FROM INDENTING NIBS & MOVING PARTS.

SAFETY RULES

GENERAL INFORMATION

WARNING

Tools are NOT insulated for use on or near

energized conductors. Use of these tools

near energized conductors may lead to

electrical shock, causing severe injury or

death. DO NOT use these tools near

energized conductors without adequately

insulating operator and surroundings.

WARNING

Pinch point hazard. Indenting Nibs at high

force can cause severe personal injury. Keep

all body parts away from moving parts of the

tool during operation.

FEATURES1.2

• Fully automatic, self-contained power tool.

• Removable battery cartridge - simply change the

cartridge for continuous use.

• One handed operation - control ram advancement

and retraction with one hand.

• Designed to crimp connectors manufactured to

ANSI C119.4.

• 360º rotating head, no dies required.

1.3

SPECIFICATIONS

HYDRAULIC COMPRESSION TOOL:

HMC5750-LI

Drive Unit: 1

Dimensions:

Weight:

Output:

Capacities:

Jaw Opening:

4.4V DC Motor

15”L x 2.5”W x 13”H

12.5 lbs. with battery

6 Tons

Up to 750 kcmil Cu

1.50”

BATTERY:

144-BAT-LI

Battery Type: Sealed Lithium Ion

Voltage:

Dimensions:

Capacities:

Weight:

Charging time:

45 min. 100% Capacity

14.4V DC

4.2”L x 3.3W x 2.6H

3.0Ah

1.2 lbs.

25 min. 80% Capacity

CHARGER:

144-CHR-LI

Input Voltage: 120 - 240 V AC Single Phase

Dimensions:

Weight:

9”L x 5.7W x 3.2H

3.5 lbs.

TA04748 A Page 2 of 8

Page 3

2.0

PARTS AND ACCESSORIES

2.1

2.3

HYDRAULIC COMPRESSION TOOL

(HMC5750-LI)

Head Latching Pin

Indenting

Nibs

Advance Trigger

Release Button

Hanging Strap

CHARGER (144-CHR-LI

LED

Indicator

Hanging

Strap

)

2.2

Release

Button

2.4

Air Vent

BATTERY (144-BAT-LI

Contact Cover

Air Vent

CARRYING CASE

)

Contacts

LED Lamp

Power Cord Inlet

Contacts

Air Vent

Power Cord

TA04748 A Page 3 of 8

Page 4

3.0

OPERATING INSTRUCTIONS

3.1

CHARGING THE BATTERY

1. Connect the power cord to the Charger 144-CHR-LI and to an AC

outlet. The LED Lamp blinks in Red [STAND BY]

NOTE: The rated input voltage for this unit is 100V-240V. Use of

voltages over 260V will result in damage to the charger.

2. Insert the Battery rmly into the charger.

The LED Lamp lights in green [CHARGING].

NOTE: Do not short-circuit the Charger by placing foreign materials

in the contacts on Charger, as this will damage the Charger.

3. Charging takes approximately 25 minutes (80% capacity) and

45 minutes (100% capacity).

When charging is nished, the LED Lamp lights in orange

[COMPLETION].

NOTE: If the LED Lamp displays solid red [HIGH TEMPERATURE],

remove the Battery from the Charger and allow it to cool down

before trying to charge it again.

4. When the battery will no longer charge or hold a charge, the LED

Lamp blinks quickly in red [IMPOSSIBLE TO CHARGE].

5. When the charger is out of order, the LED Lamp does not light up

even if AC power is supplied.

NOTE: Do not power the Charger with a portable generator.

3.2

ATTACHING & DETACHING THE BATTERY PACK

3.3

Battery

LED Lamp

Power Cord

Charger

COMPRESSION CYCLES

1. To attach the Battery, slide it into the base of the Tool

until it stops and the Latches engage.

2. After inserting the Battery, check that it is securely in

place by pulling it gently without pressing the Latches.

3. To detach the Battery, pull out the Battery while pressing

the Latches.

Tool

Battery

This guide indicates the number of compression cycles that

the HMC5750-LI can be expected to perform when the

battery is fully charged. These gures are approximate and will

vary according to the charging and other operating conditions,

such as temperature, humidity, and battery condition.

AVERAGE COMPRESSIONS

CONDUCTOR

PER CHARGE

144-BAT-LI

1/0 Cu / Al

4/0 Cu / Al

750 kcmil

3.4

100 - Conductor size is not a major

factor on this dieless tool. It

performs approximately the same

on all sizes.

SWITCH OPERATIONS

1. The indenting nibs extend when the Trigger is depressed

and stops when the Trigger is released.

2. To retract the indenting nibs, depress the Release Button.

The indenting nibs continue to retract while the Release

Button is depressed.

Trigger

Latches

(both sides)

Pull Out

Slide in

Release Button

TA04748 A Page 4 of 8

Page 5

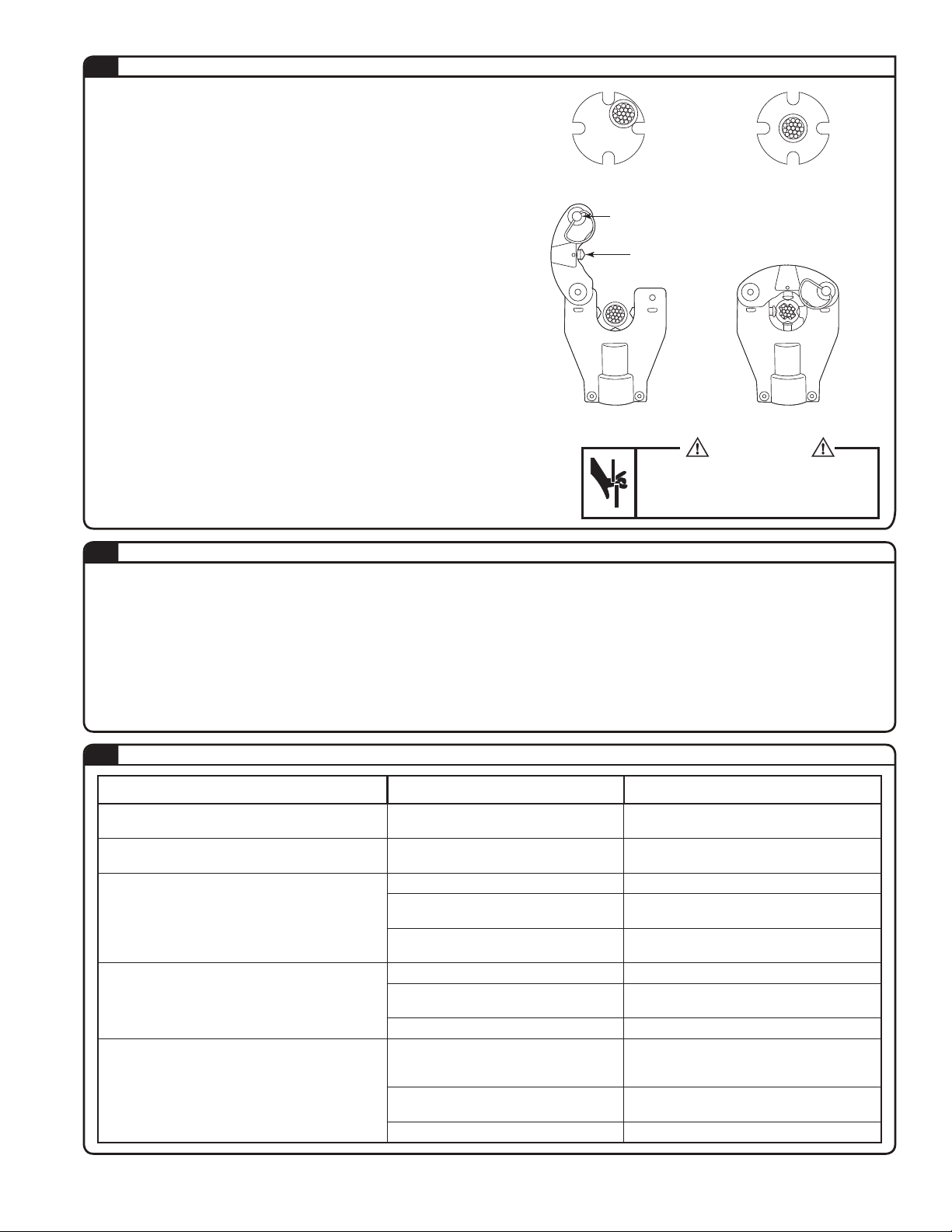

3.5

COMPRESSION OPERATION

1. Not all connectors are suitable for dieless tool applications.

Check your connector manufacturer recommendations on

using a dieless compression tool with the connector and

cable being used.

2. Retract the indenting nibs by pressing the release button.

3. Make sure the head is closed in the latched position and

that the head latching pin is fully inserted. Position the

connector, and center it between the indenting nibs. Activate

the trigger and advance the nibs so the connector is held in

place, but not yet deformed. Check connector for correct

positioning.

4. Insert the cable into the connector and activate the trigger

until the compression is completed. The LED indicator

(Step 2.1) on either side of the tool will show GREEN when a

complete compression is made. A RED indicator light will

show if the compression is incomplete, due to early release

of the trigger or a low battery. An ORANGE indicator will

show if the battery is getting low, but the compression is still

completed.

5. Press release button to retract the indenting nibs and

remove the connector from the tool. If necessary, pull the

head latching pin to unlatch the head for easier removal of

the connector from the tool.

WRONG CORRECT

Head Latching Pin

Indenting Nibs (4)

UNLATCHED LATCHED

WARNING

Pinch point hazard. Compressing identing

nibs at high force can cause severe personal

injury. Keep all body parts away from moving

parts of the tool during operation.

3.6

MAINTENANCE & INSPECTION

1. Very little maintenance is required to ensure that the tool is kept in good working condition.

2. To ensure smooth operation and prevent rust, store the tool in a cool dry area. Ensure that moving parts are lubricated regularly.

3. When the plastic housing becomes dirty, clean it with a soft soaped cloth.

4. Dust, sand, and dirt are a danger for any hydraulic device. After each use, the tool should be wiped with a clean cloth taking care

to remove any residue, especially close to the movable parts.

5. If the tool is maintained regularly, it should provide you with trouble free service.

NOTE: Always remove the battery pack from the unit before replacing parts or maintenance.

3.7

TROUBLE SHOOTING

Problem Cause Solution

Charger LED lamp indicates stand by while battery

is inserted.

The charger LED lamp indicates high or low

temperatures.

The motor does not operate at all.

The motor runs but nibs will not extend or nibs

extend but will not build pressure.

The nibs will not retract

There is dust or foreign objects lodged at

the battery contacts.

The battery is too hot or cold.

The battery is not charged. Charge the battery.

There is dust or foreign objects lodged at

the battery contacts.

The switch is misaligned.

Insufcient hydraulic oil.

Air in hydraulic system.

Defective hydraulic circuit. Consult tool service.

Tool did not complete a full cycle and

bypass.

The connector is jammed in indenting nibs.

The release button is bent or misaligned. Consult tool service.

Remove foreign objects.

Allow the cartridge to reach room temperature

before continuing.

Remove foreign objects.

Check to see if switch is aligned with trigger,

consult tool service.

Consult tool service.

Hold the tool with head towards the oor to

allow air to rise towards top of oil bladder.

Depress trigger and allow tool to reach full

pressure and bypass, then depress release

button to retract the nibs.

Depress and hold release button while prying

indenting nibs apart.

TA04748 A Page 5 of 8

Page 6

4.0

IMPORTANT OPERATING PRECAUTIONS

4.1

PRECAUTIONS FOR COMPRESSION TOOL

1. Not all connectors are suitable for dieless tool

applications. Check your connector manufacturer

recommendations on using a dieless compression tool.

2. Never operate the tool without a connector and cable in

place.

3. Always point the tool away from other people.

4. If the tool is stored for an extended period at a

temperature of less than 25º F (-5º C), the tool should be

allowed to return to room temperature to ensure smooth

operation. Use the tool only after it has been at room

temperature for 1 hour.

5. Do not drop the tool. Dropping the tool may damage the

hydraulic circuit and cause malfunctions.

6. Keep the head and indenting nibs clean and free of

debris. Solvents can be used to clean the head but

should not be used on the plastic body. Use soap &

water to clean the body.

4.3

1. The LED lamp lights up green and remains lit when the

unit starts charging a battery. The indicator turns orange

when charging is completed.

2. This unit is for charging battery 144-BAT-LI only. Do not

use the charger for any other devices.

3. Allow battery cartridges to cool before charging. Allow at

least 15 minutes between charges when charging several

batteries in succession.

4. Charge batteries at an ambient temperature of 50-95

degrees F (10-35 degrees C). Charging time is

approximately 25 minutes for 80% capacity and 45

minutes for 100% capacity.

5. Never short circuit the output contacts.

6. Do not expose the charger to water, oil or solvents.

7. Do not disassemble, modify, drop or otherwise abuse

the charger.

PRECAUTIONS FOR THE CHARGER

4.2

PRECAUTIONS FOR THE BATTERY PACK

1. Do not short circuit the contacts or expose the battery to

water, oil or solvents.

2. Do not disassemble or attempt to repair the battery or

dispose of in a re.

3. Do not drop or otherwise abuse the battery.

4. Do not leave the battery in locations where it will be

exposed to a temperature greater than 104 degrees F (40

degrees C) for an extended period.

5. The battery has a limited life. When the capacity

becomes about 1/2 that of the original capacity, the

battery should be replaced.

6. If the battery is stored without being charged, natural

drainage will cause the power to be reduced. The battery

should be charged every 3 months if not in use regularly.

WARRANTY: Thomas & Betts sells this product with the understanding that the user will perform all necessary tests to determine

the suitability of this product for the user's intended application. Thomas & Betts warrants that this product will be free from

defects in materials and workmanship for the period stated on the enclosed warranty card. Upon prompt notication of any

warranted defect, Thomas & Betts will, at its option, repair or replace the defective product. Misuse, misapplication or

modication of Thomas & Betts products immediately voids all warranties.

Limitations and Exclusions: THE ABOVE WARRANTY IS THE SOLE WARRANTY CONCERNING THIS PRODUCT, AND IS IN

LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY

DISCLAIMED. LIABILITY FOR BREACH OF THE ABOVE WARRANTY IS LIMITED TO COST OF REPAIR OR

REPLACEMENT OF THE PRODUCT, AND UNDER NO CIRCUMSTANCES WILL THOMAS & BETTS BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

TA04748 A Page 6 of 8

Page 7

5.0

PARTS BREAKDOWN

5.1

HMC5750-LI PARTS DIAGRAM

TA04748 A Page 7 of 8

Page 8

5.2

HMC5750-LI PARTS LIST

NO. DESCRIPTION CODE QTY NO. DESCRIPTION CODE QTY

M4 X 20 Screw 558-01

11

Housing (R) 1 60 P-8 Back-Up Ring (B.C.) 85-33 1

12

M3 x 6 Screw R150-02

13

Top Cover 1 62 PS-20 Pent Seal R150-24 1

14

Switch Unit 558-04 1 63 P-20 Back-Up Ring (B.C.) 35-18 1

15

LED Harness 558-05 1 64 Pump Piston (1) R150-25 1

16

Circuit Board 558-06 1 65 P-5 O-Ring 5N-35 1

17

Strap 558-07 1 66 Pump Piston (2) 150GM-01 1

18

M3 x 5 Screw ROB-94 1 67 P-3 O-Ring 16-36 1

19

Retaining Plate 458-01 1 68 Release Valve Stem ROB-135 1

20

Spring (639) 458-02 1 69 Spring (678) 558-17 1

21

Lever Stopper 558-08 1 70 Spring (66) 85-40 1

22

3 x 16 Parallel Pin 558-09

23

Switch Knob 1 72 Spring (67) 85-39 2

24

Spring R150-09 1 73 Valve Screw (10) 410-44 2

25

Housing (L) 558-11 1 74 P-42 O-Ring 9H-17 1

26

Power Unit 558-12 1 75 Ram Spring (388) UC-35 1

27

M4 x 14 Screw (NI) ROB-128B 4 76 P-28 O-Ring 300-21 1

28

Spring (598) R150-13 1 77 P-28 Back-Up Ring (B.C.) 55D-03 1

29

Push Pin R150-14 1 78 Ram UC-36 1

30

Release Lever 558-13 1 79 Retaining Screw UC-12 1

31

4 x 16 Dowel Pin (G) 24-01 1 80 P-6 O-Ring RB-70 1

32

Reservoir Cap 410-55 1 81 P-6 Back-Up Ring (B.C.) UC-28 1

33

Magnet ROB-25 1 82 M4 x 6 Screw (F.P.) 16-42 2

34

Oil Reservior R4412-01 1 83 4 x 30 Drive Pin (AW) UC-14 1

35

G-30 O-Ring 75-26 1 84 Cam Yoke Holder UC-32 1

36

M3 x 16 Screw R150-16 2 85 3 x 18 Drive Pin RF-33 1

37

Valve Block R150-17 1 86 Cam Yoke UC-33B 1

38

Spring (371) 51-71 1 87 Spring (390) 6H-11 2

39

3/16” Ball 16-49 3 88 NIB UC-34 2

40

SI-20 Ring 410-74 1 89 Roller UC-07 10

41

Filter Screen 410-73 1 90 Roller Retainer UC-08 2

42

Strainer R150-18 1

43

Valve Cartridge R150-19F 1

44

S-8 O-Ring R510A-08 1

45

P-7 O-Ring 16-60 1

46

SEPN4 Retainer R150-21 1

47

Plug 51-21 1

48

P-4 Back-Up Ring 410-47 1

49

P-4 O-Ring 410-48 1

50

Spring (341) 51-20 1

51

7/32” Ball 16-26 1

52

M4 x 4 Screw (F.P.) 85-47 3

53

1/8” Ball 40-20 2

54

M5 x 5 Screw (F.P.) 510A-05 1

55

5/32” Ball 22-21 1

56

Body 575-01 1

57

558-02

R558-03

558-10

6 59 PS-8 Pent Seal 16-44 1

1 61 Spring (590) R150-23 1

1 71 9/32” Ball 16-40 2

91 Side Jaw (C) 6H-10C 2

92 M6 x 30 Screw E3-49 2

93 M4 x 30 Screw ET-46 2

94 Roller 6H-08B 2

95 Head (1) 6H-07B 1

96 Head (2) 6H-09B 1

97 Pin (156) 6H-02A 1

98 Ce-8 Snap Ring 16-09 2

99 3 x 28 Drive Pin 38A-01 1

100 Slide Pin 6H-01A 1

101 M3 x 5 Screw UC-37A 1

102 Yoke 6H-01A 1

58 3 x 8 Dowel Pin (D) 610F-11 1

© 2013 Thomas & Betts. All Rights Reserved.

Thomas & Betts Corporation

Memphis, Tennessee

www.tnb.com

TA04748 A Page 8 of 8

Loading...

Loading...