Thomas & Betts furse ESP 120 D1, furse ESP 415 D1 Series, furse ESP 208 D1 Series, furse ESP 277 D1, furse ESP 240 D1 Installation Instructions Manual

...Page 1

Installation instructions

for mains wire-in protectors

ESP D1, D1R, D1/LCD and D1R/LCD variants

Page 2

Installation instructions for mains wire-in protectors

Introduction

This document explains how to install Furse Electronic

Systems Protectors for mains power supplies:

Single phase ESP 120 D1 | Single phase ESP 240 D1 | Single

phase ESP 277 D1 | Three phase ESP 208 D1, D1R, D1/LCD

& D1R/LCD | Three phase ESP 415 D1, D1R, D1/LCD &

D1R/LCD | Three phase ESP 480 D1, D1R, D1/LCD & D1R/LCD

These instructions are prefaced by a summary of the

Key points of installation. Each key point is explained in

detail in the section entitled Installation.

WARNING: Incorrect installation will impair the

Contents

effectiveness of the ESP units

Key points of installation 3

Before installation 4

Installation 6

Installation check (LED units) 24

Neutral-earth warning light (LED units) 25

Status indication (LED units) 26

Status indication (LCD units) 26

LCD display settings 30

Remote indication 34

Maintenance 35

Application notes 36

Remote display cut-out template 39

Key points of installation

1

Install protectors very close to the power supply to be

protected, either within the distribution panel or directly

alongside it.

2

Mount units within a panel or WBX enclosure.

3

ESP D1 units can be installed in parallel or, for power

supplies ≤125A, in-line (series) with the power supply.

4

Connect to phase(s), neutral and earth.

NOTE: Units must have a neutral connection.

5

Units installed at power distribution boards can be

installed either:

on the load side of the incoming isolator, or

on the closest available outgoing way to the

incoming supply

6

Provide a means of isolation for the ESP unit.

7

The connecting leads to phase/live terminals should be

suitably fused (125A maximum) ensuring full

discrimination with the immediate upstream supply fuse.

Page |3Page |2

Page 3

Installation instructions for mains wire-in protectors

8

Connecting leads should be 10 mm2multi stranded

cable for parallel/shunt installation. For series installation,

refer to section 6.

9

For parallel/shunt installation, keep the connecting leads as

short as possible and ideally less than 25 cm (10 inches) in

length. For series installation, keep earth lead as short as

possible.

This may be better achieved with the equivalent D1R or

D1R/LCD unit with remote display mounting flexibility.

10

Bind the connecting leads tightly over their entire length.

Before installation

1

Check that the voltage between neutral and earth does

not exceed 10 volts.

If this voltage does exceed 10 volts, the installation

is unsafe.

Find and rectify the cause of this fault before proceeding.

(For delta supplies with no neutral, see page 13).

2

Make sure that the supply voltage is suitable for the unit.

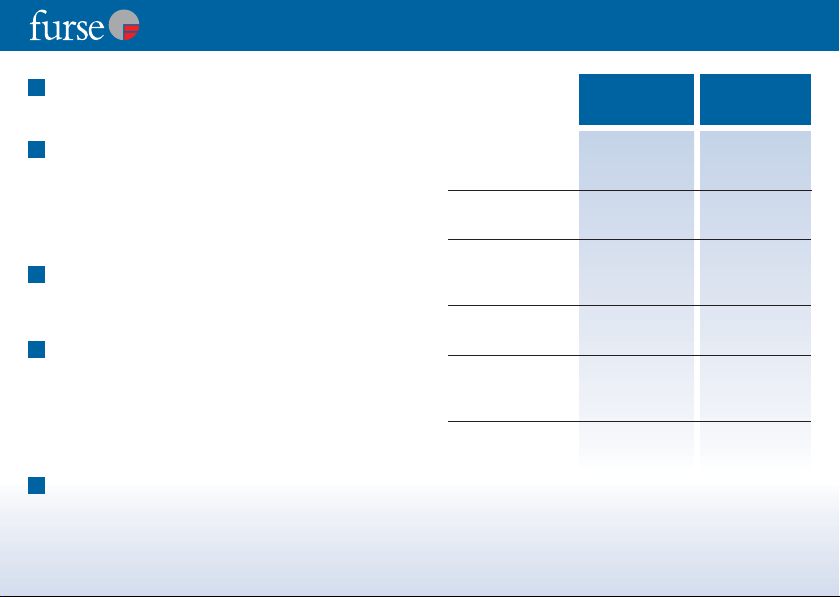

Supply Rated Unit Voltage

Voltage Range

(V

)(V

ESP 120 D1

Phase to

RMS

RMS

Neutral/Earth 110/120/127 90-150

ESP 208 D1 Series

Phase to Phase 190/208/220 156-260

ESP 240 D1

Phase to

Neutral/Earth 220/230/240 200-280

ESP 415 D1 Series

Phase to Phase 380/400/415 346-484

ESP 277 D1

Phase to

Neutral/Earth 240/254/277 232-350

ESP 480 D1 Series

Phase to Phase 415/440/480 402-600

)

Page |5Page |4

Page 4

Installation

1

Location

Protectors need to be installed very close to the power

supply to be protected. Usually the protector will be

installed at a power distribution panel either inside it

(Figure 1) or right next to it (Figure 2).

ESP D1 protectors have been designed to fit onto a

standard 35mm DIN rail (see 3 - DIN Installation) or within

a Furse WBX D enclosure.

2

Enclose the ESP unit

The ESP unit has exposed terminals. For electrical safety,

the unit must be installed within a panel or enclosure.

For standard single and three phase units, where possible,

install the unit within the power distribution panel behind

a suitable viewing window.

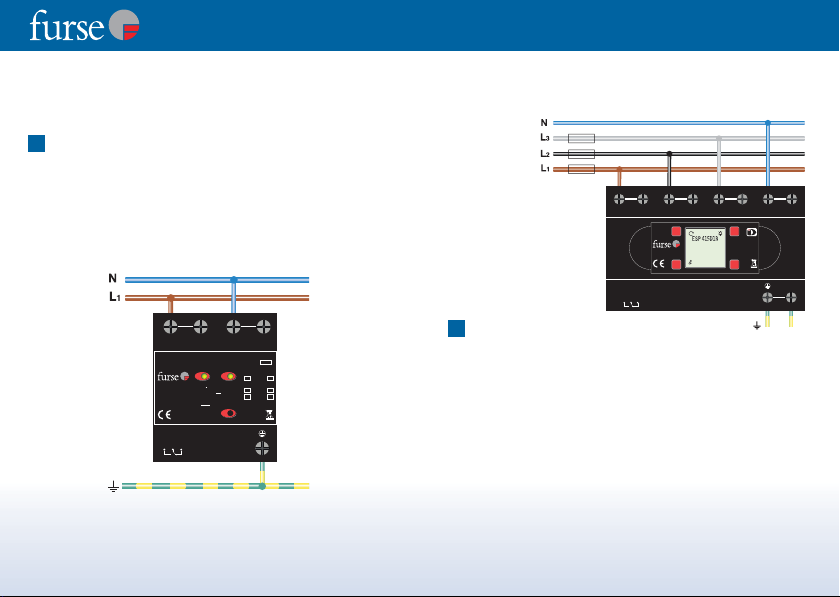

Figure 1 ESP 415

D1/LCD

installed on

a DIN rail

within a

power

distribution

panel.

Installation instructions for mains wire-in protectors

Figure 2 - ESP 415 D1/LCD installed next to a power

distribution panel in a suitable WBX D enclosure.

Alternatively, for three phase units, a remote display option

is available. Units can be installed within the power

distribution panel with the remote display mounted on the

front of the panel (see 4 - remote display).

When mounting the units in existing metal panels or

enclosures, ensure that the enclosure is securely bonded

to the earth bar to which the ESP unit will be connected.

If it is not possible to install the unit within the distribution

panel it should be mounted in a separate enclosure,

see Figure 2, as close as possible to the distribution panel

(see 12 & 13 - Length of connecting leads). Gland the

enclosure onto the power distribution panel. Suitable

enclosures are available from Furse.

Page |7Page |6

Page 5

Installation instructions for mains wire-in protectors

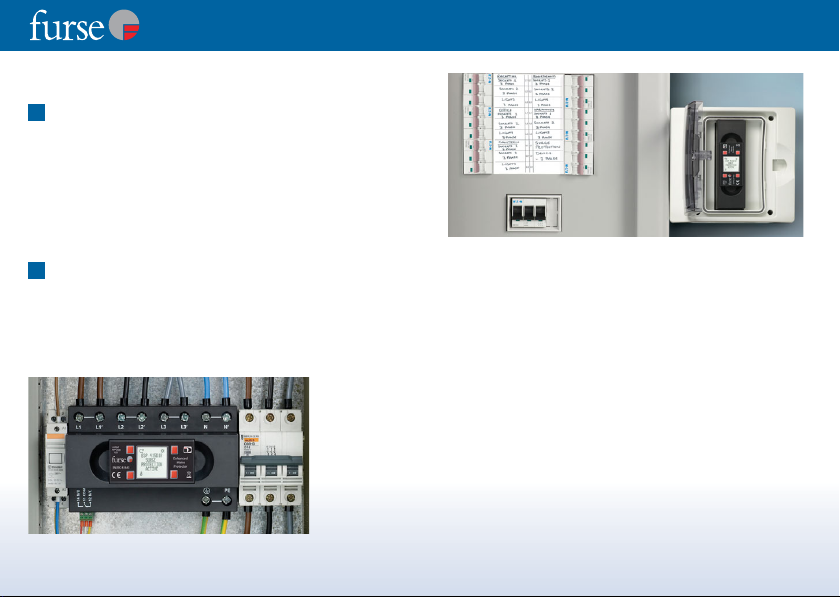

3

DIN Installation

ESP D1 Series protectors have been designed with an

innovative DIN foot for connection to standard 35mm DIN rails.

This DIN foot, comprising spring loaded steel DIN mounts,

enables rapid positioning of D1 protectors onto the rail.

Figure 3 - Reverse of

3 phase protector

showing innovative

spring loaded

DIN foot.

The spring loaded steel DIN mounts pull down and out

to lock into place ready for siting the protector.

Position the D1 protector at the preferred location on the

DIN rail and press the protector back to release the springs.

The protector locks into place.

Figure 4 - Reverse

of 3 phase protector

showing spring

loaded DIN foot

locked onto DIN rail.

Page |8

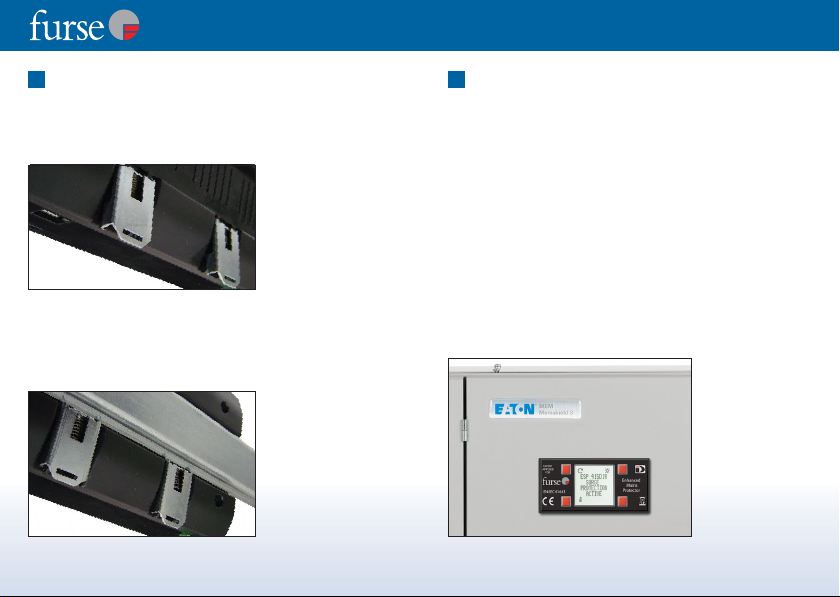

4

Remote display

Three phase ESP D1R and D1R/LCD units include a remote

mounting display to ensure optimum positioning of the

unit along with quick and easy status checking.

The remote display should be mounted in a clearly visible

position, typically on the front of the distribution panel

(see Figure 5).

For remote display connection, ensure the cable is of

sufficient length, and is unimpeded within the cabinet.

Allow a minimum of 60 mm behind the front panel for the

interconnection cable.

ESP D1R and D1R/LCD units are supplied with 1 m

interconnection cable as standard, with a 4 m cable

available as an option (contact Furse).

Figure 5 ESP 415 D1R/LCD

remote display

installed on the

front of a power

distribution panel.

Page |9

Page 6

Installation instructions for mains wire-in protectors

S

PROTECTION

AC

E

Care should be taken against static discharge when

handling the remote display unit - avoid contact with the

exposed connector.

5

Parallel connection

ESP D1 protectors can be connected in parallel with the

supply to be protected, or connected in-line (series), for

power supplies ≤125A (see 6).

For parallel connection, the connecting leads do not carry

the load current of the supply, only the current associated

with suppressing the transient overvoltage.

I

T1

imp

I

20kA

n

T2 C

I

max

U

oc

125 AgL

4kA

B

40kA

DT3

6kV

Figure 6

- Parallel

connection

for single

phase supplies.

LL1N1N

PATENT

APPLIED

ESP 240D1

FOR

STATUS INDICATION

L N

GREEN

U

280V 47-63H

zac

c

GREEN & RED REDUCED

EN/IEC 61643

RED NO PROTECTION

WARNING: If lit /

flashing disconnect

unit & check Neutral

to Earth voltage

STATUS

11

14

12

FULL PROTECTION

PROTECTION

(replace unit)

!

Figures 6 & 7 show connection diagrams for single

phase and three phase star power supplies.

Connecting leads to the unit need to be kept short in

order to minimise additive inductive voltages.

Figure 7 - Parallel

connection for

three phase

star (4 wire and

earth) supplies.

6

Series connection

LL' L2 L2' L3 L3' NN'

PATENT

APPLIED

FOR

EN/IEC 61643

STATUS

11

14

12

Enhanced

URGE

Mains

Protector

TIV

The twin terminal design of ESP D1 units enables

installation in-line (series) with the power supply

(for power supplies ≤125A). The supply cables should be

suitably rated for the specific load current. The terminals of

the ESP unit can receive up to 35 mm2stranded cable.

Any type of protector installed in parallel (shunt) with the

supply will have additive inductive voltage on the connecting

leads. This resultant voltage let-through the protector is

hence seen by the equipment to be protected (see 5

and 12). Series installation eliminates the additive voltage

associated with connecting leads on parallel installations.

PE

Page |11Page |10

Page 7

Installation instructions for mains wire-in protectors

R

SURG

P

N

A

E

Ensure the power supply does not exceed 125A

for series installations. The connecting leads to

phase/live terminals should be suitably fused (125A

maximum) ensuring full discrimination with the

immediate upstream supply fuse.

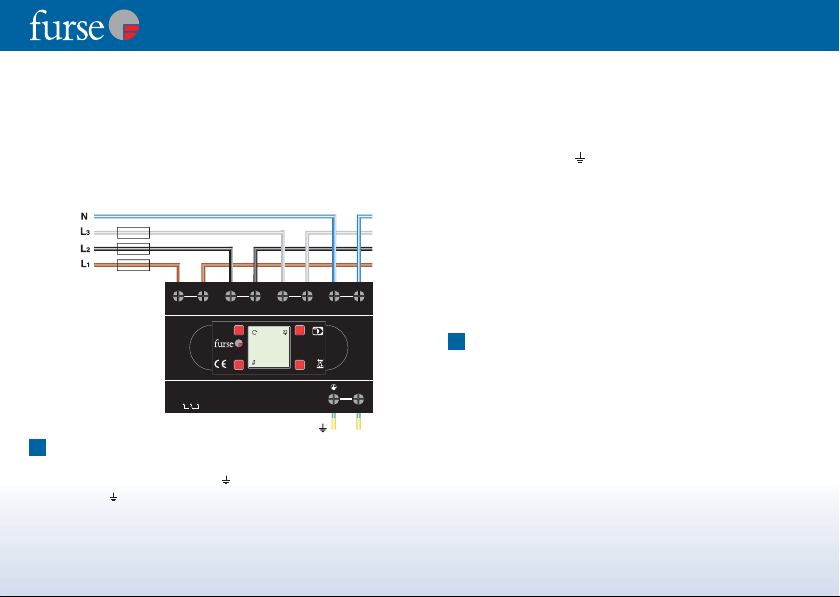

Figure 8 shows the connection diagram for three phase

star power supplies.

Figure 8 - Series

connection for

three phase star

(4 wire and

earth) supplies.

7

Connection to phase, neutral and earth

LL'L2 L2' L3 L3' NN'

PATENT

APPLIED

FOR

ESP 415D1

ROTECTIO

EN/IEC 61643

CTIV

STATUS

11

14

12

Connections are made to each supply conductor including

earth. Terminals marked L, N, (single phase units) or L1,

L2, L3, N, (three phase units) must be connected to

phase/live, neutral and earth respectively.

Under no circumstances must the ESP unit be installed

without connection to its neutral.

Where no neutral is present (eg delta supplies) the neutral (N)

terminal on the ESP unit must be connected to earth in

addition to the earth ( ) terminal. This will result in a greatly

increased earth leakage current.

On some delta supplies the voltage between phase and

earth/neutral may exceed the rating of the ESP unit.

Consequently, the supply’s phase to earth voltage must be

checked before installing the ESP unit.

We recommend that you consult Furse ESP before

installing ESP units on delta supplies.

Enhanced

E

Mains

Protector

PE

8

Connection point

(a) Protecting supplies feeding equipment in the building

The ESP unit is typically connected to the power supply

at a power distribution board/panel, either:

(i) on the load side of the incoming isolator (Figure 9).

(ii) on the closest available outgoing way to the incoming

supply (ie the incoming isolator).

Page |13Page |12

Page 8

Installation instructions for mains wire-in protectors

PE

Enhanced

Mains

Protector

EN/IEC 61643

PATENT

APPLIED

FOR

LL'L2 L2' L3 L3' NN'

11

14

12

STATUS

Figure 9 - ESP unit mounted

within a distribution board

connected to the incoming

supply on the load side

(ie downstream) of the

isolator. (Note the additional

earth bond to the metalwork

PE

Mains

Protector

Enhanced

FOR

EN/IEC 61643

PATENT

APPLIED

12

11

14

STATUS

LL'L2 L2' L3 L3' NN'

of the distribution board.)

This technique is

explained in 12(iii)

The ESP unit can be connected via one of the distribution

board’s outgoing fuseways or circuit breakers. Ideally, the

ESP unit should be connected to the outgoing way

which is nearest to the incoming supply (or isolator).

See Figure 10.

On small, compact, metal cased distribution boards, (such

as small MCB boards) the first way is preferable, although

any outgoing way is suitable.

On a large board such as a cubicle switchboard, it is better to

install the protector on the load side of the incoming isolator

Page |14

(eg in the metering section). Fitting the protector in any other

position could affect the protector’s performance.

(iii) directly to the busbars via suitable HRC fuses, switch

fuses or MCCBs - see Section 10.

Figure 10 - Three phase ESP protector connected to the nearest

available outgoing (MCB) way to the incoming supply. The MCB

also provides the means of isolation. Since there is insufficient

space within the distribution board the ESP unit has been

mounted within a separate enclosure, directly alongside the board.

Note the double connection to earth, in order to compensate for

the long connecting leads. (See 12 Length of connecting leads this also gives an alternative technique in 12(iii).)

Page |15

Page 9

(b) Protecting supplies going out of the building

The connection methods 8a (i to iii) are not suitable for

protecting a power distribution board which provides a

supply to outside the building - either to a separate building

or some other external load (eg site lighting).

To protect the equipment inside the building, from transient

overvoltages entering the board on the outgoing feed,

protection should be installed close to the external load.

See Figure 11.

Figure 11 Connection for

supplies continuing

external to the

building.

Installation instructions for mains wire-in protectors

9

Isolation

It is good practice to be able to isolate or disconnect the

ESP unit from the supply. The supply to the entire

distribution board should not be switched off on many

computer power supplies and other critical loads.

The means of isolation should therefore be installed in the

connection to the ESP unit. Figures 12 & 13 show example

connection schematics. Where it is also necessary to fuse

the connection to the ESP unit (see 10 - Fuse connecting

leads) this can be achieved through use of a switchfuse,

MCCB or type ’C’ MCB.

Figure 12 - ESP unit

installed on incoming side

of distribution board.

Page |16

PE

Mains

Protector

Enhanced

FOR

EN/IEC 61643

PATENT

APPLIED

12

11

14

STATUS

LL'L2 L2' L3 L3' NN'

Incoming

supply

fused F

S

HRC switch fuse or MCCB

F

, where F

SPD

< 0.5 FS

SPD

LL' L2 L2' L3 L3' NN'

PATENT

APPLIED

FOR

EN/IEC 61643

STATUS

11

14

12

Enhanced

Mains

Protector

PE

Page |17

Page 10

Installation instructions for mains wire-in protectors

L N

T2 C

T1

I

imp

4kA

I

n

20kA

I

max

oc

40kA

U

6kV

c

zac

U

280V 47-63H

B

DT3

125 AgL

!

GREEN

FULL PROTECTION

GREEN & RED REDUCED

PROTECTION

(replace unit)

RED NO PROTECTION

WARNING: If lit /

flashing disconnect

unit & check Neutral

to Earth voltage

EN/IEC 61643

PATENT

APPLIED

FOR

STATUS INDICATION

ESP 240D1

LL1N1N

11

14

12

STATUS

Figure 13 - Installation of

ESP unit on first outgoing

way of distribution

board, nearest to the

incoming supply.

Incoming

supply

fused F

S

10

Fuse connecting leads

HRC switch fuse or MCCB

, where F

SPD

< 0.5 FS

F

SPD

The connecting leads to the phase/live terminals of the

ESP units should be fused.

This is to protect the connecting leads in the event of a

short circuit.

The fuse to the ESP unit (F

upstream supply fuse FSby a sufficient enough factor to

ensure fuse discrimination. As a general guide a factor of

at least 2 could be used (F

maximum fuse to the ESP unit required is 125 amps

(if the supply fuse is 250 amps or greater).

) should be lower than the

SPD

≤ 0.5 FS), where the

SPD

Refer to the fuse manufacturer’s operating characteristics

to ensure discrimination, particularly where an installation

PE

Mains

Protector

Enhanced

includes a mixture of types of fuse, or of fuses and

circuit breakers.

Live/phase connecting leads can be fused by either:

(a) installing high rupture capacity (HRC) fuses or switch

FOR

EN/IEC 61643

PATENT

APPLIED

12

11

14

STATUS

LL'L2 L2' L3 L3' NN'

fuses in the connecting leads at the supply end of the

lead (See Figure 14), or

(b) installing up to a

125 amp circuit breaker

(MCCB or type ’C’ MCB).

Where the ESP unit is

installed via an outgoing

way (8b earlier) this

should incorporate

up to a 125 amp HRC

fuse or circuit breaker.

Figure 14 - Busbar

mounted HRC fuse at

the end of the live

connecting lead.

Page |19Page |18

Page 11

Installation instructions for mains wire-in protectors

11

Size of connecting leads

For parallel connection, the connecting leads between the

terminals of the ESP unit and the power supply should be

10 mm2multi stranded conductor (copper). If required,

the terminals on the ESP unit will accept connecting leads

of up to 35 mm2. (For series connection, see 6).

12

Length of connecting leads – parallel connection

For ESP units installed in parallel, the connecting leads

should be kept as short as possible and ideally should

not exceed 25 cm (10 inches) from the busbars to the

unit’s terminals.

ESP units can be mounted upside down or on their

side if this facilitates shorter connecting leads.

ESP D1/LCD units include a rotating display function for

improved legibility when units are mounted sideways or

upside down (see page 31).

ESP protectors with remote display units (D1R variants)

allow the protector to be mounted with short connecting

leads whilst allowing the display to be positioned

independently (eg conveniently on the front of the panel).

The display is connected to the protector via the supplied

1 m cable (4 m cable optional). The remote display cut-out

template, which can be found at the back of these

instructions, conforms to the standard DIN 72x36 format.

WARNING: The longer the connecting leads (between

the mains cable or busbars and the terminals of the ESP

unit), the greater the voltage let-through the protector.

If the resultant let-through voltage is higher than the

susceptibility level of the equipment to be protected,

damage will result.

Connecting leads up to 50 cm (20 inches) can be

used when:

(i) Two sets of 6 mm

2

cables are used (ie two sets of live,

neutral and earth conductors). Each set of conductors is

tightly bound together, using Ty-Raps®, tape or

spiral wrap.

This should be done for the entire length of the cable or

as far as is possible. The two sets of bound conductors

should be separated in their routeing. Ideally a distance

of 10 cm (4 inches) should be maintained between the

two sets of conductors as far as possible. See Figure 15.

(ii) Alternatively, if only one conductor needs to be longer

than 25 cm then use a pair of separated (as above)

conductors to make that connection. See Figure 10.

(iii) For metal distribution boards, if only the earth

connection needs to be longer than 25 cm, the

following procedure is suggested (see Figure 10):

Page |21Page |20

Page 12

(a) Using 6 mm2cable make one connection from the

ESP unit to the earth bar.

(b) A second short and direct connection, again using

2

6 mm

cable, should be taken from the ESP unit

to the metalwork of the distribution board.

(c) Bond the earth bar to the metalwork of the

distribution board.

The techniques outlined above (i-iii) are designed to

minimise the inductance associated with the

connecting leads.

Figure 15 - For

connecting leads

of up to 50 cm

use two sets of

conductors (L1, L2,

L3, N, ). Each set

of conductors has

been tightly bound

and separated

in their routeing.

Installation instructions for mains wire-in protectors

13

Length of connecting leads – series connection

For ESP units installed in series (for power supplies ≤125A),

the connecting lead to earth needs be kept as short as

possible and ideally should not exceed 25 cm (10 inches)

from the busbars to the unit’s terminals.

ESP units can be mounted upside down or on their

side if this facilitates shorter connecting leads.

Three phase ESP D1 protectors are available with rotating

LCD display (ESP D1/LCD variants) and remote mounting

display (ESP D1R and ESP D1R/LCD variants) for optimum

positioning of the unit whilst enabling easy ongoing

status checking.

14

Bind connecting leads – parallel connection

Connecting leads should be tightly bound together using

Ty-Raps®, tape or spiral wrap. This should be done for the

entire length of the cable or as far as is possible.

See Figure 15.

Page |23Page |22

Page 13

Installation instructions for mains wire-in protectors

Installation check (LED units)

The ESP unit should now be correctly installed. Switch the

power supply on. Check that a green LED per phase and

neutral is lit. See Figure 16. The unit is now fully operational.

Watch the WARNING light for 30 seconds. If it is flashing or lit

there is a problem with your installation (see opposite).

LL' L2 L2' L3 L3' NN'

PATENT

APPLIED

FOR

U

280V 47-63H

c

EN/IEC 61643

STATUS

14

zac

11

12

ESP 415D1

STATUS INDICATION

L1

GREEN FULL PROTECTION

GREEN & RED REDUCED PROTECTION

RED NO PROTECTION

(replace unit)

WARNING: If lit / flashing

N

disconnect unit & check

Neutral to Earth voltage

L3L2

!

Figure 16 - Status indication lights showing full protection on all

phases and neutral. On D1R units, status indication is shown on

the remote display unit.

I

4kA

T1

imp

I

20kA

n

T2 C

I

40kA

max

U

6kV

oc

125 AgL

B

DT3

PE

Neutral-earth warning light (LED units)

If the WARNING light is illuminated there is an excessive

voltage present between neutral and earth.

The WARNING light should never be illuminated.

(a) Illumination at time of installation

If the WARNING light flashes as soon as the mains supply

to the ESP unit is turned on, one of the phase/live cables

may have been connected to neutral and the neutral to

phase/live. Isolate or disconnect the ESP unit

immediately. Check the phase/live and neutral

connections and if a mistake has been made, correct it.

If all the phase/live and neutral connections are correct,

there is a fault with the mains supply (see (b) - below).

Note: The ESP unit may have suffered damage

- check the status indication (see page 26).

(b) Illumination at any time

The WARNING light will flash when the neutral to earth

voltage exceeds 30 volts. The faster the flashing, the

higher the voltage between neutral and earth (at very

high voltages the WARNING light may appear to be

permanently illuminated). Disconnect the ESP

protector immediately and check the mains supply.

The ESP protector should not be reconnected until the

cause of the fault has been identified and rectified.

Note: The ESP unit may have suffered damage

- check the status indication (see page 26).

Page |25Page |24

Page 14

Installation instructions for mains wire-in protectors

N

3

!

Status indication (LED units)

ESP units give a continuous visual display of their status. They

have a two colour indicator light for each phase and neutral:

Green only = Full protection, power on.

Green + Red = WARNING. Reduced protection,

Red only = NO PROTECTION. Replace ESP unit immediately.

No lights = No power connection or system fault.

replace unit as soon as possible.

Check external fuses and connections.

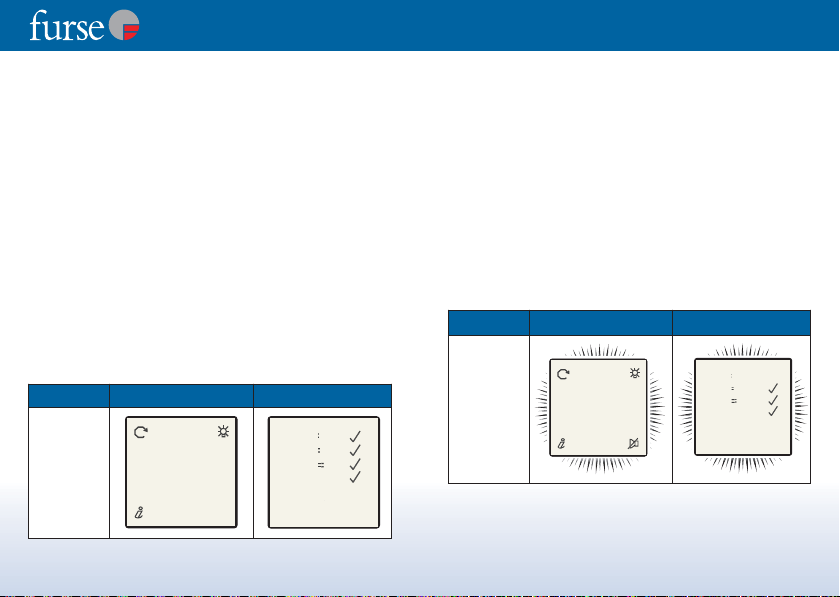

Status indication (LCD units)

Following installation, switch the power supply on.

The LCD display will illuminate for 15 seconds and show

the introductory status screen for correct performance.

The introductory screen alternates to show protector status

every 2-3 seconds (ESP 415D1R example shown).

Introductory screen Protector status

Normal

operation:

P 415D1R

URGE

PROTECTIO

TIVE

Page |26

LY ACTIVE

The unit is now fully operational. These display messages will

be visible and alternate at all times the protector is connected

and is functioning correctly.

Where a fault or power supply issue is detected by the

protector, the LCD message will change, the backlight will

flash, and the protector will sound an alert. Several types of

fault will trigger a response from the ESP protector.

Line fault – no connection or system fault

Live (including neutral) connections will register a ‘’ if

protected and functioning properly. If any of the live

connections is lost, the LCD screen will query this with ‘OFF?’.

The example below shows a power supply issue for L1.

Warning screen Alternates with

L1 Fault

(no power)

[BACK-LIT

DISPLAY

ON - FAST

FLASHING]

[AUDIBLE

ALERT]

WARNING

ISCONNECT

ND

NVESTIGATE

0V

RLY DISABLED

30V

Disconnect the unit and check external fuses and connections.

Page |27

Page 15

Installation instructions for mains wire-in protectors

T

30

ON

T

3

30

!

Line fault – protection impaired

Live connections (including neutral) will register a ‘’ if

protected and functioning properly. Where protection to a live

connection is impaired, the LCD screen will query this with ‘’,

the backlight will flash and an audible alert will sound.

The examples below show L1 has reduced or no protection.

Warning screen Alternates with

L1 Fault

(reduced

protection)

[BACK-LIT

DISPLAY

ON - SLOW

FLASHING]

[AUDIBLE

ALERT]

L1 Fault (no

protection)

[BACK-LIT

DISPLAY

ON - FAST

FLASHING]

[AUDIBLE

ALERT]

Reduced protection – replace unit as soon as possible.

No protection – replace unit immediately.

Page |28

EDUCED

PROTECTION

REPLACE

UNI

ROTECTI

EPLACE

NI

LY DISABLED

1

N

LY DISABLED

Neutral-earth warning

The Neutral-earth warning screen will display if there is an

excessive voltage present between neutral and earth, or if

there is no protection on the N-E connection. The backlight will

flash and an audible alert will sound.

Warning screen Alternates with

N – E Fault

(over 30

volts

V

=

=

0V

detected)

[BACK-LIT

DISPLAY

ON - FAST

FLASHING]

[AUDIBLE

ALERT]

(a) Illumination at time of installation

If the WARNING message and backlight flashes as soon as the

mains supply to the ESP unit is turned on, one of the phase/live

cables may have been connected to neutral and the neutral to

phase/live. Isolate or disconnect the ESP unit immediately.

WARNING

ISCONNECT

ND

NVESTIGATE

V

Page |29

Page 16

Installation instructions for mains wire-in protectors

R

E

E

GE

ON

AC

E

90

0

Check the phase/live and neutral connections and if a mistake

has been made, correct it. If all the phase/live and neutral

connections are correct, there is a fault with the mains supply

(see (b) - below).

Note: The ESP unit may have suffered damage - check the

status indication.

(b) Illumination at any time

The WARNING message and backlight will flash when the

neutral to earth voltage exceeds 30 volts.

Disconnect the ESP protector immediately and check the

mains supply.

The ESP protector should not be reconnected until the cause of

the fault has been identified and rectified. Note: The ESP unit

may have suffered damage - check the status indication.

LCD display settings

The LCD display has enhanced functionality to improve

legibility of status information. The display functions are

controlled through the 4 buttons, located near each corner of

the screen, where control icons are displayed. Display functions

include:

Page |30

Rotate display function

For rotate display, start with introductory screen

(shown below)

PATENT

APPLIED

FOR

EN/IEC 61643

PATENT

APPLIED

FOR

EN/IEC 61643

ESP 415D1R

PROTECTI

FOR

PATENT

APPLIED

Mains

Enhanced

UR

TIV

27

Protector

EN/IEC 61643

ESP 415D1

SURG

ROTECTION

ACTIV

ELECT

REEN ANGLE

Enhanced

Mains

Protector

Enhanced

Mains

Protector

Press and hold the

rotate display button

for a couple of seconds

to call up the screen

angle selection screen.

The display rotates

clockwise in 90° steps.

By selecting 90, the

screen rotates 90°

clockwise as shown left,

enabling the D1/LCD

protector or D1R/LCD

remote display to be

positioned vertically.

Page |31

Page 17

Installation instructions for mains wire-in protectors

R

E

E

AC

Enhanced

Mains

Protector

EN/IEC 61643

PATENT

APPLIED

FOR

R

E

E

Enhanced

Mains

Protector

EN/IEC 61643

PATENT

APPLIED

FOR

2

2. BUILD

2. BU

© T&B 2

Enhanced

Mains

Protector

EN/IEC 61643

PATENT

APPLIED

FOR

E

00

Enhanced

Mains

Protector

EN/IEC 61643

PATENT

APPLIED

FOR

E

3309

Enhanced

Mains

Protector

EN/IEC 61643

PATENT

APPLIED

FOR

ON

CE

Page |32

Activate backlight

PATENT

APPLIED

FOR

EN/IEC 61643

PATENT

APPLIED

FOR

EN/IEC 61643

ESP 415D1

SURG

ROTECTION

ACTIV

SP 415D1R

URGE

PROTECTION

TIVE

Silence buzzer

EDUCED

PROTECTI

REPLA

Press and hold the

activate backlight button

Enhanced

for a couple of seconds to

Mains

Protector

illuminate the display

screen.

The backlight will

activate for approximately

15 seconds.

Enhanced

Mains

Protector

ESP D1/LCD and D1R/LCD

protectors include a

buzzer alert which activates

when a unit has reduced or

no protection, or when

there is a supply fault (phase

loss, excessive N-E voltage).

To deactivate the buzzer,

firmly press the silence

buzzer button (buzzer

deactivates for 1 hour).

Protector information

ESP 415D1

SURG

ROTECTION

ACTIV

MENU

. VERSION

1. VERSION

OFTWAR

ER 2.

2. BUILD (Format: wwyy)

BUILD DAT

For Protector Information,

start with the introductory

screen (shown left). Press

and hold the information

button for a couple of

seconds to call up the

information menu.

The information menu

provides a link to the

software version (1)

and build date of the

protector (2).

Press and hold the top left

button to select software

version (1. VERSION).

Press and hold the top right

button to review protector’

build date (2. BUILD).

To exit the information

screens and return to the

introductory screen, press

and hold the bottom right

button, (EXIT).

Page |33

Page 18

Installation instructions for mains wire-in protectors

Remote indication

A remote indication of the reduced protection state is provided

for linking the protector to a building management system,

remote telemetry, PLC or directly to an indication light or buzzer.

The unit has both a normally open and a normally closed volt

free contact, powered by an ‘active‘ relay.

The terminal for the volt free contact accepts 1.5 mm

and is located on the bottom of the ESP unit. It has three

terminals, marked:

14 = NO = Normally Open

12 = NC = Normally Closed

11 = C = Common

The normally open (NO) contact is open when the ESP unit is

healthy and power is present. The normally closed (NC) contact

is closed when the unit is healthy and power is present.

As well as providing warning of the reduced protection state,

the normally closed volt free contact can also be used to signal

power loss on one or more phases, eliminating the need for

special relays. See Figure 17.

The ESP units remote indication is rated at 1 amp, 250V AC.

A minimum load of 10mA, 5V DC is required to ensure reliable

contact operation.

Page |34

2

cable

Unit Healthy

Reduced or

No protection

NO NC NO NC

OPEN

Power Present

Power Absent

Figure 17. Operation of normally closed (NC) and normally

open (NO) volt free contact.

While the relay is active and functioning correctly the LCD display

will show the 'normal operation' screens - RLY ACTIVE.

CLOSED

CLOSED

CLOSED

OPEN CLOSED

OPEN

OPEN

Maintenance

Maintenance should be conducted at least once a year and

also following lightning activity. Visually check:

(i) Visual status indication lights/LCD display

(see Status indication for interpretation).

(ii) Condition of connecting leads and terminations.

Page |35

Page 19

Installation instructions for mains wire-in protectors

Application notes

1

ESP coordination

ESP D1, D1R, D1/LCD and D1R/LCD units are designed to

fully coordinate with ESP units of equivalent system

voltage on the same installation.

For example the ESP 415 M2 located at the main

distribution panel would coordinate effectively with

the ESP 415 D1 unit typically located at sub-distribution

panels. No additional de-coupling elements such as

inductors are needed to ensure ESP units achieve

coordination.

Always ensure ESP units are used on the same installation

to ensure coordination. Mixing ESP units with alternative

manufacturers’ units could result in damage to both

protection units and connected equipment through

poor coordination.

2

RCD units

ESP units should ideally be installed before (or upstream of)

residual current devices (RCDs) and not on the load side.

ESP units should only be installed on the load side of the

RCDs if the load in question is external to the building.

Page |36

This should help to reduce any spurious tripping of such

devices due to transient overvoltages. Special transient

hardened RCDs (type ’S’) can be obtained from a number

of manufacturers.

3

Insulation tests (flash testing)

The ESP unit should be fully disconnected from the circuit

before testing. Otherwise the ESP unit will treat the

insulation test as a transient overvoltage and control the

voltage to a low level - thereby defeating the object of

the test.

4

Duplex configuration

For systems demanding extremely high reliability ESP units

can be connected in duplex format. The use of two units

will achieve an improvement in performance and increased

lifetime over a single ESP unit at high discharge current

levels.

Each unit should have its own (separate) wiring and

its own isolation.

If possible the two units should be connected to the

power supply a short distance apart either:

(a) onto the first two outgoing ways

(b) up to a metre apart on the incoming power supply

Page |37

Page 20

5

33mm (+0.6)

68mm (+0.7)

DIN 72x36

as per IEC 61554

Installing three phase units on single phase supplies

If a three phase unit is installed on a single phase mains

supply (or a supply in which one or two phases are not in

use), the ESP units spare (or unused) live terminal(s) should

be connected to live, otherwise its indication lights and

volt free contact will not work correctly.

The preferred approach is to take a connecting lead from

each spare terminal to the supply live. However, it is also

possible to connect the ESP units spare terminal(s) to

whichever live terminal is in use at the unit.

6

Thomas & Betts Limited

Furse, Wilford Road, Nottingham

NG2 1EB United Kingdom

Tel: +44 (0)115 964 3700 Fax: +44 (0)115 986 0538

www.furse.com

Use of powered screwdrivers

The use of powered screwdrivers is not recommended

unless measures are taken to ensure screws are tightened

correctly and not damaged (maximum torque value

is 4.5 Nm for these terminals).

Remote display cut-out template

Page |38

Page|39

Page 21

Thank you for reading this data sheet.

For pricing or for further information, please contact us at our UK Office, using the details

below.

UK Office

Keison Products,

P.O. Box 2124, Chelmsford, Essex, CM1 3UP, England.

Tel: +44 (0)330 088 0560

Fax: +44 (0)1245 808399

Email: sales@keison.co.uk

Please note - Product designs and specifications are subject to change without notice. The user is responsible for determining the

suitability of this product.

Loading...

Loading...