Page 1

INSTRUCTION MANUAL

GATOR® EK22GL

Battery-powered,

High-speed Crimping Tool

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

999 4521.5 © 2001 Greenlee Textron IM 1552 10/01

Page 2

EK22GL Battery-powered, High-speed Crimping Tool

Table of Contents

Description .....................................................................2

Safety ............................................................................. 2

Purpose of this Manual .................................................. 2

Important Safety Information......................................3–4

Identification ................................................................... 5

Specifications ................................................................. 5

Operation ................................................................... 6–7

Dies and Connectors...................................................... 8

Maintenance................................................................... 9

Troubleshooting ........................................................... 10

Disassembly.................................................................11

Assembly...................................................................... 12

Illustrations ............................................................. 13–15

Parts List ................................................................16–18

Description

The EK22GL Battery-powered, High-speed Crimping

Tool is a hand-held, self-contained crimping tool

intended to crimp copper cable with K22-type and

W-type dies.

Safety

Safety is essential in the use and maintenance of

Greenlee tools and equipment. This manual and any

markings on the tool provide information for avoiding

hazards and unsafe practices related to the use of this

tool. Observe all of the safety information provided.

Purpose of this Manual

This manual is intended to familiarize all personnel with

the safe operation and maintenance procedures for the

following Greenlee tool:

EK22GL Battery-powered, High-speed

Crimping Tool

Keep this manual available to all personnel.

Replacement manuals are available upon request at no

charge.

All specifications are nominal and may change as design improvements occur. Greenlee Textron shall not be liable for damages

resulting from misapplication or misuse of its products.

GATOR is a registered trademark of Greenlee Textron.

AVIA is a registered trademark of Avia International.

Blackburn is a registered trademark of Thomas & Betts.

Mobil is a registered trademark of Mobil Oil Corporation.

NUTO is a registered trademark of Exxon Corporation.

Tellus is a registered trademark of Shell Oil Company.

KEEP THIS MANUAL

Greenlee Textron / Subsidiary of Textron Inc. 2 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 3

EK22GL Battery-powered, High-speed Crimping Tool

IMPORTANT SAFETY INFORMATION

SAFETY

ALERT

SYMBOL

This symbol is used to call your attention to hazards

or unsafe practices which could result in an injury or

property damage. The signal word, defined below,

indicates the severity of the hazard. The message

after the signal word provides information for

preventing or avoiding the hazard.

Immediate hazards which, if not avoided, WILL

result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection can

result in serious eye injury from

flying debris or hydraulic oil.

Skin injection hazard:

Do not use hands to check for oil

leaks. High pressure oil easily

punctures skin causing serious

injury, gangrene, or death. If injured,

seek medical help immediately to

remove oil.

Hazards which, if not avoided, COULD result in

severe injury or death.

Hazards or unsafe practices which, if not avoided,

MAY result in injury or property damage.

Read and understand all of the

instructions and safety information in

this manual before operating or

servicing this tool.

Failure to observe this warning can

result in severe injury or death.

Electric shock hazard:

This tool is not insulated. When

using this unit near energized

electrical lines, use proper personal

protective equipment.

Failure to observe this warning can

result in severe injury or death.

Do not use solvents or flammable

liquids to clean the crimping tool.

Solvents or flammable liquids could

ignite and cause serious injury or

property damage.

An incomplete crimp can cause a fire.

• Use proper die, connector, and cable combinations. Improper combinations can result in an

incomplete crimp.

• Use only W-type dies on aluminum connectors or

aluminum wire. Mismatched components can

result in an incomplete crimp.

• The relief valve will sound to indicate a completed

crimp. If you do not hear the sound of the relief

valve, the crimp is not complete.

Failure to observe these warnings can result in

severe injury or death.

Greenlee Textron / Subsidiary of Textron Inc. 3 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 4

EK22GL Battery-powered, High-speed Crimping Tool

Greenlee Textron / Subsidiary of Textron Inc. 4 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 5

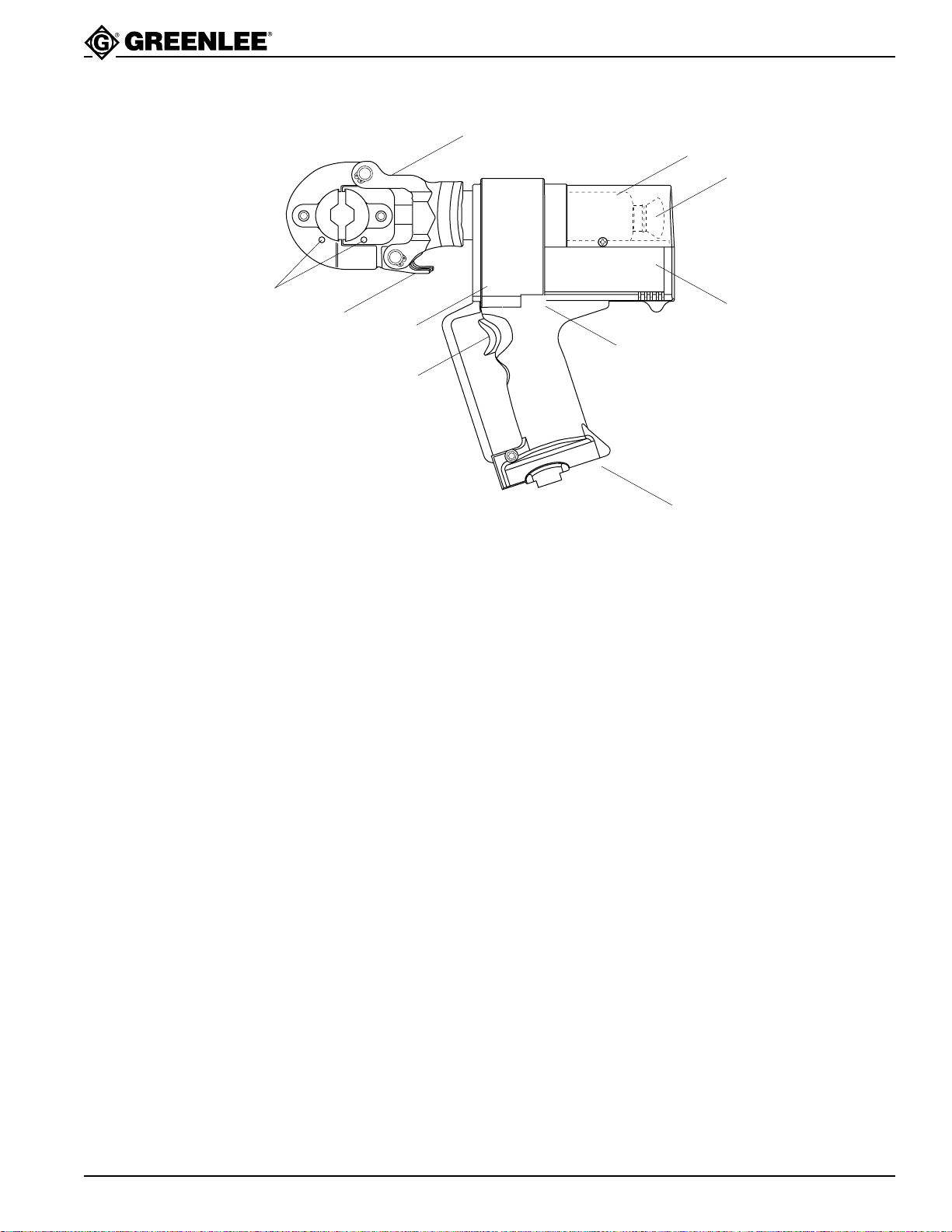

IdentificationIdentification

EK22GL Battery-powered, High-speed Crimping Tool

10

11

1. Housing

2. Retract Button

3. Battery Cartridge

4. Trigger

5. Battery Load Display

6. Locking Flange

7. Die Release Buttons

8. W-type Die Detents

9. Crimping Dies

10. Crimping Head

11. Oil Reservoir

12. Oil Plug

Specifications

Crimping Tool

Length........................................................................................... 314 mm (12-3/8")

Width........................................................................................................76 mm (3")

Height ........................................................................................... 298 mm (11-3/4")

Mass/Weight (with battery) ................................................................. 4.4 kg (9.7 lb)

Sound Level..............................................................................75 dB (A) at 1 meter

Vibration.................................................................................................... < 2.5 m/s

Motor Type....................................................................... DC permanent field motor

Motor Voltage ...............................................................................................12 VDC

Hydraulic Oil ....................................................50 ml (0.1 pint) of Shell Tellus® T 15

Crimping Capacities

Maximum Cable Size.................................................................... 600 Kcmil copper

Maximum Crimping Force................................................................55 kN (6.2 tons)

Crimping Time ..........................................................................................7 seconds

Crimps per Charge ......................................................................approximately 120

Battery

Charging Voltage ............................................................................................... 12 V

Charging Time ................................................................................................ 1 hour

7

EK22GL

6

5

2

4

3

1

2

Greenlee Textron / Subsidiary of Textron Inc. 5 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 6

Operation

EK22GL Battery-powered, High-speed Crimping Tool

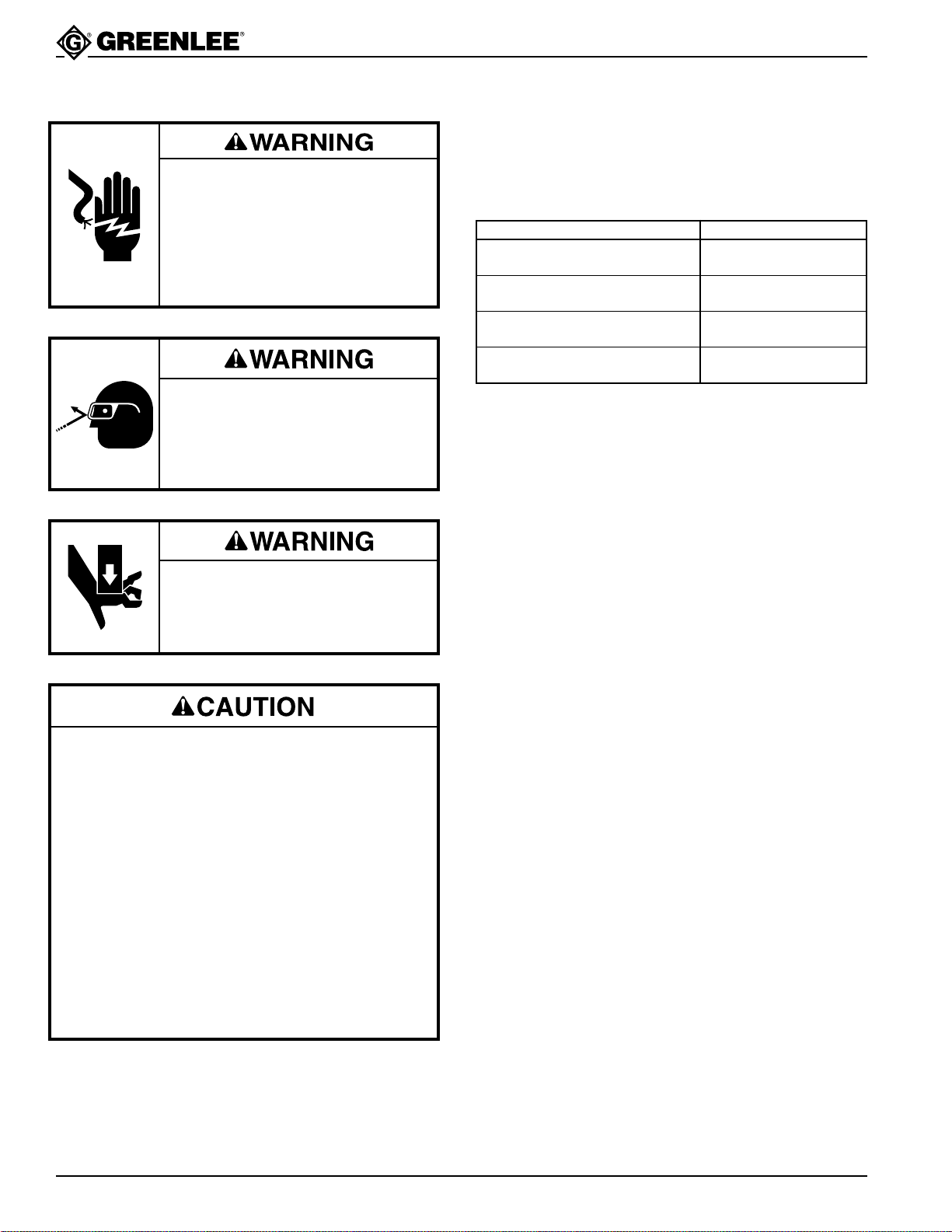

Electric shock hazard:

This tool is not insulated. When

using this unit near energized

electrical lines, use proper personal

protective equipment.

Failure to observe this warning can

result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection can

result in serious eye injury from

flying debris or hydraulic oil.

Charging the Battery

Read the instructions supplied with the battery charger.

Battery Condition

Battery Load Display Battery Condition

Momentary illumination at Normal or operating

beginning of crimp charge level

Flickering at point of Normal or operating

maximum crimping force charge level

Flickering during entire

crimping cycle

Constant illumination when

operating without a load

Low charge level

Low charge level

Installing K22-type Dies

1. Select the proper dies for the intended crimp.

2. Push the die release button.

3. Slide the die into the crimping head until it “snaps”

into place.

4. Properly position the second die. Repeat Steps

2 and 3.

Keep hands away from the crimping

head when crimping.

Failure to observe this warning can

result in severe injury or death.

• Do not operate the tool without dies. Damage to

the ram or crimping head can result.

• Do not operate with the crimping head open.

Damage to the ram or seals can result.

• This tool is not designed for continuous use.

After 30 to 40 crimping cycles, allow the crimping

tool to cool for 15 minutes.

• Do not place the tool in a vise. The crimping tool

is designed for hand-held operation.

• Protect the crimping tool from rain and moisture.

Water will damage the crimping tool and battery.

• Use this tool for the manufacturer’s intended

purpose only.

Failure to observe these precautions can result in

injury or property damage.

Installing W-type Dies

1. Push the die release button.

2. Slide the die adapter (Greenlee part number

500 4292.0) into crimping head until it “snaps”

into place.

Note: The die adapters have the “D3” die profile.

No additional dies are needed if the connector to be

crimped requires a “D3” die.

3. Repeat for the other adapter.

4. Select the proper dies for the intended crimp.

5. Press the locking flange and open the crimping

head.

6. Push the W-type die detent and slide the W-type die

into place.

7. Properly position the second die. Repeat Steps

5 and 6.

Greenlee Textron / Subsidiary of Textron Inc. 6 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 7

Operation (cont’d)

EK22GL Battery-powered, High-speed Crimping Tool

Preparing Cable

Follow the lug manufacturer’s instructions for appropriate

cable strip length.

CRIMPING DIRECTION

1ST COMPRESSION

CRIMPING DIRECTION

SIDE B

1ST COMPRESSION

SIDE A

1ST COMPRESSION

CRIMPING DIRECTION

SIDE A

SIDE B

Crimping Cable

1. Press the locking flange and open the crimping

head.

2. Insert the properly assembled connector into the

crimping head.

3. Close the crimping head.

4. Pull the trigger to make the crimp.

5. Hold the trigger down until the crimping tool

achieves pressure relief.

Notes: Pressure relief occurs at approximately

690 bar (10,000 psi) and is accompanied by an

audible “pop”.

It is normal for the battery load display to light at

both the beginning and near the end of the crimping

cycle.

6. The crimping tool returns automatically.

7. Position the crimping tool for next crimp. Repeat

Steps 4 through 6 for the number of crimps as

described in this manual.

8. Open the crimping head and remove the connector.

Notes: If it is necessary to retract the ram before a

crimping cycle is completed, push the retract button.

Pushing the retract button will result in the complete

retraction of the ram.

After completing the last crimp with W-type dies on an

aluminum connector, wipe off the excess oxide inhibitor.

An incomplete crimp can cause a fire.

• Use proper die, connector, and cable combinations. Improper combinations can result in an

incomplete crimp.

• Use only W-type dies on aluminum connectors or

aluminum wire. Mismatched components can

result in an incomplete crimp.

• The relief valve will sound to indicate a completed

crimp. If you do not hear the sound of the relief

valve, the crimp is not complete.

Failure to observe these warnings can result in

severe injury or death.

Greenlee Textron / Subsidiary of Textron Inc. 7 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 8

Dies and Connectors

Die Selection

Crimps made on copper cable with Greenlee K22-type dies and

the connectors listed here are UL classified and CSA certified.

Refer to “Connector Selection” for brand names and model

numbers of appropriate lugs as well as crimping instructions.

W-type dies can be used to crimp #6 AWG to 4/0 AWG aluminum or copper cable.

EK22GL Battery-powered, High-speed Crimping Tool

Part UPC Cable Color

Number Number Size Code

K22-0 03079 #8 AWG Red

K22-1 03080 #6 AWG Blue

K22-2 03081 #4 AWG Gray

K22-3 03082 #2 AWG Brown

K22-31 03083 #1 AWG Green

K22-4 03084 1/0 AWG Pink

K22-5 03085 2/0 AWG Black

K22-6 03086 3/0 AWG Orange

K22-7 03087 4/0 AWG Purple

K22-8 03088 250 Kcmil Yellow

K22-9 03089 300 Kcmil White

K22-10 03090 350 Kcmil Red

K22-11 03091 400 Kcmil Blue

K22-12 03092 500 Kcmil Brown

K22-13 03093 600 Kcmil Green

Connector Selection

EK22GL Crimping Range: #8 AWG to 600 Kcmil

When used with K22-type dies, this tool is UL classified and CSA certified for use with the following connector brands:

Connector Barrel

Type Type Union Crimps*

Copper

Splice Long VHS CU YS CTL SCL/SCH 54804–54820 BBCU B

Copper

Lugs

Anderson Blackburn

Short VHSS CPS YS-L CT SCSS/SCS 54504–54520 BCU A

Short VHCS CTL-2/CTL

Long VHCL CTL-L/LCN YA-2N

®

Burndy Ilsco Panduit T&B

YA-2LN/YA-L/YA-2L

YA/YA-L-TC/YA-L-2TC LCD 54204–54218

CRA/CRB

CRA-L/CRB-L

CRA-2L/CRB-2L 54850BE–54878BE

LCAS/LCA 54104–54120

LCB/LCC

54930BE–54920BE

Penn- No. of

BLU A

BBLU B

* Use the number of crimps listed in the last column

instead of the number provided with the connector:

LR9716195R7

A — #8 to 1/0: 1 crimp

2/0 to 600: 2 crimps

B — #8 to 1/0: 2 crimps

2/0 to 3/0: 3 crimps

4/0 to 600: 4 crimps

Greenlee Textron / Subsidiary of Textron Inc. 8 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 9

Maintenance

EK22GL Battery-powered, High-speed Crimping Tool

Each Operating Day

Before use:

1. Inspect dies for wear or damage such as cracks,

gouges, or chips.

2. Inspect the tool for damage or leaks. If damage is

detected, return the tool to an authorized Greenlee

service center for inspection.

Skin injection hazard:

Do not use hands to check for oil

leaks. High pressure oil easily

punctures skin causing serious

injury, gangrene, or death. If injured,

seek medical help immediately to

remove oil.

After use:

1. Wipe all tool surfaces clean with a damp cloth and

mild detergent.

Do not use solvents or flammable

cleaners to clean the tool body.

Solvents could ignite, causing

serious injury or property damage.

Monthly

1. Thoroughly clean all surfaces.

2. Check the oil level.

3. Oil the bolt joints.

Annually or After 10,000 Crimps

1. Change the hydraulic oil.

2. Return the tool to an authorized Greenlee service

center for inspection.

Checking the Oil Level

1. Remove the two screws holding the tank housing

cover.

2. Remove the tank housing cover.

3. Point the cutting head towards the ground and

remove the oil plug. Add oil if necessary.

4. Replace the oil plug and the tank housing cover.

Secure with screws.

Recommended Hydraulic Oils

AVIA® HVI 15

Shell Tellus T 15

Mobil® DTE 11

NUTO® H 15

2. Fully retract the ram. Place the tool in the carrying

case. Store in a cool, dry place.

3. Charge the battery.

Greenlee Textron / Subsidiary of Textron Inc. 9 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 10

Troubleshooting

EK22GL Battery-powered, High-speed Crimping Tool

Before You Begin

1. Make sure that the battery is charged. Recheck the

battery after several minutes to make sure the

battery is holding its charge.

Probable CauseProblem Probable Remedy

Tool is inoperative. Dirt, contaminants, etc., in ram area Clean tool.

of tool.

Crimping tool battery contacts Reform contacts.

damaged.

Tool components worn or damaged. Return tool to an authorized

Dies stop during operation Oil level is low. Check oil level. Refill reservoir.

Air in hydraulic system. Pull trigger and hold retract button

2. Use a nonflammable contact cleaner or pencil

eraser to clean the electrical contacts on the battery

and crimping tool.

3. Reinstall the battery and check the tool again.

Greenlee service center.

simultaneously. Hold for approximately

10 seconds.

Battery load display flashes Battery charge low. Charge or replace battery.

constantly.

Tool loses oil. Damaged internal seal. Return tool to an authorized

Greenlee service center.

Oil plug not installed properly. Refill reservoir and replace plug.

Greenlee Textron / Subsidiary of Textron Inc. 10 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 11

Disassembly

EK22GL Battery-powered, High-speed Crimping Tool

Main Components

1. Remove the battery.

2. Drive out the pin (37). Remove the die holder

assembly (28).

3. Loosen two screws (24).

4. Unscrew and remove crimping head assembly.

5. Remove the spring (18) and piston (15). Replace the

piston O-ring (12) and piston backup ring (13).

6. Unscrew two tank cover screws (55) and remove the

tank cover.

7. Remove the hydraulic reservoir plug (76) and drain

the hydraulic fluid.

8. Reinstall the plug.

9. Remove the remaining housing screws

(51, 56, 57, 58).

10. Remove the left housing half.

11. Remove the switch cover (53).

12. Lift the pump/motor assembly and circuit card from

the right housing half. Lift the LED from its housing

(59).

13. Slide a plastic bag over the circuit card and electronic subassemblies. Tape the bag shut to protect

the subassemblies from hydraulic oil and other

contamination.

14. Unscrew the shoulder bolt (99) and remove the

release lever (107).

15. Remove screws (108) and separate the gear

housing/motor subassembly from the pump housing.

Pump

1. Use a hooked tool to remove the reservoir O-ring

(80). Gently tug it over the reservoir.

2. Remove the reservoir (74).

3. Remove the pump piston (152).

4. Remove the screw plug (151), washer (153), pump

piston (150), valve stem (156), and spring (155).

Replace the sealing washer (154).

5. Use a piece of tape to mark the side of the relief that

is facing up. (This is a reference point for reassembly). Remove the unloading valve by unscrewing the

plug (126).

6. Remove the feeder tube subassembly by unscrewing the feeder tube (78). Replace the oil filter (77).

Remove metal chips from the magnet (82).

7. Remove the threaded bushing (72) and replace the

O-ring (73).

Motor, Gearbox, and Bearing

1. Remove the tamper-proof paper seal (96).

2. Remove two screws (92). Remove the end cap

(102).

3. Apply pressure evenly at three points around the ball

bearing (91) and gently pry the bearing up to remove

it.

4. Remove the eccentric (103), grooved ball bearing

(101), and snap ring (100) subassembly from the

shaft.

5. Remove four screws (93). Remove the mounting

block (109) from the gear housing (94).

6. Use a snap-ring removal tool to remove the snap

ring (100).

7. Unscrew four bolts (not numbered) from the gear

housing (94). Separate the gear housing from the

spacer (not numbered). Unscrew two fillister head

screws (112) to separate the spacer from the motor

(90).

Greenlee Textron / Subsidiary of Textron Inc. 11 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 12

Assembly

EK22GL Battery-powered, High-speed Crimping Tool

Motor, Gearbox, and Bearing

1. Install two fillister head screws (112) into the spacer

(not numbered) and motor (90). Tighten the screws.

2. Install four screws (not numbered) into the gear

housing (94). Tighten the screws.

3. Install four screws (93) into the mounting block (109)

and gear housing (94). Tighten the screws.

4. Replace the grooved ball bearing (101) and snap

ring (100) subassembly.

5. Replace the eccentric (103). Use a fiber mallet to tap

the eccentric onto the shaft. Replace the ball bearing

(91).

6. Align the end cap (102). Use a fiber mallet to tap the

cover until it is flush on the mounting block (109).

Install two screws (92).

7. Align the gear housing/motor subassembly so that

the pump piston (152) extends through the mounting

block (109) and makes contact with the grooved

bearing (101). Locate and start the screws (108)

through the mounting block and into the pump

housing. Tighten the screws.

Pump

1. Insert the pump piston (152) into the pump housing.

2. Insert the seal (122) and unloading valve assembly

into the pump housing. Grasp the needle valve

subassembly by the pressure relief (126) and twist it

several turns clockwise. Stop when the piece of tape

is facing up.

3. Assemble the pump piston (150), valve stem (156),

washer (153), spring (155), and screw plug (151). Be

sure to replace the sealing washer (154). Torque the

screw plug (151) to 101 Nm (75 ft-lb).

4. Install the release lever (107) so that the forked end

engages the unloading valve subassembly between

the pressure relief (126) and the support ring (127).

Install the screw (99) and washer (104).

5. Insert the threaded bushing (79) and feed tube subassembly (77, 78, 82). Screw in until snug.

6. Install the reservoir (74). Slip the O-ring (80) over the

reservoir. Using a hooked tool, carefully slip the

O-ring over the lip of the pump housing.

7. Insert the plug (76) into the reservoir.

Main Components

1. Remove the protective plastic bag from the

electronics subassembly. Insert the LED into the

LED bushing (59).

2. Lay the gear housing/motor subassembly into the

right half of the housing. Insert the circuit board into

the circuit board slot so that the wires and chip face

in the direction of the trigger.

3. Lay the wires into the case. Be sure that the wires

will not be pinched.

4. Guide the wires for the battery clip so that the

battery wires lay on top of the electronics box; install

the battery clip so that the red wire is upward.

5. Install the trigger cover (53) and plug (60). Press and

release the trigger to be sure that it operates freely.

6. Locate the right housing half on top of the left

housing half. Check for pinched wires.

7. Install the housing screws (51, 56, 57, 58).

Note: The handle screw (51) must engage the nut

(52).

8. Install the piston (15).

9. Install the spring (18).

10. Replace the front head assembly. Twist the head

base (25) until it stops; back off 3/4 of a turn and

tighten the screws (24). Be sure that the crimping

head assembly rotates freely approximately 350°.

11. Install the die holder assembly (28). Insert the pin

(37) through the ram.

12. Clamp the head assembly into a vise with the

reservoir plug facing upward. Remove the fill plug

(76) and fill the reservoir with hydraulic oil.

13. Install the battery.

14. Squeeze the trigger while pressing the release lever

for 45 to 60 seconds. Fill the reservoir with hydraulic

oil. Replace the fill plug (76).

15. Replace the tank cover and tank cover screws.

Greenlee Textron / Subsidiary of Textron Inc. 12 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 13

EK22GL Battery-powered, High-speed Crimping Tool

Greenlee Textron / Subsidiary of Textron Inc. 13 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 14

Illustration

EK22GL Battery-powered, High-speed Crimping Tool

12

13

15

18

29

21

26

14

19

16

27

17

31

24

23

25

36

34

33

30

29

34

24

35

28

33

29

33

34

36

23

37

30

32

34

22

33

19

20

29

Greenlee Textron / Subsidiary of Textron Inc. 14 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

31

23

Page 15

Illustration

EK22GL Battery-powered, High-speed Crimping Tool

76

95

98

97

111

112

90

127

110

94

104

107

128

99

74

82

75

77

78

79

83

80

122

81

123

129

121

124

120

155

130

125

126

156

73

72

150

153

154

105

151

106

152

109

141

108

100

103

93

102

101

91

92

96

61

54

140

Greenlee Textron / Subsidiary of Textron Inc. 15 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 16

Parts List

EK22GL Battery-powered, High-speed Crimping Tool

Key Part No. Description Qty

7 500 7151.3 Circuit board, programmed................................................................ 1

9 500 2948.7 Decal, identification ........................................................................... 1

10 500 2950.9 Decal, warning................................................................................... 1

11 500 6214.0 Decal, pinch hazard........................................................................... 2

12* 500 4192.4 O-ring ................................................................................................ 1

13* 500 4194.0 Backup ring ....................................................................................... 1

14 500 5844.4 Bushing ............................................................................................. 1

15 500 5834.7 Ram................................................................................................... 1

16 500 5837.1 Adapter disk ...................................................................................... 1

17* 500 5838.0 O-ring ................................................................................................ 1

18 500 5839.8 Compression spring .......................................................................... 1

19 500 4383.8 Spring ................................................................................................ 2

20 500 4384.6 Pin ..................................................................................................... 1

21 500 4179.7 Pin ..................................................................................................... 1

22 500 4385.4 Die retainer........................................................................................ 2

23 500 4396.0 Compression spring .......................................................................... 4

24 500 4168.1 Screw ................................................................................................ 2

25 500 5830.4 Bottom crimp head ............................................................................ 1

26 500 4387.0 Latch.................................................................................................. 1

27 500 4388.9 Top die holder ................................................................................... 1

28 500 4394.3 Bottom die holder .............................................................................. 1

29 500 3430.8 Retaining ring .................................................................................... 4

30 500 4400.1 Die release button ............................................................................. 2

31 500 4401.0 Die retainer........................................................................................ 2

32 500 4414.1 Pin ..................................................................................................... 2

33 500 4389.7 Die release button ............................................................................. 4

34 500 4390.0 Locking pin ........................................................................................ 4

35 500 4393.5 Threaded stud ................................................................................... 1

36 500 4395.1 Inner bushing..................................................................................... 2

37 500 4397.8 Pin ..................................................................................................... 1

500 1345.9 Housing unit (includes items 50–61)

50 500 7142.4 Housing kit......................................................................................... 1

51 500 4220.3 Screw ................................................................................................ 1

52 500 4221.1 Nut..................................................................................................... 1

53 500 7373.7 Switch cover ...................................................................................... 1

54 500 4128.2 Battery clip......................................................................................... 1

55 500 4236.0 Screw ................................................................................................ 2

56 500 4207.6 Screw ................................................................................................ 4

57 500 4209.2 Screw ................................................................................................ 2

58 500 4208.4 Screw ................................................................................................ 4

59 500 4241.6 LED bushing...................................................................................... 1

60 500 1350.5 Plug ................................................................................................... 1

61 500 3633.5 Pin, 4 x 16 ......................................................................................... 1

Greenlee Textron / Subsidiary of Textron Inc. 16 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 17

Parts List (cont’d)

Key Part No. Description Qty

72 500 4144.4 Threaded bushing ............................................................................. 1

73* 500 4143.6 O-ring ................................................................................................ 1

74 500 5861.4 Hydraulic reservoir ............................................................................ 1

75 500 4198.3 Ring ................................................................................................... 1

76 500 4122.3 Reservoir plug ................................................................................... 1

77 500 5880.0 Filter .................................................................................................. 1

78 500 5882.7 Filter adapter ..................................................................................... 1

79 500 5885.1 Threaded bushing ............................................................................. 1

80* 500 5886.0 O-ring ................................................................................................ 1

81 500 5829.0 Attachment ring ................................................................................. 1

82 500 5898.3 Magnet .............................................................................................. 1

83 500 1355.6 Pump housing ................................................................................... 1

90 500 4132.0 Motor ................................................................................................. 1

91 500 4138.0 Ball bearing ....................................................................................... 1

92 500 4155.0 Screw ................................................................................................ 2

93 500 4157.6 Screw ................................................................................................ 4

94 500 4133.9 Gearbox............................................................................................. 1

95 500 4113.4 Spacer ............................................................................................... 1

96* 500 4153.3 Seal ................................................................................................... 1

97 500 4136.3 Ground strap ..................................................................................... 1

98 500 4137.1 Capacitor ........................................................................................... 3

99 500 4163.0 Screw, socket head ........................................................................... 1

100 500 4151.7 Retaining ring .................................................................................... 1

101 500 4139.8 Grooved ball bearing ......................................................................... 1

102 500 4108.8 End cap ............................................................................................. 1

103 500 4123.1 Eccentric............................................................................................ 1

104 500 4922.4 Lock washer ...................................................................................... 1

105 500 4125.8 Spring ................................................................................................ 1

106 500 5872.0 Screw ................................................................................................ 1

107 500 5879.7 Release lever .................................................................................... 1

108 500 8403.8 Screw ................................................................................................ 2

109 500 8402.2 Eccentric case ................................................................................... 1

110 500 1351.3 Gearbox............................................................................................. 1

111 500 1352.1 Gear .................................................................................................. 1

112 500 6772.9 Screw ................................................................................................ 2

EK22GL Battery-powered, High-speed Crimping Tool

500 1354.8 Pump housing, reservoir assembly (includes items 72–83)

500 1349.1 Motor assembly (includes items 90–112)

Greenlee Textron / Subsidiary of Textron Inc. 17 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Page 18

Parts List (cont’d)

Key Part No. Description Qty

120 500 5860.6 Washer .............................................................................................. 1

121* 500 4134.7 O-ring ................................................................................................ 1

122* 500 5862.2 Seal ................................................................................................... 1

123 500 5363.0 Valve seat.......................................................................................... 1

124 500 5864.9 Plunger .............................................................................................. 1

125* 500 5869.0 O-ring ................................................................................................ 1

126 500 5871.1 Pressure relief ................................................................................... 1

127 500 5875.4 Support ring....................................................................................... 1

128* 500 5876.2 Retaining ring .................................................................................... 1

129 500 5877.0 Needle valve...................................................................................... 1

130 500 5894.0 Spring ................................................................................................ 1

140 500 4126.6 Switch................................................................................................ 1

141 500 4127.4 Battery contacts................................................................................. 1

142 500 6338.3 Circuit board, unprogrammed............................................................ 1

143 500 5899.1 Wire (not shown) ............................................................................... 1

144 500 5900.9 Wire (not shown) ............................................................................... 1

EK22GL Battery-powered, High-speed Crimping Tool

500 1593.1 Relief valve assembly (includes items 120–130)

500 1347.5 Electrical assembly (includes items 140–144)

500 1348.3 Piston pump assembly (includes items 150–156)

150 500 5891.6 Pump piston ...................................................................................... 1

151 501 0365.2 Screw plug......................................................................................... 1

152 501 0370.9 Pump piston ...................................................................................... 1

153* 501 0369.5 Washer .............................................................................................. 1

154* 501 0366.0 Sealing washer .................................................................................. 1

155 501 0367.9 Spring ................................................................................................ 1

156 501 0368.7 Valve stem......................................................................................... 1

500 4292.0 W-type die adapter

500 4625.0 W-type die release kit (includes items 23, 33, 34, 36)

500 4626.8 Die release kit (includes items 22, 23, 30–32)

* 500 1407.2 Seal kit (includes items marked with an asterisk)

500 5954.0 Case with inserts

500 2999.1 12 V battery NiCd

500 3046.9 12 V charger 110 VAC

500 3047.7 12 V charger 220 VAC

500 3048.5 12 V charger 12 VDC

Greenlee Textron / Subsidiary of Textron Inc.

4455 Boeing Drive, Rockford, IL 61109-2988 USA

Customer Service (International): 815/397-7070 • Fax: 815/397-9247

Customer Service (North America): 800/435-0786 • USA Fax: 800/451-2632, 815/397-1865

Canada Fax: 800/524-2853

www.greenlee.textron.com

Greenlee Textron / Subsidiary of Textron Inc. 18 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815/397-7070

Printed in the USA

Loading...

Loading...