Page 1

C E R T I F I E D

Applies to: Model Series DV

TABLE OF CONTENTS

INDOOR OR OUTDOOR, GAS,

DIRECT-FIRED, MAKEUP AIR/

HEATING SYSTEMS

(Specifications subject to change without notice.)

Operation/Maintenance/Service

Form RZ-NA 441-OMS

Page

MAINTENANCE

SECTION ...................... 2-4

Configuration ................................. 2

Maintenance Schedule ................... 2

1A. Blower Bearings .............................. 3

1B. Blower Belts ................................... 3

2. Filters ................................................. 3

3. Manifold Gas Pressure ...................... 3

4. Air Pressure ....................................... 4

5. Circuit Indicator Board (check lights) 4

6. Main Burner and Pilot Assembly ...... 4

OPERATION/SERVICE

SECTION ................... 5-15

Controls - Location ....................... 5

7. Electronic Circuit Board with

Diagnostic Lights.............................. 5

References: Installation Manual, Form RZ 441

Page

8. Temperature Limit Safety Controls... 5

•Manual Reset Limit Control ........... 5

•Emergency Cut Off Limit Control .. 6

9. Air Pressure Switches ........................ 6

•Low Air Flow Switch ...................... 6

•High Air Flow Switch ...................... 6

•Bypass Damper (Optional) Air

Flow Switches ................................ 6

10. Ignition System ................................ 6

11. Gas Train Including Direct-Fired

Burner, Gas Control Systems,

Manifold Arrangements and Gas

Pressure Switches ............................. 7

•Direct-Fired Burner ........................ 7

•Makeup Air Gas Control Systems .. 7

•Electronic Modulation Gas Control

Options AG30, AG31, AG32,

AG33, AG35, AG36 ...................... 7

•Electronic Modulation Gas Control

Option AG37 ................................. 7

12. Outside Air Ambient Cutoff ............ 8

13. Door Switch ..................................... 9

14. Inlet Air Controls ............................ 9

15. Dirty Filter Switch ......................... 10

16. Photoelectric Smoke Detector ....... 10

17. Firestat ........................................... 10

18. Freezestat ....................................... 10

19. Troubleshooting ............................. 11

Index ................................................... 12

Replacement Parts Manual, Form RZ 741

Page

•Manifold Arrangements ................. 8

•Gas Pressure Switches .................... 8

•Air Flow Dampers ........................... 9

•Damper Motor ................................. 9

•Potentiometer .................................. 9

•Pressure Null Switch ....................... 9

•Photohelic Pressure Switch ........... 10

Chart 1 - General Troubleshooting

Guide (Check the diagnostic lights on

the circuit board)

FOR YOUR SAFETY

WARNING: The use and storage of gasoline or

other flammable vapors and liquids in the vicinity

of this appliance is hazardous.

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

WARNING: Improper installation, adjustment,

alteration, service, or maintenance can cause

property damage, injury or death. Read the

installation, operation, and maintenance

instructions thoroughly before installing or

servicing this equipment.

KEEP THIS BOOKLET

FOR MAINTENANCE AND

SERVICE REFERENCE.

Operating/Maintenance/Service

Instructions

The information in this manual applies to Model Series DV, direct-fired heating/makeup air systems. As with any gas burning

equipment, regular maintenance procedures are required to ensure continued safety, reliability and efficiency of the installation.

If service is required, this system should be serviced only by a

qualified service person. Service information in this booklet is

intended as a guideline for a qualified gas-fired equipment service person.

Mfg No. 161442

Page 1

Page 2

DANGER: The gas burner in this direct gas-fired system is designed and equipped to provide safe and

economically controlled complete combustion. However, if the installation does not permit the burner to

receive the proper supply of combustion air, complete combustion may not occur. The result is incomplete

combustion which produces carbon monoxide, a poisonous gas that can cause death.

Always comply with the combustion air requirements in the installation codes and operating instructions.

The amount of air over the burner must be within the specified range. The burner profile plates are set at

the factory to match CFM requirements. Do not adjust the burner profile plates without contacting the

factory. FAILURE TO PROVIDE PROPER COMBUSTION AIR CAN RESULT IN A HEALTH

HAZARD WHICH CAN CAUSE PROPERTY DAMAGE, SERIOUS INJURY, AND/OR DEATH. Directfired installations should provide for air changes as required by the applicable installation codes.

Maintenance Section

This direct-fired makeup air system is designed to require only a minimum

amount of maintenance. Some maintenance procedures outlined in this Section

require inspection only and some require action. Frequency requirements of

each maintenance procedure are listed in the Maintenance Schedule. Depending

on the environment and the number of operating hours, more frequent inspection and/or cleaning may be required to certain components.

Although maintenance requirements are minimal, the routine maintenance procedures in this Section are necessary to ensure safe, reliable, and/or efficient

operation. The paragraphs which follow discuss the components and systems

that require routine inspection/maintenance. At the beginning of each paragraph,

there is a code indicating why that maintenance procedure is necessary. The

legend for that code is shown below.

Maintenance Codes

Reason for Maintenance

S = Safety (to avoid personal injury and/or property damage)

R = Continued Reliability

E = Efficient Operation

WARNING: Disconnect all power to the

system before doing any maintenance.

Failure to do so may cause electrical shock,

personal injury, or death.

Maintenance Schedule

See Chart

Quarterly

Semi-Annually

Annually

Lubricate bearings, Paragraph 1

Check the filters, Paragraph 2

Check air pressure sensing tubes,

Paragraph 4

Check blower belts, Paragraph 1

Verify gas pressures, Paragraph 3

Clean air pressure sensing tubes,

Paragraph 4

Check indicator lights, Paragraph

5

Check main burner and pilot

assembly, Paragraph 6

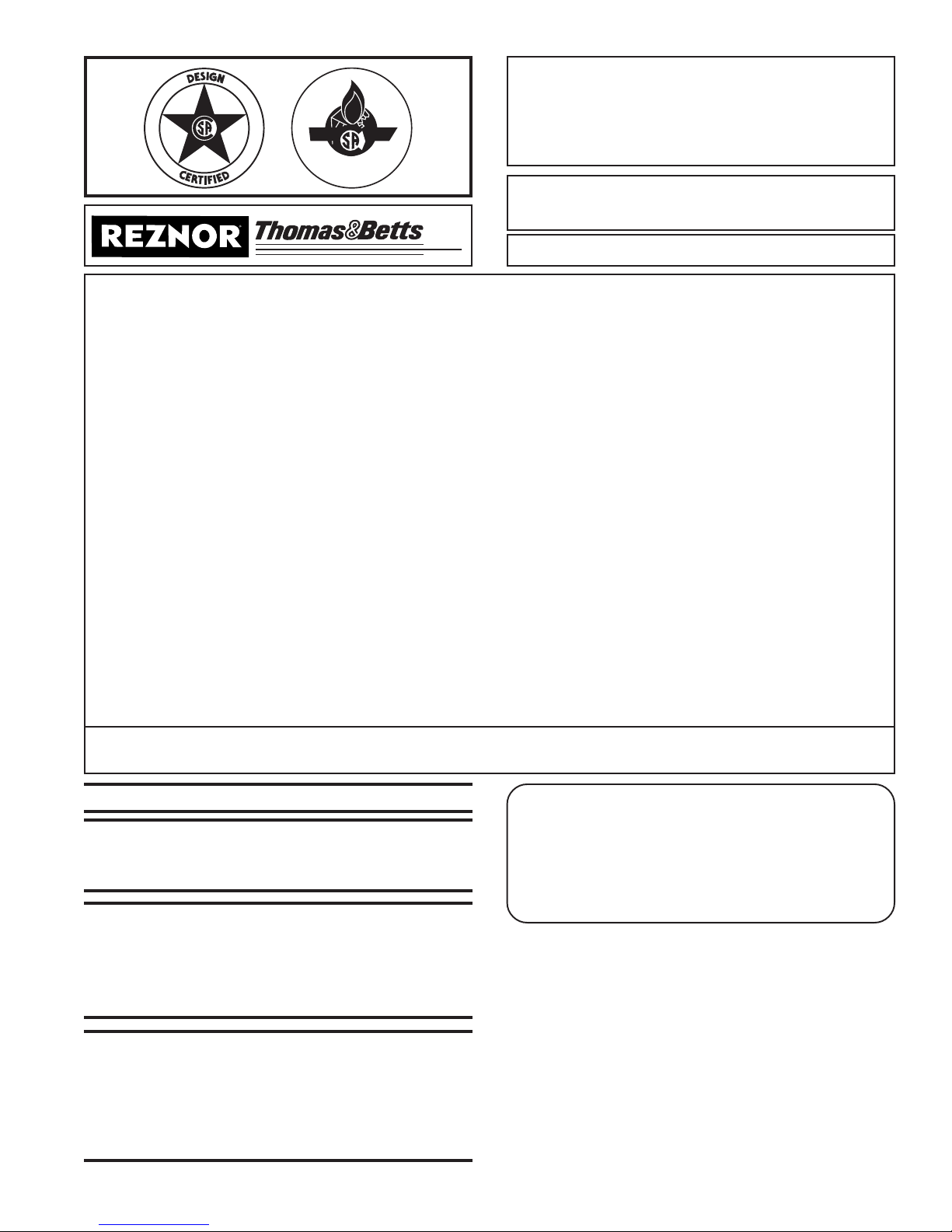

Discharge Air

Optional Return Air

Outside Air

Page 2

Figure 1 - System

Configuration

Blower

Section

Burner/Control Section

Location of Optional Filter

Cabinet (not shown)

Screened Inlet Base

Page 3

R

1. Drive Components

The blower, motor and drive components are located in the blower

cabinet at the top of the system. Systems with horizontal discharge

have a cabinet with eight removable door panels. Systems with vertical

discharge have a cabinet with six removable door panels. Remove the

panels required to access the components being serviced.

1A. Blower Bearings

All blowers are Class I with pillow block bearings. Clean the fitting and

add type NLG-2 or -2 standard grade grease. Add grease with a handgun

until a slight bead of grease forms at the seal. Be careful not to unseat

the seal by over lubricating.

NOTE: If unusual environmental conditions exist (temperatures below

o

F or above 200oF; moisture; or contaminants) more frequent lubri-

32

cation is required.

excessive motor and blower bearing wear. If adjustment is required,

adjust belt tension by means of the adjusting screw on the motor base

until the belt can be depressed 1/2" to 3/4" (Figure 2). Tighten the lock

nut on the adjusting screw. Be sure the belt is aligned in the pulleys.

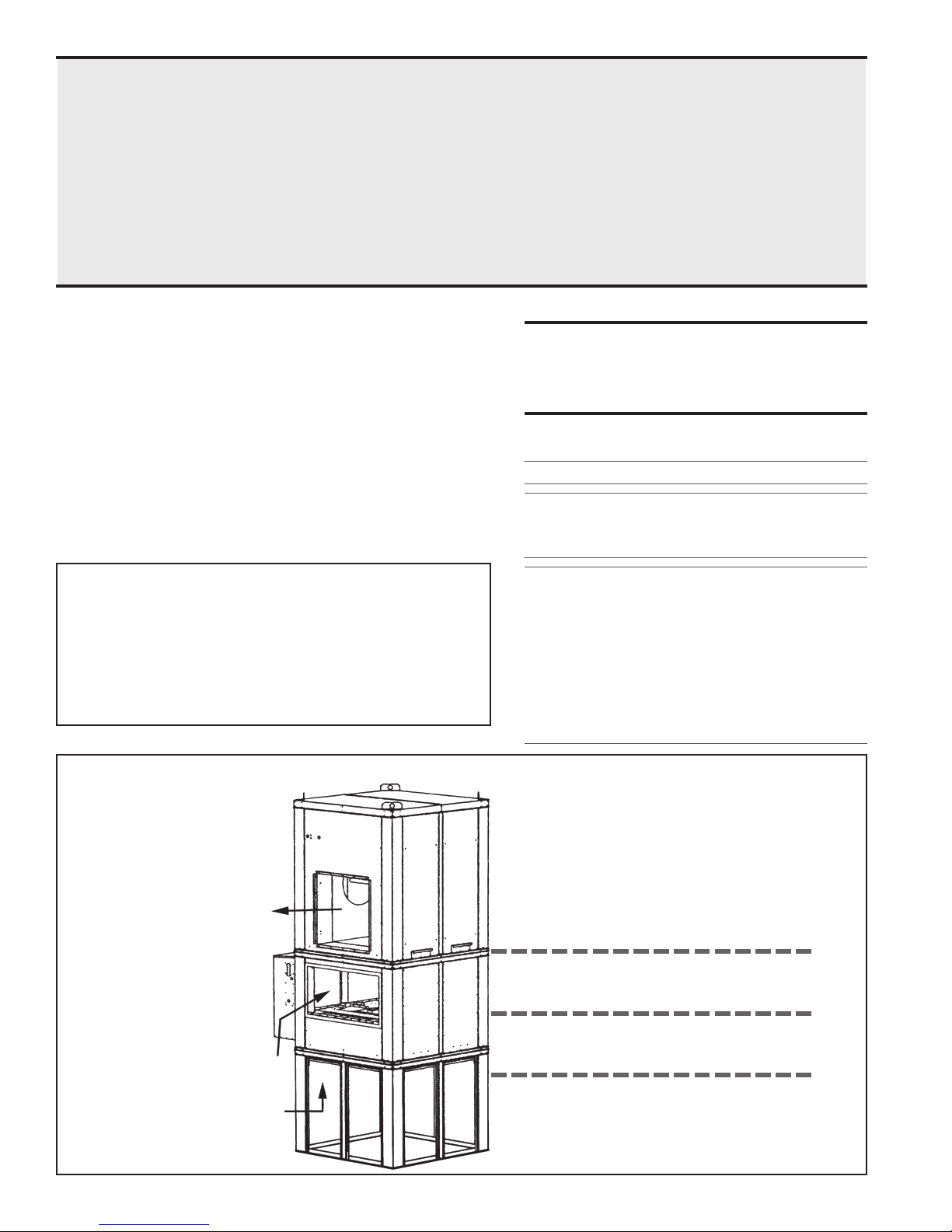

Figure 2 Belt

Tension

3/4 (19mm)

CAUTION: If the blower is unused for more than

three months, the bearings should be purged with

new grease prior to startup.

Recommended Bearing Lubrication Schedule in Months

Bearing Bore Diameter (Inches)

RPM

1/2 >1 to >1-1/2 to

to 1 1-1/2 1-15/16

to 500 6 6 6

501 - 1000 6 6 6

1001 - 1500 5 5 5

1501 - 2000 5 4 5

1B. Blower Belts

Check belts for proper tension and wear. Adjust belt tension as needed.

Replace worn belts.

Proper belt tension is important to the long life of the belt and motor. A

loose belt will cause wear and slippage. Too much tension will cause

3. Manifold Gas Pressure

S

Semiannually, check the gas pressure to the burner and to the pilot. Measure both manifold pressure and pilot supply pressure with the blower in

operation. Refer to Figure 3 for pressure tap locations. Verify against pressures listed on the rating plate.

R E

If the system includes filters, check the filters quarterly. Filters could

be either in the optional inlet base or in an optional filter cabinet.

If the filters are in the perimeter of the inlet base; they are two-inch

permanent filters. Remove and clean the filters as needed.

If the filters are in a filter cabinet (the filter cabinet is always between

the inlet base and the burner/control section), remove the filter cabinet

door panels to access the V-bank filter rack. Filters may be either 2"

disposable, 1" or 2" permanent, or 1" or 2" disposable pleated. Clean or

replace as needed.

Size 109 112 115 118 122 125

16" x 16" 4 4 - - 16 16

16" x 20" 4466- -

16" x 25" - - 6688

2. Filters

Sizes and Quantity of Filters in the Filter Cabinet

( same for all types of filters)

Figure 3 - Location of

pressure taps for

measuring burner and

pilot gas pressure.

Measure with blower

operating.

Gas

Supply

Pilot Manifold

Valve

Inlet Pressure Tap

Pilot

Regulator

Valve

Pilot Solenoid Valve

Pilot Pressure Tap

Regulator

Manifold Pressure Tap

Page 3

Page 4

S

4. Air Pressure

Profile plate sensing tubes should be checked quarterly and cleaned no

less than semiannually. If the sensing tubes become even partially

blocked, false pressure readings may be relayed. To clean, remove the

screened end caps. Clean the screens and the tubes, if necessary. Replace the cleaned end caps. Check the pressure differential across the

profile plate using a slope gauge. Air pressure differential should be

between -.5" and -.7" w.c.

To attach the slope gauge, open the control compartment door panel.

Just below the junction box, locate the tubing connections. Remove the

cap at each connection and attach the slope gauge using two fieldsupplied 1/4" x 1/8" female NPT barbed tubing connections. For instructions on measuring air pressure, see Service Section, Paragraph 9.

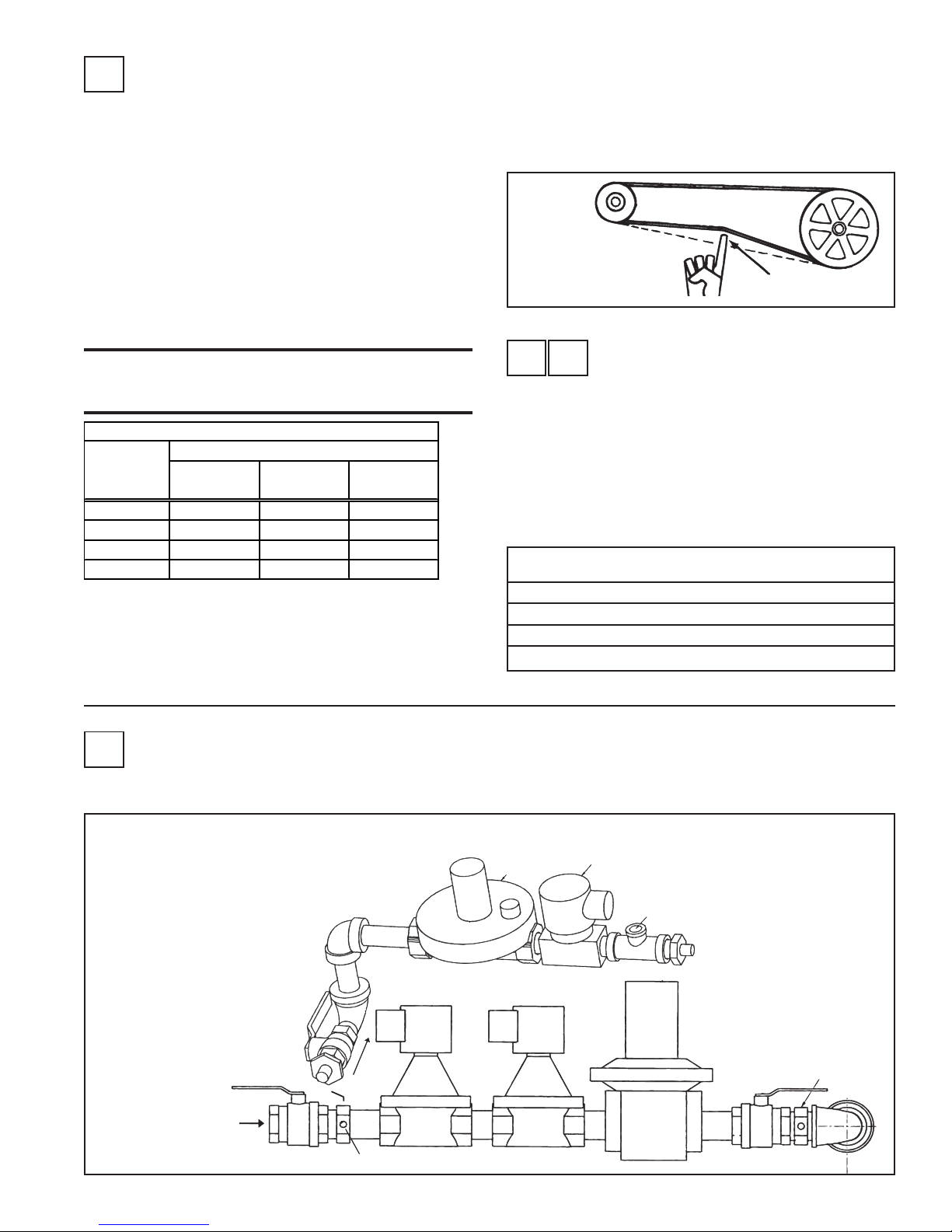

5. Circuit Indicator Board (check

R

lights)

The circuit indicator board is located in the control compartment electrical box (See Figure 7). Check operation of all indicator lights by

switching lights that are not lit with one that is currently lit. Replace all

burned out indicator bulbs (P/N 125189).

Figure 4 - Circuit

Indicator Board,

P/N 151263

Check bulbs not

lit with other

bulbs; replace

any burned out

bulbs

Row of Bulbs

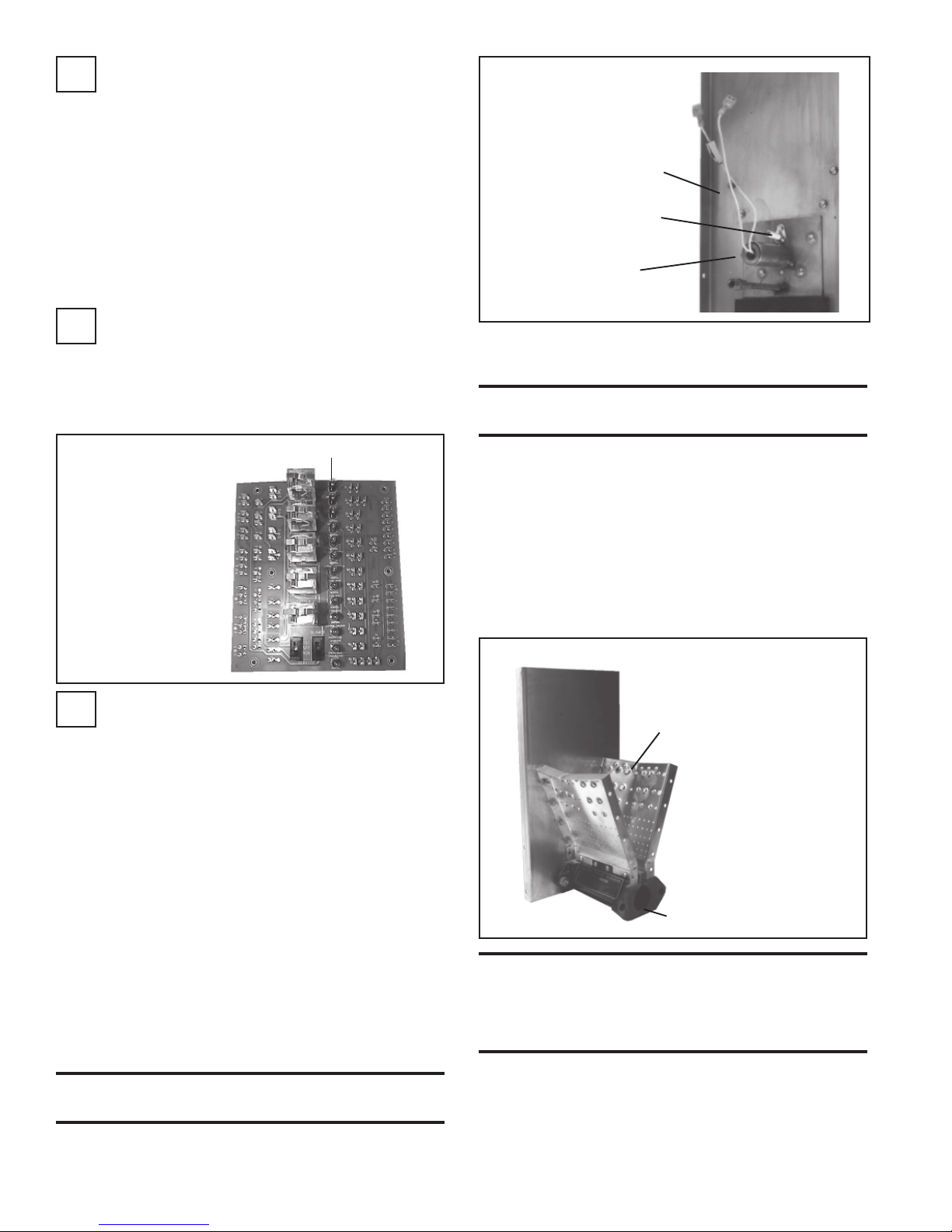

Figure 5 - Burner

End Plate showing

Hot Surface Ignitor

Burner End Plate

Flame Sensor

Ignitor

If air pressure does not unplug burner orifices or pilot tube, drill

burner orifices with a Size #50 drill and/or pilot tube with a Size #55

drill.

WARNING: Do not enlarge burner ports or

performance may be drastically affected.

Inspect the upstream and downstream sides of the mixing plates.

Remove any accumulation of scale or foreign material with a wire

brush. If any mixing plate fasteners are loose or missing, tighten or

replace. Always use zinc plated or stainless fasteners.

If any cracks are present, replace that mixing plate. Because of the

effect of flame temperature on the metal, fasteners may be difficult

to remove. Be careful not to damage the gaskets that go between the

mixing plates and the burner body. The gaskets are designed to

overlap approximately 1/16" for tight air seal.

5) Follow Steps in reverse order to re-install the pilot assembly. Close

all panels and check for proper operation.

6. Main Burner and Pilot Assembly

S

For the most part, the burner and pilot are self cleaning. However, if the

application is extremely dirty or dusty, cleaning of the burner and pilot

may be necessary. Inspect the burner annually. Follow these instructions. If it is necessary to replace any parts, use only factory-authorized replacements.

1) Turn off the gas and power supply to the system.

2) Remove the door panels in the burner/control cabinet (four or six

depending on whether or not the system has return air). Locate the

pilot.

3) Disconnect the two ignition wires (male and female quick connections) and disconnect the flame sensor lead at the burner. Remove

the set screw located in the ignitor tube (set screw holds the brass

bushing in place). Carefully remove the brass bushing and the ignitor.

Check the hot surface ignitor for cracks or unusual deterioration.

Check the flame rod for integrity. Replace the flame rod (P/N 131188)

and/or the hot surface ignitor (P/N 121865) if not in good condition.

4) Clean the burner and pilot by back-flushing, using high pressure air

(40-80 lbs). Continue until dust particles are completely expelled

from both the upstream and downstream sides of the burner.

CAUTION: Wear eye protection while pressure

cleaning and drilling.

Figure 6 - Illustration of the first Burner Section

Mixing

Plate

Full length of the

burner is made up of a

series of 6" or 12"

burner sections in a

linear or oval

configuration

Burner

WARNING: Burner profile plates are factory set

to match CFM requirements.

Do not adjust profile plates without contacting your

Sales Representative for technical assistance.

Page 4

Page 5

Operation/Service Section

Controls - Location, Operation, and Service

To service this system, it is necessary to understand the normal operation

of the controls and the function of the diagnostic circuit board. Refer to the

electrical box drawing in Figure 7 and to the individual illustrations to

identify and locate each of the controls. The wiring diagrams for this unit

are located in the main electrical box.

Figure 7 - Control Locations

Control

Relays

(high ambient limit control)

Ignition

Module

Outside Air Cutoff

Bypass

Damper

Motor

WARNING: Service work on this system

should only be done by a qualified gas service person. The service information and

the troubleshooting guides are intended as

an aid to a qualified service person.

Time Delay

Relay

24-volt Terminals

Return

Air

Damper

Motor

Status Lights

Maxitrol Amplifier

or Signal Conditioner

Optional

Dirty Filter

Pressure Switch

Circuit

Board

Optional Bypass Damper

Pressure Switches

Service

Switches

24-Volt Terminals

High

Standard Pressure

Switches

Low

Relay for

Optional 2-Speed

NOTE: Wiring diagrams for the unit are located on the inside of the electrical box door.

7. Electronic Circuit Board with Diagnostic

Lights

Location: Control Compartment Electrical Box (See Figure 7)

Function: The diagnostic lights on the circuit board are designed to assist

in troubleshooting. When the system is operating properly, the lights on

the circuit board are lit. If the system fails to operate properly, all lights on

the circuit board up to that one that represents the component or system

that has failed will be lit. For more detailed information, refer to the Troubleshooting Guide in Paragraph 19.

8. Temperature Limit Safety Controls

Location: 1) Manual Reset Limit Switch is mounted on a 2x4

electrical box located in the blower section. To access the manual

reset, remove the blower section access panel to the left of the

discharge (left when facing the discharge); 2) Emergency Cutoff

Limit Control is in the burner/control cabinet just above the electrical box.

• Manual Reset Limit Control - Blower

Cabinet

Function: The

Figure 8 Diagnostic

Circuit

Board,

P/N 151263

Column of 13

indicator

bulbs; always

replace

burned out

bulbs, P/N

125189.

manual reset limit

is a temperature

activated safety

control. Re-start

of the system can

be done only after

the limit control is

cooled and the reset button is depressed.

CAUTION: If the manual reset limit activates,

find and correct the cause before re-starting the

system.

Service: Failure of the manual reset limit requires replacement of

the control.

Transformer

Starter

Relay

Figure 9 Manual Reset

Limit

Capillary tubing is

in a holder that

extends into the

Motor

Starter

Line Voltage

Terminals

Page 5

Page 6

8. Temperature Limit Safety Controls (cont'd)

• Emergency Cut Off Limit Control

Function: The emergency cut off is a fus-

ible link high temperature limit which provides one-time redundant protection

against overheating. If the temperature

sensitive limit control malfunctions, the

electrically activated emergency cutoff will

shutdown the system.

Service: If this limit activates, the manual

limit control has failed and must be replaced. The cause for activating the emergency cut off limit control must be found and corrected before restarting the system.

Figure 11 - ECO

Limit Control,

P/N 82414

Setting 305oF

9. Air Pressure Switches

Location: Control Compartment Electrical Box (See Figure 7.)

Depending on the options selected, there are two or four switches.

Figure 12 - Air

Pressure Switch

Attach a slope gauge (0 to 1.0" scale) to the tubing connections in the

control compartment. The two connections are located below the electrical control box. Remove the caps on the 1/8" NPT test connections

and attach the slope gauge. (The recommended method for attaching the

slope gauge is to use field-supplied 1/8" female NPT x 1/4" O.D. barbed

hose connections.)

A) If the system includes an optional discharge damper, before measur-

ing burner differential air pressure, check to be sure that the damper

is fully open.

B) With the blower operating, the pressure differential on the slope

gauge should read between -.5" and -.7" w.c. If the slope gauge

reading is within those limits, no adjustments are necessary.

If the slope gauge reading is not within the setpoint limits of the air

flow switches (.2" to .9" w.c.), and the system is operating, replace

the air pressure switch(es).

If the slope gauge reading is not between -.5" and -.7" w.c., but

within the setpoint limits, clean the sensing tubes (Follow the instructions in Maintenance Section, Paragraph 4).

C) When air pressure is within the proper range, turn the disconnect

switch OFF. Disconnect the manometer and the slope gauge. Replace the caps removed to connect the slope gauge.

Service: If the pressure check determines that an air flow switch is not

functioning properly, the switch cannot be serviced and must be replaced with an identical replacement. Low air pressure switch is P/N

86986; high air pressure switch is P/N 86987; bypass damper switches,

P/N 87249 (normally closed, set to open at .5" w.c.) or P/N 87250

(normally open, set to close at .65" w.c.).

• Low Air Flow Switch

Function: The low air flow switch is a velocity pressure switch that

monitors air flow across the burner. Until the air flow attains adequate

volume for combustion, the switch remains open. When the switch

recognizes adequate air volume, it closes, permitting both the pilot and

burner to operate. Low pressure switch is normally open; it closes on

pressure rise at .2" w.c. Do not alter or adjust setting.

• High Air Flow Switch

Function: The high air flow switch is a velocity pressure switch that

monitors air flow across the burner. If the high air flow switch senses air

velocity above the prescribed limit, it will shutdown gas flow to the

burner. High pressure switch is normally closed; it opens when pressure rises above .9" w.c. Do not alter or adjust setting.

• Bypass Damper Air Flow Switches (systems

with Air Control Options AR19, AR20, AR22, AR23,

AR32, AR33, AR34, AR36, or AR37)

Function: With a bypass damper, the volume of outside air supplied

to the building is adjusted by a manually set potentiometer (Option

AR19 and AR22) or automatically by a pressure null switch (Option

AR20 or AR23), a photohelic pressure switch (Option AR36 or AR37),

or a field-supplied computer signal (Option AR33 or AR34). With

Options AR19, AR20, AR33, and AR36 the supply air is varied by

adjusting the position of a damper at the blower discharge. With Options AR22, AR23, AR34, and AR37, a return air damper is adjusted to

vary the volume of return air. The unit is arranged so that a fixed amount

(20%) of the rated volume flows over the burner at a constant velocity.

The remainder (80%) of the rated air volume flows either through a

balancing bypass damper or a combination of bypass and return air

dampers. As the supply air volume is varied by the return air or discharge damper, the balancing damper is adjusted to maintain the required air velocity over the burner. Adjustment of the bypass damper is

controlled by the bypass damper pressure switches. One pressure

switch is normally closed with a setting of .5" w.c.; the other is normally open with a setting of .65" w.c. balancing bypass damper.

Sensing Pressure Check: (requires a slope gauge, several feet of

1/4" O.D. tubing and two 1/4" O.D. barbed tees.)

Page 6

10. Ignition System

Location: Ignition Controller Module in the Control Compartment

Electrical Box (See Figures 7 and 13.); Ignitor and Flame Sensor on the

Burner (See Figure 14.)

Figure 13 - Ignition Control

Module in the Electrical

Compartment, P/N 157953

Hot Surface Ignition System with Prepurge

Time Delay and Flame Sensor with 100%

Lockout

Function: The ignition system including the controller, the hot surface

ignitor, and the flame sensor function to ignite and prove the pilot

flame. When there is a call for heat, the modular ignition controller is

energized. When the controller reads 1.4 amps going to the hot surface

ignitor, it opens the pilot valve for a 15-second trial for ignition. After

the pilot flame rod senses pilot flame, the main gas valve is energized. If

the pilot flame rod does not sense a pilot flame, the controller shuts

down the pilot valve for a 10-second interpurge and then opens it again

for a second ignition trial. If pilot flame is not proven on the second

trial, the ignition controller locks out and must be manually reset by an

interruption of the main circuit (disconnect switch).

Service: The modular ignition controller does an internal self-check

each time that it is energized and will lockout if not found to be func-

Figure 14 - Ignitor, P/N

121865, and Flame

Sensor, P/N 134706, on

the Burner

Sensor

Ignitor

Page 7

tioning properly. If the ignition controller locks out and there is no

other cause, the controller module must be replaced.

11. Gas Train Including Direct-Fired

Burner, Gas Control Systems,

Manifold Arrange-ments, and Gas

Pressure Switches

Direct-Fired Burner

Function: The design of the direct-fired burner and the con-

trolled velocity of air at the burner ensure complete combustion

through the full range of burner sizes and gas inputs as determined

by the gas control system. The velocity of air is controlled by the

profile plates and monitored by a standard low and high air pressure switch.

Service: Refer to Paragraph 6 in the Maintenance Section for

instructions on burner maintenance.

For troubleshooting guides and further explanation of Maxitrol Series 14 and

44 electronic modulation gas control systems, refer to the Maxitrol literature

in the owner's envelope.

The Option AG30, AG31, AG32 and AG35 electronic modulation systems

are comprised of Maxitrol Series 14 controls. Options AG30 and AG31

systems electronically maintain a constant discharge air temperature in the

range of 55-90°F (55-75°F for C.G.A.). Option AG31 includes an overriding

thermostat. Option AG32 system will maintain a constant discharge air

temperature in the range of 80-130°F. Option AG35 maintains a discharge

temperature range of 120-160°F.

Figure 15 - Components of the Gas Control System (Maxitrol

Series 14) used in Gas Control Options AG30, AG31, AG32,

and AG35

Amplifier,

P/N 148590

Mixing

Tube

WARNING: Burner profile plates are factory

set to match CFM requirements. Do not adjust

profile plates without contacting your Sales

Representative for technical assistance.

Makeup Air Gas Control Systems

• Electronic Modulation Gas Control

Options AG30, AG31, AG32, AG33, AG35,

AG36

Refer to the wiring diagrams in the main electrical box to determine which controls are on the system being serviced. NOTE: All

field-supplied control wiring for Maxitrol controls must not be

run inside conduit with line voltage wiring. To avoid any potential

electrical interference, all field-supplied wiring for Maxitrol controls should be shielded wiring and must be grounded at the unit

only.

Function: These makeup air gas control systems provide heated

makeup air at a temperature controlled by a discharge air sensor.

Each system is equipped with electronic modulation controls

that modulate burner flame from 1/25th of full fire input to full

fire.

The electronic modulating-type gas controls act in response to

discharge and/or room air temperature sensors to change the gas

flow rate to the burner, thus lengthening or shortening the flame.

The BTU output is varied (modulated) to maintain the required

discharge air temperature.

These modulating gas control options are electronic because in all

cases the gas valve acts to adjust the flow of the gas to the main

burner in response to DC volts emanating from an amplifier.

When the DC voltage is between 0 and 5 volts, the main valve seat

is closed. Low fire flow is accomplished through a mechanical

bypass. The low fire flow rate is set at the factory and should not

need adjustment. However, if adjustment is necessary, refer to

the Maxitrol literature that is included in the heater owner's envelope.

All of the electronic modulating gas control burner systems include low fire start. On an initial call for heat, the main burner

ignites at its lowest input. During mild weather, the burner may

then cycle off. Such full shutdown can be dictated by the outdoor

ambient cutoff control. As the outside air temperature climbs

above the setpoint of the outdoor ambient control, the burner

control circuit is de-energized. When moderately cold outside air

temperatures exist, the burner will modulate between low flame

and high flame. Low fire start and the outdoor ambient control

prevent the makeup air system from heating already warm air and

providing "too much" heat to the building.

Temperature

Selector

Option AG33 electronic modulation system is comprised of Maxitrol Series

44 controls. The low limit (20-60°F) and the high limit (60-140°F) for control of discharge air temperature are set at the amplifier located in the control

compartment. The space temperature is set at the remote selectrastat (5590°F range) located in the space. When the temperature is below the space

temperature setpoint, the control system operates the burner to automatically adjust the discharge air temperature within the maximum and minimum

limits set on the amplifier.

Temperature

Sensor

Figure 16 - Components of the Gas Control System (Maxitrol

Series 44) used in Gas Control Option AG33

Temperature

Sensor,

P/N 119617

Mixing Tube,

P/N 90323

Option AG36 is a special application gas train that is designed for controlling

the environment of a paint booth operation. The system includes a Maxitrol

A1494 amplifier, discharge air temperature sensor, dual remote discharge air

temperature selector (drying selector 80-140°F and a spray selector 6090°F), and two switches to control the operation of the modulating gas valve.

Amplifier,

P/N 157915

Temperature

Selector, P/N 86990

Figure 17 - Components of the Gas Control System used in

Option AG36 designed specifically for paint booths - controls

are mounted on a remote console

Selector,

Amplifier,

P/N 133229

Electronic Modulation

Gas Control Option

AG37

Function: Control Option AG37

does not have a duct sensor or amplifier. Instead, a Maxitrol A200 signal

conditioner is activated by a customer-supplied input signal (either 420 milliamps or 0-10 volt) to control

the modulation of the gas valve.

P/N

133230

Figure 18 - Maxitrol A200

Signal Conditioner,

P/N 134170, used in Gas

Control Option AG37

Page 7

Page 8

11. Gas Train Including Direct-Fired Burner, Gas Control Systems, and Manifold

Arrangements (cont'd)

Service - All Maxitrol Controls: Check all electrical connec-

tions. A qualified service person should refer to the Maxitrol Troubleshooting Guides for assistance in identifying problems and determining

the correct solution. None of the Maxitrol controls have field replaceable parts. All components must be replaced with identical replacement

parts.

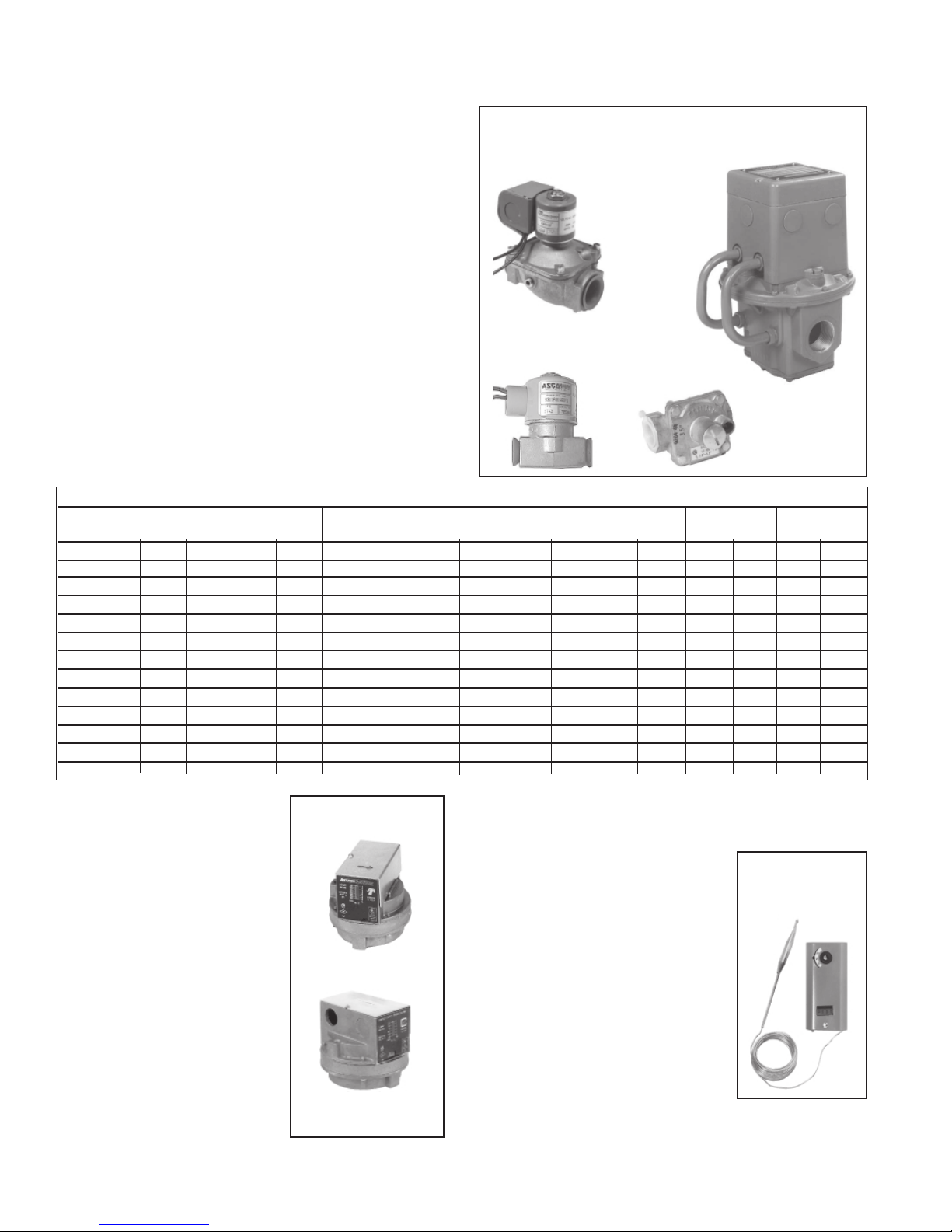

Figure 19 - Gas Manifold Control Components

Solenoid Valve

Modulating/

Regulating

Valve

Manifold Arrangements

Description: The manifold is the gas train from the gas supply con-

nection to the burner. The manifold selection ordered determines the

manifold arrangement including all of the gas train components except

the main control valve. Manifold arrangements are available for varying

BTUH ranges and gas controls and include versions that meet FM or

IRI requirements.

In addition to the Maxitrol valve and two solenoid valves, all manifold

arrangements include main gas and pilot gas shut-off cocks, a pilot

regulator, and a pilot solenoid valve.

The table below lists the pressure drops through the various types of

manifolds by option designation (BM). To determine the required minimum supply pressure for natural gas, add 5.0" w.c. to the natural gas

manifold pressure drop. For propane gas, add 2.0" w.c.

Manifold Pressure Drops (“ w.c.)

Manifold Opt BM62 BM63 BM64 BM65 BM67 BM68 BM53 BM66

Manifold Size 1" 3/4" 1" 1-1/4" 1-1/4" 2" 1-1/4" 2"

MBH Nat Pro Nat Pro Nat Pro Nat Pro Nat Pro Nat Pro Nat Pro Nat Pro

250 .56 .21 .66 .25 .43 .17 .22 .09 .19 .07 .07 .03 .22 .09 .07 .03

500 2.23 .85 2.65 1.01 1.74 .66 .89 .34 .76 .29 .27 .10 .89 .34 .27 .10

750 5.02 1.91 5.96 2.27 3.91 1.49 2.01 .77 1.71 .65 .61 .23 2.01 .77 .61 .23

1000 -- -- -- -- 6.95 2.65 3.58 1.36 3.04 1.16 1.09 .41 3.58 1.36 1.09 .41

1250 -- -- -- -- -- -- 5.59 2.13 4.76 1.81 1.70 .65 5.59 2.13 1.70 .65

1500 -- -- -- -- -- -- 8.05 3.07 6.85 2.61 2.44 .93 8.05 3.07 2.44 .93

1750 -- -- -- -- -- -- 10.96 4.17 9.32 3.55 3.33 1.27 10.96 4.17 3.33 1.27

2000 -- -- -- -- -- -- 14.31 5.45 12.18 4.64 4.34 1.66 14.31 5.45 4.34 1.66

2250 -- -- -- -- -- -- 18.11 6.90 15.41 5.87 5.50 2.09 18.11 6.90 5.50 2.09

2500 -- -- -- -- -- -- 22.36 8.52 19.02 7.25 6.79 2.59 22.36 8.52 6.79 2.59

2750 -- -- -- -- -- -- -- -- -- -- 8.21 3.13 -- -- 8.21 3.13

3000 -- -- -- -- -- -- -- -- -- -- 9.77 3.72 -- -- 9.77 3.72

Gas Pressure Switches

If the gas train includes either or both

high and low gas pressure switches,

the switches monitor gas pressure

downstream from the safety valves.

If the gas pressure in a system equipped

with a high gas pressure switch (Option BP2) exceeds the setpoint, the

switch will open the electrical circuit

to the burner, stopping all gas flow.

The high gas pressure switch is a manually reset device.

A low gas pressure switch (Option

BP3) will shutoff the gas flow if the

gas pressure drops below the setpoint

of the low pressure switch. The low

gas pressure switch will automatically

reset when the gas pressure rises above

the setpoint.

(NOTE: Both high and low gas pressure switches incorporate a vent limiting device and do not require

venting to the outdoors when used in an application installed indoors.)

Page 8

Figure 20 - Gas

Pressure Switches

Low, P/N 93850

(automatic)

High, P/N 93849

(manual reset)

Pilot Valve

Pilot Regulator

12. Outside Air Cutoff Control (Option BN2;

required on C.G.A.-certified units)

Location: The control is in the electrical

box (See Figure 7.); the sensor is in the air

inlet.

Function: After sensing pilot flame, the

burner ignites at its lowest input rate. The

"amount of heat" required to reach the desired discharge temperature also depends on

the temperature of the incoming outside air.

The outside air control is factory set at 60°F

(adjustable 25-250°F). The burner reacts

differently depending on the entering air temperature and the setting on the outside air

control. The burner --

• may not ignite (pilot valve will not open);

If the actual temperature of the outside

air is above the setpoint on the outside air control, the burner will

not ignite.

• may modulate to satisfy discharge setting;

• may shutdown; or

Figure 21 Outside Air

Cutoff Control

Page 9

Burner shutdown or modulating operation will depend on the temperature rise between the outside air and the discharge air setting.

• may remain on continuous low fire.

If the outside air control is set too high, the burner will continuously

burn on low fire as long as the control switch is set to "winter".

When the outside air control is set properly for the climate, the system

blower will continue to provide the required makeup air (ventilation) at

the ambient outdoor temperature (burner not operating) even when the

control switch is set to "winter".

Service: If the control does not function properly, replace it with an

identical switch.

13. Door Switch (Option BX1; required on

C.G.A.-certified units)

Location: The control is installed on an overhead door opening to control the operation of

the heater to coincide with the opening and closing of the door.

Function: The function of the switch is to energize and interlock the heating unit when an outside overhead door reaches approximately 80%

of full open travel. The switch will de-energize

the furnace when the overhead door closes approximately 20%. The complete switch includes

a limit switch electrically wired to the heater and a roller yoke for

mechanical activation by a field-supplied trigger on the overhead door.

Figure 22 Door Switch,

P/N 124253

14. Inlet Air Controls

WARNING: Burner profile plates are factory set

to match CFM requirements.

Do not adjust profile plates without contacting your

Sales Representative for technical assistance.

Description: The system is equipped with one of the 11 types of

inlet air control arrangements listed below. All systems provide a constant flow of outside air across the burner at the required air volume

(CFM).

Refer to the wiring diagrams in the main electrical box to determine

which controls are on the system being serviced.

zz

zOption AR1 - a constant supply of 100% makeup air

zz

zz

zOption AR19 - 100% outside makeup air with variable supply air

zz

volume (CFM). The discharge damper controlling the variable air supply is controlled by a manually set remote potentiometer and can be

varied from 100% to 20% of total rated air flow (CFM). In response to

changes in the discharge damper setting, the bypass damper balances

the volume of air so that the required fixed amount of air volume flows

over the burner.

zz

zOption AR20- 100% outside makeup air with variable supply air

zz

volume (CFM). The discharge damper controlling the variable air supply is automatically controlled by a building pressure sensor and can be

varied from 100% to 20% of total rated air flow (CFM). In response to

changes in the discharge damper setting, the bypass damper balances

the volume of air so that the required fixed amount of air volume flows

over the burner.

zz

zOption AR22 - a combination of outside makeup air and bypass

zz

return air including modulating return air and bypass air dampers. The

volume of outside air is regulated by a remotely located, manually set

potentiometer.

zz

zOption AR23 - a combination of outside makeup air and bypass

zz

return air including modulating return air and bypass air dampers. The

volume of outside air is regulated automatically by a remotely located

building pressure sensor.

zz

zOption AR32 - a combination of outside makeup air and bypass

zz

return air including a two-position actuator. The two position actuator

changes the position of the damper to provide either 100% outside air

or 20% outside/80% return air. Control is from a SPDT toggle switch

mounted on a 4x4 box (or if ordered, the switch is mounted on a remote

console).

zz

zOption AR33 - 100% outside makeup air with variable supply air

zz

volume (CFM). The discharge damper controlling the variable air supply is automatically controlled by a 0-10 VCD or 4-20 milliamp signal.

In response to changes in the discharge damper setting, the bypass

damper balances the volume of air so that the required fixed amount of

air volume flows over the burner.

zz

zOption AR34 - a combination of outside makeup air and bypass

zz

return air including modulating return air and bypass air dampers. The

volume of outside air is regulated by a 0-10 VCD or 4-20 milliamp

signal.

zz

zOption AR35 - a constant supply of 100% makeup air to the unit but

zz

including a two-position inlet shutoff damper that closes the dampers

when the system is not operating. The damper attaches to the duct

flange of the optional inlet base (used only with the optional inlet base

that has three closed sides and a duct connection for outside air).

zz

zOption AR36 - 100% outside makeup air with variable supply air

zz

volume (CFM). The discharge damper controlling the variable air supply is automatically controlled by a remotely located photohelic pressure sensor. In response to changes in the discharge damper setting, the

bypass damper balances the volume of air so that the required fixed

amount of air volume flows over the burner.

zz

zOption AR37 - a combination of outside makeup air and bypass

zz

return air including modulating return air and bypass air dampers. The

volume of outside air is regulated by a remotely located photohelic

pressure sensor.

Air Flow Dampers

Function: Dampers operate in response to controls to provide the

rated flow of makeup air to the building.

Service: Clean dampers of dust or dirt.

Damper Motor

Function: The damper motor automatically actuates the return air, bypass, and/or discharge

dampers in response to an electrical control device. The damper motor is direct-coupled to the

dampers so there is no damper linkage to adjust.

Service: There is no service required on these

motors other than external cleaning. If the motors need replaced, replace with an identical

damper motor.

Potentiometer

Function: The potentiometer is a manually set

switch that operates either the discharge damper

(Option AR19) or the return air damper (Option AR22) providing a mixture of return and

outside air. It is a remotely located switch that

requires manual adjustment.

Figure 23 Damper Motor

Figure 24 Potentiometer,

P/N 16110

Service: If the potentiometer does not func-

tion properly, replace it with an identical switch.

Pressure Null

Switch (automatic

building pressure

sensor)

Description/Function:

The pressure null switch is

a diaphragm operated differential pressure switch used

in makeup air applications

to automatically control

Figure 25 Pressure

Null Switch

(building

pressure

sensor),

P/N 88052

Page 9

Page 10

14. Inlet Air Controls (cont'd)

Pressure Null Switch (cont'd)

building pressure. It maintains a selected positive or negative pressure

setpoint by changing the amount of outside air being introduced to the

building through modulating outside air damper. As more pressure is

required in the building, the pressure null switch activates the damper

motor driving the outside air damper towards the full open position

(causing the bypass return air damper to go toward the closed position). Conversely, as less pressure is required, the switch drives the

outside air damper in the opposite direction.

Service: Clean the tubing and the screened ends of the pressure tap

vents. Be sure that the switch is installed with the diaphragm in a

vertical plane and that the pressure taps are sheltered from the wind.

For further service, follow the manufacturer's instructions included

with the switch.

Photohelic Pressure Switch (automatic

building pressure sensor)

Description/Function: The

photohelic pressure switch is a

phototransister relay operated

positive pressure switch used

in makeup air applications to

automatically control building

pressure. It maintains a selected

positive pressure setpoint by

changing the amount of outside

air being introduced to the

building through a modulating outside air damper. As more pressure is

required in the building, the switch activates the damper motor driving

the outside air damper towards the full open position (causing the

bypass return air damper to go toward the closed position). Conversely, as less pressure is required, the switch drives the outside air

damper in the opposite direction.

Service: Clean the tubing and the screened ends of the pressure tap

vents.

If the interior of the switch is protected from dust, dirt, corrosive gases

and fluids, years of trouble-free service may be expected. Zero adjustment should be checked and reset occasionally to maintain accuracy;

follow the manufacturer's instructions included with the switch.

There are no field-repairable parts in this switch. If the switch should

require repair, contact either the system or the switch manufacturer

concerning switch replacement or repair.

Figure 26 Photohelic

Pressure

Sensor,

P/N

159893

15. Dirty Filter Switch

Location: Switch is located in the

main electrical box (See Figure 7);

sensor tubes run to either side of

the filter rack; indicator light is on

the remote console.

Function: The dirty filter

switch is a pressure switch that

activates an indicator light on the

remote console when the filters

need cleaned or replaced (See Service Section, Paragraph 2). This

Figure 27 - Dirty Filter

Pressure Switch, P/N

105507

switch is only on systems with an optional console that includes a dirty

filter light. The pressure switch is set during installation so that the light

will be activated at approximately 50% filter blockage. Contacts should

close at .17 to 5.0" w.c. ± .05" w.c.

Service: Clean the sensor tubes. If the dirty filter indicator system still

does not function properly, check the setting of the switch. With clean

filters in place, blower doors closed, and blower in operation, decrease

the pressure setting by adjusting the set screw on the switch clockwise

until the filter light is energized or screw is bottomed out. At that point,

adjust the set screw three full turns counterclockwise or until the screw

is top ended.

If it is determined that the switch needs replacing, use an identical

switch. When a new switch is installed, it must be manually set; follow

the instructions above.

16. Photoelectric Smoke Detector (Option

SA1)

Location: Field-mounted in

the discharge ductwork.

Function: The detector will

shut down the system if

smoke is detected in the discharge ductwork.

Service: Clean the external

surface. Check the wiring and

connections.

Figure 28 - Photoelectric Smoke

Detector (cover removed), P/N

159553, used with sampling tube,

P/N 159714

17. Firestat (Option BD5)

Location: Field-mounted on the discharge ductwork so that the sensor

extends into the duct. This control

requires manual reset so should be

mounted in an accessible location.

Function: The firestat will shut

down the system if the temperature

in the ductwork reaches 200°F. The

switch must be manually reset.

Service: Clean the external surface. Check the wiring and connections.

Figure 29 Firestat,

P/N 42782

18. Freezestat (Option BE2)

Location: The control is in the

blower section electrical box; the

sensing bulb is field-mounted in the

discharge duct.

Function: The freezestat will shut

down the system if the discharge

temperature falls below the

setpoint. The switch is automatic

and will startup the heater when

the temperature reaches the

setpoint.

Service: Clean the external surface.

Check the wiring and connections.

Figure 30 - Freezestat

Controller, P/N 126170

REFERENCE: For service and troubleshooting information on the electrical controls, refer to the

manufacturer's literature covering that component. Component literature is included in the literature

Refer to Paragraph 19 for unit troubleshooting.

Page 10

envelope shipped with the system.

Page 11

19. Troubleshooting

Chart 1 - General Troubleshooting Guide (Check the diagnostic lights on the circuit board)

Symptom or Problem Cause and Remedy

Disconnect switch is closed, but

1.

Disconnect switch is closed, but

2.

Disconnect closed, blower switch in test position, 1. Freezestat option not ordered - verify order/wiring diagram.

3.

"firestat"

Disconnect closed, blower switch in test position, "firestat" and 1. End switch on damper motor not closed. - check end switch wiring.

4.

"free ze stat"

and the blower motor is not operating. 3. Damper motor miswired - rew ire damp er motor per wiring diagram.

Disconnect closed, blower switch in test position, 1. Blower motor not wired correctly - check wiring diagram on motor.

5.

"firestat", "freezestat"

lights are lit, but t he blower motor is not operating. 3. Faulty blower mot or relay - rep lace relay .

Disconnect closed; blower switch in test position;

6.

"free ze stat"

blower motor is operating; but t he "low air light" is not lit. 3. Faulty low air switch - replace pressure switch (P/N 86986).

Disconnect closed; blower switch in test position; 1. High air switch open - verify p ressure drop at burner.

7.

"firestat", "freezestat", "starter energized"

air"

but t he

Disconnect closed; blower switch in test position;

8.

"free ze stat", "starter energiz ed", "l ow air" and "high air"

are lit; but the

Disconnect closed; blower s wit ch in test p osition; 1. Indicator light is burned out - rep lace bulb (P/N 125189).

9.

"firestat", "freezestat", "starter energized", "low air",

"high air"

but t he

10.

"firestat", "freezestat", "starter energized", "low air",

"high air", "limit control normal"

cutoff normal "

pressure n ormal"

11.

"firestat", "freezestat", "starter energized", "low air",

"high air", "li mit controls normal", "ambient (outside air)

cutoff normal"

but t he

12.

posit ion; control s wit ch is in "winter" p osition; cause then rep lace ECO .

"control power", "high gas normal"; "low gas normal";

"firestat normal"; "system switch energize d"; "starter

energized"

ignitor is not becoming energized or beginning to glow. 4. Faulty low stage relay - replace relay.

13. Disconnect closed; blower and burner switches in run 1. Ignitor not reaching 1.4A threshold - check voltage and

position; control switch is in "winter" position;

high gas normal; "low gas normal "; "fi restat normal"; "system

switch energized"; "starter energized" and "freezestat normal"

lights are lit; ignitor glowing but

(thus the pilot valve) is not energized.

light is lit, but

lights are lit, but

and

lights are lit and the blower motor is operating; 3. High air switch option not ordered - verify order/wiring diagram.

"high air light"

"limit control normal"

and

"limit control normal"

"ambient (outsi de air) cutoff normal"

Disconnect closed; blower s wit ch in test p osition; 1. Indicator light is burned out - rep lace bulb (P/N 125189).

lights are lit; but the

Disconnect closed; blower s wit ch in test p osition; 1. Indicator light is burned out - replace bulb (P /N 125189).

and

"high gas pressure normal"

Disconnect closed; blower and burner switches in run 1. Lack of power at L1 on ignition module - ECO blown, find

and

"freezestat normal"

"free ze stat"

and

"starter energized"

is

light is

"low gas pressure normal"

"control power"

"firestat normal"

light is not lit 2. Freezest at relay cont acts are open - checking setting on cont rol.

"starter energized"

"starter energized"

lights are lit and t he 2. Indicator light is burned out - replace bulb (P/N 125189).

lit. 4. Faulty high air switch - rep lace pressure switch (P/N 86987).

not

light is not lit. 3. Faulty manual limit cont rol (s) - rep lace limit cont rol.

lights are lit; 3. High ambient control contacts open - check setting on control.

and

"ambient (outsi de air)

"low gas

lit. 5. Faulty gas p ressure switch - rep lace gas p ressure swit ch.

not

light is

lights are lit; but thermostat sett ing.

"pilot valve normal"

light is not lit. 1. Fuses are missing or blown in disconnect switch - replace fus es.

2. T ransformer not wired according to diagram - check wiring.

3. Secondary 8A fuse (on transformer) is missing or blown - replace fuse.

4. Indicator light is burned out - rep lace bulb (P/N 125189).

light is not lit. 1. See causes and remedies for Problem 1 above.

2. Op tional control relay or door switch contacts are open - to test ,

jump terminals 3 to 4 or 1 to 2.

3. Firestat opt ion not ordered - verify order/wiring diagram.

4. Firestat manual reset tripped - reset firestat control.

3. Indicator bulb is burned out - rep lace bulb (P/N 125189).

light is not lit 2. Faulty damp er relay - replace relay .

2. Faulty motor start er - rep lace (check coil firs t).

"firestat"

and

"low

"firestat"

light is

lights are lit; 4. High gas pressure switch contacts open - check gas p ressure.

lit. 5. M anual reset on switch tripp ed - reset p ressure switch manual reset.

not

"control power",

light

, 1. Low air switch open - verify p ressure drop at burner.

2. Indicator light is burned out - rep lace bulb (P/N 125189).

, 1. Indicator light is burned out - replace bulb (P/N 125189).

2. T rip p ed manual reset limit control(s) - reset manual cont rol.

2. High ambient control op tion not ordered - verify order/wiring diagram.

lit.

not

2. Low gas pressure switch option not ordered - verify order/wiring diagram.

3. Low gas pressure switch contacts op en - check setting on control.

4. Low gas pressure switch contacts op en - check gas pressure.

2. High gas pressure switch op tion not ordered - verify order/wiring diagram.

3. High gas pressure switch contacts open - check setting on control.

6. Faulty gas p ressure switch - rep lace gas p ressure swit ch.

2. Faulty burner enable relay - rep lace relay .

3. Low stage relay cont act s are not closed - check air cont roller or

5. Faulty hot surface ignitor - check cont inuity at the ignition module

and circuit board. If reading is greater than 5-6 ohms, replace ignitor.

6. Faulty ignition module - replace entire module.

current to ignitor.

2. Faulty hot surface ignitor - check cont inuity , replace ignitor.

3. Faulty ignition module - replace entire module.

Page 11

Page 12

19. Troubleshooting (cont'd)

Chart 1 (cont'd) - General Troubleshooting Guide (Check the diagnostic lights)

Symptom or Problem (cont'd) Cause and Remedy (cont'd)

14. Disconnect closed; blower and burner switches in run position; control 1. Air in pilot gas line - bleed pilot line.

switch is in "wint er" p os ition;

gas normal"; "firestat normal"; "system switch energize d"; "starter

energized" and "freezestat normal"

1.4A and has opened the pilot valve bringing on the

light; but t he p ilot flame is not present . (Aft er two t rials the unit will go

into safety lockout requiring cycling of the main disconnect switch.)

15. Disconnect closed; blower and burner switches in run position; 1. M icroamp signal on flame rod is inadequate - check position and

control switch is in "winter" p osition; all status light s are lit condition of flame rod and signal (minimum 0.5 microamps required.)

"main valve normal" light. The pilot flame is present 2. Grounding for unit or flame rod inadequate - check ground path.

except

and stable, but the (low stage portion or) main gas valve will not 3. Fault y main gas valve - replace main gas valve.

open, or rap id cycling of the main valve is occurring. 4. Faulty ignition module - rep lace ignition module.

16. Disconnect closed; blower and burner switches in run position; 1. Faulty main gas valve - replace main gas valve.

cont rol swit ch is in "winter" posit ion; all s tatus lights are lit; the 2. Inadequate timing on high fire time delay relay - adjust setting.

pilot flame and low fire on the main burner are p resent and st able, 3. Faulty high fire t ime delay relay - replace t ime delay relay .

but the unit will not p rogress t o a high fire condit ion. 4. High st age relay contacts are not closed - check control setting.

"control power", high gas normal; "l ow

lights are lit; ignitor has reached 4. Faulty ignition module - rep lace entire module.

"pilot valve normal"

2. Inadequate pilot gas pressure - verify pilot gas pressure (3.5" w.c.)

3. Faulty p ilot valve - rep lace pilot solenoid valve.

5. Inadequate main gas pressure - verify main burner pressure.

5. Inadequate main gas pressure - verify main burner gas pressure.

6. Faulty high stage relay - replace relay.

7. Faulty ignition module - rep lace entire module.

FOR SERVICE OR REPAIR, FOLLOW THESE STEPS IN ORDER:

FIRST: Contact the Installer

Name ___________________________________________________________________________

Address ___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

Phone ___________________________________________________________________________

SECOND: Contact the nearest distributor (See Yellow Pages). If no listing,

contact Authorized Factory Representative, 1-800-695-1901 (Press 1).

®

THIRD: Contact REZNOR

150 McKinley Avenue

Mercer, PA 16137

Phone: (724) 662-4400

Model No. _____________________________________________

Unit Serial No. _____________________________________________

Date of Installation _____________________________________________

Index .................................................. Page

Air Pressure ............................................. 4

Air Pressure Switches ............................... 6

Blower Bearings ....................................... 3

Circuit Indicator Board ............................ 4

Control Locations .................................... 5

Damper Motor ........................................ 9

Direct-Fired Burner ................................. 7

Dirty Filter Switch ................................ 10

Drive Components ................................. 3

Electronic Circuit Board with

Diagnostic Lights ................................. 5

Emergency Cut Off .................................. 6

/Thomas & Betts Corporation

Index .................................................. Page

Filters ....................................................... 3

Firestat .................................................... 10

Freezestat ............................................... 10

Gas Control Systems ............................... 7

Gas Pressure ............................................ 3

Gas Pressure Switches .............................. 8

Inlet Air Controls ..................................... 9

Limit Control ........................................... 5

Main Burner ............................................. 4

Maintenance Schedule ............................. 2

Maintenance Section ......................... 2-4

Maintenance/Service Access .................... 2

Index .................................................. Page

Manifold Arrangements ........................... 8

Operation/Service Section .............. 5-12

Outside Air Cutoff Control ..................... 8

Photoelectric Smoke Detector ................ 10

Photohelic Pressure Sensor ..................... 10

Pilot Assembly ........................................ 4

Potentiometer ........................................... 9

Pressure Null Switch ............................... 9

Sensing Pressure Check ........................... 6

Troubleshooting ..................................... 11

Wiring Diagram ......................... In the main

electrical box on the unit

Page 12

©2001 Thomas & Betts Corporation, All rights reserved. Printed in the U.S.A.

MANUFACTURER OF HEATING, COOLING, AND VENTILATING SYSTEMS

Trademark Note: Reznor® is registered in the United States and other countries.

(800) 695-1901; www.ReznorOnLine.com

8/01 YL Form 441OMS (Version .1)

Loading...

Loading...