Thomas & Betts COMFORT CRIMP TBM21E, COMFORT CRIMP TBM25S, COMFORT CRIMP TBM4BB Calibration Instructions Manual

Page 1

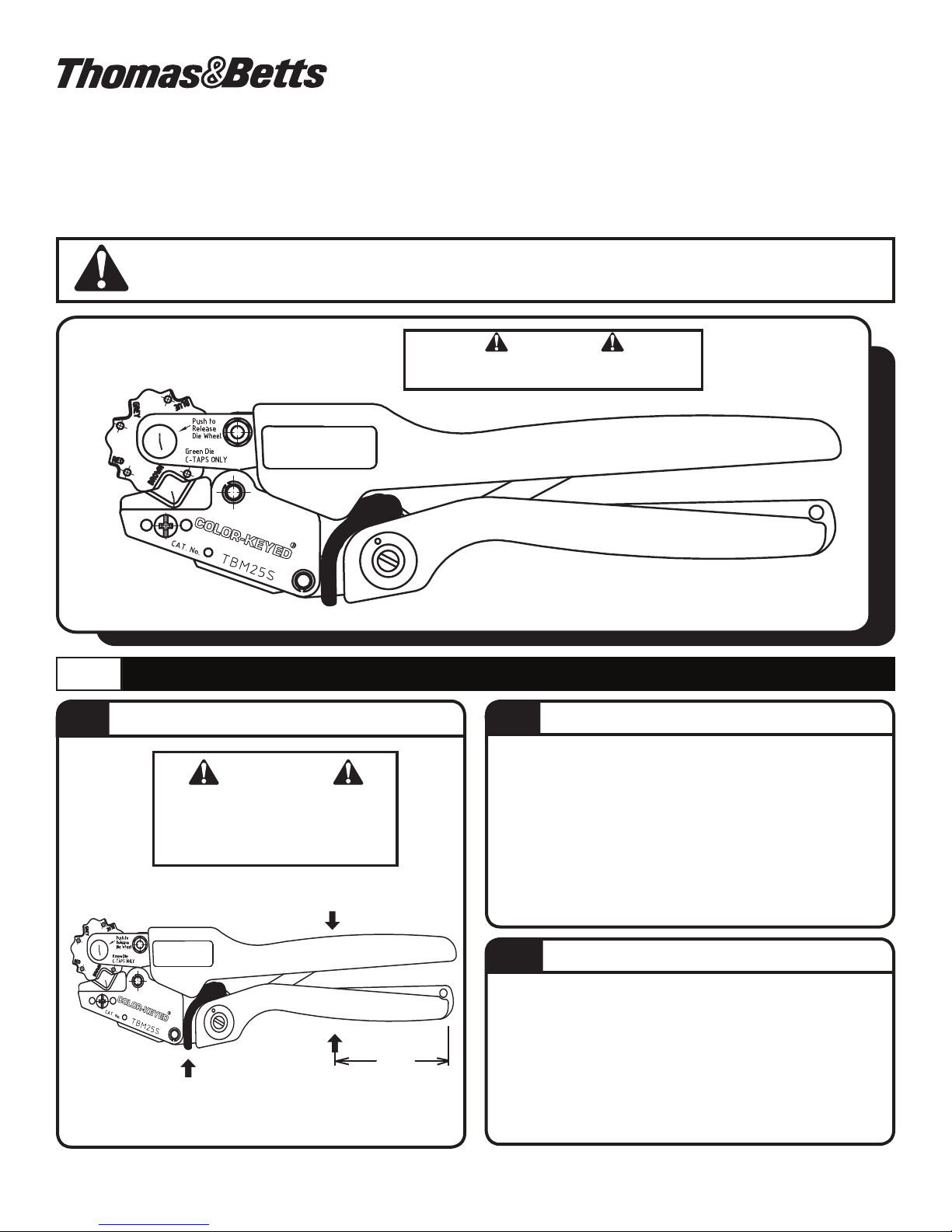

COMFORT CRIMP® COMPRESSION TOOL

TBM21E, TBM25S & TBM4BB

SHURE STAKE® TOOL CALIBRATION VERIFICATION

IMPORTANT: Read and understand all of the instructions and safety information in this

manual before operating or servicing this tool.

WARNING

HANDLES ARE NON-INSULATING.

DO NOT CRIMP ON HOT ENERGIZED WIRES.

In the event the SHURE STAKE® MECHANISM must be released, please see Figure 2.

1.0

1.1

SHURE STAKE® Mechanism

WARNING

KEEP ALL BODY PARTS AWAY

FROM DIE NEST DURING GAGING

OR CRIMPING PROCEDURE.

To release the SHURE STAKE®

mechanism, push up on the release

bar until the ratchet teeth are

disengaged.

INSTRUCTIONS FOR USE

1.2

1. Remove dust, moisture, and other contaminants with

a clean brush or a soft, lint-free cloth.

2. DO NOT use on objects that could damage the tool.

3. Make certain all pins, pivot points, and bearing

surfaces are protected with a THIN coat of any good

SAE No. 20 motor oil. DO NOT oil excessively.

4. Keep handles closed when not in use to prevent

objects from becoming lodged in the crimping dies.

5. Store tool in a cool, dry area.

1.3

1-1/2

Figure 2

SHURE STAKE

1. Squeeze handles until jaws are fully closed but

before SHURE STAKE® mechanism releases.

2. Apply a force gradually at 1 1/2” from end of handles

until SHURE STAKE® mechanism relases, see Figure

2.

3. The force required to release the SHURE STAKE®

mechanism should be 25 lbs. minimum, 43 lbs.

maximum.

Maintenance

®

Mechanism Check

Figure 1

TA01342 E Page 1 of 2

Page 2

2.0

NOTE: Calibration verification procedure should be performed whenever damage or suspected damage

has occurred or as often as operation conditions warrant.

GAGING VERIFICATION

2.1

Visual Inspection

Tool must be free of cracks, sharp edges and

any other obvious imperfections that may

affect performance of the tool. Nest area

must be free of burrs, dents or scratches.

TABLE “A”

GAGING REQUIREMENTS

NEST

RED .187 - .175

BLUE .224 - .212

GREY .277 - .265

BROWN .336 - .324

GREEN .418 - .406

GAGING

MIN. - MAX.

2.2

1. Wipe die nest before gaging.

2. Rotate wheel to desired nest.

3. Close handles until

just trips.

4. Insert gage pin into nest. The correct gage pin

size should enter nest area freely with a minimum

amount of finger pressure. The gaging shall fall

within the limits as specified in TABLE “A” (SEE

BELOW).

Figure 3

Gaging Procedure

SHURE STAKE® mechanism

GAUGE PIN

NOTICE: If tool fails any of the above tests, do not attempt repair or adjustment. Call nearest T&B sales office to arrange for repair

service. Any change, modification or alteration of the tool or use by the customer in a manner other than as specified by T&B shall void

all warranties ezpress or impled and the customer shall, therfore, assume all liability for any damage or injury cause by said changed,

modified or altered tool or improper usage of such tool.

For parts, service, repair and

calibration, contact the Thomas & Betts

Tool Service Center at 1-800-284-TOOL (8665).

WARRANTY: Thomas & Betts sells this product with the understanding that the user will perform all necessary tests to determine the suitability of this product

for the user’s intended application. Thomas & Betts warrants that this product will be free from defects in materials and workmanship for the period stated

on the enclosed warranty card. Upon prompt notification of any warranted defect, Thomas & Betts will, at its option, repair or replace the defective product or

refund the purchase price. Proof of purchase is required. Misuse or unauthorized modification of the product voids all warranties.

Limitations and Exclusions: THE ABOVE WARRANTY IS THE SOLE WARRANTY CONCERNING THIS PRODUCT, AND IS IN LIEU OF ALL OTHER

WARRANTIES EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY DISCLAIMED. LIABILITY FOR BREACH OF THE ABOVE WARRANTY IS LIMITED TO COST OF

REPAIR OR REPLACEMENT OF THE PRODUCT, AND UNDER NO CIRCUMSTANCES WILL THOMAS & BETTS BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Thomas & Betts Corporation

Memphis, Tennessee

www.tnb.com

TA01342 E Page 2 of 2© 2008 Thomas & Betts. All Rights Reserved.

Loading...

Loading...