Thomas & Betts COMFORT CRIMP SHURE STAKE ERG1802, COMFORT CRIMP SHURE STAKE ERG1806, COMFORT CRIMP SHURE STAKE ERG1804, COMFORT CRIMP SHURE STAKE ERG811, COMFORT CRIMP SHURE STAKE ERG1801 Operating Instructions Manual

Page 1

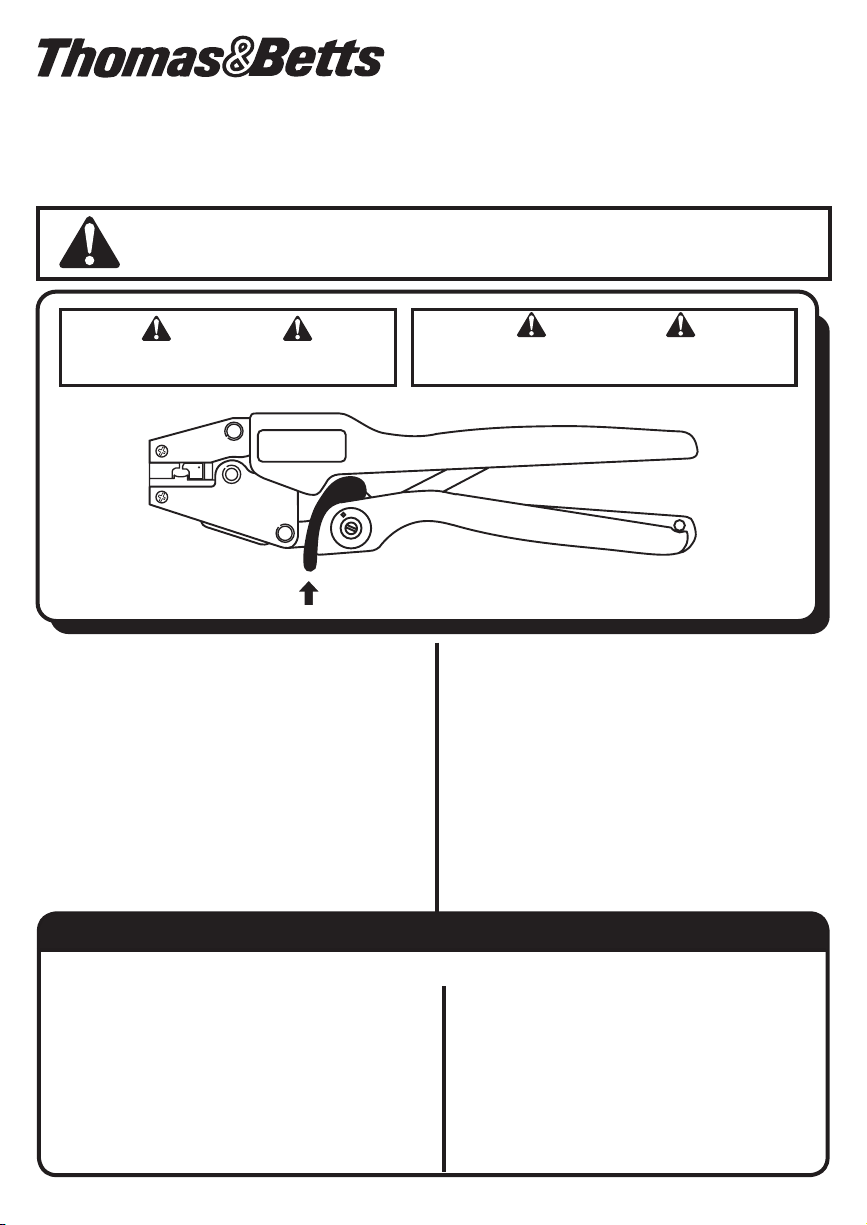

COMFORT CRIMP® SHURE STAKE

®

OPERATING INSTRUCTIONS

CAT. NOS. ERG811, ERG1801, ERG1802, ERG1804 & ERG1806

IMPORTANT: Read and understand all of the instructions and safety

information in this manual before operating or servicing this tool.

WARNING

KEEP ALL BODY PARTS AWAY FROM DIE NEST

DURING GAGING OR CRIMPING PROCEDURE.

To release the SHURE STAKE® mechanism, push up on

Figure 1

the release bar until the ratchet teeth are disengaged.

GENERAL SAFETY RULES:

1. FAMILIARIZE YOURSELF WITH THE TOOL. Read this Instruction

Sheet. Become aware of proper tool usage as well as the potential

hazards that could occur.

2.

DO NOT ABUSE TOOL.

reasonable care.

3. MAINTAIN TOOL WITH CARE. Keep tool in good condition at all

times. Keep it clean for proper performance.

4. KEEP WORK AREA CLEAN AND WELL LIT. Poor lighting and

cluttered area invite accidents.

5. USE SAFTEY GLASSES.

6. DO NOT OVER-REACH. Keep proper footing and balance at all times.

7.

NEVER ATTEMPT TO MAKE A CONNECTION TO A “HOT” LINE.

assume the power is OFF! Determine beforehand if any electrical

hazard could exist before making a connection to a line or wire.

Prevent damage by handling with

Never

WARNING

HANDLES ARE NON-INSULATING.

DO NOT CRIMP ON HOT ENERGIZED WIRES.

DESCRIPTION:

Each tool in a series, see Figure 1, is a hand operated crimping tool

utilizing non-interchangeable dies for installing certain Thomas & Betts

insulation piercing connectors on magnet wire. Incorporated in each

tool is a ratchet type SHURE STAKE

opening of the dies until a preset crimping pressure is reached, at

which point the handles can be released and the tool opened.

For certain wire combinations the dies will bottom (close), while for

others, because of the wire ll factor and type of wire, the dies will not

bottom. In order to produce an acceptable connection it is necessary

to operate the crimping tool with suitable hand pressure which is

controlled by the SHURE STAKE

checked periodically to ensure proper adjustment. This procedure is

described in succeeding paragraphs.

®

mechanism which prevents

®

mechanism. The tool should be

Operational Check & Maintenance

IMPORTANT: Crimped connector gaging should be checked regularly to insure that acceptable connections are being made.

OPERATION CHECK

1. Check operation of the tool periodically to insure its proper

adjustment. Continuous use of the tool will cause gradual wear of

movable parts. This in turn will cause the preset crimping pressure

to gradually decrease and the connector gaging to increase.

2. Once the connector gaging exceeds a specifi c value (based on the

size and type of wire), the connection will no longer be acceptable.

3. At this point, discontinue use of the tool.

4. To check the operation of the SHURE STAKE® mechanism and

connector gaging, a specifi c connector/wire combination should

be crimped and its gaging measured. (Refer to table 1, fi gure 3 and

fi gure 4, for specifi c wire combinations and only use copper.)

MAINTENANCE

1. Remove dust, moisture, and other contaminants with a clean

brush or a soft, lint-free cloth.

2. DO NOT use on objects that could damage the tool.

3. Make certain all pins, pivot points, and bearing surfaces are

protected with a THIN coat of any good SAE No. 20 motor oil.

DO NOT oil excessively.

4. Keep handles closed when not in use to prevent objects from

becoming lodged in the crimping dies.

TA02462 B Page 1 of 2

Page 2

1.0

INSTRUCTIONS FOR USE

1.1

1. Select proper connector to be installed on wire(s).

2. Select proper installing tool. (Refer to table 1).

3. Open tool handles fully.

4. Position connector barrel in center of die nest with bottom

of barrel resting on die indentor, and open end of barrel

facing into die nest.

5. Insert wire(s) into the connector. Refer to connector instruction

sheet for proper wire arrangement.

6. Compress the connector by squeezing tool handles until the

SHURE STAKE® mechanism cycle has been completed.

Release handles to open tool.

7. Remove crimped connector from tool.

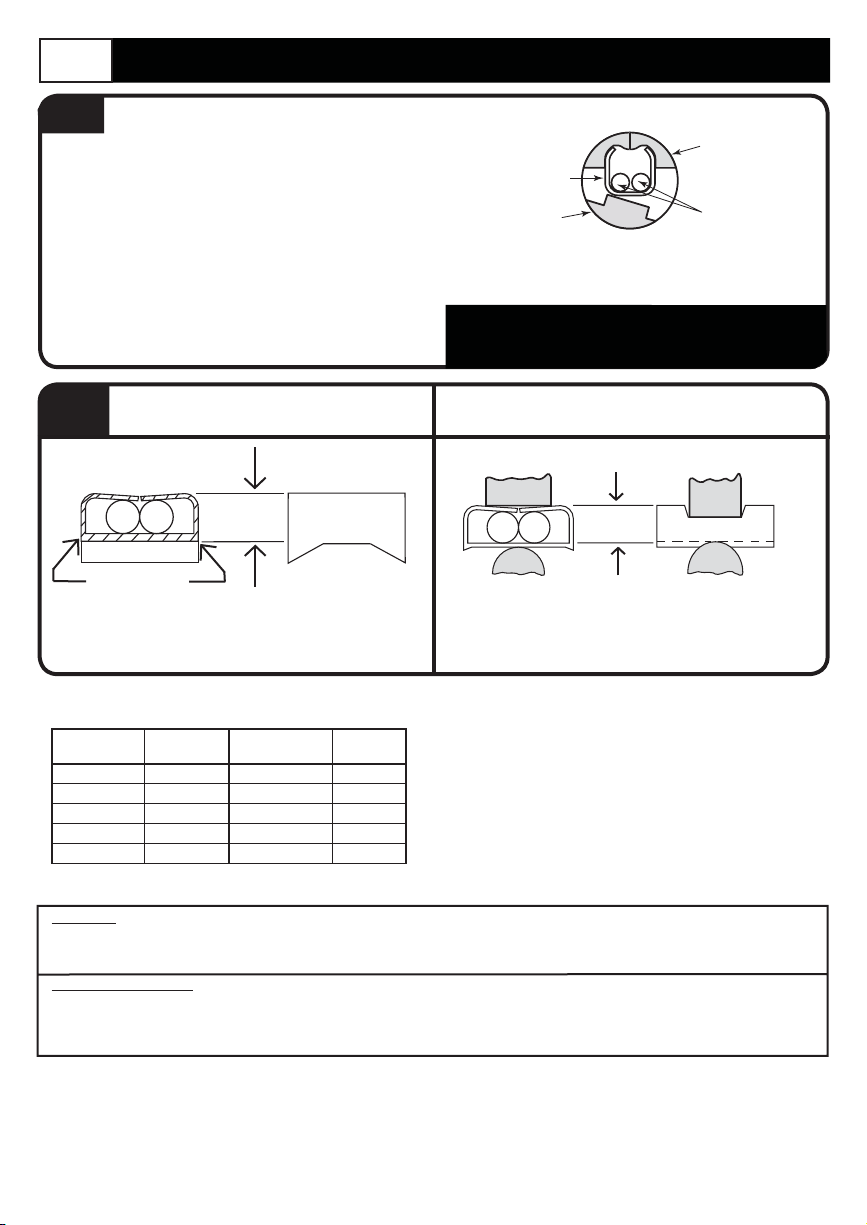

1.2

1. With a fi le, remove fl ash from connector edges.

2. Measure connector gaging with a standard micrometer. The

gaging surfaces of the connector are illustrated in Figure 3.

22L001, 22L002, 22L004

Series Connectors

GAGING

REMOVE FLASH

Figure 3

DIE NEST

CONNECTOR

DIE INDENTOR

WIRES

Figure 2

NOTE: For convenience, before placing wire(s) in the

connector, partially close the handles of the tool until

indentor die touches the connector.

22L006 Series Connectors

214420

GAGING

Measure connector gaging with a ball micrometer, or

equivalent, having a spindle diameter of 0.250. The gaging

surfaces of the connector are illustrated in Figure 4.

Figure 4

TABLE 1

Tool Connector

ERG-1801 22L001 (2) #24 Cu 0.068

ERG-1802 22L002 (2) #20 Cu 0.075

ERG-1804 22L004 (2) #32 Cu 0.033

ERG-1806 22L006 (1) #16 Cu 0.094

ERG-811 214420 (2) #20 Cu 0.103

WARRANTY: Thomas & Betts sells this product with the understanding that the user will perform all necessary tests to determine the suitability of this

product for the user’s intended application. Thomas & Betts warrants that this product will be free from defects in materials and workmanship for the

period stated on the enclosed warranty card. Upon prompt notifi cation of any warranted defect, Thomas & Betts will, at its option, repair or replace the

defective product or refund the purchase price. Proof of purchase is required. Misuse or unauthorized modifi cation of the product voids all warranties.

Limitations and Exclusions: THE ABOVE WARRANTY IS THE SOLE WARRANTY CONCERNING THIS PRODUCT, AND IS IN LIEU OF ALL OTHER

WARRANTIES EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY DISCLAIMED. LIABILITY FOR BREACH OF THE ABOVE WARRANTY IS LIMITED TO COST

OF REPAIR OR REPLACEMENT OF THE PRODUCT, AND UNDER NO CIRCUMSTANCES WILL THOMAS & BETTS BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

© 2008 Thomas & Betts. All Rights Reserved.

Series

Copper Wire

Combination

Maximum

Gaging

Thomas & Betts Corporation

Memphis, Tennessee

www.tnb.com

For parts, service, repair and

calibration, contact the Thomas & Betts

Tool Service Center at 1-800-284-TOOL (8665).

TA02462 B Page 2 of 2

Loading...

Loading...