Page 1

C E R T I F I E D

Installation and Operation ...........................Paragraphs 1-18 .... Pages 1-18

Optional Accessories ................................ Paragraphs 19-21 .. Pages 19-21

Check Installation and Start-Up ........................Paragraph 22 .. Pages 22-23

Index By Page No.

Belt Drive ............................................. 15

Blower Motor and Drive ...................... 15

Check/Test/Start-Up............................. 22

Clearances ................................................ 2

Combustion Air ...................................... 4

Combustion Air Proving Switch ........... 15

Concentric Adapter............................ 2, 5

Condensate Drain .......................... 14

Confined Space Installation .................. 10

Cased Cooling Coil (Model ACU)..... 2, 19

Control Location Illustration ................. 15

Dimensions ............................................. 3

Gas-Fired, Indoor, Vertical (Upflow)

APPLIES TO: Installation

Table of Contents

Index By Page No.

Discharge Plenum (Optional) ............ 2, 21

Duct Connections ................................. 12

Electrical Supply and Connections....... 14

Filter Cabinet (Optional) .................. 2, 20

Gas Piping and Pressures ..................... 13

Gas V alve .............................................. 16

General .................................................... 1

Hazard Intensity Levels ......................... 2

Ignition System..................................... 16

Inlet Base (Optional) ......................... 2, 21

Installation Codes ................................... 2

Mixing Cabinet (Optional) .............. 2, 21

Model CAUA

Power-Vented Heater

INST ALLATION FORM RZ 405 (Version B)

Obsoletes Form RGM 405 (V ersion A)

Index By Page No.

Motor Amps ......................................... 16

Mounting the Heater .............................. 2

Start-Up................................................. 22

Thermostat ........................................... 14

Uncrating and Preparation ...................... 2

Vent and Combustion Air ....................... 4

Determine Type of Vent ........................ 4

Power Vent Only Installation ......... 10-11

Separated-Combustion Installation ... 5-9

Warranty.................................................. 2

Wiring Diagrams .............................. 17-19

REFERENCES:

Operation/Maintenance/Service Manual, Form RZ 405-OMS

Installation Manual for Model ACU Cooling Coil, RZ 405-CC

Gas Conversion Instructions for Model CAUA, RZ 405-GC

FOR YOUR SAFETY

What to do if you smell gas:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier , call

your fire department.

W ARNING: Impr oper installation, adjustment,

alteration, service, or maintenance can cause

property damage, injury , or death. Refer to this

manual. For assistance or additional information,

consult a qualified installer , service agency , or the

gas supplier .

WARNING: Gas-fired appliances are not

designed for use in hazardous atmospheres

containing flammable vapors or combustible dust.

See Hazard Levels, page 2.

Installation Manual for Optional Filter Cabinet, RZ 405-FC

Installation Manual for Optional Mixing Box, RZ 405-MB

Installation Instructions for Optional Inlet Base, RZ 405-IB

Installation Instructions for Optional Discharge Plenum, RZ 405-DP

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

GENERAL

Installation should be done by a qualified agency in accordance with the

instructions in this manual and in compliance with all codes and requirements of authorities having jurisdiction. The instructions in this

manual apply to the heater model shown below.

Model Description

CAUA Gas-Fired,

Power-Vented,

V ertical (Upflow)

Heater

Model CAUA heaters are design-certified by the Canadian Standards

Association (CSA) to ANSI Z83.6 and CGA 2.6-M96 for industrial/

commercial installations in the United States and Canada. Heaters are

available for use with either natural or propane gas. The type of gas, the

firing rate, and the electrical characteristics are on the unit rating plate.

A Model CAUA heater requires installation of an inlet air duct or an

optional inlet air base and a supply duct or an optional discharge plenum. This heater may be installed as a separated-combustion system

(taking combustion air from outside) or as a power-vented system

(taking combustion air from the space where the heater is installed).

Mfg No. 164771, Page 1

Page 2

GENERAL (Cont'd)

Separated-combustion units are designed to separate the air for combustion and the flue products from the environment of the building in

which the unit is installed. Separated-combustion appliances are recommended for use in dust laden and some corrosive fume environments

or in buildings with negative pressure (up to .15" w.c.). If installed as a

separated-combustion system, the heater must be equipped with both

combustion air and exhaust piping to the outdoors. All Model CAUA

heaters must be vented to the outdoors.

W ARNING: Should overheating occur, or the gas

supply fail to shut off, shut off the manual gas valve

to the appliance before shutting off the electrical

supply.

W ARNING: Do not use this appliance if any part

has been under water . Immediately call a qualified

service technician to inspect the appliance and

replace any gas control which has been under

water.

CAUTION: Do not locate the heater where it may

be exposed to water spray, rain or dripping water.

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe

personal injury or death and/or property damage.

2. W ARNING: Failure to comply could r esult in severe

personal injury or death and/or property damage.

3. CAUTION: Failure to comply could result in minor

personal injury and/or property damage.

1. Installation Codes

These units must be installed in accordance with local building codes. In

the absence of local codes, in the United States, the unit must be installed in accordance with the National Fuel Gas Code ANSI Z223.1a

(latest edition). A Canadian installation must be in accordance with the

CAN/CGA B149.1 and B149.2 Installation Code for Gas Burning Appliances and Equipment. These codes are available from CSA Information Services, 1-800-463-6727. Local authorities having jurisdiction

should be consulted before installation is made to verify local codes and

installation procedure requirements.

2. Warranty

Refer to the limited warranty information on the W arranty Card in the

"Owner's Envelope".

Warranty is void if ...

a. Wiring is not in accordance with the diagram furnished with the

heater.

b. The unit is installed without proper clearance to combustible

materials.

3. Uncrating and Preparation

This unit was test operated and inspected at the factory prior to crating

and was in operating condition. If the heater has incurred any damage in

shipment, file a claim with the transporting agency.

Check the rating plate for the gas specifications and electrical characteristics of the heater to be sure that they are compatible with the gas and

electric supplies at the installation site.

Read this booklet and become familiar with the installation requirements of your particular heater. If you do not have knowledge of local

Form 405, Page 2

requirements, check with the local gas company or any other local

agencies who might have requirements concerning this installation.

Before beginning, make preparations for necessary supplies, tools, and

manpower.

Shipped-Separate Accessories

• Concentric Adapter and V ent Terminal - If the heater is installed

as a separated-combustion system, a concentric adapter assembly

is required. The concentric adapter and parts are shipped in a separate carton. Be sure that the shipped-separate carton is at the installation site. See Paragraph 7A.

• Filter Cabinet - The return air filter cabinet is shipped separately

for field installation over the inlet air opening of the heater. The inlet

air opening location is determined by the application. The filter

cabinet can attach at the opening on either the rear, the left side, or

right side of the unit. Follow the installation instructions included

with the cabinet.

• Cased Cooling Coil - Model ACU cooling coils are designed for

the Model CAUA heaters. The coil cabinet is shipped separately

for installation over the discharge opening of the heater.

• Mixing Cabinet - If outside air is desirable, a mixing cabinet with

dampers is available. The mixing cabinet is field attached to the rear

of the unit. Check to be sure that the mixing box is the configuration

ordered. Follow the installation instructions included with the

shipped-separate package.

• Inlet Base - If an optional inlet base is included, follow the instruc-

tions included with the inlet base to select the location. The heater

mounts on the inlet base; heater has a bottom inlet air opening.

• Discharge Plenum - The discharge plenum is shipped separately

for installation over the discharge opening of the heater. If the discharge plenum and a cased cooling coil are part of the installation,

the discharge plenum is factory attached to the cooling coil casing.

Also, shipped with the heater are the parts needed to install a condensate drain (needed if installing a cooling coil). Other shipped-separate

options could include a gas shutoff valve, a thermostat, a thermostat

guard, and/or a vent cap. Make sure all parts are at the site before

beginning installation.

4. Clearances

Unit must be installed so that

the clearances in the table are

provided for service and inspection and for proper spacing from combustible construction.

5. Mounting

Required Clearances

(All Sizes)

Right Side 0" (0mm)

Left Side 0" (0mm)

Front 36" (914mm)

Rear 0" (0mm)

Bottom 0" (0mm)

Flue Connector 6" (152mm)

Top 1" (25mm)

the Heater

Check the supporting structure to be used to verify that it has sufficient load-carrying capacity to support the weight of the unit. The

heater must be level.

Approximate Net Weight (lbs)

Size 150 200 250 300 350 400

Weight (lbs) 288 300 380 394 445 460

WARNING: Unit must be level for proper

operation. Do not place or add additional weight

to the heater. See Hazard Levels, page 2.

Determine the position of the heater with regard to venting, combustion air, gas supply connection, electrical supply connection, and inlet

air opening. Either cut out the inlet air opening (requires tin snips or

aviation shears) now or when attaching ductwork or filter cabinet. Use

caution when cutting the opening as the cut edges of the metal will be

sharp. NOTE: If ordered with an optional inlet base, the heater is

shipped with a bottom inlet air opening.

Page 3

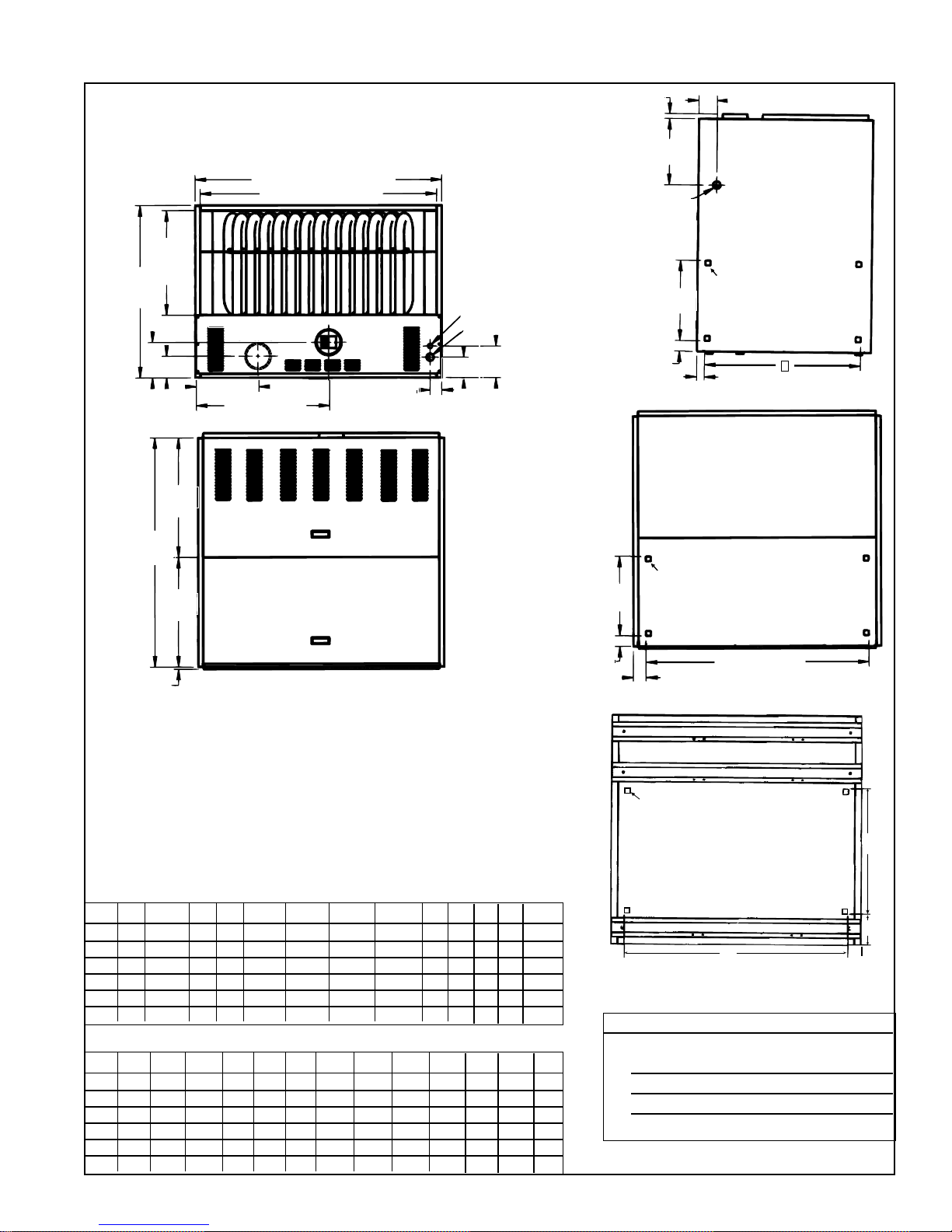

6. Dimensions

BOTTOM VIEW

Corner indicators for

cutting inlet air opening.

Control Side of Hater

M

N

P

2

(51mm)

Figure 1 - Dimensions of Model CAUA

T op View

A

Control Door

Blower Door

Plenum

Opening

B

E

24-3/8

(619mm)

46-1/2

(1181mm)

22-1/4

(565mm)

D

F

C Plenum Opening

Combustion Air Cutout

150, 200 - 5 (127mm);

250, 300, 350, 400 - 6 (152mm)

G

H

Venter Outlet

150, 200, 250 5 (127mm);

300, 350, 400 6 (152mm)

2-3/8 (60mm)

Electrical

(supply voltage)

Gas

6-3/8

4-1/8

(162mm)

(105mm)

Right

Rear

View

Side

View

2-1/8 (54mm)

16

(406mm)

1 (25mm)

13-1/4

(337mm)

Alternate

Gas

Connection

Corner indicators for

16

(406mm)

1-1/2 (38mm)

Corner indicators for cutting

inlet air opening

cutting inlet air opening

3-5/8 (92mm)

K

1/2 (13mm)

Front View

NOTE: Composite drawings are

not proportional for all sizes.

Dimensions (inches + or - 1/8")

Size A B C D E F G H J K M N P

150 38 34-3/4 36 21 7-1/4 3-3/4 12-1/2 24 33 31 19 34 4-5/8

200 38 34-3/4 36 21 7-1/4 3-3/4 12-1/2 24 33 31 19 34 4-5/8

250 50 34-3/4 48 21 7-1/4 4-3/8 12-3/4 27-1/4 45 31 16 46 4-3/4

300 50 34-3/4 48 21 7-1/4 4-3/8 12-3/4 27-1/4 45 31 16 46 4-3/4

350 50 49-3/4 48 34 7 4-3/8 14-1/8 26-3/4 45 44 32 46 4-7/8

400 50 49-3/4 48 34 7 4-3/8 14-1/8 26-3/4 45 44 32 46 4-7/8

Dimensions (mm +or- 3)

Size A B C D E F G H J K M N P

150 965 883 914 533 184 95 318 610 838 787 483 864 117

200 965 883 914 533 184 95 318 610 838 787 483 864 117

250 1270 883 1219 533 184 111 324 692 1143 787 406 1168 121

300 1270 883 1219 533 184 111 324 692 1143 787 406 1168 121

350 1270 1238 1219 864 178 111 359 679 1143 1118 813 1168 124

400 1270 1238 1219 864 178 111 359 679 1143 1118 813 1168 124

2-1/8 (54mm)

2-1/2 (64mm)

Bottom

View

J

Air Opening Dimensions

Supply Air (Discharge with duct flange) C x D

Inlet Air Opening (location selected by installer)

Right Side of Heater K x 16" (406mm)

Left Side* of Heater K x 16" (406mm)

Rear of Heater J x 16" (406mm)

Bottom of Heater M x N

*Right side is illustrated; corner indicators for opening are the same on the left side.

Mfg No. 164771, Page 3

Page 4

7. V enting and Combustion Air

WARNING: The vent must be installed in

accordance with national and local regulations.

Failure to provide proper venting could result in

death, serious injury and/or property damage. This

unit must be installed with a vent to the outside of

the building. Safe operation of any power-vented

gas-fired equipment requires a properly operating

vent system, correct provision for combustion air ,

and regular maintenance and inspection.

WARNING: Units installed in multiples require

individual vent pipe runs and vent caps.

Manifolding of vent runs is not permitted due to

possible recirculation of combustion products into

the building and back pressure effects on the

combustion air proving switch.

Venting must be in accordance with the National Fuel Gas Code Z223.1

or CAN/CGA B149.1 and B149.2, Installation Code for Gas Burning

Appliances and Equipment, and all local codes. Local requirements

supersede national requirements. Combustion air for this heater may be

either taken from the space or may be ducted from the outside using the

concentric adapter combustion air/vent system. Flue products must

always be vented to the outdoors.

Installation should be done by a qualified agency in accordance with

these instructions. The qualified service agency installing the vent or

vent/combustion air system is responsible for the installation.

The venting or venting/combustion air systems illustrated in this manual

are the only ones approved for a Model CAUA heater. However , since

more than one system is approved and requirements vary depending on

the type of installation, the first step must be deciding which vent or

vent/combustion air system is going to be installed. Review the following matrix of vent types and installation requirements. If there is any

doubt as to what type of vent is required, contact the equipment distributor before beginning installation.

Hazards of Chlorines - The presence of chlorine vapors in the combustion air of gas-fired heating equipment presents a potential corrosion hazard. Chlorine will, when exposed to flame, precipitate from the

compound, usually freon or degreaser vapors, and go into solution with

any condensation that is present in the heat exchanger or associated

parts. The result is hydrochloric acid which readily attacks all metals

including 300 grade stainless steel.

Care should be taken to separate these vapors from the combustion

process. This may be done by installing a separated combustion system and/or wise location of the furnace with regard to exhausters or

prevailing wind direction. Chlorine is heavier than air. This fact should

be kept in mind when determining installation locations of heating equipment and building exhaust systems.

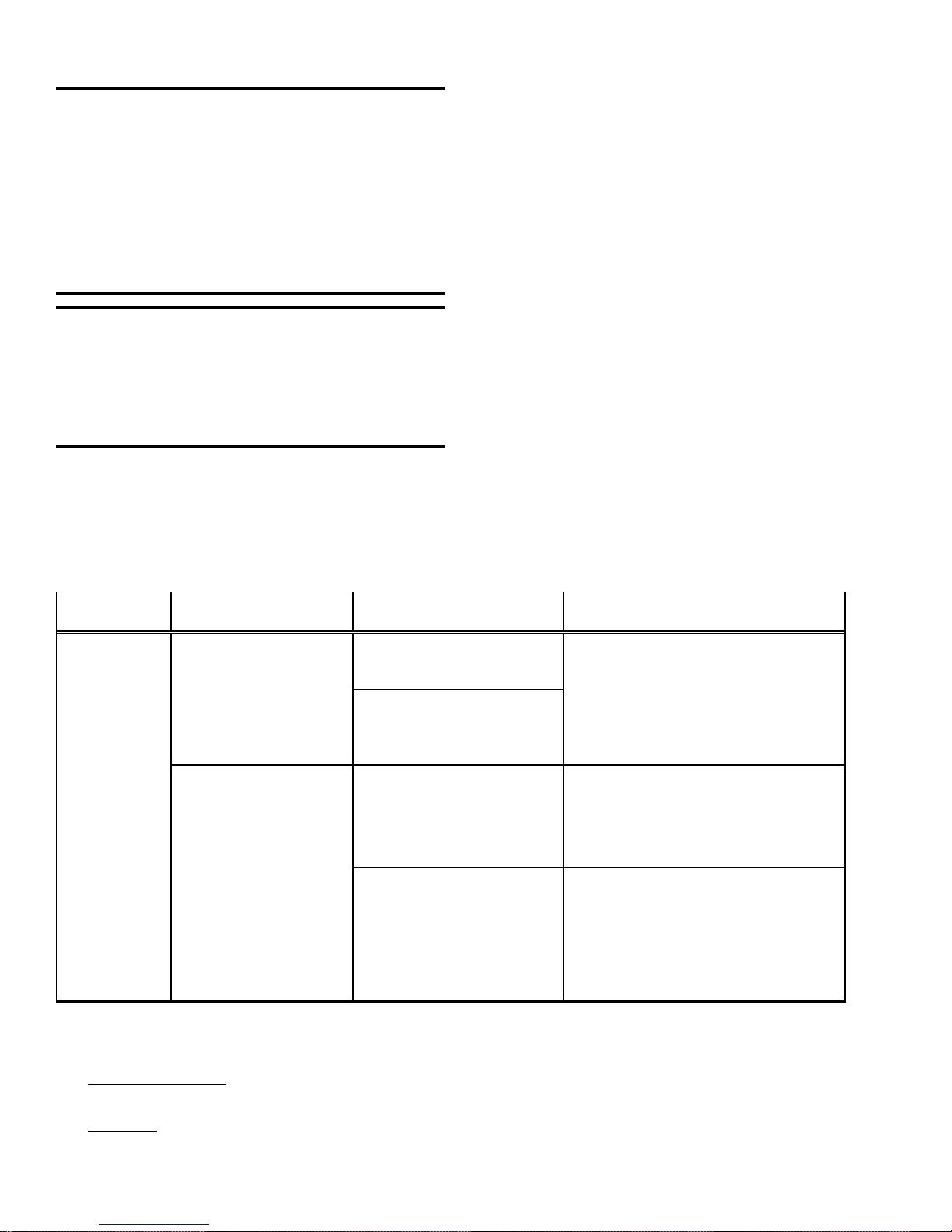

STEP 1 - Decide which V enting System to Install:

Type of

Installation

COMMERCIAL/

INDUS TRIAL

(Harmonized

ANSI Z83.8-1996

and Canadian

Standard

CAN/CGA 2.6M96)

Type of Ve nt System

(Description/Instructions)

Separated-Com bustion

(uses a po wer venter to duct

combustion air from o utdoors

and exhaust flue products to

the outdoors) -

Instructions in Section 7A)

Power-Vented

venter to draw combustion air

from the indoor space and

exhaust flue products to the

outdoors) -

Instructions in Section 7B)

(follow

(uses a power

(follow

Ve nt Configuration/Options

Required

Horizontal Vent / Option CC6

(includes concentric adapter box,

exhaust terminal, and inl et air guard)

Vertical Vent / Option CC2

(inc ludes concentric adapter box,

exhaus t terminal, and co mbustion air

inlet)

Horizontal Vent / Option CC1

Vent Cap or field-sup plied

equivalent (see page 11)

At least 1/2 of the Equivalent

Vent Length is Ver tical / Option

Vent Cap or field-supplied

CC1

equivalent (see page 11)

Type of VENT Pi pe * Re quired

Use either vent pipe approved for a Category III

appliance OR single-wall, 26-gauge or heavier

galvanized (or a mat erial of equivalent durability

and corrosion resistance) vent pipe.

Use either vent pipe approved for a Category III

appliance OR appropriately sealed 26-gauge

galvanized steel or equivalent single-wall pipe. If

local co de requires, the term inal section may be

double-wall pipe with a single-wall vent run.

Vent pipe listed above for a horizontal powervented s ystem may be used, OR vent pipe

approved for a Cat egory I heater may be used.

Single-wall pipe or double-wall (Type B) vent

pipe are suit able for use with a Category I heater.

If local code requires, the terminal section may be

double-wall pipe with a single-wall vent run.

STEP 2 - Follow the instructions that apply to the type of vent being

installed

• Separated-Combustion -- requires air inlet pipe, exhaust vent pipe, and concentric adapter kit (Option CC2 or CC6)

Using required pipe (See T able above), FOLLOW INSTRUCTIONS IN SECTION 7A

• Power Vent -- requires vent pipe and vent cap (Option CC1 or field-supplied Type L Breidert Air-x-hauster

cap)

Using required pipe (See T able above), FOLLOW INSTRUCTIONS IN SECTION 7B

Form 405, Page 4

®

or equivalent vent

Page 5

7A. Venting and Combustion Air Requirements for Separated-Combustion

Installation (must use either Option CC2 or CC6)

Specific Requirements (read all before installing)

Comply with the specific requirements and instructions in the following paragraphs and illustrations.

1. Combustion Air Inlet

Diameter is 5" for Sizes 150 and 200 and 6" for Sizes 250, 300,

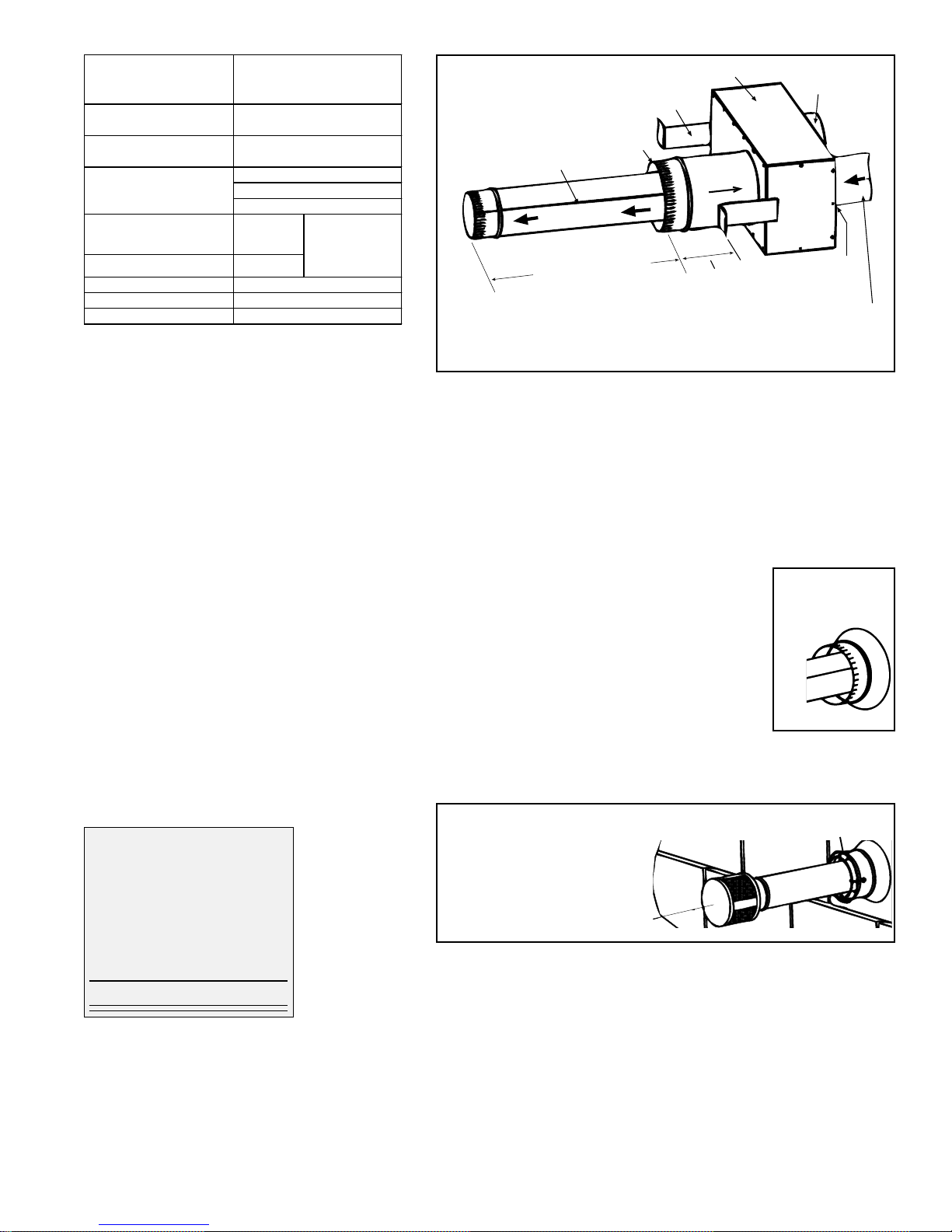

Figure 2 - Attach Combustion Air Pipe

350, and 400.

Use tin snips or aviation shears to cut out the hole in the top of

the heater (See Figure 2). Insert the pipe through the hole and

attach it to the collar inside the heater. Seal the joint. (Larger size

heaters have oval collars. If the collar is oval, form the pipe to fit

the collar.)

2. Venter Outlet

The venter outlet size is 5" for Sizes 150, 200, and 250 and 6" for

Sizes 300, 350, and 400. A minimum length of 12" of straight

pipe is required at the venter outlet.

3. Concentric Adapter

If installed as a separated-combustion unit, a concentric adapter

is required.

• Option CC2 and CC6 - The concentric adapter is a

metal box that attaches to the inside of the building. See

the illustrations and dimenstions in Figures 3A and 3B.

Option CC6 is horizontal; Option CC2 is vertical. (Option kits also include a vent terminal and combustion air

inlet or guard.)

Figure 3A - Concentric Adapter Assembly in Options CC2 and CC6

1) Remove door panel.

2) Cut out the hole.

3) Slide pipe down through hole.

4) If collar is oval, form pipe to fit. Attach pipe to collar with

Use tin snips

to cut out

hole for

combustion

air pipe

Collar for

connecting

combustion air

pipe

sheetmetal screws and seal the connection.

V enter

Outlet

View of Heater Connection Side View of V ent Terminal Connection Side

Collar for

connecting

indoor portion

of the

combustion

air pipe

Install rubber seal

for vent pipe

Collar for outside portion of the

combustion air pipe (vent pipe

extends through the box

internally concentric to the

outside portion of the combustion

air pipe)

Figure 3B - Concentric Adapter Box

Dimensions - inches (mm)

CAUA 150,200 250,300,350,400

A 5 (127) 6 (152)

B 4 (102) 5 (127)

C 4 (102) 4 (102)

D 7-1/2 (191) 7-1/2

E 5 (127) 5 (127)

F 4 (102) 5 (127)

G 16-1/2 (419) 16-1/2 (419)

H 8 (203) 10 (254)

J 6 (152) 8 (203)

J = Diameter of the

Collar for attaching the

"Outside" Portion of the

Combustion Air Pipe

Top View of the Concentric Adapter

Box Showing Air Flow

= Combustion Air Flow

= Exhaust (Vent) Gas Flow

Field-supplied vent

pipe passes

through the

rubber seal on the

concentric adapter

box, extending out

both sides of the

box

A = Diameter of the

Collar for attaching

the inside

Combustion Air Pipe

from the Heater

2 (51mm)

6 (152mm)

2 (51mm)

End View

H

F

E

B

G

D

C

Side View - Side of the

Adapter Box that Connects

to the Heater

Mfg No. 164771, Page 5

Page 6

7. V enting and Combustion Air (cont'd)

Reducer

Airflow

7A. Venting and Combustion Air Requirements for Separated-Combustion

Installation (must use either Option CC2 or CC6) (cont'd)

4. Pipe Diameter and Length

Maximum Pipe Length from Heater to Concentric Adapter -

minimum length is five feet (1524mm)

Model Pipe Diameter Maximum 90° Elbow 45° Elbow

CAUA Vent Inlet Air Length Equals* Equals*

150-200 5" 5" 40 ft 5 ft 2.5 ft

12.2 M 1524 mm 762 mm

250 5" 6" 50 ft 5 ft 2.5 ft

15.2 M 1524 mm 762 mm

300-400 6" 6" 50 ft 5 ft 2.5 ft

15.2 M 1524 mm 762 mm

*Reduce maximum length by this amount for each elbow.

Concentric Pipes (the vent pipe runs concentric through the outdoor portion of the combustion air pipe) - Sizes 150 and 200 require

a 6" diameter combustion air pipe for outdoor portion and a 4" diameter vent pipe through the concentric adapter to the terminal; Sizes

250-400 require an 8" diameter combustion air pipe for the outdoor

portion and a 5" diameter vent pipe through the concentric adapter to

the terminal.

Length depends on building construction; specific requirements are

included with the concentric adapter kit instructions.

5. Joints

Determined by type of pipe - Provide field-supplied vent pipe as

specified in the Table on page 4.

• If using single wall, 26-gauge or heavier galvanized pipe, secure

slip-fit connections using sheet metal screws or rivets. Seal all

joints. Seal combustion air pipe with pressure sensitive tape ordinarily used for warm-air ductwork. Seal flue exhaust pipe with

Instructions and Requirements for Installing

Option CC6

Option CC6 Package includes:

Qty Description 150, 250, 300,

200 350, 400

1 Complete Horizontal Vent Kit 157158 82131

(Same as Option CC6)

1 Concentric Box Assembly 155392 68404

(See Figures 3A and 3B)

1 Screened 155096 53316

Exhaust Assy

1 Inlet 151755 124940

Guard

4 #10-16x1/2" lg Screws (to 37661 37661

attach the inlet guard)

1 Rubber seal for vent pipe opening 164492 164493

in concentric adapter

1 Tube of high temperature (450°F) 53335 53335

silicone sealant

Field-supplied installation requirements:

• Thimble (a thimble is not required if wall is of non-combustible construction)

• Flashing

• Vent pipes (see requirements on pages 4 and 6)

• Combustion air pipes (see requirements on pages 4 and 6)

Form 405, Page 6

either tape suitable for 550°F (such as Option FA1, P/N 98266) or

high-temperature (450°F) silicone sealant.

• If using Category III vent pipe, follow the pipe manufacturer's in-

structions for joining pipe sections.

In Concentric Pipes (outdoor portion) from Concentric Adapter

Box to Air Inlet and Vent Terminal - Follow the installation instruc-

tions for the specific option (CC6 for horizontal vent; CC2 for vertical

vent).

Joints Requiring Taper-type Connections (See Figure 4) - When

the diameter of the pipe in the vent pipe run is different from the vent

pipe in the terminal section, the joint must be made with a taper-type

pipe connector. Install the connector no more than 6" (152mm) from the

concentric adapter box. A 5" to 4" reducer is required in the vent pipe on

Sizes 150 - 200; a 6" to 5" reducer is required on Sizes 300 - 400.

Figure 4 - When joining different pipe diameters, use tapertype pipe connectors

Taper-type Connector

Either collar

or smaller

diameter pipe

Secure joints with sheetmetal

screws and seal.

6. Support

Support horizontal runs every six feet (1829mm); do not rely on the

heater or concentric adapter for support of either horizontal or vertical

pipes.

7. Clearance

Clearance from the vent pipe to combustibles is 6" (152mm). Do not

enclose the vent pipe.

Horizontal

• Mounting brackets for concentric adapter box (or box may be

mounted flush, depending on building construction)

• T aper-type reducers as required (see requirements above)

Installation Instructions for Option CC6

1. Determine the location on the outside wall for the vent terminal

(Applies to all horizontal vent kits). In most applications, the terminal

would be on a level with the heater mounting height. Allow 1/4" per foot

downward pitch toward the terminal for draining of condensation.

The distance of the termination of the horizontal vent from adjacent public

walkways, adjacent buildings, openable windows, and building openings

must be in accordance with local codes or, in the absence of local codes,

must conform with National Fuel Gas Code. Local codes supersede all

provisions in these instructions and in the National Fuel Gas Code. Minimum clearances for the horizontal vent terminal are as shown in the table on

page 7.

Products of combustion can cause discoloration of some building finishes

and deterioration of masonry materials. Applying a clear silicone sealant

that is normally used to protect concrete driveways can protect masonry

materials. If discoloration is an esthetic problem, relocate the vent or install

a vertical vent.

WARNING: All vent terminals must be positioned or

located away from fresh air intakes, doors and

windows to preclude combustion products from

entering occupied space. See Hazard Levels, page 2.

Vent Terminal/Combustion Air Inlet

Page 7

Minimum Clearances for Vent

Structure

Forced air inlet within 10 ft

(3.1m)

Combustion air inlet of

another appliance

Door, window, or gravity air

inlet (any bu i ld ing ope n i ng)

Electric meter, gas meter *

and relief equipment

Gas regulator * 3 ft (0.9m)

Adjoining bu ilding or parap et 6 ft (1.8m)

Adjacent public walkway s 7 ft (2.1m) above

Grade (ground level) 7 ft (2.1m) abov e

Termi nation Location (all

directions unless specified)

3 ft (0.9m) above

6 ft (1.8m)

4 ft (1.2m) horizontally

4 ft (1.2m) below

1 ft (30cm) above

4 ft (1.2m)

horizontally

*Do not terminate

th e vent directly

above a gas meter

or service regulator.

2. Prepare clearance hole through the outside wall for a 6"

diameter pipe (Size 150 or 200) or an 8" diameter pipe

(Size 250, 300, 350, or 400). Outside wall construction

thickness should be between 1" (25mm) minimum and 30"

(762mm) maximum. The larger diameter combustion air

pipe serves as clearance for the exhaust pipe on non-combustible construction. A thimble may or may not be required depending on wall construction and/or local codes.

3. Prepare the concentric adapter box.

3a) Determine whether field-supplied brackets are

required. The box must be positioned so that the

distance from the outside of the wall to the box is a

minimum of 12" (305mm). Maximum distance is 60"

(1524mm). If brackets are used, box should be angled

slightly to allow for downward pitch of pipes. If used,

attach brackets securely; do not leave any unsealed

holes in the adapter box.

If brackets are not used, when the box is installed,

position it tight against the wall.

3b) Install the rubber seal and the vent pipe. Locate the

vent pipe opening (no collar) and place the rubber seal

around and over the edge of the metal.

Determine the length of the section of vent pipe by

adding the requirements. On the heater side of all Sizes

except CAUA 250, the vent pipe must extend no more

than 6" (152mm) (length limit does not apply to Size

250 because the pipe diameter does not change); plus

6" (152mm) through the box; plus bracket length; plus

the width of the wall; plus a minimum of 18" (457mm)

Worksheet - Determine Length of

Vent Pipe through the Box

inches mm

Heater Side (max if + 6 152

diameter changes)

Width of Box + 6 152

Bracket Length + __ ___

Width of Wall + __ ___

Terminal Side (min) + 18 457

Length of Pipe =

on the outside (if

the inlet air pipe

extends recommended 2"

(51mm) beyond

the wall).

Lubricate the seal

and pipe with liquid soap or a rubber lubricant. (Installation Tip:

Spray cooking oil

works well as a lubricant for this task.)

Being sure the pipe is in the proper flow direction,

slide the end through the box and push it out through

the rubber seal. Push evenly using caution not to displace the seal from its position on the edge of the hole.

If the rubber seal moves, slide the pipe back slightly,

re-position the seal, and slide the pipe through again.

Position the vent pipe so that it will extend a minimum

of 16" past the end of the combustion air pipe. See

5A

Combustion air pipe

Seal the seam in the vent pipe.

Vent Flow

16 (406mm) minimum

Concentric Adapter Box

Field-supplied

mounting brackets

Combustion

Air Flow

2 (51mm)

approx plus

wall thickenss

Vent Pipe - when a taper-type

the vent pipe; the connection

Collar for

combustion

air pipe.

Install rubber seal in

vent pipe opening.

reducer is required in

must be no more than 6

(152mm) from the box.

Figure 5A. On all Sizes except 250, no more than 6" (152mm) of vent pipe

should extend out the heater side. Any time the pipe is re-positioned, re-check

the seal to be sure that it has not rolled. Adjust the pipe and seal until the pipe is

the correct length on each side of the box and the seal is over the edge of the hole

and tight to the entire circumference of the pipe.

3c) Attach the outside portion of the combustion air pipe to the box. Determine

the length by measuring the bracket length (if brackets are used), plus the wall

thickness, plus 2" (51 mm). The inlet pipe should extend beyond the outside

wall approximately 2" (51mm). Attach the inlet air pipe to the collar of the

concentric adapter with sheetmetal screws being careful not to penetrate the

vent pipe.

4. Attach the concentric adapter box to the wall. Insert

the vent pipe and combustion air pipe through the wall.

Push the concentric adapter box flush against the inside

wall or attach to the wall with the field-supplied brackets.

Caulk or flash inlet air pipe on the outside wall. Flashing is

Flash or caulk

the inlet air pipe

on the outside

wall

field supplied.

5. Slide the inlet guard over the end of the vent pipe

and position it on the end of the combustion air pipe. See

Figure 5B. Attach the guard to the inlet air pipe with the

5B

four 1/2" lg screws provided.

6. Position the vent cap on the end of the vent pipe. Align the cap so that its baffle

strips are positioned on the horizontal and vertical centerlines (See Figure 5C).

Attach the exhaust cap to the vent pipe with sheetmetal screws.

First, attach the inlet air guard;

Second, attach the exhaust cap

Inlet Air Guard

5C

IMPORTANT: Install

exhaust cap with baffles

positioned on horizontal and

vertical centerlines as illustrated.

7. Horizontal vent terminal/combustion air inlet Option CC6 is installed and ready

for connection to the heater.

8. Connect the Concentric Adapter Box to the Heater - Use the pipe specified

and joints required for type of pipe. If collar or opening at the heater or adapter are

different diameters from the pipe (use only diameters allowed on page 6), make joint

connection with field-supplied taper-type reducer or enlarger.

A minimum of 12" (305 mm) of straight pipe is required at the venter outlet.

Due to the high temperature, do not enclose the exhaust pipe or place pipe closer

than 6" (152 mm) to combustible material.

Installation of the horizontal vent and combustion air system on your separatedcombustion unit is complete. Refer to Figure 5D and verify that all installation

requirements are met. Continue to Paragraph 8.

Mfg No. 164771, Page 7

Page 8

7. V enting and Combustion Air (cont'd)

7A. Venting and Combustion Air Requirements for Separated-Combustion

Installation (must use either Option CC2 or CC6) (cont'd)

Figure 5D - Installation of a T ypical SeparatedCombustion Unit with Horizontal V ent and Combustion

Air Pipes (Option CC6)

Building Overhang

Side View

Vent Pipe

- PITCH

TO

DRAIN

6-15/16 (176mm)

16(406mm)

minimum

24(610mm)

minimum

Wall

Concentric Adapter Box

Combustion Air Pipe

(PITCH TO DRAIN)

6ft (1829mm)

Adjoining

Building

minimum

3 ft (914mm)

minimum

3 ft (914mm)

Thimble

IMPORTANT NOTE: Exhaust cap must be installed so the baffles

are positioned on horizontal and vertical centerlines.

minimum

Building Projection

Inlet Air

Guard

Screened

Exhaust

Cap

60 (1524mm) maximum

12 (305mm) minimum

Wall

"Through-the-W all" View of a typical

installation of a horizontal vent/inlet air

terminal and concentric adapter

Top

View

Concentric Adapter

Seal Joints

Combustion Air Pipe

Seal joints; see Require-

ment No. 5 on page 6.

Vent (Flue Exhaust) Pipe

Maximum Length (See Requirement

No. 4 on page 6.)

Minimum length is 5 ft (1.5M)

(Option CC6)

Instructions and Requirements for Installing a

(Requires Concentric Adapter Kit, Option CC2)

V ertical V ent T erminal/Combustion Air Package

(Option CC2) includes:

Qty Description 150, 250,300,

200 350,400

1 Complete Vertical Vent Kit 157156 54444

(Same as Option CC2)

1 Concentric Box Assembly 155392 68404

1 Exhaust 155631 53326

T erminal

1 Combustion 155635 53330

Air Inlet

1 Rubber seal for vent pipe 164492 164493

opening in concentric adapter

1 Tube of High Temperature 53335 53335

(450°F) Silicone Sealant

Field-supplied installation requirements:

• Thimble (a thimble is not required if wall is of noncombustible construction)

• Flashing

• Vent pipes (see requirements on pages 4 and 6)

• Combustion air pipes (see requirements, pages 4 and 6)

• Mounting brackets for concentric adapter box (or box

may be mounted flush, depending on building construction)

• Taper-type reducers as required (see requirements on

page 6)

Form 405, Page 8

Installation Instructions for Option CC2

1. Determine the location for the vent terminal on the roof, allowing room for the

concentric adapter box inside. A thimble may or may not be required depending

on building construction and/or local codes. Prepare a hole through the roof for

the combustion air pipe (Sizes 150 and 200, pipe is 6"; Sizes 250-400, pipe is 8").

The air inlet pipe must be flashed or sealed to the roof. Flashing is to be supplied

by the installer as required by roof construction and/or codes.

WARNING: All vent terminals must be positioned or

located away from fresh air intakes, doors and windows to

preclude combustion products from entering occupied

space. See Hazard Levels, Page 2.

2. Prepare the concentric adapter box.

2a) Determine whether field-supplied brackets are required. If used, attach

brackets securely; do not leave any unsealed holes in the adapter box.

If brackets are not used, when installed, the box should be tight against

the roof.

2b) Install the rubber seal and the

vent pipe. Locate the vent pipe open-

ing and place the rubber seal around

and over the edge of the metal.

Determine the length of the section of

vent pipe by adding the requirements.

On the heater side of all Sizes except

CAUA 250, the vent pipe must extend no more than 6" (152mm) (length

limit does not apply to Size 250 be-

Vertical

Vent Terminal/Combustion Air Inlet

W orksheet - Determine Length of

Vent Pipe through the Box

inches mm

Heater Side (max if + 6 152

diameter changes)

Width of Box + 6 152

Bracket Length + __ ___

Width of Roof + __ ___

Inlet Pipe Height + __ ___

Terminal Side (min) + 22 559

Length of Pipe =

Page 9

9-3/8

(238mm)

12 (305mm)

6 ft (1829mm)

minimum

11 (279mm)

18(457mm)

minimum

Wall or

Adjoining

Building

Flashing

(field supplied)

Roof

Concentric

Adapter

Thimble

5 ft (1524mm)

maximum (Size

according to

anticipated

snow depth.

"X" is the length of combustion air

pipe required through and above

the roof

"X" must equal roof thickness

plus clearance required for

anticipated snow

plus ridge and/or

parapet clearance

Seal the seam in

the vent pipe.

"X" must not

Install the vent pipe

by inserting it into the

terminal side of the

box and pushing it out

through the seal on the

heater side.

ent Flow

V

NOTE: Be sure flow

direction is correct.

exceed 60"

(1524mm)

Combustion

air pipe

Field-supplied

mounting brackets

Air Flow

Combustion

Concentric

Adapter Box

Collar for combustion

Vent Pipe - when a taper-type reducer

is required in the vent pipe; it must be no

more than 6 (152mm) from the box.

air pipe.

Install seal

in vent pipe

opening

cause the pipe diameter does not change); plus bracket length;

plus the width of the roof; plus the length of the outer inlet air

pipe; plus a minimum of 22" (559mm).

Lubricate the seal and pipe with liquid soap or a rubber lubricant. (Installation Tip: Spray cooking oil works well as a lubricant for this task.) Being sure the pipe is in the proper flow

direction, slide the end through the box and push it out through

the rubber seal. Push evenly using caution not to displace the

seal from its position on the edge of the hole. If the rubber seal

moves, slide the pipe back slightly, re-position the seal, and

slide the pipe through again.

Position the vent pipe so that it will extend a minimum of 22"

(559mm) past the end of the combustion air pipe. See Figure

6B.

A maximum of 6" (152mm) of vent pipe should extend out the

heater side. Any time the pipe is re-positioned, re-check the

seal to be sure that it has not rolled. Adjust the pipe and seal

until the pipe is the correct length on each side of the box and

the seal is over the edge of the hole and tight to the entire

circumference of the pipe.

6A

2c) Attach the outside portion of the com-

bustion air pipe to the box. Determine

the length of the combustion air pipe so

that dimension "X" (Figure 6A) is equal

to the roof thickness, plus snow depth

and ridge or parapet clearance, but does

not exceed 60" (1524 mm). Attach the

combustion air pipe to the collar with

sheetmetal screws being careful not to

penetrate the vent pipe.

3. Attach the concentric adapter. Insert

the vent pipe and combustion air pipe up

through the roof and secure the adapter box.

Flash the combustion air pipe to the outside

of the roof as required.

4. Slide the combustion air inlet over the

6C

1)Slide combustion

air inlet over the

vent pipe

2)Fasten to the end

of the combus-

tion air pipe

3)Seal the top joint

with silicone

Install field-supplied

flashing at roof

opening (flashing not

illustrated).

Exhaust

Terminal

12" (305mm)

minimum

Box to the Heater - Use the pipe speci-

fied and joints required for type of pipe.

If collars at the heater or adapter are different diameters from the pipe (use only

diameters allowed on page 6), make connection with field-supplied taper-type reducer or enlarger .

A minimum of 12" (305 mm) of

Combustion

Air Inlet

straight pipe is required at the venter

outlet. Due to the high temperature, do

not enclose the vent pipe or place pipe

closer than 6" (152 mm) to combustible

6D

material.

Installation of the vertical vent and combustion air system on your separated-combustion unit is complete. Refer to Figure 6E and verify that all

6B

22"

(559mm)

minimum

Snow

Clearance

vent pipe and fasten the collar

to the end of the combustion air

pipe with sheet metal screws

(See Figure 6C). Seal joint at top

between vent pipe and combustion air inlet with silicone sealant to prevent water leakage.

5. Attach the exhaust terminal with sheet metal screws (See

Figure 6D).

6. Vertical vent terminal/combustion air inlet is installed and ready

for connection to the heater.

7. Connect Concentric Adapter

installation requirements are met.

Figure 6E - Installation of Separated-Combustion Unit with V ertical V ent and Combustion Air Pipes (Option CC2)

Vent

Termina

l

Flue

Exhaust

(Vent )

Pipe

Rear

View

Vent

Pipe

Seal with high

temperature silicone

rubber sealant supplied

with the kit.

Combustion

Air Inlet

Flashing

(field supplied)

Combustion Air Pipe

Roof

Concentric

Adapter

Side View

"Through-the-Roof" View of a typical installation

of a vertical vent/inlet air terminal and concentric

adapter (Option CC2)

Mfg No. 164771, Page 9

Page 10

7. V enting and Combustion Air (cont'd)

7B. Venting and Combustion Air Requirements for Power Vent Drawing

Combustion Air from THE INSIDE SPACE and Venting Flue Products to

the Outdoors (vent cap is required)

If the environment has a positive pressure and is such that it is

not detrimental to combustion air, this system may be installed.

To provide combustion air to the heater sufficient air must enter

the equipment location to replace that exhausted through the

heater vent system. In the past, the infiltration of outside air

assumed in heat loss calculations (one air change per hour) was

assumed to be sufficient. However, current construction methods

using more insulation, vapor barriers, tighter fitting and gasketed

doors and windows, weather-stripping, and/or mechanical exhaust fans may now require the introduction of outside air through

wall openings or ductwork to the equipment room.

The requirements for combustion and ventilation air depend upon

whether the unit is located in a confined or unconfined space. An

"unconfined space" is defined as a space whose volume is not less

than 50 cubic feet per 1000 BTUH of the installed appliance.

Under all conditions, enough air must be provided to ensure

there will not be a negative pressure condition within the equipment room or space. Follow the specific requirements below for

a confined space installation.

Confined Space Installation - Do not install a unit in a confined space without providing wall openings leading to and from

the space. Provide openings near the floor and ceiling for ventilation and air for combustion as shown in Figure 7, depending on

the combustion air source as noted in Items 1, 2, and 3 below.

Figure 7 - Confined Space:

A space whose

volume is less than

50 cubic feet per

1000 BTUH of the

installed appliance

input rating

Add total BTUH of all appliances in the confined space and

divide by figures below for square inch free area size of each (top

and bottom) opening.

1. Air from inside the building -- openings 1 square inch free

area per 1000 BTUH. Never less than 100 square inches free area

for each opening. See (1) in Figure 7.

2. Air from outside through duct -- openings 1 square inch free

area per 2000 BTUH. See (2) in Figure 7.

3. Air direct from outside -- openings 1 square inch free area per

4000 BTUH. See (3) in Figure 7.

NOTE: For further details on supplying combustion air to a

confined space, see the National Fuel Gas Code ANSI Z223.1a

(latest edition).

Specific V enting Requirements ( read all

before installing)

1) Venter (Flue) Outlet

Venter

Outlet

Size:

Venter Outlet Attachment Requirements:

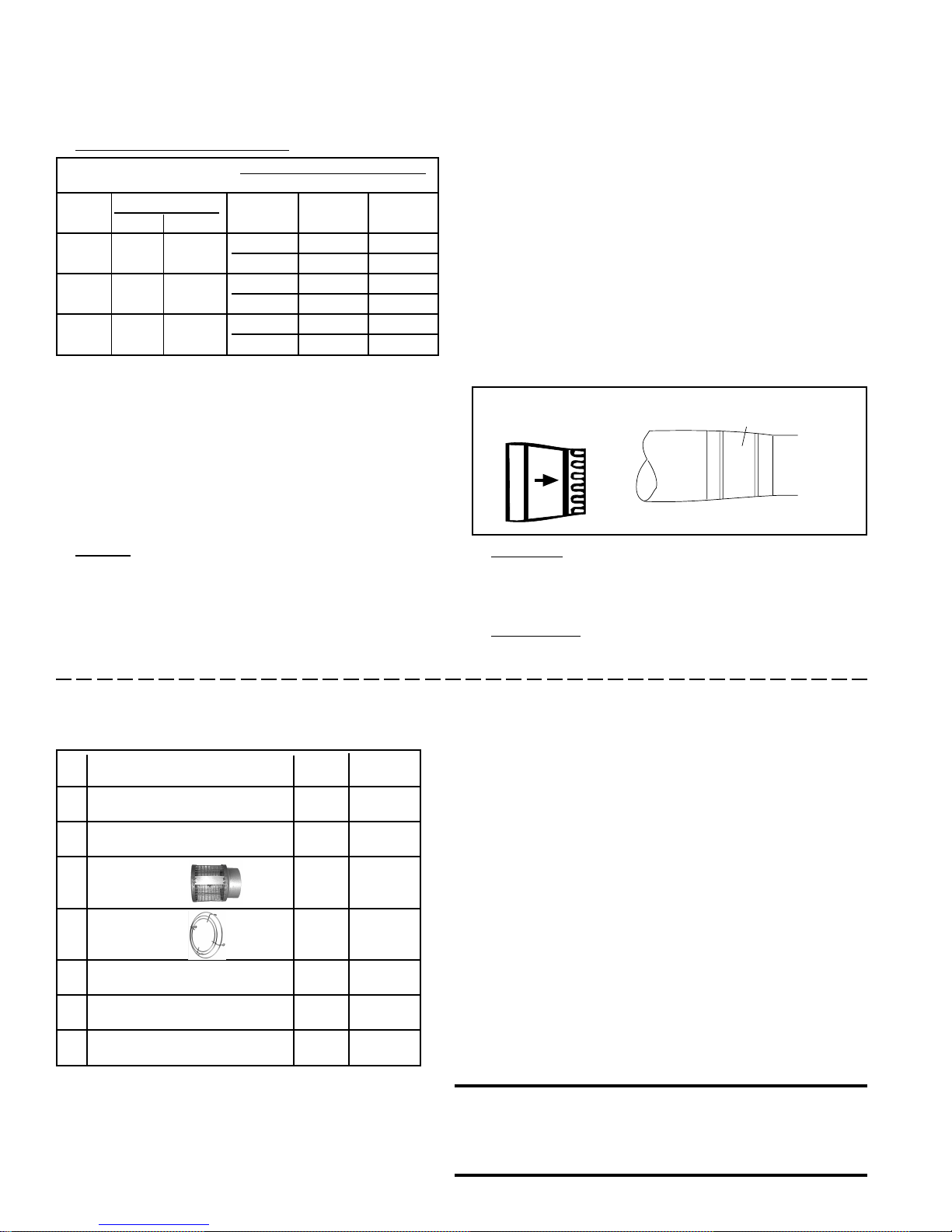

• A minimum of 12" of straight pipe is required at the venter

outlet before installing an elbow in the vent system. An elbow

should never be attached directly to the venter. An elbow

attached to the straight pipe can be in any position at or above

horizontal. See Figure 8.

Form 405, Page 10

Model Size 150, 200, 250 300, 350, 400

Outlet Diameter 5" 6"

V ent in any

position above

horizontal

A minimum of 12" of

straight pipe is required

before an elbow

• Do not install dampers or any other type of flue restrictor device.

2) Vent Pipe Diameter and Length

Maximum V ent Length - minimum length is 5 ft (1.5M)

CAUA Pipe Maximum 90° Elbow 45° Elbow

Diameter Length Equals* Equals*

150-250 5" 50 ft (15.2M) 5 ft (1.5M) 2.5 ft (.8M)

300-400 6" 50 ft (15.2M) 5 ft (1.5M) 2.5 ft (.8M)

*Reduce by this amount for each elbow.

Note: If the system contains all vertical pipe or a combination of horizontal

and vertical vent pipe, the Maximum Permissible Vent Length may be increased one foot (305mm) for each foot (305mm) of vertical rise up to a

maximum increase of ten feet (3M).

3) Vent Pipe and Joints

Provide field-supplied vent pipe as specified in the Table on page 4.

• If using single wall, 26-gauge or heavier galvanized pipe, secure slip-fit

connections using sheet metal screws or rivets. Seal pipe joints either with

tape suitable for 550°F (such as Option FA1, P/N 98266) or high-temperature silicone sealant.

• If using Category III vent pipe, follow pipe manufacturer's instructions

for joining pipe sections. When attaching Category III pipe to the venter

outlet or the vent cap, make secure, sealed joints following a procedure

that best suits the style of Category III pipe being used.

• If using double-wall (Type B) vent pipe (at least 1/2 of the equivalent vent

length must be vertical), follow pipe manufacturer's instructions for joining pipe sections. For joining double-wall pipe to the venter outlet collar,

single-wall pipe, and/or the vent cap, follow the instructions below:

Instructions for attaching double-wall (Type B) vent pipe to the venter outlet, a single-wall pipe run, or to the vent cap (use these in-

structions for either full length double-wall or terminal only):

Hardware and Sealant Required: 3/4" long sheetmetal screws; and a tube of

high temperature silicone sealant

1) Look for the "flow" arrow on the vent pipe; attach according to the

arrow. Slide the pipe so that the venter outlet, the single-wall pipe, or the

vent cap is inside the double-wall pipe.

2 ) Drill a hole through the pipe into the outlet collar, the single-wall pipe,

or the vent cap. (Hole should be slightly smaller than the sheet metal

screw being used.) Using a 3/4" long sheet metal screw, attach the pipe.

Do not overtighten. Repeat, drilling and inserting two additional screws

evenly spaced (120° apart) around the pipe.

3 ) Use silicone sealant to seal any gaps. If there is an annular opening, run

a large bead of sealant in the opening. The bead of sealant must be large

enough to seal the opening, but it is not necessary to fill the full volume

of the annular area.

4) Vent System Support

Lateral runs should be supported every six feet (1.8M) using a non-combustible material, such as strap steel or chain. Do not rely on the heater for

support of either horizontal or vertical vent pipe.

Figure 8 - Alternate

V ent Directions

Page 11

5) Condensation

Any length of single-wall vent pipe exposed to cold air or run

through an unheated area or an area with an ambient temperature

of 45°F or less must be insulated along its entire length with a

minimum of 1/2" foil-faced fiberglass, 1-1/2# density insulation.

Where extreme conditions are anticipated, install a means of condensate disposal.

6) Vent Terminal (Pipe and Vent Cap)

The vent system must be terminated with the type of vent cap

approved for use with this heater. The vent cap must be the same

size as the vent pipe. Use either a vent cap available from the

Figure 8 - Horizontal V ent T erminals

Single-Wall Vent

Run and SingleWall Terminal

Roof or Building Overhang

12

(305mm)

minimum

3 (1M)

minimum

6 (2M)

minimum

heater manufacturer (Option CC1) or a field-supplied cap. If the vent cap is

field-supplied, use a Type L Breidert Air-x-hauster® or equivalent vent cap.

(T ype L Air-x-hauster

®

is a trademark of The G. C. Breidert Company.) Use

of a vent cap supplied by the pipe manufacturer is not permitted; the vent

cap must be the type approved for use with this heater. A different style

vent cap could cause nuisance problems or unsafe conditions.

See the illustrations in Figures 9A and 9B for requirements of vertical and

horizontal vent termination. The vent terminal pipe may be either singlewall or double-wall (Type B). If double-wall pipe is used in the vent terminal with a single-wall vent run, follow the instructions on page 10 to attach

the vent cap and to connect the double-wall pipe to the single-wall vent pipe

run.

Single-Wall

V ent Run

and Double-

Roof or Building Overhang

Wall

Terminal

Adjoining Building

12

(305mm)

6 (152mm) minimum

minimum

3 (1M)

minimum

6 (2M)

minimum

Adjoining Building

Wall

Approved clearance

thimble for single-wall

vent pipe is required

when flue pipe extends

through combustible

materials.

Pitch flue pipe down toward outlet

1/4 per foot for condensate drainage.

(NOTE: Applies to entire horizontal

vent run.)

Note position of vent

cap openings.

Horizontal Vent Terminal Clearances

A vent cap is required. Maintain a clearance

of 12" from the wall to the vent terminal cap

for stability under wind conditions.

Products of combustion can cause discoloration of some building finishes and deterioration of masonry materials. Applying a clear

silicone sealant that is normally used to protect concrete driveways can protect masonry

materials. If discoloration is an esthetic problem, relocate the vent or install a vertical vent.

Figure 9 - V ertical Vent T erminals

Single-Wall Vent

Run and SingleWall Terminal

Structure Minimum Clearances for Vent Termination

Forced air inlet within 10 ft (3.1m) 3 ft (0.9m) above

Combustion air inlet of another appliance 6 ft (1.8m)

Door, window, or gravity air inlet 4 ft (1.2m) horizontally

(any building opening) 4 ft (1.2m) below

Electric meter, gas meter* and relief 4 ft (1.2m) *Do not terminate the vent

equipment horizontally directly above a gas meter

Gas regulator* 3 ft (0.9m) or service regulator.

Adjoining building or parapet 6 ft (1.8m)

Adjacent public walkways 7 ft (2.1m) above

Grade (ground level) 7 ft (2.1m) above

Parapet or

Wall

Approved clearance

thimble for single-wall

vent pipe is required

when flue pipe extends

through combustible

materials. Follow

the requirements

of the double-wall

pipe manufacturer.

Follow instructions on page 10 to join single

and double-wall pipe and to seal the connection.

Location (all directions unless specified)

1 ft (30cm) above

Pitch flue pipe down toward

outlet 1/4 per foot for condensate drainage.

(NOTE: Applies to entire

horizontal vent run.)

Single-Wall V ent

Run and DoubleWall Terminal

Note position of

Parapet or

vent cap openings.

6 (2M) minimum

Roof - pitched

from 0 to 45°

Parapet or Adjoining Building

Approved clearance thimble

for single-wall vent pipe is

required when flue pipe

extends through

combustible materials.

Vertical flue extension to

be 6 (152mm) higher than

anticipated snow depth but

no less than 2 feet (610mm)

above the roof.

Vertical pipe extension

must be insulated.Roof Flashing

6 (2M) minimum

Roof Flashing

Roof - pitched

from 0 to 45°

6 (152mm) minimum

Parapet or Adjoining Building

Follow instructions on page 10

to join single and double-wall

pipe and to seal the connection.

Vertical flue extension

to be 6 (152mm) higher

than anticipated snow

depth but no less than

2 feet (610mm) above the

roof.

Approved clearance thimble

for single-wall vent pipe is

required when flue pipe extends

through combustible materials.

Follow the requirements of the

double-wall pipe manufacturer.

Mfg No. 164771, Page 11

Page 12

8. Duct Connections and

Ductwork

Both inlet air ductwork and supply air discharge ductwork are required

unless the heater is equipped with an optional inlet base and/or an

optional discharge plenum. IMPORTANT NOTE: If a Model ACU

cased cooling coil is part of the installation, it must be installed before

attaching discharge ductwork. Installation of a filter cabinet is recommended when a cooling coil is installed.

Discharge Duct Connection - The discharge duct connects to the top

of the heater or to the outlet of the optional cooling coil cabinet. See

Figures 10 and 11. Connect the ductwork plenum to the duct flange as

illustrated in Figure 11.

1) The duct connection on the top of the heater has a 90° flange.

2) The duct may either have no flange or a 90° flange.

3) Position ductwork around the outside of the heater flange.

4) If the ductwork has a flange, drill holes vertically through duct

flange into the top of the heater and secure with sheetmetal

screws. If the ductwork does not have a flange, drill holes horizontally through the ductwork and the heater flange; secure with

sheetmetal screws.

Figure 10 - T op V iew showing Discharge Duct

Connection Dimensions (inches)

A

The cut edges of the metal will be sharp.

If installing an optional filter or filter/mixing cabinet shipped with the

heater, attach the cabinet at the "cutout" opening (See Optional Accessories, Paragraph 18 or 19). Depending on the cabinet and how it is

installed, the inlet opening may be horizontal or vertical.

Attach the ductwork to the heater or to the inlet cabinet.

Figure 12 - Duct Opening for Connecting the Inlet Air

Duct to the field-installed Filter or Mixing Cabinet

Depending on the heater size and whether the cabinet is on the side

or the rear, the inlet opening may be either vertical (on the top of the

filter cabinet) or horizontal (on the side of the filter cabinet.)

Filter Cabinet Inlet Opening

150, 200 - Rear or Side Filter Cabinet - 32 (813mm)

250, 300 - Side Filter Cabinet - 32 (313mm)

250, 300 - Rear Filter Cabinet - 45-1/8 (1146mm)

350, 400 - Rear or Side Filter Cabinet = 45-1/8 (1146mm)

16

(406mm)

Inlet

Opening

B

Combustion Air Knockout

Venter Outlet

2-3/8 (60mm)

Electrical

Gas

4-1/8

(105mm)

6-3/8

(162mm)

Size 150, 200 250, 300 350, 400

A 36" (914mm) 48" (1219mm) 48" (1219mm)

B 21" (533mm) 21" (533mm) 34" (864mm)

Figure 1 1 - Connecting Discharge Ductwork

Removable

Access Panel in

the Ductwork 6" x 10"

(152mm x

254mm)

minimum

Attach to Duct

Flange

Heater

Inlet Air Ductwork - The location of the inlet air duct connection

depends on the installation. Corner indicators for the opening are provided on the right side, the left side, and the rear of the heater. (See

Dimensions in Figure 1, page 3.) Determine where the inlet air opening(s)

should be and cut out using tin snips or aviation shears. CAUTION:

Form 405, Page 12

Requirements and Suggestions for Connecting

and Installing Ducts

• Type of Ductwork - The type of duct installation to be used de-

pends in part on the type of construction of the building.

• Ductwork Material - Rectangular duct should be constructed of

not lighter than No. 26 U.S. gauge galvanized iron or No. 24 B & S

gauge aluminum.

• Ductwork Structure - All duct sections 24 inches or wider, and

over 48 inches in length, should be cross broken on top and bottom

and should have standing seams or angle-iron braces. Joints should

be S and drive strip, or locked.

• Through Masonry Walls - No warm air duct should come in con-

tact with masonry walls. Insulate around all air duct through masonry walls with not less than 1/2" (1" is recommended) of insulation.

• Through Unheated Space - Insulate all exposed warm air ducts

passing through an unheated space with at least 1/2" (1" is recommended) of insulation.

• Duct Supports - Suspend all ducts securely from buildings mem-

bers. Do not support ducts from unit duct connections.

• Duct Sizing - Proper sizing of the supply air ductwork is neces-

sary to ensure a satisfactory heating installation. The recognized

authority for such information is the Air Conditioning Contractors

Association, 1228 17th Street N.W., Washington, D.C. 20036. A

manual covering duct sizing in detail may be purchased directly

from them.

CAUTION: An external duct system static pressure

not within the limits shown on the rating plate, or

improper motor pulley or belt adjustment, may

overload the motor. See Hazard Levels, page 2.

• Removable Panels - The ducts should have removable access pan-

els on both upstream and downstream sides of the furnace. These

openings must be accessible when the furnace is in service and

should be a minimum of 6" x 10" in size so smoke or reflected light

may be observed inside the casing to indicate the presence of leaks

in the heat exchanger. The covers for the openings must be attached

in such a manner as to prevent leakage. See Figure 11.

Page 13

9. Gas Piping and Pressures

From Gas Supply

From

Gas

Supply

6 Drip Leg

NOTE:

Connections

shown are by

the installer.

To Controls

Manual

Gas Valve

Immediately upstream of the gas

supply connection, install a manual

shutoff valve with a 1/8 NPT

plugged tap accessible for test

gauge connection.

Ground Joint Union

WARNING: This appliance is equipped for a

maximum gas supply pressure of 1/2 pound, 8

ounces, or 14 inches water column. Supply

pressure higher than 1/2 pound requires

installation of an additional lockup-type service

regulator external to the unit.

PRESSURE TESTING SUPPL Y PIPING

T est Pr essures Above 1/2 PSI: Disconnect the heater and manual

valve from the gas supply line which is to be tested. Cap or plug the

supply line.

Test Pressures Below 1/2 PSI: Before testing, close the manual

valve on the heater.

All piping must be in accordance with requirements outlined in the

National Fuel Gas Code ANSI Z223.1a (latest edition) or CAN/CGAB149.1 and B149.2 (See Paragraph 1). Gas supply piping installation

should conform with good practice and with local codes.

Unit heaters are orificed for operation with natural gas having a heating

value of 1000 (± 50) BTUH per cubic ft or propane gas with a heating

value of 2550 BTUH per cubic ft. If the gas at the installation site does

not meet these specifications, consult the factory for proper orificing.

Pipe joint compounds (pipe dope) shall be resistant to the action

of liquefied petroleum gas or any other chemical constituents of

the gas being supplied.

Install a ground joint union and manual shutoff valve upstream of the

unit control system as shown in Figure 13. The 1/8" plugged tapping in

the shutoff valve provides connection for a supply line pressure test

gauge. The National Fuel Gas Code requires the installation of a trap

with a minimum 3" drip leg. Local codes may require a minimum drip

leg longer than 3" (typically 6"). Bleed gas lines of trapped air.

Gas connection is either 1/2" or 3/4" depending on size and type of gas.

Size Gas Gas Connection

150-200 Natural 1/2"

250-400 Natural 3/4"

150-400 Propane 1/2"

Leak-test all connections by brushing on a leak-detecting solution.

Figure 13 Supply Piping

Connection

WARNING: All components of a gas supply

system must be leak tested prior to placing

equipment in service. NEVER TEST FOR

LEAKS WITH AN OPEN FLAME. Failure to

comply could result in personal injury , property

damage or death.

Manifold or Orifice Pressure Settings

Measuring manifold gas pressure cannot be done until the heater is in

operation. It is included in the steps of the "Check-Test-Start" procedure in Paragraph 22. The following warnings and instructions apply.

WARNING: Manifold gas pressure must never

exceed 3.5" w.c. for natural gas or 10" w.c. for

propane gas.

For Natural Gas: Manifold gas pressure is regulated by the combina-

tion valve to 3.5" w .c. Inlet pressure to the valve must be a minimum of

5" w.c. or as noted on the rating plate and a maximum of 14" w.c.

For Propane Gas: Manifold gas pressure is regulated by the combination valve to 10" w.c. Inlet pressure to the valve must be a minimum of

11" w .c. and a maximum of 14" w.c.

Before attempting to measure or adjust manifold gas pressure, the inlet

Sizing a Gas Supply Line

Length Diameter of Pipe

of 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

Pipe Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane

20’ 92 56 190 116 350 214 730 445 1100 671 2100 1281

30’ 73 45 152 93 285 174 590 360 890 543 1650 1007

40’ 63 38 130 79 245 149 500 305 760 464 1450 885

50’ 56 34 115 70 215 131 440 268 670 409 1270 775

60’ 50 31 105 64 195 119 400 244 610 372 1105 674

70’ 46 28 96 59 180 110 370 226 560 342 1050 641

80’ 43 26 90 55 170 104 350 214 530 323 990 604

90’ 40 24 84 51 160 98 320 195 490 299 930 567

100’ 38 23 79 48 150 92 305 186 460 281 870 531

125’ 34 21 72 44 130 79 275 168 410 250 780 476

150’ 31 19 64 39 120 73 250 153 380 232 710 433

175’ 28 17 59 36 110 67 225 137 350 214 650 397

200’ 26 16 55 34 100 61 210 128 320 195 610 372

Note: When sizing supply lines, consider pos sibilities of future expans ion and increased requirements.

Capacity of Piping

Specific Gravity for Natural Gas -- 0.6 (Natural Gas -- 1000 BTU/Cubic Ft)

Specific Gravity for Propane Gas -- 1.6 (Propane Gas -- 2550 BTU/Cubic Ft)

Refer to National Fuel Gas Code for additional information on line sizing.

- Cubic Feet p er Hour based on 0.3" w.c. Pressure Drop

Mfg No. 164771, Page 13

Page 14

9. Gas Piping and

Pressures (cont'd)

Manifold Pressure Settings (cont'd)

(supply) pressure must be within the specified range for the

gas being used both when the heater is in operation and on

standby. Incorrect inlet pressure could cause excessive manifold gas pressure immediately or at some future time.

Instructions to Check Manifold

Pressure (when unit is operating):

1) With the manual valve positioned to prevent flow to the

main burners, connect a manometer to the 1/8" pipe outlet

pressure tap in the valve. NOTE: A manometer (fluid-filled

gauge) is recommended rather than a spring type gauge due

to the difficulty of maintaining calibration of a spring type

gauge.

2) Open the valve and operate the heater. Measure the gas

pressure to the manifold. Normally adjustments should not

be necessary to the factory preset regulator.

If adjustment is necessary, set pressure to correct settings

by turning the regulator screw IN (clockwise) to increase

pressure. Turn regulator screw OUT (counterclockwise) to

decrease pressure.

10. Burner Condensate

Drain

If an optional cooling coil is installed on a Model CAUA

heater (either now or at a later time), a burner condensate

drain line must be installed.

The following parts to install the drain line are packaged and

shipped with all Model CAUA heaters.

Qty P/N Description

1 165955 6-ft length of 3/8" I.D. Tubing

1 165952 90° Nylon Fitting, 1/4" NPT x 3/8"

tubing

1 110628 1/4" NPT Brass Nut

1 171527 1/4" Locknut, Hex, T& B 139

1 165953 Sealing Washer

2 20913 Nylon Wire Ties, T&B #TY-24M

1 87556 Snap Bushing, Heyco SB 625-8

Instructions for Installing the Burner

Condensate Drain (Figure 14)

1. Remove the burner compartment door.

2. The burner box cover is in two sections. On the left side

of the burner box cover, disconnect the flame sensor wire

and the flame rollout switch wires. Disconnect the silicone tubing from the static tap. Remove the left section

of the burner box cover.

3. Determine which side of the cabinet will be most conve-

nient for the drain line. Remove the hole plug on that side

and insert the snap bushing from the package.

4. Locate the hole in the bottom center of the burner pan

and remove the plug. Follow the instructions in Figure 14

to install the drain. Complete all steps as listed in the

illustration.

When installation of the burner condensate drain is com-

plete, re-assemble the heater.

Figure 14 - Burner Condensate Drain Connection

!!

! Hex Locknut (silver)

1

2

3

4

1) Assemble the brass nut, the sealing washer, and the 90° fitting.

2) Position the threaded fitting up through the hole so that the hose barb is

toward the bushing in the side of the cabinet. Attach using the silver-colored

locknut.

3) Under the burner, push the tubing onto the hose barb, being sure that it is

secure. Maintaining a downward slope, extend the hose out through the

cabinet side.

4) Just after exiting the cabinet, create a trap in the line by making a loop in

the hose. Secure the loop with the wire ties.

5) Continue downward with the tubing, connecting it into the coil drain pipe.

!!

—Burner Bottom Pan—

""

" Sealing Washer

""

##

# Brass Nut

##

$$

$ 90° Nylon Fitting

$$

1 1. Electrical Supply and Connections

All electrical wiring and connections, including electrical grounding, MUST be

made in accordance with the National Electric Code ANSI/NFPA No. 70 (latest

edition) or, in Canada, the Canadian Electrical Code, Part I-C.S.A. Standard C22.1.

In addition, the installer should be aware of and comply with any local ordinances

or gas company requirements.

Check the rating plate on the heater for the supply voltage and current requirements. A separate line voltage supply with fused disconnect switch should be run

directly from the main electrical panel to the heater. All external wiring must be

within approved conduit and have a minimum temperature rise rating of 60°C.

Conduit from the disconnect switch must be run so as not to interfere with the

service panels of the heater.

The electrical supply and control wiring enter at the top of the heater (See Figure

1, page 3) and connect to the terminal strip behind the gas valve (See Figure 15).

Consult the wiring diagram supplied with your heater. T ypical wiring diagrams are

on pages 17 and 18.

CAUTION: If any of the original wire as supplied with the

appliance must be replaced, it must be replaced with wiring

material having a temperature rating of at least 105°C,

except for sensor lead wires which must be 150°C. See

Hazard Levels, page 2.

12. Thermostat and Connections

A thermostat is not standard equipment but is an installation requirement. Use

either an optional thermostat available with the heater or a field-supplied 24-volt

thermostat. Install according to the thermostat manufacturer's instructions. Control wiring enters on the right side of the heater and connects to the terminal strip

in the control compartment; see Figure 15.

Make sure that the heat anticipator setting on the thermostat is in accordance with

the amperage value noted on the wiring diagram of your heater.

W ARNING: If you turn off the power supply , turn off the

gas. See Hazard Levels, page 2.

Form 405, Page 14

Page 15

Pressure Switch

Transformer

Terminal Strip

Venter

Ignition Control

Module

Gas

Valve

Contactors

Figure 15 - Control

Locations

Limit Control

Supply Wiring Terminal Block

(behind the gas valve)

(Line voltage enters the control

compartment through a hole in

the top of the heater cabinet.)

Thermostat

Terminal Strip

(Thermostat wires enter

the control compartment

through a hole in the right

side of the heater cabinet.)

13. Combustion Air Proving

Switch

The combustion air proving switch is a pressure sensitive switch

that monitors air pressure to ensure that proper combustion air is

available.

The switch is single pole/double throw with the normally open

contacts closing when the proper airflow is sensed in the system.

On start-up when the heater is cold, the sensing pressure is at the

most negative level, and as the heater and flue system warm up, the

sensing pressure becomes less negative. After the system has reached

equilibrium (about 20 minutes), the sensing pressure levels off.

If a restriction or excessive flue length or turns cause the sensing

pressure to be outside the switch setpoint, the pressure switch will

function to shut off the main burners. The main burners will remain

off until the system has cooled and/or the flue system resistance is

reduced. The table below lists the approximate water column negative pressure readings and switch setpoints for sea level operating

conditions.

Model Start-Up Equilibrium Set Point Set Point

Size Cold “OFF”“ON”

150 1.45 1.05 .75 .90

200 1.50 1.05 .75 .90

250 1.55 1.10 .75 .90

300 1.60 1.15 .75 .90

350 1.30 1.05 .75 .90

400 1.20 1.00 .75 .90

DANGER: Safe operation of this unit requires

proper venting flow. NEVER bypass the combustion air proving switch or attempt to operate

the unit without the venter running and the

proper flow in the vent system. Hazardous

conditions could result. See Hazard Levels, page

2.

14. Blower Motor and Drive

Model CAUA units are equipped with either direct drive motor(s) and

blower(s) or adjustable belt-drive blower(s) and motor.

Direct Drive

All direct drive blower motors are 1 horsepower. Sizes 150-200 have a

single motor. Size 150 has a 12-9 blower; Size 200 has a 12-12 blower.

Sizes 250-400 have dual motors with dual 12-9 blowers.

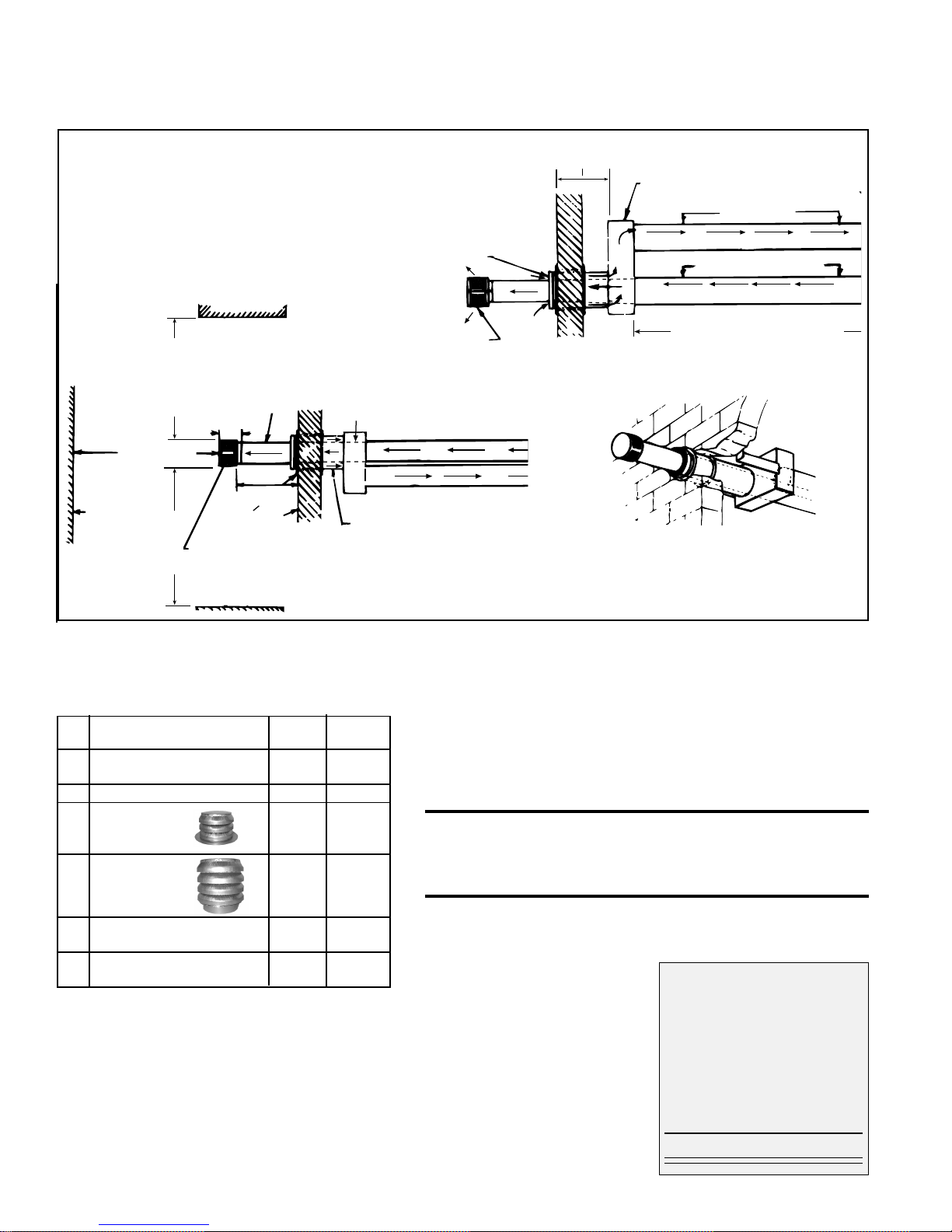

Belt Drive

The motor horsepower on a belt drive unit is whatever was specified on

the order ranging in size from 1/4 HP to 5 HP . Check the heater rating plate

and the motor rating plate.

As part of the start-up procedure, check belt tension. Proper belt tension

is important to the long life of the belt and motor. A loose belt will cause

wear and slippage. Too much tension will cause excessive motor and blower

bearing wear. Adjust the belt tension by turning the adjusting screw on the

motor base until the belt can be depressed 3/4". (See Figure 16.) After

correct tension is achieved, re-tighten the locknut on the adjustment screw.

Be sure that the belt is aligned in the pulleys.

Figure 16 Check Belt

Tension

Most blower motors are equipped with thermal overload protection of the

automatic, reset type. If the motor is not equipped with thermal overload

protection, the unit will be equipped with a starter. The adjustable setting

on the starter will be factory set to match the amp draw of the motor and

sealed. No change should be made to the starter setting unless the original

motor is replaced. Starters are equipped with a manual reset. If an overload

condition is experienced, the condition must be corrected and the starter

must be manually reset.

After the installation is complete including all ductwork, the amp draw of