Page 1

BPI42CR and BPI42300CR

Battery Operated Hydraulic Crimping Tool

Operating Instruction Manual

IMPORTANT: Read and understand all of the instructions and safety information

in this manual before operating or servicing this tool.

Table of Contents

1.0 General Characteristics . . . . . . . . . . . . . . . . . . 2

2.0 Instructions for Use . . . . . . . . . . . . . . . . . . . . 3

3.0 Battery and Charger Use . . . . . . . . . . . . . . . . . 4-5

4.0 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 5

5.0 Spare Parts List . . . . . . . . . . . . . . . . . . . . . . 6

5.1 Table 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2 Table 2 . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TA04492 C Page 1 of 8

Page 2

1.0

GENERAL CHARACTERISTICS

WARNING

1. BEFORE USING THE TOOL, CAREFULLY READ

INSTRUCTIONS IN THIS MANUAL.

2. WHEN OPERATING THE TOOL NEVER PLACE HANDS OR

OTHER BODY PARTS BETWEEN THE CRIMPING DIES.

3. DO NOT USE IN WATER OR IN THE RAIN.

4. ALWAYS ENSURE CORRECT LATCHING AND SECURITY

OF THE TOOL HEAD.

5. DO NOT SHORT CIRCUIT THE BATTERY TERMINALS.

6. ALWAYS RECYCLE THE BATTERIES.

7. DO NOT DISCARD BATTERIES INTO DOMESTIC REFUSE

OR WASTE DISPOSAL.

Ni-MH

3

1.1

BATTERY OPERATED

HYDRAULIC CRIMPING TOOL

This “BPI42CR” hydraulic tool is powered by 9.6 V DC

Ni-MH battery. The tool is well balanced for optimum

control, quiet operation, very little vibration and

lightweight construction enabling the operator to hold the

tool in one hand while positioning the connector with the

other hand. It is equipped with an automatic system that

opens the dies once the crimping operation is completed.

The residual battery capacity level is automatically

displayed after every cycle

BPI42CR includes the following:

• Battery • Wrist Strap • Spare Battery

• Battery Charger • Carrying Case

.

5 6 71 2 4 4

1.3

(Directive 2006/42/EC, annexe 1, point 1.7.4.2 letter u)

The weighted continuous acoustic pressure level

equivalent

A at the work place LPA is equal to............66.8 dB (A

The maximum value of the weighted acoustic

displacement pressure

C at the work place L

The acoustic power level emitted by the machine

LWA is equal to...............................................75 dB (A)

1.4

(Directive 2006/42/EC, annexe 1, point 2.2.1.1)

Tests performed in compliance with UNI ENV 25349

and UNI EN 28663 part 1st Standards, and under

operating conditions more severe than normal,

certify that the weighted root mean square in

frequency of the acceleration the upper limbs are

exposed to for each biodynamic reference axis does

not exceed 2.5 m/sec

1.5

27

ACOUSTIC NOISE

is....................<130 dB (C)

pCPeak

RISK DUE TO VIBRATION

2

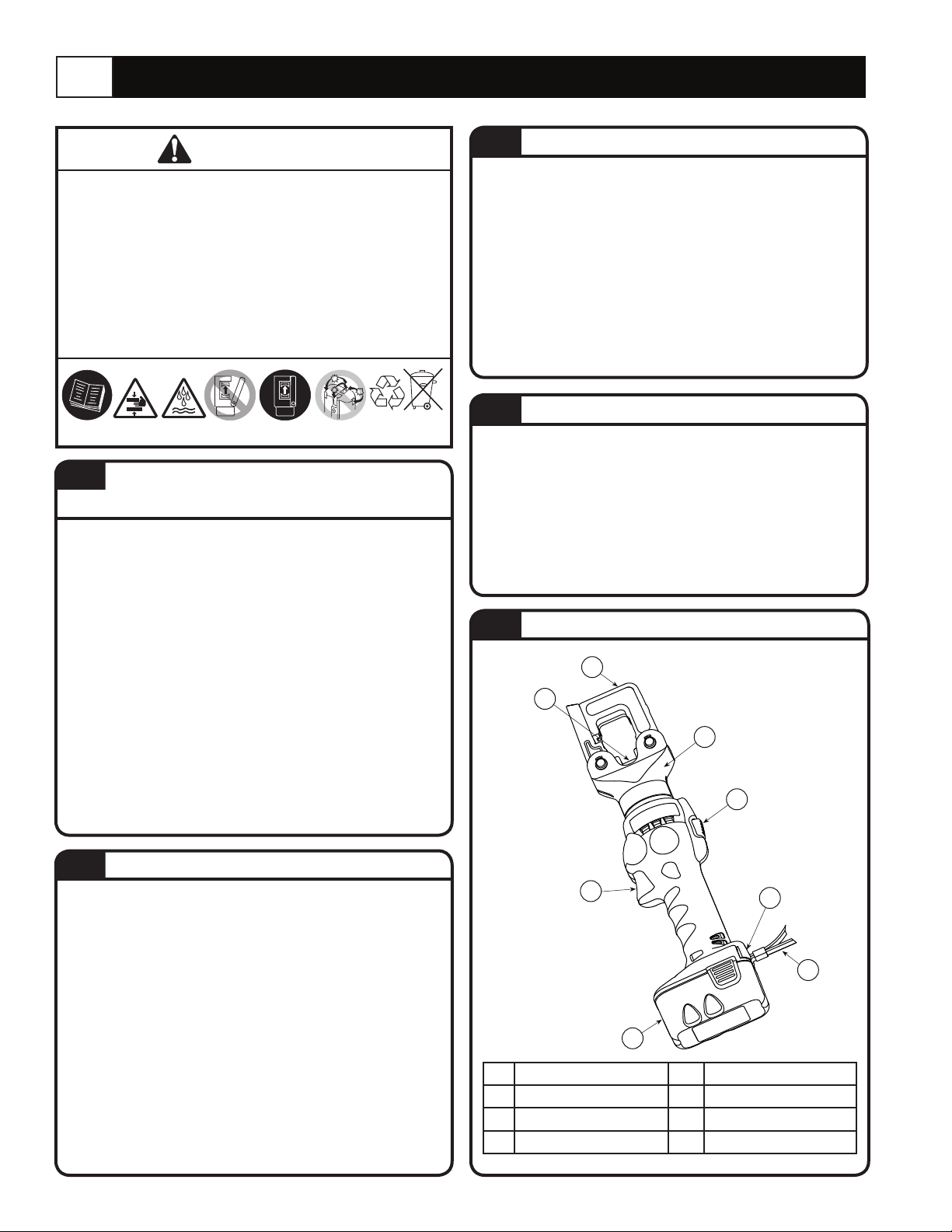

OVERALL VIEW

24

600

)

BPI42300CR includes the following:

• Battery • Wrist Strap • Spare Battery

• Battery Charger • Carrying Case • Die Set

1.2

Suitable for installing electric compression connectors

for conductors from 8 AWG up to 300 Cu, 4/0 AL.

Crimping Force Nominal.............................4 Tons

Rated Operating Pressure..........................5600 psi

Dimensions:

Length..............................................................14.6”

Width..................................................................4.2”

Height.................................................................2.6”

Weight (with battery).....................................5.3 lbs

Motor...........................................................9.6V DC

Battery - direct current..........9.6 V - 2.0 Ah Ni-MH

Oil Recommended..................AGIP ARNICA 22 or

SHELL TELLUS TX22 or equivalent

Safety...............the tool is provided with a

maximum pressure relief safety valve.

TA04492 C Page 2 of 8

APPLICATION RANGE

Fig. 1

Operating Button

3

Wrist Strap

13

Battery Condition Display

11

Battery

2

8

3

2

Pressure Release Button

8

Upper Die Support

24

Lower Die Support

27

Head Complete

600

11

See 3.1

(Fig. 4)

13

Page 3

2.0

INSTRUCTIONS FOR USE

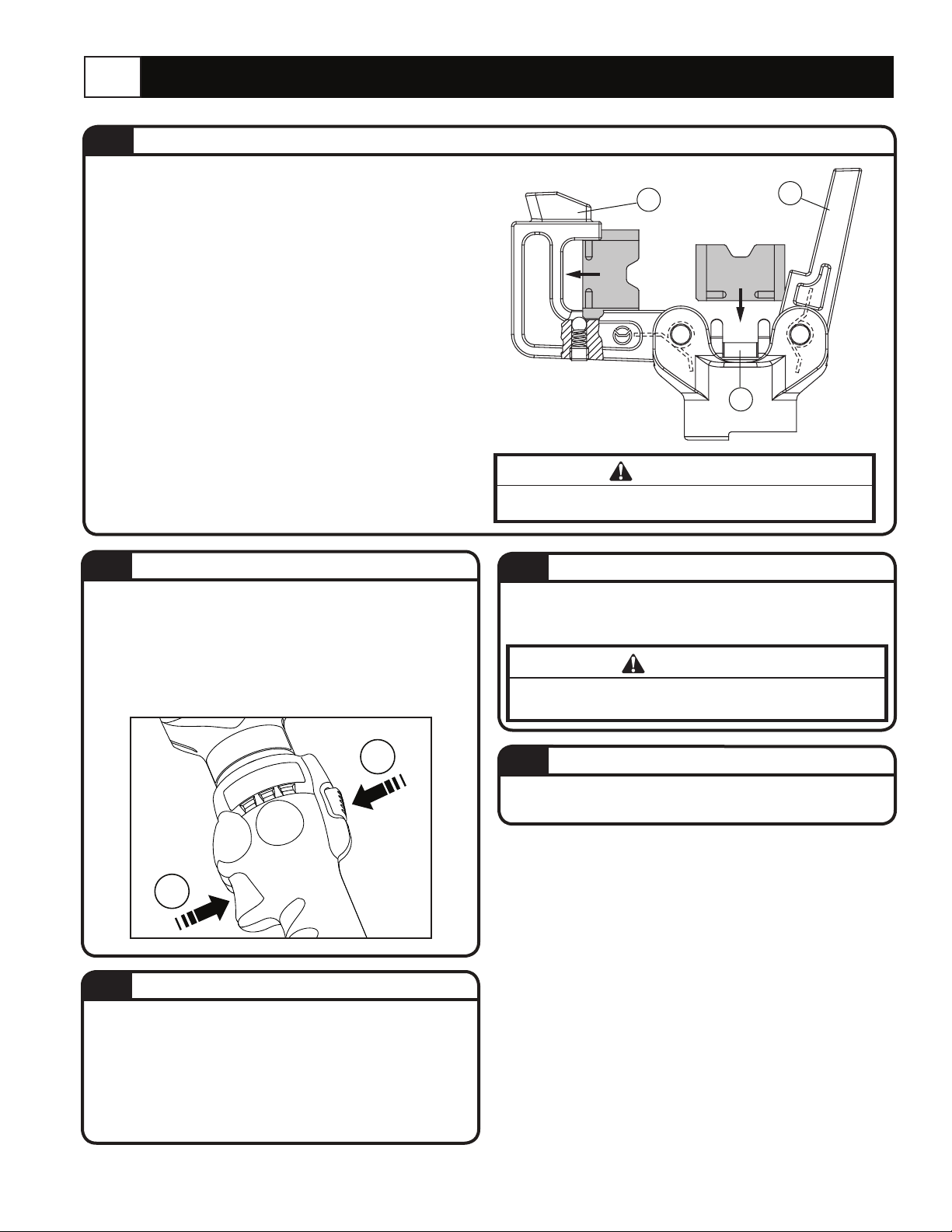

2.1

The tool is supplied with the batteries completely discharged;

before use, fully charge the batteries using the charger supplied.

See section 3.0

The tool can be easily carried using either the handle or wrist

strap, see Fig. 1.

With the tool at rest, proceed as follows:

• Select the appropriate die set for the connector. (Ref: Check

Thomas & Betts instruction sheet for the connector and make

sure color code of die matches color code of connector.)

• Open the latch (25) and release the upper die holder (24).

• Insert one die into the upper die holder (24) and one die into

the lower die support (27).

• Close the latch (25).

• Insert the conductor in the connector.

• Position the connector between the dies and ensure the

correct location of the crimp. (See connector(s) instruction

sheet for number of crimps.)

Ensure that the latch and upper die holder are fully

secured, otherwise damage may occur during tool

operation.

2.2

Make sure the dies are exactly positioned on desired

crimp point, otherwise reopen dies following instructions

as per Step 2.5 and reposition the connector.

DIE ADVANCEMENT (Refer to Fig. 3)

• Press the operating button (3) to activate the motor-

pump and advance the lower die. To halt the

advancement, release the operating button (3) and the

motor will stop.

PREPARATION (Refer to Figs. 1, 2 & 3)

24

27

25

Fig. 2

WARNING

When operating the tool never place hands or other body

2.4

• For ease of operation, the tool head can be rotated

through 180º, allowing the operator to work in the most

comfortable position.

parts between the crimping dies.

HEAD ROTATION

WARNING

Do not attempt to rotate the head when the hydraulic

circuit is pressurized.

8

3

Fig. 3

2.3

• Continue pressing the operating button (3), the ram will

• Continue tool operation until the maximum pressure

• The dies will automatically open until the ram is fully

COMPRESSION (Refer to Fig. 3)

gradually move forward until the two dies touch.

relief valve is activated and a “click” is heard.

retracted. To interrupt automatic retraction of the ram,

quickly press the operating button (3).

2.5

RELEASE OF DIES (Refer to Fig. 3)

• By pressing the pressure release button (8) , the ram will

retract and open the dies.

TA04492 C Page 3 of 8

Page 4

3.0

BATTERY AND CHARGER USE

The tool is supplied with the batteries completely discharged; before use, fully charge the batteries using the charger supplied.

(Refer to Fig. 4)

3.1

BATTERY STATUS

• After releasing the operating button, the residual

battery capacity is automatically displayed for 5

seconds on the indicator (11).

The number of LEDs illuminated indicates the residual

capacity:

LEDs

11

6 LEDs illuminated: Fully Charged

3 LEDs illuminated: 50% capacity

1 LED illuminated: Minimum charge

To replace the battery, press the two red buttons at the

same time and slide the battery forward.

3.2

GENERAL BATTERY & CHARGER USE

Fig. 4

This tool is supplied with a battery charger CFC 120Y and adapter CBA96-144,

which is required for 9.6V batteries (CB9620H). With the adapter removed, the

same charger may be used with the 14.4 V Batteries common to other Thomas &

Betts battery operated tools.

For optimum battery life, please follow the rules:

• Use the battery until the automatic residual energy display still has 1-2 red

LEDs showing: this means the battery is almost completely discharged

and no loss in the life of the battery has been produced. This is particularly

important when charging a new battery the rst 2-3 times in order to

maximize the available energy level.

• Allow the battery to cool down to ambient temperature prior to recharging.

• Rest the battery charger for at least 15 minutes between charges.

Back of Tool

CHARGER SPECIFICATIONS

Input Voltage 100-120V~50-60Hz

Output Voltage 7.2-14.4V

Charging Current 2.4A

Trickle Charge 60mA

Weight 1.1 lbs.

BATTERY

ADAPTER

Fig. 5

3.3

•

OPERATING LOCATIONS The chargers are designed for use in dry areas. All ventilation slots must be kept unobstructed. If

possible, keep away from heat sources and out of direct sunlight as ambient temperatures in excess of 35°C may increase

charging times considerably.

•

AC SUPPLY CONNECTION Before connecting the charger, check that the AC-supply voltage and frequency are the same

as those indicated on the charger. The charger is ready for operation when the power cord is connected to the live AC

supply.

•

PUTTING INTO SERVICE AND OPERATION Left-hand, red LED If the charger is connected to the AC supply and the left

hand LED goes red, the charger is OK. If the left-hand LED is red and flashing the charger has a fault. Further charging is

not possible.

•

CHARGING PROCEDURE (See table on the right.)

The battery charger checks the voltage, temperature,

short-circuit and polarity of the batteries before charging.

The safety elements (bi-metal strip or NTC resistor) are

checked via the temperature contact.

If the safety elements are OK, the right-hand LED goes

green and the charging procedure commences.

Charging state detection is a special feature of this charging

method. If the right-hand led remains switched off, the

internal circuit of the battery either is open or there is a

condition of polarity inversion. (Continued on next page)

BATTERY CHARGER OPERATION

LED, left-hand, red

Red LED on

Red LED ashing

LED, right-hand, multi-coloured

Green LED on

Green LED ashing

Red/green LED ashing

Red LED on

Red LED ashing

Charger is connected to the supply

and ready for operation

Charger is defective

Charging started

100%

Battery is full charged

The power supply is less than 10,5 V

(only for CFC12-24IC)

Battery is defective

Battery is too hot or too cold

TA04492 C Page 4 of 8

Page 5

(Continued)

Green flashing (right-hand LED): The battery is fully charged and the charger automatically switches over to the trickle-

charge mode. The battery can be left indefinitely in the charger without sustaining any damage. Overcharging is impossible.

Red flashing (right-hand LED): The safety elements are defective or the battery is too hot or too cold. The battery should be

removed from the charger so that it can return to its proper temperature range.

Continuous red (right-hand LED): The battery is defective.

•

CHARGING TIMES The following table lists the various charging times (the charging time depends on the depth of

discharge). A new or seldom used battery will achieve full power after 5 charge/discharge cycles.

Battery Type

Nominal capacity (Ah)

NI-Cd 2.0 55 min

NI-MH (CB9620H)* 2.0 55 min

NI-MH (CB9630H)* 3.0 85 min

NI-MH 3.0 85 min

* To charge these batteries use the CBA96-144 adapter (Refer to Fig. 5)

•

WARNING

The left-hand LED flashes red to indicate a charger fault.

A charger malfunction has occurred and it is not possible to continue charging.

Do not use the charger to charge other batteries.

If batteries are new or have not been used for some time, it is quite likely that they will not reach their nominal capacity. This

is not a fault and is normal under these circumstances.

Full capacity will be reached after about the 5 charge/discharge cycles.

The charger monitors the battery-pack temperature. Batteries with temperatures above 65°C or below 5°C will not be

charged.

The charger is designed to charge both Ni-Cd and Ni-MH batteries: with Ni-MH batteries a more noticeable heating of the

cells will occur. This is not a fault.

4.0

The tool is completely sealed, and requires very little daily maintenance. Compliance with the following

recommendations, should help to maintain the optimum performance of the tool:

Maximum Charging Time

CFC120V

MAINTENANCE

4.1

Dust, sand and dirt are a danger for any hydraulic device.

After every use, the tool must be wiped with a clean cloth

taking care to remove any residue, especially close to

moveable parts.

4.2

When not in use, the tool should be stored and transported

in the plastic case to prevent damage. This case is suitable

for storing the tool, the accessories, and die sets.

Plastic Case: size 18.3x12.4x4.56 inches, (465x315x116 mm)

weighs 3.3lbs. (1,5 kg).

THOROUGH CLEANING

STORAGE

(Refer to Fig 6)

Fig. 6

TA04492 C Page 5 of 8

Page 6

5.0

SPARE PARTS LIST

When ordering spare parts always specify the following:

• Code number of item

• Name of item

• Type of tool

• Tool serial number

Warranty is void if replaced parts are not Thomas & Betts original replacement parts.

TA04492 C Page 6 of 8

For parts or service, contact the tool service center at 1-800-284-TOOL (8665).

Page 7

5.1

TABLE 1

15

16

See TABLE 2

10

17

12

1

3

9

8

5

6

13

2

7

11

XXXXXX

4

Serial number of tool

Code Nº

6000577 1 – – Right+Left Shell 1

2598498 2 – – Battery 1

6000579 3 – – Operating Button 1

6000584 4 – – Protection 1

6000591 5 – – Rod 1

6000593 6 – – Spring 1

6000580 7 – – Contact 1

6000581 8 – – Pres. Release Button 1

6000582 9 – – Button Reinforcement 1

6000301 10 – – Mechanical Group 1

6000586 11 – – Compl. Electr. Circit 1

6900650 12 – – Screw 6

6000589 13 – – Wrist Strap 1

Main 1st Sub 2nd Sub

ITEMS

DESCRIPTION QTY

6232220 15 – – Label TA03948 1

6232558 16 – – Label TA04490 1

6232500 17 – – Label T.G. 0704 1

For parts or service, contact the tool service center at 1-800-284-TOOL (8665).

WARRANTY: Thomas & Betts sells this product with the understanding that the user will perform all necessary tests to determine the suitability of this product for the user’s intended

application. Thomas & Betts warrants that this product will be free from defects in materials and workmanship for the period stated on the enclosed warranty card. Upon prompt notication

of any warranted defect, Thomas & Betts will, at its option, repair or replace the defective product or refund the purchase price. Proof of purchase is required. Misuse or unauthorized

modication of the product voids all warranties.

Limitations and Exclusions: THE ABOVE WARRANTY IS THE SOLE WARRANTY CONCERNING THIS PRODUCT, AND IS IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY DISCLAIMED.

LIABILITY FOR BREACH OF THE ABOVE WARRANTY IS LIMITED TO COST OF REPAIR OR REPLACEMENT OF THE PRODUCT, AND UNDER NO CIRCUMSTANCES WILL THOMAS

& BETTS BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

TA04492 C Page 7 of 8

Page 8

5.2

TABLE 2

16

4

15

3

4

65

320

67

16

350

600

25

26

24

23

22

67

28

21

58

20

64

65

66

360

71

27

59

1

69

68

2

1

72

75

70

42

34

24

26

31

18

19

30

27

17

310

62

77

63

45

18

4

19

18

10

8

6

57

500

57

17

9

11

210

9

8

7

11

220

21

400

15

17

100

1

250

16

20

15

300

Code Nº

6040240 4 – – Back-up Ring 1

6360300 15 – – O-Ring 1

6620490 16 – – Ram 1

6520030 17 – – Spring 1

6040556 18 – – Ram Guide Ring 1

6780252 27 – – Die Support 1

6900629 28 – – Screw 1

6900013 34 – – Screw 1

6362020 57 – – Seal 1

6520382 59 – – Spring 2

Main 1st Sub 2nd Sub

6000233 100 – –

6000357 100 1 – Housing 1

6000358 100 4 – Gear 1

6760004 100 8 – Pin 3

6900008 100 9 – Screw 2

6000849 100 10 – Washer 2

6740020 100 11 – Ball 2

6000363 100 15 – Gear 3

6402009 100 16 – Bearing 1

6402006 100 17 – Washer 1

ITEMS

DESCRIPTION QTY

Actuating Mechanical Group

6000328 100 18 – Washer 1

6760012 100 19 – Pin 2

6000315 100 20 – Spacer 3

6000231 100 210 – Complete Disc 1

6000229 100 210 6 Disc 1

6000227 100 210 7 Ball Support 1

6700080 100 210 8 Circlip 1

6650136 100 210 9 Washer 1

6000232 100 220 – Complete Cam 1

6000595 100 250 – Complete Motor 1

6000662 300 – – Hydraulic Group 1

6000560 300 15 – Ring 1

6720072 300 16 – Reservoir 1

6300027 300 17 – Valve Piston 1

6000561 300 18 – Grub Screw 1

6520232 300 19 – Spring 1

6620378 300 21 – Pumping Ram 1

6000563 300 24 – Valve Rod 1

6000575 300 26 – Spring Support 1

6000565 300 27 – Cap 1

Code Nº

6641027 300 30 – Washer 1

6000567 300 31 – Lockout 1

6000603 300 45 – Pressure Release Lever 1

6000570 300 57 – Spring 1

6740100 300 62 – Ball 1

6520160 300 63 – Spring 1

6340590 300 64 – Grub Screw 1

6520200 300 65 – Spring 1

6740120 300 66 – Ball 7/32” 1

3041046 300 67 – Tie 2

6640205 300 68 – Washer 1

1

6900052 300 69 – Screw M4X6 1

6000602 300 70 – Spring 1

6900054 300 71 – Screw M4X6 1

6360022 300 72 – O-Ring 1

6360125 300 75 – O-Ring 1

6641020 300 77 – Washer D6 CU 1

6160081 300 310 – Body 1

6000697 300 320 – Release Group 1

6520240 300 320 1 Spring 1

Main 1st Sub 2nd Sub

ITEMS

DESCRIPTION QTY

6000318 300 320 2 Spring 1

6900021 300 320 3 Screw M3X8 1

6000849 300 320 4 Washer 1

6000608 300 320 65 Spring Support 1

6000596 300 350 – Cap 1

6000588 300 360 – Lever 1

6000601 300 400 – Complete Membrane 1

6900602 300 500 – Suction Screw 1

6860148 600 – – Complete Head 1

6780163 600 1 – Head Support 1

6560370 600 20 – Pin 2

6520403 600 21 – Spring 1

6340138 600 22 – Grub Screw 1

6520942 600 23 – Spring 1

6780124 600 24 – Die Support 1

6370270 600 25 – Latch 1

6520482 600 26 – Spring 1

6040725 600 42 – Circlip 2

6740020 600 58 – Ball 1

Thomas & Betts Corporation

Memphis, Tennessee

www.tnb.com

TA04492 C Page 8 of 8© 2012 Thomas & Betts. All Rights Reserved.

Loading...

Loading...