Thomas ultra air-pacT-35HD Owner's Manual

1419 ILLINOIS AVE., SHEBOYGAN, WI 53081 USA (920) 457-4891

OWNER'S MANUAL

and

OPERATING INSTRUCTIONS

for

Model

T-35HD

Portable, Oilless Heavy Duty Air Compressor

W0B.L PISTON COMPRESSOR

GENERAL

DESCRIPTION

Performance in tandem with portability makes the Air-Pac

T-35

Ultra

our finest, most convenient tank compressor which is perfect for the

professional and serious do-it-yourselfer. This compressor includes

air storage tank, and an automatic pressure switch control.

SPECIFICATIONS

Voltage

.....................................................................

11

5V,

60Hz

Starting Voltage (min.)

.....................................................

90

V

Fuse Requirements

............................................................

15

A

Safety Valve Setting

..............................

140

PSlG

(965.3

KPa)

Air Displacement

.......................................

4.5

CFM

(127

LPM)

Air Delivery

................................................

2.95

CFM @ 50

PSI

........................................................

(83.54

LPM @ 345

KPa)

................................................................

2.65

CFM @ 80

PSI

........................................................

(75.05

LPM @ 552

KPa)

..............................................................

2.55

CFM @ 100

PSI

.....................................................

(72.22

LPM @ 689.5

KPa)

Amps at Working Pressure

........................................

10 5

A

.....................................

Automatic Control

Starts

@

100

PSlG

.............................................................................

(689.5

KPa)

.................................................................

Stops @ 125

PSlG

.............................................................................

(861.9

KPa)

..........................................................................

Tank Size

3

Gal.

.............................................................

Shipping Weight

48

Ibs.

........................................................................

Cord

6

ft.

(1.83

M)

PSI

=

Pounds Per Square Inch CFM = Cubic Feet Per Minute

KPa = Kilopascals

LPM

=

Liters Per Minute

APPLICATION

Ideal as primary or secondary air source for almost any

operation. Particularly suitable for shops, garages; and

factories where repetitive use demands high reliability.

purchased the compressor.

To place parts orders, provide the model data located

on the nameplate of the compressor and call our

National Parts center at

1-800-323-0620.

GENERAL MAINTENANCE AND SERVICE

A

WARNING:

Read and understand the information in this

owner's manual before operating

air compressor.

1.

The compressor should be located in a dry, clean, and well

ventilated area.

2.

Inspect before use: hose, plug, and cord for signs of damage.

Do not use if a deficiency is found. Contact your nearest service

center for replacement parts. Never operate a damaged unit.

3.

Do not tamper with safety valve as it has been factory set.

Any adjustment with this valve could cause serious injury.

4.

This air compressor needs no lubrication. Applying oil to any

part could result in polluted air delivery to the air-handling

equipment.

5.

Compressed air must never be aimed at anyone because it can

cause serious injury. Keep children away. WEAR EYE

PROTECTION.

6.

All air compressors generate heat even under normal operating

conditions. To avoid serious burns, never touch the air compres

sor during or immediately after operation.

7.

When unit is not in use, wrap cord around compressor and store

in dry place. Do not abuse cord.

8.

Before servicing, cleaning, or removal of any part, shut off power

and relieve pressure from tank.

9.

This system produces

125

PSI. To avoid rupture and injury, do

not operate this pump with components rated less than

125

PSI

working pressure (including but not limited to spray guns, hose

and hose connections without pressure regulator).

If warranty service or repair is needed contact your nearest

authorized service center. If one does not exist contact the

factory. Unauthorized repairs or

teardown of the unit will void

factory warranty.

Part

No.

642143

Rev. H 7/01 01994

Thomas

Industries

Inc.,

Printed in

U.S.A.

All

Rights Resewed

SETUP

Location of Air Compressor

Operate air compressor in a clean, dry and well ventilated area. The

air filter must be kept clear of obstructions which could reduce air

flow to the compressor. The air compressor should be located at

least 12" away from walls or other obstructions that could interfere

with the flow of air.

Extension Cords

To avoid voltage drop and power loss to motor, use additional hose

instead of an extension cord. If an extension cord must be used, use

only a 3-wire extension cord equipped with a 3-blade grounding plug

and a 3-slot receptacle that will accept the plug on the compressor.

Be sure to use an extension cord heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. Make sure the

extension cord is in aood condition.

NOTE: Wire size increases as gauge number decreases.

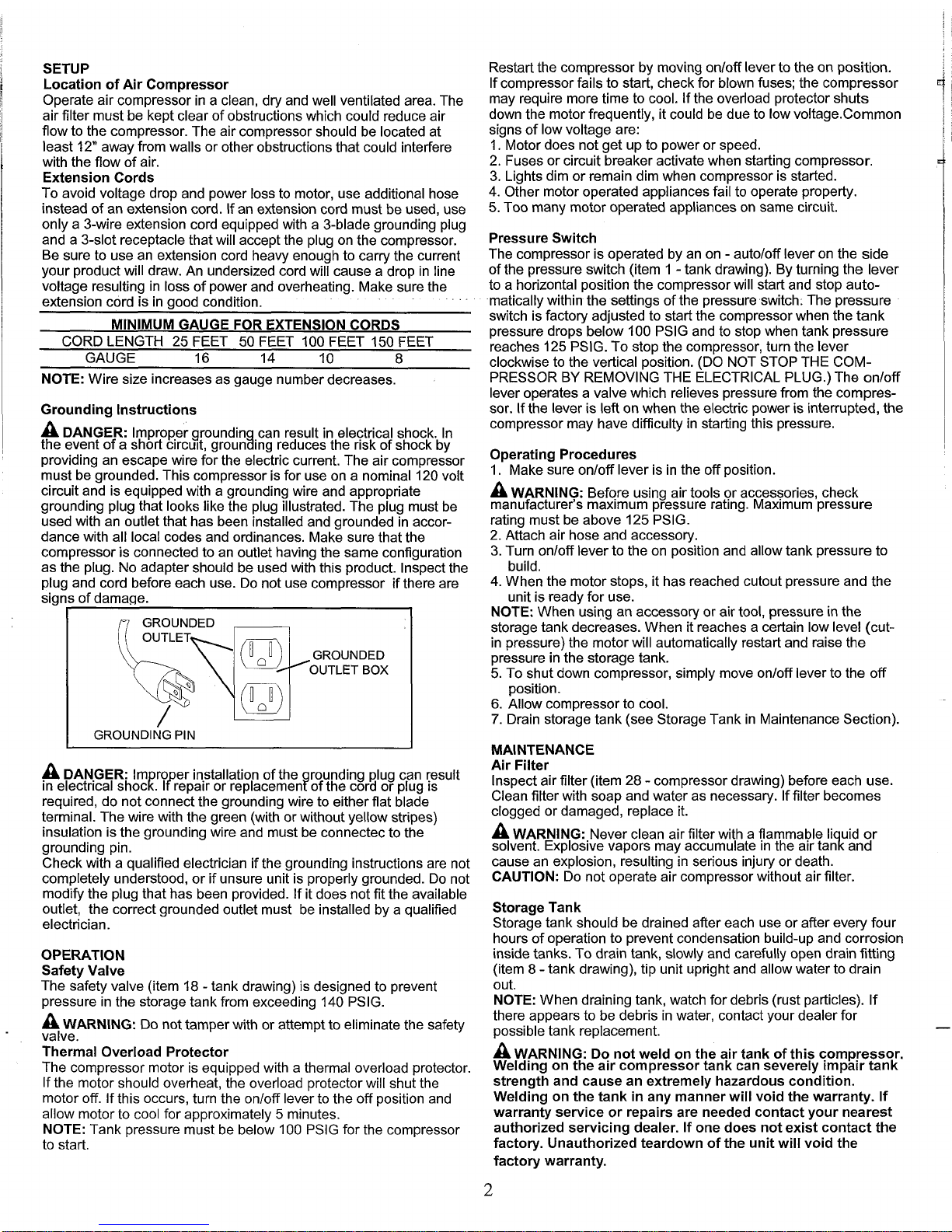

Grounding Instructions

A

DANGER: Improper groundin can result in electrical shock. In

the event of a short circuit,

groun!ing reduces the risk of shock by

providing an escape wire for the electric current. The air compressor

must be grounded. This compressor is for use on a nominal 120 volt

circuit and is equipped with a grounding wire and appropriate

grounding plug that looks like the plug illustrated. The plug must be

used with an outlet that has been installed and grounded in accordance with all local codes and ordinances. Make sure that the

compressor is connected to an outlet having the same configuration

as the plug. No adapter should be used with this product. lnspect the

plug and cord before each use. Do not use compressor if there are

signs of damage.

I

n

GROUNDED

I

/

I

GROUNDING PIN

A

DANGER: Im ro er installation of the rounding plug can result

in electrical shock

l?repair or replacemenfof the cord or plug is

required, do not connect the grounding wire to either flat blade

terminal. The wire with the green (with or without yellow stripes)

insulation is the grounding wire and must be connectec to the

grounding pin.

Check with a qualified electrician if the grounding instructions are not

completely understood, or if unsure unit is properly grounded. Do not

modify the plug that has been provided. If it does not fit the available

outlet, the correct grounded outlet must be installed by a qualified

electrician.

OPERATION

Safety Valve

The safety valve (item 18

-

tank drawing) is designed to prevent

pressure in the storage tank from exceeding 140 PSIG.

A

WARNING: Do not tamper with or attempt to eliminate the safety

-

valve.

Thermal Overload Protector

The compressor motor is equipped with a thermal overload protector.

If the motor should overheat, the overload protector will shut the

motor off. If this occurs, turn the onloff lever to the off position and

allow motor to cool for approximately

5

minutes.

NOTE: Tank pressure must be below 100 PSIG for the compressor

to start.

Restart the compressor by moving onloff lever to the on position.

If compressor fails to start, check for blown fuses; the compressor

may require more time to cool. If the overload protector shuts

down the motor frequently, it could be due to low

voltage.Common

signs of low voltage are:

1. Motor does not get up to power or speed.

2.

Fuses or circuit breaker activate when starting compressor.

3. Lights dim or remain dim when compressor is started.

4. Other motor operated appliances fail to operate property.

5. Too many motor operated appliances on same circuit.

Pressure Switch

The compressor is operated by an on

-

autoloff lever on the side

of the pressure switch (item 1 -tank drawing). By turning the lever

to a horizontal position the compressor will start and stop automatically within the settings of the pressure switch. The pressure

switch is factory adjusted to start the compressor when the tank

pressure drops below 100 PSIG and to stop when tank pressure

reaches 125 PSIG. To stop the compressor, turn the lever

clockwise to the vertical position. (DO NOT STOP THE COMPRESSOR BY REMOVING THE ELECTRICAL PLUG.) The onloff

lever operates a valve which relieves pressure from the compressor. If the lever is left on when the electric power is interrupted, the

compressor may have difficulty in starting this pressure.

Operating Procedures

1. Make sure onloff lever is in the off position.

A

WARNING: Befqre using air tools or acces~ories, check

manufacturer's maximum pressure rating. Maximum pressure

rating must be above 125 PSIG.

2.

Attach air hose and accessory.

3.

Turn onloff lever to the on position and allow tank pressure to

build.

4.

When the motor stops, it has reached cutout pressure and the

unit is ready for use.

NOTE: When using an accessory or air tool, pressure in the

storage tank decreases. When it reaches a certain low level

(cutin pressure) the motor will automatically restart and raise the

pressure in the storage tank.

5.

To shut down compressor, simply move onloff lever to the off

position.

6.

Allow compressor to cool.

7.

Drain storage tank (see Storage Tank in Maintenance Section).

MAINTENANCE

Air Filter

lnspect air filter (item 28

-

compressor drawing) before each use.

Clean filter with soap and water as necessary. If filter becomes

clogged or damaged, replace it.

A

WARNING:.N~~~~ clean air filter with a flammable li uid or

solvent. Explosive vapors may accumulate

in the as tan% and

cause an explosion, resulting in serious injury or death.

CAUTION: Do not operate air compressor without air filter.

Storage Tank

Storage tank should be drained after each use or after every four

hours of operation to prevent condensation build-up and corrosion

inside tanks. To drain tank, slowly and carefully open drain fitting

(item 8 -tank drawing), tip unit upright and allow water to drain

out.

NOTE: When draining tank, watch for debris (rust particles). If

there appears to be debris in water, contact your dealer for

possible tank replacement.

A

WARNING: Do not weld on the air tank of this compressor.

Welding on the air compressor tank can severely impair tank

strength and cause an extremely hazardous condition.

Welding on the tank in any manner will void the warranty. If

warranty service or repairs are needed contact your nearest

authorized servicing dealer. If one does not exist contact the

factory. Unauthorized

teardown of the unit will void the

factory warranty.

Loading...

Loading...