Page 1

Part No. 642485 Rev. H 08/08 ©2006 Gardner Denver Thomas Inc.,

Printed in U.S.A. All Rights Reserved

OWNER’S MANUAL and OPERATING INSTRUCTIONS for

Portable, Perma-Lube™ Heavy Duty

WOB•L PISTON AIR COMPRESSOR

Model T-617HDN

3524 WASHINGTON AVE., SHEBOYGAN, WI 53081 USA 1-800-558-7721 www.thomasairpac.com

WARNING: Read and understand the information in this

owner’s manual before operating air compressor.

Page 2

TABLE OF CONTENTS

Page #

General Description.......................................................... 1

Application......................................................................... 1

Safety................................................................................. 2

Set-Up................................................................................ 3

Operating Instructions..................................................... 4

Maintenance...................................................................... 6

Spanish Language Instructions....................................... 7

Exploded View & Parts List............................................. 10

French Language Instructions........................................ 15

Compressor Troubleshooting......................................... 21

Limited Warranty.............................................................. 22

Page 3

1

GENERAL DESCRIPTION

The Airpac model T-617HDN is an electrically powered air compressor

with a thermally protected motor, mounted to a 2 gallon air storage tank.

Tank pressure is regulated by a combination of a pressure switch and a

safety valve. The pressure switch will turn the compressor on when tank

pressure drops below 100 PSIG, and turn the compressor off when tank

pressure reaches 122 PSIG. The safety valve prevents tank pressure

from exceeding 140 PSIG.

SPECIFICATIONS

Voltage .............................................................................................. 115V, 60Hz

Fuse Requirements..................................................................................... 10A

Safety Valve Setting .......................................................... 140 PSIG (965 KPa)

Air Displacement .............................................................. 1.75 CFM (49.5 LPM)

Air Delivery .......................................................................... .90 CFM @ 100 PSI

.............................................................................. (25.48 LPM @ 689.5 KPa)

Amps at Working Pressure ........................................................................ 3.9 A

Automatic Control ................................................................. Starts @ 98 PSIG

...................................................................................................... (675.7 KPa)

.......................................................................................... Stops @ 122 PSIG

...................................................................................................... (841.2 KPa)

Tank Size .............................................................................................. 2 Gal.

Shipping Weight........................................................................................ 32 Ibs.

Cord ................................................................................................. 6 ft. (1.83 M)

Sound Level .............................................................................................. 60 dB

PSI = Pounds Per Square Inch CFM = Cubic Feet Per Minute

KPa = Kilopascals LPM = Liters Per Minute

APPLICATION

Ideal as primary or secondary air source for almost any operation, the

Renegade T-617HDN is particularly suitable for shops, garages, and

factories where repetitive use demands high reliability. The

T-617HDN will operate:

1 Finish Nail Guns

Visit www.thomasairpac.com for more information

Page 4

SAFETY FIRST

1. The compressor should be located in a dry, clean, and well ventilated

area.

2. Inspect hose, plug, and cord for signs of damage before use. Do not use

if a deciency is found. Contact your nearest service center for replacement

parts. Never operate a damaged unit.

3. Do not tamper with the safety valve. It has been factory set. Any

adjustment of this valve could cause serious injury.

4. This air compressor needs no lubrication. Applying oil to any part could result

in polluted air delivery to the air-handling equipment.

5. Compressed air must never be aimed at anyone because it can cause serious

injury. Keep children away. WEAR EYE PROTECTION.

6. All air compressors generate heat even under normal operating conditions.

To avoid serious burns, never touch the air compressor during or immediately

after operation.

7. When unit is not in use, wrap cord securely and store in dry place. Do not

abuse cord or plug.

8. Before servicing, cleaning, or removal of any part, shut off power and relieve

pressure from tank.

9. This system produces 125 PSI. To avoid rupture and injury, do not operate

this pump with components rated less than 125 PSI working pressure (including

but not limited to spray guns, hose and hose connections without pressure

regulator).

If warranty service or repair is needed contact your nearest

authorized service center. If one does not exist in your area,

contact the factory. Unauthorized repairs or teardown of the

unit will void the factory warranty.

This symbol points out important safety instructions which

if not followed could endanger the personal safety and/or

property of yourself and others. Read and understand the

information in this owner’s manual and the engine owners

manual before operating.

2

Page 5

SET-UP

Location of Air Compressor

Operate air compressor in a clean, dry and well ventilated area. The air lter

must be kept clear of obstructions which could reduce air ow to the compressor.

The air compressor should be located at least 12” away from walls or other

obstructions that could interfere with the ow of air.

1. Remove the air compressor from the carton and

place it on its side.

2. Install the 4 rubber feet with the screws

included in the accessory kit as shown.

3. Close the tank drain valve.

4. Remove 2 head screws and install handle

with hardware included in accessory kit.

5. Turn on/auto/off lever on the pressure switch

to the “OFF” position.

6. Attach air hose to the compressor manifold.

7. Plug the power cord into a grounded outlet

or approved extension cord. (See Grounding

Instruction section) Turn the on/auto/off lever

on the pressure switch to the “ON” position.

Extension Cords

To avoid voltage drop and power loss to motor, use additional hose instead

of an extension cord. If an extension cord must be used, use only a 3-wire

extension cord equipped with a 3-blade grounding plug and a 3-slot receptacle

that will accept the plug on the compressor. Be sure to use an extension cord

heavy enough to carry the current your product will draw. An undersized cord

will cause a drop in line voltage resulting in loss of power and overheating.

Make sure the extension cord is in good condition.

NOTE: Wire size increases as gauge number decreases.

3

MINIMUM GAUGE FOR EXTENSION CORDS

CORD LENGTH 25 FEET 50 FEET 100 FEET 150 FEET

GAUGE 12 12 10 8

tank drain

valve

attach feet

(2) each side

attach air hose

Page 6

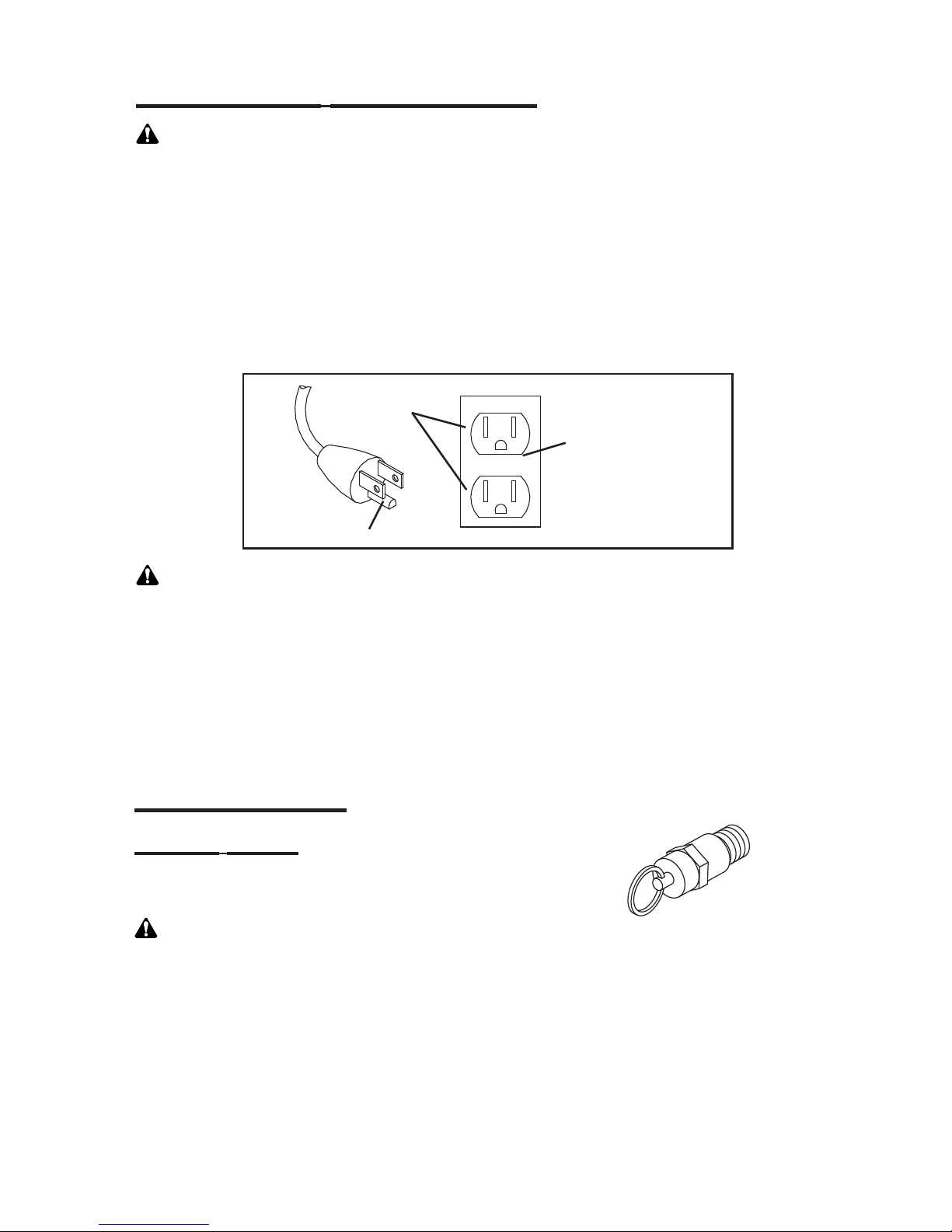

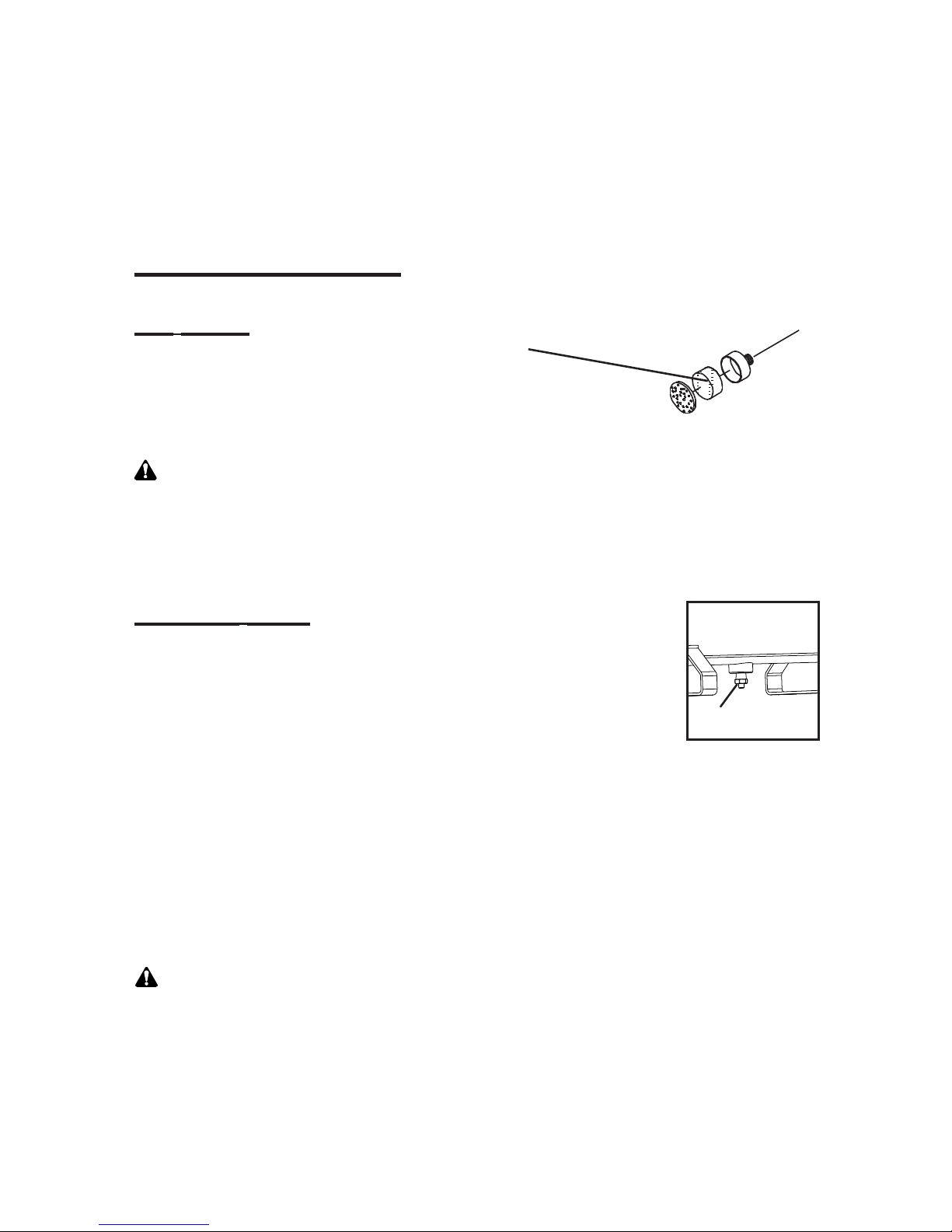

Grounding Instructions

DANGER: Improper grounding can result in electrical shock. In the event of a

short circuit, grounding reduces the risk of shock by providing an escape wire for

the electric current. The air compressor must be grounded. This compressor is

for use on a nominal 120 volt circuit and is equipped with a grounding wire and

appropriate grounding plug that looks like the plug illustrated. The plug must be

used with an outlet that has been installed and grounded in accordance with

all local codes and ordinances. Make sure that the compressor is connected

to an outlet having the same conguration as the plug. No adapter should be

used with this product. Inspect the plug and cord before each use. Do not use

compressor if there are signs of damage.

DANGER: Improper installation of the grounding plug can result in electrical

shock. If repair or replacement of the cord or plug is required, do not connect

the grounding wire to either at blade terminal. The wire with the green (with or

without yellow stripes) insulation is the grounding wire and must be connected to

the grounding pin. Check with a qualied electrician if the grounding instructions

are not completely understood, or if unsure unit is properly grounded. Do not

modify the plug that has been provided. If it does not t the available outlet, the

correct grounded outlet must be installed by a qualied electrician.

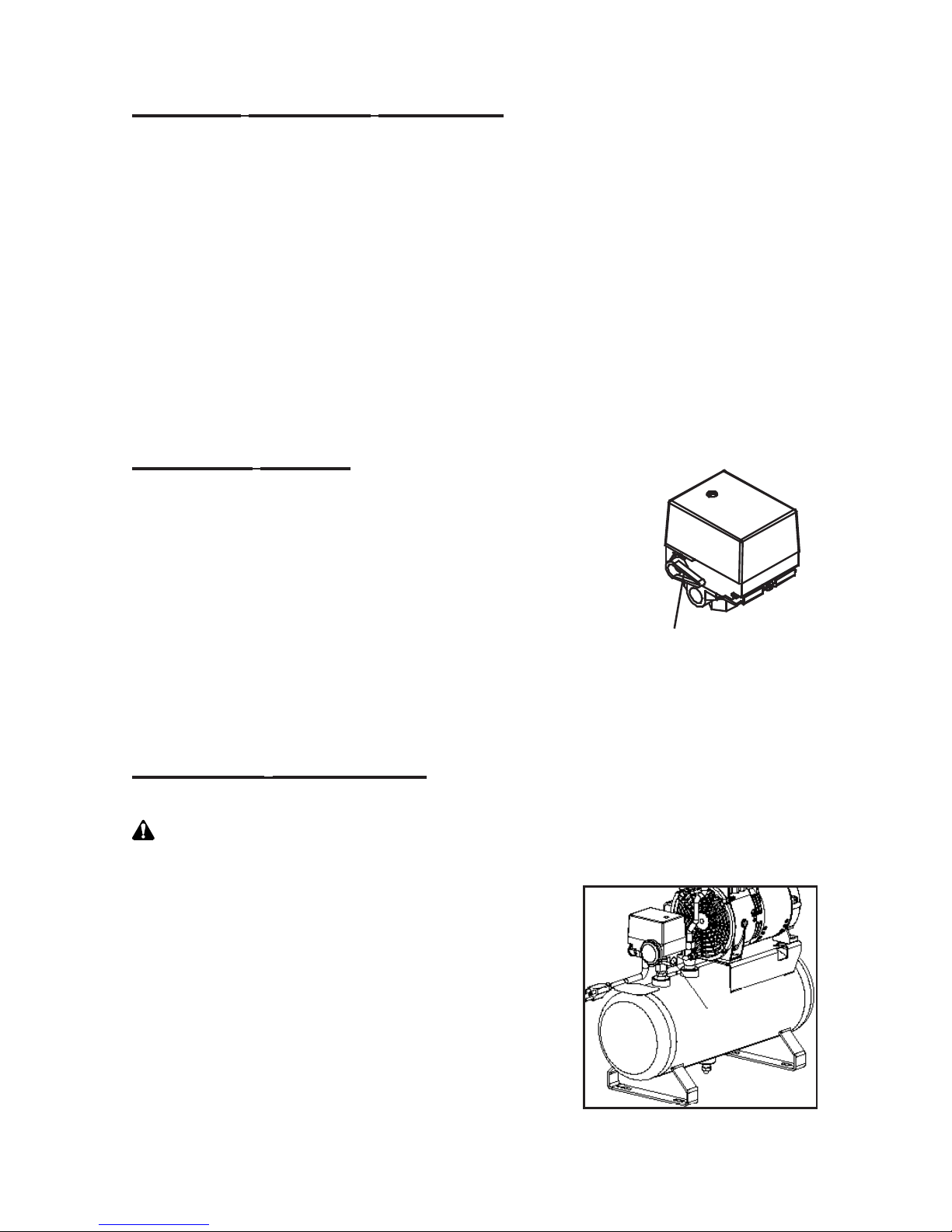

OPERATION

Safety Valve

The safety valve is designed to prevent pressure

in the storage tank from exceeding 140 PSIG.

WARNING: Do not tamper with or attempt to eliminate the safety valve.

4

GROUNDED

OUTLET BOX

GROUNDED

OUTLET

GROUNDING PIN

Page 7

5

Thermal Overload Protector

The compressor motor is equipped with a thermal overload protector. If the motor

should overheat, the overload protector will shut the motor off. If this occurs,

turn the on/off lever to the off position and allow motor to cool for approximately

5 minutes.

NOTE: Tank pressure must be below 100 PSIG for the compressor to start.

Restart the compressor by moving on/off lever to the on position. If compressor

fails to start, check for blown fuses; the compressor may require more time to

cool. If the overload protector shuts down the motor frequently, it could be due

to low voltage.Common signs of low voltage are:

1. Motor does not get up to power or speed.

2. Fuses or circuit breaker activate when starting compressor.

3. Lights dim or remain dim when compressor is started.

4. Other motor operated appliances fail to operate property.

5. Too many motor operated appliances on same circuit.

Pressure Switch

The compressor is operated by an on - auto/off lever on

the side of the pressure switch. By turning the lever to

the “AUTO” position the compressor will start and stop

automatically within the settings of the pressure switch. The

pressure switch is factory adjusted to start the compressor

when the tank pressure drops below 100 PSIG and to

stop when tank pressure reaches 122 PSIG. To stop the

compressor, turn the lever clockwise to the “OFF” position.

(DO NOT STOP THE COMPRESSOR BY REMOVING THE

ELECTRICAL PLUG.) The on/off lever operates a valve which relieves pressure

from the compressor. If the lever is left on when the electric power is interrupted,

the compressor may have difculty in starting under this pressure.

Operating Procedures

1. Make sure on/off lever is in the off position.

WARNING: Before using air tools or accessories, check manufacturer’s

maximum pressure rating. Maximum pressure rating must be above 122

PSIG.

2. Attach air hose and accessory to compressor.

(Remove orange pull plug rst.)

3. Turn on/off lever to the on position and allow tank

pressure to build.

4. When the motor stops, it has reached cutout

pressure and the unit is ready for use.

attach air hose

Lever

Page 8

NOTE: When using an accessory or air tool, pressure in the storage tank

decreases. When it reaches a certain low level (cut-in pressure) the motor will

automatically restart and raise the pressure in the storage tank.

5. To shut down compressor, simply move on/off lever to the off position.

6. Allow compressor to cool.

7. Drain storage tank (see Storage Tank in Maintenance Section).

MAINTENANCE

Air Filter

Inspect air lter before each use. Clean lter

with soap and water as necessary. Squeeze

excess moisture from lter and allow to dry before

re-installing. If lter becomes clogged or damaged,

replace it.

WARNING: Never clean air lter with a ammable liquid or solvent.

Explosive vapors may accumulate in the air tank and cause an explosion,

resulting in serious injury or death.

CAUTION: Do not operate air compressor without air lter.

Storage Tank

The storage tank should be drained after each use or after every

four hours of operation to prevent condensation build-up and

corrosion inside the tanks. To drain tank, slowly and carefully

open drain tting, tip unit upright and allow water to drain out.

Always drain tank before storing compressor.

DO NOT over tighten drain valve when closing. The drain valve on this tank

seals primarily through the o-ring seal. Over tightening the valve can damage

the o-ring and may cause premature failure. To prevent damage, stop closing

the valve as soon as air can no longer be heard escaping from the valve, or

when nger tight.

NOTE: When draining tank, watch for debris (rust particles). If there appears

to be debris in water, contact your dealer for possible tank replacement. The

appearance of rust inside the tank will compromise its’ ability to hold pressure

and can cause bursting.

WARNING: Do not weld on the air tank of this compressor. Welding

on the air compressor tank can severely impair tank strength and cause

an extremely hazardous condition. Welding on the tank in any manner

will void the warranty. If warranty service or repairs are needed contact

your nearest authorized servicing dealer. If one does not exist contact

the factory. Unauthorized teardown of the unit will void the factory

warranty.

6

tank

drain

Page 9

7

REGLAS PARA UNA OPERACION SEGURA

PRECAUCION: Antes de operar el compressor de aire, lea este manual del

propietario y asegúrese de comprender la información aqui contenida.

1. El compresor debe ubicarse en una zona seca, timpia y bien ventilada.

2. Antes del uso, inspeccione la manguera, el tapón y elcable para

asegurarse de que estén en buenas condiciones. En caso contrario, no use

el compresor. Las unidades dañadas nunca deben operarse. Para la obtención

de piezas de reemplazo, consulte con su centro de servicio más próximo.

3. El ajuste de la válvula de alivio de seguridad ha sido jado en la fábrica.

No lo altere. Los ajustes de esta válvula peudan provocar lesiones

graves.

4. Esta unidad no requiere lubricación. Puesto que el compresor no requiere

ser aceitado, la aplicación de aceite a cualquier componente podría resultar

en el suministro de aire contaminado al equipo correspondiente.

5. El ujo de aire comprimido no debe dirigirse a ninguna persona porque puede

provocar lesiones graves. No permita que se acerquen los niños.

UTILICE PROTECTORES PARA LOS OJOS.

6. Todos los compresores de aire generan calor, aun bajo condiciones de

operacion normales. Para evitar quemaduras graves no toque el cabeza ni los

componentes del escape del compresor durante la operación o inmediatamente

después de ella.

7. Cuando la unidad no esté en uso, enrolle el cablealrededor del compresor

y guárdelo en un lugar seco. No maltrate el cordón.

8. ANTES DEL SERVICIO, LA LIMPIEZA 0 EL DESMONTAJE DE

CUALQUIER PIEZA, APAGUE LA UNIDAD Y ALIVIE LA PRESION.

9. ESTE SISTEMA PUEDE PRODUCIR HASTA 9,5 kg/cm2 (135 psi). PARA

EVITAR RUPTURAS DE COMPONENTES Y LESIONES CORPORALES, NO

OPERE LA UNIDAD CON ACCESORIOS (POR EJEMPLO, PISTOLAS DE

PULVERIZACION, MANGUERAS Y CONECTORES DE MANGUERAS) CUYA

PRESION NOMINAL DE TRABAJO SEA INFERIOR A 9,5 kg/cm2 (135 psi).

Si se requieren reparaciones o servicio de garantia, póngase en contacto con

el centro de servicio autorizado más cercano. Si no dispone de un centro,

póngase en contacto con la fábrica. Las reparaciones o el desmontaje de la

unidad sin autorización anularán la garantía de fábrica.

APLICACIONES

Este compresor es ideal como unidad neumática primaria o secundaria para

prácticamente cualquier tipo de operación. Especialmente indicado para

talleres, garajes y fábricas en donde el uso continuo exige gran abilidad.

Page 10

8

EL MANTENIMIENTO GENERAL Y SERVICIO

Lea y entienda la información de este maual del propletario del compresor que opera.

ESPECIFICACIONES

Voltaje.......................................................................................................... 115V, 60Hz

Requisitos del Fusible ............................................................................................ 10 A

Regulación de Valvulas de Seguridad..........................................140 PSIG (965.3KPa)

Desplazamiento de Aire.................................................................. 1.70 CFM (48 LPM)

Descarga de Aire ............... 0.90 CFM @ 100 PSI.............. (25.48 LPM @ 689.5 KPa)

Amps a Presión de Trabajo ................................................................................... 3.9 A

Control Automático .................Comienza @ 98 PSIG ................................(675.7 KPa)

..................................Para @ 122 PSIG .......................................(841.2 KPa)

Tamaño del Tanque ............................................................................................. 2 Gal.

Peso ................................................................................................................... 32 Ibs.

Cable conductor .....................................................................................6 pies (1.83 M)

PSI - Libras Por Pulgadas Cuadradas CFM - Pies Cúbicos Por Minuto

DISPOSICION DE LA UNIDAD UBICACION DEL COMPRESOR DE AIRE

Haga uso del compresor de aire en un área limpia, seca y bien ventilada. El ltro de

aire debe mantenerse libre de obstrucciones que pudieran reducir el ujo de aire que

recibe el compresor. El compresor de aire debe ubicarse por lo menos a 12” de paredes

y otras obstrucciones que puedan interferir con el ujo del aire.

1. Saque el compresor de aire de la caja de cartón y

colóquela a un lado.

2. Instale las 4 patas de caucho con los tornillos incluidos

en el kit de accesorios como se muestra.

3. Cierre la válvula de drenaje del tanque.

4. Quite el tapón de lengüeta anaranjado del puerto de

admisión en la cabeza del compresor e instale el ltro de

admisión que se proporciona en el kit de accesorios.

5. Quite 2 tornillos de cabeza e instale la manija con

los accesorios del kit.

6. Gire la palanca on/auto/off en el conmutador de

presión a la posición de apagado (OFF).

7. Sujete la manguera de aire al colector del

compresor.

8. Conecte el cable eléctrico a una salida puesta a

tierra o a otra extensión aprobada. (Vea la sección

Instrucciones para descarga a tierra.) Gire la

palanca on/auto/off en el conmutador de presión

a la posición de encendido (ON).

manguera

neumática

Page 11

9

CABLES DE CONEXION

Para evitar al motor disminución de tensión y pérdida de potencia, use una manguera

adicional en lugar de un extension electrica. Si hay necesidad de usar un extension

electrica, use únicamente un cable de conexión de 3 hilos equipado con un enchue de

tierra de 3 gajos y un tomacorriente de tres ranuras que acepte el enchufe del compresor.

Asegúrese de que el cable de conexión esté en buen estado.

NOTA: El tamaño del cable aurnenta conforme el calibre disminuye.

INSTRUCCIONES PARA LA CONEXION A TIERRA

PELIGRO: Una Conexión a tierra incorrecta puede dar como resultado un choque

electrico. En caso de un corto circuito, la conexión a tierra disminuye el riesgo de un

choque ya que provee un cable de escape para la corriente eléctrica.

El compresor de aire debe tener una conexión a tierra. El cable del compresor de

aire viene listo con un cable con conexión a tierre y un enchufe con conexión a tierra

apropiado. El enchufe debe ser usado con un tomacorriente que al ser instalado

haya seguido las leyes y ordenanzas locales para efectos de conexiones a tierra. El

tomacorriente debe tener la misma conguración del enchufe. No use un adaptador.

No le haga modicaciones al enchufe que se provee. Si no encaja bien en el

tomacorriente existente, un electricista profesional debe instalar el tomacorriente

correspondiente. Inspeccione el enchue y el cable cada vez que use la unidad.

No use el compresor si presenta señales de averías.

PELIGRO: Si la instalación del enchue conectado a tierra es hecha

incorrectamente, puede producirse un choque eléctrico. Si necesita reparar o

reemplazar el cable o el enchufe, no conecte el cable a tierra a ninguno de los

dos gajos planos del terminal. El alambre con el aislamiento verde (con o sin

rayas amarillas) es el alambre conectado a tierra. Consulte con un electrista

calicado si no comprende completamente las instrucciones que se dan aqui

para hacer la conexión a tierra, o si no está seguro de haber hecho la conexión

a tierra en forma apropiada.

TOMACORRIENTE

CONECTADO A

TIERRA ESTUCHE

TOMACORRIENTE

CONECTADO A

TIERRA

CLAVIJA

CONECTADA A TIERRA

MEDIDAS MINIMAS PARA LOS CABLES DE CONEXION

LONGITUD DEL CABLE 25 PIES 50 PIES 100 PIES 150 PIES

CALIBRE 12 12 10 8

Page 12

COMPRESSOR PARTS LIST

10

EXPLODED VIEW

AND PARTS LIST

Item

No.

Part No. Description Qty

17 647076 Fan Guard 1

18 603178 Capacitor Bracket 1

19 625434 Screw 8/16” x 3/8 Torx 2

20 603025 Capacitor 8mfd/450V 1

21 603167 Capacitor Cover 1

22 625449 Screw 8/32” x 3/8 Torx 2

23 633160 Strain Relief Bushing 1

24 660710 Filter Body 1

25 641034 Filter-Foam 1

26 660767 Filter-Body Cap 1

27 629081 Handle 1

28 625379 Screw-Handle 2

29 626014 Washer-Handle 2

Item

No.

Part No.

Component

Part

Description Qty

1 666459-S Conn. Rod Ass’y-Service 1

2* 625088 Eccentric Set Screw 1

3* 624396 Piston Cup 1

4 625180 Screw-Cup Retainer 1

5* 626397 Piston Cup Retainer 1

6* 670031 Cylinder Sleeve 1

7 610869-500 Head 1

8* 623143 O-Ring Head Gasket 1

9 625175 Screw-Head 4

10* 621647 Valve Backer 1

11* 617562 Valve Keeper Strip 2

12* 621485 Valve Flapper-Int. & Exh. 2

13 621632-540 Valve Plate 1

14* 625094 Screw-Valve Plate 2

15* 623071 O-ring-Valve Plate 1

16 638281 Fan-Black 1

Page 13

TANK PARTS LIST

11

46

50

45

37

41

43

42

35

36

33

34

47

48

30

49

31

44

38

39

32

40

39

Item

No.

Part No. Description Qty

30 602657 Pressure Switch 1

31 615779 Sleeve - Self Aligning 1

32 618149 Exhaust Tube 1

33 615826 Unloader Tube 1

34 624925 Fitting 1

35 617677 Drain Cock Assembly 1

36 624361 Elbow - Unloader Tube 1

37 624654 Bumper 1

38 624510 Insert-Unloader Tube 2

39 624511 Insert-Exhaust Tube 1

Item

No.

Part No. Description Qty

40 624517 Connector - Head 1

41 625206 Screw-Cprsr. Mounting 4

42 626563 Washer- Cprsr. Mounting 4

43 626509 Lock Washer-Cprsr. Mtng. 4

44 626766 Nut - Compression 1

45 625406 Screw - Bumper 4

46 633660 Cord 1

47 633957 Safety Valve 1

48 638262 Gauge - Pressure 1

49 638322 Check Valve Assembly 1

50 669470-540 Tank Assembly 1

Page 14

12

OPERACION

VALVULA DE SEGURIDAD

La válvula de seguridad ha sido diseñada para prevenir

que la presión en los tanques de almacenamiento exceda

á 140 PSIG.

PRECAUCION: No altere ni trate de eliminar la válvulade seguridad.

PROTECTOR TERMICO PARA SOBRECARGA

El motor del compresor está equipado con un protector térmico para sobrecarga.

Si el motor se llegara a recalentar, este protector apagará el motor. Si esto

ocurre, apague la unidad y deje que el motor se enfríe aproximadamente unos

5 minutos.

NOTA: La presión del tanque debe estar bajo 110 PSIG para que el compresor

arranque.

Encienda la unidad para volver a arrancar el compresor. Si elcompresor no

arranca, revise la unidad en busca de fusibles quemados; el compresor puede

necesitar más tiempo para enfriarse. Si el protector de sobrecarga apaga el

motor frecuentemente, podri’a ser que hay voltaje bajo.Indicaciones comunes

de un voltaje bajo son:

1. El motor no llega a su capacidad y velocidad.

2. Los fusibles y el cortacircuitos se activan cuando searranca el compresor.

3. Las luces bajan su intensidad al arrancar el compresor permanecen

amortiguadas.

4. Otros aparatos operados por el motor no funcionan en forma apropiada.

5. Hay demasiados aparatos operados por el motor en el mismo circuito.

FUNCIONAMIENTO DEL INTERRUPTOR DE PRESION

El compresor es operado por medio de una

palanca ON/AUTO-OFF, localizada en un

lado del interruptor de presion. Gire la

palanca a la posicion “ON-AUTO”, y el

compresor arrancara y parara automatica-

mente dentro del rango de presion del interruptor.

El interruptor esta ajustado de fabrica para arrancar

el compresor a presiones inferiores de 110 PSI, y para

cuando la presion alcanza 135 PSI en el tanque. Para

parar el compresor, gire la palanca a la posicion “OFF”. (NO PARE EL

COMPRESOR REMOVIENDO LA CLAVIJA DEL TOMACORRIENTE). La

palanca ON-OFF opera una valvula, la cual alivia la presion del compresor.

Si la palanca se deja en “ON” cuando la corriente electrica es interrumpida,

entoces el compresor podria tener dicultad para arrancar.

Page 15

13

PROCEDIMIENTO PARA EL FUNCIONAMIENTO

1. Asegúrese de que la unidad está apagada.

PRECAUCION: Antes de usar herramientas o accesorios neumáticos,

revise la capacidad de presión máxima del fabricante. Le capacidad de presión

máxima debe estar sobr e 135 PSIG.

2. Una la manguera neumática y el accesorio.

3. Ponga la palanca de conectar y desconectar

en posición on” y deje que la presión del tanque

aumente.

4. Cuando el motor se para, ha alcanzado presión

de desconexión y la unidad está lista para usarse.

5. Para apagar el compresor, simplemente mueva

la palanca de conectar y desconectar a la posición “off”.

6. Deje enfriar el compresor.

7. Drene los tanques de almacenamiento (veáse

Tanques de Almacenamiento en la Sección de Mantenimiento).

MANTENIMIENTO

FILTRO DE AIRE

Revise el ltro de aire antes de cada uso.

Limpie el ltro con agua y jabón según sea

necessario. Apriete el ltro para eliminar el

exceso de humedad y deje que se seque antes

de volverlo a instalar Si el ltro está obstruído o

dañado, reemplácelo.

ADVERTENCIA: No opere el compresor de aire sin ltro de aire.

PRECAUCION: Nunca limpie el ltro de aire con un liquido inamable o un

disolvente. Vapores explosivos podrían acumularse en los tanques de aire y

causar una explosión, dando como resultado lesiones serias o muerte.

manguera

neumática

Page 16

14

ADVERTENCIA: No suelde en los tanques de aire de estos compresores.

Soldar en los tanques de aire de estos compresores puede dañar

seriamente la fortaleza del tanque y causar una situación extremadamente

peligrosa. Una soldadura de cualquier tipo en los tanques puede ocasionar

la perdida de la garantia. Si algun servicio de garantia o cualquier reparo

es necesario comuniquese con su distribuidor más cercano. Si este no

existe, comuniquese con la fábrica. Cualquier desmontaje desautorizado

en la unidad cancelara la garantia de la fábrica.

TANQUES DE ALMACENAMIENTO

Los tanques de almacenamiento deben vaciarse

después de cada uso o después de cada cuatro

horas de operación para prevenir la creación de

condensación y corrosión dentro de los tanques.

Para vaciar los tanques, lentamente y con mucho

cuidado abra los accesorios de desague, incline la

unidad hacia el drenaje y deje que se desagüe.

NOTA: Cuando esté drenado los tanques, fjese si salen trozos de metal corrido,

se esto ocurre debe contactar a su distribuidor para posible reemplazo del

tanque.

tanques

desagüe

Page 17

15

ATTENTION: Veuillez lire attentivement ce manuel d’utilisation avant de vous

servir de ce compresseur d’air

1. Le compresseur doit être utilisé dans un endroit sec, propre et bien aéré.

2. Avant l’emploi, examiner le tuyau, la che et le l électrique pour repére tous

signes de déterioration. Ne pas utiliser l’appareil en cas de défaut de fonctionnement

ou de matériel. Addressez-vous au service entretien le plus proche pour obtenir des

pièces de rechange. Ne jamais utiliser un appareil défectueux.

3. Ne pas modier la pression de la soupape de sûreté: elle a été réglée en

usine. Tout autre réglage pourrait entráiner un risque de blessure grave.

4. Ce compresseur d’air ne nécessite aucune lubrication. Le graissage des pièces

risque de polluer l’air comprimé alimentant les accessoires pneumatiques.

5. L’air comprimé ne doit jamais être pointé sur une personne, car il peut entráiner des

blessures graves. Eloigner les enfants de l’endroit de travail. PORTER DES LUNETTES

DE PROTECTION.

6. Tous les compresseurs d’air produisent de la chaleur, même dans des conditions de

fonctionnement normales. An d’eviter tes brûlures, ne jamais toucher le compresseur

d’air pendant ou tout de suite après utilisation.

7. Quand il n’est pas utilisé, enrouler le l électrique autour du compresseur et stocker

dans un endroit sec. Faire attention à ne pas endommager le l électrique.

8. AVANT D’UTILISER, DE NETTOYER OU DE RETIRER TOUT ACCESSOIRE,

DEBRANCHER L’APPAREIL ET REDUIRE LA PRESSION.

9. CE SYSTEME PEUT PRODUIRE 9,5 kg/cm2 (135 psi). POUR EVITER TOUTE

RUPTURE POUVANT ENTRAINER DES BLESSURES, NE PAS UTILISER CETTE

POMPE AVEC DES ACCESSOIRES PREVUS POUR UNE PRESSION INFERIEURE

A 9,5kg/cm2 (135 psi) (Y COMPRIS MAIS NON LIMITE AUX PISTOLETS A PEINTURE,

TUYAUX ET RACCORDS DES TUYAUX).

Si des réparations ou un entretien en cours de garantie s’avèrent nécessaires,

addressez-vous au service entretien agréé le plus proche. S’il n’y en a pas, addressezvous à l’usine. Des réparations ou un démontage non permis

annuleront la garantie usine.

UTILISATION

Idéal comme source d’air primaire ou secondaire pour pratiquement toute opération.

Particulièrement pratique pour boutiques et garages ainsi que pour les usines où un

usage répété requiert un appareil de haute abilité.

PRECAUTIONS D’EMPLOI

Page 18

16

Lisez et comprenez l’information dans le manuel de ce propriétaire

avant d’opérer le compresseur.

CARACTERISTIOUES

Voltage..........................................................................................................115V, 60Hz

Fusibles...................................................................................................................10 A

Réglage de la soupape de Sûreté.............................................. 140 PSiG (965,3 KPa)

Volume d’air déplace ..................................................................... 1,70 CFM (48 LPM)

Débit d’air ........................... 0,90 CPM à 100 PSI............... (25.48 LPM à 689,5 KPa)

Ampéres quand l’appareil est sous pression .................................................. 3,9 AMP

Contrôle automatique .................... Démarre à 98 PSIG............................ (675,7 KPa)

......................................... S’arrête à 122 PSIG............................ (841,2 KPa)

Poids................................................................................................................. 32 livres

Contenance des réservoirs ..............................................................................2 gallons

Fil électrique ......................................................................................... 6 pieds (1.83m)

PSI - Livres par pouce carré CFM - Pieds cubes par minute

USAGE INSTALLATION

Emplacement du compresseur d’air

Faites fonctionner le compresseur d’air dans un endroit propre, sec et bien áeré. Le

ltre à air ne doit jamais être bouché, ce qui réduirait le débit d’air au compresseur. Le

compresseur d’air doit être placé à 4m (12 pieds) au moins de murs ou d’autres éléments

d’obstruction qui pourraient interférer avec le débit de l’air.

1. Retirer le compresseur d’air du carton et le placer sur

sa partie latérale.

2. Monter les 4 pieds en caoutchouc à l’aide des vis fournies

avec l’ensemble d’accessoires comme indiqué.

3. Fermer le robinet de vidange du réservoir.

4. Enlever 2 vis de tête et installer le levier de manœ

uvre à l’aide du matériel fourni avec l’ensemble

d’accessoires.

5. Activer/placer en mode automatique ou

désactiver le levier sur le pressostat en position

‘’OFF’’.

6. Relier le tuyau d’air au distributeur du compresseur.

7. Raccorder le câble d’alimentation dans une prise de

courant à contact de mise à la terre ou une rallonge

agréée. (Voir la partie des procédures de mise à l

a terre). Activer/placer en mode automatique ou

désactiver le levier sur le pressostat en position ‘’ON’’.

ENTRETIEN GÉNÉRAL ET SERVICE

Relier le tuyau d’air

Page 19

17

Rallonge Électrique

Pour éviter des chutes de voltage et des pertes de puissance au moteur,

utilisez des tuyaux supplémentaires au lieu d’une rallonge électrique.

Si une rallonge doit être utilisée, n’utilisez qu’une rallonge électrique

à trois ls avec une che à troisbroches (prise de terre) et une prise à

trois trous pour recevoir la che qui se trouve sur le compresseur d’air.

Assurez-vous que la rallonge est en bon état.

REMARQUE: La grosseur du l augmente lorsque ie chiffre du cali-

bre diminue.

Instructions de mise à la terre

DANGER: Une mauvaise mise à la terre peut causer des électrocutions.

En cas de court-circuit, la mise à la terre réduit le risque d’électrocution

en permettant au courrant de s’échapper. Le compresseur d’air doit être

mis à la terre. Le l électrique du compresseur d’air est équipé d’un l

de terre et d’une che de terre appropries. La che doit être utilisée

avec une prise installée et mise à la terre selon les règlements et les

ordonnances locales. La prise doit avoir le même conguration que la che.

Ne pas utiliser d’adaptateur.Ne modiez pas la che qui vous est fournie. Si

celle-ci ne s’adapte pas à la prise disponible, il faut faire installer la prise

correcte par un électricien. Inspectez la che et ie t électrique avant

chaque utilisation. N’utilisez pas le compresseur d’air si ces élements

sont endommagés.

DANGER!: Une mauvais installation de la che de terre peut causer

une électrocution. S’il faut réparer ou changer le l électrique, ne

raccordez pas le l de terre à n’importe quelle che plate de terre.

PRISE AVEC

PRISE DE

TERRE BOITE

PRISE AVEC

PRISE DE

TERRE

FICHE DE TERRE

CALIBRE MINIMUM DES RALLONGES ELECTRIQUES

DE RALLONGE 25 PIEDS 50 PIEDS 100 PIEDS 150 PIEDS

CALIBRE 12 12 10 8

Page 20

18

Le l recouvert d’un isolant vert (avec ou sans raies jaunes) est le

l de terre. Faites vérier l’installation par un électricien qualié si

vouscomprenez pas entiérement les instructions concernant la mise à

la terre, ou si vous n’êtes pas sûr que l’appareil soit correctement mis

à la terre.

FONCTIONNEMENT

Soupape de sûreté

La soupape de sûreté est concue pour

que la pression qui se trouve dans les

réservoirs d’accumulation n’excède pas

165 PSIG.

ATTENTION!: N’essayez pas de modier ou de supprimer la soupape

de sûreté.

Protecteur de surchauffe

Le moteur du compresseur est équipé d’un protecteur de surchauffe.

Si le moteur vient à surchauffer, le protecteur de surchauffe arrêtera le

moteur. Si cela arrive, mettez le levier marche/arrêt sur la position arrêt

et laissez le moteur se refroidir pendant environ cinq minutes.

REMARQUE: La pression du réservoir doit être inférieure à 110

PSIG pour que le compresseur puisse redémarrer. Redémarrez le

compresseur en mettant le levier marche/arrêt à la position marche.

Si le compresseur ne démarre pas, vériez les fusibles pour voir s’ils

n’ont pas sauté; iI se peut que le compresseur ait besoin de plus de

temps pour refroidir. Si le protecteur de surchauffe arrête fréquemment

le moteur, cela peut venir d’un faible voltage. Les signes habituels d’un

faible voltage sont les suivants:

1. Le motteur manque de puissance ou ne peut atteindre la vitesse

normale.

2. Les fusibles ou le disjoncteur sautent lorsque le compresseur

démarre.

3. Les lumières des lampes baissent ou restent faibles lorsque le

compresseur démarre.

4. D’autres appareils à moteur ne marchent pas correctement.

5. Trop d’appareils à moteur sont sur le même circuit électrique.

Page 21

19

COMPRESSEUR DE PRESSION

Le compresseur fonctionne par un leveir en action

auto/fermé au-dessus de la côté de commutateur

de pression. En tournant le levier à la position

horizontal e le compresseur démarrera et cessera

automatiquement à l’interieur de la position

de commutateur de pression. Le commutateur

de pression est fait dans la fabrique et ajusté

pour mettre en marche le compresseur quand

la pression du réservoir tombe au-dessous de

110 PSIG et de cesser quand la pression de

réservoir atteind jusqu’a 135 PSIG. Pour fermer le compresseur tourner

le levier dans sens des aguilles d’une montre á la position verticale.

(NE FERMER JAMAIS LE COMPRESSEUR PAR ENLEVEMENT LE

TAMPON ELECTRIQUE). Le levier de en action/ferme fonctionne la

soupape qui soulage la pression de compresseur. Si le levier est laissé

en action quand la puissance électrique est interrompue, le compresseur

peut avoir la difculté de démarrer avec cette pression.

MODE D’EMPLOI

1. Assurez-vous que le levier marche/arret se trouve sur la position

position d’arrêt.

ATTENTION!: Avant de vous servir d’outils ou d’accessoires à air

comprimé, vériez le taux maximum de pression recommandé par le

fabricant. Ce taux doit être supérieur à 122 PSIG.

2. Attachez le tuyau el l’accessoire.

3. Mettez le levier sur la position marche et laissez la pression monter

dans le réservoir.

4. Quand le moteur s’arrête, il a atteint son niveau de pression d’arrét

et l’appareil est prét à fonctionner.

REMARQUE: Quand vous utilisez un accessoire ou un outil à air

comprimé, la pression dans les réservoirs d’accumulation décroít. Quand

celle-ci atteint un certain niveau minimum (perte de pression) le moteur

redémarrera aussitôt automatiquement et

fera monter la pression dans les réservoirs.

5. Pour arrêter le compresseur, mettez le

levier marche/arrêt sur la position arrêt.

6. Laissez la compresseur se refroidir.

7. Vindangez les réservoirs d’accumulation

(voir réservoirs d’accumulation à la section

entretien).

Page 22

20

ENTRETIEN

Filtre à air

Vériez le ltre à air avant chaque utilisation de l’appareil. Nettoyez le

ltre avec du savon et de l’eau si nécessaire.

Éliminez l’excès d’humidité du ltre et laissez-le

sécher avant de le remettre en place.Si le ltre est

bouché ou endommagé, remplacez-le.

ATTENTION!: Ne jamais nettoyer le ltre à air avec un liquide ou

un dissolvant inammable. Des gaz explosibles peuvent s’accumuler

dans les réservoirs et provoquer une explosion pouvant causer de très

graves blessures ou même la mort.

ATTENTION!: Ne faites pas marcher le compresseur sans ltre à

air.

Réservoirs d’accumulation

Les réservoirs d’accumulation doivent être

purgés après chaque utilisation ou toutes les

quatre heures de marche pour empêcher une

accumulation de condensation et la corrosion

de l’intérieur des réservoirs. Pour purger les

réservoirs, ouvrez lentement et soigneusement

les raccords de purge penchez l’appareil du côté

des raccords et laissez l’eau sortir.

REMARQUE: Quand vous purgez les réservoirs, regardez s’il se trouve

des débris (particules de rouille). Si oui, contactez votre concessionnaire

pour un éventuel remplacement des réservoirs.

ATTENTION!: Ne faites pas de soudures sur les réservoirs

de ces compresseurs. Des soudures sur les réservoirs de ces

compresseurs à air pourraient sérieusement affaiblir la résistance

des réservoirs et créer des conditions trés dangereuses. N’importe

quelle soudure sur un réservoir annulera la garantie. Si des travaux

sous garantie ou des réparations sont nécessaires addressez-vous

à un fournisseur/réparateur autorisé. S’il n’y en a pasprès de chez

vous contactez l’usine. Le démontage nonautorisé de l’appareil

annulera la garantie.

tank

drain

Page 23

21

ELECTRIC COMPRESSOR TROUBLESHOOTING

The following guide has been compiled to assist the consumer in identifying problems

that may be encountered with electric compressors. Please inspect for possible

causes and contact an authorized service center when necessary.

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Motor Won’t Start No Power to Compressor

Switch Lever in “Off” Position

Faulty Start Relay

Faulty Start Capacitor

Check Circuit Breaker or

Fuse.

Move Switch Lever to On

Position.

Compressor Won’t

Restart

Check Valve Leaks

Low Voltage to compressor

Pressure Switch Hanging Up

Inspect Check ValveContact Service Center.

Connect Unit to Sufcient

Voltage Source.

Inspect Pressure SwitchContact Service Center.

Low Air Output Leak At Fitting(s)

Broken Valve Flapper

Debris in Valves

Faulty Head Gasket

Faulty Valve Plate Gasket

Worn Piston Cup

Inspect Fittings-If Loose or

Damaged Contact Service

Center.

Compressor Won’t

Shut Off

Leak At Fitting(s)

Broken Valve Flapper

Debris in Valves

Faulty Head Gasket

Faulty Valve Plate Gasket

Worn Piston Cup

Relief Valve Leaking

Inspect Fittings-If Loose or

Damaged Contact Service

Center.

Water in Air Lines or

Tools

Tank Not Drained Regularly Drain Air from Tank(s)

through Drain Valves.

Ensure Air Lines are Free

of Moisture.

Low Pressure to Tools Damaged Gauge on Regulator

Regulator Not Adjusted Properly

Faulty Regulator

Inspect Gauge-Contact

Service Center.

Adjust Regulator to

Required Pressure.

Inspect Regulator-Contact

Service Center.

These procedures require special xtures, tools or asssembly techniques

available only through a Service Center. For service, contact the dealer from whom

you purchased the compressor. To order parts, visit our website, www.thomasairpac.

com, or call our Customer Service Center at 1-800-848-7735.

ATTENTION: The automatic pressure switch prevents this

unit from running if the tank pressure exceeds 100PSI. If the

compressor will not start, drain the pressure from the tank.

Page 24

Thomas Products Division of

Gardner Denver Thomas, Inc.

C/O Customer Service

3524 Washington Avenue

Sheboygan, Wisconsin 53081

Phone: (800) 558-7721

Fax: (920) 451-6307

www.thomasairpac.com

Limited Warranty

The Gardner Denver Thomas, Inc. Compressor is warranted to you, the original

purchaser, for a period of one year from date of original purchase to be free from

defects in material and workmanship. If during the specied warranty period you

believe the purchased product or any part thereof has such a defect, you must return

the product or part during such period, with proof of purchase and at your cost, to the

nearest authorized service center (consult the list of service centers enclosed with the

product) for repair, or replacement of the defective part. If you do not know the location

of the nearest service center, contact Gardner Denver Thomas, Inc. at the address

below for instructions. If the product or part is found to have been defective in material

or workmanship, it will be repaired or replaced (as deemed necessary by the repair

center), free of charge, and returned to the purchaser at the purchaser’s cost. If the

repair work must be done at the Gardner Denver Thomas, Inc. factory, transportation

costs of the product or part, to and from the factory, must be paid by the purchaser.

The warranty shall not apply to any compressor, which in Thomas’ judgement has

been subject to misuse, negligence or accident, or which has been operated from an

inadequate power supply. All wearing and consumable parts are excluded under the

terms of this warranty. This warranty shall not apply to compressors that require oil for

operation, which have been operated with oil levels below that specied by Gardner

Denver Thomas, Inc.

THE MANUFACTURER LIMITS THE DURATION OF THE IMPLIED WARRANTY OF

MERCHANTABILITY TO THE LIMITED WARRANTY PERIOD SET FORTH ABOVE,

AND OTHERWISE DISCLAIMS ALL IMPLIED WARRANTIES WITH RESPECT TO

THE PRODUCT AND IT’S PARTS INCLUDING, WITHOUT LIMITATION, THE IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Thomas’ total liability for any and all claims, damages, losses and injuries arising out of

or relating to any breach of warranty shall not exceed the purchase price of the product.

IN NO EVENT WHETHER IN CONTRACT, OR TORT, OR OTHERWISE SHALL

THOMAS BE LIABLE FOR LIQUIDATED, INDIRECT, EXEMPLARY, INCIDENTAL,

SPECIAL OR CONSEQUENTIAL DAMAGES, EXPENSES OR COSTS, INCLUDING

BUT NOT LIMITED TO: (1) LOSS OF PROFITS, BUSINESS, OR GOODWILL; (2)

LOSS OF USE OF EQUIPMENT OR FACILITIES; OR (3) LOSS RESULTING FROM

UNUSABLE MACHINERY OR FACILITY DOWNTIME, HOWSOEVER CAUSED AND

EVEN IF THE POTENTIAL FOR SUCH DAMAGES WAS DISCLOSED AND/OR

KNOWN.

The remedy provided in this Limited Warranty for defective product is purchaser’s

sole and exclusive remedy, subject to your state law. Further, this Warranty gives you

specic legal rights, and you may also have other rights, which may vary, from state

to state.

If you believe warranty service is needed, contact your nearest authorized service

center. If one does not exist in your area, please contact the manufacturer:

22

Loading...

Loading...