© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

2

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Copyright © 2016 Third Dimension

All rights reserved.

You must not reproduce or distribute any part of this

publication in any form or by any means, electronic or

mechanical, without prior permission in writing from

Third Dimension. This includes photocopying, recording

or any other information storage or retrieval system.

This version produced on 16 September 2016

For support with your GapGun Pro please contact Third

Dimension:

Brabazon Office Park, Bristol, BS34 7PZ, UK

T: +44 (0)3333 44 3000

F: +44 (0)3333 44 0041

E: support@third.com

www.third.com

The laser complies with IEC60825-1 AM2:2001.

Because your blink reflex provides enough protection, it

is called eye safe

• Do not shine in eyes

• Do not view with optical instruments

• Do not shine in open space

• Take care around reflective surfaces

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

3

Page

Operator Guide 3

The GapGun Pro 4

Measuring with the GapGun 8

Checking Sensor Calibration 14

Administrator Guide 15

Creating a Checkplan 17

Measuring a Works Order 20

Setting nominals and tolerances 21

Glossary 23

4

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

A. Laser source

B. Camera

C. Green indicator LEDs

D. Vchange collar release

E. Trigger

F. On / Off switch

G. USB slot

H. Touch screen display

I. Head power indicator

J. Red laser activity indicator

K. Drop Protection jacket

L. V-Standoff

M. Wrist strap

H

I

J

K

L

M

A

B

C

E

F

D

G

M

A. Desktop battery charger

B. GapGun Pro with VChange sensor

C. Calibration gauge block

D. Hex tool training artifact

E. Docking station

F. Docking Station Cabling

G. Calibration pin gauge

H. Gauge block cleaning brush

I. Clip-on rechargeable battery pack

J. Spare rechargeable battery

K. GapGun software memory stick

L. Space for Shock protection sensor jacket

M. Extra VChange Sensors

N. Standoffs

O. Desktop charger power supply

E

B

O

E

G

D

J

A

C

K

F

H

L

M

N

N I M

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

5

The clip on battery pack attaches onto the base

of the handle and provides power for additional

4-6 hours.

The Desktop charger will recharge the battery in

about 1.5 hours.

The VChange sensor system allows sensor heads

to be quickly and easily changed without using

any tools. The Vchange system can be retrofitted

to existing MX+ handles and sensors. Sensor

heads can be freely interchanged between

different handles.

To swap the sensor head squeeze the orange

release tabs on the Vchange collar and pull the

sensor off the handle. Push the new sensor into

place until the collar lock clicks. The sensor can

be swapped without turning off the GapGun.

The GapGun Pro has an internal battery which can

power the GapGun for 4 to 5 hours of normal use.

The battery can be recharged using the docking

station or via the clip-on battery which can be used to

extend the period of use by a further 4-6 hours.

6

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Some heads have a three position mask in front of the laser. Turning the laser cap changes the mask:

Position I places a mask line in the centre of the laser line. This artificially divides the laser line into a left and

right side. It can be used to measure features where it is difficult to identify the left and right sides

of a feature.

Position II is the default position which allows the full width of the laser line to be used.

Position III masks the laser on the right and left ends of the line presenting a shorter laser line on the feature.

The Docking Station connects the GapGun to the PC

though an Ethernet connection.

It also powers the GapGun, recharges the internal

battery and is a safe place to store the GapGun.

Standoffs are used in applications where the

parts being measured can’t possibly move. The

standoffs help stabilise the GapGun and position

it correctly.

The black V standoffs are for measuring gaps and

the grey H standoffs are for sealant beads.

I

II

III

III

II

I

I

II

III

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

7

Protect the GapGun by always using the Head

Jacket (above) and wrist loop.

Before each use: check lenses are clean, check

for any damage and verify calibration.

If the GapGun is dropped, check it for damage

and verify calibration.

The GapGun lenses need to be clean: Inspect the

highlighted areas for dust, grease or fingerprints;

clean them with the kit provided if required.

The GapGun Pro is designed for indoor use; keep

the system and its accessories dry and clean. Do

not use solvents on any surface.

Always verify calibration before use by measuring the Gauge Block or Pin Gauge supplied with your system. See

the Checking Head Calibration section in this manual for more details on running the Head Check checkplan.

FOV15/40/80 To perform a calibration check successfully, place the gauge block on a flat, stable surface.

Using the V-standoff, locate the tip in the gap to position the sensor at the correct distance

from the block.

FOV7 To perform a calibration check successfully. Using the V-standoff, locate the pin into the V

from the top of the standoff, taking care not to apply undue pressure to the pin.

NOTE: Failure to follow these steps may cause false calibration failures.

FOV 15 / 40 / 80 FOV 7

8

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

A

B

C

D

The SPC3D PC application is used to open Checkplans,

load Works Orders onto the GapGun and store the

measurements that are made.

A. Context-sensitive command ribbon.

B. Checkplan tree view.

C. Tabbed Properties, Results and GapGuns windows.

D. Tabbed Workspace, Checkplan and Live display.

1

This guide shows how use a Checkplan to verify

accuracy of the GapGun by measuring a calibration

block gauge or pin gauge.

It uses the pre-defined Calibration Checkplan. Open

this in SPC3D by selecting Open from the ribbon menu.

Place the GapGun onto the Docking Station.

The display will show the GapGun locating the SPC3D

host.

If Wi-Fi has been configured the GapGun will already be

connected.

2

When using the GapGun, it will have been

preconfigured to guide you through a sequence of

locations to scan (Features), each one has a picture, a

type of measurement (e.g. gap and flush) and a set of

tolerances.

This configuration is called a Checkplan, and an

instruction to measure a specific object with the

Checkplan is called a Works Order.

CHECKPLAN: Hex

SN: ####

GROUP: Gaps

1 Rounded

2 Square cut

3 Rounded square

GROUP: RADII

1 Radius

2 Twin Radius

CHECKPLAN: Hex

SN: 0001

GROUP: Gaps

1 Rounded

2 Square cut

3 Rounded

square

GROUP: RADII

1 Radius

2 Twin Radius

CHECKPLAN: Hex

SN: 0002

GROUP: Gaps

1 Rounded

2 Square cut

3 Rounded

square

GROUP: RADII

1 Radius

2 Twin Radius

CHECKPLAN: Hex

SN: 0003

GROUP: Gaps

1 Rounded

2 Square cut

3 Rounded

square

GROUP: RADII

1 Radius

2 Twin Radius

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

9

3

4

To navigate on the GapGun tap on an item to select that action or pull the trigger if the item is already selected.

To download a Works Order based on the Calibration Checkplan:

3. Tap on the “Download…” item. Note: If the “Download…” item is not shown then there is a problem

connecting the GapGun to SPC3D.

4. Tap on the SPD3D server that is to supply the checkplan.

5. Tap on the name of the Checkplan to be downloaded. The GapGun can now be undocked and clipped into the

Clip-on battery pack.

6. Tap the name of the Checkplan to start measuring.

5

7

8

By default, a Works Order gives a list of five Jobs to perform. This allows you to make measurements on five separate

parts (or five times on the same part.) For each Job just pulling the trigger will take you through the menus in the

right sequence.

7. Pull the trigger to enter the selected Job.

8. Enter the serial number of the part to be measured in this Job.

9. This menu shows Groups of Features for each type of GapGun head. Click on the one that matches your

GapGun head type.

10. Pull the trigger to measure each Feature using the following steps.

9

10

6

10

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

11. Start with the GapGun 10cm/4” away from the feature, then pull the trigger. If standoffs are being used then

locate them on the object and this will place the GapGun in the correct range immediately.

12. Aim the laser line at right angles across the feature. Move the GapGun closer keeping it perpendicular to the

feature. The arrows on the display show whether to move the GapGun towards or away from the feature.

13. When the GapGun is at the best position the green LEDs will appear. When the count reaches eight the

measurement is made. The measurement can be delayed by keeping the trigger pulled.

13

12

11

14. The GapGun should to be moved closer to the feature.

15. The GapGun should be moved away from the feature.

16. The green LEDS will be lit and the counters will start to turn green. “Trigger Lock” is displayed when

measurement has been delayed by pulling the trigger.

17. When the counters all turn green the GapGun will beep and the measurement will be made.

If “Measurement Failed” is shown try again, however this may mean that the wrong virtual tool is being used.

14

15

16

17

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

11

+15

°

-15°

The GapGun must be held within ±15° of a perpendicular

line from the feature to be measured. The most accurate

measurements are made closest to the perpendicular.

Standoffs can be used to guarantee alignment.

Because the camera is set on a different axis from the

laser, edges can obscure parts of the feature.

Switching the GapGun round will solve this problem.

The laser stripe should be placed at right angles to the feature. Use standoffs to guarantee alignment.

For best performance with surface finish or colour differences always use U series measurement heads—these have

industry leading performance on challenging surfaces.

Always use M series measurement heads for measuring reflective finishes. When using U series light from the laser

can be reflected indirectly off the object back to the camera and return false readings.

12

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

18. The measured results will be green if successful and in tolerance. If the measurement failed or the results were

out of tolerance they will be shown in red. Pulling the trigger will move on to measure the next Feature.

19. If the measurement failed then Review screen is displayed. Tapping on a measured Feature will also show this

screen. Use <Remeasure> to try again, <Delete> to delete an incorrectly taken measurement, <Save> to store

it, <View> to display. <Error code> allows the operator to enter a code for a non-measurable Feature.

20. When the Group is complete, pull the trigger or tap the top line to return to the Group screen.

If everything is green then the calibration of the GapGun has been verified.

19

18

20

21. Each Group shows the percentage of Features that have been measured. Tap or Trigger moves to the next

Group. When all Groups are complete Trigger or Back arrow will return to the Jobs screen.

22. Tap or Trigger moves to the next Checkplan. Trigger or Back arrow will move to the Works Orders screen when

all Checkplans are complete.

23. “Lock & exit” prepares the results to return them to SPC3D. “Save & exit” saves results if more measurements

are to be made. “Lock & upload” will upload the results to SPC3D immediately.

24. The WorksOrders shows that the Calibration checkplan is locked ready for uploading. Place the GapGun onto

the Docking Station and tap on the name “Calibration” to begin the upload.

21

22

23

24

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

13

The results from the measurements are displayed in the

Results Tab. Click on the Checkplan, Group or Feature

to see results for that selection.

Measurements that are outside the tolerances are

flagged in red for easy identification.

25. Tap “Upload” to begin uploading. Unlock will allow more results to be added to a locked Checkplan.

26. Select the SPC3D server which supplied the checkplan.

27. When the data has been sent back to SPC3D the Checkplan can be removed from the Works Orders list. Use

Download... to download the next set of Jobs.

28

25

26

27

14

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

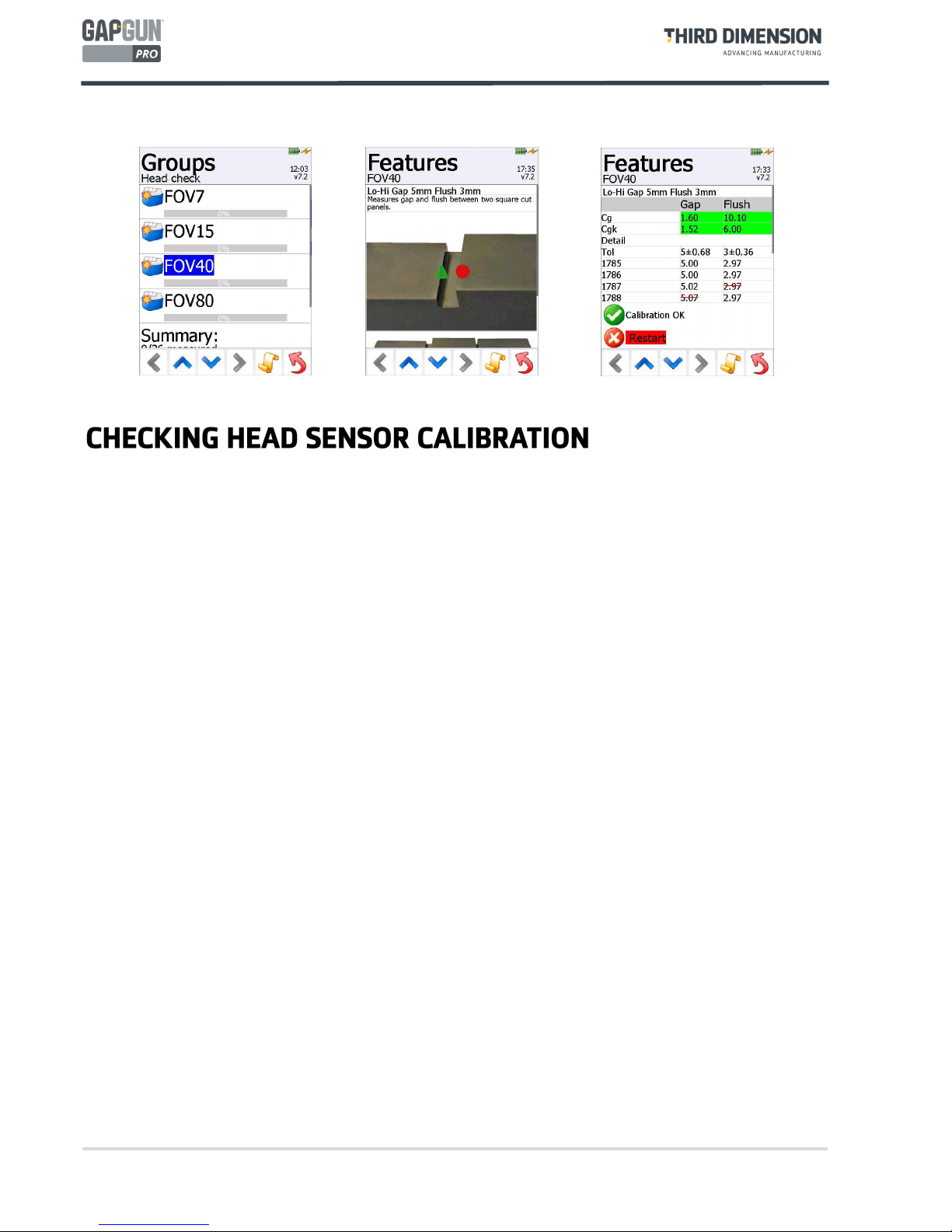

The calibration of the head can be checked by selecting the

Head Check

item at any time during measurement.

1. The Operator should then select the Group relevant to the head installed on the Gapgun.

2. Each of the features on the gauges should be tested using the up and down arrows.

3. Each measurement must be taken at least three times and the Cg and Cgk calculated. The check can be

restarted at any time by tapping Restart. Once enough successful measurements have been captured the result

is shown, in green if the calibration is okay and in red if it is out of calibration. The Operator should seek advice

on how to proceed from a Supervisor.

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

15

16

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

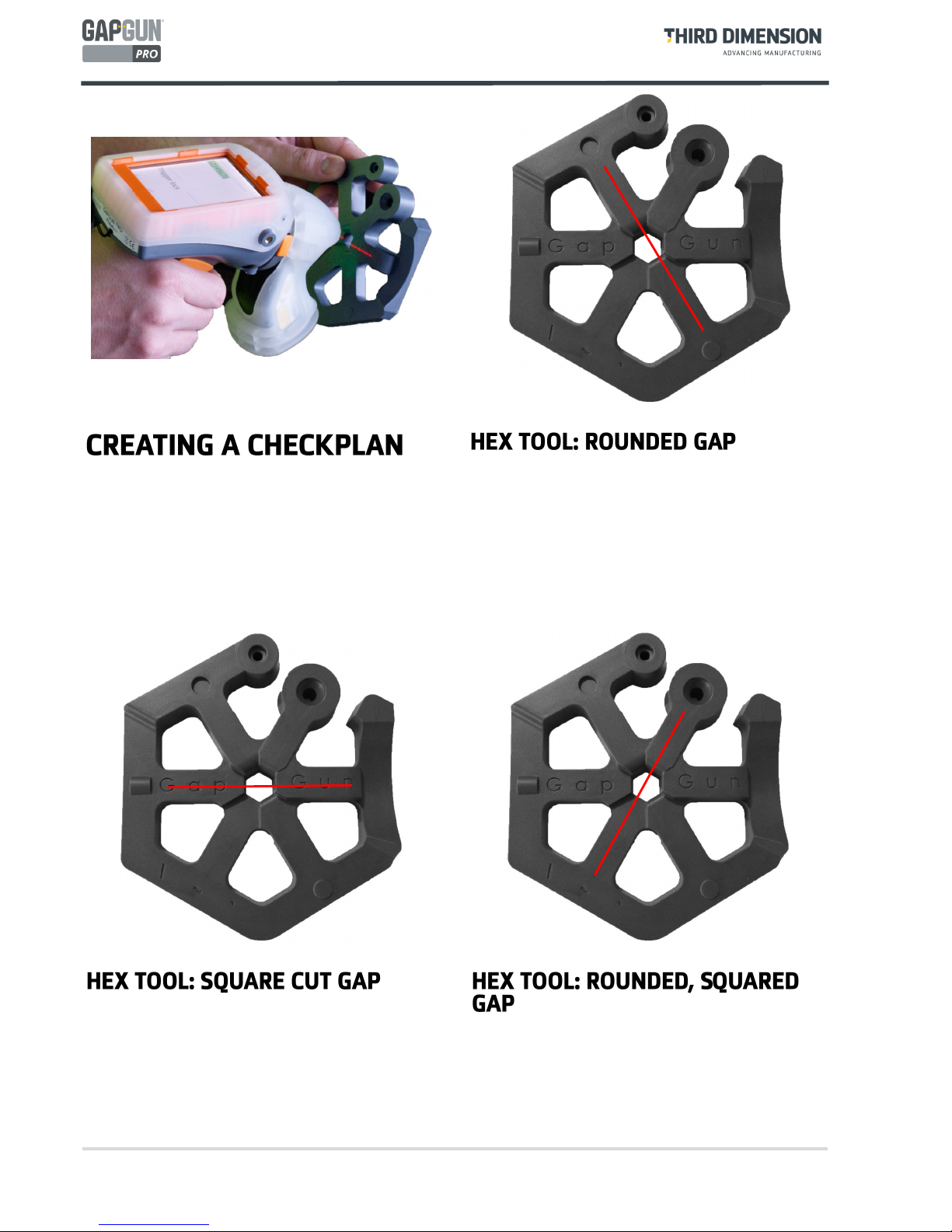

This guide demonstrates how to configure a GapGun

Checkplan to measure three Gap/Flush features on the

Hex Tool training artifact supplied with the GapGun.

The Square cut gap has square cut edges as found in

many industrial or aerospace applications, such as

panels on aircraft.

This feature has embossed lettering which shows how

the GapGun can ignore surface imperfections around

the feature when measuring.

The Hex Tool training artifact provides a wealth of

features to practice on. This guide uses three common

features.

The Rounded Gap consists of a gap and flush (step) that

have rounded edges as found on many consumer items

such as cars and white goods.

The Rounded, square gap has one side is rounded and

the other square, as found for example in automotive

ring gauges.

One side of this feature is set at an angle, to show how

the GapGun can cope with geometries that are

challenging to measure manually.

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

17

A

B

C

D

The SPC3D PC application is used to configure

Checkplans, collect measurements and configure

Features.

A. Context-sensitive command ribbon.

B. Checkplan tree view.

C. Tabbed Properties, Results and GapGuns windows.

D. Tabbed Workspace, Checkplan and Live display.

The GapGun uses a Checkplan to describe what

Features are to be measured and in what order.

Features can be put into Groups so that related

measurements can kept together.

The first step is to create a new Checkplan and give it a

descriptive name ‘Hex’.

A Checkplan can have one or more Groups, for example

grouping Features on one part of the object. A Group

can be copied to create repeating sets of Features or

mirrored to create a Group for the opposite side of the

object.

Add a Group to the Checkplan and give it a descriptive

name ‘Gaps’.

1

2

SPC3D is used to define the checkplan and configure the

features that are to be measured. These are combined

into a Works Order which is downloaded to the GapGun

to tell the operator what to measure and where to

measure each feature.

The measured results are then returned to SPC3D to be

stored and formatted for further processing.

Checkplan

Feature 1

Feature 2

Feature 3

Group 1

Group 2

18

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Feature describes the measurement of a feature on a

part. This can have multiple measurement values, for

example Gap and Flush.

Add three Features:

Rounded - set the link to \Tools\GapFlush\PanelRad

Square - set the link to \Tools\GapFlush\PanelGF

RndSq - set the link to \Tools\GapFlush\CRV_SQR

Markers can be added to indicate which way to aim the

GapGun. The triangle indicates the left side and the

circle indicates the right, these symbols are also etched

onto the sides of the GapGun head.

The Plus, Cross and Done buttons can be used to

manage user-defined markers.

A picture of the feature can be added so that the

operator knows the precise location of the feature and

how to orientate the GapGun.

Right-click the Feature name and click on “Define

Instruction graphic…”

Select a graphic from the left hand panel or click on

the Green Plus button to import a new picture. Delete

graphics using the Cross Button or click the ‘None’

button to remove the graphic from the Feature.

4

5 6

3

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

19

7

It is recommended that the Checkplan is saved before

downloading to the GapGun this will make reviewing

measurements easier later on.

Select the Checkplan tab in the workspace then click the

Save icon on the ribbon or right-click the Checkplan

name and select Save.

8

Place the GapGun onto the Docking Station.

The GapGun will show the GapGun locating the SPC3D

host.

If Wi-Fi has been configured the GapGun will already be

connected.

To download a Checkplan to the GapGun it must first

be opened in SPC3D.

Select Open from the ribbon and select the required

Checkplan file. These files can be freely copied, emailed

or renamed.

On the GapGun the checkplan becomes a Works Order

which tells the operator what to measure.

The Operator Guide describes how to download the

Checkplan onto the GapGun and return the results.

10

9

20

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

By default, a Works Order gives a list of five Jobs to perform. This allows you to make measurements on five

separate parts (or five times on the same part.) For each Job just pulling the trigger will take you through the

menus in the right sequence.

Pull the trigger to enter the selected Job.

Enter the serial number of the part to be measured in this Job.

There is only one group in our checkplan so select this Group.

Pull the trigger to measure each Feature using the following steps.

The measurements must always be made in the same orientation so that the sign of the flush is the same.

When measuring as shown the flush will be negative, but when measured the other way round it will be

positive.

Take the measurement as described in the operator manual.

The GapGun will display the dimensions of the gap and flush measured. If the GapGun reports ERR11 then

the wrong tool is being used, ERR13 indicates that the GapGun is no being held stably enough to get good

images.

11

12

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

21

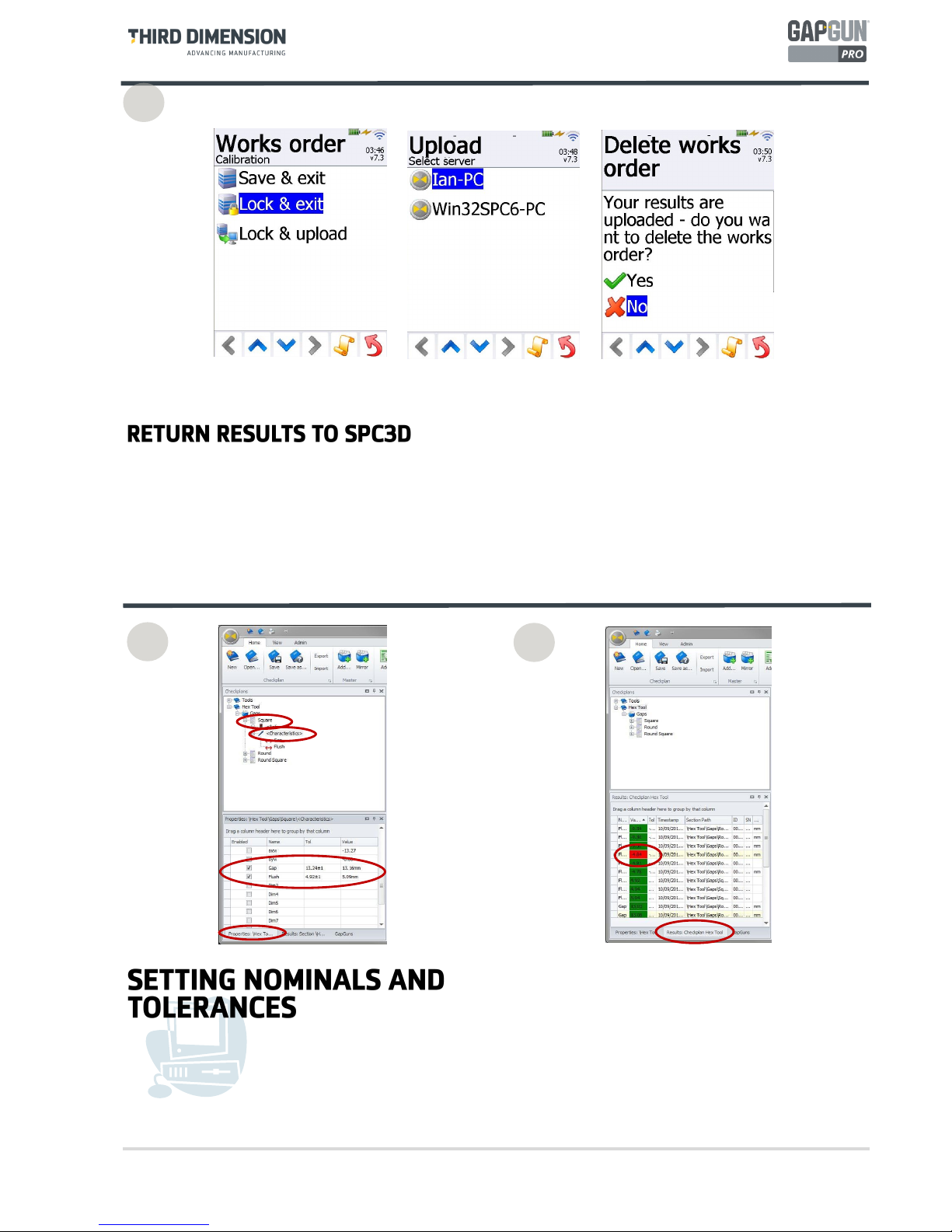

.

The nominal value (and tolerances) can also be set from

engineering drawings. Select the Feature, expand the

tree then select Characteristics.

In the Properties tab locate the Characteristics being

measured and enter the nominal and tolerance values.

Once all the measurements have been taken then use the Back button to get to the Save & exit menu.

If the GapGun is connected to the network the select Lock and Upload to return the results to SPC3D

Otherwise, Lock & exit prepares the results to be upload later when the GapGun has been connected to

SPC3D.

Once the nominals and tolerances have been set, the

Results tab will show values which are in and out of

tolerance as soon as the results are uploaded from the

GapGun.

14

15

13

22

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Now the Checkplan has the nominal and tolerance

values set, the Checkplan is ready for use.

Select the Checkplan workspace and then save the

Checkplan or right-click the Checkplan name and select

Save.

16

To use the new Checkplan open it in SPC3D, place the

GapGun onto the Docking Station and download it or

connect to Wi-Fi and download it wirelessly.

Measure the Hex Tool against the nominals and

tolerances defined, and upload the measured data to

SPC3D.

17

Create a Checkplan to measure the radius on the

rounded gap by experimenting with different tools to

see what they do.

Right click on one the rounded gap Feature and select

Properties, then change the Link combo box to try

different ways of measuring.

Use the techniques described to measure another

object such as a car body, or an airframe.. The

principles are the same.

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

23

Characteristic

A measurement to be made of an object, for example, gap, flush, radius, angle,

depth, height, width, roughness, chamfer, burr, proud. A feature will typically have

a number of characteristics measured.

Checkplan

A set of Groups which describe the list of features which need to be measured on

an object.

Feature

A feature is a point on an object that is to be measured. It can have a number of

measurements depending on what characteristics are to measured,

e.g. Gap and Flush

FOV7, FOV15,

FOV40, FOV80

The GapGun can have a number of different heads to measure different sized features. The FOV, Field Of View defines the length of the feature to be scanned in

millimetres.

GapGun Pro

GapGun Pro is an improved highly flexible and configurable handheld measurement system designed to deliver enterprise level product build quality checks.

GapGun MX+

GapGun MX+ is a flexible and configurable handheld measurement system designed to deliver enterprise level product build quality checks.

Hex Tool

A demonstration artefact which exhibits all of the pre-defined tools measured by

the GapGun Virtual Tools library.

Group

A set of related Features, for example the features to be measured on one side of

an object. A second Group could be added for a similar object or mirrored to measure the other side of an object.

Object

The object is the target of the measurements. It may have multiple features that are

to be measured.

e.g. The Hex Tool has 21 features that can be measured.

SPC3D

PC based application software to create Checkplans, to manage delivery of Works

Orders to GapGuns, to retrieve measurements made and to customize Virtual

Tools.

Standoffs

To improve reliability and repeatability, standoffs can be used to help the operator

place the GapGun in the optimal position for accurate measurement. Customized

standoffs can be constructed for particular user requirements.

Virtual Tool

The GapGun can measure a number of dimensions of a feature, for example, the

gap between two panels and the flush height difference between the panels. The

GapGun comes with a set of pre-defined Virtual Tools to measure a wide variety of

features. They are organised into Tool families: Angle, Edge, GapFlush, Position,

Radius, Rivet, Seal, Surface and Custom. These tools are described in the Tools Appendix.

Works Order

One or more Checkplans downloaded to a GapGun to allocate a series of measurements to be made on one or more objects by this GapGun. When the Works Order

is complete, the results are be uploaded to SPC3D.

24

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

GapGun Pro Wi-Fi Data Sheet

Third Dimension Software Ltd affirms, that the equipment manufactured by the Company fulfils the

requirements of directives listed below.

Manufacturer

Third Dimension Software Ltd.

Contact

Details

Unit 3 Brabazon Office Park, Bristol. BS34 7PZ England

Tel. +44 (0)3333443000

Fax. +44 (0)3333440041

Email: info@third.com

Equipment

Control system for measurement of physical dimension using GapGun

measurement sensor.

Trade Name

GapGun Pro

Model

GG14-0067

Overview

Third Dimension is a world leading developer and manufacturer of non-contact, precision profile

measurement solutions.

Third Dimension has a long track record of supplying metrology equipment and services to the

largest names in aerospace, automotive and energy sectors worldwide.

The GapGun is a laser gauge, profile measurement system that quickly and accurately quantifies

local features such as gap and flush, step, weld and mismatch, radii, scratches, seals, dents, rivets

and fasteners. It is a proven technology, used worldwide by most major automotive and aerospace

OEMs.

The GapGun takes conventional laser scanning a step further by not only scanning a surface to

record its shape, but also automatically analysing the information to pick out specific dimensions

(gap, flush, angle, etc) and then comparing these against tolerance bands. The measured data is then

recorded for statistical process control or traceability purposes.

Providing a fully auditable trail of every single product that is measured, GapGun removes risk by

proving the quality of manufacture and in turn providing significant time and cost savings for our

customers.

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

25

Typical Application

Features/Benefit

With greatly improved speed, ease of use, portability and ruggedness, the GapGun Pro measures gap

and flush, radius, edge break, burr, countersink, scratch, weld, seal, angle and more, as the ultimate

quality inspection tool.

Ultra fast processing capability – The GapGun Pro's new, superfast processor means that

measurements can be collected faster than ever before, with speed improvements of up to 20x over

manual techniques, reducing cycle time and increasing efficiency

New VChange sensor system – GapGun Pro includes Third Dimension's ergonomic new VChange

sensor interface, which allows the sensor to remove, change and reattach sensors, in just seconds,

making multiple sensor use on the shop floor easier than ever. A vast range of measurements can be

collected using just one system and Third Dimension's extensive range of interchangeable VChange

sensors.

Fully integrated Wi-Fi – The integrated Wi-Fi connection of the GapGun Pro means instant results

access direct to the PC, with no additional hardware or cables required, giving operators total

autonomous measurement capability. This also allows for enhanced portability and convenience on

the shop floor.

Extra high capacity internal battery – GapGun Pro can operate completely standalone for around

four hours, plus a further 6.5 hours by simply attaching it to a light weight interchangeable clip on

battery pack.

Robust construction – GapGun Pro’s evolved, rugged design makes it durable for a wide range of

challenging and unique manufacturing environments

High definition colour touch screen – With 4x resolution of that on the GapGun Plus Series, this

screen is clear, highly responsive, easy to navigate and readable in a huge array of conditions.

26

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Features

Standards Conforms to 802.11a/b/g/e/i/h/j, drafts 802.11k/r, and single-stream 802.11n standards

Frequency Band 2.4GHz & 5GHz

Security Supports WPA/WPA2 (802.11i)

Quality of Service Supports 802.11e and WMM

Antenna Internal only (InSide WLAN)

Operating Temperature 0-40oC (32-104oF)

Dimensions (W x D x H) 90 x 135 x 190mm (3.5 x 5.3 x 7.5”)

Networking and Security

Security

WEP64/128, TKIP, AES (CCMP), WPA-EAP-TLS, WPA-PSK, WPA2-EAP-TLS, WPA2

-PSK

Channels

2.4 GHz channels: 1-13

5 GHz channels: 36-140 (U-NII Band 1, 2, 2e)

Wireless LAN

Standard 802.11

Radio Redpine Signals RS9110 + Airoha 8230

RF output power 2.4 GHz

802.11b (DSSS): +17dBm (typ.)

802.11g (OFDM): +15dBm (typ.)

802.11n (OFDM): +15dBm (typ.)

RF output power 5 GHz

802.11a (OFDM): +9dBm (typ.)

802.11n (OFDM): +9dBm (typ.)

Output frequency 2.4 GHz

2.412 - 2.462 GHz, channel 1 - 11 (FCC domain)

2.412 - 2.472 GHz, channel 1 - 13 (ETSI, TELEC domain)

5 MHz channel separation

Output frequency 5 GHz

5.180 - 5.240 GHz, U-NII-1 / Channel 36, 40, 44, 48 (FCC, IC, ETSI domain)

5.260 - 5.320 GHz, U-NII-2 / Channel 52, 56, 60, 64 (FCC, IC, ETSI domain)

5.500 - 5.700 GHz, U-NII-2e / Channel 100, 104, 108,112, 116, 120, 124, 128, 132, 136,

140 (FCC, ETSI domain)

5.500 - 5.700 GHz, U-NII-2e / Channel 100, 104, 108,112, 116, 132, 136, 140 (IC domain)

5.745 - 5.825 GHz, U-NII-3 / Channel 149, 153, 157, 161, 165 (FCC domain)

TPC and DFS slave/client operation on 5.260 - 5.320 GHz, 5.500 - 5.700 GHz

20 MHz channel separation

Data Rates 20 Mbps

Modulation

DSSS (BPSK, QPSK, CCK) for 802.11b

OFDM (BPSK, QPSM, 16QAM, 64QAM) for 802.11 g/n

Transmit Power 20dBm

Receiver Sensitivity -69 dBm to -89dBm across the frequency range

Power Requirements

Supply Voltage 12V dc

Charger Voltage 240V/110V ac

Regulatory Approvals

FCC (US) Yes

IC (Canada) Yes

CE/ETSI (Europe) Yes

C-TICK (Australia) No

Telec (Japan) Yes

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

27

Safety

BS EN 60825-1:2014- Safety of laser products

BS EN 60950-1:2006+A12:2011 – Information technology equipment safety.

Declaration

General

The conformity to mentioned standards of each manufactured unit is ensured according our quality

control standards BS EN ISO9001:2008.

Europe

The placement of the CE marking on our product Third Dimension Software Ltd is declaring, on its

sole responsibility, conformity with all of the legal requirements to achieve CE marking. Third

Dimension Software Ltd is thus ensuring validity for that product to be sold throughout the

European Economic Area (EEA).

USA (FCC)

This device contains : FCC ID: PVH0941

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

this device may not cause harmful interference, and

this device must accept any interference received, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

28

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Canada (IC)

This device contains : IC ID: 5325A-0941

Operation is subject to the following two conditions:

this device may not cause interference, and

this device must accept any interference, including interference that may cause undesired

operation of the device.

Son utilisation est soumise aux deux conditions suivantes:

Cet appareil ne doit pas causer d’interférences et

il doit accepter toutes interférences reçues, y compris celles susceptibles d’avoir des effets

indésirables sur son fonctionnement.

This device complies with Industry Canada licence-exempt RSS standard(s). Under Industry Canada

regulations, this radio transmitter may only operate using an antenna of a type and maximum (or

lesser) gain approved for the transmitter by Industry Canada.

To reduce potential radio interference to other users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for

successful communication.

The device for operation in the band 5150-5250 MHz is only for indoor use to reduce the potential

for harmful interference to co-channel mobile satellite systems; the maximum antenna gain

permitted for devices in the bands 5250-5350 MHz and 5470-5725 MHz shall comply with the e.i.r.p.

limit; and the maximum antenna gain permitted for devices in the band 5725-5825 MHz shall comply

with the e.i.r.p. limits specified for point-to-point and non point-to-point operation as appropriate.

Operation in the 5600-5650 MHz band is not allowed in Canada. High-power radars are allocated as

primary users (i.e. priority users) of the bands 5250-5350 MHz and 5650-5850 MHz and that these

radars could cause interference and/or damage to LE-LAN devices.

This equipment complies with IC RSS-102 radiation exposure limits set forth for an uncontrolled

environment.

This equipment should be installed and operated with minimum distance 20cm between the

radiator & your body.

Conformité aux normes d’IC Cet appareil est conforme à la(aux) norme(s) RSS sans licence d’Industry

Canada.

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

29

Son utilisation est soumise aux deux conditions suivantes :

Cet appareil ne doit pas causer d’interférences et il doit accepter toutes interférences

reçues, y compris celles susceptibles d’avoir des effets indésirables sur son fonctionnement.

Conformément aux réglementations d’Industry Canada, cet émetteur radio ne peut

fonctionner qu’à l’aide d’une antenne dont le type et le gain maximal (ou minimal) ont été

approuvés pour cet émetteur par Industry Canada.

Pour réduire le risque d’interférences avec d’autres utilisateurs, il faut choisir le type d’antenne et

son gain de telle sorte que la puissance isotrope rayonnée équivalente (p.i.r.e) ne soit pas supérieure

à celle requise pour obtenir une communication satisfaisante.

Le dispositif de fonctionnement dans la bande 5150-5250 MHz est réservé à une utilisation en

intérieur pour réduire le risque d'interférences nuisibles à la co-canal systèmes mobiles par satellite,

le gain d'antenne maximal autorisé pour les appareils dans les bandes 5250-5350 MHz et 5470-5725

MHz doit se conformer à la pire limite, et le gain d'antenne maximal autorisé pour les appareils dans

la bande 5725-5825 MHz doivent être conformes avec le pire limites spécifiées à point-à-ponctuelles

et non point-à-point de fonctionnement selon qu'il convient.

Opération dans la bande 5600-5650 MHz n'est pas autorisée au Canada. Haute puissance radars sont

désignés comme utilisateurs principaux (c.-àutilisateurs prioritaires) des bandes 5250-5350 MHz et

5650-5850 MHz et que ces radars pourraient causer des interférences et / ou des dommages à

dispositifs LAN-EL.

Cet équipement respecte les limites d’exposition aux rayonnements IC RSS-102 définies pour un

environnement non contrôlé. Il doit être installé et utilisé en maintenant une distance minimum de

20cm entre le radiateur et votre corps.

Japan (TELEC)

204-310004

Specified radio equipment such as wireless LAN and business purpose radio used in Japan is required

to conform to the technical standards regulated by the Ministry of Internal Affairs and

communications (MIC) of Japan.

Technical regulations conformity certification is to certify that the specified radio equipment

conforms to the technical standards under the Radio Law of Japan.

The specified radio equipment as defined as the radio equipment used for small-scale radio station

specified in the Ordinance of Technical Regulations Conformity Certification of Specified Radio

Equipment.

The following three pages contain the TELEC test certificate.

30

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

31

32

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

33

Certificate Release

Issued: 12th March 2015

Third Dimension Software Ltd.

Signed:

Steve Robinson, Principal Engineer

This declaration has been issued under the sole responsibility of Third Dimension Software Ltd.

Loading...

Loading...