Think & Tinker ModuLam 130 Operator's Manual

ModuLam

130

Dry-film Lamination

Engine

Think & Tinker, Ltd.

Table of Contents

Safety First............................................................................................................................................1

Characteristics......................................................................................................................................2

Control Panel........................................................................................................................................3

Functions and Operation ......................................................................................................................4

A. Indicator lamps ..............................................................................................................................4

B. Preset functions..............................................................................................................................5

C. Temperature Control......................................................................................................................6

D. Motor / Speed Control....................................................................................................................6

Operation..............................................................................................................................................7

Cold Lamination.................................................................................................................................7

A. Cold laminating when the ModuLam is first turned on...............................................................7

B. Cold laminating with a hot machine............................................................................................7

Hot lamination....................................................................................................................................7

A. Hot laminating when the ModuLam is first turned on .................................................................7

B. Shutting down after hot lamination.............................................................................................8

Laminating Temperature and Speed....................................................................................................8

A. Adjusting laminating speed to compensate for changes in the thickness of the film or substrate..8

B. If the combination of film and paper is thinner than 1 step or thicker than 4 steps, adjust the

laminating temperature using the following chart............................................................................8

Change of step according to temperature.....................................................................................8

Tips for achieving perfect lamination..................................................................................................9

Appendix.............................................................................................................................................10

Laminating Photoresist and Soldermask............................................................................................10

Lamination Record and Setting Guide............................................................................................... 14

Specifications ......................................................................................................................................15

Safety First

Before using your Composer laminator, there are a few precautions that should be observed.

1. To prevent the possibility of electrical shock, do not operate near sinks, bathtubs, etc.

2. Always check the electrical requirements printed on the bottom of your laminator before

plugging into a wall outlet.

3. If an extension cord or "outlet expander" is used, check its power rating to insure that it is

compatible with the requirements of the laminator.

4. Do not use the unit if the power cord or case is damaged in any way.

5. Do not allow the power cord to touch hot surfaces.

6. Turn the power off when the unit is not in use, unattended or not intended to be used.

7. Do not rest anything (including your hand) on top of the unit when it is in operation as it can get

quite hot.

8. Do not operate machine around inflammable liquids.

9. Do not allow water to enter the machine. If a drink is spilled into the unit, unplug the power cord

from the wall and allow the liquid to dry before using the laminator again.

10. Do not force substrates through the machine. You may damage the rollers and void your

warranty.

ModuLam 130 Operators Manual page 1

Characteristics

Uniformity of

lamination

High

performance

Safety

Power saving

Soft-touch

©

control panel

Each Think & Tinker lamination engine is equipped with 6 Ceracon©

internally heated rollers. The front two rollers are act as pre-heaters,

raising the temperature of the laminating film to a temperature just

below the melting point of the adhesive. They also serve to squeeze

out any trapped air. The second pair of rollers is heated to the adhesion

fusion temperature, laminating the film to the substrate uniformly,

without voids or air pocket. The final pair of rollers are unheated and

serve to tension the laminated material as it is cooling to insure a flat,

stress free end product.

The custom microprocessor based lamination controller offers precise

digital control of both the lamination temperature and the motor speed.

Four pre-programmed combinations of speed and temperature reduce

the task of setting up the laminator to pressing a button and waiting for

the rollers to come up to operating temperature.

The laminator shell is constructed of heat resistant, non-flammable

plastic, protecting the user from the hot lamination elements and any

danger of electric shock.

The digital lamination controller insures that only the right amount of

heat is delivered to the lamination rollers, saving considerable energy

over other pouch style laminators that use switch type thermostats. The

use of a dc pulsed drive motor minimizes motor heating, resulting in

further energy savings.

All functions are controlled by depressing the desired Soft -touch

button. Signal lights and an audible alarm provide immediate feedback

that the operating parameters have been changed. An over temperature

alarm alerts the operator that the lamination temperature for the target

film has been exceeded and the user should wait until the unit cools

down.

©

ModuLam 130 Operators Manual page 2

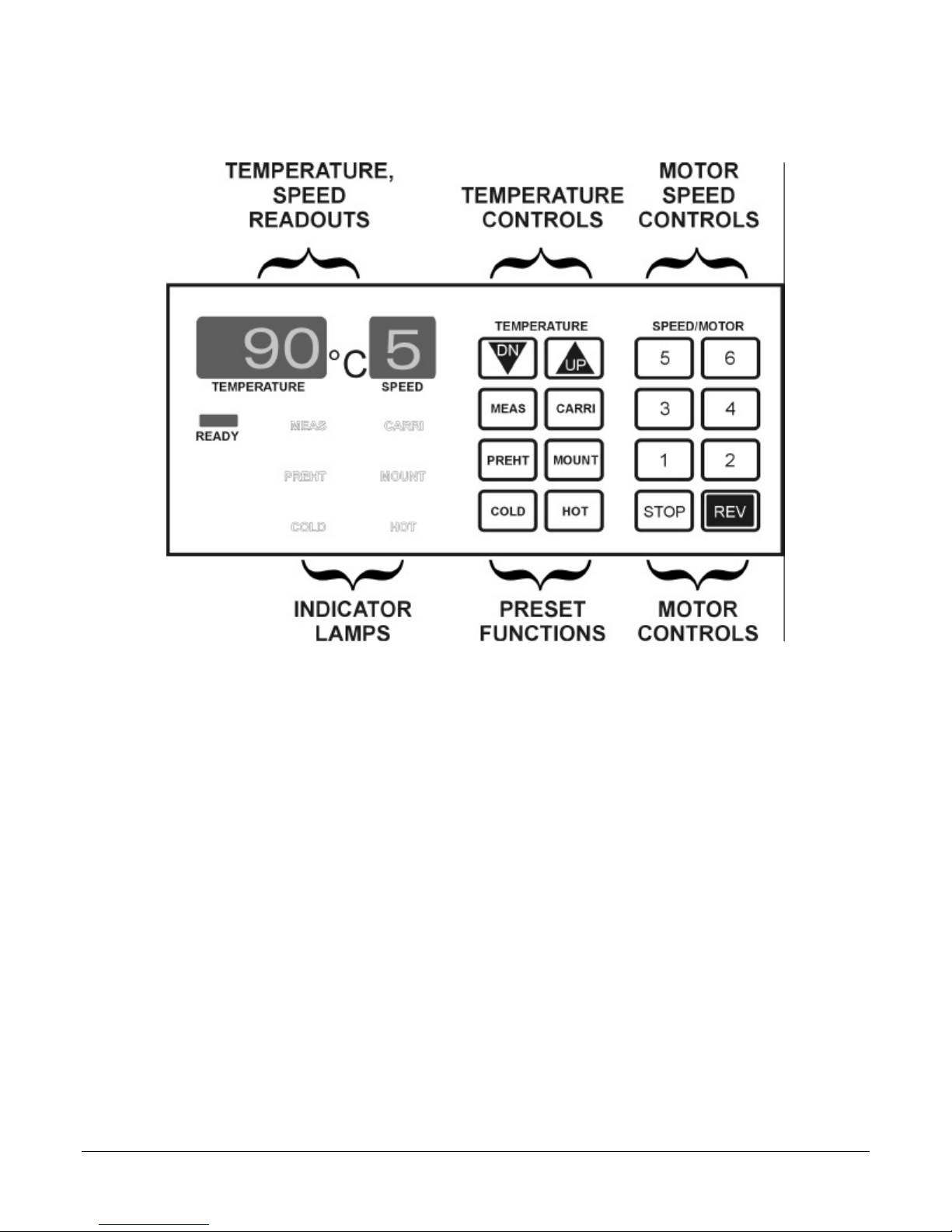

Control Panel

ModuLam 130 Operators Manual page 3

Functions and Operation

Soft-touch© Control Panel

A. Indicator lamps

Specific lamps are illuminated to indicate the state of one or mo re of the operating parameters of the

laminator.

Temperature Indicator – displays the target operating temperature. Also used to

display the current fusion roll temperature when the MEASURE function is selected.

Roller Speed Indicator – displays the current “running speed” of the lamination

rollers

COLD

MEAS

PREHT

HOT

Indicates that the current chosen pre-set function is COLD (room temperature)

lamination. (temp. = RT , speed = 2 )

Indicates that the MEASURE (MEAS) function has been selected and the

temperature indicator is displaying the current temperature of the fusion rollers.

Indicates that the PRE-HEAT (PREHT) function has been selected. (temp. = 80°C,

speed = 2 )

Indicates that the HOT function has been selected. (temp. = 90°C, speed = 5)

MOUNT

CARRI

READY

Indicates that the MOUNTING (MOUNT) function is selected. (temp. = 130°C,

speed = 1)

Indicates that the MATTING (MOUNT) function is selected. (temp. = 110°C, speed

= 2)

Indicates the state of the rollers. Changes state according to the temperature of the

rollers as follows:

OFF – the temperature of the fusion rollers is below the set point

BLINKING – the temperature of the fusion rollers is above the set point

ON – the temperature of the fusion rollers is at the set point (+/- 3°C)

ModuLam 130 Operators Manual page 4

Loading...

Loading...